CN116331418A - Marine monitoring platform laying method and device - Google Patents

Marine monitoring platform laying method and deviceDownload PDFInfo

- Publication number

- CN116331418A CN116331418ACN202310441677.8ACN202310441677ACN116331418ACN 116331418 ACN116331418 ACN 116331418ACN 202310441677 ACN202310441677 ACN 202310441677ACN 116331418 ACN116331418 ACN 116331418A

- Authority

- CN

- China

- Prior art keywords

- monitoring platform

- platform

- hull

- monitoring

- hanger

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B27/00—Arrangement of ship-based loading or unloading equipment for cargo or passengers

- B63B27/36—Arrangement of ship-based loading or unloading equipment for floating cargo

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B27/00—Arrangement of ship-based loading or unloading equipment for cargo or passengers

- B63B27/04—Arrangement of ship-based loading or unloading equipment for cargo or passengers of derricks, i.e. employing ships' masts

- B63B27/06—Arrangement of ship-based loading or unloading equipment for cargo or passengers of derricks, i.e. employing ships' masts with slewing force exerted at pivoted end

- B—PERFORMING OPERATIONS; TRANSPORTING

- B63—SHIPS OR OTHER WATERBORNE VESSELS; RELATED EQUIPMENT

- B63B—SHIPS OR OTHER WATERBORNE VESSELS; EQUIPMENT FOR SHIPPING

- B63B27/00—Arrangement of ship-based loading or unloading equipment for cargo or passengers

- B63B27/10—Arrangement of ship-based loading or unloading equipment for cargo or passengers of cranes

- B63B27/12—Arrangement of ship-based loading or unloading equipment for cargo or passengers of cranes of gantry type

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- Ocean & Marine Engineering (AREA)

- Jib Cranes (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及海洋监测技术领域,具体为一种海用监测平台布放方法及装置。The invention relates to the technical field of marine monitoring, in particular to a method and device for deploying a marine monitoring platform.

背景技术Background technique

对于海洋监测有多种方式,其中之一是使用大型监测平台,将监测平台放置在监测位置,使其漂浮在海中。监测平台中有很多提交较大的类型,如外径1.4m,长12m,重约14.5吨,形式鱼雷的长条形监测平台。这一类监测平台需要用具有足够运载力的船只进行运输,并将其放置于海洋中。目前来说,因为船舶技术的成熟,大型监测平台的运输由现代船舶进行即可,但是对于运输到监测平台的预设下放位置之后,大型监测平台需要脱离船体并入水,这一过程的实施则因为监测平台的大体积和大自重,导致难以实施。将平台水平吊起,然后令其整个延伸处船体之外,之后下放入水,虽然这一方式看似可以确保平台的平稳入水,但是目前的船舶用吊具无法实现,吊具延伸至船体外侧12米以上的距离,其支撑结构无法承担平台的集中。而如果直接将平台从船侧推下,虽然可能能够接近水平状态入水,但是因为其大自重问题,瞬间和水面接触的冲击力可能导致平台壳体乃至内部组件受损。如果将平台从船体尾部或者头部沿平台长度方向外推,那么平台会一端先入水,然后另外一端随后倾斜入水,如果采用下推方式进行这一操作,平台在这一过程中短时间内其整体不同部位受力区别过大,很有可能出现弯折或者折断受损的情况。而且,此种入水方式也会因为平台入水后的不稳定,可能导致平台撞击船舶,导致二者受损。因此,如何确保平台平稳入水,且入水过程中平台自身不会受到损伤或者对船舶造成损伤,便是需要解决的技术问题。There are many ways for ocean monitoring, one of which is to use a large monitoring platform, place the monitoring platform at the monitoring position, and make it float in the sea. There are many large types of monitoring platforms, such as a long strip monitoring platform in the form of a torpedo with an outer diameter of 1.4m, a length of 12m, and a weight of about 14.5 tons. This type of monitoring platform needs to be transported by a ship with sufficient carrying capacity and placed in the ocean. At present, due to the maturity of ship technology, the transportation of large-scale monitoring platforms can be carried out by modern ships. However, after transporting to the preset lowering position of the monitoring platform, the large-scale monitoring platform needs to be separated from the hull and enter the water. The implementation of this process requires Because of the large volume and heavy weight of the monitoring platform, it is difficult to implement. The platform is hoisted horizontally, and then its entire extension is outside the hull, and then lowered into the water. Although this method seems to ensure the smooth entry of the platform into the water, it cannot be realized with the current ship spreader, which extends to the hull. At a distance of more than 12 meters outside, its supporting structure cannot bear the concentration of the platform. However, if the platform is directly pushed down from the side of the ship, although it may be able to enter the water in a nearly horizontal state, due to its large dead weight, the impact force of the instantaneous contact with the water surface may cause damage to the platform shell and even internal components. If the platform is pushed out from the stern or head of the hull along the length of the platform, one end of the platform will enter the water first, and then the other end will then tilt into the water. The difference in force between different parts of the whole is too large, and it is likely to be bent or broken. Moreover, this way of entering the water may also cause the platform to collide with the ship due to the instability of the platform after entering the water, resulting in damage to both. Therefore, how to ensure that the platform enters the water smoothly and that the platform itself will not be damaged or cause damage to the ship during the water entry process is a technical problem that needs to be solved.

发明内容Contents of the invention

针对现有技术的不足,本发明提供了一种海用监测平台布放方法及装置,解决大型海用监测平台的布放问题。Aiming at the deficiencies of the prior art, the present invention provides a method and device for deploying a marine monitoring platform to solve the problem of deploying a large marine monitoring platform.

为实现上述目的,本发明提供如下技术方案:一种海用监测平台布放方法,包括步骤:In order to achieve the above object, the present invention provides the following technical solution: a method for deploying a marine monitoring platform, comprising steps:

S1、对要布放监测平台的海洋状况进行监测,选择适宜投放监测平台的时间;S1. Monitor the state of the ocean where the monitoring platform is to be deployed, and select a suitable time for launching the monitoring platform;

S2、调整监测平台至准备投放的摆放姿态,使其端部朝向船体尾端,连接船体上的吊具和监测平台上的吊点;S2. Adjust the monitoring platform to the placement posture ready to be released, so that its end is facing the tail end of the hull, and connect the sling on the hull and the lifting point on the monitoring platform;

S3、调整船体至准备投放的姿态,并保持航向移动;S3. Adjust the hull to the attitude ready for launching, and keep moving in the course;

S4、监测平台朝向船尾方向移动,并且部分监测平台主体延伸至船尾外部;S4. The monitoring platform moves towards the stern, and part of the main body of the monitoring platform extends to the outside of the stern;

S5、逐渐翻转监测平台,翻转方向为使监测平台的轴线由水平朝向竖直的方向倾斜翻转,在翻转过程中,监测平台的一个端部入水;S5. Gradually turn over the monitoring platform. The turning direction is to make the axis of the monitoring platform turn from horizontal to vertical. During the turning process, one end of the monitoring platform enters the water;

S6、监测平台与船体进行分离,并在水中逐渐恢复为水平姿态,分离吊钩与监测平台的吊点;S6. The monitoring platform is separated from the hull, and gradually returns to a horizontal posture in the water, and the suspension hook and the lifting point of the monitoring platform are separated;

S7、通过吊具,将监测平台的重力锚投入至水中,完成布放。S7. Put the gravity anchor of the monitoring platform into the water through the spreader to complete the deployment.

优选为,所述步骤S1中,布放监测平台时的海洋状况要求在二级海况以下,没有长周期的涌浪,且涌浪浪高小于50cm。Preferably, in the step S1, the sea state when deploying the monitoring platform is required to be below the second sea state, there is no long-period swell, and the height of the swell is less than 50 cm.

优选为,所述步骤S2中,监测平台固定设置在平台支架上,平台支架与船体滑动连接;Preferably, in the step S2, the monitoring platform is fixedly arranged on the platform support, and the platform support is slidingly connected with the hull;

所述吊具包括“门”形的吊架,吊架上侧中部设置滑轮组件;The spreader includes a "door"-shaped hanger, and a pulley assembly is arranged in the middle of the upper side of the hanger;

沿监测平台长度方向至少设置三处吊点,包括,Set at least three lifting points along the length of the monitoring platform, including,

第一吊点,设置在监测平台靠近船体中部的方向;The first lifting point is set in the direction where the monitoring platform is close to the middle of the hull;

第二吊点,位于第一吊点和第三吊点之间;The second lifting point is located between the first lifting point and the third lifting point;

第三吊点,设置在监测平台远离船体中部的方向;The third lifting point is set in the direction where the monitoring platform is away from the middle of the hull;

吊具上设置有主吊缆和副吊缆,其中:The spreader is provided with a main suspension cable and an auxiliary suspension cable, among which:

主吊缆,一端通过两根分吊缆分别与第一吊点和第二吊点固定连接,另一端绕过滑轮组件后与主缆收放组件连接;One end of the main suspension cable is fixedly connected to the first suspension point and the second suspension point through two sub-suspension cables, and the other end is connected to the main cable retractable assembly after bypassing the pulley assembly;

副吊缆,设置有两根,其一端均与第三吊点连接,另一端分别与吊架上部两侧的副缆收放组件连接;There are two auxiliary suspension cables, one end of which is connected to the third suspension point, and the other end is respectively connected to the auxiliary cable retractable components on both sides of the upper part of the hanger;

所述监测平台(100)的调整姿态为监测平台方向与船体首尾方向一致。The adjustment attitude of the monitoring platform (100) is that the direction of the monitoring platform is consistent with the fore-and-aft direction of the hull.

优选为,所述步骤S3具体为,船体保持低速移动,船体迎着风向和涌浪的方向航行。Preferably, the step S3 is specifically that the hull keeps moving at a low speed, and the hull sails against the direction of the wind and the direction of the swell.

优选为,所述步骤S2中的吊架下端与船体转动连接,吊架初始状态为朝向船体中部方向倾斜;Preferably, the lower end of the hanger in the step S2 is rotationally connected with the hull, and the initial state of the hanger is inclined toward the middle of the hull;

所述步骤S4具体包括,The step S4 specifically includes,

S401、平台支架带动监测平台向船体外侧移动,监测平台延伸至船体外侧的部分长度为,以监测平台整体长度为,满足,吊架保持为初始状态;S401. The platform support drives the monitoring platform to move to the outside of the hull. The length of the part of the monitoring platform extending to the outside of the hull is , and the overall length of the monitoring platform is . Satisfied, the hanger remains in the initial state;

S402、平台支架带动监测平台继续向船体外侧移动,满足;以吊架与船体中部方向水平面的夹角为,在监测平台的移动过程中,吊架转动立起至角度满足,。S402. The platform support drives the monitoring platform to continue to move to the outside of the hull, satisfying; taking the angle between the hanger and the horizontal plane in the middle of the hull as , during the movement of the monitoring platform, the hanger rotates and stands until the angle meets.

优选为,所述步骤S5具体包括,Preferably, the step S5 specifically includes,

S501、监测平台保持与平台支架固定连接的状态下,由平台支架带动进行翻转,以监测平台中心线朝向船体一侧水平面的夹角为,将监测平台翻转至角度满足,;在翻转过程中,监测平台端部逐渐入水;吊架随着平台支架的动作转动至满足,;确保住吊缆和副吊缆均处于受力状态。S501. When the monitoring platform remains fixedly connected to the platform support, it is driven by the platform support to turn over, and the angle between the center line of the monitoring platform and the horizontal plane on the side of the hull is , and the monitoring platform is turned over until the angle is satisfied; during the turning process, Monitor that the end of the platform gradually enters the water; the hanger rotates with the action of the platform support to meet the requirements; ensure that the suspension cables and auxiliary suspension cables are under stress.

优选为,所述步骤S5还包括,Preferably, the step S5 also includes,

S502,吊架维持角度不变,平台支架继续带动监测平台转动至。S502, the angle of the hanger remains unchanged, and the platform support continues to drive the monitoring platform to rotate to.

优选为,所述步骤S6具体包括,Preferably, the step S6 specifically includes,

S601,当完成步骤S502后,分离监测平台和平台支架;S601, after step S502 is completed, separate the monitoring platform and the platform support;

S602、船体保持前进状态,延长吊缆使监测平台由竖直朝向水平方向恢复姿态,同时吊架继续转动至满足,;依次解除三个吊点处吊缆与监测平台的连接,回收平台支架,完成对监测平台主体的布放 。S602. Keep the hull moving forward, extend the suspension cable to restore the posture of the monitoring platform from the vertical to the horizontal direction, and at the same time, the hanger continues to rotate until it is satisfied; successively release the connection between the suspension cable and the monitoring platform at the three lifting points, and recover the platform support. Complete the deployment of the main body of the monitoring platform.

本方案还提供一种海用大型监测平台布放装置,应用于前述的布放方法,包括,This solution also provides a deployment device for a large marine monitoring platform, which is applied to the aforementioned deployment method, including,

平台支架,用于承载监测平台;The platform bracket is used to carry the monitoring platform;

牵引组件,设置在船体尾端,带动平台支架进行平移;The traction component is arranged at the tail end of the hull, and drives the platform bracket to move in translation;

翻转机构,与平台支架连接,可将平台支架朝向船体后侧进行翻转;The turning mechanism is connected with the platform support, and can turn the platform support towards the rear side of the hull;

吊具,设置在船体尾端,用于在布放监测平台时,悬吊监测平台。The spreader is arranged at the rear end of the hull, and is used for suspending the monitoring platform when the monitoring platform is deployed.

优选为,所述牵引组件包括,Preferably, the traction assembly includes,

轨道,固定铺设在船体上,轨道的长度方向为船体长度方向一致;The track is fixedly laid on the hull, and the length direction of the track is consistent with the length direction of the hull;

牵引车,架设在轨道上,其上设置所述翻转机构,牵引车通过翻转机构与平台支架连接。The tractor is erected on the track, and the turning mechanism is arranged on it, and the tractor is connected with the platform support through the turning mechanism.

与现有技术相比,具备以下有益效果:结合本方案的方法和装置,可以平稳的实现大型海用监测平台的入海布放,且布放过程中,借助平台支架和吊具确保监测平台的缓慢平稳入水,避免了监测平台入水时可能出现的设备损伤问题。借助吊具和平台支架的翻转结构,以二者配合翻转的方式带动监测平台倾斜入水,确保平台入水过程中获得极佳稳定性的和安全性。Compared with the existing technology, it has the following beneficial effects: combined with the method and device of this scheme, the large-scale marine monitoring platform can be deployed smoothly into the sea, and during the deployment process, the monitoring platform is ensured by means of platform brackets and spreaders. Slowly and steadily enter the water, avoiding possible equipment damage when the monitoring platform enters the water. With the help of the overturning structure of the spreader and the platform bracket, the monitoring platform is tilted into the water by the way of the two cooperating overturning, so as to ensure the excellent stability and safety of the platform during the process of entering the water.

附图说明Description of drawings

图1为本发明实施例的监测平台投放准备状态示意图;Fig. 1 is a schematic diagram of a monitoring platform launch preparation state according to an embodiment of the present invention;

图2为本发明实施例的步骤S401状态示意图;FIG. 2 is a schematic diagram of the state of step S401 according to an embodiment of the present invention;

图3为本发明实施例的步骤S402状态示意图;FIG. 3 is a schematic diagram of the state of step S402 according to an embodiment of the present invention;

图4为本发明实施例的步骤S501状态示意图;FIG. 4 is a schematic diagram of the state of step S501 according to an embodiment of the present invention;

图5为本发明实施例的步骤S502状态示意图;FIG. 5 is a schematic diagram of the state of step S502 according to an embodiment of the present invention;

图6为本发明实施例的步骤S601状态示意图;FIG. 6 is a schematic diagram of the state of step S601 according to an embodiment of the present invention;

图7为本发明实施例的步骤S602状态示意图;FIG. 7 is a schematic diagram of the state of step S602 according to an embodiment of the present invention;

图8为本发明实施例的监测平台主体完成投放状态示意图;Fig. 8 is a schematic diagram of the delivery status of the main body of the monitoring platform according to the embodiment of the present invention;

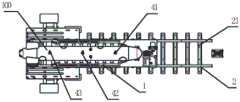

图9为本发明实施例的监测平台及牵引组件俯视图;Fig. 9 is a top view of the monitoring platform and the traction assembly of the embodiment of the present invention;

图10为本发明实施例的监测平台及牵引组件主视图;Fig. 10 is a front view of the monitoring platform and the traction assembly of the embodiment of the present invention;

图11为图10的A局部放大图;Fig. 11 is a partial enlarged view of A in Fig. 10;

图12为本发明实施例的吊具结构示意图;Fig. 12 is a schematic structural diagram of a spreader according to an embodiment of the present invention;

图13为本发明实施例的锁死机构放大图;Fig. 13 is an enlarged view of the locking mechanism of the embodiment of the present invention;

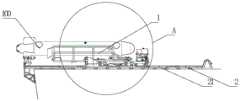

图14为本发明实施例的监测平台及牵引组件左视图;Fig. 14 is a left view of the monitoring platform and the traction assembly of the embodiment of the present invention;

图中:In the picture:

1、平台支架;2、牵引组件;21、轨道;22、牵引车;23、锁死机构;231、锁死踏板;232、锁死轴;233、夹板;3、翻转机构;4、吊具;41、第一吊点;42、第二吊点;43、第三吊点;44、主吊缆;45、分吊缆;46、副吊缆;47、吊架;48、基座。1. Platform support; 2. Traction component; 21. Track; 22. Tractor; 23. Locking mechanism; 231. Locking pedal; 232. Locking shaft; 233. Splint; 3. Turning mechanism; 4.

实施方式Implementation

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

请参阅图1-图12,本发明提供以下技术方案:Please refer to Fig. 1-Fig. 12, the present invention provides following technical scheme:

一种海用监测平台布放方法,包括步骤:A method for deploying a marine monitoring platform, comprising the steps of:

S1、对要布放监测平台100的海洋状况进行监测,选择适宜投放监测平台100的时间;考虑到布放时的操作安全性,选择布放监测平台100时的海洋状况要求在二级海况以下,没有长周期的涌浪,且涌浪浪高小于50cm。此处的二级海况指的是浪高范围在0.1-0.5m,波浪很小,波长尚短,但波形显著。波峰不破裂,因而不是显白色,而是仅呈玻璃色。对于小型渔船来说,有晃动影响,张帆可随风移行约每小时2-3海里。S1. Monitor the state of the ocean where the

S2、调整监测平台100至准备投放的摆放姿态,使其端部朝向船体尾端,连接船体上的吊具4和监测平台100上的吊点;该状态下,监测平台100的长度方向与船体的长度方向一致,为了便于布放,将监测平台放置在船尾端。S2, adjust the

S3、调整船体至准备投放的姿态,船体保持低速移动,且船体选择迎着风向和涌浪的方向航行。S3. Adjust the hull to the posture ready to launch, keep moving at a low speed, and choose to sail in the direction facing the wind and swell.

S4、监测平台100朝向船尾方向移动,并且部分监测平台100主体延伸至船尾外部;S4. The

S5、逐渐翻转监测平台100,翻转方向为使监测平台100的轴线由水平朝向竖直的方向倾斜翻转,在翻转过程中,监测平台100的一个端部入水;S5. Gradually turn over the

S6、监测平台100与船体进行分离,并在水中逐渐恢复为水平姿态,分离吊钩与监测平台100的吊点;S6. The

S7、通过吊具,将监测平台100的重力锚投入至水中,完成布放。S7. Put the gravity anchor of the

通过本方案进行,考虑到监测平台100自身的长度和自重问题,采用将其先旋转达成端部部分局部入水,然后再配合船体移动令平台整体缓慢入水的方式,这一方式实施的过程中,监测平台100可以在入水时的大部分过程从整体受到支撑到局部受到支撑,最后变为不受支撑入水,船体施加给监测平台100的支撑力量是平缓消减的,因此可以保证监测平台100入水的稳定性,同时也在其入水过程中对监测平台有更好的掌控性,有效减少入水时可能发生的碰撞和损坏问题,极大的提高了操作安全性。Through this plan, considering the length and self-weight of the

在上述实施方案的基础上,步骤S2中,监测平台100固定设置在平台支架1上,平台支架1通过牵引组件2与船体滑动连接;牵引组件2,设置在船体尾端,带动平台支架1进行平移;平台支架1的作用为承载监测平台100,牵引组件2可以采用不同的实施方式,只需满足可以带动平台支架1平移和翻转,且在任何需要止停时,能够确保平台支架1停止运动即可。On the basis of the above-mentioned embodiment, in step S2, the

在上述实施方案的基础上,吊具4包括“门”形的吊架47,吊架47上侧中部设置滑轮组件,吊具4和平台支架1设置在船尾处;参见图12,该图为吊具4的结构示意图,吊具4的两侧支撑结构下分别设置一个基座48,吊具4两侧的支撑结构与基座48转动连接。基座48固定在船体的船板上。滑轮组件承担主吊缆44的拉力,在吊架47上部两侧还分别对称设置副吊缆46的相关收放组件,如小型的缆线收放装置,或者对应副吊缆46的滑轮组件。On the basis of the above-mentioned embodiment, the

参见图9,沿监测平台100长度方向至少设置三处吊点,包括,Referring to Fig. 9, at least three hanging points are set along the length direction of the

第一吊点41,设置在监测平台100靠近船体中部的方向;The

第二吊点42,位于第一吊点41和第三吊点43之间;The

第三吊点43,设置在监测平台100远离船体中部的方向;The

第一吊点41和第二吊点42在起吊时起到主要的承重作用,第三吊点43主要是起到止荡左右补偿的作用。The

参见图4,该图中展示了吊缆的布局展示,因为该图中的设备角度可以便于展示吊缆状态,其它附图中吊缆省略展示。吊具4上设置有主吊缆44和副吊缆46,其中主吊缆44一端通过两根分吊缆45分别与第一吊点41和第二吊点42固定连接,另一端绕过滑轮组件后与主缆收放组件连接,主缆收放组件可以固定设置在牵引组件2上,也可以直接固定在船板上。副吊缆46设置有两根,其一端均与第三吊点43连接,另一端分别与吊架47上部两侧的副缆收放组件连接;通过副吊缆46对监测平台100一方面提供辅助的拉力,另一方面结合两根副吊缆46与吊架47上的两点形成三角结构,便于对监测平台100布放过程中进行止荡,及监测平台入水后,一定程度调整其方向。Refer to Figure 4, which shows the layout of the suspension cables, because the angle of the equipment in this figure can facilitate the display of the suspension cables, and the suspension cables are omitted in other drawings. The

在上述实施方案的基础上,步骤S2中的吊架47初始状态为朝向船体中部方向倾斜;此时吊架47和监测平台100及平台支架1的状态如图1所示。On the basis of the above embodiment, the initial state of the

步骤S4具体包括,Step S4 specifically includes,

S401、平台支架1带动监测平台100向船体外侧移动,监测平台100延伸至船体外侧的部分长度为,以监测平台整体长度为,满足,吊架47保持为初始状态;如图2所示,在牵引组件2的带动下,平台支架1携带监测平台100运动,令监测平台100的端部移动至船体外侧,露出船体的部分大约为监测平台100长度的三分之一,平台支架1依然位于船体上。S401, the

S402、平台支架1带动监测平台100继续向船体外侧移动,;以吊架47与船体中部方向水平面的夹角为,在监测平台100的移动过程中,吊架47转动立起至角度,。参见图3,其展示的为本步骤状态,平台支架1和监测平台100均部分移动至船体外侧,平台支架1和监测平台100约为二分之一长度至于船体外侧。且此时吊架47开始向竖直方向立起,此时吊架47并不对监测平台100施力,立起姿态为后续环节准备。S402. The

在前述实施方案的基础上,步骤S5具体包括,On the basis of the foregoing embodiments, step S5 specifically includes,

S501、参见图4,监测平台100保持与平台支架1固定连接的状态下,由平台支架1带动进行翻转,以监测平台100中心线朝向船体一侧水平面的夹角为,将监测平台100翻转至角度,;在翻转过程中,监测平台100端部逐渐入水;吊架47随着平台支架1的动作转动至,;此状态下,需要确保住吊缆44和副吊缆均处于受力状态,确保后续环节的安全。S501. Referring to FIG. 4 , when the

S502,参见图5,吊架47维持角度不变,平台支架1继续带动监测平台100转动至。通过配合前一环节的吊架47角度,结合此时的监测平台100位置状态,基本可以令监测平台100的三个吊点受到竖直向上的拉力,结合平台支架1对其施加的固定力,监测平台100相当于贴附在船尾端,该状态下虽然监测平台100变为竖直,但是在吊具4和平台支架1的作用下,其整体依然是稳定的。S502 , referring to FIG. 5 , the angle of the

在上述实施方案的基础上,步骤S6具体包括,On the basis of the above-mentioned embodiment, step S6 specifically includes,

S601,当完成步骤S502后,分离监测平台100和平台支架1,船体保持前进状态;如图6所示状态,将监测平台100和平台支架1之间的连接固定结构解除,保持吊具4对监测平台100的悬吊力量,对应释放主吊缆44和副吊缆46,随着船体的移动,因为监测平台100下端以入水,在水的阻力下,伴随吊缆的释放,其下端会逐渐远离船体的,上端贴着平台支架100下滑,呈现如图6中的倾斜状态。S601, after step S502 is completed, the

S602、继续延长吊缆使监测平台100由竖直朝向水平方向恢复姿态,同时吊架47继续转动至满足,至;如图7状态,监测平台100已经接近水平漂浮,此时因为浮力的作用,吊具4承受的力量降低,所以可以将吊具4进一步翻转,令其安全的探出船体外,此状态下吊具4的作用从悬吊为主变为悬吊为辅,调整监测平台100在水中的位置为主。船体引擎停止工作,仅依靠惯性小幅度缓慢前行。令监测平台100进一步和船体远离。依次解除三个吊点处吊缆与监测平台100的连接,回收平台支架1,此时便基本完成了对于监测平台100本体的布放,如图8展示。S602, continue to extend the suspension cable to restore the posture of the

步骤S7中,吊缆则继续延长,当船体离开监测平台100投放地点约100米后,用吊具4将监测平台100配套的重力锚吊入海中并释放,完成对监测平台100的全部布放过程,确保平台支架1和吊具4均复位即可 。In step S7, the suspension cable continues to be extended, and when the hull is about 100 meters away from the

在上述实施方案的基础上,本方案还提供一种海用大型监测平台布放装置,应用于前述的布放方法,包括用于承载监测平台100的平台支架1。设置在船体尾端的牵引组件2,牵引组件2用于带动平台支架1进行平移;平台支架1下侧设置翻转机构3,翻转机构3与平台支架1连接,可将平台支架1朝向船体后侧进行翻转;翻转机构3采用液压驱动系统,通过液压杆从下侧推动平台支架1转动。在船体尾端还设置有吊具4,吊具4用于在布放监测平台100时,悬吊监测平台100。On the basis of the above embodiments, this solution also provides a large-scale marine monitoring platform deployment device, which is applied to the aforementioned deployment method, and includes a

在上述实施方案的基础上,参见图9至图11,牵引组件2包括固定铺设在船体上的轨道21,轨道21的长度方向为船体长度方向一致;在轨道22上架设牵引车22,牵引车22承载平台支架1,翻转机构3设置在牵引车22和平台支架1之间,牵引车22通过翻转机构3与平台支架1连接。牵引车22自身具备动力系统,可以沿轨道21运动。本方案仅为实施方案中的一种,并不仅限于轨道和轨道车的结构实施形式,只需满足可以平稳带动平台支架1移动即可。因为考虑到监测平台100自身性质的特殊性,因此选用了这结构,具有更好的承重力。On the basis of above-mentioned embodiment, referring to Fig. 9 to Fig. 11,

在上述实施方案的基础上,牵引车22包括车体,车体下部两侧设置支撑轮,牵引车通过支撑轮沿轨道21移动;牵引车22依靠锚链组件做为动力,在锚链组件的作用下,牵引车22沿轨道21运动。锚链组件包括为做为动力源的液压马达,液压马达的动力输出端与锚链轮联动,驱动锚链轮转动。对应锚链轮设置有锚链,锚链的两端分别与轨道21两端的固定块固定连接,与锚链轮对应设置有张紧轮,锚链绕过锚链轮和张紧轮。液压马达和锚链轮均设置在牵引车22上,根据锚链轮的转动方向不同,带动牵引车朝向轨道21的不同方向运动。On the basis of the above-mentioned embodiments, the

在上述实施方案的基础上,牵引车22和轨道21之间设置有若干个锁死机构23,锁死机构23用于在牵引车22停止时锁紧支撑轮和轨道21。参见图13,为了便于展示,图13为相当于图11角度的侧视图,通过该方向放大展示锁死机构23。本方案的轨道21采用工字型轨道,锁死机构23包括两个位于轨道21两侧的夹板233,夹板233下部对应轨道的上部横向结构开设凹槽,其中一个夹板233为固定夹板,另一个夹板233为活动夹板,活动夹板233的上部与锁死机构所在位置的固定结构铰接。两个夹板233之间贯穿设置一个锁死轴232,锁死轴232的两端分别延伸至两个夹板233外侧,其中一端转动连接锁死踏板231,锁死踏板231设置在固定夹板的外侧,锁死踏板231与锁死轴232的连接处为凸轮结构。当需要固定牵引车22位置时,只需踩下锁死踏板231,便可利用夹板233夹紧轨道21。On the basis of the above embodiments, several locking

在上述实施方案的基础上,参见图14,平台支架1其上部整齐形成开口向上的抛物线凹槽形状,整体尺寸为6150*3200*2200mm,用于放置监测平台100。在凹槽内侧的支撑板上安装圆柱形导轨,便于监测平台100在其内滑动。为防止监测平台100在翻转架内滑动过程中损伤其表面玻璃微珠浮材,在监测平台100内侧敷设一层聚氨酯材料的缓冲层,聚氨酯缓冲层朝向监测平台的一面附加橡胶板,聚氨酯缓冲层的另一面附加钢板层。橡胶板保护监测平台100的外层材料和增加摩擦力的作用,聚氨酯板和橡胶板和普通钢板为三种介质,振动波在穿过三层介质后会有相应的能量损失从而减低震动的传导,同时橡胶板为软性材料也可以有效的进行缓冲和吸震作用。On the basis of the above embodiment, referring to FIG. 14 , the upper part of the

在上述实施方案的基础上,翻转机构3包括两个支架油缸,支架油缸一端与平台支架1转动连接,另一端与牵引车22转动连接。平台支架1中部与牵引车22尾端的支撑结构转动连接,当支架油缸延长时,可以推动平台支架1翻转抬高。On the basis of the above embodiment, the

在平台支架1上设置锁止结构,锁止结构包括“Z”形结构的挂钩,挂钩中部与平台支架1的架体转动连接,挂钩一端与锁止油缸联动,通过锁止油缸驱动挂钩转动,对应平台支架1的竖直状态位置,船尾端设置挂环,当平台支架1竖直后,通过锁止油缸推动挂钩,令挂钩勾住挂环,进一步提高平台支架1的稳定性。A locking structure is provided on the

在上述实施方案的基础上,吊具4通过其自身的驱动机构进行翻转,参见图4至图7,吊架47的侧部为立杆结构,立杆下端与基座48转动连接,每个基座48还与一根支杆的一端转动连接,立杆和该之间设置第一吊架油缸,通过第一吊架油缸,可以改变立杆和支杆的夹角,第一吊架油缸的两端分别与支杆的中部和立杆的中部偏上位置转动连接,在支杆下侧还设置第二吊架油缸,第二吊架油缸一端与支杆远离基座48的端部位置转动连接,另一端与基座48或者船板上侧转动连接。通过这一结构,吊架47在运动时可以受到两侧共计四个油缸的推拉,具有更好的稳定性、安全性和牢固程度,此外,也具有更大的活动范围,便于后期以更好的位置投放监测平台100的重力锚。On the basis of the above-mentioned embodiment, the

最后应说明的是:以上所述仅为本发明的优选实施例而已,并不用于限制本发明,尽管参照前述实施例对本发明进行了详细的说明,对于本领域的技术人员来说,其依然可以对前述各实施例所记载的技术方案进行修改,或者对其中部分技术特征进行等同替换。凡在本发明的精神和原则之内,所作的任何修改、等同替换、改进等,均应包含在本发明的保护范围之内。Finally, it should be noted that: the above is only a preferred embodiment of the present invention, and is not intended to limit the present invention. Although the present invention has been described in detail with reference to the foregoing embodiments, for those skilled in the art, it still The technical solutions recorded in the foregoing embodiments may be modified, or some technical features thereof may be equivalently replaced. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included within the protection scope of the present invention.

Claims (10)

Translated fromChinesePriority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310441677.8ACN116331418A (en) | 2023-04-23 | 2023-04-23 | Marine monitoring platform laying method and device |

| CN202311264549.7ACN117302433A (en) | 2023-04-23 | 2023-09-27 | Marine monitoring platform laying method and device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310441677.8ACN116331418A (en) | 2023-04-23 | 2023-04-23 | Marine monitoring platform laying method and device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN116331418Atrue CN116331418A (en) | 2023-06-27 |

Family

ID=86895097

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202310441677.8AWithdrawnCN116331418A (en) | 2023-04-23 | 2023-04-23 | Marine monitoring platform laying method and device |

| CN202311264549.7APendingCN117302433A (en) | 2023-04-23 | 2023-09-27 | Marine monitoring platform laying method and device |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202311264549.7APendingCN117302433A (en) | 2023-04-23 | 2023-09-27 | Marine monitoring platform laying method and device |

Country Status (1)

| Country | Link |

|---|---|

| CN (2) | CN116331418A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116853417A (en)* | 2023-09-05 | 2023-10-10 | 青岛国数信息科技有限公司 | Retraction device suitable for shipborne lifting sonar and working method thereof |

| CN117002686A (en)* | 2023-09-21 | 2023-11-07 | 厦门大学 | Argo buoy delivery device and delivery method |

| CN117302433A (en)* | 2023-04-23 | 2023-12-29 | 自然资源部第一海洋研究所 | Marine monitoring platform laying method and device |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5253605A (en)* | 1992-12-21 | 1993-10-19 | Applied Remote Technology, Inc. | Method and apparatus for deploying and recovering water borne vehicles |

| US20080202405A1 (en)* | 2007-02-26 | 2008-08-28 | Physical Sciences, Inc. | Launch and Recovery Devices for Water Vehicles and Methods of Use |

| US7712429B1 (en)* | 2007-06-28 | 2010-05-11 | United States Of America As Represented By The Secretary Of The Navy | Launch and recovery system for unmanned undersea vehicles |

| SG190756A1 (en)* | 2010-12-07 | 2013-07-31 | Thales Sa | System for launching and recovering underwater vehicles, notably towed underwater vehicles |

| KR20160039022A (en)* | 2014-09-30 | 2016-04-08 | 바다중공업 주식회사 | Davit device for lifeboat |

| CN106240772A (en)* | 2016-08-26 | 2016-12-21 | 中国海洋大学 | A kind of ship base underwater glider lays recovery system and lays accordingly and recovery method |

| CN109050839A (en)* | 2018-08-23 | 2018-12-21 | 青岛晨明海洋装备技术有限公司 | A kind of draw off gear of underwater glider and autonomous underwater vehicle |

| CN112977730A (en)* | 2021-03-08 | 2021-06-18 | 凯若普(厦门)技术服务有限公司 | Jacket transportation and installation system |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7475649B2 (en)* | 2006-07-18 | 2009-01-13 | Shepherd John D | Davit system for small boats |

| US8221028B2 (en)* | 2010-03-31 | 2012-07-17 | Propulsion, Gas Turbine, And Energy Evaluations, Llc | Boat lift operated by boat's propulsive force |

| KR101620909B1 (en)* | 2014-06-30 | 2016-05-31 | 대우조선해양 주식회사 | Fall Guidance Apparatus of Free Fall Lifeboat and Guide Method Thereof |

| CN106926978B (en)* | 2017-03-30 | 2019-02-22 | 中国船舶科学研究中心(中国船舶重工集团公司第七0二研究所) | Chute type buoy extension and retraction system based on buoyancy |

| CN107618420B (en)* | 2017-09-26 | 2024-01-12 | 苏州飞驰环保科技股份有限公司 | Auxiliary device convenient for launching of small river channel ship |

| CN108146581B (en)* | 2017-12-19 | 2022-07-08 | 西北工业大学 | An underwater equipment deployment and recovery device |

| DK202000013Y4 (en)* | 2019-03-20 | 2020-09-17 | Harco Aps | Apparatus for launching and salvaging a submarine from and to an offshore location |

| FR3105775B1 (en)* | 2019-12-26 | 2025-03-14 | Thales Sa | Device for recovering a ship at sea |

| CN111891296A (en)* | 2020-08-11 | 2020-11-06 | 中国船舶工业集团公司第七0八研究所 | Submersible transport and distribution recovery system and method |

| CN215323178U (en)* | 2021-04-30 | 2021-12-28 | 南通航海机械集团有限公司 | Slide rail adjustable type ship-borne boat folding and unfolding device |

| CN115848564A (en)* | 2022-12-12 | 2023-03-28 | 宜昌测试技术研究所 | Slip cloth puts tray |

| CN116331418A (en)* | 2023-04-23 | 2023-06-27 | 自然资源部第一海洋研究所 | Marine monitoring platform laying method and device |

- 2023

- 2023-04-23CNCN202310441677.8Apatent/CN116331418A/ennot_activeWithdrawn

- 2023-09-27CNCN202311264549.7Apatent/CN117302433A/enactivePending

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5253605A (en)* | 1992-12-21 | 1993-10-19 | Applied Remote Technology, Inc. | Method and apparatus for deploying and recovering water borne vehicles |

| US20080202405A1 (en)* | 2007-02-26 | 2008-08-28 | Physical Sciences, Inc. | Launch and Recovery Devices for Water Vehicles and Methods of Use |

| US7712429B1 (en)* | 2007-06-28 | 2010-05-11 | United States Of America As Represented By The Secretary Of The Navy | Launch and recovery system for unmanned undersea vehicles |

| SG190756A1 (en)* | 2010-12-07 | 2013-07-31 | Thales Sa | System for launching and recovering underwater vehicles, notably towed underwater vehicles |

| KR20160039022A (en)* | 2014-09-30 | 2016-04-08 | 바다중공업 주식회사 | Davit device for lifeboat |

| CN106240772A (en)* | 2016-08-26 | 2016-12-21 | 中国海洋大学 | A kind of ship base underwater glider lays recovery system and lays accordingly and recovery method |

| CN109050839A (en)* | 2018-08-23 | 2018-12-21 | 青岛晨明海洋装备技术有限公司 | A kind of draw off gear of underwater glider and autonomous underwater vehicle |

| CN112977730A (en)* | 2021-03-08 | 2021-06-18 | 凯若普(厦门)技术服务有限公司 | Jacket transportation and installation system |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117302433A (en)* | 2023-04-23 | 2023-12-29 | 自然资源部第一海洋研究所 | Marine monitoring platform laying method and device |

| CN116853417A (en)* | 2023-09-05 | 2023-10-10 | 青岛国数信息科技有限公司 | Retraction device suitable for shipborne lifting sonar and working method thereof |

| CN116853417B (en)* | 2023-09-05 | 2024-01-09 | 青岛国数信息科技有限公司 | Retraction device suitable for shipborne lifting sonar and working method thereof |

| CN117002686A (en)* | 2023-09-21 | 2023-11-07 | 厦门大学 | Argo buoy delivery device and delivery method |

Also Published As

| Publication number | Publication date |

|---|---|

| CN117302433A (en) | 2023-12-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN116331418A (en) | Marine monitoring platform laying method and device | |

| CN105314069B (en) | Catamaran for offshore wind turbine installation | |

| US20130291779A1 (en) | Apparatus to launch and recover a boat | |

| CN110325776A (en) | Method of installing a pile adapted to support an offshore wind turbine, wave induced motion compensated pile holding system, vessel and pile holding device | |

| US4369538A (en) | Apparatus for transfer of persons and goods between structures offshore | |

| EP1705111B1 (en) | Mooring apparatus with moveable ballast weight | |

| FI84248C (en) | Offshore load handling systems | |

| CN110042837A (en) | The automatic horizontally-arranged device of pile driving barge pile frame | |

| WO2023041730A1 (en) | Installation and/or removal of a wind turbine component for a floating foundation wind turbine | |

| JP2024519473A (en) | Erection crane and installation vessel | |

| CN112829880A (en) | A mining vehicle deployment and recovery system suitable for deep sea mining | |

| JP2003534982A (en) | Wind propulsion ship | |

| US5848574A (en) | Multi-hull watercraft with self-righting capabilities | |

| CN116513377A (en) | Marine monitoring platform recycling method and device | |

| CN108974257B (en) | Rescue boat winding and unwinding devices | |

| JP4160011B2 (en) | Work ship capable of storing pile driver | |

| CN118597344A (en) | A built-in small boat launching and retracting system | |

| CN113619733B (en) | Intelligent retraction method of modularized dinghy retraction device | |

| CN113335456B (en) | Modular boat retraction device | |

| CN114761320B (en) | Propulsion wing of mobile vehicle and mobile vehicle including such propulsion wing | |

| CN114041012A (en) | Systems for Offshore Power Generation | |

| JP2002068077A (en) | Oil collecting device for collecting oil floating on the water surface | |

| CN221519958U (en) | Bridge rack roll-on-roll-off ship | |

| CN219192504U (en) | Quick transfer device of marine vessel | |

| CN222347256U (en) | A gun array release rack |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| WW01 | Invention patent application withdrawn after publication | ||

| WW01 | Invention patent application withdrawn after publication | Application publication date:20230627 |