CN116295957A - Magnetic electronic skin for tactile perception - Google Patents

Magnetic electronic skin for tactile perceptionDownload PDFInfo

- Publication number

- CN116295957A CN116295957ACN202310419268.8ACN202310419268ACN116295957ACN 116295957 ACN116295957 ACN 116295957ACN 202310419268 ACN202310419268 ACN 202310419268ACN 116295957 ACN116295957 ACN 116295957A

- Authority

- CN

- China

- Prior art keywords

- pdms

- magnetic

- electronic skin

- ndfeb

- film

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01L—MEASURING FORCE, STRESS, TORQUE, WORK, MECHANICAL POWER, MECHANICAL EFFICIENCY, OR FLUID PRESSURE

- G01L1/00—Measuring force or stress, in general

- G01L1/12—Measuring force or stress, in general by measuring variations in the magnetic properties of materials resulting from the application of stress

- G01L1/127—Measuring force or stress, in general by measuring variations in the magnetic properties of materials resulting from the application of stress by using inductive means

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Measuring Magnetic Variables (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明基于钕铁硼磁性颗粒(Nd2Fe14B1)和聚二甲基硅氧烷(PDMS)设计了一种高柔性、高灵敏度磁性电子皮肤,能够准确快速检测到施加在电子皮肤上的动态和静态力,可安装在机械手上进行精确抓取等工作。The present invention designs a highly flexible and highly sensitive magnetic electronic skin based on NdFeB magnetic particles (Nd2 Fe14 B1 ) and polydimethylsiloxane (PDMS), which can accurately and quickly detect the The dynamic and static force can be installed on the manipulator for precise grasping and other work.

背景技术Background technique

机械手作为机器人与外界进行信息交互的主要途径,承担着感知并识别外界刺激的重要任务。触觉传感器作为机械手的核心部件,需要精确感知施加在接触物体上的静态和动态力从而对物体进行属性判断、形状识别等,从而完成精确抓取任务,对传感器的灵敏度和柔性有很高的要求。现有的磁性薄膜主要由磁性纳米颗粒(MNPs)所制作的水凝胶组成(Hongwei Zhou,Zhaoyang Jin,Yang Gao,et al.Thermoresponsive,magnetic,adhesiveand conductive nanocomposite hydrogels for wireless and non-contact flexiblesensors,Colloids and Surfaces A:Physicochemical and Engineering Aspects,Volume 636,2022),磁性纳米颗粒一般由铁、钴、镍等金属氧化物组成的磁性内核及包裹在磁性内核外的高分子聚合物组成(一般为具有超顺磁或铁磁性质的Fe3O4或γ-Fe2O3),这类磁性水凝胶薄膜存在灵敏度不高,需要额外偏置磁场等问题。钕铁硼颗粒类磁性薄膜利用霍尔元件的霍尔效应可以将磁场的变化转化为电信号并进行放大和输出,如(Yan Y,HuZ,Yang Z,Yuan W,Song C,Pan J,Shen Y.Soft magnetic skin for super-resolutiontactile sensing with force self-decoupling.Sci Robot.2021Feb 24,6(51):8801.),该方案采用了正弦磁化对磁性薄膜进行充磁,并用霍尔元件检测磁场变化;但由于正弦磁化为单面磁化以及霍尔元件灵敏度不高的原因,造成阵列式的传感器存在分辨率低,某些特定地方的受力点检测不到以及霍尔元件的抗干扰能力差和灵敏度不高,导致磁性电子皮肤存在耦合效应强,对工作温度较为敏感,信号输出会随温度变化,对微小力的反馈不明显等问题。As the main way for the robot to exchange information with the outside world, the manipulator undertakes the important task of sensing and identifying external stimuli. As the core component of the manipulator, the tactile sensor needs to accurately perceive the static and dynamic forces applied to the contact object to perform attribute judgment and shape recognition on the object, so as to complete the precise grasping task, which has high requirements for the sensitivity and flexibility of the sensor. . Existing magnetic films are mainly composed of hydrogels made of magnetic nanoparticles (MNPs) (Hongwei Zhou, Zhaoyang Jin, Yang Gao, et al. Thermoresponsive, magnetic, adhesive and conductive nanocomposite hydrogels for wireless and non-contact flexible sensors, Colloids and Surfaces A: Physicochemical and Engineering Aspects, Volume 636, 2022), magnetic nanoparticles are generally composed of a magnetic core composed of iron, cobalt, nickel and other metal oxides and a polymer wrapped outside the magnetic core (generally with super Paramagnetic or ferromagnetic Fe3O4 or γ-Fe2O3), this type of magnetic hydrogel film has problems such as low sensitivity and the need for an additional bias magnetic field. NdFeB granular magnetic film can convert the change of magnetic field into electrical signal and amplify and output it by using Hall effect of Hall element, such as (Yan Y, HuZ, Yang Z, Yuan W, Song C, Pan J, Shen Y.Soft magnetic skin for super-resolution tactile sensing with force self-decoupling.Sci Robot.2021Feb 24,6(51):8801.), this scheme uses sinusoidal magnetization to magnetize the magnetic film, and uses a Hall element to detect the magnetic field However, due to the fact that the sinusoidal magnetization is single-sided magnetization and the sensitivity of the Hall element is not high, the resolution of the array sensor is low, the force point in some specific places cannot be detected, and the anti-interference ability of the Hall element is poor. And the sensitivity is not high, resulting in strong coupling effect of the magnetic electronic skin, it is more sensitive to the working temperature, the signal output will change with the temperature, and the feedback to the small force is not obvious.

发明内容Contents of the invention

本发明的目的是针对目前柔性电子皮肤灵敏度低,抗干扰能力差,对工作环境要求高等问题,基于钕铁硼磁性颗粒的磁导效应提出一种高灵敏度,高柔性,抗干扰能力强的磁性电子皮肤。该电子皮肤由钕铁硼磁性粒子、聚二甲基硅氧烷和隧道磁阻元件组成。钕铁硼颗粒和聚二甲基硅氧烷经过一定比例混合制作出一种高柔性磁性薄膜(钕铁硼-PDMS磁性薄膜),作为磁性电子皮肤的感知部分。当外界施加压力时,磁性皮肤的变形导致颗粒的相对位置发生变化,从而引起磁感应强度的变化。Z轴隧道磁阻元件作为检测部分,磁场的变化会引起其内部磁阻的改变,由电桥电路将电阻的变化转化为电信号进行输出。本发明的电子皮肤具有灵敏度高,柔性高,尺寸小,抗干扰能力强的优点,可以实现对动态和静态力的精确测量。压力为5N时,电压输出达到峰值1601.183mV。传感器0-1N内灵敏度为423mV/N,1-5N内灵敏度为294mV/N,较其他磁性电子皮肤灵敏度明显提高。The purpose of the present invention is to solve the current flexible electronic skin with low sensitivity, poor anti-interference ability, and high requirements for the working environment. Based on the magnetic permeability effect of NdFeB magnetic particles, a magnetic device with high sensitivity, high flexibility, and strong anti-interference ability is proposed. electronic skin. The electronic skin is composed of NdFeB magnetic particles, polydimethylsiloxane and tunnel magnetoresistance elements. NdFeB particles and polydimethylsiloxane are mixed in a certain proportion to produce a highly flexible magnetic film (NdFeB-PDMS magnetic film), which is used as the sensing part of the magnetic electronic skin. When external pressure is applied, the deformation of the magnetic skin causes the relative position of the particles to change, causing a change in the magnetic induction. The Z-axis tunnel magneto-resistance element is used as the detection part, and the change of the magnetic field will cause the change of its internal reluctance, and the bridge circuit converts the change of resistance into an electrical signal for output. The electronic skin of the invention has the advantages of high sensitivity, high flexibility, small size and strong anti-interference ability, and can realize accurate measurement of dynamic and static forces. When the pressure is 5N, the voltage output reaches a peak value of 1601.183mV. The sensitivity of the sensor within 0-1N is 423mV/N, and the sensitivity within 1-5N is 294mV/N, which is significantly higher than other magnetic electronic skins.

本发明的技术方案是:Technical scheme of the present invention is:

一种用于触觉感知的磁性电子皮肤,所述的磁性皮肤包括钕铁硼-PDMS磁性薄膜、PDMS基底、TMR元件、柔性印刷电路板;A magnetic electronic skin for tactile perception, the magnetic skin includes a NdFeB-PDMS magnetic film, a PDMS substrate, a TMR element, and a flexible printed circuit board;

其中,9个TMR元件以3×3阵列分布在柔性印刷电路板上,PDMS基底包覆TMR元件并覆盖在柔性印刷电路板上;PDMS基底上覆盖有钕铁硼-PDMS磁性薄膜;Among them, 9 TMR elements are distributed on the flexible printed circuit board in a 3×3 array, and the PDMS substrate covers the TMR element and covers the flexible printed circuit board; the PDMS substrate is covered with NdFeB-PDMS magnetic film;

所述的磁性电子皮肤包括钕铁硼-PDMS磁性薄膜,PDMS基底,TMR元件;The magnetic electronic skin includes a NdFeB-PDMS magnetic film, a PDMS substrate, and a TMR element;

所述的钕铁硼-PDMS磁性薄膜由钕铁硼颗粒和聚二甲基硅氧烷混合而成,二者质量比例为3:1,厚度为0.4mm~0.6mm;The NdFeB-PDMS magnetic thin film is formed by mixing NdFeB particles and polydimethylsiloxane, the mass ratio of the two is 3:1, and the thickness is 0.4 mm to 0.6 mm;

所述的PDMS基底的厚度为2.8mm~3.2mm;The thickness of the PDMS substrate is 2.8 mm to 3.2 mm;

所述的钕铁硼-PDMS磁性薄膜的制备方法,包括如下步骤:The preparation method of described NdFeB-PDMS magnetic thin film, comprises the steps:

将钕铁硼磁性粒子与PDMS预聚体以3:1的比例混合,放入搅拌机搅拌100~150分钟,得到钕铁硼-PDMS预聚体;在长方体模具中喷涂一层PDMS脱模剂,随后将钕铁硼-PDMS预聚体倒入模具中,在70~90℃氮气环境下固化100~150分钟;之后在110~130℃氮气环境下继续固化50~80分钟;最后在室温下冷却40~70分钟,得到钕铁硼-PDMS柔性薄膜;Mix NdFeB magnetic particles and PDMS prepolymer at a ratio of 3:1, put them into a mixer and stir for 100-150 minutes to obtain NdFeB-PDMS prepolymer; spray a layer of PDMS release agent on the cuboid mold, Then pour the NdFeB-PDMS prepolymer into the mold and cure it in a nitrogen environment at 70-90°C for 100-150 minutes; then continue to cure it in a nitrogen environment at 110-130°C for 50-80 minutes; finally cool it at room temperature 40-70 minutes to obtain NdFeB-PDMS flexible film;

将得到的柔性薄膜放入充磁机中进行充磁,得到钕铁硼-PDMS磁性薄膜;Put the obtained flexible film into a magnetizer for magnetization to obtain NdFeB-PDMS magnetic film;

所述的PDMS预聚体为主剂和助剂混合而成,主剂和固化剂的质量比为15:1;所述的主剂具体为poly(dimethyl-methylvinylsiloxane)预聚物或四硅烷(三甲基甲硅烷氧基);固化剂具体为带乙烯基侧链的预聚物及交联剂poly(dimethyl-methylhydrogenosiloxane)或四甲基四乙烯基环四硅氧烷。The PDMS prepolymer is formed by mixing the main agent and the auxiliary agent, and the mass ratio of the main agent and the curing agent is 15:1; the main agent is specifically poly(dimethyl-methylvinylsiloxane) prepolymer or tetrasilane ( trimethylsilyloxy group); the curing agent is specifically a prepolymer with a vinyl side chain and a crosslinking agent poly(dimethyl-methylhydrogenosiloxane) or tetramethyltetravinylcyclotetrasiloxane.

所述的钕铁硼磁性颗粒的粒径为100~200μm;The particle size of the NdFeB magnetic particles is 100-200 μm;

所述的TMR元件为Z轴磁敏方向,SOT23-5封装,尺寸为3mm×3mm×1.45mm;The TMR element is Z-axis magnetosensitive direction, SOT23-5 package, the size is 3mm×3mm×1.45mm;

所述的高灵敏度磁性电子皮肤中,柔性印刷电路板的基底材质为聚酰亚胺,电路分布在柔性基板上。9个TMR元件以3×3的方式焊接在柔性印刷电路板上;In the high-sensitivity magnetic electronic skin, the base material of the flexible printed circuit board is polyimide, and the circuits are distributed on the flexible substrate. 9 TMR components are soldered on the flexible printed circuit board in a 3×3 manner;

所述的用于触觉感知的磁性电子皮肤的制备方法,包括如下步骤:The preparation method of the magnetic electronic skin for tactile perception comprises the following steps:

将焊接有9个TMR元件的柔性印刷电路板放入长方体模具中,平铺在模具底面;在电路板上倒入PDMS预聚体,在PDMS预聚体上方放入钕铁硼-PDMS磁性薄膜,薄膜周围被模具支撑,与PDMS预聚体顶部保持良好接触。将模具整体放入70~90℃高温氮气环境下进行固化100~150分钟,之后进行40~70分钟的常温冷却,得到完整的磁性电子皮肤;Put the flexible printed circuit board welded with 9 TMR components into the cuboid mold and lay it flat on the bottom of the mold; pour PDMS prepolymer on the circuit board, and put NdFeB-PDMS magnetic film on top of the PDMS prepolymer , the film is supported around the mold and keeps in good contact with the top of the PDMS prepolymer. Put the mold as a whole into a high-temperature nitrogen environment at 70-90°C to cure for 100-150 minutes, and then cool it at room temperature for 40-70 minutes to obtain a complete magnetic electronic skin;

所述的磁性电子皮肤整体长15~50mm,宽10~30mm,高3.4~3.8mm,可根据需求扩大皮肤面积。The overall length of the magnetic electronic skin is 15-50mm, the width is 10-30mm, and the height is 3.4-3.8mm, and the skin area can be enlarged according to the requirement.

本发明的实质性特点为:Substantive features of the present invention are:

该高灵敏度磁性电子皮肤由钕铁硼-PDMS磁性薄膜,PDMS基底,TMR元件,柔性印刷电路板四部分组成,能够完全贴合在机械手指骨内侧或人体皮肤上,可以对不同物体软硬程度,表面形状进行识别判断。电子皮肤基底中的3×3个TMR元件焊接在柔性印刷电路板上。磁化后的钕铁硼-PDMS磁性薄膜受力产生形变,并将受力产生的变形通过磁导效应转化为磁场的变化;TMR元件检测到磁场信号的微弱变化,经隧道磁阻效应转化为磁阻值的变化,再经电桥电路转化为电信号进行输出;钕铁硼-PDMS磁性薄膜用于感知外界力的变化并提供稳定的偏置磁场,使TMR元件始终处于线性工作区间;PDMS柔性基底用于固定钕铁硼-PDMS磁性薄膜与TMR元件的相对位置,对施加的力起到缓冲作用并对整个电子皮肤起到保护作用;将磁性电子皮肤安装在三指机械手上对不同硬度,不同形状的物体进行抓取,采集到的信号经动态信号采集卡接收并输出到电脑端屏幕上进行数据可视化处理,通过对比输出电压的形状可以对不同物体的硬度情况和形状大小进行区分。The high-sensitivity magnetic electronic skin is composed of NdFeB-PDMS magnetic film, PDMS substrate, TMR element, and flexible printed circuit board. It can be completely attached to the inside of the mechanical finger bone or human skin, and can be used for different objects. , the surface shape is recognized and judged. 3×3 TMR elements in the electronic skin substrate are soldered on a flexible printed circuit board. The magnetized NdFeB-PDMS magnetic film is deformed by force, and the deformation generated by the force is converted into a change of the magnetic field through the permeance effect; the weak change of the magnetic field signal is detected by the TMR element, which is converted into a magnetic field by the tunnel magnetoresistance effect. The change of the resistance value is converted into an electrical signal by the bridge circuit for output; NdFeB-PDMS magnetic film is used to sense the change of external force and provide a stable bias magnetic field, so that the TMR element is always in the linear working range; PDMS flexible The substrate is used to fix the relative position of the NdFeB-PDMS magnetic film and the TMR element, buffer the applied force and protect the entire electronic skin; the magnetic electronic skin is installed on the three-finger manipulator for different hardness, Objects of different shapes are grasped, and the collected signals are received by the dynamic signal acquisition card and output to the computer screen for data visualization processing. By comparing the shape of the output voltage, the hardness and shape of different objects can be distinguished.

本发明的有益效果为:The beneficial effects of the present invention are:

1、利用磁性能高,比重轻,形状自由度大的钕铁硼磁性颗粒和柔性强的聚二甲基硅氧烷所制作的磁性薄膜作为感知部分,选用高灵敏度TMR元件作为检测部分,形成磁性电子皮肤,实现对触觉的精确感知。图4为垂直施加在电子皮肤上的压力F与输出电压U的对应关系,当施加的压力在0-1N时,磁性电子皮肤的输出电压峰值为423.941mV,当压力达到5N时,输出电压峰值为1601.183mV,较现有磁性电子皮肤灵敏度大幅提高。图5可以看出该电子皮肤实际输出值和理论值基本一致,该电子皮肤可以满足机械手进行高精度任务时的需求。1. Using NdFeB magnetic particles with high magnetic properties, light specific gravity, and large degree of freedom in shape and magnetic film made of flexible polydimethylsiloxane as the sensing part, and using high-sensitivity TMR elements as the detection part to form Magnetic electronic skin realizes precise perception of touch. Figure 4 shows the corresponding relationship between the pressure F applied vertically on the electronic skin and the output voltage U. When the applied pressure is 0-1N, the peak value of the output voltage of the magnetic electronic skin is 423.941mV. When the pressure reaches 5N, the peak value of the output voltage is It is 1601.183mV, and the sensitivity is greatly improved compared with the existing magnetic electronic skin. It can be seen from Figure 5 that the actual output value of the electronic skin is basically consistent with the theoretical value, and the electronic skin can meet the needs of the manipulator for high-precision tasks.

2、将9个TMR元件以3×3的方式焊接在柔性印刷电路板上,TMR元件和柔性印刷电路板覆盖在PDMS之下,增加了电子皮肤整体的柔性,将其安装在三指机械手内侧可完全贴敷在指骨表面,弯曲度最大可达120°,提高了机械手的灵活性和精确性。将其贴敷在皮肤表面可以紧密贴合人体皮肤,随皮肤进行弯曲变形,具有良好的柔韧性。2.

3、电子皮肤的高柔性和高灵敏度特性可以使其在与不同形状,不同硬度的物体接触时完美贴合并进行更精确的区分。图7抓取实验的结果显示,将电子皮肤安装在三指机械手上对硬度不同的两个圆柱体(邵氏硬度差为10度)进行抓取实验时,电子皮肤中4~6TMR的平均输出分别为708.29mV和760.11mV,可以精确区分不同物体的硬度,为机械手提供准确的触觉感知信息。3. The high flexibility and high sensitivity of the electronic skin can make it perfectly fit and distinguish more accurately when it comes into contact with objects of different shapes and hardness. The results of the grasping experiment in Figure 7 show that when the electronic skin is installed on a three-fingered manipulator to perform grasping experiments on two cylinders with different hardness (Shore hardness difference is 10 degrees), the average output of the electronic skin is 4-6TMR They are 708.29mV and 760.11mV respectively, which can accurately distinguish the hardness of different objects and provide accurate tactile perception information for the manipulator.

4、TMR元件采用自由覆盖组装。PDMS直接在TMR周围固化,在起到保护缓冲作用的同时将TMR位置固定在最适工作磁场强度的位置,提高电子皮肤的灵敏度,更有效传递信息。4. TMR components are assembled by free covering. PDMS is directly cured around the TMR, which can fix the position of the TMR at the position of the optimum working magnetic field strength while playing a protective buffer role, improving the sensitivity of the electronic skin and transmitting information more effectively.

5、电子皮肤的PDMS柔性基底采用浇筑固化方式形成,缩小TMR与磁性薄膜间距的同时使TMR工作在最适磁场,并为磁性薄膜的变形留有充足的空间,电子皮肤的受力提高至5N,减小了皮肤整体的空间。5. The PDMS flexible substrate of the electronic skin is formed by pouring and curing. While reducing the distance between the TMR and the magnetic film, the TMR works in the most suitable magnetic field, and there is enough space for the deformation of the magnetic film. The force of the electronic skin is increased to 5N , reducing the overall space of the skin.

6、将电子皮肤的磁性薄膜和PDMS柔性基底集成到焊接有TMR的柔性印刷电路板上,出线端在TMR双引脚的方向上,减少输出的干扰性并提高电路板的效率,便于安装到机械手上。6. Integrate the magnetic film of the electronic skin and the PDMS flexible substrate into the flexible printed circuit board welded with TMR, and the outlet end is in the direction of the TMR double pins, which reduces the interference of the output and improves the efficiency of the circuit board, which is easy to install on On the manipulator.

附图说明Description of drawings

图1是磁性电子皮肤的各部分拆分示意图;Figure 1 is a schematic diagram of the disassembly of each part of the magnetic electronic skin;

图2是磁性电子皮肤的整体组装图;Figure 2 is the overall assembly diagram of the magnetic electronic skin;

图3是磁性电子皮肤的柔性印刷电路板电路图;Fig. 3 is the circuit diagram of the flexible printed circuit board of magnetic electronic skin;

图4是磁性电子皮肤的静态力灵敏度曲线图;Fig. 4 is a static force sensitivity curve diagram of the magnetic electronic skin;

图5是磁性电子皮肤输出电压的实验值与计算值曲线图;Fig. 5 is a curve diagram of the experimental value and the calculated value of the output voltage of the magnetic electronic skin;

图6是将电子皮肤集成到三指机械手上分别抓取材质相同,形状不同的物体时的输出电压示意图,(a)为抓取长宽高为40mm×40mm×52mm的长方体时输出电压,(b)为抓取直径40mm,高52mm的圆柱体时输出电压,材质均为木制;Figure 6 is a schematic diagram of the output voltage when the electronic skin is integrated into the three-finger manipulator to grab objects with the same material and different shapes, (a) is the output voltage when grabbing a cuboid with a length, width and height of 40mm×40mm×52mm, ( b) Output voltage when grabbing a cylinder with a diameter of 40mm and a height of 52mm, and the material is all wood;

图7是配备电子皮肤的三指机械手抓取邵氏硬度差为10度的两个橡胶圆柱体时的输出电压示意图,其中圆柱体底面直径40mm,高52mm。Figure 7 is a schematic diagram of the output voltage when a three-finger manipulator equipped with an electronic skin grabs two rubber cylinders with a Shore hardness difference of 10 degrees, where the diameter of the bottom surface of the cylinder is 40mm and the height is 52mm.

图8为磁性薄膜磁极分布图;Fig. 8 is a distribution diagram of the magnetic poles of the magnetic film;

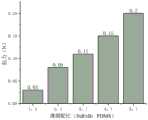

图9为磁性薄膜不同配比与拉力的对应关系。Fig. 9 is the corresponding relationship between different proportions of the magnetic film and the pulling force.

具体实施方式Detailed ways

本发明基于钕铁硼磁性颗粒的磁导效应与TMR元件的隧道磁阻效应设计出的电子皮肤由钕铁硼-PDMS磁性薄膜、PDMS柔性基底、TMR元件、柔性印刷电路板构成,能够对不同大小、不同方向的静态以及动态力进行精确感知,对不同物体的形状、硬度进行准确区分;多极磁化后的钕铁硼-PDMS薄膜用于提供稳定磁场并感知信息。对磁化薄膜施加压力时,薄膜发生形变,内部磁畴分布发生变化,进而改变周围的磁场分布。下方的TMR感受到磁场的微弱变化,经过隧道磁阻效应把磁场信号转化为内部磁阻值的变化,再经由电桥电路转化为电压值进行输出。输出后的电压值经动态信号采集卡进行采集,采集的信号经电脑端进行数据可视化处理。9个TMR元件以3×3的方式焊接在柔性印刷电路板表面,TMR阵列整体覆盖在PDMS内部。将电子皮肤整体安装在三指机械手指尖内侧用于检测抓取物体时指尖受力情况并判断所抓取物体物理属性。高灵敏度特性使机械手可以快速准确感受力的变化情况,高柔性特点使机械手抓取物体时可以完全贴敷物体表面进行信息识别,体积小的特点使机械手抓取时不受阻碍,还原机械手本身的灵活性。The electronic skin designed based on the permeance effect of NdFeB magnetic particles and the tunnel magnetoresistance effect of TMR elements is composed of NdFeB-PDMS magnetic film, PDMS flexible substrate, TMR element, and flexible printed circuit board, which can be used for different The size, static and dynamic forces in different directions can be accurately sensed, and the shape and hardness of different objects can be accurately distinguished; the multi-pole magnetized NdFeB-PDMS film is used to provide a stable magnetic field and sense information. When pressure is applied to the magnetized film, the film deforms, and the distribution of internal magnetic domains changes, which in turn changes the distribution of the surrounding magnetic field. The TMR below feels the weak change of the magnetic field, and converts the magnetic field signal into the change of the internal magnetoresistance value through the tunnel magnetoresistance effect, and then converts it into a voltage value through the bridge circuit for output. The output voltage value is collected by the dynamic signal acquisition card, and the collected signal is processed by the computer terminal for data visualization. Nine TMR elements are welded on the surface of the flexible printed circuit board in a 3×3 manner, and the TMR array is entirely covered inside the PDMS. The electronic skin is installed on the inside of the tip of the three-finger robot as a whole to detect the force on the fingertip when grasping the object and judge the physical properties of the grasped object. The high-sensitivity feature enables the manipulator to quickly and accurately feel the change of force. The high flexibility feature enables the manipulator to completely attach the surface of the object for information recognition when grabbing the object. The small size makes the manipulator unhindered when grasping, restoring the originality of the manipulator itself. flexibility.

本实施例的高灵敏度电子皮肤由1个薄膜感知部分和9个TMR检测部分组成。感知部分为长30mm,宽20mm,高0.5mm的钕铁硼(Nd2Fe14B)-PDMS磁性薄膜,检测部分为Z轴磁敏方向的TMR2503元件,封装形式为SOT23-5,尺寸3mm×3mm×1.45mm。钕铁硼-PDMS磁性薄膜与TMR元件均为水平放置,平行于柔性印刷电路板,各个TMR元件与磁性薄膜的间隔均相同。TMR元件间间隔均相同,长方向间距7mm,宽方向间距2.5mm,9个TMR均完全覆盖在PDMS柔性基底中。当外力施加在磁性薄膜表面时,薄膜受力产生形变,内部磁畴随之变化,进而引起磁场强度的变化,经由TMR元件将周围磁场强度的变化转化为电压信号,从而精确感知力的大小。实验结果表明,薄膜所受总压力为1N时,电子皮肤各TMR输出电压平均值为423.941mV,灵敏度为423mV/N,所受压力为5N时,各TMR输出电压平均值为1601.183mV,在1-5N内的灵敏度为294mV/N,能够为机械手提供精确触觉感知。将9个TMR传感单元以3×3的方式焊接在柔性印刷电路板表面,TMR与电路板之间形成电气连接,覆盖在浇筑的PDMS柔性基底内形成高灵敏度磁性电子皮肤。The high-sensitivity electronic skin of this embodiment is composed of 1 film sensing part and 9 TMR detecting parts. The sensing part is a NdFeB (Nd2 Fe14 B)-PDMS magnetic film with a length of 30mm, a width of 20mm, and a height of 0.5mm. The detection part is a TMR2503 element in the Z-axis magnetosensitive direction. The package is SOT23-5, and the size is 3mm× 3mm×1.45mm. Both the NdFeB-PDMS magnetic film and the TMR element are placed horizontally, parallel to the flexible printed circuit board, and the intervals between each TMR element and the magnetic film are the same. The spacing between the TMR elements is the same, the spacing in the long direction is 7 mm, and the spacing in the width direction is 2.5 mm. The nine TMRs are completely covered in the PDMS flexible substrate. When an external force is applied to the surface of the magnetic film, the film is deformed by the force, and the internal magnetic domain changes accordingly, which in turn causes a change in the magnetic field strength. The change in the surrounding magnetic field strength is converted into a voltage signal through the TMR element, thereby accurately sensing the magnitude of the force. The experimental results show that when the total pressure on the film is 1N, the average output voltage of each TMR of the electronic skin is 423.941mV, and the sensitivity is 423mV/N. When the pressure is 5N, the average output voltage of each TMR is 1601.183mV. The sensitivity within -5N is 294mV/N, which can provide precise tactile perception for the manipulator. Nine TMR sensing units are welded on the surface of the flexible printed circuit board in a 3×3 manner, an electrical connection is formed between the TMR and the circuit board, and a high-sensitivity magnetic electronic skin is formed by covering in the poured PDMS flexible substrate.

以下结合图对发明做进一步详述。本实施例仅为对发明的具体说明,不视为对保护范围的限定。The invention is described in further detail below in conjunction with the drawings. This embodiment is only a specific description of the invention and is not considered as limiting the scope of protection.

实施例1Example 1

本发明所述的磁性电子皮肤结构如图1所示,由钕铁硼-PDMS磁性薄膜1、PDMS基底2、TMR元件3、柔性印刷电路板4构成;The structure of the magnetic electronic skin according to the present invention is shown in Figure 1, which is composed of NdFeB-PDMS

其位置关系如图2,9个TMR元件以3×3阵列分布在柔性印刷电路板4上,PDMS基底2包覆TMR元件并覆盖在柔性印刷电路板4上;PDMS基底2上覆盖有钕铁硼-PDMS磁性薄膜1;The positional relationship is shown in Figure 2. Nine TMR elements are distributed on the flexible printed

所述的PDMS柔性基底由PDMS主剂和固化剂以15:1混合制作而成,为长方体,长30mm,宽20mm,厚3mm,下方固定有3×3个TMR元件;The PDMS flexible substrate is made by mixing PDMS main agent and curing agent at a ratio of 15:1, and is a cuboid with a length of 30 mm, a width of 20 mm, and a thickness of 3 mm, with 3×3 TMR elements fixed underneath;

所述的钕铁硼-PDMS磁性薄膜由钕铁硼与PDMS以3:1的比例混合而成(PDMS由PDMS主剂和固化剂以15:1比例混合而成),经多极磁化可以产生9对N、S极,分别对应9个TMR元件的位置;The NdFeB-PDMS magnetic film is made by mixing NdFeB and PDMS in a ratio of 3:1 (PDMS is made by mixing PDMS main agent and curing agent in a ratio of 15:1), and can be produced by multi-pole magnetization. 9 pairs of N and S poles, corresponding to the positions of 9 TMR elements;

所述的PDMS基底边缘与柔性印刷电路板平齐,钕铁硼-PDMS磁性薄膜置于PDMS柔性基底上方正中心,在垂直方向的投影完全覆盖3×3个TMR元件;The edge of the PDMS substrate is flush with the flexible printed circuit board, and the NdFeB-PDMS magnetic film is placed in the center above the PDMS flexible substrate, and the projection in the vertical direction completely covers 3×3 TMR elements;

所述的完整电子皮肤如图2所示,长30mm,宽20mm,高3.6mm,施加5N的压力时,电子皮肤的磁性薄膜向下发生变形,下降距离为1.0mm,撤去压力后可以迅速恢复原状,在有效测力范围内薄膜不会触碰内部TMR元件;The complete electronic skin is shown in Figure 2, with a length of 30mm, a width of 20mm, and a height of 3.6mm. When a pressure of 5N is applied, the magnetic film of the electronic skin deforms downward with a drop distance of 1.0mm, and it can recover quickly after the pressure is removed. In the original state, the film will not touch the internal TMR element within the effective force measurement range;

经过测试得知,磁性电子皮肤各位置的灵敏度一致;After testing, it is found that the sensitivity of each position of the magnetic electronic skin is consistent;

所述的TMR元件长3mm,宽3mm,高1.45mm,完全覆盖在PDMS柔性基底内部;The TMR element is 3mm long, 3mm wide, and 1.45mm high, and is completely covered inside the PDMS flexible substrate;

所述的柔性印刷电路板基底材质为聚酰亚胺,电路分布在基底上;TMR元件以3×3的方式排布在电路板表面,X方向上间隔为7mm,Y方向上间隔为2.5mm;柔性印刷电路板平面尺寸为30mm×20mm,可以完整贴敷在Robotiq三指机械手指尖部分;The base material of the flexible printed circuit board is polyimide, and the circuit is distributed on the base; the TMR elements are arranged on the surface of the circuit board in a 3×3 manner, with an interval of 7 mm in the X direction and 2.5 mm in the Y direction ;The plane size of the flexible printed circuit board is 30mm×20mm, which can be completely pasted on the tip of the Robotiq three-finger manipulator;

所述的柔性印刷电路板如图3所示,U1~U9表示9个TMR元件的焊接位置,V1+~V9+代表9个TMR的V+端,V1-~V9-代表9个TMR的V-端;5、9、14、6、18、23、7、8、12分别对应9个TMR的V1-~V9-出线端;15、20、24、16、11、13、17、21、22分别对应9个TMR的V1+~V9+出线端;19为VCC端,10为GND端;25~40为过孔;以U1为例,41为U1的V1-端,42为U1的GND端,43为U1的VCC端,44为U1的空脚,45为U1的V+端;The flexible printed circuit board is shown in Figure 3, U1-U9 represent the welding positions of the nine TMR components, V1+-V9+ represent the V+ terminals of the nine TMRs, and V1-~V9- represent the V- terminals of the nine TMRs; 5, 9, 14, 6, 18, 23, 7, 8, and 12 respectively correspond to the V1-~V9-outlet terminals of 9 TMRs; 15, 20, 24, 16, 11, 13, 17, 21, and 22 respectively correspond to V1+~V9+ outlet terminals of 9 TMRs; 19 is VCC terminal, 10 is GND terminal; 25~40 are via holes; taking U1 as an example, 41 is the V1- terminal of U1, 42 is the GND terminal of U1, and 43 is U1 44 is the empty pin of U1, and 45 is the V+ terminal of U1;

所述的柔性印刷电路板中,底板上侧设置一列1×20的输出;各个传感器之间的电气连接方式为并联。10和19输出端与直流电源相连,用于给电路供电;V1+~V9+,V1-~V9-端与数据采集卡相连,用于采集不同压力下的输出电压信号。In the flexible printed circuit board, a column of 1×20 outputs is arranged on the upper side of the base plate; the electrical connection mode between the sensors is parallel connection. The output terminals 10 and 19 are connected to the DC power supply for supplying power to the circuit; V1+~V9+, V1-~V9- terminals are connected to the data acquisition card for collecting output voltage signals under different pressures.

每个TMR元件位置下方各设置一组焊盘,分别为VCC端焊盘,GND端焊盘,空脚焊盘,V+焊盘,V-焊盘;9个TMR组成的阵列中,每个VCC端焊盘串联,GND端焊盘串联。A group of pads are set under each TMR component position, which are VCC terminal pads, GND terminal pads, empty pads, V+ pads, and V- pads; in an array composed of 9 TMRs, each VCC The terminal pads are connected in series, and the GND terminal pads are connected in series.

所述的钕铁硼-PDMS磁性薄膜由钕铁硼颗粒和聚二甲基硅氧烷混合而成,长30mm,宽20mm,高0.5mm。钕铁硼磁性颗粒经雾化后,粉末粒径大小在150um左右,保证粉末晶体结构完好。PDMS由主剂和固化剂以15:1比例混合而成。将钕铁硼磁性粒子与PDMS预聚体以3:1的比例混合,放入搅拌机搅拌120分钟,使钕铁硼颗粒分布均匀并保证PDMS主剂与固化剂充分接触,制备钕铁硼-PDMS预聚体。在长方体模具中喷涂一层PDMS脱模剂,使其表面形成一层微米级别的半永久性薄膜。将钕铁硼-PDMS预聚体倒入模具中,在80℃氮气环境下固化120分钟,进行初步固化;之后在120℃氮气环境下继续固化60分钟,用以完全去除复合薄膜中的气泡;最后在25℃条件下冷却60分钟,使薄膜完全固化,得到钕铁硼-PDMS柔性薄膜。将得到的柔性薄膜放入充磁机中进行充磁,为使薄膜可以进行解耦,对薄膜进行多极充磁,得到钕铁硼-PDMS磁性薄膜。薄膜充磁完成后的磁极分布如图8所示,每个小长方体磁极大小均在8~10mm×5~7mm×0.2~0.3mm之间。所述的充磁为公知技术,也可以通过商业委托进行。The NdFeB-PDMS magnetic thin film is formed by mixing NdFeB particles and polydimethylsiloxane, with a length of 30mm, a width of 20mm and a height of 0.5mm. After the NdFeB magnetic particles are atomized, the powder particle size is about 150um, which ensures that the powder crystal structure is intact. PDMS is made by mixing the main agent and curing agent at a ratio of 15:1. Mix the NdFeB magnetic particles and the PDMS prepolymer at a ratio of 3:1, put them in a mixer and stir for 120 minutes, so that the NdFeB particles are evenly distributed and ensure that the PDMS main agent and the curing agent are fully contacted to prepare NdFeB-PDMS prepolymer. Spray a layer of PDMS release agent in the cuboid mold to form a micron-scale semi-permanent film on its surface. Pour the NdFeB-PDMS prepolymer into the mold, and cure it under 80°C nitrogen environment for 120 minutes for preliminary curing; then continue curing under 120°C nitrogen environment for 60 minutes to completely remove the air bubbles in the composite film; Finally, it was cooled at 25° C. for 60 minutes to completely solidify the film to obtain a flexible NdFeB-PDMS film. Put the obtained flexible film into a magnetizer for magnetization, in order to decouple the film, perform multi-pole magnetization on the film to obtain NdFeB-PDMS magnetic film. The magnetic pole distribution after the film magnetization is completed is shown in Figure 8, and the size of each small cuboid magnetic pole is between 8-10mm×5-7mm×0.2-0.3mm. The described magnetization is a known technology, and can also be carried out through commercial entrustment.

所述的TMR元件为Z轴磁敏方向,SOT23-5封装,尺寸为3mm×3mm×1.45mm;The TMR element is Z-axis magnetosensitive direction, SOT23-5 package, the size is 3mm×3mm×1.45mm;

实施例2-5Example 2-5

其他步骤同实施例1,不同之处为,磁性薄膜制备中,钕铁硼和PDMS的比例由3:1改为1:1、2:1、4:1;5:1;都用径向充磁方式;Other steps are the same as in Example 1, the difference is that in the preparation of the magnetic film, the ratio of NdFeB and PDMS is changed from 3:1 to 1:1, 2:1, 4:1; 5:1; all use radial Magnetization method;

发现1:1时充磁效果不佳,磁场不高;配比不同时,将磁性薄膜放在钢铁表面,对其施加拉力,配比与拉力之间的对应关系如图9所示;而5:1时薄膜又不够柔软,柔性不高;所以确定为3:1较佳。It is found that the magnetization effect is not good and the magnetic field is not high when the ratio is 1:1; when the ratio is different, the magnetic film is placed on the steel surface and a pulling force is applied to it. The corresponding relationship between the ratio and the pulling force is shown in Figure 9; and 5 : 1, the film is not soft enough, and the flexibility is not high; so it is determined to be 3: 1 is better.

实施例6、7Example 6, 7

其他步骤同实施例1,磁性薄膜充磁方式由径向充磁改为轴向多极充磁、正弦充磁;Other steps are the same as in Example 1, and the magnetization method of the magnetic film is changed from radial magnetization to axial multi-pole magnetization and sinusoidal magnetization;

将实施例1、实施例6、实施例7中得到的三种薄膜放在钢铁表面进行拉力测试,测试设备为推拉力计,钢铁固定在推拉力计正下方,磁性薄膜吸附在钢铁表面,推拉力计粘接磁性薄膜,利用推拉力计缓慢对薄膜施加拉力,结果显示轴向多级充磁的方式拉力相较其他两种更大,证明在薄膜周围产生磁场更强,所以确定比例为3:1,充磁方式为轴向多极充磁较佳。Put the three kinds of films obtained in Example 1, Example 6, and Example 7 on the steel surface for tensile testing. The testing equipment is a push-pull gauge. The steel is fixed directly below the push-pull gauge. The magnetic film is adsorbed on the steel surface. The force gauge is bonded to the magnetic film, and the push-pull force gauge is used to slowly apply tension to the film. The results show that the axial multi-stage magnetization method has a greater pulling force than the other two methods, which proves that the magnetic field generated around the film is stronger, so the ratio is determined to be 3 : 1, the magnetization method is better for axial multi-pole magnetization.

实施例8-13Example 8-13

其他步骤同实施例1,PDMS配比由15:1改为10:1,12:1,14:1,16:1,18:1,20:1;Other steps are the same as in Example 1, and the ratio of PDMS is changed from 15:1 to 10:1, 12:1, 14:1, 16:1, 18:1, 20:1;

发现配比太低PDMS固化后硬度高,比例太高PDMS不易固化,且固化后表面粘性大,多次施加力后易破裂,所以确定为15:1较佳。It is found that the hardness of PDMS is high after curing if the ratio is too low, and PDMS is not easy to cure if the ratio is too high, and the surface is viscous after curing, and it is easy to break after multiple application of force, so it is determined that 15:1 is better.

实施例14-17Examples 14-17

其他步骤同实施例1,PDMS高度由3mm改为2.6mm,2.8mm,3.2mm,3.4mm;Other steps are the same as in Example 1, the height of PDMS is changed from 3mm to 2.6mm, 2.8mm, 3.2mm, 3.4mm;

发现在3mm时TMR输出效果最明显,更贴近理论值。It is found that the TMR output effect is the most obvious at 3mm, which is closer to the theoretical value.

测试例1:以TMR元件作为检测部分,测试长30mm,宽20mm的磁性薄膜在0-5N范围内的压力与输出电压的关系。本实施例的主要目的是研究电子皮肤的输入输出对应关系和对压力的灵敏度。Test example 1: TMR element is used as the detection part to test the relationship between the pressure and the output voltage of a magnetic film with a length of 30mm and a width of 20mm in the range of 0-5N. The main purpose of this embodiment is to study the input-output correspondence and the sensitivity to pressure of the electronic skin.

实验平台搭建:按照图1和图2所示将电子皮肤组装完成;实验平台由数显式推拉力计,可调节压力机,DH-8303动态数据采集卡,直流稳压电源,计算机组成;将电子皮肤固定在数显式推拉力计正下方的底座上,调节压力机的转动轴,使推拉力计的触点正对电子皮肤的中心;设置推拉力计的模式使其能够对电子皮肤施加动态力和静态力;直流稳压电源为电子皮肤中的TMR元件提供稳定工作电压,9对V+和V-分别对应动态数据采集卡的9个通道,电子皮肤的输出电压经采集卡采集后在电脑端进行显示。Construction of the experimental platform: As shown in Figure 1 and Figure 2, the electronic skin is assembled; the experimental platform is composed of a digital push-pull force gauge, an adjustable press, a DH-8303 dynamic data acquisition card, a DC regulated power supply, and a computer; The electronic skin is fixed on the base directly below the digital push-pull force gauge, and the rotation axis of the press is adjusted so that the contact point of the push-pull force gauge is facing the center of the electronic skin; the mode of the push-pull force gauge is set so that it can exert pressure on the electronic skin Dynamic force and static force; the DC regulated power supply provides a stable working voltage for the TMR components in the electronic skin. The 9 pairs of V+ and V- correspond to the 9 channels of the dynamic data acquisition card respectively. displayed on the computer.

实验过程与结果:利用数显式推拉力计对电子皮肤逐渐施加0-5N的力,间隔为0.5N。推拉力计触点挤压电子皮肤的薄膜部分使其变形,变形后的薄膜内部磁畴排列方式发生变化,其产生的磁场随之改变。下方的TMR元件检测到磁场强度的微弱变化,内部磁阻发生改变,经电桥电路后输出电压信号。在0-5N内,每隔0.5N的间隔对电子皮肤施加压力的输出电压图如图4所示,图示表明撤去施加的外力后,电子皮肤可以迅速恢复到原状,具有良好的耐用性和稳定性。测力分辨率为0.05N,当压力为1N时,输出电压的最大值为423.941mV,灵敏度为423mV/N;当压力为5N时,输出电压达到最大值,为1601.183mV,在1-5N内的灵敏度为294mV/N;该电子皮肤的灵敏度和灵活性明显高于目前的磁性薄膜传感器,具有优良的特性;如图5所示为电子皮肤的受力实验值与理论值的对比,可以看出实验值与理论值基本相符,误差在3%以内。Experimental process and results: Use a digital push-pull force gauge to gradually apply a force of 0-5N to the electronic skin with an interval of 0.5N. The contact of the push-pull force gauge squeezes the film part of the electronic skin to deform it, and the arrangement of the magnetic domains inside the deformed film changes, and the magnetic field generated by it changes accordingly. The TMR element below detects the weak change of the magnetic field strength, the internal magnetic resistance changes, and the voltage signal is output after passing through the bridge circuit. Within 0-5N, the output voltage diagram of applying pressure to the electronic skin at intervals of 0.5N is shown in Figure 4. The diagram shows that after the external force is removed, the electronic skin can quickly return to its original state, and it has good durability and stability. The force measurement resolution is 0.05N. When the pressure is 1N, the maximum output voltage is 423.941mV, and the sensitivity is 423mV/N; when the pressure is 5N, the output voltage reaches the maximum value, which is 1601.183mV, within 1-5N The sensitivity of the electronic skin is 294mV/N; the sensitivity and flexibility of the electronic skin are significantly higher than the current magnetic film sensor, and it has excellent characteristics; as shown in Figure 5, the comparison between the experimental value and the theoretical value of the electronic skin can be seen The experimental value is basically consistent with the theoretical value, and the error is within 3%.

本发明涉及的软件或协议均为公知技术。The software or protocols involved in the present invention are all known technologies.

测试例2:将高灵敏度磁性电子皮肤安装在Robotiq三指机械手的指尖内侧(三个指尖各安装一块电子皮肤),电子皮肤可以严密贴敷在机械手指尖,三指机械手与Universal Robots UR5e六轴机械臂相连,机械手配备有操控台。利用计算机计算出抓取力度,速度和抓取位移,使在抓取过程中保持一致,对形状不同的木制长方体(40mm×40mm×52mm)和木制圆柱体(底面直径40mm,高52mm)进行抓取以及对邵氏硬度差为10度的两个橡胶圆柱体(底面直径40mm,高52mm)进行抓取。Test example 2: Install the high-sensitivity magnetic electronic skin on the inside of the fingertip of the Robotiq three-finger manipulator (one electronic skin is installed on each of the three fingertips). The electronic skin can be tightly attached to the tip of the robot finger. The six-axis robotic arm is connected, and the manipulator is equipped with a console. Use the computer to calculate the grasping force, speed and grasping displacement, so that they are consistent during the grasping process. For different shapes of wooden cuboids (40mm×40mm×52mm) and wooden cylinders (bottom diameter 40mm, height 52mm) Grasping and gripping were performed on two rubber cylinders (diameter of

实验过程与结果:调整三指接机械手的抓取角度和抓取位置,使指尖的电子皮肤可以完全贴敷在被抓物体表面,保证各TMR均有输出。图6(a)为抓取木制长方体时各TMR的输出电压,范围在516.74mV~534.03mV之间,平均输出电压为526.30mV,误差允许范围内可认定各TMR元件输出电压相等;图6(b)为抓取木制圆柱体时各TMR的输出电压,1~3和7~9TMR元件输出电压范围在356.83mV~369.15mV之间,平均输出电压为364.04mV,4~6TMR元件输出在730.95mV~740.28mV之间,平均输出电压为737.03mV;误差允许范围内可认为1~3与7~9TMR元件输出电压相等,4~6TMR元件输出电压相等;通过分析各TMR元件输出电压大小并进行对比可以初步判断抓取物体的表面形状,图6(b)中4~6TMR元件与其余6个TMR元件输出差距越大,表示所抓取圆柱体的表面曲率越大;图7(a)为抓取橡胶圆柱体时各TMR元件输出电压,1~3和7~9TMR元件输出电压在303.21mV~319.15mV之间,平均输出电压为312.85mV,4~6TMR元件输出电压在700.67mV~715.33mV之间,平均输出电压为708.30mV;图7(b)为抓取较(a)所示圆柱体邵氏硬度高10度的橡胶圆柱体时各TMR的输出电压,1~3和7~9TMR元件的输出电压范围为350.29mV~368.61mV之间,平均输出电压为359.73mV,4~6TMR元件输出电压在752.75mV~767.31mV之间,平均输出电压为760.11mV;误差允许范围内可认为1~3与7~9TMR元件输出电压相等,4~6TMR元件输出电压相等;分析输出可知当机械手抓取硬度不同的物体时,该电子皮肤可以精确识别硬度大小,输出电压越高表示所抓取物体的硬度越大,同时发挥了该电子皮肤灵敏度高的优势。Experimental process and results: Adjust the grasping angle and position of the three-finger joint manipulator so that the electronic skin on the fingertips can be completely attached to the surface of the grasped object, ensuring that each TMR has an output. Figure 6(a) shows the output voltage of each TMR when grabbing a wooden cuboid. The range is between 516.74mV and 534.03mV, and the average output voltage is 526.30mV. It can be determined that the output voltage of each TMR element is equal within the allowable range of error; Figure 6 (b) is the output voltage of each TMR when grabbing a wooden cylinder. The output voltage range of 1~3 and 7~9TMR elements is between 356.83mV~369.15mV, the average output voltage is 364.04mV, and the output of 4~6TMR elements is at Between 730.95mV and 740.28mV, the average output voltage is 737.03mV; within the allowable range of error, it can be considered that the output voltages of 1~3 and 7~9TMR components are equal, and the output voltages of 4~6TMR components are equal; by analyzing the output voltage of each TMR component and The comparison can preliminarily judge the surface shape of the grasped object. In Figure 6(b), the greater the output gap between the 4-6 TMR elements and the other 6 TMR elements, the greater the surface curvature of the grasped cylinder; Figure 7(a) To grasp the output voltage of each TMR element when grabbing the rubber cylinder, the output voltage of 1~3 and 7~9TMR elements is between 303.21mV~319.15mV, the average output voltage is 312.85mV, and the output voltage of 4~6TMR elements is 700.67mV~715.33 Between mV, the average output voltage is 708.30mV; Figure 7(b) is the output voltage of each TMR when grabbing a rubber cylinder with a Shore hardness 10 degrees higher than that of the cylinder shown in (a), 1~3 and 7~ The output voltage range of 9TMR components is between 350.29mV~368.61mV, the average output voltage is 359.73mV, the output voltage of 4~6TMR components is between 752.75mV~767.31mV, the average output voltage is 760.11mV; the error can be considered within the allowable range The output voltages of 1~3 and 7~9TMR elements are equal, and the output voltages of 4~6TMR elements are equal; the analysis of the output shows that when the manipulator grabs objects with different hardness, the electronic skin can accurately identify the hardness, and the higher the output voltage, the better the grip. The harder the object, the higher the sensitivity of the electronic skin.

本发明提出一种由钕铁硼、PDMS、隧道磁阻元件(TMR)组成的磁性电子皮肤。钕铁硼和PDMS以3:1的比例混合制作而成磁性薄膜(其中PDMS的制作方法为主剂:固化剂=15:1,具有比一般的主剂:固化剂=10:1的比例更加柔软的特性),磁性薄膜经轴向多极磁化使其正反面存在极性相反的磁场,极大的增加了薄膜的磁场强度,尤其在边缘部分距离底面较近的距离时比单面多级磁化具有更高的磁场强度;中间PDMS缓冲层同样按照主剂:固化剂=15:1的比例进行调制,使磁性皮肤的灵敏度更高;利用隧道磁阻元件(TMR)作为检测部分,TMR作为一种新型磁传感器,具有成本低、精度高、灵敏度高、功耗低、温度稳定性好、工作温度范围宽等优点,结合磁性薄膜和TMR高精度优点,设计了用于触觉感知的高柔性、高灵敏度的磁性电子皮肤,在智能机械手人机交互领域具有广阔应用前景。The invention proposes a magnetic electronic skin composed of NdFeB, PDMS and tunnel magnetoresistance (TMR). NdFeB and PDMS are mixed in a ratio of 3:1 to form a magnetic film (the production method of PDMS is the main agent: curing agent = 15: 1, which is more effective than the general main agent: curing agent = 10: 1). Soft characteristics), the magnetic film is magnetized by axial multi-pole so that there are magnetic fields with opposite polarities on the front and back, which greatly increases the magnetic field strength of the film, especially when the edge part is closer to the bottom surface than the single-sided multi-level The magnetization has a higher magnetic field strength; the middle PDMS buffer layer is also modulated according to the ratio of main agent: curing agent = 15:1, so that the sensitivity of the magnetic skin is higher; the tunnel magnetoresistance element (TMR) is used as the detection part, and TMR is used as the detection part. A new type of magnetic sensor has the advantages of low cost, high precision, high sensitivity, low power consumption, good temperature stability, and wide operating temperature range. Combining the advantages of magnetic thin film and TMR high precision, a highly flexible sensor for tactile sensing is designed. , high-sensitivity magnetic electronic skin, which has broad application prospects in the field of human-computer interaction of intelligent manipulators.

本发明未尽事宜为公知技术。Matters not covered in the present invention are known technologies.

Claims (8)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310419268.8ACN116295957A (en) | 2023-04-18 | 2023-04-18 | Magnetic electronic skin for tactile perception |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310419268.8ACN116295957A (en) | 2023-04-18 | 2023-04-18 | Magnetic electronic skin for tactile perception |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN116295957Atrue CN116295957A (en) | 2023-06-23 |

Family

ID=86792673

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202310419268.8APendingCN116295957A (en) | 2023-04-18 | 2023-04-18 | Magnetic electronic skin for tactile perception |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN116295957A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN119880235A (en)* | 2025-01-20 | 2025-04-25 | 河北工业大学 | Three-dimensional force-temperature bimodal touch sensor based on magnetic film |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106370327A (en)* | 2016-10-08 | 2017-02-01 | 中国科学院深圳先进技术研究院 | Flexible pressure sensor and manufacturing method thereof |

| CN111351773A (en)* | 2018-12-21 | 2020-06-30 | 中国科学院苏州纳米技术与纳米仿生研究所 | Gas sensor based on swelling dynamic response and preparation method thereof |

| CN111993446A (en)* | 2020-07-03 | 2020-11-27 | 北京大学 | Magnetic field-based flexible tactile sensor |

| CN113488339A (en)* | 2021-07-15 | 2021-10-08 | 华东师范大学 | Flexible supercapacitor based on carbon-based composite electrode and preparation method thereof |

| CN114459638A (en)* | 2022-02-11 | 2022-05-10 | 河北工业大学 | Large-force-measuring-range flexible touch sensing array based on L-shaped iron gallium wires |

| CN114716967A (en)* | 2022-03-21 | 2022-07-08 | 广东省载诚新材料有限公司 | Organic silicon elastomer, organic silicon OCA optical cement, and preparation method and application thereof |

| CN114739541A (en)* | 2022-04-11 | 2022-07-12 | 中国科学院宁波材料技术与工程研究所 | A kind of flexible tactile sensor and its application |

| CN114777965A (en)* | 2022-04-13 | 2022-07-22 | 中北大学 | Flexible capacitive pressure sensor and preparation method thereof |

| US20220276038A1 (en)* | 2021-03-01 | 2022-09-01 | City University Of Hong Kong | Electromechanical sensor and a method of sensing an object or a tactile input using the sensor |

- 2023

- 2023-04-18CNCN202310419268.8Apatent/CN116295957A/enactivePending

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106370327A (en)* | 2016-10-08 | 2017-02-01 | 中国科学院深圳先进技术研究院 | Flexible pressure sensor and manufacturing method thereof |

| CN111351773A (en)* | 2018-12-21 | 2020-06-30 | 中国科学院苏州纳米技术与纳米仿生研究所 | Gas sensor based on swelling dynamic response and preparation method thereof |

| CN111993446A (en)* | 2020-07-03 | 2020-11-27 | 北京大学 | Magnetic field-based flexible tactile sensor |

| US20220276038A1 (en)* | 2021-03-01 | 2022-09-01 | City University Of Hong Kong | Electromechanical sensor and a method of sensing an object or a tactile input using the sensor |

| CN113488339A (en)* | 2021-07-15 | 2021-10-08 | 华东师范大学 | Flexible supercapacitor based on carbon-based composite electrode and preparation method thereof |

| CN114459638A (en)* | 2022-02-11 | 2022-05-10 | 河北工业大学 | Large-force-measuring-range flexible touch sensing array based on L-shaped iron gallium wires |

| CN114716967A (en)* | 2022-03-21 | 2022-07-08 | 广东省载诚新材料有限公司 | Organic silicon elastomer, organic silicon OCA optical cement, and preparation method and application thereof |

| CN114739541A (en)* | 2022-04-11 | 2022-07-12 | 中国科学院宁波材料技术与工程研究所 | A kind of flexible tactile sensor and its application |

| CN114777965A (en)* | 2022-04-13 | 2022-07-22 | 中北大学 | Flexible capacitive pressure sensor and preparation method thereof |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN119880235A (en)* | 2025-01-20 | 2025-04-25 | 河北工业大学 | Three-dimensional force-temperature bimodal touch sensor based on magnetic film |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Hellebrekers et al. | Soft magnetic tactile skin for continuous force and location estimation using neural networks | |

| CN113074842B (en) | Magnetic flexible tactile sensing structure and application based on folding magnetization method | |

| CN109489874B (en) | Carbon fiber flexible pressure distribution sensing device and force measuring method thereof | |

| CN114739541A (en) | A kind of flexible tactile sensor and its application | |

| CN113091960B (en) | Folding magnetization method, flexible tactile sensing structure and flexible tactile sensor | |

| CN103499271A (en) | Thickness measurement device | |

| CN114209304A (en) | Amphibious flexible three-dimensional force position measuring device, preparation method and application thereof | |

| CN117419846A (en) | Novel magnetic-sensitive tactile multidimensional force sensor | |

| Li et al. | A high-sensitivity magnetic tactile sensor with a structure-optimized Hall sensor and a flexible magnetic film | |

| Chen et al. | Development and characterization of a highly sensitive magnetic electronic skin for intelligent manipulators | |

| CN117949118A (en) | Flexible touch sense sensing array for position and slippage detection | |

| CN116295956A (en) | A Tactile Sensing Array Based on Iron Cobalt Vanadium and Epoxy | |

| CN116295957A (en) | Magnetic electronic skin for tactile perception | |

| CN119141572A (en) | Multidimensional force touch perception electronic skin and preparation method thereof | |

| CN209541957U (en) | A kind of dot matrix pliable pressure distributed sensor device | |

| CN113970390B (en) | High-sensitivity flexible magnetostrictive tactile sensor array for manipulator | |

| CN203550904U (en) | Thickness measurement device | |

| Lin et al. | Dual-mode flexible sensor based on magnetic film for wearable smart finger sleeve | |

| Zhang et al. | A magnetostrictive tactile sensing unit and the integration of sensor array for intelligent manipulator | |

| CN117484552A (en) | Multifunctional electronic skin based on magnetic induction and stress sense self-decoupling and preparation method thereof | |

| CN118794570A (en) | A wearable electronic skin with a knitted structure | |

| CN120385961A (en) | A soft-mesh magnetic sensor for tactile and non-tactile sensing | |

| CN207263908U (en) | A kind of sensor module | |

| CN118471646A (en) | An electronic skin based on origami magnetized soft magnetic film | |

| CN105203012A (en) | Magnetic thickness sensor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |