CN1632488A - Fiber Bragg Grating Dynamometer Anchor Cable Stress Sensor - Google Patents

Fiber Bragg Grating Dynamometer Anchor Cable Stress SensorDownload PDFInfo

- Publication number

- CN1632488A CN1632488ACN 200410061482CN200410061482ACN1632488ACN 1632488 ACN1632488 ACN 1632488ACN 200410061482CN200410061482CN 200410061482CN 200410061482 ACN200410061482 ACN 200410061482ACN 1632488 ACN1632488 ACN 1632488A

- Authority

- CN

- China

- Prior art keywords

- fiber

- stress

- grating

- optical

- anchor cable

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000835fiberSubstances0.000claimsabstractdescription57

- 238000003466weldingMethods0.000claimsabstractdescription17

- 238000005259measurementMethods0.000claimsabstractdescription15

- 239000002184metalSubstances0.000claimsdescription10

- 239000013307optical fiberSubstances0.000claimsdescription8

- 230000003287optical effectEffects0.000claimsdescription7

- 238000005538encapsulationMethods0.000claimsdescription3

- 238000004021metal weldingMethods0.000claimsdescription2

- 238000000034methodMethods0.000abstractdescription4

- 238000009529body temperature measurementMethods0.000abstractdescription3

- 238000010586diagramMethods0.000description4

- 229910000831SteelInorganic materials0.000description3

- 238000009434installationMethods0.000description3

- 238000012544monitoring processMethods0.000description3

- 239000010959steelSubstances0.000description3

- 239000000853adhesiveSubstances0.000description2

- 230000001070adhesive effectEffects0.000description2

- 239000011248coating agentSubstances0.000description2

- 238000000576coating methodMethods0.000description2

- 239000003292glueSubstances0.000description2

- 238000004806packaging method and processMethods0.000description2

- 238000012536packaging technologyMethods0.000description2

- 238000004458analytical methodMethods0.000description1

- 238000007405data analysisMethods0.000description1

- 230000007423decreaseEffects0.000description1

- 238000001514detection methodMethods0.000description1

- 230000005672electromagnetic fieldEffects0.000description1

- 230000007613environmental effectEffects0.000description1

- 230000003862health statusEffects0.000description1

- 238000009413insulationMethods0.000description1

- 239000005416organic matterSubstances0.000description1

- 229910000679solderInorganic materials0.000description1

Images

Landscapes

- Length Measuring Devices By Optical Means (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及桥梁工程领域锚索的应力测量,特别是基于光纤光栅的测力计锚索应力测量。The invention relates to the stress measurement of the anchor cable in the field of bridge engineering, in particular to the stress measurement of the anchor cable of a dynamometer based on an optical fiber grating.

背景技术Background technique

应力环广泛的应用在土木工程和桥梁工程领域的锚索应力测量,现有技术一般使用电类应力传感器。电类应力传感器受湿度、温度的影响容易降低绝缘性能,避雷性差,受电磁场的影响容易产生噪声等,耐环境性差。而且,电类应力传感器不适用于分布式的复用结构,要进行多点测量平均到每个测量点的成本就会增加。另外,系统的信噪比不高,很难处理微弱应力的检出信号。Stress rings are widely used in the stress measurement of anchor cables in the fields of civil engineering and bridge engineering. In the prior art, electrical stress sensors are generally used. Electrical stress sensors are easily affected by humidity and temperature to reduce insulation performance, have poor lightning protection, and are prone to generate noise due to the influence of electromagnetic fields, and have poor environmental resistance. Moreover, electrical stress sensors are not suitable for distributed multiplexing structures, and the average cost of each measurement point will increase for multi-point measurement. In addition, the signal-to-noise ratio of the system is not high, and it is difficult to process the detection signal of weak stress.

在日本专利厅公开的特开2004-125587中提到,采用光纤衍射光栅的土木用中央孔型测力传感器。将光纤传感器引入应力环中避免了电类传感器的缺点,但是其中的FBG传感器和中空状的圆筒部的结合是使用粘合剂粘贴的方式,粘合剂会吸收应力,产生冗余现象。In Japanese Patent Application Laid-Open No. 2004-125587, it is mentioned that a central hole type load cell for civil engineering using an optical fiber diffraction grating is mentioned. Introducing the fiber optic sensor into the stress ring avoids the disadvantages of the electrical sensor, but the combination of the FBG sensor and the hollow cylindrical part is pasted with an adhesive, which will absorb the stress and cause redundancy.

发明内容Contents of the invention

本发明旨在提供一种光纤光栅测力计锚索应力传感器,应用于桥梁锚索应力的测量和锚索安装时的监测。在安装锚索时会分别固定拉索的每根钢缆,如果在操作时没有应力的监测无法将拉力均匀施加在每根钢缆上,这样受力较大的钢缆会比较容易断裂。如果压力环上受力均匀且大小适度则说明锚索的状态健康。另外实践证明温度也是影响锚索健康状态的重要因素,当温度降低时桥梁的拉索会收缩,拉力加大增加了钢缆断裂的可能性,所以有效的进行温度的测量和补偿也是本发明要解决的问题。The invention aims to provide a fiber grating dynamometer anchor cable stress sensor, which is applied to the measurement of bridge anchor cable stress and the monitoring of anchor cable installation. When the anchor cable is installed, each steel cable of the stay cable will be fixed separately. If there is no stress monitoring during operation, the tension cannot be evenly applied to each steel cable, so that the steel cable with greater force will be easier to break. If the force on the pressure ring is uniform and moderate, it means that the anchor cable is in good condition. In addition, practice has proved that temperature is also an important factor affecting the health of the anchor cable. When the temperature decreases, the cable of the bridge will shrink, and the increase in tension will increase the possibility of cable breakage. Therefore, effective temperature measurement and compensation are also the key points of the present invention. solved problem.

一种光纤光栅测力计锚索应力传感器,主要包括:环形弹性体、六个光纤光栅应力传感器、两个光纤光栅温度传感器,其中光纤光栅应力传感器和光纤光栅温度传感器采用无胶化封装技术制备;光纤光栅应力传感器和光纤光栅温度传感器和环形弹性体采用激光点焊的方式附着,光纤光栅温度传感器焊接的方向垂直于环形弹性体承受的应力方向。A fiber grating dynamometer anchor cable stress sensor, mainly comprising: a ring elastic body, six fiber grating stress sensors, two fiber grating temperature sensors, wherein the fiber grating stress sensor and the fiber grating temperature sensor are prepared by non-glue packaging technology The fiber grating stress sensor and the fiber grating temperature sensor are attached to the ring elastic body by laser spot welding, and the welding direction of the fiber grating temperature sensor is perpendicular to the stress direction of the ring elastic body.

如前所述的一种光纤光栅测力计锚索应力传感器,其中光纤光栅应力传感器和光纤光栅温度传感器的无胶化封装结构包括:光纤光栅、金属片,光纤光栅表面有金属镀层,并有金属焊点将光纤光栅和金属片焊接在一起。As mentioned above, a fiber grating dynamometer anchor cable stress sensor, wherein the glue-free packaging structure of the fiber grating stress sensor and the fiber grating temperature sensor includes: a fiber grating, a metal sheet, a metal coating on the surface of the fiber grating, and Metal solder joints weld the fiber grating and the metal sheet together.

如前所述的一种光纤光栅测力计锚索应力传感器,其中六个光纤光栅应力传感器均匀的分布在环形弹性体的外表面和内表面,通过激光电焊机焊接,焊接方向平行于环形弹性体承受的应力方向。A fiber grating dynamometer anchor cable stress sensor as mentioned above, in which six fiber grating stress sensors are evenly distributed on the outer surface and inner surface of the annular elastic body, welded by a laser welding machine, and the welding direction is parallel to the annular elastic The direction of the stress on the body.

如前所述的一种光纤光栅测力计锚索应力传感器,其中两个光纤光栅温度传感器分别位于环形弹性体的外表面和内表面,对本锚索应力测量系统进行温度补偿。As mentioned above, a fiber grating dynamometer anchor cable stress sensor, in which two fiber grating temperature sensors are respectively located on the outer surface and inner surface of the annular elastic body, to perform temperature compensation for the anchor cable stress measurement system.

本发明采用无胶化封装技术制备光纤光栅传感器以及用激光点焊和环形弹性体附着的方法,避免了粘合剂结合产生的冗余现象以及有机物易疲劳分解的问题。提高了这种锚索应力测量系统的传感性能和使用寿命。环形弹性体的内外表面都分布有光纤光栅应力传感器,来自不同位置传感器的应力值可以反应锚索所受应力是否均匀。另外,光纤光栅温度传感器的焊接方向和环形弹性体承受的应力方向垂直,避免应力的影响可准确的反应温度的变化,也可同时对光纤光栅应力传感器做出温度补偿。The invention adopts the glue-free encapsulation technology to prepare the optical fiber grating sensor and the method of laser spot welding and annular elastic body attachment, which avoids the redundant phenomenon caused by the bonding of the adhesive and the problem that the organic matter is easily fatigued and decomposed. The sensing performance and service life of the anchor cable stress measurement system are improved. Fiber Bragg grating stress sensors are distributed on the inner and outer surfaces of the annular elastic body, and the stress values from sensors at different positions can reflect whether the stress on the anchor cable is uniform. In addition, the welding direction of the fiber grating temperature sensor is perpendicular to the stress direction of the annular elastic body, so as to avoid the influence of stress, it can accurately reflect the temperature change, and can also make temperature compensation for the fiber grating stress sensor at the same time.

附图说明Description of drawings

图1.光纤光栅测力计锚索应力传感器结构图Figure 1. Structural diagram of fiber grating dynamometer anchor cable stress sensor

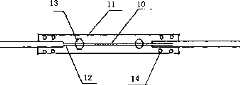

图2.光纤光栅无胶化封装技术制备传感头结构图Figure 2. Structural diagram of sensor head prepared by fiber grating non-glue encapsulation technology

图3.锚索测力计安装示意图Figure 3. Installation diagram of anchor cable dynamometer

图4.锚索应力测量系统结构图Figure 4. Structural diagram of anchor cable stress measurement system

具体实施方式Detailed ways

光纤光栅测力计锚索应力传感器结构如图1.所示,包括1-环形弹性体、2-光纤光栅应力传感器、3-光纤光栅温度传感器、8-光缆引出座、9-光缆等几个部分。其中光纤光栅应力传感器和光纤光栅温度传感器采用无胶化封装技术制备;光纤光栅应力传感器和光纤光栅温度传感器和环形弹性体采用激光点焊14的方式附着,光纤光栅温度传感器焊接的方向垂直于环形弹性体承受的应力方向。如前所述的光纤光栅测力计锚索应力传感器结构,其中六个光纤光栅应力传感器2均匀的分布在环形弹性体的外表面和内表面,通过激光电焊机焊接,焊接方向平行于环形弹性体承受的应力方向。如前所述的光纤光栅测力计锚索应力传感器结构,其中两个光纤光栅温度传感器3分别位于环形弹性体的外表面和内表面,对本锚索应力测量系统进行温度测量和温度补偿。The structure of the fiber grating dynamometer anchor cable stress sensor is shown in Figure 1. It includes 1-annular elastic body, 2-fiber grating stress sensor, 3-fiber grating temperature sensor, 8-optical cable outlet, 9-optical cable, etc. part. Among them, the fiber grating stress sensor and the fiber grating temperature sensor are prepared by glue-free packaging technology; the fiber grating stress sensor, the fiber grating temperature sensor and the annular elastic body are attached by

如前所述的光纤光栅测力计锚索应力传感器,其中光纤光栅应力传感器和光纤光栅温度传感器的无胶化封装结构如图2所示,包括:光纤光栅10、金属片11,光纤光栅表面有金属镀层13,并有金属焊点14将光纤光栅和金属片焊接在一起。As mentioned above, the fiber grating dynamometer anchor cable stress sensor, wherein the glue-free packaging structure of the fiber grating stress sensor and the fiber grating temperature sensor is shown in Figure 2, including:

如图3所示环形弹性体1安装在锚索座5和锚索头6之间,拉索4从承压筒的中间穿过如图2所示。安装好后拉索处于紧张状态,环形弹性体受压,位于环形弹性体上的光纤光栅应力传感器实时检测该压力。当某根或某些拉索松弛或断裂,环形弹性体上的受压情况会发生改变,位于环形弹性体上不同位置的光纤光栅应力传感器的测量值会监测到这种改变。As shown in FIG. 3 , the annular

如图4.所示是本发明应用在桥梁上的锚索应力环测量系统,在每个锚索上安装应力环,引出的光缆串联后进入光调制解调器,最后的测量值输入分析计算机进行数据分析,对桥梁的健康状况实时的监测。As shown in Figure 4, it is the anchor cable stress ring measurement system applied on the bridge by the present invention. A stress ring is installed on each anchor cable, and the optical cable drawn out enters the optical modem after being connected in series, and the final measured value is input into the analysis computer for data analysis. , Real-time monitoring of the health status of the bridge.

Claims (4)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 200410061482CN1632488A (en) | 2004-12-31 | 2004-12-31 | Fiber Bragg Grating Dynamometer Anchor Cable Stress Sensor |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 200410061482CN1632488A (en) | 2004-12-31 | 2004-12-31 | Fiber Bragg Grating Dynamometer Anchor Cable Stress Sensor |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN1632488Atrue CN1632488A (en) | 2005-06-29 |

Family

ID=34846361

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 200410061482PendingCN1632488A (en) | 2004-12-31 | 2004-12-31 | Fiber Bragg Grating Dynamometer Anchor Cable Stress Sensor |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN1632488A (en) |

Cited By (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN100381845C (en)* | 2006-07-20 | 2008-04-16 | 上海交通大学 | Fiber Bragg Grating Door Switch State Sensor Probe |

| CN101571380B (en)* | 2009-06-09 | 2011-04-06 | 中国人民解放军海军工程大学 | Wide range fiber grating strain transducer |

| CN101738170B (en)* | 2009-12-18 | 2011-05-04 | 北京科技大学 | Distributed fiber sensor for large deformation measurement |

| CN102162760A (en)* | 2010-12-29 | 2011-08-24 | 中铁大桥局集团武汉桥梁科学研究院有限公司 | Cable force monitoring device for attached-type stay cable |

| CN101526409B (en)* | 2009-04-20 | 2012-12-05 | 重庆大学 | Super large cable force self-sensing intelligent cable and measuring method based on fiber strain sensing |

| CN103353367A (en)* | 2013-07-04 | 2013-10-16 | 中山大学 | Rock and soil reinforcement bar outer end force sensor based on fiber bragg grating |

| CN103822738A (en)* | 2014-01-03 | 2014-05-28 | 重庆大学 | Stress sensor based on fiber gratings |

| EP2484834A4 (en)* | 2009-09-30 | 2014-07-16 | Fasten Group Company Ltd | INTELLIGENT BRIDGE CABLES SYSTEM WITH INTEGRATED FIBER NETWORK SENSOR |

| CN104280169A (en)* | 2014-10-17 | 2015-01-14 | 武汉理工大学 | Ring type fiber bragg grating force measurement device and application thereof |

| CN104697682A (en)* | 2014-04-04 | 2015-06-10 | 南京大学(苏州)高新技术研究院 | Fiber Bragg grating strain-measuring method and fiber Bragg grating strain sensor |

| CN104897321A (en)* | 2015-06-24 | 2015-09-09 | 潍坊学院 | Prefabricated opening concrete tubular pile body inner wall shearing strength testing device and method |

| CN105421501A (en)* | 2015-12-15 | 2016-03-23 | 中国一冶集团有限公司 | Method for monitoring working state of anchor rod and deformation condition of surrounding soil at sludge environment |

| CN106436570A (en)* | 2016-08-31 | 2017-02-22 | 杭州浙锚预应力有限公司 | Intelligent stay cable anchor device |

| CN106906824A (en)* | 2015-12-22 | 2017-06-30 | 中国水利水电科学研究院 | Distribution type fiber-optic prestressing force intellectual monitoring anchor cable |

| CN107367239A (en)* | 2016-05-12 | 2017-11-21 | 中国计量大学 | A kind of loop configuration high-temperature pipe outer wall strain detecting fiber-optic grating sensor part |

| CN107957306A (en)* | 2018-01-11 | 2018-04-24 | 盐城工学院 | A kind of Character of Cable Force of Cable stayed Bridge stress torsion detection sensor based on fiber grating |

| CN108627289A (en)* | 2018-06-07 | 2018-10-09 | 广西大学 | A kind of high sensitivity dynamometry ring sensor |

| CN110082023A (en)* | 2019-05-09 | 2019-08-02 | 湖北工业大学 | A kind of real-time monitoring for cable force device and monitoring method |

| CN110864840A (en)* | 2019-11-29 | 2020-03-06 | 北京瑞格星科技有限公司 | Cable force measuring sensor |

| CN111337170A (en)* | 2020-03-20 | 2020-06-26 | 南京智慧基础设施技术研究院有限公司 | Optical fiber sensing method for detecting tension of stay cable |

- 2004

- 2004-12-31CNCN 200410061482patent/CN1632488A/enactivePending

Cited By (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN100381845C (en)* | 2006-07-20 | 2008-04-16 | 上海交通大学 | Fiber Bragg Grating Door Switch State Sensor Probe |

| CN101526409B (en)* | 2009-04-20 | 2012-12-05 | 重庆大学 | Super large cable force self-sensing intelligent cable and measuring method based on fiber strain sensing |

| CN101571380B (en)* | 2009-06-09 | 2011-04-06 | 中国人民解放军海军工程大学 | Wide range fiber grating strain transducer |

| EP2484834A4 (en)* | 2009-09-30 | 2014-07-16 | Fasten Group Company Ltd | INTELLIGENT BRIDGE CABLES SYSTEM WITH INTEGRATED FIBER NETWORK SENSOR |

| CN101738170B (en)* | 2009-12-18 | 2011-05-04 | 北京科技大学 | Distributed fiber sensor for large deformation measurement |

| CN102162760A (en)* | 2010-12-29 | 2011-08-24 | 中铁大桥局集团武汉桥梁科学研究院有限公司 | Cable force monitoring device for attached-type stay cable |

| CN102162760B (en)* | 2010-12-29 | 2012-10-10 | 中铁大桥局集团武汉桥梁科学研究院有限公司 | An attached cable force monitoring device |

| CN103353367A (en)* | 2013-07-04 | 2013-10-16 | 中山大学 | Rock and soil reinforcement bar outer end force sensor based on fiber bragg grating |

| CN103353367B (en)* | 2013-07-04 | 2016-10-26 | 中山大学 | A kind of rock-reinforcing rod member outer end based on fiber grating force cell |

| CN103822738A (en)* | 2014-01-03 | 2014-05-28 | 重庆大学 | Stress sensor based on fiber gratings |

| CN104697682A (en)* | 2014-04-04 | 2015-06-10 | 南京大学(苏州)高新技术研究院 | Fiber Bragg grating strain-measuring method and fiber Bragg grating strain sensor |

| CN104280169A (en)* | 2014-10-17 | 2015-01-14 | 武汉理工大学 | Ring type fiber bragg grating force measurement device and application thereof |

| CN104897321A (en)* | 2015-06-24 | 2015-09-09 | 潍坊学院 | Prefabricated opening concrete tubular pile body inner wall shearing strength testing device and method |

| CN104897321B (en)* | 2015-06-24 | 2016-08-24 | 潍坊学院 | Wall shearing stress method of testing in a kind of pre-formed members concrete tubular pile pile body |

| CN105421501A (en)* | 2015-12-15 | 2016-03-23 | 中国一冶集团有限公司 | Method for monitoring working state of anchor rod and deformation condition of surrounding soil at sludge environment |

| CN106906824A (en)* | 2015-12-22 | 2017-06-30 | 中国水利水电科学研究院 | Distribution type fiber-optic prestressing force intellectual monitoring anchor cable |

| CN107367239A (en)* | 2016-05-12 | 2017-11-21 | 中国计量大学 | A kind of loop configuration high-temperature pipe outer wall strain detecting fiber-optic grating sensor part |

| CN106436570A (en)* | 2016-08-31 | 2017-02-22 | 杭州浙锚预应力有限公司 | Intelligent stay cable anchor device |

| CN107957306A (en)* | 2018-01-11 | 2018-04-24 | 盐城工学院 | A kind of Character of Cable Force of Cable stayed Bridge stress torsion detection sensor based on fiber grating |

| CN108627289A (en)* | 2018-06-07 | 2018-10-09 | 广西大学 | A kind of high sensitivity dynamometry ring sensor |

| CN110082023A (en)* | 2019-05-09 | 2019-08-02 | 湖北工业大学 | A kind of real-time monitoring for cable force device and monitoring method |

| CN110082023B (en)* | 2019-05-09 | 2021-03-16 | 湖北工业大学 | A kind of cable force real-time monitoring device and monitoring method |

| CN110864840A (en)* | 2019-11-29 | 2020-03-06 | 北京瑞格星科技有限公司 | Cable force measuring sensor |

| CN111337170A (en)* | 2020-03-20 | 2020-06-26 | 南京智慧基础设施技术研究院有限公司 | Optical fiber sensing method for detecting tension of stay cable |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1632488A (en) | Fiber Bragg Grating Dynamometer Anchor Cable Stress Sensor | |

| CN101245988B (en) | Prestress Loss Monitoring Method Based on Optical Fiber Brillouin Full-Scale Sensing | |

| US8425111B2 (en) | Bridge intelligent cable system with built-in fiber grating sensor | |

| Ansari | Practical implementation of optical fiber sensors in civil structural health monitoring | |

| CN201535705U (en) | Fiber bragg grating pipeline stress hoop | |

| CN100417963C (en) | Distributed long gauge fiber Bragg grating strain sensor and manufacturing method thereof | |

| CN1166921C (en) | Method and device for monitoring long-term working state of fiber grating anchor cable | |

| JP6139026B2 (en) | FBG sensor for measuring maximum distortion, method for manufacturing and using the same | |

| CN209802308U (en) | Surface-mounted fiber grating strain sensor with temperature compensation | |

| CN102607611B (en) | Embedded type double-layer packaging fiber bragg grating sensor and manufacturing method thereof | |

| CN101787676A (en) | Method for assembling cable built-in fiber bragg grating strain transducer | |

| CN103383246A (en) | High-sensitivity fiber Bragg grating strain sensor | |

| CN103277387A (en) | Intelligent bolt for optical fiber grating sensor | |

| Duan et al. | FBG smart bolts and their application in power grids | |

| CN107300365A (en) | High precision and high sensitivity fiber Bragg grating strain sensor | |

| CN101245989A (en) | Prestress Loss Monitoring Method Based on Fiber Reinforced Resin-Fiber Bragg Grating Smart Rib | |

| CN101275916A (en) | Distributed non-slip optical fiber strain sensor and manufacturing method thereof | |

| CN111323187A (en) | Device and method for monitoring dynamic contact state of main cable and main cable saddle of suspension bridge | |

| CN202511807U (en) | Embedded type double-layer packaging fiber grating sensor | |

| CN110319958A (en) | The preparation and application of fiber bragg grating sensing device and the pressure rings using it | |

| CN202216784U (en) | A fiber grating cable force sensor with temperature self-compensation | |

| CN102706390A (en) | Surface fiber Bragg grating sensor with double packaging layers and manufacturing method of surface fiber Bragg grating sensor | |

| CN103837273A (en) | Stress monitoring device and manufacturing method | |

| Li et al. | Strain transferring of embedded fiber Bragg grating sensors | |

| WO2009126991A1 (en) | Method and system for monitoring strain in a structure using an optical fibre |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C02 | Deemed withdrawal of patent application after publication (patent law 2001) | ||

| WD01 | Invention patent application deemed withdrawn after publication |