CN201584931U - Low-temperature semiconductor power generating device recycling waste heat of medium and small-sized equipment in industry to generate power - Google Patents

Low-temperature semiconductor power generating device recycling waste heat of medium and small-sized equipment in industry to generate powerDownload PDFInfo

- Publication number

- CN201584931U CN201584931UCN2009202134128UCN200920213412UCN201584931UCN 201584931 UCN201584931 UCN 201584931UCN 2009202134128 UCN2009202134128 UCN 2009202134128UCN 200920213412 UCN200920213412 UCN 200920213412UCN 201584931 UCN201584931 UCN 201584931U

- Authority

- CN

- China

- Prior art keywords

- thermoelectric conversion

- small

- conversion elements

- heat

- size

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000004065semiconductorSubstances0.000titleclaimsabstractdescription16

- 239000002918waste heatSubstances0.000titleabstractdescription5

- 238000004064recyclingMethods0.000titleabstract2

- 238000006243chemical reactionMethods0.000claimsabstractdescription28

- 229910052797bismuthInorganic materials0.000claimsabstractdescription16

- JCXGWMGPZLAOME-UHFFFAOYSA-Nbismuth atomChemical compound[Bi]JCXGWMGPZLAOME-UHFFFAOYSA-N0.000claimsabstractdescription16

- XSOKHXFFCGXDJZ-UHFFFAOYSA-Ntelluride(2-)Chemical compound[Te-2]XSOKHXFFCGXDJZ-UHFFFAOYSA-N0.000claimsabstractdescription16

- 239000000919ceramicSubstances0.000claimsabstractdescription12

- XUIMIQQOPSSXEZ-UHFFFAOYSA-NSiliconChemical compound[Si]XUIMIQQOPSSXEZ-UHFFFAOYSA-N0.000claimsabstractdescription7

- 238000001816coolingMethods0.000claimsabstractdescription7

- 229910052710siliconInorganic materials0.000claimsabstractdescription7

- 239000010703siliconSubstances0.000claimsabstractdescription7

- 229910052782aluminiumInorganic materials0.000claimsabstractdescription5

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000claimsabstractdescription5

- 239000004411aluminiumSubstances0.000claimsabstractdescription5

- 239000011159matrix materialSubstances0.000claimsabstractdescription5

- 238000011084recoveryMethods0.000claimsdescription9

- 230000005855radiationEffects0.000claimsdescription6

- 229920000642polymerPolymers0.000abstractdescription3

- 238000005265energy consumptionMethods0.000abstract1

- 239000007789gasSubstances0.000description4

- 239000000463materialSubstances0.000description4

- 230000000694effectsEffects0.000description3

- 238000010276constructionMethods0.000description1

- 238000007599dischargingMethods0.000description1

- 230000005611electricityEffects0.000description1

- 238000005516engineering processMethods0.000description1

- 230000007613environmental effectEffects0.000description1

- 238000004519manufacturing processMethods0.000description1

- 230000005676thermoelectric effectEffects0.000description1

Images

Landscapes

- Compositions Of Oxide Ceramics (AREA)

Abstract

Description

Technical field

A kind of cryogenic semiconductor Blast Furnace Top Gas Recovery Turbine Unit (TRT) that reclaims industrial middle-size and small-size equipment cogeneration of the utility model design.

Background technology

In recent years, along with global economy ground high speed development to the energy particularly the demand of fossil energy increasing rapidly, and the energy crisis and the environmental problem that produce also more and more serious thereupon.But it is to have slatterned as waste heat or used heat greatly that the heat that the fossil energy in daily production produces has.And present semi-conductor thermoelectric material is to utilize the thermoelectric effect of material itself can realize the direct energy and material of changing between heat energy and the electric energy.The semiconductor heat electrical effect is to utilize Seebeck (Seebeck) effect, and promptly the temperature when p, two kinds of semiconductor two ends of n does not just have electrical potential difference at the semiconductor two ends simultaneously, just has electric current to flow through after connecting an external loop, realizes thermo-electric generation.Because semi-conductor thermoelectric material has that volume is little, reliability is high, pollution-free, noiselessness and the characteristics that have the temperature difference just can generate electricity are applied in this low-temperature cogeneration device the low temperature exhaust heat that can utilize traditional generator to use again effectively.Therefore developing the cryogenic semiconductor Blast Furnace Top Gas Recovery Turbine Unit (TRT) can reclaim industrial middle-size and small-size equipment cogeneration, reaches the effect that environment protecting and power-saving reduces discharging.

Summary of the invention:

The purpose of this utility model provides near the small-sized low-temperature generation device of a kind of heat source temperature 100 ℃, utilizes problem again with the waste heat that solves some middle-size and small-size equipment.The cryogenic semiconductor Blast Furnace Top Gas Recovery Turbine Unit (TRT) of industrial middle-size and small-size equipment cogeneration is reclaimed in the utility model design, comprise heat collector, thermoelectric generator and heat radiation cooling system are formed, it is characterized in that: thermoelectric generator has adopted a plurality of high performance P/N type bismuth telluride-based thermoelectric conversion elements, be rectangular flake structure, a plurality of thermoelectric conversion elements are connected in series, respectively place a potsherd and clamping at top and bottom, stick a slice thermal conductive silicon film on the potsherd of top, connect filling porous polymeric seal in the thermoelectric conversion element matrix that connects between each thermoelectric conversion element by the aluminium electrode.It is characterized in that: heat collector is the ceramic wafer at high performance P/N type bismuth telluride-based thermoelectric conversion element top.It is characterized in that: the heat radiation cooling system is the ceramic wafer of high performance P/N type bismuth telluride-based thermoelectric conversion element bottom.The utility model has the advantages that the low temperature exhaust heat that can reclaim near the middle-size and small-size equipment of heat source temperature 100 ℃, it can be utilized again, thereby reduce the consumption of the energy.

Description of drawings:

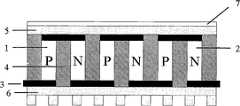

Fig. 1 is a structural representation of the present utility model, Fig. 2 is that 49 generating elements are connected in series, the matrix of having formed a 7*7, among Fig. 1 the 1, the 2nd, the bismuth telluride base semiconductor generating element of P type and N type, the 3rd, the aluminium electrode of Connection Element, the 4th, the porous polymer of filling, the 5th, top ceramic wafer, the 6th, bottom ceramic wafer, the 7th, thermal conductive silicon film, 8 is generating elements among Fig. 2, the 4th, and the porous polymer of filling.

Below in conjunction with accompanying drawing and construction embodiment the utility model is made detailed operation instruction.

Embodiment:

Comprise heat collector, thermoelectric generator and heat radiation cooling system composition among the figure, it is characterized in that: thermoelectric generator has adopted a plurality of high performance P/N type bismuth telluride-based thermoelectric conversion elements, be rectangular flake structure, a plurality of thermoelectric conversion elements are connected in series, respectively place a potsherd and clamping at top and bottom, stick a slice thermal conductive silicon film on the potsherd of top, connect filling porous polymeric seal in the thermoelectric conversion element matrix that connects between each thermoelectric conversion element by the aluminium electrode.It is characterized in that: heat collector is the ceramic wafer at high performance P/N type bismuth telluride-based thermoelectric conversion element top.It is characterized in that: the heat radiation cooling system is the ceramic wafer of high performance P/N type bismuth telluride-based thermoelectric conversion element bottom.After the low temperature exhaust heat of industrial middle-size and small-size equipment is delivered to the radiator of thermal conductive silicon film stickup, by the thermal conductive silicon film on the potsherd that is delivered to high performance P/N type bismuth telluride-based thermoelectric conversion element top, and produce the temperature difference up and down between the potsherd at high performance P/N type bismuth telluride-based thermoelectric conversion element, thereby high performance P/N type bismuth telluride-based thermoelectric conversion element has electric current to produce, and the ceramic wafer of high performance P/N type bismuth telluride-based thermoelectric conversion element bottom is that imbricated texture is to dispel the heat better, the ceramic wafer of keeping high performance P/N type bismuth telluride-based thermoelectric conversion element top and the bottom has the temperature difference, and continues to produce electric current output.

Claims (3)

1. reclaim the cryogenic semiconductor Blast Furnace Top Gas Recovery Turbine Unit (TRT) of industrial middle-size and small-size equipment cogeneration, comprise heat collector, thermoelectric generator and heat radiation cooling system are formed, it is characterized in that: thermoelectric generator has adopted a plurality of high performance P/N type bismuth telluride-based thermoelectric conversion elements, be rectangular flake structure, a plurality of thermoelectric conversion elements are connected in series, respectively place a potsherd and clamping at top and bottom, stick a slice thermal conductive silicon film on the potsherd of top, connect filling porous polymeric seal in the thermoelectric conversion element matrix that connects between each thermoelectric conversion element by the aluminium electrode.

2. by the cryogenic semiconductor Blast Furnace Top Gas Recovery Turbine Unit (TRT) of the industrial middle-size and small-size equipment cogeneration of the described recovery of claim 1, it is characterized in that: heat collector is the ceramic wafer at high performance P/N type bismuth telluride-based thermoelectric conversion element top.

3. by the cryogenic semiconductor Blast Furnace Top Gas Recovery Turbine Unit (TRT) of the industrial middle-size and small-size equipment cogeneration of the described recovery of claim 1, it is characterized in that: the heat radiation cooling system is the ceramic wafer of high performance P/N type bismuth telluride-based thermoelectric conversion element bottom.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2009202134128UCN201584931U (en) | 2009-12-18 | 2009-12-18 | Low-temperature semiconductor power generating device recycling waste heat of medium and small-sized equipment in industry to generate power |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2009202134128UCN201584931U (en) | 2009-12-18 | 2009-12-18 | Low-temperature semiconductor power generating device recycling waste heat of medium and small-sized equipment in industry to generate power |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201584931Utrue CN201584931U (en) | 2010-09-15 |

Family

ID=42726945

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2009202134128UExpired - LifetimeCN201584931U (en) | 2009-12-18 | 2009-12-18 | Low-temperature semiconductor power generating device recycling waste heat of medium and small-sized equipment in industry to generate power |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201584931U (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102104353A (en)* | 2009-12-18 | 2011-06-22 | 上海超日太阳能科技股份有限公司 | Semiconductor generating device using low-temperature waste heat |

| CN102510243A (en)* | 2011-11-12 | 2012-06-20 | 张英华 | Power generating device by waste heat of automobiles |

| CN102544346A (en)* | 2010-12-24 | 2012-07-04 | 中国电子科技集团公司第十八研究所 | Bismuth telluride thermoelectric generator |

| CN102735891A (en)* | 2012-06-08 | 2012-10-17 | 中国科学院电工研究所 | Temperature-difference micro-source applied to measurement of superconductive electrical equipment |

| CN103066892A (en)* | 2012-12-14 | 2013-04-24 | 浙江大学 | External array-type thermoelectric generator single body provided with natural cold end |

| CN103219927A (en)* | 2013-03-21 | 2013-07-24 | 中国科学院电工研究所 | Passive power supply for electrical device detection |

| CN104576001A (en)* | 2014-12-31 | 2015-04-29 | 联合汽车电子有限公司 | Thermoelectric power generation cooling device of ignition coil |

- 2009

- 2009-12-18CNCN2009202134128Upatent/CN201584931U/ennot_activeExpired - Lifetime

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102104353A (en)* | 2009-12-18 | 2011-06-22 | 上海超日太阳能科技股份有限公司 | Semiconductor generating device using low-temperature waste heat |

| CN102544346A (en)* | 2010-12-24 | 2012-07-04 | 中国电子科技集团公司第十八研究所 | Bismuth telluride thermoelectric generator |

| CN102510243A (en)* | 2011-11-12 | 2012-06-20 | 张英华 | Power generating device by waste heat of automobiles |

| CN102510243B (en)* | 2011-11-12 | 2014-04-16 | 张英华 | Power generating device by waste heat of automobiles |

| CN102735891A (en)* | 2012-06-08 | 2012-10-17 | 中国科学院电工研究所 | Temperature-difference micro-source applied to measurement of superconductive electrical equipment |

| CN102735891B (en)* | 2012-06-08 | 2016-03-02 | 中国科学院电工研究所 | A kind of temperature difference micro battery being applied to the electric device measuring of superconduction |

| CN103066892A (en)* | 2012-12-14 | 2013-04-24 | 浙江大学 | External array-type thermoelectric generator single body provided with natural cold end |

| CN103066892B (en)* | 2012-12-14 | 2015-02-11 | 浙江大学 | External array-type thermoelectric generator single body provided with natural cold end |

| CN103219927A (en)* | 2013-03-21 | 2013-07-24 | 中国科学院电工研究所 | Passive power supply for electrical device detection |

| CN103219927B (en)* | 2013-03-21 | 2015-08-26 | 中国科学院电工研究所 | A kind of passive power supply detected for electric equipment |

| CN104576001A (en)* | 2014-12-31 | 2015-04-29 | 联合汽车电子有限公司 | Thermoelectric power generation cooling device of ignition coil |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN201584931U (en) | Low-temperature semiconductor power generating device recycling waste heat of medium and small-sized equipment in industry to generate power | |

| CN1960118B (en) | Power generation system of hybrid energy sources based on photovoltaic effect, and thermoelectric effect of solar energy | |

| CN204068767U (en) | A wearable thermoelectric power generation device | |

| CN102104346B (en) | A kind of light-concentrating photovoltaic-temperature difference power-generating integrated device | |

| CN109104138B (en) | A flexible film-like photothermal-electric conversion device | |

| CN201656818U (en) | DC refrigerator driven by solar photovoltaic power and temperature-difference power | |

| CN204290782U (en) | The high power Multipurpose thermal electric device of rectilinear or horizontal | |

| CN102072641A (en) | Generating system using surface residual heat of dry cement rotary kiln | |

| Fathabadi | Replacing commercial thermoelectric generators with a novel electrochemical device in low-grade heat applications | |

| CN104410328A (en) | Novel low-temperature-difference generating heat dissipation technology | |

| CN108599720A (en) | A kind of solid matter CPV assembly radiating devices | |

| CN115913059A (en) | Photovoltaic thermoelectric coupling flexible power generation device | |

| CN205070938U (en) | Thermoelectric generation system based on solar cell panel | |

| CN107017824A (en) | A kind of electric combined generating device of photoelectric heat | |

| CN102104353A (en) | Semiconductor generating device using low-temperature waste heat | |

| CN201726340U (en) | Solar photoelectricity and thermoelectricity conversion system | |

| CN202652115U (en) | Solar thermoelectric power generation device | |

| CN101106344A (en) | A temperature difference power generation device | |

| CN105227132A (en) | Based on the thermo-electric generation system of solar panel | |

| CN104702153A (en) | Semiconductor temperature difference power generation device | |

| CN205160410U (en) | Water -cooled semiconductor thermal power generation module | |

| CN201878059U (en) | Semiconductor temperature difference generating device for recovering waste heat in concentrated photovoltaic power generation | |

| CN204376778U (en) | A kind of portable wearable temperature difference electricity generation device | |

| CN203840238U (en) | Solar energy vacuum tube idle sunning power generation device and idle sunning power generation module group | |

| CN110635019A (en) | A photothermoelectric conversion device with improved light utilization efficiency |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| PP01 | Preservation of patent right | Effective date of registration:20130912 Granted publication date:20100915 | |

| RINS | Preservation of patent right or utility model and its discharge | ||

| PD01 | Discharge of preservation of patent | Date of cancellation:20140912 Granted publication date:20100915 | |

| RINS | Preservation of patent right or utility model and its discharge | ||

| C56 | Change in the name or address of the patentee | ||

| CP03 | Change of name, title or address | Address after:201406 Shanghai city Fengxian District Jianghai Economic Zone Patentee after:Assist prosperous integrated Science and Technology Co., Ltd. Patentee after:Shanghai Chaori Solar Engineering Co., Ltd. Address before:201406, Shanghai, Fengxian District South Town Wang Yang Economic Zone, flag Road, No. 738 Patentee before:Shanghai Chaori Solar Energy Science & Technology Co., Ltd. Patentee before:Shanghai Chaori Solar Engineering Co., Ltd. | |

| CX01 | Expiry of patent term | Granted publication date:20100915 | |

| CX01 | Expiry of patent term |