CN201193811Y - light emitting device - Google Patents

light emitting deviceDownload PDFInfo

- Publication number

- CN201193811Y CN201193811YCNU2008200052237UCN200820005223UCN201193811YCN 201193811 YCN201193811 YCN 201193811YCN U2008200052237 UCNU2008200052237 UCN U2008200052237UCN 200820005223 UCN200820005223 UCN 200820005223UCN 201193811 YCN201193811 YCN 201193811Y

- Authority

- CN

- China

- Prior art keywords

- light

- emitting diode

- diode chip

- emitting device

- printed circuit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 239000003566sealing materialSubstances0.000claimsabstractdescription22

- 239000000463materialSubstances0.000claimsabstractdescription8

- 238000004026adhesive bondingMethods0.000claimsabstract3

- 239000000758substrateSubstances0.000claimsdescription19

- 229910052751metalInorganic materials0.000claimsdescription11

- 239000002184metalSubstances0.000claimsdescription11

- 239000004925Acrylic resinSubstances0.000claimsdescription3

- 229920000178Acrylic resinPolymers0.000claimsdescription3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-NSilicium dioxideChemical compoundO=[Si]=OVYPSYNLAJGMNEJ-UHFFFAOYSA-N0.000claimsdescription3

- 239000003822epoxy resinSubstances0.000claimsdescription3

- 229920000647polyepoxidePolymers0.000claimsdescription3

- 239000000741silica gelSubstances0.000claimsdescription3

- 229910002027silica gelInorganic materials0.000claimsdescription3

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical compound[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000claimsdescription2

- 229910052782aluminiumInorganic materials0.000claimsdescription2

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000claimsdescription2

- 229910052802copperInorganic materials0.000claimsdescription2

- 239000010949copperSubstances0.000claimsdescription2

- ATJFFYVFTNAWJD-UHFFFAOYSA-NTinChemical compound[Sn]ATJFFYVFTNAWJD-UHFFFAOYSA-N0.000claims1

- 239000004411aluminiumSubstances0.000claims1

- 229910000679solderInorganic materials0.000abstractdescription20

- 238000000034methodMethods0.000abstractdescription6

- 238000005253claddingMethods0.000abstract1

- 239000003292glueSubstances0.000abstract1

- 230000008595infiltrationEffects0.000abstract1

- 238000001764infiltrationMethods0.000abstract1

- 239000000126substanceSubstances0.000description6

- 230000000149penetrating effectEffects0.000description4

- 230000008569processEffects0.000description4

- 238000007789sealingMethods0.000description4

- 230000007547defectEffects0.000description3

- 239000008393encapsulating agentSubstances0.000description3

- 238000010586diagramMethods0.000description2

- 230000000694effectsEffects0.000description2

- 238000005516engineering processMethods0.000description2

- 238000010304firingMethods0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 238000011160researchMethods0.000description2

- 238000005476solderingMethods0.000description2

- NIXOWILDQLNWCW-UHFFFAOYSA-Nacrylic acid groupChemical groupC(C=C)(=O)ONIXOWILDQLNWCW-UHFFFAOYSA-N0.000description1

- 230000009286beneficial effectEffects0.000description1

- 238000004519manufacturing processMethods0.000description1

- 229920001690polydopaminePolymers0.000description1

- 230000000750progressive effectEffects0.000description1

Images

Landscapes

- Led Device Packages (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本实用新型涉及一种领域的发光装置,特别是涉及一种使用表面黏着技术的发光二极管装置。The utility model relates to a light-emitting device in a field, in particular to a light-emitting diode device using surface adhesion technology.

背景技术Background technique

近年来,发光二极管芯片在照明领域上的使用,呈现倍数成长。例如发光二极管芯片广泛的应用在车尾灯、手机、PDA及其它电子产品内。In recent years, the use of light-emitting diode chips in the field of lighting has shown multiple growth. For example, light-emitting diode chips are widely used in car taillights, mobile phones, PDAs and other electronic products.

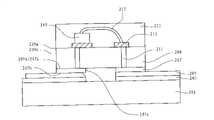

请参阅图1所示,其是绘示一传统发光装置,包括电极107、印刷电路板109、发光二极管芯片的导电端(pad)111、封胶物质113以及发光二极管芯片117,其中,电极107是围绕在印刷电路板109的两侧面,并电性连接导电端111。封胶物质113则位于电极107以及导电端111之上,用以包覆发光二极管芯片117以及金属线119。Please refer to FIG. 1 , which shows a conventional light-emitting device, including an

在焊接此一传统发光装置在一基板101上时,一般是使用焊料105,如焊锡,将发光装置,包括印刷电路板109以及其上的封胶物质113黏着在基板101的导电端103之上。然而在此黏着过程中,焊料105可能会延着电极107渗入印刷电路板109与封胶物质113之间,导致印刷电路板109与封胶物质113剥离,甚至使金属线119断裂,发光二极管芯片117因而丧失功能。When soldering this conventional light-emitting device on a

因此需要一个新的发光装置,能够在组装的过程中保护原有的结构不被破坏,以正常地执行其应有的功能。Therefore, a new light-emitting device is needed, which can protect the original structure from being damaged during the assembly process, so as to perform its proper function normally.

由此可见,上述现有的传统发光装置在结构与使用上,显然仍存在有不便与缺陷,而亟待加以进一步改进。为了解决传统发光装置存在的问题,相关厂商莫不费尽心思来谋求解决之道,但长久以来一直未见适用的设计被发展完成,而一般产品又没有适切的结构能够解决上述问题,此显然是相关业者急欲解决的问题。It can be seen that the above-mentioned existing conventional light-emitting devices obviously still have inconveniences and defects in structure and use, and need to be further improved urgently. In order to solve the problems existing in traditional light-emitting devices, relevant manufacturers have tried their best to find a solution, but no suitable design has been developed for a long time, and general products do not have a suitable structure to solve the above-mentioned problems. This is obvious. It is a problem that relevant industry players are eager to solve.

有鉴于上述现有的传统发光装置存在的缺陷,本设计人基于从事此类产品设计制造多年丰富的实务经验及专业知识,并配合学理的运用,积极加以研究创新,以期创设一种新型结构的发光装置,能够改进一般现有的传统发光装置,使其更具有实用性。经过不断的研究、设计,并经反复试作样品及改进后,终于创设出确具实用价值的本实用新型。In view of the defects of the above-mentioned existing traditional light-emitting devices, the designer actively researches and innovates on the basis of years of rich practical experience and professional knowledge in the design and manufacture of such products, and cooperates with the application of academic theories, in order to create a new type of structure. The light emitting device can improve the general existing traditional light emitting device to make it more practical. Through continuous research, design, and after repeated trial samples and improvements, the utility model with practical value is finally created.

发明内容Contents of the invention

本实用新型的主要目的在于,克服现有的传统发光装置存在的缺陷,而提供一种新的发光装置,所要解决的技术问题是使其在组装的过程中能够避免焊料沿着电极渗入印刷电路板与封胶物质之间,破坏发光二极管芯片的功能,从而更加适于实用,且具有产业上的利用价值。The main purpose of the utility model is to overcome the defects of the existing traditional light-emitting device and provide a new light-emitting device. The technical problem to be solved is to prevent the solder from penetrating into the printed circuit along the electrodes during the assembly process. Between the board and the sealing material, the function of the light-emitting diode chip is destroyed, so it is more suitable for practical use and has industrial utilization value.

本实用新型的目的及解决其技术问题是采用以下的技术方案来实现的。依据本实用新型提出的一种发光装置,其包括:The purpose of this utility model and the solution to its technical problems are achieved by adopting the following technical solutions. According to a light emitting device proposed by the present invention, it includes:

一发光二极管芯片,具有多个导电端;A light-emitting diode chip with multiple conductive terminals;

一封胶物质,用以包覆该发光二极管芯片以及该些导电端;an encapsulant substance used to cover the light-emitting diode chip and the conductive ends;

一印刷电路板,接合在该封胶物质,用以固定该发光二极管芯片,该印刷电路板包含:A printed circuit board, bonded to the sealing material to fix the light emitting diode chip, the printed circuit board includes:

一第一表面,该第一表面是面向该发光二极管芯片;a first surface, the first surface is facing the LED chip;

一第二表面,该第二表面是背向该发光二极管芯片;a second surface, the second surface is facing away from the LED chip;

一第三表面,该第三表面是围绕该第一表面以及该第二表面;以及a third surface surrounding the first surface and the second surface; and

多个贯穿孔,贯穿在该第一表面与该第二表面之间,该些贯穿孔的内壁具有电镀金属层;以及a plurality of through-holes, penetrating between the first surface and the second surface, the inner walls of the through-holes have an electroplated metal layer; and

多个电极,具有一第四表面、一第五表面以及一第六表面,该第四表面与该第五表面是分别面向与背向该第二表面,该第六表面则围绕该第四表面与该第五表面,A plurality of electrodes having a fourth surface, a fifth surface and a sixth surface, the fourth surface and the fifth surface are respectively facing and facing away from the second surface, and the sixth surface surrounds the fourth surface with the fifth surface,

其中,该发光二极管芯片的该些导电端是藉由该些贯穿孔的该些电镀金属层电性连接至该些电极。Wherein, the conductive ends of the LED chip are electrically connected to the electrodes through the electroplated metal layers of the through holes.

本实用新型的目的及解决其技术问题还可以采用以下的技术措施来进一步实现。The purpose of this utility model and the solution to its technical problems can also be further realized by adopting the following technical measures.

前述的发光装置,其中所述的该封胶物质的材质是环氧树脂、丙烯酸树脂(压克力)或硅胶。In the aforementioned light-emitting device, the material of the sealing material is epoxy resin, acrylic resin (acrylic) or silica gel.

前述的发光装置,其中所述的更包含一基板,该基板是由一焊料黏接在该些电极。The aforementioned light-emitting device further includes a substrate, and the substrate is bonded to the electrodes by a solder.

前述的发光装置,其中所述的该焊料是填充在该些电极的该第五表面与该基板之间。In the aforementioned light-emitting device, the solder is filled between the fifth surface of the electrodes and the substrate.

前述的发光装置,其中所述的该些电极的该第六表面是接触该基板,该焊料则填充在该些电极的该五表面与该基板之间。In the aforementioned light-emitting device, wherein the sixth surface of the electrodes is in contact with the substrate, and the solder is filled between the five surfaces of the electrodes and the substrate.

前述的发光装置,其中所述的该焊料是为焊锡。In the aforementioned light-emitting device, the solder is solder.

前述的发光装置,其中所述的该些电极的材质是铜或铝。In the aforementioned light-emitting device, the materials of the electrodes are copper or aluminum.

本实用新型与现有技术相比具有明显的优点和有益效果。由以上技术方案可知,为了达到前述发明目的,本实用新型的主要技术内容如下:Compared with the prior art, the utility model has obvious advantages and beneficial effects. As can be seen from the above technical solutions, in order to achieve the aforementioned object of the invention, the main technical contents of the present utility model are as follows:

本实用新型提出一种发光装置,包括发光二极管芯片、封胶物质、印刷电路板以及电极,其中发光二极管芯片具有导电端,封胶物质则用以包覆发光二极管芯片以及发光二极管芯片的导电端。印刷电路板接合于封胶物质,此印刷电路板是用以固定发光二极管芯片。印刷电路板包括第一表面、第二表面、第三表面以及贯穿孔,第一表面以及第二表面是分别面向以及背向发光二极管芯片,第三表面则围绕第一表面以及第二表面,贯穿孔则贯穿在第一表面与第二表面之间。发光二极管芯片的导电端则藉由贯穿孔电性连接至电极。The utility model proposes a light-emitting device, which includes a light-emitting diode chip, a sealing material, a printed circuit board, and an electrode, wherein the light-emitting diode chip has a conductive end, and the sealing material is used to cover the light-emitting diode chip and the conductive end of the light-emitting diode chip . The printed circuit board is bonded to the sealing material, and the printed circuit board is used to fix the LED chip. The printed circuit board includes a first surface, a second surface, a third surface and a through hole. The first surface and the second surface are respectively facing and facing away from the light-emitting diode chip, and the third surface surrounds the first surface and the second surface and penetrates The hole runs through between the first surface and the second surface. The conductive end of the LED chip is electrically connected to the electrode through the through hole.

借由上述技术方案,本实用新型发光装置至少具有下列优点:With the above technical solution, the light emitting device of the present invention has at least the following advantages:

本实用新型的发光二极管芯片的导电端是藉由印刷电路板内的贯穿孔与电极电性连接,因此能够避免焊料沿着电极渗入发光二极管芯片与印刷电路板之间,保护电子装置、发光二极管芯片的功能。The conductive end of the light-emitting diode chip of the utility model is electrically connected to the electrode through the through hole in the printed circuit board, so it can prevent the solder from penetrating into the space between the light-emitting diode chip and the printed circuit board along the electrode, and protect the electronic device and the light-emitting diode. function of the chip.

综上所述,本实用新型特殊结构的发光装置,其具有上述诸多的优点及实用价值,并在同类产品中未见有类似的结构设计公开发表或使用而确属创新,其不论在结构上或功能上皆有较大的改进,在技术上有较大的进步,并产生了好用及实用的效果,且较现有的传统发光装置具有增进的多项功效,从而更加适于实用,而具有产业的广泛利用价值,诚为一新颖、进步、实用的新设计。To sum up, the light-emitting device with the special structure of the utility model has the above-mentioned many advantages and practical value, and no similar structural design has been published or used in similar products, so it is indeed innovative, regardless of its structure Or the function has been greatly improved, the technology has made great progress, and has produced a useful and practical effect, and has a number of enhanced functions compared with the existing traditional light-emitting devices, so it is more suitable for practical use. And it has wide application value in the industry, and it is a novel, progressive and practical new design.

上述说明仅是本实用新型技术方案的概述,为了能够更清楚了解本实用新型的技术手段,并可依照说明书的内容予以实施,以下以本实用新型的较佳实施例并配合附图详细说明如后。The above description is only an overview of the technical solution of the utility model. In order to understand the technical means of the utility model more clearly and implement it according to the contents of the specification, the following is a detailed description of the preferred embodiment of the utility model with accompanying drawings. back.

本实用新型的具体实施方式由以下实施例及其附图详细给出。The specific embodiment of the utility model is given in detail by the following examples and accompanying drawings.

附图说明Description of drawings

图1是传统发光装置的结构示意图。Fig. 1 is a schematic structural view of a conventional light emitting device.

图2是依照本实用新型一实施例的一种上射式发光装置的结构示意图。FIG. 2 is a schematic structural view of an up-emitting light emitting device according to an embodiment of the present invention.

图3是依照本实用新型另一实施例的一种侧射式发光装置的结构示意图。Fig. 3 is a schematic structural view of a side-firing light emitting device according to another embodiment of the present invention.

101:基板 103:导电端101: Substrate 103: Conductive terminal

105:焊料 107:电极105: Solder 107: Electrode

109:印刷电路板 111:导电端109: Printed circuit board 111: Conductive terminal

113:封胶物质 117:发光二极管芯片113: Sealing substance 117: LED chip

119:金属线 201:基板119: Metal wire 201: Substrate

203:导电端 205:焊料203: Conductive terminal 205: Solder

207:电极 207a:第四表面207:

207b:第五表面 207c:第六表面207b:

209:印刷电路板 209a:第一表面209: Printed

209b:第二表面 209c:第三表面209b:

211:贯穿孔 213:导电端211: Through hole 213: Conductive end

215:封胶物质 217:金属线215: Sealing substance 217: Metal wire

219:发光二极管芯片219: LED chip

具体实施方式Detailed ways

为更进一步阐述本实用新型为达成预定发明目的所采取的技术手段及功效,以下结合附图及较佳实施例,对依据本实用新型提出的发光装置其具体实施方式、结构、特征及其功效,详细说明如后。In order to further explain the technical means and effects of the utility model to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and efficacy of the light-emitting device proposed according to the utility model will be described below in conjunction with the accompanying drawings and preferred embodiments. , as detailed below.

依照本新型的一实施例,发光装置包括一发光二极管芯片、一封胶物质、一印刷电路板以及多个电极,其中发光二极管芯片具有多个导电端,封胶物质则用以包覆发光二极管芯片以及其导电端。印刷电路板接合在封胶物质,并用以固定发光二极管芯片。According to an embodiment of the present invention, the light-emitting device includes a light-emitting diode chip, a sealing substance, a printed circuit board and a plurality of electrodes, wherein the light-emitting diode chip has a plurality of conductive terminals, and the sealing substance is used to cover the light-emitting diode chip and its conductive terminals. The printed circuit board is bonded to the sealing material and used to fix the light emitting diode chip.

印刷电路板包括一第一表面、一第二表面、一第三表面以及多个贯穿孔,其中,第一表面与第二表面分别面向以及背向发光二极管芯片,第三表面则围绕第一表面以及第二表面,贯穿孔是贯穿在第一表面与第二表面之间,贯穿孔的内壁则具有电镀金属层。The printed circuit board includes a first surface, a second surface, a third surface and a plurality of through holes, wherein the first surface and the second surface respectively face and face away from the LED chip, and the third surface surrounds the first surface and the second surface, the through hole runs through between the first surface and the second surface, and the inner wall of the through hole has an electroplated metal layer.

在此一实施例中,电极具有一第四表面、一第五表面以及一第六表面,其中第四表面与第五表面是分别面向与背向第二表面,第六表面则围绕第四表面与第五表面,发光二极管芯片的导电端则藉由贯穿孔电性连接至电极的第四表面。In this embodiment, the electrode has a fourth surface, a fifth surface and a sixth surface, wherein the fourth surface and the fifth surface face and face away from the second surface respectively, and the sixth surface surrounds the fourth surface and the fifth surface, the conductive end of the LED chip is electrically connected to the fourth surface of the electrode through the through hole.

由上述本实用新型的实施例可知,发光二极管芯片的导电端是藉由印刷电路板内的贯穿孔与电极电性连接,因此能够避免焊料沿着电极渗入发光二极管芯片与印刷电路板之间,保护电子装置、发光二极管芯片的功能。From the above-mentioned embodiments of the present invention, it can be known that the conductive end of the LED chip is electrically connected to the electrode through the through hole in the printed circuit board, so that the solder can be prevented from penetrating into the space between the LED chip and the printed circuit board along the electrode. Function of protecting electronic devices and light-emitting diode chips.

请参阅图2所示,是本实用新型发光装置一实施例的一种上射式发光装置的结构示意图,其主要包括:电极207、印刷电路板209、贯穿孔211、发光二极管芯片的导电端(pad)213、封胶物质215、金属线217以及发光二极管芯片219。Please refer to FIG. 2 , which is a structural schematic diagram of an up-emitting light-emitting device according to an embodiment of the light-emitting device of the present invention, which mainly includes:

印刷电路板209具有第一表面209a、第二表面209b、第三表面209c以及多个贯穿孔211,其中第一表面209a以及第二表面209b分别面向与背向发光二极管芯片219,第三表面209c则围绕第一表面209a与第二表面209b。发光二极管芯片219的导电端213是藉由贯穿孔211电性连接至电极207。电极207则具有第四表面207a、第五表面207b以及第六表面207c,贯穿孔211是接触电极207的第四表面207a,第六表面207c则围绕第四表面207a以及第五表面207b。The printed

在图2中,封胶物质215是用以包覆发光二极管芯片219、金属线217以及发光二极管芯片导电端213。封胶物质215的材质可以是环氧树脂、丙烯酸树脂以及硅胶等。在此一发光二极管结构当中,封胶物质215是与印刷电路板209接合,以包覆导电端213。In FIG. 2 , the

在焊接此一发光装置在一基板201上时,是使用焊料205,例如焊锡,将电极207以及其上的发光装置黏着在基板201的导电端203之上。由于电极207并未接直接接触导电端213以及封胶物质215,而是设置在印刷电路板209的第二表面209b,因此在组装过程当中,焊料205不会延着电极207渗入印刷电路板209与封胶物质215之间,能够保护发光二极管芯片219,避免其被破坏。When soldering the light emitting device on a

请参阅图3所示,是本实用新型发光装置另一实施例的一种侧射式发光装置的结构示意图。Please refer to FIG. 3 , which is a schematic structural diagram of a side-firing light emitting device according to another embodiment of the light emitting device of the present invention.

与图2的不同之处在于印刷电路板209以及发光二极管芯片219的摆放方式。在图3的侧射式发光装置中,电极207以及印刷电路板209是由其第六表面207c以及第三表面209c与基板201耦接,焊料205则填充在电极207的第五表面207b与基板导电端203的垂直交叉处,用来将电极207以及其上的印刷电路板209焊接在基板201之上。The difference from FIG. 2 lies in the arrangement of the printed

同样的,由于电极207并未接直接接触导电端213以及封胶物质215,而是设置在印刷电路板209的第二表面209b,焊料205因而不会延着电极207渗入印刷电路板209与封胶物质215之间,因此能够保护发光二极管芯片219,使其能够行使原有的功能。Similarly, since the

以上所述,仅是本实用新型的较佳实施例而已,并非对本实用新型作任何形式上的限制,虽然本实用新型已以较佳实施例揭露如上,然而并非用以限定本实用新型,任何熟悉本专业的技术人员,在不脱离本实用新型技术方案的范围内,当可利用上述揭示的技术内容作出些许更动或修饰为等同变化的等效实施例,但凡是未脱离本实用新型技术方案内容,依据本实用新型的技术实质对以上的实施例所作的任何简单修改、等同变化与修饰,均仍属于本实用新型技术方案的范围内。The above are only preferred embodiments of the present utility model, and do not limit the utility model in any form. Although the utility model has been disclosed as above with preferred embodiments, it is not intended to limit the utility model. Any Those skilled in the art, without departing from the scope of the technical solutions of the present utility model, may use the technical content disclosed above to make some changes or modify equivalent embodiments with equivalent changes, but all without departing from the technical solutions of the present utility model Solution content, any simple modifications, equivalent changes and modifications made to the above embodiments according to the technical essence of the utility model still belong to the scope of the utility model technical solution.

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNU2008200052237UCN201193811Y (en) | 2008-03-21 | 2008-03-21 | light emitting device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CNU2008200052237UCN201193811Y (en) | 2008-03-21 | 2008-03-21 | light emitting device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN201193811Ytrue CN201193811Y (en) | 2009-02-11 |

Family

ID=40393346

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNU2008200052237UExpired - LifetimeCN201193811Y (en) | 2008-03-21 | 2008-03-21 | light emitting device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN201193811Y (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2012151762A1 (en)* | 2011-05-09 | 2012-11-15 | 深圳市华星光电技术有限公司 | Led light source module, backlight module, and liquid crystal display |

| CN104279527A (en)* | 2013-07-11 | 2015-01-14 | 华通电脑股份有限公司 | Circuit board integrating backlight module and manufacturing method thereof |

- 2008

- 2008-03-21CNCNU2008200052237Upatent/CN201193811Y/ennot_activeExpired - Lifetime

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2012151762A1 (en)* | 2011-05-09 | 2012-11-15 | 深圳市华星光电技术有限公司 | Led light source module, backlight module, and liquid crystal display |

| CN104279527A (en)* | 2013-07-11 | 2015-01-14 | 华通电脑股份有限公司 | Circuit board integrating backlight module and manufacturing method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101447541B (en) | Semiconductor device with a plurality of transistors | |

| US8378370B2 (en) | LED package structure | |

| KR20130069602A (en) | Organic el illumination device | |

| CN101572285A (en) | Light emitting device package and method of manufacturing the same | |

| CN102255030B (en) | Light emitting module | |

| CN101630668A (en) | Encapsulation structure of compound semiconductor element and photoelectric element and manufacturing method thereof | |

| CN115117225A (en) | Light-emitting substrate, manufacturing method thereof and display device | |

| CN106576433B (en) | A printed circuit board | |

| CN105789065A (en) | A chip packaging structure, terminal equipment and method | |

| CN201193811Y (en) | light emitting device | |

| CN103474550A (en) | Light emitting diode packaging structure and manufacturing method thereof | |

| JP5114773B2 (en) | Surface mount light emitting device | |

| CN220085592U (en) | Display panel and spliced display device | |

| CN104470210A (en) | Circuit board, manufacturing method thereof, and display device | |

| TWI593141B (en) | Method of manufacturing package structure | |

| CN202167538U (en) | Package structure | |

| CN2532661Y (en) | Elastic dielectric body for the package to be fixed on the printed circuit board | |

| CN101231990A (en) | Pluggable roll-to-roll packaging structure and electronic device using same | |

| CN203932109U (en) | Luminous package and bearing structure thereof | |

| CN201025615Y (en) | Packaging structure of light emitting diode | |

| CN201039583Y (en) | Multi-layer high-heat-conductivity metal substrate and high-heat-conductivity metal plate with same | |

| CN2886805Y (en) | The structure in which the light-emitting diode circuit is integrated on the heat-dissipating substrate | |

| CN204272501U (en) | Circuit board and display unit | |

| CN203787409U (en) | A semiconductor packaging structure | |

| JP7625609B2 (en) | Light-emitting substrate, its manufacturing method, and display device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CX01 | Expiry of patent term | Granted publication date:20090211 | |

| CX01 | Expiry of patent term |