CN1163641A - Ozone Assisted Laundry Laundry Method - Google Patents

Ozone Assisted Laundry Laundry MethodDownload PDFInfo

- Publication number

- CN1163641A CN1163641ACN 95196239CN95196239ACN1163641ACN 1163641 ACN1163641 ACN 1163641ACN 95196239CN95196239CN 95196239CN 95196239 ACN95196239 ACN 95196239ACN 1163641 ACN1163641 ACN 1163641A

- Authority

- CN

- China

- Prior art keywords

- ozone

- water

- laundry

- contact

- wash water

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Accessory Of Washing/Drying Machine, Commercial Washing/Drying Machine, Other Washing/Drying Machine (AREA)

- Treatment Of Water By Oxidation Or Reduction (AREA)

Abstract

Description

Translated fromChinese本发明涉及洗衣房废水处理和洗衣方法,特别是涉及使用臭氧做为清洁和消毒剂的洗衣方法。本发明是转让给本发明受让人的美国专利NO.5,097,556、5,181,399和5,241,720的改进。美国专利NO.5,097,556、5,181,399和5,241,720所讨论的内容和技术在此引为参考。The invention relates to laundry room waste water treatment and a laundry method, in particular to a laundry method using ozone as a cleaning and disinfectant. The present invention is an improvement of US Patent Nos. 5,097,556, 5,181,399 and 5,241,720, assigned to the assignee of the present invention. The content and techniques discussed in US Patent Nos. 5,097,556, 5,181,399 and 5,241,720 are incorporated herein by reference.

臭氧是一种在室温下由自由的独立氧分子相结合而形成的气体,它是很强的氧化剂,并且已证实,臭氧可有效地将织物上的臭味、污秽和其它沾染物去除。在以前的发明中,揭示了一种使用闭合环路水系统的洗衣房洗衣过程,此过程中的洗衣水水源进行了臭氧处理,然后输送到一系列的洗衣房洗衣设备中。用过的洗衣水在循环的末端收集起来,并回流到储存设备中用于再重复使用。诸如污秽、棉屑等废物在洗衣水再循环到水源之前在洗衣循环的末端处从洗衣水中除去。洗衣水过滤、再循环、以及洗衣过程中损失水的补充均包括在本发明所揭示的洗衣过程的步骤中。Ozone, a gas formed at room temperature from the combination of free individual oxygen molecules, is a strong oxidizing agent and has been shown to be effective in removing odors, dirt and other contaminants from fabrics. In a previous invention, a laundry laundry process using a closed loop water system was disclosed where the laundry water source was ozone treated and then delivered to a series of laundry laundry equipment. Spent laundry water is collected at the end of the cycle and returned to storage for reuse. Waste such as soil, lint, etc. is removed from the wash water at the end of the wash cycle before it is recirculated to the water source. Laundry water filtration, recirculation, and replenishment of water lost during the laundry process are all included in the steps of the laundry process disclosed in the present invention.

尽管以前所发明的洗衣过程运行比较成功,但对于大多数商业应用来讲,其设备太庞大,并且对洗衣来讲,设备比较费力、且维护强度大。本发明涉及一种为实现改进结果的改进洗衣方法,特别是涉及臭氧发生效率的改进、洗衣水挟带臭氧方法的改进,最终产生较紧凑的系统设计,并提高了自动化,降低了维护要求。通过增加氧和/或干空气气体浓缩机,臭氧发生可大大增强。尽管与臭氧发生设备有关的总占用面积减少,但氧产量的提高允许较多量的臭氧产生,因而,可以在许多空间有限的地方使用。再则,产量的提高使更多量的臭氧、以更快的速率溶解在水中,该速率使水中臭氧的含量得以维持。这降低了起动次数,提高了消毒速度、提高了除臭速度、提高了其它水或污垢的氧化速度。这使得可以使用较小尺寸的储水箱和水接触箱使与这些水容器有关的总占用面积减小,因而可以在空间有限的区域内安装和使用。另外,通过使用可在臭氧发生器与接触箱和储存箱所使用的文杜里管之间的管线上产生真空的文杜里喷管,可使臭氧挟带增强。另外,通过对储存箱和接触箱限流、在输水管线上产生背压,可使臭氧挟带进一步加强。10~30Psi的此背压可大大地提高溶解率。当输送臭氧/空气混合物时,文杜里喷管起混合器的作用。在文杜里喷管后可以设置、也可以不设置用于产生涡流的静态混合器。可以增设臭氧接触延长器,以提高臭氧与水的接触时间,这也可以提高溶解率。这些接触延长器可以装设、也可以不装设用于增强挟带的静态混合器。进一步讲,氧和/或干空气臭氧发生器产量的提高,在最大溶解不如空间节省那么重要的场所,可以减少或去除臭氧接触延长器,因而是减小了与臭氧接触延长器及其管路有关的占用面积。臭氧发生器可以装设可选电压调节器,使得可根据需要提高或降低臭氧的含量。明确地讲,此项调节每天在系统的初始起动阶段、或当由于存在大量的水成污垢,使系统对臭氧的需求量增加时使用。这使得在处理具有不均匀特性的衣物或水时具有较大的灵活性。While previously invented laundry processes operate relatively successfully, the equipment is too large for most commercial applications and relatively laborious and maintenance intensive for laundry. The present invention relates to an improved laundry process for improved results, and more particularly to improved ozone generation efficiency, improved ozone entrainment in wash water, resulting in a more compact system design with increased automation and reduced maintenance requirements. Ozone generation can be greatly enhanced by adding oxygen and/or dry air gas concentrators. Although the overall footprint associated with the ozone generating equipment is reduced, the increased oxygen production allows for higher volumes of ozone to be produced and, thus, can be used in many places where space is limited. Furthermore, the increase in production yields a greater amount of ozone dissolved in the water at a faster rate at which the ozone level in the water is maintained. This reduces the number of starts, increases the rate of disinfection, increases the rate of deodorization, and increases the rate of oxidation of other water or dirt. This allows the use of smaller sized storage tanks and water contact tanks resulting in a reduced overall footprint associated with these water containers, allowing installation and use in areas where space is limited. Additionally, ozone entrainment can be enhanced through the use of a venturi nozzle that creates a vacuum in the line between the ozone generator and the venturi used in the contact and storage tanks. In addition, ozone entrainment can be further enhanced by restricting flow in storage and contact tanks and creating back pressure on water lines. This back pressure of 10-30 Psi can greatly increase the dissolution rate. The venturi nozzle acts as a mixer when delivering the ozone/air mixture. A static mixer for generating vortices may or may not be provided after the Venturi nozzle. An ozone contact extender can be added to increase the contact time between ozone and water, which can also increase the dissolution rate. These contact extenders may or may not be equipped with static mixers for enhanced entrainment. Furthermore, increased production of oxygen and/or dry air ozone generators, where maximum dissolution is not as important as space savings, can reduce or eliminate ozone contact extenders, thereby reducing the amount of ozone contact extenders and their piping. the relevant occupied area. The ozone generator can be equipped with an optional voltage regulator so that the ozone level can be increased or decreased as required. Specifically, this adjustment is used daily during the initial start-up of the system, or when the system's demand for ozone increases due to the presence of large amounts of aqueous fouling. This allows greater flexibility when dealing with laundry or water with uneven properties.

本发明也涉及多层过滤的处理过程。首先是粗网或袋过滤器,将大的棉屑颗粒和其它材料去除。除后是为滤除较细小棉屑而设计的一个或多个过滤器。然后可将储存箱用作浮选容器,对臭氧气体提供足够的背压将其泵入到储存箱中。这将产生成百万的气泡,使溶解的固体浮到储存箱的顶部,通过溢流、迫使漂浮的固体越过储存箱顶部的溢流堰而将其去除。在储存箱后部可装设一个或多个设计用来滤除洗衣水中更小细粒的精细过滤器。The invention also relates to the process of multi-layer filtration. The first is a coarse mesh or bag filter, which removes large lint particles and other materials. After the removal is one or more filters designed to remove finer lint. The storage tank can then be used as a flotation vessel, providing sufficient back pressure for the ozone gas to pump it into the storage tank. This creates millions of air bubbles that float the dissolved solids to the top of the storage tank where they are removed by overflow, forcing the floating solids over an overflow weir at the top of the storage tank. One or more fine filters designed to remove smaller particles from the wash water may be located in the rear of the storage tank.

其它新特性包括可选使用水软化剂,用于消除当地水源的硬度。当加入软化剂时,这一特性降低了有关所生成水输送的时间。另一个特性是可选的将废气从接触箱的顶部再循环、并挟带进入储存箱中的过程。这可降低所需要发生的氧量,并降低需要排放和/或损坏的臭氧量。Other new features include the optional use of a water softener to remove hardness from local water sources. This characteristic reduces the time involved in the transport of the water formed when softeners are added. Another feature is the optional recirculation of exhaust gas from the top of the contact tank and entrainment into the storage tank. This reduces the amount of oxygen that needs to be generated and reduces the amount of ozone that needs to be emitted and/or damaged.

本发明的目的之一是提供一种使用臭氧对洗涤材料进行清洁和除垢的改进的洗衣房废水处理系统。这种系统节约水,可减少或不需要热水、肥皂和化学物质,可大大地降低运行成本。It is an object of the present invention to provide an improved laundry wastewater treatment system using ozone for cleaning and descaling of wash materials. This system conserves water, reduces or eliminates hot water, soap and chemicals, and can greatly reduce operating costs.

本发明的另一个目的是提供一种改进的洗衣房处理系统。该系统利用有助于氢氧基(OH)生成的中性至略碱性PH,促进与臭氧相结合的先进的氧化化学过程,从而强化清洁过程。Another object of the present invention is to provide an improved laundry room treatment system. The system utilizes a neutral to slightly basic pH that favors hydroxyl (OH) formation, promoting advanced oxidation chemistry combined with ozone to enhance the cleaning process.

本发明的另一个目的是提供一种使用挟带在洗涤水中的臭氧进行洗涤的洗衣房洗涤系统。该系统具有改进的臭氧挟带系统,用于提高臭氧洗涤过程的效率。Another object of the present invention is to provide a laundry room washing system for washing using ozone entrained in washing water. The system has an improved ozone entrainment system for increasing the efficiency of the ozone scrubbing process.

本发明的另一个目的是提供一种使用氧和/或干空气生成挟带在洗涤水中的臭氧的洗衣房洗涤系统。该系统具有增大的臭氧产量,可以提高臭氧洗涤过程的效率,可清洁污垢的水,减小总尺寸,提高可靠性。Another object of the present invention is to provide a laundry room washing system that uses oxygen and/or dry air to generate ozone entrained in the wash water. The system features increased ozone production, which increases the efficiency of the ozone scrubbing process, cleans fouled water, reduces overall size, and improves reliability.

本发明的另一个目的是提供一种使用接触延长器的洗衣房洗涤系统。根据需要,此接触延长器可提高臭氧与洗涤水之间的接触时间,从而提高臭氧的溶解率,并维持最大的臭氧浓度。Another object of the present invention is to provide a laundry room washing system using a contact extender. This contact extender increases the contact time between ozone and wash water as needed, thereby increasing the rate of ozone dissolution and maintaining maximum ozone concentration.

本发明的另一个目的是提供一种使用装有静态混合器的接触延长器的洗衣房洗涤系统。根据需要,此接触延长器可以增加臭氧与洗涤水之间的混合,从而提高臭氧的溶解率,并维持最大的臭氧浓度。Another object of the present invention is to provide a laundry room washing system using a contact extender equipped with a static mixer. As needed, this contact extender can increase the mixing between ozone and wash water, thereby increasing the dissolution rate of ozone and maintaining the maximum ozone concentration.

本发明的另一个目的是提供一种使用限流的洗衣房洗涤系统。该限流在文杜里管道的流出侧产生背压,使一定百分比的臭氧气体溶解到加工水中,从而提高臭氧的溶解率,并维持最大的臭氧浓度。Another object of the present invention is to provide a laundry room washing system using flow limiting. This flow restriction creates a back pressure on the outflow side of the Venturi pipe, allowing a certain percentage of ozone gas to dissolve into the process water, thereby increasing the ozone dissolution rate and maintaining a maximum ozone concentration.

本发明的另一个目的是提供一种使用限流的洗衣房洗涤系统。该限流产生背压使一定百分比的臭氧气体溶解到储存箱的水中,该水可用来使废物漂浮到储存箱的顶部,并使所述废物随溢流的水排走。本发明的另一个目的是提供一种使用多层过滤系统的洗衣房洗涤系统。该多层过滤系统在水再循环和再使用之前,首先用粗滤器将棉屑和其它大的残渣滤除,而后是对包括漂浮着的溶解和悬浮固体在内的非常细小的废物滤除。Another object of the present invention is to provide a laundry room washing system using flow limiting. This flow restriction creates a back pressure that dissolves a percentage of the ozone gas into the water in the storage tank which can be used to float the waste to the top of the storage tank and allow said waste to drain away with the overflowing water. Another object of the present invention is to provide a laundry washing system using a multi-layer filtration system. The multi-layer filtration system uses a strainer to remove lint and other large debris first, followed by very fine waste including floating dissolved and suspended solids, before water is recirculated and reused.

本发明的另一个目的是提供一种再循环洗衣房洗涤系统。根据需要,该再循环将接触箱中的废气用于储存箱中。另外,可在臭氧废气的再循环中使用增高的背压,这将降低系统产生的总废气量。Another object of the present invention is to provide a recirculating laundry room washing system. This recirculation uses the exhaust gas from the contact tank in the storage tank, as required. Additionally, increased back pressure can be used in the recirculation of the ozone exhaust, which will reduce the total exhaust produced by the system.

本发明的另一个目的是提供一种使用底部开孔口箱的洗衣房洗涤系统。该孔口箱可进行箱体排放和/或颗粒排放,用于将箱中沉积的废物去除。Another object of the present invention is to provide a laundry room washing system using a bottom opening box. The orifice box is capable of box drain and/or particle drain for removal of waste deposited in the box.

本发明的另一个目的是提供一种在箱上使用可进行溢流循环槽盖的洗衣房洗涤系统。随着箱中水位的升高,迫使漂浮的颗粒和残渣进入或流过清除堰。Another object of the present invention is to provide a laundry room washing system using a tank cover for overflow circulation on the tank. As the water level in the tank rises, the floating particles and debris are forced into or over the removal weir.

本发明的另一个目的是提供一种使用可选精细过滤器(能够过滤大多数微小细粒)的洗衣房洗涤系统。该过滤器用于在大多数所要求的地点中确保最好的水质。Another object of the present invention is to provide a laundry room washing system using an optional fine filter capable of filtering most microscopic particles. This filter is used to ensure the best water quality in most required locations.

本发明的另一个目的是提供一种使用溶解空气浮选(DAF)技术的洗衣房洗涤系统。该技术可进一步清洁洗涤水,并大大提高水的再循环能力。Another object of the present invention is to provide a laundry room washing system using dissolved air flotation (DAF) technology. This technology further cleans the wash water and greatly increases water recirculation.

这些以及其它的目的可在下述示图和技术说明中得到体现。These and other objectives are embodied in the diagrams and technical descriptions that follow.

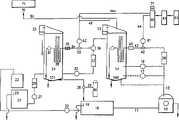

图1所示为根据本发明的闭合环路洗衣房废水处理和洗涤系统。该系统在当废物负荷低,并且水回收优先时使用。Figure 1 shows a closed loop laundry room wastewater treatment and washing system in accordance with the present invention. This system is used when the waste load is low and water recovery is a priority.

图2所示为根据本发明的闭合环路洗衣房废水处理和洗涤系统。该系统在当废物负荷高、并且水回收优先时使用。Figure 2 shows a closed loop laundry room wastewater treatment and washing system in accordance with the present invention. This system is used when the waste load is high and water recovery is a priority.

图3所示为根据本发明的无回流洗衣房洗涤系统。Figure 3 shows a non-reflux laundry room washing system in accordance with the present invention.

参照图1,洗衣房废水处理、洗涤过程和系统包括一台或多台洗衣机10。洗衣机10的类型可在商用洗衣厂、洗衣店、宾馆、学校、宿舍、或其它类似的,需进行大量洗涤的场所见到。每台洗衣机都可独立于其它洗衣机运行,并由连接到储水或接触箱14上的供水管线12提供臭氧化的洗涤水。利用供水泵16经供水管线12将洗涤水由接触箱14供入到洗衣机中。接触箱14中的洗涤水已与臭氧结合,可在不使用或少量使用用于增强洗涤清洁效果的热水、肥皂、洗衣粉、或其它化学产品的情况下达到最大清洁。可增加一台可选加工泵17,用于提高送至洗衣机10中的洗涤水流量。使用启动洗衣机用的加工泵16将洗涤水泵入到洗衣机10中。洗衣机10通过排放管11将废水排放到用于收集废水进行再循环的集水槽18中。如果集水槽18太满了,那么溢流堰19就将废水溢流至排放口9,以避免溢出。在一个洗涤循环完成后,利用集水槽泵20,经合适的袋或网过滤器22将集水槽18中用过的洗涤水泵入到储水箱21中。储水箱21具有一溢流堰25,用于在如果储水箱21太满时将水溢流到排放口13,以避免溢出。储水箱21中的水由泵27经细粒过滤器29传送到储存箱24中。也可利用补充水阀28将淡水经补充水供给管26加入到储存箱24或集水槽18中。如果当地水源的水硬度高,那么可加入可选水软化剂60。水软化剂可将妨碍臭氧生成的离子(Fe、Mn、Mg、Ca)除去,因为这些离子将会氧化并消耗系统中的一部分臭氧,使臭氧的实际含量难以维持。Referring to FIG. 1 , the laundry room wastewater treatment, washing process and system includes one or

泵30将水从储存箱24中泵出,使其通过细粒或微粒过滤器32。系统中由过滤器22起始的过滤器组起多层过滤系统的作用,也就是逐级从再循环水中过滤出的颗粒的尺寸起来越小。由于初始过滤器22不聚集任何颗粒,因此这可防止过滤器22阻塞。然后水通过次喷射管52,将臭氧从臭氧气体管线44上吸走。然后气/水混合物从次喷射管52上排出,经管线34进入到静态混合器35和接触延长器38中。静态混合器可如图所示设置,或者设置在位于接触延长器38后部的箱24中,混合器搅拌气/水混合物以加强溶解。混合器采用非活动静叶或折流板组件形式。次喷射器52装有止回阀62,用于防止水回流到臭氧发生器40中。如图所示接触延长器38位于箱24中,然而它也可以设置在箱24的外部。接触延长器38由直径为4英寸的PVC管构成,以在流注到箱24中之前形成向上、向下流动的曲折通道。由于接触时间,即臭氧进入到退出水柱的时间,通常为5~15秒,这取决于接触箱的高度,而接触延长器38可使接触时间提高到60秒或更多。气泡在水柱中停留的时间越长,可有越多的臭氧通过相界由气体转变为液体。因而延长器的使用可导致较高的臭氧含量或较快的充注时间。接触延长器38或静态混合器35可装设可选限流阀或接头37,用于限流和产生背压从限流处回至泵的管线上的背压引起压力升高,至使含臭氧的气体进入溶液中,再次产生较高的臭量含量或较快的充注时间。另外,当压力释放时,成百万的气泡形成,这些气泡携带悬浮的固体至箱顶部使其被撇去。当要将漂浮的废物溢流到溢流堰23中时,可将储存箱24中的水位升高。排放口101用于在必要时将储存箱排空。如同所要求的,使用传送泵30可使储存箱24中的水流经精细过滤器32。流动控制阀39将水流从储存箱24引入到接触箱14中。使用阀39使得一个泵可以起两个作用。由于将水从储存箱24传送到接触箱14中的传送泵仅部分时间使用,因此如果洗衣机10不需要较多的水时,再循环泵30通过阀进行控制也可将水引回到储存箱24中。由于在到达14之前,挟带氧的水就产生、并被过滤,使系统的电抽吸减少,因而储存箱24及其再循环回路的费用得到节省。A

用泵16将接触箱14中的水经主喷射管42泵入到管线43中,并在流经静态混合器45、接触延长器46和可选限流器47后泵回到接触箱中。主喷射器42装有止回阀61,用于防止水流回到臭氧发生器中。接触箱14中的水位可在要将漂浮废物溢流到溢流堰13中时升高。运行时,水在泵16的作用下沿轨道流动,直至洗衣机10需要水时其被短接。洗衣机上的阀开启,轨道中的压力迫使水进入洗衣机中,而不是通过文杜里喷管42。如果洗衣机经常需要水则使用可选泵17,那么就没有足够的臭氧化时间。Water in

生产臭氧时,氧浓度越大,所产生的臭氧就越多。使在氧浓缩机41中浓缩的氧通过臭氧发生器40而产生臭氧,臭氧发生器为一电晕放电电场。压缩机53为压力摆动吸收氧浓缩机41提供压缩空气。氧浓缩机可提供含氧量达50%至几乎100%的气体,而较佳的浓度为80~95%。臭氧发生器40为商用型电晕放电装置。臭氧发生装置包括可对臭氧产量进行调节的电压调节器。如果流量不变,电压升高,那么臭氧产量也增高。臭氧发生器产生的臭氧在接触箱14和储存箱24中与水结合。当含有50~100%干氧及其余为干大气的压缩空气通过高压放电源,最好是通过电晕放电发生器时,一部分气体转化为带电的氧离子,这些氧离子再结合形成O3,即臭氧。电压调节器77或177也可用来改变臭氧的产生量。如果流量不变,压力增高,则臭氧的产生量也增高。臭氧由臭氧发生器40产出,利用喷管42挟带入水中。喷管42最好是文杜里喷管,可在臭氧输送管44和44a中产生真空。臭氧经臭氧喷射管线43供入到接触箱14中。在接触箱14中,臭氧与洗涤水混合进入洗涤水中。然后气/水混合物可通过管线43进入到混合器45、接触延长器46、以及产生限流和背压的可选限流阀或接头47中。静态混合器45、接触延长器46和接头47的作用与前面设置的静态混合器35相同。排放口100用于在必要时将接触箱14排空。When producing ozone, the greater the oxygen concentration, the more ozone is produced. The oxygen concentrated in the

接触箱14和储存箱24经废气管线50将多余的臭氧排出。废气被引入到排放口70或可选臭氧破坏装置71中。

参照图2,洗衣房废水处理、洗涤过程和系统包括1台或多台洗衣机110。这些洗衣机110的类型可在商用洗衣厂、洗衣店、宾馆、学校、宿舍、或其它类似的需进行大量洗涤的场所见到。每台洗衣机都可独立运行,并由连接到储水或接触水箱114供水线112提供臭氧化的洗涤水。利用供水泵116经供水管线112将洗涤水由接触箱114供入到洗衣机中。接触箱114中的洗涤水已与臭氧结合,可在不使用或少量使用用于增强洗涤清洁效果的热水、肥皂、洗衣粉或其它化学产品的情况下达到最大清洁。可增加一台可选加工泵117,用于提高送至洗衣机110中的洗涤水流量。使用启动洗衣机用的加工泵116将洗涤水泵入到洗衣机110中。洗衣机110通过排放管111将废水排放到用于收集废水进行再循环的集水槽118中。如果集水槽118太满了,那么溢流堰119就将废水溢流放掉,以避免溢出.在一个洗涤循环完成后,利用集水槽泵120、经可将诸如棉绒、钮扣等粗物滤除的合适的袋或网过滤器122,将集水槽118中用过的洗涤水泵入到储水箱121中。储水箱121具有一溢流堰125,用于在如果储水箱121太满时将水溢流到排放口排出,以避免溢出。在储水箱121中可加入能粘结悬浮物的助聚剂或聚合物,用于使脏物漂浮在水面以便撇去,此助聚剂或聚合物来自储存器181。聚合物可利用聚合物泵180,经输送管线182泵入。储水箱121中的水由泵13 1传送到高压储存箱132中。高压储存箱132使用由与压缩空气供给管线152相接的压气机151提供的压缩空气,加压到45~80Psi。Referring to FIG. 2 , the laundry room wastewater treatment and washing process and system include one or

溶解空气浮选(DAF)或固体物去除箱134保持为OPsi。高压储存箱132中的水经流量分配器190排放进入DAF134中,产生成百万的气泡使悬浮脏物浮动到顶部以便将其撇去。利用聚合物泵280经供给管线282将二次混合聚合物从聚合物储存箱281供入到DAF134中。流量分配器190将水水平引入,产生成百万的气泡将微粒和固体沉积物浮动到DAF134的顶部。用撇渣器191将固体废物从DAF134的顶部除去,并经溢流堰192撇入到污物收集箱193中。次撇渣器205装设在DAF134的底部,这使得沉积的废物可通过排放口202清除。由固体物去除箱134底部而来的相当清洁的水流入到水箱135中,而不是如实施例1所述进入到储存箱中。A dissolved air flotation (DAF) or

然后使用传送泵138将水从水箱135传送到接触箱114中。经水箱135进入到接触箱114中的水由过滤器136进行了过滤,将剩余的较细微粒进行了滤除,使得进入到接触箱中的水基本上无脏物和沉积物。一旦由水箱135传送来的水将接触箱114注满,流量控制阀149就关闭,利用供水管线148建立一再循环回路。这使得接触箱114中的水可经过滤器136进行连续的过滤。排放口201用于在必要时将接触箱114排空。The water is then transferred from the

如果在传送到接触箱114中之前需要将水预臭氧化,那么可增加一可选臭氧再循环回路至水箱135。用泵169经管路168使水再循环。文杜里喷管162经与臭氧排放管线150相连接的管线164将臭氧气体吸入。喷管162装有止回阀165用于防止水回流入臭氧发生器140。由水箱135而来的废气经排放管线166排出。An optional ozone recirculation loop to the

利用水补给阀128经水补给管线126给接触箱114或集水槽118补充淡水。如果当地水源的水质很硬时,可加入可选水软化剂160。Fresh water is supplied to the

反向传送管线143形成水反向传送回路,使水连续地循环回入接触箱114中,并使用混合器153、接触延长器146以及可选流量限制接头147使回流的水与接触箱中的水混合。可增设过滤器139对接触箱114中的水进行进一步的细滤。接触箱114中的水位可在需要将漂浮的废物溢流入溢流堰113中时,升高。排放口200用于在需要时将接触箱排空。

在臭氧发生器中以上述同样的方式生成臭氧。臭氧由臭氧发生器产出,利用喷射管142将臭氧挟带入水中。喷射管142最好是文杜里喷管,其可将臭氧供给管线144和144a抽真空。喷射管142装有止回阀145,用于防止水回流入臭氧发生器。臭氧通过臭氧喷射管线143供入接触箱114中。臭氧挟带进入喷射管142中的水中。接触箱114经废气管线150将多余的臭氧排出。废气被引入到排放口170或可选臭氧破坏装置171中。Ozone is generated in the same manner as above in the ozone generator. Ozone is produced by an ozone generator, which is entrained into the water by means of

参照图3,除将再循环部件去除外,系统与图1所示的相同。此系统显示出了当淡水加入到系统中时控制用浮动器90的使用。Referring to Figure 3, the system is the same as that shown in Figure 1, except that the recirculation component is removed. This system shows the use of a

在使用中,提供了使用研究或商用洗衣房洗衣机10、110或类似的洗衣设备的闭式连续水流回路。认为没必要将所揭示的系统仅限于这些大型洗衣系统,通过使用较小的设备和流体流动设备,同样也适合于家用。尽管系统可用于35磅的最小商用洗衣机,但通常每台设备具有高达125磅的洗涤能力。在不使设备设计产生明显改变的情况下,对流动线路进行稍许的改进,可制造出用于连续管道洗衣机的设备。In use, a closed continuous water flow circuit is provided using a research or commercial

总之,本发明的系统提供了一种在减少或不用热水、以及诸如肥皂或洗衣粉类化学用品的情况下,使用臭氧洗衣的闭合回路再循环洗涤水系统。另外系统还包括一种用于加强洗衣机用洗涤水挟带臭氧的文杜里喷管。In summary, the system of the present invention provides a closed loop recirculating wash water system for laundry using ozone with reduced or no hot water and chemicals such as soap or laundry detergent. In addition, the system also includes a venturi nozzle for enhancing the entrainment of ozone in the washing water of the washing machine.

认为在不超出如下权利要求所述本发明范围的情况下,可以对如上所述系统和设备进行改进。It is believed that modifications may be made to the system and apparatus described above without departing from the scope of the invention as set forth in the following claims.

Claims (13)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN 95196239CN1163641A (en) | 1994-07-22 | 1995-07-21 | Ozone Assisted Laundry Laundry Method |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US08/279,019 | 1994-07-22 | ||

| CN 95196239CN1163641A (en) | 1994-07-22 | 1995-07-21 | Ozone Assisted Laundry Laundry Method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN1163641Atrue CN1163641A (en) | 1997-10-29 |

Family

ID=5083163

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN 95196239PendingCN1163641A (en) | 1994-07-22 | 1995-07-21 | Ozone Assisted Laundry Laundry Method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN1163641A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107720900A (en)* | 2017-10-30 | 2018-02-23 | 文世杰 | A kind of method for treating water of washing machine water processing unit |

- 1995

- 1995-07-21CNCN 95196239patent/CN1163641A/enactivePending

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107720900A (en)* | 2017-10-30 | 2018-02-23 | 文世杰 | A kind of method for treating water of washing machine water processing unit |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US5493743A (en) | Ozone assisted laundry wash process and waste water treatment system | |

| US5787537A (en) | Method of washing laundry and recycling wash water | |

| US5409616A (en) | Method and apparatus to restore grey water | |

| US5928490A (en) | Laundry wash process and waste water treatment system | |

| US5868937A (en) | Process and system for recycling and reusing gray water | |

| CA2674353C (en) | Immediate cleaning and recirculation of cleaning fluid and method of using same | |

| US5178755A (en) | UV-enhanced ozone wastewater treatment system | |

| US3841116A (en) | Multiple automatic washer system | |

| JPH06105983A (en) | Washing water treatment / washing method | |

| WO2007050503A2 (en) | Methods and systems for treating wastewater | |

| JP2001113090A (en) | Washing machine | |

| PL173192B1 (en) | System for and method of treating sewage | |

| JP3402854B2 (en) | Continuous washing machine | |

| KR20180012985A (en) | Method and system for treating high-concentrated industrial wastewater | |

| US4211652A (en) | Water reclamation process | |

| US4211651A (en) | Water reclamation process | |

| US20220098074A1 (en) | Carwash and Wastewater Regeneration System | |

| KR102199304B1 (en) | System for improving the reuse efficiency of anthracite and activated carbon | |

| WO2006078797A2 (en) | Methods and systems for treating wastewater | |

| CN1163641A (en) | Ozone Assisted Laundry Laundry Method | |

| JPH10305762A (en) | Treating method for car washing drainage and device therefor | |

| CN108503076A (en) | A kind of two level pretreating process for emulsified oily watewater | |

| JP2000202460A (en) | Cleaning device | |

| JPH0645030B2 (en) | Ozone water treatment equipment | |

| JP3752643B2 (en) | Waste water and circulating water purification equipment |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C01 | Deemed withdrawal of patent application (patent law 1993) | ||

| WD01 | Invention patent application deemed withdrawn after publication |