CN116408313A - Automatic laser composite cleaning equipment and cleaning method thereof - Google Patents

Automatic laser composite cleaning equipment and cleaning method thereofDownload PDFInfo

- Publication number

- CN116408313A CN116408313ACN202310367162.8ACN202310367162ACN116408313ACN 116408313 ACN116408313 ACN 116408313ACN 202310367162 ACN202310367162 ACN 202310367162ACN 116408313 ACN116408313 ACN 116408313A

- Authority

- CN

- China

- Prior art keywords

- laser

- cleaning

- head

- cleaned

- continuous

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B7/00—Cleaning by methods not provided for in a single other subclass or a single group in this subclass

- B08B7/0035—Cleaning by methods not provided for in a single other subclass or a single group in this subclass by radiant energy, e.g. UV, laser, light beam or the like

- B08B7/0042—Cleaning by methods not provided for in a single other subclass or a single group in this subclass by radiant energy, e.g. UV, laser, light beam or the like by laser

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B13/00—Accessories or details of general applicability for machines or apparatus for cleaning

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B15/00—Preventing escape of dirt or fumes from the area where they are produced; Collecting or removing dirt or fumes from that area

- B08B15/04—Preventing escape of dirt or fumes from the area where they are produced; Collecting or removing dirt or fumes from that area from a small area, e.g. a tool

Landscapes

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Cleaning In General (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及激光清洗领域,特别涉及一种自动的激光复合清洗设备及其清洗方法。The invention relates to the field of laser cleaning, in particular to an automatic laser composite cleaning device and a cleaning method thereof.

背景技术Background technique

激光清洗作为一种新型的清洗方式,相比于传统的机械清洗、物理化学清洗,具有高可控性、环保性、易自动化及高清洗精度等优点,它通过高能量的激光束照射到零件待清洗表面上,使表面的污染物、锈斑或涂层发生剥离、气化或爆炸等物理化学反应,从而达到有效清洁表面的效果,目前广泛应用于航空航天、轨道交通、半导体、模具和文物修复等行业。激光按照控制方式不同分为连续激光和脉冲激光,现有的激光清洗设备大多采用单一类型激光进行清洗,由于连续激光能量较高,导致对基体损伤的控制难度加大;脉冲激光脉宽较短,需要进行多次扫描,效率较低,成本投入较大。针对一些零件表面较厚污染物的清洗去除存在一定的缺陷,清洗效果不甚理想。同时目前大多清洗设备为手持式的清洗机,自动化程度低,对操作人员有较高的要求,其仅能对结构较为简单的零件进行激光清洗,对于一些复杂结构零件以及大批量需求的场合,容易产生清洗效果不佳的问题。As a new cleaning method, laser cleaning has the advantages of high controllability, environmental protection, easy automation and high cleaning precision compared with traditional mechanical cleaning and physical and chemical cleaning. It irradiates parts with high-energy laser beams On the surface to be cleaned, the pollutants, rust spots or coatings on the surface will undergo physical and chemical reactions such as peeling, gasification or explosion, so as to achieve the effect of effectively cleaning the surface. At present, it is widely used in aerospace, rail transit, semiconductors, molds and cultural relics Restoration and other industries. Lasers are divided into continuous lasers and pulsed lasers according to different control methods. Most of the existing laser cleaning equipment uses a single type of laser for cleaning. Due to the high energy of the continuous laser, it is more difficult to control the damage of the substrate; the pulse width of the pulsed laser is short. , multiple scans are required, the efficiency is low, and the cost investment is large. There are certain defects in the cleaning and removal of thicker pollutants on the surface of some parts, and the cleaning effect is not ideal. At the same time, most of the current cleaning equipment is a hand-held cleaning machine, which has a low degree of automation and has high requirements for operators. It can only perform laser cleaning on parts with relatively simple structures. For some complex structural parts and large-scale requirements, It is easy to produce the problem of poor cleaning effect.

发明内容Contents of the invention

针对现有技术中存在的不足,本发明提供了一种自动的激光复合清洗设备及其清洗方法,解决现有技术中的激光清洗设备自动化程度不高以及对一些结构复杂零件和较厚污物的激光清洗技术的问题。Aiming at the deficiencies in the prior art, the present invention provides an automatic laser composite cleaning device and its cleaning method, which solves the problem of the low degree of automation of the laser cleaning equipment in the prior art and the problem of some parts with complex structures and thicker dirt. The problem of laser cleaning technology.

本发明是通过以下技术手段实现上述技术目的的。The present invention achieves the above-mentioned technical purpose through the following technical means.

一种自动的激光复合清洗设备,包括五轴运动平台、激光复合清洗工作组件、底座和机架,所述五轴运动平台位于底座上,所述五轴运动平台上放置待清洗零件,用于使待清洗零件移动、摆动和旋转;An automatic laser composite cleaning equipment, including a five-axis motion platform, a laser composite cleaning working assembly, a base and a frame, the five-axis motion platform is located on the base, and the parts to be cleaned are placed on the five-axis motion platform for moving, oscillating and rotating the parts to be cleaned;

所述激光复合清洗工作组件包括激光复合清洗头、纳秒脉冲激光器和高功率连续激光器;所述纳秒脉冲激光器用于产生脉冲激光束,所述高功率连续激光器用于产生连续激光束;所述激光复合清洗头包括连续激光头和脉冲激光头,所述连续激光头和脉冲激光头分别通过连接座安装在所述机架上;所述连续激光头可移动安装在连接座上,用于调整连续激光头与脉冲激光头之间距离;所述连续激光束通过连续激光头聚焦到待清洗零件表面,所述脉冲激光束通过脉冲激光头聚焦到待清洗零件表面,所述连续激光束倾斜于脉冲激光束,且所述连续激光束位于脉冲激光束前方,使连续激光光斑在先扫描清洗,脉冲激光光斑在后扫描清洗。The laser composite cleaning working assembly includes a laser composite cleaning head, a nanosecond pulse laser and a high-power continuous laser; the nanosecond pulse laser is used to generate a pulsed laser beam, and the high-power continuous laser is used to generate a continuous laser beam; The laser composite cleaning head includes a continuous laser head and a pulsed laser head, and the continuous laser head and the pulsed laser head are respectively installed on the frame through a connecting seat; the continuous laser head is movably mounted on the connecting seat for Adjust the distance between the continuous laser head and the pulsed laser head; the continuous laser beam is focused on the surface of the part to be cleaned by the continuous laser head, the pulsed laser beam is focused on the surface of the part to be cleaned by the pulsed laser head, and the continuous laser beam is inclined The continuous laser beam is located in front of the pulsed laser beam, so that the continuous laser spot is scanned and cleaned first, and the pulsed laser spot is scanned and cleaned afterward.

进一步,所述五轴运动平台包括Y轴向滑台、X轴向滑台、Z轴向滑台、绕Y轴摆动平台和绕Z轴旋转平台;所述绕Z轴旋转平台、绕Y轴摆动平台、X轴向滑台和Y轴向滑台从上至下安装于所述底座上;所述Z轴向滑台安装在机箱上,所述Z轴向滑台上安装机架;所述Y轴向滑台、X轴向滑台和Z轴向滑台分别连接驱动组件,所述驱动组件包括伺服电机驱动器,所述伺服电机驱动器的动力输出端分别通过丝杠与Y轴向滑台、X轴向滑台和Z轴向滑台传动连接;所述绕Y轴摆动平台和绕Z轴旋转平台均分别连接伺服电机驱动器和分度装置。Further, the five-axis motion platform includes a Y-axis slide table, an X-axis slide table, a Z-axis slide table, a swing platform around the Y axis, and a rotation platform around the Z axis; The swing platform, the X-axis slide table and the Y-axis slide table are installed on the base from top to bottom; the Z-axis slide table is installed on the chassis, and the Z-axis slide table is installed with a frame; The Y-axis slide table, the X-axis slide table and the Z-axis slide table are respectively connected to the drive assembly, the drive assembly includes a servo motor driver, and the power output end of the servo motor driver is connected to the Y-axis slide table through a screw respectively. Table, X-axis sliding table and Z-axis sliding table are connected by transmission; the swing platform around the Y axis and the rotating platform around the Z axis are respectively connected to the servo motor driver and the indexing device.

进一步,所述连续激光头内部安装冷却装置,用于降低清洗时产生的高温;所述连续激光头上设有激光测距仪,用于测量连续激光头到待清洗零件的距离;所述纳秒脉冲激光器与脉冲激光头之间和高功率连续激光器与连续激光头之间分别设有激光整形组件,用于调整激光束路径和出射姿态。Further, a cooling device is installed inside the continuous laser head to reduce the high temperature generated during cleaning; a laser range finder is provided on the continuous laser head to measure the distance from the continuous laser head to the parts to be cleaned; the nanometer There are laser shaping components between the second pulse laser and the pulse laser head and between the high-power continuous laser and the continuous laser head, which are used to adjust the laser beam path and exit attitude.

进一步,还包括吸尘装置,所述吸尘装置包括吸尘罩、吸尘管和吸尘箱;所述吸尘箱位于机箱上,所述吸尘箱通过吸尘管与吸尘罩连接,所述吸尘罩位于待清洗零件上方,所述吸尘罩上设有缺口,用于使连续激光束和脉冲激光束穿过吸尘罩聚焦待清洗零件表面。Further, it also includes a dust suction device, the dust suction device includes a dust suction hood, a dust suction pipe and a dust collection box; the dust collection box is located on the chassis, and the dust suction box is connected to the dust suction hood through the dust suction pipe, The dust suction hood is located above the parts to be cleaned, and a gap is provided on the dust suction hood for allowing the continuous laser beam and the pulsed laser beam to pass through the dust suction hood and focus on the surface of the parts to be cleaned.

进一步,所述吸尘罩外圈缠绕橡胶布;所述吸尘管为竹节软管,用于调节形状位置;所述吸尘箱上安装旋转手柄,所述旋转手柄与吸尘管通过传动机构相连,用于将吸尘管收回至机箱内。Further, rubber cloth is wrapped around the outer ring of the dust collection hood; the dust suction pipe is a bamboo tube for adjusting the shape and position; a rotary handle is installed on the dust collection box, and the rotary handle and the dust suction pipe The mechanism is connected, and is used for retracting the suction pipe into the cabinet.

进一步,还包括控制系统,所述控制系统包括上位机、下位机控制器和电源系统;所述上位机通过信号线与下位机控制器相连,用于参数设置和状态显示并下发指令给下位机控制器去执行;所述下位机控制器设于所述机箱内,所述下位机控制器分别与五轴运动平台和所述激光复合清洗工作组件通过信号传输线连接;所述电源系统设于所述机箱内,用于设备供电。Further, it also includes a control system, the control system includes an upper computer, a lower computer controller and a power supply system; the upper computer is connected to the lower computer controller through a signal line, and is used for parameter setting and status display and sends instructions to the lower computer The machine controller is executed; the lower machine controller is set in the chassis, and the lower machine controller is respectively connected with the five-axis motion platform and the laser composite cleaning working component through a signal transmission line; the power supply system is set in the The inside of the chassis is used for power supply of equipment.

进一步,所述机架上设有图像采集装置;所述图像采集装置包括图像传感器和工业镜头;所述图像采集装置与所述上位机通过信号传输线连接,用于实时监测并发送清洗工件表面图像特征至上位机,当所述控制系统通过图像识别检测到工件过烧或达不到清洗要求时,则所述控制系统发出报警。Further, the frame is provided with an image acquisition device; the image acquisition device includes an image sensor and an industrial lens; the image acquisition device is connected to the host computer through a signal transmission line for real-time monitoring and sending images of the surface of the cleaned workpiece The feature goes to the host computer. When the control system detects that the workpiece is over-burned or fails to meet the cleaning requirements through image recognition, the control system sends out an alarm.

一种自动的激光复合清洗设备的清洗方法,包括如下步骤:An automatic cleaning method for laser composite cleaning equipment, comprising the steps of:

参数设置步骤:根据待清洗零件设置所述高功率连续激光器输出连续激光束的平均功率和扫描速度;设置所述纳秒脉冲激光器输出脉冲激光束的平均功率、扫描速度、脉冲宽度和脉冲频率;Parameter setting step: setting the average power and scanning speed of the continuous laser beam output by the high-power continuous laser according to the parts to be cleaned; setting the average power, scanning speed, pulse width and pulse frequency of the pulsed laser beam output by the nanosecond pulse laser;

激光复合清洗步骤:将待清洗零件安装在五轴运动平台上,通过上位机下发指令控制五轴运动平台移动,将待清洗零件移动至激光复合清洗头正下方;开启激光器,产生的激光束经过所述激光整形组件整形后,聚焦到零件待清洗表面,形成前后分布的连续激光光斑与脉冲激光光斑;激光清洗时保持连续激光光斑在前,脉冲激光光斑在后进行扫描清洗;清洗过程中,所述控制系统控制所述激光复合清洗头和所述五轴运动平台联动,对所述待清洗零件进行复合清洗。Laser compound cleaning steps: install the parts to be cleaned on the five-axis motion platform, control the movement of the five-axis motion platform through the command issued by the host computer, and move the parts to be cleaned to directly under the laser compound cleaning head; turn on the laser, and the generated laser beam After being reshaped by the laser shaping component, it is focused on the surface of the part to be cleaned to form continuous laser spots and pulsed laser spots; during laser cleaning, the continuous laser spot is kept in front, and the pulsed laser spot is followed by scanning and cleaning; during the cleaning process , the control system controls the linkage between the laser composite cleaning head and the five-axis motion platform to perform composite cleaning on the parts to be cleaned.

进一步,所述控制系统通过调节所述连续激光清洗头与脉冲激光清洗头之间的距离,通过对连续激光束和脉冲激光束的作用间距控制,用于控制脉冲清洗前的预热程度以及防止局部过热而导致待清洗零件基材烧蚀。Further, the control system is used to control the degree of preheating before pulse cleaning and prevent Local overheating leads to ablation of the substrate of the part to be cleaned.

本发明的有益效果在于:The beneficial effects of the present invention are:

1.本发明所述的自动的激光复合清洗设备及其清洗方法,通过控制系统对五轴运动平台和激光复合清洗头的联动控制,如此便实现了对待清洗零件的五轴光机电协同控制激光复合清洗,尤其是对于一些结构复杂零件或是表面污物较厚难以去除的零件,从而显著提升了清洗效率,易可实现自动化清洗。1. The automatic laser composite cleaning equipment and its cleaning method described in the present invention, through the linkage control of the five-axis motion platform and the laser composite cleaning head by the control system, the five-axis optical-mechanical-electrical coordinated control of the laser for the parts to be cleaned is thus realized. Composite cleaning, especially for some parts with complex structures or parts with thick surface dirt that is difficult to remove, thus significantly improving the cleaning efficiency, and it is easy to realize automatic cleaning.

2.本发明所述的自动的激光复合清洗设备及其清洗方法,在激光复合清洗头中的连续清洗头在结构设计上相对于脉冲激光头可调,从而可自由的控制连续激光与脉冲激光的作用间距,可以控制脉冲清洗前的预热程度以及避免待清洗零件局部因过热而导致烧蚀损伤破坏零件基材。2. The automatic laser composite cleaning equipment and cleaning method thereof of the present invention, the continuous cleaning head in the laser composite cleaning head is adjustable in structural design relative to the pulse laser head, so that the continuous laser and pulse laser can be freely controlled The action distance can control the degree of preheating before pulse cleaning and avoid ablation damage and damage to the base material of the parts to be cleaned due to local overheating.

3.本发明所述的自动的激光复合清洗设备及其清洗方法,采用激光测距仪测量清洗头至工件的距离并实时显示在上位机界面,可确保激光束始终保持在零件被清洗部位的法线方向,实现定焦清洗的良好清洗效果。3. The automatic laser composite cleaning equipment and its cleaning method described in the present invention use a laser rangefinder to measure the distance from the cleaning head to the workpiece and display it on the host computer interface in real time, which can ensure that the laser beam is always kept at the position where the part is to be cleaned. Normal direction, to achieve a good cleaning effect of fixed-focus cleaning.

4.本发明所述的自动的激光复合清洗设备及其清洗方法,采用图像采集装置对清洗过程中的清洗零件表面实时监测并发送显示在上位机界面,可对清洗过程中的异常现象及时反馈并产生报警提示。4. The automatic laser composite cleaning equipment and its cleaning method according to the present invention adopts an image acquisition device to monitor in real time the surface of the cleaned parts in the cleaning process and send and display it on the host computer interface, which can provide timely feedback on abnormal phenomena in the cleaning process And generate an alarm prompt.

5.本发明所述的自动的激光复合清洗设备及其清洗方法,采用吸尘装置吸收处理清洗作业时产生的粉尘,吸尘罩口环绕有橡胶布且正对零件,复合激光通过吸尘罩开口照射至零件表面,吸尘效果好,进行清洗作业时可保证清洁的清洗环境,进而提高清洗质量,同时吸尘管可自由伸缩调节,停止清洗作业时可收回至机箱中,操作更加灵活。5. The automatic laser composite cleaning equipment and cleaning method thereof according to the present invention adopts a dust suction device to absorb and process the dust generated during the cleaning operation. The opening irradiates the surface of the parts, and the dust absorption effect is good. During the cleaning operation, a clean cleaning environment can be ensured, thereby improving the cleaning quality. At the same time, the suction pipe can be freely retracted and adjusted.

附图说明Description of drawings

为了更清楚地说明本发明实施例或现有技术中的技术方案,下面将对实施例或现有技术描述中所需要使用的附图作简单地介绍,下面描述中的附图是本发明的一些实施例,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,显而易见地还可以根据这些附图获得其他的附图。In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. For some embodiments, it is obvious to those skilled in the art that other drawings can be obtained based on these drawings without any creative effort.

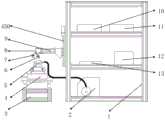

图1为本发明所述的自动的激光复合清洗设备的平面示意图;Fig. 1 is the schematic plan view of the automatic laser compound cleaning equipment of the present invention;

图2为本发明所述的五轴运动平台的结构示意图;Fig. 2 is a schematic structural view of the five-axis motion platform of the present invention;

图3为本发明所述的激光复合清洗头的结构示意图;Fig. 3 is the structural representation of the composite laser cleaning head of the present invention;

图4为本发明所述的吸尘装置的结构示意图;Fig. 4 is a schematic structural view of the dust collection device of the present invention;

图5为本发明所述的激光复合清洗头内部激光整形组件的原理示意图;5 is a schematic diagram of the principle of the laser shaping component inside the laser composite cleaning head according to the present invention;

图6为本发明所述的激光清洗方法的实施原理图一;Fig. 6 is the implementation schematic diagram 1 of the laser cleaning method according to the present invention;

图7为本发明所述的激光清洗方法的实施原理图二;Fig. 7 is the implementation schematic diagram 2 of the laser cleaning method of the present invention;

图8为本发明所述的自动的激光复合清洗设备的三维图。Fig. 8 is a three-dimensional view of the automatic laser composite cleaning equipment according to the present invention.

图中:In the picture:

1-机箱;2-吸尘装置;210-吸尘罩;220-吸尘管;230-吸尘箱;240-旋转手柄;3-底座;4-五轴运动平台;410-绕Z轴旋转平台;420-绕Y轴摆动平台;430-Y轴向滑台;440-X轴向滑台;450-Z轴向滑台;5-待清洗零件;6-激光测距仪;7-激光复合清洗头;710-脉冲激光清洗头;720-连续激光清洗头;730-连接座;740-滑块;750-滑槽;760-冷却水管;8-图像采集装置;9-机架;10-纳秒脉冲激光器;11-高功率连续激光器;12-电源系统;13-下位机控制器。1-chassis; 2-vacuum collection device; 210-vacuum cover; 220-vacuum pipe; 230-vacuum box; 240-rotary handle; 3-base; Platform; 420-swing platform around Y axis; 430-Y axial slide table; 440-X axial slide table; 450-Z axial slide table; 5-parts to be cleaned; 6-laser range finder; 7-laser Composite cleaning head; 710-pulse laser cleaning head; 720-continuous laser cleaning head; 730-connecting seat; 740-slider; 750-chute; 760-cooling water pipe; 8-image acquisition device; 9-frame; 10 - nanosecond pulse laser; 11 - high power continuous laser; 12 - power supply system; 13 - lower computer controller.

具体实施方式Detailed ways

下面详细描述本发明的实施例,所述实施例的示例在附图中示出,其中自始至终相同或类似的标号表示相同或类似的元件或具有相同或类似功能的元件。下面通过参考附图描述的实施例是示例性的,旨在用于解释本发明,而不能理解为对本发明的限制。Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

在本发明的描述中,需要理解的是,术语“中心”、“纵向”、“横向”、“长度”、“宽度”、“厚度”、“上”、“下”、“轴向”、“径向”、“竖直”、“水平”、“内”、“外”等指示的方位或位置关系为基于附图所示的方位或位置关系,仅是为了便于描述本发明和简化描述,而不是指示或暗示所指的装置或元件必须具有特定的方位、以特定的方位构造和操作,因此不能理解为对本发明的限制。此外,术语“第一”、“第二”仅用于描述目的,而不能理解为指示或暗示相对重要性或者隐含指明所指示的技术特征的数量。由此,限定有“第一”、“第二”的特征可以明示或者隐含地包括一个或者更多个该特征。在本发明的描述中,“多个”的含义是两个或两个以上,除非另有明确具体的限定。In describing the present invention, it is to be understood that the terms "central", "longitudinal", "transverse", "length", "width", "thickness", "upper", "lower", "axial", The orientation or positional relationship indicated by "radial", "vertical", "horizontal", "inner", "outer", etc. is based on the orientation or positional relationship shown in the drawings, and is only for the convenience of describing the present invention and simplifying the description , rather than indicating or implying that the device or element referred to must have a particular orientation, be constructed and operate in a particular orientation, and thus should not be construed as limiting the invention. In addition, the terms "first" and "second" are used for descriptive purposes only, and cannot be interpreted as indicating or implying relative importance or implicitly specifying the quantity of indicated technical features. Thus, a feature defined as "first" and "second" may explicitly or implicitly include one or more of these features. In the description of the present invention, "plurality" means two or more, unless otherwise specifically defined.

在本发明中,除非另有明确的规定和限定,术语“安装”、“相连”、“连接”、“固定”等术语应做广义理解,例如,可以是固定连接,也可以是可拆卸连接,或一体地连接;可以是机械连接,也可以是电连接;可以是直接相连,也可以通过中间媒介间接相连,可以是两个元件内部的连通。对于本领域的普通技术人员而言,可以根据具体情况理解上述术语在本发明中的具体含义。In the present invention, unless otherwise clearly specified and limited, terms such as "installation", "connection", "connection" and "fixation" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection , or integrally connected; it may be mechanically connected or electrically connected; it may be directly connected or indirectly connected through an intermediary, and it may be the internal communication of two components. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention according to specific situations.

如图1和图8所示,本发明所述的自动的激光复合清洗设备,包括五轴运动平台4、激光复合清洗工作组件、控制系统、底座3、机架9和机箱1;如图2所示,所述五轴运动平台4包括X轴向滑台440、Y轴向滑台430、绕Y轴摆动平台420、绕Z轴旋转平台410和Z轴向滑台450;所述Z轴向滑台450安装在机架9上,所述绕Z轴旋转平台410、绕Y轴摆动平台420、X轴向滑台440和Y轴向滑台430从上至下安装于所述底座3上;所述Z轴向滑台450安装在机箱1上;所述Y轴向滑台430、X轴向滑台440和Z轴向滑台450分别连接驱动组件,所述驱动组件包括伺服电机驱动器,所述伺服电机驱动器的动力输出端分别通过丝杠与Y轴向滑台430、X轴向滑台440和Z轴向滑台450传动连接;所述绕Y轴摆动平台420和绕Z轴旋转平台410均分别连接伺服电机驱动器和分度装置。在进行清洗作业时,实现工件沿X、Y、Z轴向移动、绕Y轴向摆动以及绕Z轴向旋转运动,从而可清洗零件多个表面,提升清洗效率。As shown in Figures 1 and 8, the automatic laser composite cleaning device of the present invention includes a five-axis motion platform 4, a laser composite cleaning working assembly, a control system, a base 3, a frame 9 and a cabinet 1; as shown in Figure 2 As shown, the five-axis motion platform 4 includes an X-axis slide table 440, a Y-axis slide table 430, a Y-axis swing platform 420, a Z-axis rotation platform 410, and a Z-axis slide table 450; The sliding platform 450 is installed on the frame 9, and the rotating platform 410 around the Z axis, the swinging platform 420 around the Y axis, the sliding platform 440 in the X axial direction and the sliding platform 430 in the Y axial direction are installed on the base 3 from top to bottom Above; the Z-axis sliding table 450 is installed on the chassis 1; the Y-axis sliding table 430, the X-axis sliding table 440 and the Z-axis sliding table 450 are respectively connected to a driving assembly, and the driving assembly includes a servo motor drive, the power output end of the servo motor driver is connected to the Y-axis slide table 430, the X-axis slide table 440 and the Z-axis slide table 450 through the screw respectively; The shaft rotating platforms 410 are respectively connected with servo motor drivers and indexing devices. During the cleaning operation, the workpiece can move along the X, Y, and Z axes, swing around the Y axis, and rotate around the Z axis, so that multiple surfaces of the parts can be cleaned and the cleaning efficiency can be improved.

所述激光复合清洗工作组件包括激光复合清洗头7、纳秒脉冲激光器10和高功率连续激光器11;所述纳秒脉冲激光器10用于产生脉冲激光束,所述高功率连续激光器11用于产生连续激光束;如图3所示,所述激光复合清洗头7包括连续激光头720和脉冲激光头710,所述连续激光头720和脉冲激光头710分别通过连接座730安装在所述机架9上;所述连续激光头720可移动安装在连接座730上,用于调整连续激光头720与脉冲激光头710之间距离;高功率连续激光器11和纳秒脉冲激光器10设置于机箱1内并分别和连续激光清洗头720和脉冲激光头710通过光纤传输线电连接;所述连续激光束通过连续激光头720聚焦到待清洗零件5表面,所述脉冲激光束通过脉冲激光头710聚焦到待清洗零件5表面,所述连续激光束倾斜于脉冲激光束,且所述连续激光束位于脉冲激光束前方,使连续激光光斑在先扫描清洗,脉冲激光光斑在后扫描清洗。The laser composite cleaning working assembly includes a laser

所述控制系统包括上位机(未在图中表示)、下位机控制器13和电源系统12;所述上位机通过信号线与下位机控制器13相连,用于参数设置和状态显示并下发指令给下位机控制器去执行;所述下位机控制器13设于所述机箱内,所述电源系统12设于所述机箱内,用于设备供电。激光复合清洗头7和五轴运动平台4和下位机控制器13通过信号传输线电连接,下位机控制器13控制激光复合清洗头7和五轴运动平台4联动,以对待清洗零件5进行五轴联动激光复合清洗。The control system includes a host computer (not shown in the figure), a

所述连续激光头720内部安装冷却装置760,用于降低清洗时产生的高温;所述连续激光头720上设有激光测距仪6,用于测量连续激光头720到待清洗零件5的距离;所述纳秒脉冲激光器10与脉冲激光头710之间和高功率连续激光器11与连续激光头720之间分别设有激光整形组件,用于调整激光束路径和出射姿态。所述激光复合清洗头7内设有激光整形组件(未在图中表示);所述激光整形组件包括准直镜、二维扫描振镜和场镜,适于调整激光束路径和出射姿态,如图5所示;所述连续激光清洗头720与脉冲激光清洗头710通过连接座相连,且连续激光清洗头720可通过滑块740在滑槽750上移动,相对于脉冲激光清洗头710距离可调,以对连续激光和脉冲激光的作用间距进行自由控制;所述连续激光激光清洗头720上安装有激光测距仪6,所述激光测距仪6与所述上位机通过串口相连接,测量清洗头至工件表面所得距离和位移参数传输显示至上位机界面,从而保证焦点位置,提高清洗可靠性;所述连续激光清洗头内部装有冷却水管760,可及时进行降温处理。The inside of the

所述机架9横梁上设有图像采集装置8;所述图像采集装置8包括图像传感器和工业镜头;所述图像采集装置8与所述上位机通过信号传输线连接,适于实时监测并发送清洗零件5表面图像特征至上位机,当检测到零件过烧或达不到清洗效果时,将会产生自动报警提示。Described

所述机箱1内设有吸尘装置2,用于及时吸纳清洗作业时产生的废气粉尘,保证清洗环境清洁;所述吸尘装置2包括吸尘罩210、吸尘管220和吸尘箱230;所述吸尘箱230位于机箱1上,所述吸尘箱230通过吸尘管220与吸尘罩210连接,所述吸尘罩210位于待清洗零件5上方,所述吸尘罩210上设有缺口,用于使连续激光束和脉冲激光束穿过吸尘罩210聚焦待清洗零件5表面。所述吸尘罩210外圈缠绕橡胶布,提升粉尘吸收效果;所述吸尘管220为竹节软管,用于调节形状位置;所述吸尘箱230上安装旋转手柄240,所述旋转手柄240与吸尘管220通过传动机构相连,在停止清洗作业后用于将吸尘管220收回至机箱1内。The

本发明所述的自动的激光复合清洗设备的清洗方法,包括如下步骤:The cleaning method of the automatic laser composite cleaning equipment of the present invention comprises the following steps:

参数设置步骤:根据待清洗零件5设置所述高功率连续激光器11输出连续激光束的平均功率和扫描速度;设置所述纳秒脉冲激光器10输出脉冲激光束的平均功率、扫描速度、脉冲宽度和脉冲频率;Parameter setting step: set the average power and scanning speed of the continuous laser beam output by the high-power

激光复合清洗步骤:将待清洗零件5安装在五轴运动平台上,通过上位机下发指令控制五轴运动平台5移动,将待清洗零件5移动至激光复合清洗头正下方;开启高功率连续激光器11和纳秒脉冲激光器10,激光束通过光纤传导至激光复合清洗头7经过激光整形组件整形后,聚焦到待清洗零件5表面,形成前后分布的连续激光光斑与脉冲激光光斑,可选地,光斑可调整成线形或者矩形;激光清洗时保持连续激光光斑在前,脉冲激光光斑在后进行扫描清洗,如图6所示;清洗过程中,所述控制系统控制所述激光复合清洗头和所述五轴运动平台联动,对所述待清洗零件5进行复合清洗。可选地,扫描方式可以是逐行扫描或是螺旋线扫描,可选地,连续激光清洗头720相对于脉冲激光头710距离可调,只需要拖动滑块740在滑槽750内移动到相应位置并用紧定螺钉锁死便可实现连续激光和脉冲激光的作用间距自由调节,可以控制脉冲清洗前的预热程度以及避免待清洗零件5局部因过热而导致烧蚀损伤破坏零件基材。在清洗过程中,图像采集装置8实时采集并发送清洗零件表面图像特征至上位机,当检测到零件过烧或无明显清洗效果时,将会产生自动报警提示,实现良好的人机交互。吸尘装置2将产生的废气粉尘及时吸纳至吸尘箱230内,保证人身健康和清洗作业环境清洁,进而提高清洗质量。Laser compound cleaning steps: install the

可选地,若待清洗零件5表面规整时,对焦完毕后,激光复合清洗头7保持不动,控制系统下发指令使X轴向滑台440、Y轴向滑台430运动,待一行清洗完毕后换行清洗直至整个零件清洗完毕;进一步地,若待清洗零件5为不规整零件(表面不平整、存在高低不平),控制系统变换加工指令控制激光复合清洗头7和五轴运动平台4联动,保证激光束始终在被清洗部位的法线方向,如图7所示,且激光复合清洗头6与待清洗零件表面5的焦距自适应变化,对待清洗零件5进行五轴光机电协同控制激光复合清洗,提升清洗效率,亦可实现自动化。Optionally, if the surface of the

下面通过两个具体实施例来详细描述本申请的一种自动的激光复合清洗设备及清洗方法的步骤和原理。The steps and principles of an automatic laser composite cleaning device and cleaning method of the present application will be described in detail below through two specific embodiments.

实施例1Example 1

对厚度为2mm,长宽为50mmX50mm的Q235钢板表面锈蚀进行激光复合清洗,具体过程如下:The surface corrosion of Q235 steel plate with a thickness of 2mm and a length and width of 50mmX50mm is subjected to laser composite cleaning. The specific process is as follows:

参数设置步骤:Parameter setting steps:

在控制系统上位机界面设置波长为1064nm的高功率连续激光器的输出功率为1000W,扫描速度为4000mm/s,设置波长为1064nm的纳秒脉冲激光器输出功率为200W,脉冲宽度为100ns,脉冲频率为50KHZ,扫描速度为2000mm/s。Set the output power of the high-power continuous laser with a wavelength of 1064nm to 1000W and the scanning speed to 4000mm/s on the host computer interface of the control system, and set the output power of the nanosecond pulsed laser with a wavelength of 1064nm to 200W, the pulse width to 100ns, and the pulse frequency to 50KHZ, scanning speed is 2000mm/s.

将锈蚀钢板固定在旋转平台上,通过上位机界面控制X轴向滑台440、Y轴向滑台430移动,将锈蚀钢板移动至激光复合清洗头7正下方,开启高功率连续激光器11和纳秒脉冲激光器10,激光束通过光纤传导至清洗头经过激光整形组件整形后,透过吸尘罩210开口,聚焦到待锈蚀钢板表面,形成前后分布的线形连续激光与线形脉冲激光,利用激光测距仪6进行激光复合清洗头7的对焦,待激光在最亮时则对焦完毕,随即将安装在机架9横梁上的激光复合清洗头7高度固定,清洗时始终保持连续激光激光在前,主要是利用连续激光的热效应可以高效去除厚清洗层,而脉冲激光光斑在后进行二次加工,其去除机理主要为热振动形式,安全稳定且热效率低。可选地,扫描方式可以是逐行扫描或是螺旋线扫描,可选地,连续激光清洗头720相对于脉冲激光头710距离可调,只需要拖动滑块740在滑槽750内移动到相应位置并用紧定螺钉锁死便可实现连续激光和脉冲激光的作用间距自由调节,可以在一定程度上避免待清洗零件5局部因过热而导致烧蚀损伤破坏零件基材。在清洗过程中,图像采集装置8实时采集并发送清洗零件表面图像特征至上位机,当检测到零件过烧或无明显清洗效果时,将会产生自动报警提示,实现良好的人机交互。吸尘装置2将产生的废气粉尘及时吸纳至吸尘箱230内,保证人身健康和清洗作业环境清洁,进而提升清洗质量,清洗结束后,可将吸尘管220通过旋转手柄240收回至机箱1内,更加灵活可控。Fix the corroded steel plate on the rotating platform, control the movement of the X-axis sliding table 440 and the Y-axis sliding table 430 through the host computer interface, move the corroded steel plate directly under the laser

实施例2Example 2

对厚度为2mm,长宽为100mmX100mm的6061铝合金表面油漆涂层进行激光复合清洗,具体过程如下:Laser compound cleaning is performed on the 6061 aluminum alloy surface paint coating with a thickness of 2mm and a length and width of 100mmX100mm. The specific process is as follows:

参数设置步骤:Parameter setting steps:

在控制系统上位机界面设置波长为1064nm的高功率连续激光器的输出功率为1500W,扫描速度为3000mm/s,设置波长为1064nm的纳秒脉冲激光器输出功率为500W,脉冲宽度为100ns,脉冲频率为50KHZ,扫描速度为1500mm/s。Set the output power of the high-power continuous laser with a wavelength of 1064nm to 1500W and the scanning speed to 3000mm/s on the host computer interface of the control system, and set the output power of the nanosecond pulse laser with a wavelength of 1064nm to 500W, the pulse width to 100ns, and the pulse frequency to 50KHZ, scanning speed is 1500mm/s.

激光复合清洗步骤和实施例1一样,此处不再赘述。The laser composite cleaning steps are the same as those in

应当理解,虽然本说明书是按照各个实施例描述的,但并非每个实施例仅包含一个独立的技术方案,说明书的这种叙述方式仅仅是为清楚起见,本领域技术人员应当将说明书作为一个整体,各实施例中的技术方案也可以经适当组合,形成本领域技术人员可以理解的其他实施方式。It should be understood that although this description is described according to various embodiments, not each embodiment only includes an independent technical solution, and this description of the description is only for clarity, and those skilled in the art should take the description as a whole , the technical solutions in the various embodiments can also be properly combined to form other implementations that can be understood by those skilled in the art.

上文所列出的一系列的详细说明仅仅是针对本发明的可行性实施例的具体说明,它们并非用以限制本发明的保护范围,凡未脱离本发明技艺精神所作的等效实施例或变更均应包含在本发明的保护范围之内。The series of detailed descriptions listed above are only specific descriptions for feasible embodiments of the present invention, and they are not intended to limit the protection scope of the present invention. Any equivalent embodiment or All changes should be included within the protection scope of the present invention.

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310367162.8ACN116408313A (en) | 2023-04-07 | 2023-04-07 | Automatic laser composite cleaning equipment and cleaning method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310367162.8ACN116408313A (en) | 2023-04-07 | 2023-04-07 | Automatic laser composite cleaning equipment and cleaning method thereof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN116408313Atrue CN116408313A (en) | 2023-07-11 |

Family

ID=87055966

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202310367162.8APendingCN116408313A (en) | 2023-04-07 | 2023-04-07 | Automatic laser composite cleaning equipment and cleaning method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN116408313A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117680441A (en)* | 2023-12-22 | 2024-03-12 | 浙江中数激光装备有限公司 | An intelligent laser cleaning system for parts |

| CN117840134A (en)* | 2024-01-20 | 2024-04-09 | 上海工程技术大学 | Magnetic field assisted laser cleaning device and method |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN201632768U (en)* | 2010-01-06 | 2010-11-17 | 北京希波尔科技发展有限公司 | Laser tool blade milling machine |

| CN208262098U (en)* | 2018-05-30 | 2018-12-21 | 武汉可为光电自动化科技股份有限公司 | A kind of laser cutting machine with smoking dust-arrester |

| CN213968099U (en)* | 2020-12-22 | 2021-08-17 | 镇江长悦光电科技有限公司 | Composite cleaning laser lens |

| CN114653686A (en)* | 2022-03-10 | 2022-06-24 | 江苏大学 | Paint laser cleaning method |

| CN115213173A (en)* | 2021-04-15 | 2022-10-21 | 大族激光科技产业集团股份有限公司 | Laser cleaning system and working method thereof |

- 2023

- 2023-04-07CNCN202310367162.8Apatent/CN116408313A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN201632768U (en)* | 2010-01-06 | 2010-11-17 | 北京希波尔科技发展有限公司 | Laser tool blade milling machine |

| CN208262098U (en)* | 2018-05-30 | 2018-12-21 | 武汉可为光电自动化科技股份有限公司 | A kind of laser cutting machine with smoking dust-arrester |

| CN213968099U (en)* | 2020-12-22 | 2021-08-17 | 镇江长悦光电科技有限公司 | Composite cleaning laser lens |

| CN115213173A (en)* | 2021-04-15 | 2022-10-21 | 大族激光科技产业集团股份有限公司 | Laser cleaning system and working method thereof |

| CN114653686A (en)* | 2022-03-10 | 2022-06-24 | 江苏大学 | Paint laser cleaning method |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117680441A (en)* | 2023-12-22 | 2024-03-12 | 浙江中数激光装备有限公司 | An intelligent laser cleaning system for parts |

| CN117840134A (en)* | 2024-01-20 | 2024-04-09 | 上海工程技术大学 | Magnetic field assisted laser cleaning device and method |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107199251B (en) | A kind of laser cleaner | |

| CN107297365B (en) | A desktop laser precision cleaning device with dual-wavelength composite energy distribution | |

| CN116408313A (en) | Automatic laser composite cleaning equipment and cleaning method thereof | |

| CN107626689B (en) | Ultrasonic-assisted laser surface cleaning system and cleaning method thereof | |

| CN110813935A (en) | Laser cleaning equipment and laser cleaning method for complex component | |

| CN110548730A (en) | Laser cleaning device and method for aluminum alloy anodic oxide film and surface paint film composite layer | |

| CN109047184B (en) | Laser cleaning equipment and method suitable for inner and outer walls of rotary body | |

| CN109261650A (en) | A kind of laser cleaning system and its cleaning method of nuclear reactor tank body fused salt | |

| CN208853384U (en) | A kind of laser cleaning system | |

| CN108856175A (en) | A kind of laser cleaning system and its cleaning method | |

| CN111054702B (en) | Laser cleaning equipment for surface treatment of annular component | |

| CN208644390U (en) | A laser-arc multi-purpose welding equipment with laser cleaning function | |

| CN116851921A (en) | Laser texturing system and method, prefabricated plate and railway vehicle | |

| CN111659985A (en) | Multilayer and multi-pass welding system and method for arc welding robot | |

| CN102451953A (en) | Multi-functional laser processing manufacturing system | |

| CN110280915A (en) | A kind of laser drilling device and method improving drilling quality based on underwater punching | |

| CN107321717A (en) | A kind of hand-held adaptive laser cleaner of transformation into itself's dual-wavelength laser beam | |

| CN207343403U (en) | Ultrasonic wave added Laser Surface Cleaning system | |

| CN119035906A (en) | Trackless weld joint tracking welding robot system | |

| CN114653677B (en) | Ultrasonic-assisted laser-induced cavitation bubble automatic cleaning device | |

| CN110340492A (en) | Double laser vision tracking welding device and welding method for deep wave steep slope welding seam | |

| CN209272049U (en) | A laser cleaning equipment suitable for the inner and outer walls of the rotating body | |

| CN107695351A (en) | Successively alternative dual-mode laser cleaning method and cleaning device in metal 3D printing | |

| CN114789168B (en) | Laser cleaning system and cleaning method | |

| CN111992545B (en) | Cleaning device and cleaning method for lower circular seam oxide skin of water heater liner |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |