CN201300517Y - Mould for manufacturing foldable artificial glass body - Google Patents

Mould for manufacturing foldable artificial glass bodyDownload PDFInfo

- Publication number

- CN201300517Y CN201300517YCNU2008202019093UCN200820201909UCN201300517YCN 201300517 YCN201300517 YCN 201300517YCN U2008202019093 UCNU2008202019093 UCN U2008202019093UCN 200820201909 UCN200820201909 UCN 200820201909UCN 201300517 YCN201300517 YCN 201300517Y

- Authority

- CN

- China

- Prior art keywords

- mold

- mould

- drainage

- balloon

- drainage valve

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000011521glassSubstances0.000titleclaimsdescription9

- 238000004519manufacturing processMethods0.000titleabstractdescription22

- 238000002347injectionMethods0.000claimsabstractdescription19

- 239000007924injectionSubstances0.000claimsabstractdescription19

- 239000003292glueSubstances0.000claimsabstractdescription15

- 210000005252bulbus oculiAnatomy0.000claimsdescription5

- 125000006850spacer groupChemical group0.000claims3

- 210000004127vitreous bodyAnatomy0.000abstractdescription21

- 238000010438heat treatmentMethods0.000abstractdescription9

- 210000001525retinaAnatomy0.000abstractdescription6

- 239000003814drugSubstances0.000abstractdescription3

- 229940079593drugDrugs0.000abstractdescription3

- 230000035699permeabilityEffects0.000abstractdescription2

- 239000012530fluidSubstances0.000abstract1

- 230000004410intraocular pressureEffects0.000abstract1

- 238000013268sustained releaseMethods0.000abstract1

- 239000012730sustained-release formSubstances0.000abstract1

- 239000000463materialSubstances0.000description20

- 239000000017hydrogelSubstances0.000description8

- 238000001816coolingMethods0.000description4

- 238000000034methodMethods0.000description4

- 239000000203mixtureSubstances0.000description4

- 229920002545silicone oilPolymers0.000description4

- 238000001356surgical procedureMethods0.000description4

- 238000010586diagramMethods0.000description3

- 210000001508eyeAnatomy0.000description3

- 238000000465mouldingMethods0.000description3

- 229940126585therapeutic drugDrugs0.000description3

- 208000002177CataractDiseases0.000description2

- 239000004480active ingredientSubstances0.000description2

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000description2

- 229910052782aluminiumInorganic materials0.000description2

- 238000012377drug deliveryMethods0.000description2

- 230000004438eyesightEffects0.000description2

- 239000011261inert gasSubstances0.000description2

- 230000001788irregularEffects0.000description2

- 239000007788liquidSubstances0.000description2

- VNWKTOKETHGBQD-UHFFFAOYSA-NmethaneChemical compoundCVNWKTOKETHGBQD-UHFFFAOYSA-N0.000description2

- 235000013855polyvinylpyrrolidoneNutrition0.000description2

- 229920000036polyvinylpyrrolidonePolymers0.000description2

- 239000000243solutionSubstances0.000description2

- TXEYQDLBPFQVAA-UHFFFAOYSA-NtetrafluoromethaneChemical compoundFC(F)(F)FTXEYQDLBPFQVAA-UHFFFAOYSA-N0.000description2

- 208000010412GlaucomaDiseases0.000description1

- 206010064487Oral mucosal exfoliationDiseases0.000description1

- 206010035148PlagueDiseases0.000description1

- 241000607479Yersinia pestisSpecies0.000description1

- 210000002159anterior chamberAnatomy0.000description1

- 201000010099diseaseDiseases0.000description1

- 208000037265diseases, disorders, signs and symptomsDiseases0.000description1

- 230000000694effectsEffects0.000description1

- 238000004945emulsificationMethods0.000description1

- 238000005516engineering processMethods0.000description1

- 230000004330high hyperopiaEffects0.000description1

- 208000010073high hyperopiaDiseases0.000description1

- 229920001477hydrophilic polymerPolymers0.000description1

- 238000002513implantationMethods0.000description1

- 238000001746injection mouldingMethods0.000description1

- 230000002045lasting effectEffects0.000description1

- 230000007774longtermEffects0.000description1

- 239000003345natural gasSubstances0.000description1

- 230000003204osmotic effectEffects0.000description1

- 238000012856packingMethods0.000description1

- 229920006254polymer filmPolymers0.000description1

- 239000002861polymer materialSubstances0.000description1

- 229920001296polysiloxanePolymers0.000description1

- 239000001267polyvinylpyrrolidoneSubstances0.000description1

- 239000011148porous materialSubstances0.000description1

- 230000001225therapeutic effectEffects0.000description1

- 231100000331toxicToxicity0.000description1

- 230000002588toxic effectEffects0.000description1

- 231100000419toxicityToxicity0.000description1

- 230000001988toxicityEffects0.000description1

- 230000009466transformationEffects0.000description1

- 238000011282treatmentMethods0.000description1

- 238000011269treatment regimenMethods0.000description1

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description1

Images

Classifications

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P40/00—Technologies relating to the processing of minerals

- Y02P40/50—Glass production, e.g. reusing waste heat during processing or shaping

- Y02P40/57—Improving the yield, e-g- reduction of reject rates

Landscapes

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese【技术领域】【Technical field】

本实用新型涉及一种眼科治疗制品的制造模具,特别是指一种制造折叠式人工玻璃体的模具。The utility model relates to a manufacturing mold of an ophthalmic treatment product, in particular to a mold for manufacturing a folded artificial vitreous body.

【背景技术】【Background technique】

目前国内外对玻璃体替代物研究众多,主要有惰性气体、硅油、重硅油、过氟化碳液体,以及上世纪九十年代国内外研究热点的高分子亲水性聚合物水凝胶等。但它们的治疗效果均不甚理想,有的能引起严重的并发症。如,惰性气体如C3F8,容易发生白内障,在术后两周左右失去填塞作用,不能对视网膜产生持久的顶压作用;过氟化碳液体对视网膜有毒性,不能长期留置在玻璃体腔,仅限于术中使用,且容易残留于眼内,与水起反应后更难以取出;目前临床应用比较广泛的硅油替代物,可引起白内障和青光眼,且本身在一定的时间内会乳化,乳化后必须取出,但取出后视网膜易发生再次脱离,反复多次的手术,不仅加重了患者的经济负担,而且严重损害了患者的视力;即使手术成功,由于硅油屈光指数小,对视网膜下方裂孔顶压效果差,同时填充后必然使眼球屈光度向高度远视方向改变,因而患者的视力也非常差;另外患者术后必须是长期俯卧位,以防止硅油流入前房,因而患者非常痛苦。水凝胶主要有PVP水凝胶、PVA水凝胶、PAM水凝胶和聚乙烯吡咯烷酮水凝胶等,但这些水凝胶在眼科还处于实验阶段,迄今为止还没有一种水凝胶进入临床应用,对眼内毒性缺乏远期疗效观察,且价格非常昂贵,患者难以负担。因此寻找更符合生理、更经济的玻璃体替代物势在必行,也是这个世纪困扰玻璃体视网膜疾病医生的难题之一。At present, there are many studies on vitreous substitutes at home and abroad, mainly including inert gas, silicone oil, heavy silicone oil, perfluorocarbon liquid, and high molecular hydrophilic polymer hydrogel, which was a research hotspot at home and abroad in the 1990s. But their therapeutic effects are not ideal, and some can cause serious complications. For example, inert gases such as C3F8 are prone to cataracts, and lose their packing effect about two weeks after surgery, and cannot produce a lasting pressure on the retina; perfluorocarbon liquids are toxic to the retina and cannot be left in the vitreous cavity for a long time. It is used during surgery, and it is easy to remain in the eye, and it is more difficult to remove after reacting with water; currently, the silicone oil substitute that is widely used in clinical practice can cause cataract and glaucoma, and it will emulsify within a certain period of time, so it must be removed after emulsification , but the retina is prone to re-detachment after removal. Repeated operations not only increase the financial burden of the patient, but also seriously damage the patient's vision; At the same time, after filling, the diopter of the eyeball will inevitably change to the direction of high hyperopia, so the patient's vision is also very poor; in addition, the patient must be in a prone position for a long time after surgery to prevent silicone oil from flowing into the anterior chamber, so the patient is very painful. Hydrogels mainly include PVP hydrogels, PVA hydrogels, PAM hydrogels and polyvinylpyrrolidone hydrogels, etc., but these hydrogels are still in the experimental stage in ophthalmology, and no hydrogel has entered the field so far. In clinical application, there is no long-term efficacy observation on intraocular toxicity, and the price is very expensive, which is difficult for patients to afford. Therefore, it is imperative to find a more physiological and economical vitreous substitute, which is also one of the problems that plague doctors of vitreoretinal diseases in this century.

如何制成一个结构和功能都与自然玻璃体相同的人工玻璃体是保证玻璃体手术成功的关键因素之一。玻璃体的成分目前还没有完全了解,在现有的科学技术条件下,要求制作出形态和功能都很完美的人工玻璃体是不切实际的。现有的玻璃体替代物有时也称为人工玻璃体,植入方法均是在术中将其直接注入到玻璃体腔,来支撑视网膜,防止视网膜再脱离。因此,改变研究思路,不去追求制作完全生理性的人工玻璃体,而是应用新的治疗策略-应用折叠式人工玻璃体去替代自然的玻璃体,它主要由携带引流阀的高分子薄膜球囊、引流管组成,配备辅助工具:弹射手柄。How to make an artificial vitreous with the same structure and function as the natural vitreous is one of the key factors to ensure the success of vitreous surgery. The composition of the vitreous body is not yet fully understood. Under the current scientific and technological conditions, it is impractical to produce an artificial vitreous body with perfect shape and function. The existing vitreous substitutes are sometimes called artificial vitreous, and the implantation method is to inject it directly into the vitreous cavity during the operation to support the retina and prevent further detachment of the retina. Therefore, instead of pursuing the production of a completely physiological artificial vitreous body, change the research idea, but apply a new treatment strategy - applying a folded artificial vitreous body to replace the natural vitreous body, which mainly consists of a polymer film balloon with a drainage valve, drainage tube, equipped with auxiliary tools: ejection handle.

【发明内容】【Content of invention】

本实用新型的目的在于提供一种可以制造出这样的人工玻璃体的制造模具:机械性能和生物相容性较高、工艺先进稳定的折叠式人工玻璃体、控制和调节其压力的引流阀。The purpose of the utility model is to provide a manufacturing mold capable of manufacturing such an artificial vitreous body: a folding artificial vitreous body with high mechanical properties and biocompatibility, advanced and stable technology, and a drainage valve for controlling and adjusting its pressure.

为实现本实用新型目的,提供以下技术方案:For realizing the purpose of the utility model, the following technical solutions are provided:

提供一种用于制造折叠式人工玻璃体的模具,其包括上合模、下合模和型芯,型芯设置于上合模和下合模之间,且连接有引流管针,引流管针与注胶通道连接,在上合模和/或下合模上设有加热孔。Provided is a mold for manufacturing a folded artificial vitreous body, which includes an upper clamping mold, a lower clamping mold and a core, the core is arranged between the upper clamping mold and the lower clamping mold, and is connected with a drainage tube needle, and the drainage tube needle It is connected with the glue injection channel, and a heating hole is arranged on the upper clamping mold and/or the lower clamping mold.

该上合模设有滑块,型芯连接有定位片,该定位片可定位于滑块中。作为较佳实施例,该定位片的主轴与引流管针主轴延长线成直角,且与型芯的圆心在同一平面上。该引流管针通过引流阀与注胶管道连接。该引流阀底部设有与眼球表面相吻合的弧度,并且该引流阀底部嵌有硬性薄片。The upper clamping mold is provided with a slide block, the core is connected with a positioning piece, and the positioning piece can be positioned in the slide block. As a preferred embodiment, the main axis of the positioning piece is at right angles to the extension line of the main axis of the drainage tube needle, and is on the same plane as the center of the core. The drainage needle is connected with the glue injection pipeline through the drainage valve. The bottom of the drainage valve is provided with a radian matching the surface of the eyeball, and a hard sheet is embedded in the bottom of the drainage valve.

该注胶通道可同时连接多个型芯,通过注胶通道同时向多个型芯注胶,实现批量式机械制造。The glue injection channel can connect multiple cores at the same time, and inject glue to multiple cores through the glue injection channel at the same time, so as to realize batch mechanical manufacturing.

该模具还连接有温控设备,以控制合适的制造温度。The mold is also connected with a temperature control device to control the proper manufacturing temperature.

采用上述制造折叠式人工玻璃体的模具的折叠式人工玻璃体制造方法如下:应用注射成型法将加工材料注入上述模具内,经加热硫化后,形成折叠式人工玻璃体。采用本实用新型模具的制作方法具体包括如下步骤:The manufacturing method of the folding artificial vitreous body using the above-mentioned mold for manufacturing the folding artificial vitreous body is as follows: the processing material is injected into the above-mentioned mold by the injection molding method, and the folding artificial vitreous body is formed after heating and vulcanizing. Adopt the manufacturing method of mold of the present utility model to specifically comprise the steps:

(1)取高分子天然或改性材料均匀混合,抽真空后备用;(1) Get high molecular natural or modified materials and evenly mix them, and set aside after vacuumizing;

(2)在引流阀处涂布适量加工材料,放置硬性薄片;(2) Apply appropriate amount of processing material at the drainage valve and place a hard sheet;

(3)将型芯放入上合模和下合模之间,合上模具并锁模;(3) Put the core between the upper clamping mold and the lower clamping mold, close the mold and lock the mold;

(4)从注胶通道注入步骤(1)中准备好的加工材料,并使其充满模腔;(4) Inject the processed material prepared in step (1) from the injection channel, and make it fill the mold cavity;

(5)通过加热孔对模具进行加热,使模腔内的材料固化;(5) The mold is heated through the heating hole to solidify the material in the mold cavity;

(6)开模,冷却后取出型芯,剥出囊袋制品。(6) Open the mold, take out the core after cooling, and peel off the pouch product.

为延长模具寿命并为下一次制造做好准备,在每次玻璃体制造完成剥出囊袋制品之后,都对模具进行清理。To prolong mold life and prepare for the next fabrication, the mold is cleaned after each glass body fabrication after the pouch product is stripped.

步骤(2)中,在引流阀处涂布硅胶材料,放置硬性薄片,该硬性薄片可防止引流阀被穿透,保障其气密性。若采用人工注胶方式,可预先在上、下合模涂布适量材料。In step (2), the silicone material is coated on the drainage valve, and a hard sheet is placed, which can prevent the drainage valve from being penetrated and ensure its airtightness. If the manual glue injection method is used, an appropriate amount of material can be pre-coated on the upper and lower molds.

步骤(6)中取出的囊袋制品可作进一步加工,对球囊剥离口涂布适量加工材料,然后将囊袋制品置于与球囊剥离口形状相吻合的封口器,进行剥离口的二次成型,并利用修剪器修整粘合完毕的剥离口。该封口器工作温度范围在60℃-300℃,最佳工作温度为110℃,工作时间大于2秒,最佳时间为6秒左右。The pouch product taken out in step (6) can be further processed, and an appropriate amount of processing material is applied to the peeling port of the balloon, and then the pouch product is placed in a sealer that matches the shape of the peeling port of the balloon, and the second step of the peeling port is performed. Secondary molding, and use the trimmer to trim the glued peeling mouth. The working temperature range of the sealer is 60°C-300°C, the best working temperature is 110°C, the working time is more than 2 seconds, and the best time is about 6 seconds.

步骤(5)中的加热温度控制在80℃-300℃范围内,最佳加热温度为160℃。The heating temperature in step (5) is controlled within the range of 80°C-300°C, and the optimum heating temperature is 160°C.

该制作方法中可以通过改变球囊材料的孔径、运用纳米技术、改变球囊壁厚、改变球囊内介质的渗透压,从而控制球囊的通透性,并经引流阀注入治疗药物或自然玻璃体有效成分,使该方法得出的囊袋制品成为一个药物缓释系统。In this manufacturing method, the permeability of the balloon can be controlled by changing the pore size of the balloon material, using nanotechnology, changing the wall thickness of the balloon, and changing the osmotic pressure of the medium in the balloon, and injecting therapeutic drugs or natural gas through the drainage valve. The effective components of the vitreous body make the pouch product obtained by the method a drug slow-release system.

采用上述制造方法及制造模具制造出来的折叠式人工玻璃体,其包括球囊、连接球囊的引流管和引流阀,引流管的内、外口分别与球囊和引流阀相衔接,球囊上有小凹结构。The folded artificial vitreous body produced by the above-mentioned manufacturing method and mold includes a balloon, a drainage tube connected to the balloon, and a drainage valve. The inner and outer ports of the drainage tube are respectively connected with the balloon and the drainage valve. There is a small concave structure.

该引流阀底部设有弧度,与眼球表面相吻合,且该引流阀底部嵌有硬性薄片,防止引流阀被穿透,保障其气密性,该引流阀经过多次穿刺后,仍可保持其密封性。该引流阀可设有裂隙,以调节球囊内压力。该引流阀可为任意形状,如三角形、梯形、四边形,或不规则形状。There is a radian at the bottom of the drainage valve, which coincides with the surface of the eyeball, and a hard sheet is embedded at the bottom of the drainage valve to prevent the drainage valve from being penetrated and ensure its airtightness. After multiple punctures, the drainage valve can still maintain its tightness. The drainage valve can be provided with a slit to adjust the pressure inside the balloon. The diversion valve can be in any shape, such as triangle, trapezoid, quadrangle, or irregular shape.

该折叠式人工玻璃体可以作为药物缓释系统(drug delivery system,DDS),其中包含有治疗药物或自然玻璃体有效成分。The folded artificial vitreous can be used as a drug delivery system (DDS), which contains active ingredients of therapeutic drugs or natural vitreous.

对比现有技术,本实用新型具有以下优点:Compared with the prior art, the utility model has the following advantages:

本实用新型模具由上、下合模与型芯组成;模具各项数据均参照人眼的生理参数;同时配备加压、加热、冷却和温控设备;通过注射成型的折叠式人工玻璃体的球囊、引流管与引流阀为一次成型,整体性好,引流管柔软,对眼部组织损伤小,引流阀体积小,柔软,与组织相容性好。The mold of the utility model is composed of upper and lower clamping molds and a core; all the data of the mold refer to the physiological parameters of the human eye; at the same time, it is equipped with pressurization, heating, cooling and temperature control equipment; The sac, drainage tube and drainage valve are formed at one time, with good integrity, the drainage tube is soft, and causes little damage to eye tissues, and the drainage valve is small in size, soft, and has good compatibility with tissues.

【附图说明】【Description of drawings】

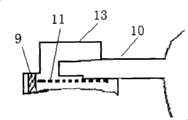

图1为本实用新型模具的剖面视图;Fig. 1 is the sectional view of mold of the present utility model;

图2为本实用新型模具的俯视图;Fig. 2 is the top view of the mold of the present utility model;

图3为本实用新型模具的引流阀的俯视图;Fig. 3 is the top view of the drainage valve of the utility model mold;

图4为制品引流阀的侧视图;Fig. 4 is a side view of the product drainage valve;

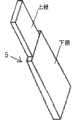

图5a、5b为本实用新型模具的型芯的示意图;Fig. 5a, 5b are the schematic diagrams of the core of the utility model mold;

图6为本实用新型模具的定位片的示意图;Fig. 6 is the schematic diagram of the positioning piece of the utility model mold;

图7为本实用新型制品折叠式人工玻璃体示意图。Fig. 7 is a schematic diagram of a folded artificial vitreous body of the product of the present invention.

【具体实施方式】【Detailed ways】

请参阅图1~图4,本实用新型用于制造折叠式人工玻璃体的模具其包括上合模1、下合模2和型芯3,型芯3设置于上合模1和下合模2之间,且连接有引流管针10,引流管针10与注胶通道4连接,在上合模1和/或下合模2上设有加热孔6。Please refer to Fig. 1~Fig. 4, the mold that the utility model is used for manufacturing folding artificial vitreous body comprises upper clamping mold 1, lower clamping mold 2 and core 3, and core 3 is arranged on upper clamping mold 1 and lower clamping mold 2 Between, and is connected with

该上合模1设有滑块7,型芯3连接有定位片5,该定位片5可定位于滑块7中。该引流管针10通过引流阀13与注胶管道4连接。The upper clamping mold 1 is provided with a

请参阅图5、6,该型芯连接定位片5,该定位片5分为上下两段,该定位片5上段固定在滑块7中。Please refer to Fig. 5, 6, this mold core connects

型芯3所连接的引流管针10通过引流阀13与上合模1的注胶通道4连接,引流阀内设有硬性薄片,本实施例中采用铝片11,且通过定位针9来定位。The

采用上述模具来进行制造的折叠式人工玻璃体制造方法,其包括如下步骤:Adopt above-mentioned mold to carry out the folding type artificial vitreous body manufacturing method of manufacturing, it comprises the steps:

(1)取高分子天然或改性材料均匀混合,抽真空后备用;(1) Get high molecular natural or modified materials and evenly mix them, and set aside after vacuumizing;

(2)在引流阀处涂布适量加工材料,放置硬性薄片;(2) Apply appropriate amount of processing material at the drainage valve and place a hard sheet;

(3)将型芯放入上合模和下合模之间,合上模具并锁模;(3) Put the core between the upper clamping mold and the lower clamping mold, close the mold and lock the mold;

(4)从注胶通道注入准备好的加工材料,并使其充满模腔;(4) Inject the prepared processing material from the injection channel and make it fill the mold cavity;

(5)通过加热孔对模具进行加热,使模腔内的材料固化;(5) The mold is heated through the heating hole to solidify the material in the mold cavity;

(6)开模,冷却后取出型芯,剥出囊袋制品;(6) open mold, take out core after cooling, strip off pouch product;

(7)清理模具;(7) Clean the mold;

(8)球囊剥离口涂布适量加工材料,置于封口器,进行剥离口的二次成型。(8) Coat an appropriate amount of processing material at the peeling port of the balloon, place it in a sealer, and carry out secondary molding of the peeling port.

具体来说,包括如下步骤:Specifically, it includes the following steps:

1)取高分子天然或改性材料均匀混合,抽真空后备用;1) Mix natural or modified polymer materials evenly, and vacuumize for later use;

2)在引流阀处涂布适量加工材料,放置硬性薄片。若为人工注胶,需预先在上、下合模涂布适量加工材料;若为机械注胶,上下合模可涂布加工材料,亦可不涂;2) Apply a proper amount of processing material at the drainage valve and place a hard sheet. If it is manual glue injection, it is necessary to apply an appropriate amount of processing material on the upper and lower molds in advance; if it is mechanical injection, the upper and lower molds can be coated with processing materials or not;

3)放入并调整型芯,若为人工注胶,需预先向注胶通道推入适量加工材料,以排除注胶通道内的空气,再合上模具,锁模后注胶;若为机械注胶,合上模具,锁模后(锁模力0-100N),抽真空,排尽模具内的空气,再从注胶通道注入加工材料;3) Put in and adjust the core. If it is artificial injection, it is necessary to push an appropriate amount of processing materials into the injection channel in advance to remove the air in the injection channel, then close the mold, and inject the glue after locking the mold; if it is mechanical Inject glue, close the mold, after clamping (clamping force 0-100N), vacuumize, exhaust the air in the mold, and then inject processing materials from the injection channel;

4)加热至160℃(80℃-300℃),开模,冷却后取出型芯,剥出囊袋制品;4) Heat to 160°C (80°C-300°C), open the mold, take out the core after cooling, and peel off the pouch product;

5)清理模具;5) Clean the mold;

6)球囊剥离口涂布适量加工材料,置于封口器,进行剥离口的二次成型。封口器与剥离口形状相吻合。封口器工作温度为110℃(60℃-300℃),时间为6秒钟左右(大于2秒);6) Apply an appropriate amount of processing material to the peeling port of the balloon, place it in a sealer, and perform secondary molding of the peeling port. The sealer matches the shape of the peeling port. The working temperature of the sealer is 110°C (60°C-300°C), and the time is about 6 seconds (more than 2 seconds);

7)利用修剪器修整粘合完毕的剥离口;7) Use a trimmer to trim the bonded peeling port;

8)模具需冷却至常温(<30℃)后(可能范围<100℃),再进行囊袋的制作。8) The mold needs to be cooled to normal temperature (<30°C) (possible range <100°C) before making the pouch.

如图7所示,采用上述制造方法及制造模具制造出来的折叠式人工玻璃体,其包括球囊14、连接球囊的引流管15和引流阀16,引流管15的内、外口分别与球囊14和引流阀16相衔接,球囊14上有小凹结构17。As shown in Figure 7, the folded artificial vitreous body manufactured by the above-mentioned manufacturing method and the manufacturing mold includes a

结合参阅图4,该引流阀16底部设有弧度,与眼球表面相吻合,且该引流阀16底部嵌有硬性薄铝片11,防止引流阀被穿透,保障其气密性,该引流阀经过多次穿刺后,仍可保持其密封性。该引流阀可设有裂隙,以调节球囊内压力。该引流阀可为任意形状,如:三角形、四边形、梯形或不规则形状。Referring to Fig. 4, the bottom of the

该折叠式人工玻璃体可以作为药物缓释系统(drug delivery system,DDS),其中包含有治疗药物或自然玻璃体有效成分。The folded artificial vitreous can be used as a drug delivery system (DDS), which contains active ingredients of therapeutic drugs or natural vitreous.

以上所述仅为本实用新型的较佳实施例,本实用新型的保护范围并不局限于此,任何基于本实用新型技术方案上的等效变换均属于本实用新型保护范围之内。The above descriptions are only preferred embodiments of the present utility model, and the protection scope of the present utility model is not limited thereto. Any equivalent transformation based on the technical solution of the present utility model falls within the protection scope of the present utility model.

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNU2008202019093UCN201300517Y (en) | 2008-10-15 | 2008-10-15 | Mould for manufacturing foldable artificial glass body |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNU2008202019093UCN201300517Y (en) | 2008-10-15 | 2008-10-15 | Mould for manufacturing foldable artificial glass body |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201300517Ytrue CN201300517Y (en) | 2009-09-02 |

Family

ID=41084135

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNU2008202019093UExpired - LifetimeCN201300517Y (en) | 2008-10-15 | 2008-10-15 | Mould for manufacturing foldable artificial glass body |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201300517Y (en) |

- 2008

- 2008-10-15CNCNU2008202019093Upatent/CN201300517Y/ennot_activeExpired - Lifetime

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8573961B2 (en) | Mold for manufacturing a foldable artificial vitreous body | |

| JP6023799B2 (en) | Adjustable intraocular lens | |

| US9370446B2 (en) | Method of altering the refractive properties of an eye | |

| JP5058408B2 (en) | Corneal implant and method for producing the same | |

| US20040127932A1 (en) | Dip-molded polymeric medical devices with reverse thickness gradient, and method of making same | |

| US20100210996A1 (en) | Method for laser correction of refractive errors of an eye with a thin cornea | |

| US9681984B2 (en) | Method of altering the refractive properties of an eye | |

| CN110037853B (en) | Folding artificial glass body, mould and manufacturing method thereof | |

| US10195081B1 (en) | Method of prevention of capsular opacification and fibrosis after cataract extraction and/or prevention of fibrosis around a shunt or stent after glaucoma surgery | |

| CN221691613U (en) | Negative pressure ring device for sclera crosslinking | |

| US7879088B2 (en) | Capsular bag for artificial vitreous body and method for manufacturing the same | |

| US10206569B1 (en) | Corneal intraocular pressure sensor and a surgical method using the same | |

| CN201300517Y (en) | Mould for manufacturing foldable artificial glass body | |

| CN110900975A (en) | Mould for manufacturing folding artificial glass body | |

| WO2013007090A1 (en) | Foldable artificial vitreous body bolus injector | |

| CN202607924U (en) | Mold for preparing cornea collagen membrane | |

| CN207477601U (en) | Integral type gas-liquid exchanges syringe needle | |

| HK1157284A (en) | Manufacturing method of foldable artificial vitreous body and mould thereof | |

| CN117017611B (en) | A riboflavin dripping beaker for corneal collagen cross-linking surgery | |

| HK1157284B (en) | Manufacturing method of foldable artificial vitreous body and mould thereof | |

| CN219250643U (en) | Prevent postoperative sclera lamella adhesion device | |

| CN216496021U (en) | Special position needle that fills of ICL implantation | |

| CN120022134A (en) | Personalized contact lens microneedle device for the treatment of corneal ectatic disease | |

| Titiyal et al. | Deep anterior lamellar keratoplasty with Intacs explantation in keratoconus | |

| CN118370768A (en) | Preparation method of a soluble microneedle patch loaded with black phosphorus quantum dots and its application in treating infectious keratitis |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CX01 | Expiry of patent term | Granted publication date:20090902 | |

| CX01 | Expiry of patent term |