CN1918361A - Suppressing fluid communication to or from a wellbore - Google Patents

Suppressing fluid communication to or from a wellboreDownload PDFInfo

- Publication number

- CN1918361A CN1918361ACNA2005800046555ACN200580004655ACN1918361ACN 1918361 ACN1918361 ACN 1918361ACN A2005800046555 ACNA2005800046555 ACN A2005800046555ACN 200580004655 ACN200580004655 ACN 200580004655ACN 1918361 ACN1918361 ACN 1918361A

- Authority

- CN

- China

- Prior art keywords

- wellbore

- fluid

- polymer

- particles

- formation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000012530fluidSubstances0.000titleclaimsabstractdescription73

- 238000004891communicationMethods0.000titleclaimsabstractdescription18

- 239000002245particleSubstances0.000claimsabstractdescription62

- 229920000642polymerPolymers0.000claimsabstractdescription43

- 230000015572biosynthetic processEffects0.000claimsabstractdescription38

- 239000007787solidSubstances0.000claimsabstractdescription35

- 238000000034methodMethods0.000claimsabstractdescription21

- 229920013730reactive polymerPolymers0.000claimsabstractdescription13

- 239000000203mixtureSubstances0.000claimsdescription36

- 239000003822epoxy resinSubstances0.000claimsdescription34

- 229920000647polyepoxidePolymers0.000claimsdescription34

- 239000004568cementSubstances0.000claimsdescription15

- 239000003795chemical substances by applicationSubstances0.000claimsdescription12

- 239000003054catalystSubstances0.000claimsdescription10

- 239000000126substanceSubstances0.000claimsdescription10

- 239000000463materialSubstances0.000claimsdescription8

- 239000000945fillerSubstances0.000claimsdescription7

- 230000002401inhibitory effectEffects0.000claimsdescription7

- 239000000701coagulantSubstances0.000claimsdescription5

- 229920001568phenolic resinPolymers0.000claimsdescription5

- 239000005011phenolic resinSubstances0.000claimsdescription5

- KXGFMDJXCMQABM-UHFFFAOYSA-N2-methoxy-6-methylphenolChemical compound[CH]OC1=CC=CC([CH])=C1OKXGFMDJXCMQABM-UHFFFAOYSA-N0.000claimsdescription3

- 239000012809cooling fluidSubstances0.000claimsdescription3

- 238000010438heat treatmentMethods0.000claimsdescription3

- 229910052751metalInorganic materials0.000claimsdescription3

- 239000002184metalSubstances0.000claimsdescription3

- 239000004645polyester resinSubstances0.000claimsdescription2

- 229920001225polyester resinPolymers0.000claimsdescription2

- 239000004793PolystyreneSubstances0.000claims1

- 150000008442polyphenolic compoundsChemical class0.000claims1

- 229920002223polystyrenePolymers0.000claims1

- 229920001187thermosetting polymerPolymers0.000claims1

- 239000004634thermosetting polymerSubstances0.000claims1

- 238000005755formation reactionMethods0.000description30

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description17

- 238000007789sealingMethods0.000description12

- LNEPOXFFQSENCJ-UHFFFAOYSA-NhaloperidolChemical compoundC1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1LNEPOXFFQSENCJ-UHFFFAOYSA-N0.000description11

- 238000006243chemical reactionMethods0.000description10

- 229920003986novolacPolymers0.000description10

- 239000004593EpoxySubstances0.000description9

- IISBACLAFKSPIT-UHFFFAOYSA-Nbisphenol AChemical compoundC=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1IISBACLAFKSPIT-UHFFFAOYSA-N0.000description9

- 229920005989resinPolymers0.000description9

- 239000011347resinSubstances0.000description9

- 229930195733hydrocarbonNatural products0.000description8

- 238000002347injectionMethods0.000description7

- 239000007924injectionSubstances0.000description7

- 239000007788liquidSubstances0.000description7

- 239000004215Carbon black (E152)Substances0.000description6

- 125000003700epoxy groupChemical group0.000description6

- 150000002430hydrocarbonsChemical class0.000description6

- 239000003921oilSubstances0.000description6

- 230000035699permeabilityEffects0.000description6

- 239000004848polyfunctional curativeSubstances0.000description6

- 239000012267brineSubstances0.000description5

- GYZLOYUZLJXAJU-UHFFFAOYSA-Ndiglycidyl etherChemical classC1OC1COCC1CO1GYZLOYUZLJXAJU-UHFFFAOYSA-N0.000description5

- 238000004519manufacturing processMethods0.000description5

- HPALAKNZSZLMCH-UHFFFAOYSA-Msodium;chloride;hydrateChemical compoundO.[Na+].[Cl-]HPALAKNZSZLMCH-UHFFFAOYSA-M0.000description5

- 239000000725suspensionSubstances0.000description5

- BRLQWZUYTZBJKN-UHFFFAOYSA-NEpichlorohydrinChemical compoundClCC1CO1BRLQWZUYTZBJKN-UHFFFAOYSA-N0.000description4

- 229940106691bisphenol aDrugs0.000description4

- 150000001875compoundsChemical class0.000description4

- 125000003055glycidyl groupChemical groupC(C1CO1)*0.000description4

- 239000000843powderSubstances0.000description4

- LCFVJGUPQDGYKZ-UHFFFAOYSA-NBisphenol A diglycidyl etherChemical compoundC=1C=C(OCC2OC2)C=CC=1C(C)(C)C(C=C1)=CC=C1OCC1CO1LCFVJGUPQDGYKZ-UHFFFAOYSA-N0.000description3

- WSFSSNUMVMOOMR-UHFFFAOYSA-NFormaldehydeChemical compoundO=CWSFSSNUMVMOOMR-UHFFFAOYSA-N0.000description3

- -1Glycidyl epoxy resinsChemical compound0.000description3

- ISWSIDIOOBJBQZ-UHFFFAOYSA-NPhenolChemical compoundOC1=CC=CC=C1ISWSIDIOOBJBQZ-UHFFFAOYSA-N0.000description3

- HEMHJVSKTPXQMS-UHFFFAOYSA-MSodium hydroxideChemical compound[OH-].[Na+]HEMHJVSKTPXQMS-UHFFFAOYSA-M0.000description3

- 238000004132cross linkingMethods0.000description3

- 238000005553drillingMethods0.000description3

- 238000002474experimental methodMethods0.000description3

- KUBDPQJOLOUJRM-UHFFFAOYSA-N2-(chloromethyl)oxirane;4-[2-(4-hydroxyphenyl)propan-2-yl]phenolChemical compoundClCC1CO1.C=1C=C(O)C=CC=1C(C)(C)C1=CC=C(O)C=C1KUBDPQJOLOUJRM-UHFFFAOYSA-N0.000description2

- VTYYLEPIZMXCLO-UHFFFAOYSA-LCalcium carbonateChemical compound[Ca+2].[O-]C([O-])=OVTYYLEPIZMXCLO-UHFFFAOYSA-L0.000description2

- 239000004971Cross linkerSubstances0.000description2

- 150000001412aminesChemical class0.000description2

- 230000008901benefitEffects0.000description2

- 239000000110cooling liquidSubstances0.000description2

- 125000001183hydrocarbyl groupChemical group0.000description2

- 239000004850liquid epoxy resins (LERs)Substances0.000description2

- 230000000704physical effectEffects0.000description2

- 238000000053physical methodMethods0.000description2

- 238000012360testing methodMethods0.000description2

- OMIGHNLMNHATMP-UHFFFAOYSA-N2-hydroxyethyl prop-2-enoateChemical compoundOCCOC(=O)C=COMIGHNLMNHATMP-UHFFFAOYSA-N0.000description1

- HRPVXLWXLXDGHG-UHFFFAOYSA-NAcrylamideChemical compoundNC(=O)C=CHRPVXLWXLXDGHG-UHFFFAOYSA-N0.000description1

- PHXKSXAIMPVYRM-UHFFFAOYSA-NNC1=CC=CC=C1.NC1=CC=CC=C1.C(C)C(C1=CC=CC=C1)CCChemical compoundNC1=CC=CC=C1.NC1=CC=CC=C1.C(C)C(C1=CC=CC=C1)CCPHXKSXAIMPVYRM-UHFFFAOYSA-N0.000description1

- 239000004952PolyamideSubstances0.000description1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-NSiliconChemical compound[Si]XUIMIQQOPSSXEZ-UHFFFAOYSA-N0.000description1

- 229910000831SteelInorganic materials0.000description1

- 238000009825accumulationMethods0.000description1

- 239000002253acidSubstances0.000description1

- 230000002378acidificating effectEffects0.000description1

- 150000007513acidsChemical class0.000description1

- 230000009471actionEffects0.000description1

- 239000004844aliphatic epoxy resinSubstances0.000description1

- 125000001931aliphatic groupChemical group0.000description1

- 150000008064anhydridesChemical class0.000description1

- 238000013459approachMethods0.000description1

- 230000004888barrier functionEffects0.000description1

- 229910000019calcium carbonateInorganic materials0.000description1

- QXJJQWWVWRCVQT-UHFFFAOYSA-Kcalcium;sodium;phosphateChemical compound[Na+].[Ca+2].[O-]P([O-])([O-])=OQXJJQWWVWRCVQT-UHFFFAOYSA-K0.000description1

- 230000003197catalytic effectEffects0.000description1

- 239000002131composite materialSubstances0.000description1

- 238000009833condensationMethods0.000description1

- 230000005494condensationEffects0.000description1

- 239000002826coolantSubstances0.000description1

- 238000001816coolingMethods0.000description1

- 229920001577copolymerPolymers0.000description1

- 229920006037cross link polymerPolymers0.000description1

- 239000003431cross linking reagentSubstances0.000description1

- 238000005520cutting processMethods0.000description1

- 239000011353cycloaliphatic epoxy resinSubstances0.000description1

- 150000004985diaminesChemical class0.000description1

- 239000000428dustSubstances0.000description1

- 230000000694effectsEffects0.000description1

- 230000007613environmental effectEffects0.000description1

- 229920006334epoxy coatingPolymers0.000description1

- 239000008398formation waterSubstances0.000description1

- 230000009477glass transitionEffects0.000description1

- 125000002887hydroxy groupChemical group[H]O*0.000description1

- 230000001788irregularEffects0.000description1

- 239000012948isocyanateSubstances0.000description1

- 150000002513isocyanatesChemical class0.000description1

- 238000002156mixingMethods0.000description1

- 239000000178monomerSubstances0.000description1

- 238000005502peroxidationMethods0.000description1

- 229920002647polyamidePolymers0.000description1

- 238000006116polymerization reactionMethods0.000description1

- 239000004814polyurethaneSubstances0.000description1

- 229920002635polyurethanePolymers0.000description1

- 238000003825pressingMethods0.000description1

- 150000003141primary aminesChemical class0.000description1

- 230000008569processEffects0.000description1

- 150000003839saltsChemical class0.000description1

- 150000003335secondary aminesChemical class0.000description1

- 239000010703siliconSubstances0.000description1

- 229910052710siliconInorganic materials0.000description1

- 238000004088simulationMethods0.000description1

- 238000007711solidificationMethods0.000description1

- 230000008023solidificationEffects0.000description1

- 239000002904solventSubstances0.000description1

- 239000012798spherical particleSubstances0.000description1

- 239000010959steelSubstances0.000description1

- 238000003786synthesis reactionMethods0.000description1

- 150000003512tertiary aminesChemical class0.000description1

- 230000009974thixotropic effectEffects0.000description1

- 239000011800void materialSubstances0.000description1

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K8/00—Compositions for drilling of boreholes or wells; Compositions for treating boreholes or wells, e.g. for completion or for remedial operations

- C09K8/50—Compositions for plastering borehole walls, i.e. compositions for temporary consolidation of borehole walls

- C09K8/504—Compositions based on water or polar solvents

- C09K8/506—Compositions based on water or polar solvents containing organic compounds

- C09K8/508—Compositions based on water or polar solvents containing organic compounds macromolecular compounds

- C09K8/5086—Compositions based on water or polar solvents containing organic compounds macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K8/00—Compositions for drilling of boreholes or wells; Compositions for treating boreholes or wells, e.g. for completion or for remedial operations

- C09K8/50—Compositions for plastering borehole walls, i.e. compositions for temporary consolidation of borehole walls

- C09K8/504—Compositions based on water or polar solvents

- C09K8/506—Compositions based on water or polar solvents containing organic compounds

- C09K8/508—Compositions based on water or polar solvents containing organic compounds macromolecular compounds

- C09K8/512—Compositions based on water or polar solvents containing organic compounds macromolecular compounds containing cross-linking agents

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B33/00—Sealing or packing boreholes or wells

- E21B33/10—Sealing or packing boreholes or wells in the borehole

- E21B33/13—Methods or devices for cementing, for plugging holes, crevices or the like

- E21B33/138—Plastering the borehole wall; Injecting into the formation

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mining & Mineral Resources (AREA)

- Materials Engineering (AREA)

- Organic Chemistry (AREA)

- Geology (AREA)

- Environmental & Geological Engineering (AREA)

- Fluid Mechanics (AREA)

- Physics & Mathematics (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Geochemistry & Mineralogy (AREA)

- Sealing Material Composition (AREA)

- Consolidation Of Soil By Introduction Of Solidifying Substances Into Soil (AREA)

- Solid-Sorbent Or Filter-Aiding Compositions (AREA)

- Devices And Processes Conducted In The Presence Of Fluids And Solid Particles (AREA)

- Water Treatment By Sorption (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及一种抑制到或从地下地层井筒的流体连通的方法,以及一种用于井筒的井内流体。The present invention relates to a method of inhibiting fluid communication to or from a subterranean formation wellbore, and a wellbore fluid for the wellbore.

背景技术Background technique

在地下地层中钻井和操作期间,存在许多需要抑制井下流体连通的情况。During drilling and operation in subterranean formations, there are many situations where it is desirable to inhibit downhole fluid communication.

例如,从烃油或气井中产出的流体通常包含大量的水。这里的术语水习惯上还包括盐水。所述水的水源可为从含烃储层附近地层突入的地层水或者从地面注入地层的水。For example, fluids produced from hydrocarbon oil or gas wells often contain large amounts of water. The term water here customarily also includes salt water. The source of the water may be formation water intruding from the formation near the hydrocarbon-bearing reservoir or water injected into the formation from the ground.

产出流体中的水降低了油或气井的举升能力,并且一旦产出,所述水会成为环境问题。通常,产出流体的含水量会随着井的年龄而增加,并且在某些阶段又需要对所述井进行处理以便产出较少量的水。Water in produced fluids reduces the lift capacity of an oil or gas well and, once produced, can become an environmental problem. Typically, the water content of produced fluids increases with the age of the well, and at some stage the well needs to be treated in order to produce less water.

一种类似的作业是抑制通过井筒周围地层内的裂缝所产生的流体连通。裂缝可使钻井液不希望地漏入周围地层,因而需要封闭通过裂缝所产生的流体连通。A similar operation is to inhibit fluid communication through fractures in the formation surrounding the wellbore. Fractures can allow drilling fluid to leak undesirably into the surrounding formation, thus requiring closure of the fluid communication created through the fractures.

其它需要抑制井下流体连通的情况会在井筒套管泄漏的情况下出现,例如当套管后面具有空腔或当金属套管与周围水泥之间存在空隙或环状空间时。这些情况将在此之后称之为水泥不规则。Other situations where downhole fluid communication needs to be inhibited arise where the wellbore casing leaks, for example when there is a cavity behind the casing or when there is a void or annulus between the metal casing and the surrounding cement. These conditions will hereinafter be referred to as cement irregularities.

在需要封闭情况的示例中,地下地层由多个层叠的储油层构成,井筒穿过地层延伸并在所有储油层处具有射孔孔眼。在生产一段时间之后,对测井、油藏和生产数据的研究显示了一些油层仍具有高的含烃饱和度而其它油层已经被水波及到。因此需要选择性地抑制井筒与水波及地层之间的流体连通。In an example of a situation where containment is required, a subterranean formation consists of multiple stacked reservoirs through which a wellbore extends with perforations at all of the reservoirs. After a period of production, studies of well logs, reservoir and production data show that some reservoirs still have high hydrocarbon saturation while others have been swept by water. It is therefore desirable to selectively inhibit fluid communication between the wellbore and the water-swept formation.

这不是一项直接的任务。申请人已经在如下情况下面临了这一问题:在相对较大的井筒套管(直径为7″=18cm)利用较小的管柱(直径为3.5″=9cm)、并在较高的井底温度(≥110℃)、不同层之间具有较高的压差(达到3000psi=21MPa)下的完井是复杂的。This is not a straightforward task. Applicants have faced this problem in relatively large wellbore casings (7" = 18 cm in diameter) with smaller tubing strings (3.5" = 9 cm in diameter) and in higher wells Completion at low temperature (≥ 110°C), high pressure difference between different layers (up to 3000 psi = 21 MPa) is complicated.

在如此高的压差下,常规的水泥封闭不是一种可行的选择。With such high differential pressures, conventional cement sealing is not a viable option.

如果其它选择在本领域是可行的,显然仅有那些很复杂的机械选择是可行的。If other options are available in the art, obviously only those very complex mechanistic options are available.

一种机械选择将是设置具有多区的选择性完井段。这将暗示首先要将现有完井段即井下管柱和设备的组件移走。之后,要设置选择性的完井段,其中利用封隔器部件将所有相关层隔离,以便能够通过阀来控制从这些区域中的某一区域进行开采。One mechanical option would be to set up selective completions with multiple zones. This would imply the removal of the existing completion first, ie components of downhole tubing and equipment. Afterwards, selective completion sections are set in which all relevant zones are isolated by packer components so that production from one of these zones can be controlled by valves.

另一种常规的机械选择为:在现有的射孔段上方的衬管内注水泥以封闭所有射孔孔眼与井筒之间的流体连通,随后对含烃区域进行再射孔。此外,这需要去除所有现有的完井段。Another conventional mechanical option is to cement the liner above the existing perforated interval to seal fluid communication between all perforated holes and the wellbore, followed by reperforating the hydrocarbon-bearing zone. Additionally, this required removal of all existing completions.

所有这些机械选择都是费钱和费时的,因为在每一种情况下都首先要将现有的完井段去除,从而在现场需要钻机。All of these mechanical options are costly and time consuming, since in each case the existing well completion is first removed, requiring a drilling rig on site.

公开号为EP1369401的欧洲专利申请披露了用于井筒内的密封合成物,该合成物包括水、胶结材料和水溶性可交联材料如丙烯酸2-羟乙酯单体(2-hydroxyethyl acrylate monomer)或丙烯酰胺与t-丙烯酸丁酯(t-butyl acrylate)的共聚物。这种密封合成物能够比常规的水泥承受更高的压差(最大的回流压力)。所述合成物能够通过现有的完井段进入井筒中。通过施加挤注压力,可交联材料与水渗入井筒周围地层一段距离并在那儿进行交联。水泥在与井筒的交界面处停留并在此处进行凝固。已知的密封合成物相对难于制备和处理并在作业中需要专门的技能。例如在井筒流体或井内局部热区域的影响下水泥能够在管或井筒内凝固,并且将挠性管或生产油管内凝固的水泥移走是非常昂贵的。此外,在注水泥之后需要利用粘稠的盐水将过量的水泥循环出。这将使整个油井完井段暴露在盐水-水泥的混合物中,这种混合物将会对油井内的关键部件如气举阀和偏心工作筒造成潜在的污染。European Patent Application Publication No. EP1369401 discloses a sealing composition for use in a wellbore comprising water, a cementitious material and a water-soluble cross-linkable material such as 2-hydroxyethyl acrylate monomer Or acrylamide and t-butyl acrylate (t-butyl acrylate) copolymer. This sealing composition is able to withstand a higher differential pressure (maximum return pressure) than conventional cement. The composition is capable of entering the wellbore through the existing completion. By applying squeeze pressure, the cross-linkable material penetrates some distance into the formation around the wellbore with water and cross-links there. The cement stays at the interface with the wellbore and solidifies there. Known sealing compositions are relatively difficult to prepare and handle and require special skills in operation. Cement can set within the tubing or wellbore, for example under the influence of wellbore fluids or localized hot zones within the wellbore, and it is very expensive to remove solidified cement within coiled tubing or production tubing. Furthermore, the excess cement needs to be circulated out with viscous brine after cementing. This would expose the entire well completion to the brine-cement mixture, which would potentially contaminate critical components within the well such as gas lift valves and eccentric mandrels.

美国专利申请US3525398公开了一种用于密封可渗透地层内裂缝的方法,其中粒状可变形的固态树脂的触变性悬浮液被注入到所述裂缝中,并且所述颗粒在压力作用下发生变形从而在裂缝内形成基本不可渗透的隔层。另一种在裂缝内提供液体密封的物理方法可从美国专利US3302719中得知,其中,将固态聚合物/蜡/树脂颗粒在压裂过程中注入以形成暂堵,其随后可被地层烃类所溶解。然而另一种提供地下液体密封的物理方法可从国际专利申请公开文献WO 01/74967中得知,其中形成凝胶的聚合物被注入循环漏失区并在此处膨胀。US patent application US3525398 discloses a method for sealing fractures in permeable formations, wherein a thixotropic suspension of granular deformable solid resin is injected into the fracture and the particles are deformed under pressure such that A substantially impermeable barrier forms within the fracture. Another physical method of providing a liquid seal within a fracture is known from US Pat. No. 3,302,719, wherein solid polymer/wax/resin particles are injected during fracturing to form temporary plugs, which can then be replaced by formation hydrocarbons. dissolved. Yet another physical method of providing a subterranean liquid seal is known from International Patent Application Publication WO 01/74967, wherein a gel-forming polymer is injected into the loss-of-circulation zone and expands there.

发明内容Contents of the invention

本发明的目的在于提供一种抑制井筒与周围地层之间的流体连通的改进了的方法。It is an object of the present invention to provide an improved method of inhibiting fluid communication between a wellbore and the surrounding formation.

本发明的另一目的在于提供一种适用于这一改进方法的特殊的井内流体。Another object of the present invention is to provide a specific well fluid suitable for this improved method.

为此,提供一种用于抑制到或从地下地层内井筒的流体连通的方法,所述方法包括:To this end, a method for inhibiting fluid communication to or from a wellbore within a subterranean formation is provided, the method comprising:

-提供一种包括载液内的固体颗粒的井内流体,所述固体颗粒包括活性聚合物;- providing a well fluid comprising solid particles in a carrier fluid, said solid particles comprising a reactive polymer;

-将所述井内流体注入井筒以便载液穿过井筒与其周围地层之间的界面,所述颗粒在所述界面处聚积;并且- injecting said wellbore fluid into a wellbore so that the carrier fluid passes through the interface between the wellbore and its surrounding formation where said particles accumulate; and

-使所述聚合物形成抑制通过界面的流体连通的固体塞。- Allowing the polymer to form a solid plug inhibiting fluid communication through the interface.

还提供一种用在井筒内的井内流体,所述井内流体包括载液内的固体颗粒,所述固体颗粒包括活性聚合物。本发明还涉及这种井内流体在井筒内的使用,尤其是用于抑制界面处的流体连通。Also provided is a well fluid for use in a wellbore, the well fluid comprising solid particles in a carrier fluid, the solid particles comprising a reactive polymer. The invention also relates to the use of such well fluids within a wellbore, in particular for inhibiting fluid communication at interfaces.

本发明是基于申请人的观察而获得的,载液内的固体聚合物颗粒形成一种用在井筒内的、特别容易处理的密封合成物。标准的砾石充填混合装置足以用于制备所述井内流体。就像制备复杂的多成分的水泥混合物那样所需的专门的水泥混合器不是必需的。由于不存在灰尘成分,因而本发明为操作员提供了一种更加安全的系统。The present invention is based on the applicant's observation that solid polymer particles in a carrier fluid form a particularly easy-to-handle sealing composition for use in a wellbore. A standard gravel pack mixing device is sufficient for preparing the well fluid. No special cement mixer is necessary, as is required for preparing complex multi-component cement mixtures. The present invention provides a safer system for the operator due to the absence of dust components.

术语聚合物塞包括沿着所述界面形成的聚合物层。使所述活性聚合物进行反应以便形成固体塞。适宜地是,所述聚合物塞不能被油藏流体所溶解。由活性聚合物形成的聚合物塞比常规的密封系统能够承受更高的压差,如21MPa甚至更高。根据聚合物的机械特性,无限制的聚合物耐压强度可高达50MPa或更高。例如,可使用盐水或烃类流体(如柴油)作为载液。The term polymer plug includes polymer layers formed along said interface. The living polymer is reacted to form a solid plug. Suitably, the polymer plug is insoluble by reservoir fluids. The polymer plug formed by the reactive polymer can withstand a higher differential pressure than conventional sealing systems, such as 21 MPa or even higher. Depending on the mechanical properties of the polymer, the unrestricted polymer compressive strength can be as high as 50 MPa or more. For example, brine or a hydrocarbon fluid such as diesel may be used as a carrier fluid.

所述颗粒为固体,适宜地是在地面条件下没有粘性。对于特定的应用可对化学和物理性质进行适应性选择。可优选地是,所述颗粒包含至少50wt%的聚合物或聚合物合成物,更加优选地是至少90wt%,最优选地是它们仅仅含有聚合物或聚合物合成物。The particles are solid, suitably non-sticky under ground conditions. The chemical and physical properties can be adaptively selected for a particular application. It is preferred that the particles comprise at least 50 wt% polymer or polymer composition, more preferably at least 90 wt%, most preferably they contain only polymer or polymer composition.

将所述载液挤入地层以便所述固体颗粒聚积在所述界面处。为此,优选对所述颗粒的尺寸进行选择以便它们到达所述界面而不会显著地进入地层,适宜地是所述尺寸小于10cm,优选小于2cm,通常约为1cm或更小。当所述界面被从井筒伸入地层的射孔孔眼形成时,所述颗粒在1mm到2cm之间的范围内适宜地具有最小的线性尺寸。当所述界面由裂缝构成时,所述最小的线性尺寸适宜在500微米到2cm之间。为了补救水泥不规则,颗粒要适宜地小,在1-200微米的范围内。还可对所述颗粒的形状进行适宜地选择,如通常为球形、柱形或立方形,但还可以是不规则的。The carrier fluid is squeezed into the formation so that the solid particles accumulate at the interface. For this reason, the size of the particles is preferably selected so that they reach the interface without significantly entering the formation, suitably less than 10 cm, preferably less than 2 cm, usually about 1 cm or less. When the interface is formed by perforations extending from the wellbore into the formation, the particles suitably have a smallest linear dimension in the range between 1mm and 2cm. When the interface is formed by cracks, the smallest linear dimension is suitably between 500 microns and 2 cm. To remedy cement irregularities, the particles are suitably small, in the range of 1-200 microns. The shape of the particles can also be suitably chosen, such as generally spherical, cylindrical or cubic, but also irregular.

所述颗粒聚积在所述界面处,并且不像现有的密封合成物的水溶性可交联的物质那样,所述颗粒不能渗入地层以便在固化之后直接在所述界面处形成固体层或塞。这种界面处的固体层具有如下优点:如果需要,通过标准的射孔技术可直接和选择性地再次恢复流体连通。另外,也即如果所述密封在深入地层某一距离的地方形成,再射孔可能会成为问题。界面处的固体层的另一优点为:可产出的烃被闭锁在某一位置的风险被消除了。The particles accumulate at the interface and, unlike the water-soluble cross-linkable substances of existing sealing compositions, the particles cannot penetrate into the formation to form a solid layer or plug at the interface directly after curing . Such a solid layer at the interface has the advantage that fluid communication can be directly and selectively re-established, if desired, by standard perforating techniques. Also, that is, if the seal forms some distance deep into the formation, reperforation can become a problem. Another advantage of the solid layer at the interface is that the risk of producible hydrocarbons being locked in place is eliminated.

已知的可固化聚合物或聚合物合成物如酚醛树脂合成物、聚脂树脂合成物、环氧树脂合成物或聚亚安酯合成物可被用作活性聚合物颗粒。适宜地是,可固化的合成物包括至少两种不同的化合物,如活性聚合物链和交联剂或硬化剂,通常所述化合物发生交联反应以形成(交联的)聚合物网。每种活性聚合物颗粒适宜包含两种化合物。Known curable polymers or polymer compositions such as phenolic resin compositions, polyester resin compositions, epoxy resin compositions or polyurethane compositions can be used as active polymer particles. Suitably, the curable composition comprises at least two different compounds, such as living polymer chains and a crosslinking agent or hardener, typically said compounds undergoing a crosslinking reaction to form a (crosslinked) polymer network. Each living polymer particle suitably contains two compounds.

界面处的温度通常会高于地面的温度。含油储层的温度通常在110到180摄氏度之间,如150摄氏度。仅通过使活性聚合物处于界面温度足够长的时间(如1-24小时)就能够使其进行反应。交联适宜地出现在颗粒内和颗粒之间以便形成细微的密封结构。The temperature at the interface will usually be higher than that at the ground. The temperature of an oil-bearing reservoir is usually between 110 and 180 degrees Celsius, such as 150 degrees Celsius. The reactive polymer can be reacted simply by subjecting it to the interface temperature for a sufficiently long period of time (eg, 1-24 hours). Crosslinking desirably occurs both within and between particles so as to form finely sealed structures.

根据特定活性聚合物在升高的温度下反应的速度,在将活性聚合物颗粒注入之前需要将冷却液注入井筒,例如为了使所要密封界面附近井筒内的温度降低20-50开氏绝对温度(Kelvin)。以这种方式可使聚合物颗粒不会过早地在沿着井筒向下到达界面处的通道内反应。Depending on the rate at which a particular active polymer reacts at elevated temperatures, cooling fluid may need to be injected into the wellbore prior to injecting the active polymer particles, for example in order to reduce the temperature in the wellbore near the interface to be sealed by 20-50 Kelvin absolute ( Kelvin). In this way the polymer particles are prevented from reacting prematurely in the passage down the wellbore to the interface.

另一种选择是对活性聚合物进行选择以便为了发生所述反应需要额外地加热到高于界面处地层温度。在这种情况下,一种合适的加热器例如悬挂在电缆上的电加热器可被用在井筒内以便使所述反应发生。此外,利用加热液如热盐水对界面的预冲洗可被用于局部地和暂时地加热地层。Another option is to choose the active polymer so that additional heating above the formation temperature at the interface is required for the reaction to occur. In this case, a suitable heater, such as an electric heater suspended from a cable, may be used in the wellbore to allow the reaction to occur. In addition, preflushing of the interface with a heating fluid, such as hot brine, can be used to locally and temporarily heat the formation.

选择聚合物颗粒和载液的相对密度以使所述颗粒的密度约等于或高于或低于载液的密度。适宜地是,环境温度下的密度可为500kg/m3或更高,但是不能超过1500kg/m3。相同密度的颗粒将会浮在所述液体中以便获得相对稳定的悬浮液,所述悬浮液能够在地面容易地进行处理。更高密度的颗粒将会具有这样的效果:即不能聚积在界面的过量颗粒将会自动地沉积在井筒底部。另一方面,当所述颗粒比所述液体轻时,过量的颗粒将易于向上浮到表面,从而将它们除去。The relative densities of the polymer particles and the carrier liquid are selected such that the particles have a density about equal to or higher or lower than the density of the carrier liquid. Suitably, the density at ambient temperature may be 500 kg/m3 or higher, but not more than 1500 kg/m3 . Particles of the same density will float in the liquid in order to obtain a relatively stable suspension which can be easily handled at ground level. The higher density of particles will have the effect that excess particles that cannot accumulate at the interface will automatically deposit at the bottom of the wellbore. On the other hand, when the particles are lighter than the liquid, excess particles will tend to float up to the surface where they can be removed.

本发明还提供一种用于井筒内的井内流体,所述井内流体还包括载液内的固体颗粒,所述固体颗粒包括活性聚合物。这种井内流体(处理液)能够有效地和可靠地密封射孔孔眼、以及裂缝和其它井筒与地层之间的流体可渗透界面。可优选地是,井内流体的活性聚合物包括环氧树脂合成物,所述环氧树脂合成物包含环氧树脂、固化剂、以及可选的促凝剂、催化剂和/或填充物质。The present invention also provides a well fluid for use in a wellbore, the well fluid further comprising solid particles in a carrier fluid, the solid particles comprising an active polymer. This wellbore fluid (treatment fluid) is capable of effectively and reliably sealing perforated perforations, as well as fractures and other fluid-permeable interfaces between the wellbore and the formation. It may be preferred that the reactive polymer of the well fluid comprises an epoxy resin composition comprising epoxy resin, curing agent, and optionally coagulants, catalysts and/or filler substances.

附图说明Description of drawings

现在,将结合附图对本发明的实施例进行更加详尽的描述,其中:Embodiments of the present invention will now be described in more detail in conjunction with the accompanying drawings, wherein:

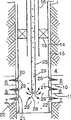

图1-4示出了在伸入分层储层的井筒内实施本发明所述方法的多个阶段;以及Figures 1-4 illustrate various stages of implementing the methods of the present invention in a wellbore extending into a stratified reservoir; and

图5示出了用于测试本发明的示意性的测试容器。Figure 5 shows a schematic test vessel for testing the present invention.

在不同附图中所用的相同附图标记表示相同或相似的对象。The use of the same reference numbers in different drawings indicates the same or similar items.

具体实施方式Detailed ways

参看图1,图1示出了从地面(未示出)延伸入地层4的井筒1的下部分。在该示例中所述地层是分层的。层6和7含有烃油,层8含有水。层6、7、8由边界或不可渗透的层10、11隔离。井筒1具有由金属套管柱构成的套管14,套管14与井筒1的井壁之间的环空15充满水泥。井下完井段由伸到地面的油管16和封隔器18标识出。Referring to Figure 1, there is shown a lower portion of a wellbore 1 extending from the surface (not shown) into a

流体通过射孔孔眼20、21、22按照箭头所示的方向从层6、7、8进入井筒1并通过油管16被采到地面。这种流体含有油23和从层8流出的大量的水24。需要密封住从含水层8流出特别是通过射孔孔眼21流出的水,所述射孔孔眼21形成在井筒与含水层之间的界面处。The fluid enters the wellbore 1 from the

为此参看图2,首先穿过油管16将挠性管25下入,并通过挠性管25将冷却液27注入井筒1,该流体由此在地层6、7、8内流动一段距离。冷却液可为含有2wt%KCL的水。注入的体积和速率可根据温度模拟来确定。通常可以1-5bbls/min(0.159-0.795m3/min)的速率将200-2000bbls(31.8-318m3)的冷却液注入地层,以便使界面处的温度下降20-50开氏绝对温度(kelvin)。Referring to FIG. 2 for this purpose, a

参看图3,在停止注入冷却液之后,立即将一种特殊的井内流体28通过挠性管泵入井筒。根据本发明,所述井内流体包括悬浮在载液内的固态活性聚合物颗粒29。所述颗粒的浓度在总井内流体的1-50wt%之间,所述颗粒的尺寸在0.1mm与5cm之间。对于球形颗粒来说,所述颗粒的尺寸为不同颗粒的加权平均直径。对于不同形状的颗粒来说,沿各个线性方向的颗粒最大范围可被确定并且最小的线性尺寸可被确定为所述最大范围中的最小的,并且总的颗粒尺寸为不同颗粒的最小线性尺寸的加权平均值。Referring to Fig. 3, immediately after the coolant injection is stopped, a

一种合适的活性聚合物(合成物)包括环氧树脂和交联剂,这两种物质均包含在同一颗粒内。A suitable reactive polymer (composite) includes an epoxy resin and a crosslinker, both contained within the same particle.

至少一部分载液通过射孔孔眼20、21、22流入地层6、7、8,所述载液同样为含有2wt%KCL的水。由于它们尺寸的原因,活性聚合物颗粒将不会渗入地层并将会在井筒与地层之间的界面处在射孔通道内聚积。这会由于降低了注入能力而导致压力增加从而会在地面被注意到。注入会适宜地持续到获得了最大的地面压力。将压力(被称为过平衡)维持一段时间,如2-16个小时。在此期间,所述界面处的温度再次增加到接近通常的地层温度。选择活性聚合物合成物以便在这一温度增长情况下发生反应。合适地是,地表温度下以及注入期间颗粒向下流入井筒过程中的温度下的反应速度可被忽略。在形成固体塞的固化反应开始之前,在升高的温度下会发生固体颗粒的某些软化。优选地是:聚合物的玻璃化转变温度在反应之后高于密封界面处的环境温度。固化的聚合物基本上是不可变形的。At least a portion of the carrier fluid, which is also water containing 2 wt% KCl, flows into the

在地层温度下,在颗粒内和相邻的颗粒之间会发生交联,以便在界面处形成堵塞或聚合物的密封层31。选择在升高的温度下能够软化的合适的颗粒以便它们能够互相紧密接触从而形成良好的粒间结合。在固化之后所述聚合物膨胀以形成更好的密封也是可能的。一种胀大的聚合物仍被认为是一种固态聚合物。At formation temperatures, cross-linking occurs within the grains and between adjacent grains to form a plug or

在活性聚合物固化以后,射孔孔眼20、21、22被封住以便井筒与层6、7、8间流体连通被抑制住。收回所述挠性管并利用本领域已知的技术通过油管16对储油层6、7选择性地进行再射孔。After curing of the reactive polymer, the

所述结果在图4中示出。油23通过新射孔孔眼35、36从层6、7流入,并且从层8产出的水通过界面处的密封层31而被抑制住。The results are shown in FIG. 4 .

显然,如果颗粒向井筒中的注入及在界面处的积聚远快于所进行的反应,则可不需要冷却步骤。Clearly, the cooling step may not be required if the injection of particles into the wellbore and accumulation at the interface is much faster than the reaction takes place.

在优选实施例中,所述活性聚合物为环氧树脂混合物。环氧树脂混合物通常包括环氧树脂、交联剂或固化剂、可选择地还有促凝剂、催化剂和/或填充材料。对于这一混合物中的每一组分,许多合适的物质在本领域是公知的。In a preferred embodiment, the reactive polymer is an epoxy resin mixture. Epoxy resin mixtures typically include an epoxy resin, a crosslinker or curing agent, optionally also a setting accelerator, catalyst and/or filler material. Many suitable materials are known in the art for each component of this mixture.

环氧树脂为含有多于一个环氧基的分子。环氧树脂的两种主要类别可为相区别的缩水甘油基环氧树脂(glycidyl epoxy)和无缩水甘油基环氧树脂(non-glycidyl epoxy)。缩水甘油基环氧树脂还可被分为缩水甘油醚、缩水甘油酯和缩水甘油胺。所述无缩水甘油基环氧树脂为脂肪族的或脂环族的环氧树脂。通过合适的二羟基化合物、二元酸或二胺与环氧氯丙烷的缩合反应可制得缩水甘油基环氧树脂。无缩水甘油基环氧树脂可通过烯烃双键(olefinic double bond)的过氧化反应而制得。Epoxy resins are molecules that contain more than one epoxy group. Two main classes of epoxy resins can be distinguished as glycidyl epoxy and non-glycidyl epoxy. Glycidyl epoxy resins can also be classified into glycidyl ethers, glycidyl esters, and glycidyl amines. The non-glycidyl epoxy resin is an aliphatic or cycloaliphatic epoxy resin. Glycidyl epoxy resins can be prepared by condensation of appropriate dihydroxy compounds, dibasic acids or diamines with epichlorohydrin. Glycidyl-free epoxy resins can be prepared by peroxidation of olefinic double bonds.

合适的和普通的缩水甘油醚环氧树脂为双酚-A的二环氧甘油醚(diglycidyl ether)(DGEBA)和酚醛环氧树脂。双酚-A的二环氧甘油醚(DGEBA)可在具有碱性催化剂时通过使双酚-A与环氧氯丙烷反应而合成。DGEBA树脂的性质取决于构成树脂链的重复单元的数量,也称作聚合度。通常在许多商业产品中所述数量在0到25之间。Suitable and common glycidyl ether epoxy resins are diglycidyl ether of bisphenol-A (DGEBA) and epoxy novolac resins. Diglycidyl ether of bisphenol-A (DGEBA) can be synthesized by reacting bisphenol-A with epichlorohydrin in the presence of a basic catalyst. The properties of DGEBA resins depend on the number of repeating units that make up the resin chain, also known as the degree of polymerization. Typically the number is between 0 and 25 in many commercial products.

其它合适的环氧树脂为酚醛环氧树脂,其为可溶可熔酚醛树脂的缩水甘油醚。酚与甲醛在酸性催化剂的作用下过度反应以生成可溶可熔酚醛树脂。酚醛环氧树脂可通过使可溶可熔酚醛树脂与环氧氯丙烷在氢氧化钠作为催化剂的情况下进行反应而被合成。酚醛环氧树脂通常含有多个环氧基。每个分子的环氧基数量取决于在开始的可溶可熔酚醛树脂中酚式羟基的数量、它们反应的程度和合成期间低分子种类聚合的程度。多个环氧基使得这些树脂获得了高的交联密度,其导致了极好的耐温性、耐化学性和耐溶性。除此之外,酚醛环氧树脂还表现出了升高的温度下的非常好的性能、良好的模塑性和机械性能。Other suitable epoxy resins are epoxy novolacs, which are glycidyl ethers of novolak resins. Phenol and formaldehyde react excessively under the action of an acidic catalyst to produce novolac phenolic resin. Epoxy novolacs can be synthesized by reacting novolac phenolic resins with epichlorohydrin with sodium hydroxide as a catalyst. Epoxy novolacs typically contain multiple epoxy groups. The number of epoxy groups per molecule depends on the number of phenolic hydroxyl groups in the starting novolac resin, the extent to which they react and the extent to which low molecular species polymerize during synthesis. The multiple epoxy groups enable these resins to achieve a high crosslink density, which results in excellent temperature, chemical and solvent resistance. In addition to this, epoxy novolacs exhibit very good properties at elevated temperatures, good moldability and mechanical properties.

另一种合适的环氧树脂也可被使用,如基于邻甲酚(orto-cresol)而不是双酚-A的环氧树脂。Another suitable epoxy resin may also be used, such as an epoxy resin based on orto-cresol instead of bisphenol-A.

所述的固化过程为化学反应,其中,环氧树脂中的环氧基与固化剂(硬化剂)反应以形成高度交联的三维网状。为了将环氧树脂转化为刚性物质,必须利用硬化剂将所述树脂固化。根据固化剂的选择,环氧树脂能够在5-160℃的任意实际温度下快速地、容易地固化。所述合成物适于在需要密封的位置处的温度下进行固化,特别是高于50℃,优选在80℃到150℃之间。The curing process is a chemical reaction in which the epoxy groups in the epoxy resin react with a curing agent (hardener) to form a highly cross-linked three-dimensional network. In order to convert an epoxy resin into a rigid substance, the resin must be cured with a hardener. Depending on the choice of curing agent, epoxy resins can be cured quickly and easily at any practical temperature from 5°C to 160°C. The composition is suitable for curing at a temperature at the location where sealing is required, in particular above 50°C, preferably between 80°C and 150°C.

用于环氧树脂的多种固化剂在本领域是公知的。用于环氧树脂的普通固化剂包括胺、聚酰胺、酚醛树脂、酐、异氰酸盐和聚硫醇。固化系统的固化动力(cure kinetics)和Tg依赖于硬化剂的分子结构。树脂和硬化剂的选择依赖于应用和所需的性质。环氧树脂—硬化系统的化学计量法还影响了被固化物质的性质。A variety of curing agents for epoxy resins are known in the art. Common curing agents for epoxy resins include amines, polyamides, phenolic resins, anhydrides, isocyanates, and polymercaptans. The cure kinetics andTg of the curing system depend on the molecular structure of the hardener. The choice of resin and hardener depends on the application and desired properties. The stoichiometry of the epoxy-hardening system also affects the properties of the substance being cured.

胺是用于环氧树脂固化的最普通的固化剂。一级胺和二级胺与环氧树脂高度反应。三级胺一般用作催化剂,通常称作用于固化反应的促凝剂。过量催化剂的应用会获得较快的固化,但是常常会消耗工作寿命和热稳定性。催化剂的催化活性影响最终被固化聚合物的物理性质。Amines are the most common curing agents used for curing epoxy resins. Primary and secondary amines are highly reactive with epoxy resins. Tertiary amines are generally used as catalysts, often referred to as coagulants for curing reactions. Application of excess catalyst results in faster cure, but often at the expense of working life and thermal stability. The catalytic activity of the catalyst affects the physical properties of the final cured polymer.

环氧树脂还可利用酚硬化剂进行固化。促凝剂的使用优选用于发生完全固化。Epoxy resins can also be cured with phenolic hardeners. The use of a coagulant is preferred for complete curing to occur.

本发明的合适的环氧树脂合成物还可基于液态环氧树脂,其可与固化剂混合并用于承受不完全的固化反应从而形成用于注入井筒的具有环氧树脂的固态聚合物。固体颗粒在暴露于界面处合适的温度之后,通过进一步与固化剂反应,所述固体颗粒还能够被进一步固化。例如,液态环氧树脂可为环氧基含量为5500-5700mmol/kg的酚醛环氧树脂。另一示例为环氧基含量为5000-5500mmol/kg的中等粘度的双酚-A/环氧氯丙烷树脂,如所公知的EPIKOTE 828材料。两种情况下的固化剂可为二乙基甲苯二苯胺(di-ethyl-toluene-di-aniline)。Suitable epoxy resin compositions of the present invention may also be based on liquid epoxy resins that can be mixed with a curing agent and used to undergo an incomplete curing reaction to form a solid polymer with epoxy resin for injection into the wellbore. The solid particles can also be further cured by further reacting with the curing agent after exposure to the appropriate temperature at the interface. For example, the liquid epoxy resin may be a novolak epoxy resin with an epoxy group content of 5500-5700 mmol/kg. Another example is a medium viscosity bisphenol-A/epichlorohydrin resin with an epoxy content of 5000-5500 mmol/kg, such as the well known EPIKOTE 828 material. The curing agent in both cases may be di-ethyl-toluene-di-aniline.

合适的合成物还可基于粉末涂层环氧树脂成分,如EPIKOTE1001或者3003,或者基于高温粉末涂层成分。EPIKOTE为市售的分解性能产品(Resolution Performance Product)物质。Suitable compositions are also based on powder coat epoxy resin compositions such as EPIKOTE 1001 or 3003, or on high temperature powder coat compositions. EPIKOTE is a commercially available resolution performance product (Resolution Performance Product) substance.

可将填充物质添加到环氧树脂合成物中以降低成本、限制固化后的收缩、限制固体颗粒的粘附特性、和/或控制颗粒的密度。碳酸钙、硅、或玻璃球可用作合适的填充物质。Filler substances can be added to epoxy resin compositions to reduce cost, limit shrinkage after curing, limit the adhesion properties of solid particles, and/or control the density of the particles. Calcium carbonate, silicon, or glass spheres can be used as suitable filler substances.

示例example

本发明已经在所谓的封堵实验中进行了测试。参考图5,渗透率为500毫达西(milliDarcy)的贝雷砂岩的柱状岩心50被固定在钢制容器53内,该钢制容器53可被放置在烘炉(未示出)内。在岩心50的一个表面上钻有一个小的射孔孔眼60。岩心的外径和高度都为5cm,并且射孔孔眼的直径为0.8cm、深度为1em。利用环氧树脂65对射孔孔眼60之外和与表面55相对的表面63之外的岩心表面进行液封。制备不具有填充物质的粉碎了的高温环氧树脂涂层粉末在2%的KCl盐水中悬浮液,其中颗粒的尺寸低于1mm并且固体的重量百分比为20%。以0.5-1bar的压力将所述悬浮液挤入射孔扩眼。使所述合成物在150℃下固化48小时以在射孔孔眼60内和岩心50与射孔孔眼60之间的界面区域68处形成固体塞。之后,通过将180bar的液体压力(盐水)在150℃下由开口70压入表面63来确定所形成的渗透率。所形成的渗透率(恢复的渗透率)为岩心原始渗透率的0.02%。在另一实验中,将粉末悬浮液以25bar的压力挤入射孔孔眼并以同样的方式固化和测试。虽然切割经过处理的岩心表明在较高的压力下所述塞70深入岩心的深度比在较低的压力下要深,但是恢复的渗透率与第一个实验类似。The invention has been tested in so-called plugging experiments. Referring to Figure 5, a cylindrical core 50 of Bere Sandstone with a permeability of 500 milliDarcy is secured within a steel container 53 which may be placed in an oven (not shown). A small perforation 60 is drilled into one surface of the core 50 . The outer diameter and height of the core are both 5 cm, and the perforation holes have a diameter of 0.8 cm and a depth of 1 em. The core surface outside the perforations 60 and outside the surface 63 opposite the surface 55 is fluid sealed with epoxy 65 . A suspension of pulverized high temperature epoxy coating powder without filler material in 2% KCl brine was prepared, wherein the particle size was below 1 mm and the solids were 20% by weight. The suspension is squeezed into the perforated reaming at a pressure of 0.5-1 bar. The composition was allowed to cure at 150° C. for 48 hours to form a solid plug within the perforation 60 and at the interface region 68 between the core 50 and the perforation 60 . The resulting permeability was then determined by pressing a liquid pressure (brine) of 180 bar at 150° C. through the opening 70 into the surface 63 . The resulting permeability (restored permeability) was 0.02% of the core's original permeability. In another experiment, the powder suspension was squeezed into perforation holes at a pressure of 25 bar and cured and tested in the same way. The recovered permeability was similar to the first experiment, although cutting the treated core showed that the plug 70 penetrated deeper into the core at the higher pressure than at the lower pressure.

Claims (9)

Translated fromChineseApplications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP04100547 | 2004-02-12 | ||

| EP04100547.1 | 2004-02-12 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN1918361Atrue CN1918361A (en) | 2007-02-21 |

Family

ID=34854693

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNA2005800046555APendingCN1918361A (en) | 2004-02-12 | 2005-02-10 | Suppressing fluid communication to or from a wellbore |

Country Status (8)

| Country | Link |

|---|---|

| EP (1) | EP1721059A1 (en) |

| CN (1) | CN1918361A (en) |

| AU (1) | AU2005212638B2 (en) |

| CA (1) | CA2554237A1 (en) |

| EA (1) | EA008963B1 (en) |

| NO (1) | NO20064082L (en) |

| NZ (1) | NZ548688A (en) |

| WO (1) | WO2005078235A1 (en) |

Cited By (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2011069339A1 (en)* | 2009-12-11 | 2011-06-16 | 安东石油技术(集团)有限公司 | Isolating particles for preventing channeling in production section of oil-gas well, completion method and production method using the same |

| WO2011069342A1 (en)* | 2009-12-11 | 2011-06-16 | 安东石油技术(集团)有限公司 | Segmental flow-control method for flow-control filter string in oil -gas well and oil-gas well structure |

| WO2011069340A1 (en)* | 2009-12-11 | 2011-06-16 | 安东石油技术(集团)有限公司 | Oil-gas well structure for facilitating extracting downhole filter string and method for extracting string |

| WO2011069447A1 (en)* | 2009-12-11 | 2011-06-16 | 安东石油技术(集团)有限公司 | Method and system for segmental flow control in oil -gas well |

| CN101705809B (en)* | 2009-12-11 | 2012-12-26 | 安东石油技术(集团)有限公司 | Segmented current controlling method of current controlling filter pipe column of oil-gas well having sand control pipe |

| CN104285029A (en)* | 2012-03-21 | 2015-01-14 | 沙特阿拉伯石油公司 | Inflatable collar and downhole method for moving a coiled tubing string |

| CN108533241A (en)* | 2018-02-07 | 2018-09-14 | 中石油煤层气有限责任公司 | A kind of CBM Fracturing method |

| CN111173486A (en)* | 2018-11-13 | 2020-05-19 | 奎德奈特能源股份有限公司 | Hydrogeological fracture energy storage system with desalination |

| CN111963099A (en)* | 2020-08-19 | 2020-11-20 | 中国石油天然气股份有限公司 | Construction method of temporary plugging resin system for repairing natural gas well in ancient world |

| CN114086915A (en)* | 2021-11-02 | 2022-02-25 | 河北省地矿局第三水文工程地质大队 | Leakage stopping method for leakage of geothermal drilling weathering zone |

| RU2776018C1 (en)* | 2021-06-06 | 2022-07-12 | Дмитрий Сергеевич Леонтьев | Method for eliminating flows behind the casing in a petroleum production borehole from an underlying aquifer |

| US11927085B2 (en) | 2009-08-10 | 2024-03-12 | Quidnet Energy Inc. | Hydraulic geofracture energy storage system with desalination |

| US12331622B2 (en) | 2009-08-10 | 2025-06-17 | Quidnet Energy Inc. | Hydraulic geofracture energy storage system and associated methods |

Families Citing this family (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6951250B2 (en) | 2003-05-13 | 2005-10-04 | Halliburton Energy Services, Inc. | Sealant compositions and methods of using the same to isolate a subterranean zone from a disposal well |

| US7267174B2 (en) | 2005-01-24 | 2007-09-11 | Halliburton Energy Services, Inc. | Methods of plugging a permeable zone downhole using a sealant composition comprising a crosslinkable material and a reduced amount of cement |

| US8703659B2 (en) | 2005-01-24 | 2014-04-22 | Halliburton Energy Services, Inc. | Sealant composition comprising a gel system and a reduced amount of cement for a permeable zone downhole |

| US7832490B2 (en)* | 2007-05-31 | 2010-11-16 | Baker Hughes Incorporated | Compositions containing shape-conforming materials and nanoparticles to enhance elastic modulus |

| MX2010006455A (en) | 2007-12-14 | 2010-09-28 | Schlumberger Technology Bv | Methods of treating subterranean wells using changeable additives. |

| US8596361B2 (en) | 2007-12-14 | 2013-12-03 | 3M Innovative Properties Company | Proppants and uses thereof |

| DK178243B1 (en) | 2008-03-06 | 2015-09-28 | Mærsk Olie Og Gas As | Fremgangsmåde til forsegling af en ringformet åbning i et borehul |

| DK178742B1 (en) | 2008-03-06 | 2016-12-19 | Maersk Olie & Gas | Method and apparatus for injecting one or more treatment fluids down into a borehole |

| DK178489B1 (en) | 2008-03-13 | 2016-04-18 | Maersk Olie & Gas | Tools and methods for sealing openings or leaks in a wellbore |

| EP2359048A1 (en)* | 2008-11-20 | 2011-08-24 | Brinker Technology Limited | Sealing method and apparatus |

| FR2968702B1 (en)* | 2010-12-14 | 2012-12-28 | Geotechnique Consulting | METHOD FOR DRILLING AND SHAPING A WELL |

| CA2861562C (en) | 2012-01-18 | 2019-09-24 | Maersk Olie Og Gas A/S | Sealing fluid for setting a packer |

| RU2504650C1 (en)* | 2012-07-27 | 2014-01-20 | Открытое акционерное общество "Татнефть" имени В.Д. Шашина | Method of development of flooded oil deposit |

| US10093770B2 (en) | 2012-09-21 | 2018-10-09 | Schlumberger Technology Corporation | Supramolecular initiator for latent cationic epoxy polymerization |

| WO2015002635A1 (en)* | 2013-07-01 | 2015-01-08 | Halliburton Energy Services, Inc. | Downhole injection assembly having an annular orifice |

| US11091964B1 (en)* | 2020-03-26 | 2021-08-17 | Halliburton Energy Services, Inc. | Method to manage tandem single string reactive LCM pill applications |

| US11434410B2 (en) | 2020-07-07 | 2022-09-06 | Halliburton Energy Services, Inc. | Methods of making and using a wellbore servicing fluid for controlling losses in permeable zones |

| US11542424B1 (en) | 2021-12-09 | 2023-01-03 | Halliburton Energy Services, Inc. | Wellbore servicing fluids and methods for controlling fluid losses in permeable zones |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3302719A (en)* | 1965-01-25 | 1967-02-07 | Union Oil Co | Method for treating subterranean formations |

| US3525398A (en)* | 1968-11-19 | 1970-08-25 | Phillips Petroleum Co | Sealing a permeable stratum with resin |

| US3808520A (en) | 1973-01-08 | 1974-04-30 | Chevron Res | Triple coil induction logging method for determining dip, anisotropy and true resistivity |

| US5485882A (en)* | 1994-10-27 | 1996-01-23 | Exxon Production Research Company | Low-density ball sealer for use as a diverting agent in hostile environment wells |

| US5656930A (en) | 1995-02-06 | 1997-08-12 | Halliburton Company | Method for determining the anisotropic properties of a subterranean formation consisting of a thinly laminated sand/shale sequence using an induction type logging tool |

| US5703773A (en) | 1996-02-08 | 1997-12-30 | Western Atlas International, Inc. | Real-time 2-dimensional inversion process and its application to induction resistivity well logging |

| US5781436A (en) | 1996-07-26 | 1998-07-14 | Western Atlas International, Inc. | Method and apparatus for transverse electromagnetic induction well logging |

| EP0840142B1 (en) | 1996-10-30 | 2004-04-14 | Baker Hughes Incorporated | Method and apparatus for determining dip angle, and horizontal and vertical conductivities |

| US6044325A (en) | 1998-03-17 | 2000-03-28 | Western Atlas International, Inc. | Conductivity anisotropy estimation method for inversion processing of measurements made by a transverse electromagnetic induction logging instrument |

| US6328106B1 (en)* | 1999-02-04 | 2001-12-11 | Halliburton Energy Services, Inc. | Sealing subterranean zones |

| US6257335B1 (en)* | 2000-03-02 | 2001-07-10 | Halliburton Energy Services, Inc. | Stimulating fluid production from unconsolidated formations |

| WO2001074967A1 (en)* | 2000-04-04 | 2001-10-11 | Heying Theodore L | Methods for reducing lost circulation in wellbores |

- 2005

- 2005-02-10CNCNA2005800046555Apatent/CN1918361A/enactivePending

- 2005-02-10WOPCT/EP2005/050589patent/WO2005078235A1/enactiveApplication Filing

- 2005-02-10EAEA200601465Apatent/EA008963B1/ennot_activeIP Right Cessation

- 2005-02-10EPEP05707992Apatent/EP1721059A1/ennot_activeWithdrawn

- 2005-02-10CACA002554237Apatent/CA2554237A1/ennot_activeAbandoned

- 2005-02-10NZNZ548688Apatent/NZ548688A/enunknown

- 2005-02-10AUAU2005212638Apatent/AU2005212638B2/ennot_activeCeased

- 2006

- 2006-09-11NONO20064082Apatent/NO20064082L/ennot_activeApplication Discontinuation

Cited By (25)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11927085B2 (en) | 2009-08-10 | 2024-03-12 | Quidnet Energy Inc. | Hydraulic geofracture energy storage system with desalination |

| US12331622B2 (en) | 2009-08-10 | 2025-06-17 | Quidnet Energy Inc. | Hydraulic geofracture energy storage system and associated methods |

| GB2489161A (en)* | 2009-12-11 | 2012-09-19 | Anton Oilfield Serv Group Ltd | Oil-gas well structure for facilitating extracting downhole filter string and method for extracting string |

| GB2489359A (en)* | 2009-12-11 | 2012-09-26 | Anton Oilfield Serv Group Ltd | Isolating particles for preventing channeling in production section of oil-gas well, completion method and production method using the same |

| CN101705808B (en)* | 2009-12-11 | 2012-05-30 | 安东石油技术(集团)有限公司 | Sectional flow control method for flow control filter pipe column of oil-gas well with bushing outside channel |

| CN101705810B (en)* | 2009-12-11 | 2012-09-05 | 安东石油技术(集团)有限公司 | Segmented current controlling method of current controlling filter pipe column of oil-gas well having perforated pipe |

| CN101701517B (en)* | 2009-12-11 | 2012-09-05 | 安东石油技术(集团)有限公司 | Method for facilitating pulling out of downhole filter pipe from oil and gas well structure |

| GB2488940A (en)* | 2009-12-11 | 2012-09-12 | Anton Oilfield Serv Group Ltd | Segmental flow-control method for flow-control filter string in oil-gas well and oil-gas well structure |

| WO2011069340A1 (en)* | 2009-12-11 | 2011-06-16 | 安东石油技术(集团)有限公司 | Oil-gas well structure for facilitating extracting downhole filter string and method for extracting string |

| WO2011069447A1 (en)* | 2009-12-11 | 2011-06-16 | 安东石油技术(集团)有限公司 | Method and system for segmental flow control in oil -gas well |

| CN101705809B (en)* | 2009-12-11 | 2012-12-26 | 安东石油技术(集团)有限公司 | Segmented current controlling method of current controlling filter pipe column of oil-gas well having sand control pipe |

| CN101705802B (en)* | 2009-12-11 | 2013-05-15 | 安东石油技术(集团)有限公司 | Anti-crossflow packing particles for production sections of oil and gas wells |

| WO2011069339A1 (en)* | 2009-12-11 | 2011-06-16 | 安东石油技术(集团)有限公司 | Isolating particles for preventing channeling in production section of oil-gas well, completion method and production method using the same |

| GB2489161B (en)* | 2009-12-11 | 2015-05-13 | Anton Bailin Oilfield Technologies Beijing Co Ltd | Oil-gas well structure for facilitating extracting a downhole filter string and method for extracting the string |

| US9080426B2 (en) | 2009-12-11 | 2015-07-14 | Anton Bailin Oilfield Technologies (Beijing) Co., Ltd | Anti-channeling pack-off particles used in a production section of an oil-gas well, and completion method and production method using such particles |

| GB2489359B (en)* | 2009-12-11 | 2016-08-31 | Anton Bailin Oilfield Tech (Beijing) Co Ltd | Anti-Channeling pack-off particles used in a production section of an oil-gas well, completion method and production method using such particles. |

| WO2011069342A1 (en)* | 2009-12-11 | 2011-06-16 | 安东石油技术(集团)有限公司 | Segmental flow-control method for flow-control filter string in oil -gas well and oil-gas well structure |

| US9664014B2 (en) | 2009-12-11 | 2017-05-30 | Anton Bailin Oilfield Technologies (Beijing) Co., Ltd. | Method and system for segmental flow control in oil-gas well |

| CN104285029A (en)* | 2012-03-21 | 2015-01-14 | 沙特阿拉伯石油公司 | Inflatable collar and downhole method for moving a coiled tubing string |

| CN104285029B (en)* | 2012-03-21 | 2017-05-10 | 沙特阿拉伯石油公司 | Downhole method and expandable collar for moving a coiled tubing string |

| CN108533241A (en)* | 2018-02-07 | 2018-09-14 | 中石油煤层气有限责任公司 | A kind of CBM Fracturing method |

| CN111173486A (en)* | 2018-11-13 | 2020-05-19 | 奎德奈特能源股份有限公司 | Hydrogeological fracture energy storage system with desalination |

| CN111963099A (en)* | 2020-08-19 | 2020-11-20 | 中国石油天然气股份有限公司 | Construction method of temporary plugging resin system for repairing natural gas well in ancient world |

| RU2776018C1 (en)* | 2021-06-06 | 2022-07-12 | Дмитрий Сергеевич Леонтьев | Method for eliminating flows behind the casing in a petroleum production borehole from an underlying aquifer |

| CN114086915A (en)* | 2021-11-02 | 2022-02-25 | 河北省地矿局第三水文工程地质大队 | Leakage stopping method for leakage of geothermal drilling weathering zone |

Also Published As

| Publication number | Publication date |

|---|---|

| AU2005212638A1 (en) | 2005-08-25 |

| WO2005078235A1 (en) | 2005-08-25 |

| EA200601465A1 (en) | 2007-04-27 |

| NO20064082L (en) | 2006-11-10 |

| AU2005212638B2 (en) | 2007-11-29 |

| CA2554237A1 (en) | 2005-08-25 |

| EP1721059A1 (en) | 2006-11-15 |

| NZ548688A (en) | 2010-06-25 |

| EA008963B1 (en) | 2007-10-26 |

| WO2005078235A9 (en) | 2006-12-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1918361A (en) | Suppressing fluid communication to or from a wellbore | |

| US3854533A (en) | Method for forming a consolidated gravel pack in a subterranean formation | |

| US5604184A (en) | Chemically inert resin coated proppant system for control of proppant flowback in hydraulically fractured wells | |

| RU2405920C2 (en) | Method for formation of packings in multiple perforation channels in casing string of well bore | |

| RU2398959C2 (en) | Procedure for stimutation of underground producing reservoir including multitude of producing intervals (versions) | |

| US3176768A (en) | Sand consolidation | |

| US4972906A (en) | Method for selective plugging of a zone in a well | |

| US3339633A (en) | Polyepoxide consolidation of earthern materials | |

| AU2012271322B2 (en) | Composition of polybutadiene-based formula for downhole applications | |

| US20050263283A1 (en) | Methods for stabilizing and stimulating wells in unconsolidated subterranean formations | |

| US3612181A (en) | Method for consolidating incompetent formations | |

| AU2017400546B2 (en) | Delayed release of resin curing agent | |

| US20200362233A1 (en) | Compositions of, and methods for making, lightweight proppant particles | |

| CA2993264C (en) | Sugar based epoxy resins with enhanced properties for sand consolidation in subterranean formations | |

| Wasnik et al. | Application of resin system for sand consolidation, mud-loss control, and channel repairing | |

| GB2518442A (en) | Method of treating a borehole | |

| US10005954B2 (en) | Plant extracted oil based polyepoxy resin composition for improved performance of natural sand placed in fracture | |

| AU2015401505A1 (en) | Swellable glass particles for reducing fluid flow in subterranean formations | |

| US3878893A (en) | Method for forming a consolidated gravel pack in a well borehole | |

| US3416603A (en) | Consolidation of subterranean formations | |

| CN101080549A (en) | Method of sealing an annular space in a wellbore | |

| WO2017164883A1 (en) | Remedial treatment of wells with voids behind casing | |

| CA1082589A (en) | Method of consolidating a subterranean formation | |

| US10501681B2 (en) | Inorganic clay particulate additive for consolidating treatments | |

| US3384173A (en) | Consolidation of subterranean formations |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication | Open date:20070221 |