CN201548257U - Combined instrument automatic detection device - Google Patents

Combined instrument automatic detection deviceDownload PDFInfo

- Publication number

- CN201548257U CN201548257UCN2009203098152UCN200920309815UCN201548257UCN 201548257 UCN201548257 UCN 201548257UCN 2009203098152 UCN2009203098152 UCN 2009203098152UCN 200920309815 UCN200920309815 UCN 200920309815UCN 201548257 UCN201548257 UCN 201548257U

- Authority

- CN

- China

- Prior art keywords

- speedometer

- tachometer

- unit

- water temperature

- gauge

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Landscapes

- Arrangements For Transmission Of Measured Signals (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域:Technical field:

本实用新型涉及一种组合仪表自动检测装置。The utility model relates to an automatic detection device for a combined instrument.

背景技术:Background technique:

汽车仪表对于驾驶员非常重要,一旦仪表损坏或指示不准会对驾驶员的驾驶判断造成误导,会涉及驾乘人员的安全得不到保障。因为汽车仪表的显示本身只是被动的显示,受车速传感器、水温传感器、转速传感器、燃油传感器等的影响,因此可以设计一种自动检测装置实时的对汽车仪表进行自动检测,可以快捷地判断汽车仪表的指示的准确性,排除因各传感器输入与实车不符信息的原因,快速高效地解除故障,使驾驶员的安全得到保障。The car instrument is very important to the driver. Once the instrument is damaged or the indication is inaccurate, it will mislead the driver's driving judgment, and the safety of the drivers and passengers will not be guaranteed. Because the display of the car meter itself is only a passive display and is affected by the speed sensor, water temperature sensor, speed sensor, fuel sensor, etc., an automatic detection device can be designed to automatically detect the car meter in real time, which can quickly judge the car meter. The accuracy of the instructions, eliminate the reasons for the discrepancy between the input of each sensor and the actual vehicle, and quickly and efficiently resolve the fault, so that the safety of the driver is guaranteed.

发明内容:Invention content:

本实用新型主要解决了汽车仪表损坏或指示不准对驾驶员的驾驶判断造成误导,影响驾乘人员安全的问题,提供了一种组合仪表自动检测装置。The utility model mainly solves the problem of misleading the driver's driving judgment caused by the damaged or inaccurate indication of the automobile instrument and affecting the safety of the drivers and passengers, and provides an automatic detection device for a combined instrument.

本实用新型解决其技术问题所采用的技术方案是:一种组合仪表自动检测装置,组合仪表包括转速表、车速表、燃油表和水温表,还包括用于检测转速表、车速表指针运行情况以及检测燃油表、水温表显示数值的检测单元,检测单元连接至控制处理单元,控制单元包括存储有预先设定的转速表、车速表、燃油表、水温表运行数据的存储模块和将检测单元检测到的数据与存储模块存储的数据进行比较的处理模块,存储模块连接到组合仪表上,处理模块连接至显示单元。上述检测单元检测的转速表、车速表指针运行情况为检测转速表、车速表指针摆动所指的数值;在存储模块内预先存储有转速表、车速表、燃油表、水温表运行数据,该数据预先设定好存储在存储模块内,该数据为模拟与组合仪表对应的转速表传感器、车速表传感器、燃油表传感器、水温表传感器的输出信号,其设定没有要求,如预先设定车速表的数值可以为20、40、60或80码,并可以设置1分钟来回工作4或6个或更多各循环。该存储模块与组合仪表相连,在自动监测装置工作时存储单元将数据发送到组合仪表,使组合仪表按照设定的数据进行指示,这样实现了在汽车未发动的情况下对组合仪表进行检测,操作非常方便。The technical scheme adopted by the utility model to solve the technical problem is: an automatic detection device for a combination meter, the combination meter includes a tachometer, a speedometer, a fuel meter and a water temperature meter, and also includes a function for detecting the operation of the tachometer and speedometer pointer. And a detection unit for detecting the values displayed by the fuel gauge and the water temperature gauge. The detection unit is connected to the control processing unit. The processing module compares the detected data with the data stored in the storage module, the storage module is connected to the combination instrument, and the processing module is connected to the display unit. The running conditions of the tachometer and speedometer pointer detected by the above detection unit are the values indicated by the swing of the tachometer and speedometer pointer; the operation data of the tachometer, speedometer, fuel meter and water temperature meter are pre-stored in the storage module. It is pre-set and stored in the storage module. The data is analog output signals of the tachometer sensor, speedometer sensor, fuel gauge sensor, and water temperature gauge sensor corresponding to the combination instrument. There is no requirement for its setting. The value can be 20, 40, 60 or 80 yards, and can be set to work back and forth for 4 or 6 or more cycles in 1 minute. The storage module is connected with the combination meter, and the storage unit sends the data to the combination meter when the automatic monitoring device is working, so that the combination meter will give instructions according to the set data, thus realizing the detection of the combination meter when the car is not started, It is very convenient to operate.

作为上述方案的一种优选方案,所述检测单元由分别检测转速表、车速表、燃油表和水温表的四个检测模块构成,所述检测模块分别与对应的仪表相连接。这使得对转速表、车速表、燃油表和水温表的检测同步进行,使得检测更加快捷。As a preferred solution of the above solution, the detection unit is composed of four detection modules for respectively detecting the tachometer, the speedometer, the fuel gauge and the water temperature gauge, and the detection modules are respectively connected with corresponding instruments. This makes the detection of the tachometer, speedometer, fuel gauge and water temperature gauge synchronized, making the detection faster.

作为上述方案的一种优选方案,所述控制单元还包括有对转速表、车速表、燃油表、水温表运行数据进行预先设定的输入模块。使使用者可以自行设定所要检测的数值,方便操作。As a preferred solution of the above solution, the control unit further includes an input module for presetting the operating data of the tachometer, speedometer, fuel gauge, and water temperature gauge. The user can set the value to be detected by himself, which is convenient for operation.

作为上述方案的一种优选方案,包括有控制检测装置开启和关闭的开关单元,该开关单元为汽车的点火开关或里程表清零键。该使用模式与自动检测模式切换为:在汽车点火开关关闭状态下,长按里程表清零按钮直到点火开关打开6S后,即可进入自动检测模式;在自动检测模式下,只需按一次里程表清零按钮或将点火开关关闭。与汽车上现有部件相结合,方便操作,降低了制造成本。As a preferred solution of the above solution, it includes a switch unit for controlling the detection device to be turned on and off, and the switch unit is an ignition switch of a car or an odometer reset key. The use mode and the automatic detection mode are switched as follows: when the ignition switch of the car is off, press and hold the odometer reset button until the ignition switch is turned on for 6 seconds, then you can enter the automatic detection mode; in the automatic detection mode, you only need to press the mileage once Press the meter reset button or turn off the ignition switch. Combining with the existing components on the car, it is easy to operate and reduces the manufacturing cost.

本实用新型的优点是:成本低,操作方便,且能使检测问题时判断快捷,误判率很低,解决了汽车仪表损坏或指示不准对驾驶员的驾驶判断造成误导,影响驾乘人员安全的问题。The utility model has the advantages of low cost, convenient operation, fast judgment when detecting problems, and low misjudgment rate, which solves the problem of misleading the driver's driving judgment caused by damage to the car instrument or inaccurate indication, and affecting the driver and passengers safety issue.

附图说明Description of drawings

下面结合附图和实施例对本实用新型进一步说明。Below in conjunction with accompanying drawing and embodiment the utility model is further described.

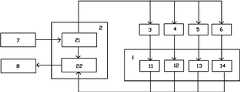

图1是本实用新型的一种结构框视图;Fig. 1 is a kind of structural frame view of the utility model;

图2是本实用新型转速表和车速表检测单元的一种工作流程图;Fig. 2 is a kind of working flow chart of tachometer and speedometer detection unit of the present utility model;

图3是本实用新型燃油表和水温表检测单元的一种工作流程图。Fig. 3 is a working flow chart of the detection unit of the fuel gauge and the water temperature gauge of the utility model.

具体实施方式:Detailed ways:

下面通过实施例,并结合附图,对本实用新型的技术方案作进一步的说明。The technical solutions of the present utility model will be further described below through the embodiments and in conjunction with the accompanying drawings.

实施例:Example:

组合仪表包括转速表3、车速表4、燃油表5和水温表6,根据图1所示,本实用新型自动检测装置包括检测转速表、车速表、燃油表和水温表检测单元1,该检测单元由四个检测模块构成,分别为转速表检测模块11、车速表检测模块12、燃油表检测模块13和水温表检测模块14,这些检测模块分别与其对应的仪表相连接,检测单元输出端与控制处理单元2相连,该控制处理单元包括存储模块21和处理模块22,检测模块连接到处理模块上,该存储模块连接到处理模块上,并且连接到各个仪表的线路上,对每个仪表发送模拟各个仪表对应的传感器输出的信号,在存储模块上还连接有对转速表、车速表、燃油表、水温表运行数据进行预先设定的输入模块7。处理模块连接到显示单元,该显示单元为汽车组合仪表面板上的液晶显示屏,对检测后的结果进行显示。本检测装置通过点火开关或里程表清零键对检测装置进行开启和关闭。Combination instrument comprises

本自动检测装置在使用前,需要预先设定好转速表、车速表、燃油表、水温表运行数据,其存储在存储模块内,该数据可以在检测装置生产后就设定不变,也可以在存储模块上设置一输入模块7,对转速表、车速表、燃油表、水温表运行数据进行重新设定,以满足使用者对仪表不同数值进行检测的要求。该预先设定的数据在检测装置运行时会发送到组合仪表上,即为模拟与组合仪表对应的转速表传感器、车速表传感器、燃油表传感器、水温表传感器的输出信号,使组合仪表安装设定好的运行数据进行指示,如可以设定转速表由指示到2000转,然后再有2000转指示到0,并如此循环,设定一分钟4次循环;设定车速表指示由0指示到80码,然后由80码回到0,并设定一分钟4次循环;设定水温表、燃油表显示阻值为75欧姆相对应的格数。使用时,在汽车点火开关关闭状态下,长按里程表清零按钮直到点火开关打开6S后,即可进入自动检测模式,此时存储模块将预先设定的数据发送到各仪表,则仪表按照设定的运行数据进行指示,同时监测单元对各仪表的运行情况进行监测,然后将监测的数据发送到处理模块,在处理模块内将监测到的数据与预先设定好的数据进行比较,是否存在差别,然后判断仪表是否损坏。如图2所示,转速表和车速表检测单元的工作流程为:开启自动检测模式,转速表与车速表的检测自动开始,两者是同步进行,各自检测按预先设定的输入信号的转速表和车速表的运行情况。在自动检测模式下,若转速表或车速表不能按照预先设定的参数模式,进行指示或有其他异常现象,则说明仪表指示不准或已经损坏,反之则说明转速表或车速表正常。通过预先设定转速表或车速表对应传感器的输入参数,进行自动检测现象与起动发动机后的现象对比,检查人员可以马上作出判定,是仪表的问题还是对应传感器输入信号问题,方便、快捷、针对性地解决问题。如图3所示,燃油表和水温表检测单元的工作流程:开启自动检测模式,燃油表与水温表的检测自动开始,两者检测同步进行,各自通过检测两个仪表显示格数对应的电阻值,并在原公里数液晶显示屏显示电阻值,然后处理模块将预先设定的阻值与仪表上显示的两个电阻值进行比对,若有差异,则说明仪表指示不准或已经损坏。反之则说明燃油表或水温表正常。全部检测完毕后,处理模块将结果显示在液晶显示屏上,如可以预先设定显示的数据第一位表示转速表,第二位表示车速表,第三位表示水温表、第四为表示燃油表,而设定数值0为表示正常,1则表示损坏,这样使用者通过观察液晶显示屏上的监测结果数据很容易就判断处哪个仪表损坏。Before using the automatic detection device, it is necessary to pre-set the operating data of the tachometer, speedometer, fuel gauge, and water temperature meter, which are stored in the storage module. The data can be set unchanged after the detection device is produced, or can be An

尽管本文较多地使用了检测单元、控制处理单元、存储模块和处理模块等术语,但并不排除使用其它术语的可能性。使用这些术语仅仅是为了更方便地描述和解释本发明的本质;把它们解释成任何一种附加的限制都是与本发明精神相违背的。Although terms such as detection unit, control processing unit, storage module and processing module are frequently used in this document, the possibility of using other terms is not excluded. These terms are used only for the purpose of describing and explaining the essence of the present invention more conveniently; interpreting them as any kind of additional limitation is against the spirit of the present invention.

Claims (4)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2009203098152UCN201548257U (en) | 2009-09-08 | 2009-09-08 | Combined instrument automatic detection device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN2009203098152UCN201548257U (en) | 2009-09-08 | 2009-09-08 | Combined instrument automatic detection device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201548257Utrue CN201548257U (en) | 2010-08-11 |

Family

ID=42603432

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN2009203098152UExpired - Fee RelatedCN201548257U (en) | 2009-09-08 | 2009-09-08 | Combined instrument automatic detection device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201548257U (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102589604A (en)* | 2012-02-24 | 2012-07-18 | 惠州市德赛西威汽车电子有限公司 | System and method for verifying automobile instrument |

| CN104360681B (en)* | 2014-11-05 | 2017-04-05 | 上海德科电子仪表有限公司 | The monitoring method of automobile combination meter monitoring system |

| CN113218416A (en)* | 2021-04-15 | 2021-08-06 | 东风电驱动系统有限公司 | Automatic test method and system for automobile instrument subtotal mileage zero clearing function |

| CN116448158A (en)* | 2023-04-12 | 2023-07-18 | 中国第一汽车股份有限公司 | Test method, device and electronic device for combination meter in vehicle |

- 2009

- 2009-09-08CNCN2009203098152Upatent/CN201548257U/ennot_activeExpired - Fee Related

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102589604A (en)* | 2012-02-24 | 2012-07-18 | 惠州市德赛西威汽车电子有限公司 | System and method for verifying automobile instrument |

| CN104360681B (en)* | 2014-11-05 | 2017-04-05 | 上海德科电子仪表有限公司 | The monitoring method of automobile combination meter monitoring system |

| CN113218416A (en)* | 2021-04-15 | 2021-08-06 | 东风电驱动系统有限公司 | Automatic test method and system for automobile instrument subtotal mileage zero clearing function |

| CN116448158A (en)* | 2023-04-12 | 2023-07-18 | 中国第一汽车股份有限公司 | Test method, device and electronic device for combination meter in vehicle |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN201548257U (en) | Combined instrument automatic detection device | |

| CN107357254A (en) | Intelligent instrument device and system | |

| CN201569692U (en) | Automobile instrument comprehensive checking device | |

| CN201297940Y (en) | Motor meter and diagnostic system thereof | |

| US20090118893A1 (en) | Method of integrated detection for automobile instruments | |

| KR101499092B1 (en) | An diagnosis device for an automobile | |

| CN205010008U (en) | Automobile -used liquid crystal display instrument system | |

| CN203957893U (en) | Heavy motor vehicle LNG fuel surplus detects and read out instrument | |

| CN202531256U (en) | Engine oil level metering device | |

| CN206223714U (en) | A kind of brake fluid detection means | |

| CN110624200A (en) | Fire extinguisher failure automatic alarm system applied to automobiles and its realization method | |

| CN201566497U (en) | Instrument cluster with adjustable speed limiter | |

| CN215573562U (en) | Transmission shaft noise detection device | |

| CN209894289U (en) | Fuel tank liquid level sensor resistance simulator | |

| CN203758585U (en) | Diagnostic test system for fuel gauge | |

| CN201615947U (en) | Reversing radar with self-diagnosis function with graphic and sound display | |

| JP4001522B2 (en) | Fuel consumption display device for vehicles | |

| CN201293650Y (en) | Automatic scanner for combined instrument core | |

| CN102435445A (en) | System for detecting starting and flameout of automobile and detection method thereof | |

| JP2012083608A (en) | Display mechanism monitoring device | |

| CN202177822U (en) | Automobile ECU (Electric Control Unit) testing device based on ARM (Advanced RISC Machines) SCM (single-chip microcomputer) | |

| JP2001194204A (en) | Display device for remaining running distance for vehicle | |

| CN201203533Y (en) | EFI Gasoline Engine Management System Test and Diagnosis Instrument | |

| CN104764505A (en) | Method and device for indicating automobile fuel meter | |

| CN205130941U (en) | Automobile -used gas combination meter |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20100811 Termination date:20170908 | |

| CF01 | Termination of patent right due to non-payment of annual fee |