CN116275022A - Ultrahigh-toughness porous Ti-based memory alloy composite material and preparation method thereof - Google Patents

Ultrahigh-toughness porous Ti-based memory alloy composite material and preparation method thereofDownload PDFInfo

- Publication number

- CN116275022A CN116275022ACN202310313310.8ACN202310313310ACN116275022ACN 116275022 ACN116275022 ACN 116275022ACN 202310313310 ACN202310313310 ACN 202310313310ACN 116275022 ACN116275022 ACN 116275022A

- Authority

- CN

- China

- Prior art keywords

- memory alloy

- based memory

- composite material

- alloy composite

- zrh

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F1/00—Metallic powder; Treatment of metallic powder, e.g. to facilitate working or to improve properties

- B22F1/12—Metallic powder containing non-metallic particles

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/02—Compacting only

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/10—Sintering only

- B22F3/1003—Use of special medium during sintering, e.g. sintering aid

- B22F3/1007—Atmosphere

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/24—After-treatment of workpieces or articles

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F9/00—Making metallic powder or suspensions thereof

- B22F9/02—Making metallic powder or suspensions thereof using physical processes

- B22F9/04—Making metallic powder or suspensions thereof using physical processes starting from solid material, e.g. by crushing, grinding or milling

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F3/00—Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering; Apparatus specially adapted therefor ; Presses and furnaces

- B22F3/24—After-treatment of workpieces or articles

- B22F2003/248—Thermal after-treatment

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22F—WORKING METALLIC POWDER; MANUFACTURE OF ARTICLES FROM METALLIC POWDER; MAKING METALLIC POWDER; APPARATUS OR DEVICES SPECIALLY ADAPTED FOR METALLIC POWDER

- B22F9/00—Making metallic powder or suspensions thereof

- B22F9/02—Making metallic powder or suspensions thereof using physical processes

- B22F9/04—Making metallic powder or suspensions thereof using physical processes starting from solid material, e.g. by crushing, grinding or milling

- B22F2009/043—Making metallic powder or suspensions thereof using physical processes starting from solid material, e.g. by crushing, grinding or milling by ball milling

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/25—Process efficiency

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Powder Metallurgy (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及记忆合金复合材料,尤其涉及一种超高强韧性多孔Ti基记忆合金复合材料及其制备方法。The invention relates to a memory alloy composite material, in particular to an ultrahigh-strength porous Ti-based memory alloy composite material and a preparation method thereof.

背景技术Background technique

医用金属材料因具有较高的力学性能(包括高的断裂强度与抗疲劳性能),成为临床应用最为广泛的承力植入材料。目前临床使用的医用金属植入材料包括医用不锈钢、钴基合金、钛合金及纯金属(如锆、铌、钽)等。同时,骨植入体还需要有良好的生物相容性和生物力学性能,以保证骨植入体的治疗效果和长期安全可靠性。Due to their high mechanical properties (including high fracture strength and fatigue resistance), medical metal materials have become the most widely used load-bearing implant materials in clinical practice. Currently clinically used medical metal implant materials include medical stainless steel, cobalt-based alloys, titanium alloys, and pure metals (such as zirconium, niobium, and tantalum). At the same time, bone implants also need to have good biocompatibility and biomechanical properties to ensure the therapeutic effect and long-term safety and reliability of bone implants.

近年来发展起来的多孔β相Ti基记忆合金(Ti-Nb基、Ti-Mo基和Ti-Ta基合金)不但继承了致密Ti基记忆合金良好的生物相容性和独特的超弹性特性,同时,孔隙结构的引入可以有效降低合金的弹性模量,解决植入体与人体骨因弹性模量不匹配而引起的“应力屏蔽”问题,有助于骨组织的长入和植入体的固定。Porous β-phase Ti-based memory alloys (Ti-Nb-based, Ti-Mo-based and Ti-Ta-based alloys) developed in recent years not only inherit the good biocompatibility and unique superelastic properties of dense Ti-based memory alloys, At the same time, the introduction of the pore structure can effectively reduce the elastic modulus of the alloy, solve the "stress shielding" problem caused by the mismatch between the elastic modulus of the implant and the human bone, and help the ingrowth of bone tissue and the implant. fixed.

因此,多孔β相Ti基记忆合金成为更有医用潜力的新型硬组织替代材料。人体骨(包括皮质骨和松质骨)的孔隙率在30-90%的范围内,然而目前能满足人体骨压缩强度要求的多孔Ti基记忆合金的孔隙率都未超过40%。超过40%的孔隙率会使多孔Ti基记忆合金的强度大幅降低,低于骨植入材料强度要求(>200MPa),同时韧性变差,限制了高孔隙率多孔Ti基记忆合金作为骨植入材料的应用。有文献报道,孔隙率为50%的多孔钛基记忆合金的压缩强度约为150MPa,仅为致密基体压缩强度的七分之一,且韧性下降约17%。因此,需要设法提升高孔隙率Ti基记忆合金的强度和韧性,这是医用高孔隙率Ti基记忆合金急需要解决的关键问题。Therefore, the porous β-phase Ti-based memory alloy has become a new type of hard tissue replacement material with more medical potential. The porosity of human bone (including cortical bone and cancellous bone) is in the range of 30-90%, but the porosity of porous Ti-based memory alloys that can meet the compressive strength requirements of human bone does not exceed 40%. Porosity exceeding 40% will greatly reduce the strength of porous Ti-based memory alloys, which is lower than the strength requirements of bone implant materials (>200MPa), and the toughness will become poor at the same time, which limits the use of porous Ti-based memory alloys with high porosity as bone implants. application of materials. It has been reported in the literature that the compressive strength of a porous titanium-based memory alloy with a porosity of 50% is about 150 MPa, which is only one-seventh of the compressive strength of a dense matrix, and the toughness drops by about 17%. Therefore, it is necessary to try to improve the strength and toughness of high-porosity Ti-based memory alloys, which is a key problem that needs to be solved urgently for medical high-porosity Ti-based memory alloys.

有研究报道,通过添加高强纤维作为增强体可有效提升多孔材料的强度。It has been reported that the strength of porous materials can be effectively improved by adding high-strength fibers as reinforcements.

例如通过渗流法制备的高孔隙率铝合金/铝芯氧化铝纤维复合泡沫材料,其中添加5%(体积比)氧化铝纤维,孔隙率为82%的复合泡沫材料的屈服强度提高了448%,断裂韧性也明显提升。利用立体编织技术制造的纤维正交分布的纤维增强仿生人工骨陶瓷复合材料,其孔隙率约为64%,压缩强度可达30MPa,远高于未添加纤维的仿生人工骨(约6MPa)。可见通过添加高强纤维增强多孔材料是具有显著效果的。For example, the high-porosity aluminum alloy/aluminum core alumina fiber composite foam material prepared by infiltration method, in which 5% (volume ratio) alumina fiber is added, the yield strength of the composite foam material with a porosity of 82% is increased by 448%. Fracture toughness is also significantly improved. The fiber-reinforced biomimetic artificial bone-ceramic composite material with orthogonal distribution of fibers produced by three-dimensional weaving technology has a porosity of about 64% and a compressive strength of 30 MPa, which is much higher than that of biomimetic artificial bone without fibers (about 6 MPa). It can be seen that adding high-strength fibers to strengthen porous materials has a significant effect.

目前,在航空航天领域对Mof/Ti复合材料的大量研究和成功应用的经验表明,具有高强度且耐高温的Mo纤维对于致密态钛合金的强度和韧性有明显提升作用。At present, a large amount of research and successful application experience on Mof /Ti composite materials in the aerospace field shows that Mo fibers with high strength and high temperature resistance can significantly improve the strength and toughness of dense titanium alloys.

例如采用真空热压法制备的Mof//TiAl复合材料在室温下的屈服强度高达1148MPa,比基体的屈服强度提高了近90%,复合材料的断裂韧性相较于基体提升近一倍。For example, the yield strength of the Mof/ /TiAl composite prepared by the vacuum hot pressing method is as high as 1148MPa at room temperature, which is nearly 90% higher than that of the matrix, and the fracture toughness of the composite is nearly double that of the matrix.

同时,Mo元素具有良好的生物相容性。因此,选择Mo纤维对医用多孔Ti基记忆合金进行增强增韧处理是可行的。迄今为止,尚未见到利用Mo纤维增强多孔Ti基合金的相关报道,迫切需要开发出利用Mo纤维增强高孔隙率Ti基记忆合金复合材料的制备方法,提升高孔隙率Ti基记忆合金的强度与韧性,以满足高孔隙率Ti基记忆合金作为人体硬组织修复与替换材料的力学性能要求。At the same time, Mo element has good biocompatibility. Therefore, it is feasible to select Mo fibers to strengthen and toughen medical porous Ti-based memory alloys. So far, there has been no report on the use of Mo fibers to reinforce porous Ti-based alloys. It is urgent to develop a preparation method for using Mo fibers to reinforce high-porosity Ti-based memory alloy composites to improve the strength of high-porosity Ti-based memory alloys. Toughness, to meet the mechanical performance requirements of high-porosity Ti-based memory alloy as a material for human hard tissue repair and replacement.

本发明提供一种超高强韧性多孔Ti基记忆合金复合材料及其制备方法,解决了传统医用高孔隙率Ti基记忆合金强度低、韧性差的难题。The invention provides an ultrahigh-strength toughness porous Ti-based memory alloy composite material and a preparation method thereof, which solves the problems of low strength and poor toughness of traditional medical high-porosity Ti-based memory alloys.

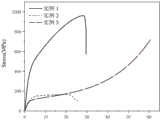

本发明所制备的多孔Ti基复合材料压缩强度高达700MPa,压缩应变提升至60%以上,力学性能得到全面显著提升,且制备工艺简单、成本低廉,易于工业化生产。The compressive strength of the porous Ti-based composite material prepared by the invention is as high as 700 MPa, the compressive strain is increased to more than 60%, the mechanical properties are comprehensively and significantly improved, and the preparation process is simple, the cost is low, and the industrial production is easy.

本发明通过下述技术方案实现:The present invention realizes through following technical scheme:

一种超高强韧性多孔Ti基记忆合金复合材料的制备方法,其特征在于包含以下操作步骤:A method for preparing an ultrahigh-strength toughness porous Ti-based memory alloy composite material, characterized in that it comprises the following steps:

步骤一:将TiH2,ZrH2和Nb粉末球磨处理,将Mo纤维进行裁剪;Step 1: ball milling TiH2 , ZrH2 and Nb powders, and cutting Mo fibers;

步骤二:将处理好的TiH2,ZrH2和Nb粉末和Mo纤维,混合;Step 2: Mix the treated TiH2 , ZrH2 and Nb powders with Mo fibers;

步骤三:将步骤二中的Mo/TiH2-Nb-ZrH2混合粉体与造孔剂(碳酸氢铵颗粒)按照一定重量比混合,并在混粉机上以一定速度混合一段时间。Step 3: Mix the Mo/TiH2 -Nb-ZrH2 mixed powder in Step 2 with the pore-forming agent (ammonium bicarbonate particles) according to a certain weight ratio, and mix them on a powder mixer at a certain speed for a period of time.

步骤四:将Mo/TiH2-Nb-ZrH2/造孔剂混合粉体在液压机上冷压成型,得到生胚;Step 4: Cold pressing the Mo/TiH2 -Nb-ZrH2 /pore-forming agent mixed powder on a hydraulic press to obtain green embryos;

步骤五:将生胚放入真空烧结炉中升温和烧结,随炉冷却。Step 5: Put the raw embryo into the vacuum sintering furnace to heat up and sinter, and cool down with the furnace.

步骤六:将烧结样品进行固溶处理。Step 6: Perform solid solution treatment on the sintered sample.

步骤一中,以原子百分数计,TiH2,ZrH2和Nb粉末的纯度均大于99.5%;Mo丝中Mo含量≥99.3%。In the first step, the purity of TiH2 , ZrH2 and Nb powders is greater than 99.5% in terms of atomic percentage; the Mo content in the Mo wire is ≥99.3%.

步骤一中,处理是指:将高纯TiH2,ZrH2和Nb粉末用等离子放电球磨机球磨8h以上;Mo纤维长度裁剪至小于12mm。In the first step, the treatment refers to: milling the high-purity TiH2 , ZrH2 and Nb powders with a plasma discharge ball mill for more than 8 hours; cutting the Mo fiber length to less than 12 mm.

步骤三中,Mo纤维直径为30μm,与Mo/TiH2-Nb-ZrH2和造孔剂的混合粉末的体积比不超过5%;混粉机的转速不超过200r/min,混合时间不超过30min。In step 3, the diameter of the Mo fiber is 30 μm, and the volume ratio of the mixed powder with Mo/TiH2 -Nb-ZrH2 and the pore-forming agent does not exceed 5%; the speed of the powder mixer does not exceed 200r/min, and the mixing time does not exceed 30min.

步骤三中,造孔剂与Mo/TiH2-Nb-ZrH2混合粉体的重量比大于30%,混粉机的转速小于100r/min,混合时间5~10min。In step three, the weight ratio of the pore-forming agent to the Mo/TiH2 -Nb-ZrH2 mixed powder is greater than 30%, the speed of the powder mixer is less than 100 r/min, and the mixing time is 5-10 minutes.

步骤四中,生胚的冷压成型压力为300~660MPa,保压时间5~30min。In step 4, the cold-press forming pressure of the raw embryo is 300-660 MPa, and the holding time is 5-30 minutes.

步骤五中,将生胚放入真空烧结炉中升温和烧结,随炉冷却,具体是指:在0~200℃区间打开真空泵,以5℃/min升温速率在10-3Pa真空下快速升温,在生坯脱氢温度200~800℃区间关闭真空泵并在H2气氛下以2℃/min升温速率缓慢升温至800℃,在800℃保温1h;之后在800~1100℃区间再次打开真空泵,以5℃/min升温速率在10-3Pa真空下快速升温至1100℃,在1100℃真空烧结5h,随炉冷却。In step 5, put the green embryo into a vacuum sintering furnace to heat up and sinter, and cool down with the furnace, specifically: turn on the vacuum pump in the range of 0-200°C, and rapidly raise the temperature at a heating rate of 5°C/min under a vacuum of 10-3 Pa , turn off the vacuum pump at the green body dehydrogenation temperature range of 200-800°C and slowly raise the temperature to 800°C at a heating rate of 2°C/min underH2 atmosphere, and keep it at 800°C for 1 hour; then turn on the vacuum pump again at the range of 800-1100°C, Rapidly raise the temperature to 1100°C under 10-3 Pa vacuum at a heating rate of 5°C/min, sinter at 1100°C for 5 hours in vacuum, and cool with the furnace.

步骤六中,将烧结样品进行固溶处理,具体是指:将烧结样品密封在玻璃管中,在氩气保护下进行固溶处理,固溶处理温度为900℃,保温时间为1h,之后在冰水中快速冷却。In step six, the sintered sample is subjected to solution treatment, which specifically refers to: sealing the sintered sample in a glass tube, and performing solution treatment under the protection of argon. The solution treatment temperature is 900 ° C, and the holding time is 1 hour. Cool quickly in ice water.

上述方法制备的Mof/多孔Ti基记忆合金复合材料的孔隙率高于50%,相较于相同孔隙率下未添加Mo纤维的多孔样品,压缩强度从180MPa提升至700MPa,提升了近300%,压缩应变从25%提升至60%以上,力学性能得到全面显著提升。作为人体硬组织修复和替换材料具有极大的应用潜力。The porosity of the Mof /porous Ti-based memory alloy composite prepared by the above method is higher than 50%. Compared with the porous sample without Mo fibers added under the same porosity, the compressive strength is increased from 180MPa to 700MPa, which is nearly 300% higher. , the compressive strain is increased from 25% to more than 60%, and the mechanical properties have been significantly improved in an all-round way. It has great application potential as a material for human hard tissue repair and replacement.

本发明的原理:Mo纤维可以将高孔隙率Ti基合金的多个单独的孔有机地连接起来,当多孔合金受力变形时,孔壁可以将应力传递到高强度的Mo纤维上,Mo纤维起到抵抗应力的作用,并阻碍裂纹在基体中的扩展,提升了多孔合金孔壁基体抵抗应力的能力,以及促进多孔合金进入致密化阶段,从而大幅提升了多孔合金的强度。同时,纤维的拔出以及纤维对裂纹扩展的偏转作用对多孔合金的韧性也有明显提高效果。Principle of the present invention: Mo fibers can organically connect multiple individual pores of high-porosity Ti-based alloys, and when the porous alloy is deformed by force, the pore walls can transfer stress to high-strength Mo fibers, and Mo fibers Play the role of resisting stress, and hinder the expansion of cracks in the matrix, improve the ability of the porous alloy pore wall matrix to resist stress, and promote the porous alloy to enter the densification stage, thereby greatly improving the strength of the porous alloy. At the same time, the pulling out of fibers and the deflection effect of fibers on crack propagation can also significantly improve the toughness of porous alloys.

本发明相对于现有技术,具有如下的优点及效果:Compared with the prior art, the present invention has the following advantages and effects:

本发明针对医用高孔隙率Ti基记忆合金强度低、韧性差的问题,用粉末冶金方式制备了Mof/多孔Ti基记忆合金复合材料,在50%孔隙率下,相较于无纤维增强多孔Ti基记忆合金,Mof/多孔Ti基记忆合金复合材料的压缩强度和压缩应变分别提升了近三倍和两倍以上,增强及增韧效果显著,且制备方法简单,对设备要求低。The present invention aims at the problems of low strength and poor toughness of medical high-porosity Ti-based memory alloys, and prepares Mof /porous Ti-based memory alloy composite materials by powder metallurgy. Under 50% porosity, compared with non-fiber reinforced porous The compressive strength and compressive strain of Ti-based memory alloy and Mof /porous Ti-based memory alloy composite material are increased by nearly three times and more than two times, respectively, and the strengthening and toughening effects are remarkable, and the preparation method is simple and requires low equipment.

通过使用高纯TiH2和ZrH2氢化物粉,有效降低了多孔钛合金的烧结温度,缓解了高温烧结时Mo/Ti的界面反应,获得了优异的Mo/Ti界面结合,确保了Mo纤维的增强增韧效果。By using high-purityTiH2 andZrH2 hydride powders, the sintering temperature of the porous titanium alloy is effectively reduced, the interfacial reaction of Mo/Ti during high-temperature sintering is alleviated, and excellent Mo/Ti interfacial bonding is obtained, ensuring the Mo fiber Enhance toughening effect.

Mo元素为无毒元素,生物相容性较好,适宜作为医用钛合金的合金化元素。Mo is a non-toxic element with good biocompatibility and is suitable as an alloying element for medical titanium alloys.

附图说明Description of drawings

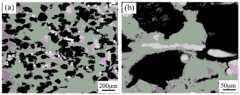

图1为本发明图1是实施例1,孔隙率为7%的近致密Ti-12Nb-18Zr记忆合金的SEM形貌。Fig. 1 is the present invention Fig. 1 is embodiment 1, the SEM morphology of the near-dense Ti-12Nb-18Zr memory alloy with a porosity of 7%.

图2是实施例2,孔隙率为50.3%的医用高孔隙率Ti-12Nb-18Zr记忆合金的SEM形貌。Fig. 2 is embodiment 2, the SEM morphology of the medical high porosity Ti-12Nb-18Zr memory alloy with a porosity of 50.3%.

图3是实施例3,孔隙率为53.1%的Mo纤维增强医用高孔隙率Ti-12Nb-18Zr记忆合金复合材料的SEM形貌。Fig. 3 is Example 3, the SEM morphology of the Mo fiber reinforced medical high porosity Ti-12Nb-18Zr memory alloy composite material with a porosity of 53.1%.

图4是实施例1-3制备的近致密Ti-12Nb-18Zr记忆合金、高孔隙率Ti-12Nb-18Zr记忆合金和Mof/Ti-12Nb-18Zr复合材料的压缩断裂曲线。从图中可以看出,高孔隙率的引入使得记忆合金的压缩强度和韧性发生明显降低,而Mo纤维的加入使得Mof/Ti-12Nb-18Zr复合材料的力学性能得到显著提升,并且复合材料的韧性要远远超过近致密态基体合金。Fig. 4 is the compression fracture curves of the near-dense Ti-12Nb-18Zr memory alloy, the high-porosity Ti-12Nb-18Zr memory alloy and the Mof /Ti-12Nb-18Zr composite material prepared in Examples 1-3. It can be seen from the figure that the introduction of high porosity significantly reduces the compressive strength and toughness of the memory alloy, while the addition of Mo fibers significantly improves the mechanical properties of the Mof /Ti-12Nb-18Zr composite, and the composite The toughness is much higher than that of the near-dense matrix alloy.

具体实施方式Detailed ways

下面结合具体实施例对本发明作进一步具体详细描述。The present invention will be described in further detail below in conjunction with specific embodiments.

实施例1:Example 1:

步骤一:在手套箱中将粉末纯度大于99.5%的TiH2、Nb和ZrH2粉按照Ti、Nb和Zr原子比为70:12:18配比进行称取。将称取好的粉末放入等离子放电球磨机上球磨8h,获得均匀混合的TiH2-Nb-ZrH2粉末;Step 1: Weigh TiH2 , Nb and ZrH2 powders with a powder purity greater than 99.5% in a glove box according to the atomic ratio of Ti, Nb and Zr being 70:12:18. Put the weighed powder into a plasma discharge ball mill and mill it for 8 hours to obtain a uniformly mixed TiH2 -Nb-ZrH2 powder;

步骤二:将混合粉末在液压机上冷压制成生胚,冷压成型压力为660MPa(液压机的最大压力),保压时间5min。Step 2: cold press the mixed powder on a hydraulic press to form green embryos, the cold press forming pressure is 660MPa (the maximum pressure of the hydraulic press), and the holding time is 5 minutes.

步骤三:将所得生坯放入真空管式炉中分段升温和烧结,在0~200℃区间打开真空泵,以5℃/min升温速率在10-3Pa真空下快速升温,在生坯脱氢温度200~800℃区间关闭真空泵并在H2气氛下以2℃/min升温速率缓慢升温至800℃,在800℃保温1h;之后在800~1100℃区间再次打开真空泵,以5℃/min升温速率在10-3Pa真空下快速升温至1100℃,在1100℃真空烧结5h,随炉冷却。Step 3: put the obtained green body into a vacuum tube furnace to heat up and sinter in stages, turn on the vacuum pump in the range of 0-200°C, and rapidly raise the temperature at a heating rate of 5°C/min under a vacuum of 10-3 Pa, and dehydrogenate the green body Turn off the vacuum pump at a temperature of 200-800°C and slowly raise the temperature to 800°C at a heating rate of 2°C/min underH2 atmosphere, and keep it at 800°C for 1 hour; then turn on the vacuum pump again at a temperature of 800-1100°C, and heat up at a rate of 5°C/min The temperature was rapidly raised to 1100°C at a rate of 10-3 Pa vacuum, sintered at 1100°C for 5 hours in vacuum, and cooled with the furnace.

步骤四:所得烧结样品密封在充满Ar气的玻璃管中进行固溶处理,固溶温度为900℃,固溶时间为1h,之后在冰水中快速冷却样品。Step 4: The obtained sintered sample was sealed in a glass tube filled with Ar gas for solution treatment, the solution temperature was 900° C., and the solution time was 1 h, and then the sample was rapidly cooled in ice water.

实施例2:Example 2:

步骤一:在手套箱中将粉末纯度大于99.5%的TiH2、Nb和ZrH2粉按照Ti、Nb和Zr原子比为70:12:18配比进行称取。将称取好的粉末放入等离子放电球磨机上球磨8h,获得均匀混合的TiH2-Nb-ZrH2粉末。Step 1: Weigh TiH2 , Nb and ZrH2 powders with a powder purity greater than 99.5% in a glove box according to the atomic ratio of Ti, Nb and Zr being 70:12:18. The weighed powder was put into a plasma discharge ball mill and ball-milled for 8 hours to obtain uniformly mixed TiH2 -Nb-ZrH2 powder.

步骤二:将TiH2-Nb-ZrH2混合粉末与碳酸氢铵造孔剂按照造孔剂重量比为45%的比例混合,然后将其放在混粉机上以100r/min的速度混合5min。Step 2: Mix the TiH2 -Nb-ZrH2 mixed powder with the ammonium bicarbonate pore-forming agent at a ratio of 45% by weight of the pore-forming agent, and then put it on a powder mixer and mix for 5 minutes at a speed of 100 r/min.

步骤三:将TiH2-Nb-ZrH2/碳酸氢铵混合粉体在液压机上冷压制成生胚,冷压成型压力为300MPa,保压时间5min。Step 3: Cold press the mixed powder of TiH2 -Nb-ZrH2 /ammonium bicarbonate on a hydraulic press to form green embryos, the cold pressing pressure is 300 MPa, and the holding time is 5 minutes.

步骤四:将所得生坯放入真空管式炉中分段升温和烧结,在0~200℃区间打开真空泵,以5℃/min升温速率在10-3Pa真空下快速升温,在生坯脱氢温度200~800℃区间关闭真空泵并在H2气氛下以2℃/min升温速率缓慢升温至800℃,在800℃保温1h;之后在800~1100℃区间再次打开真空泵,以5℃/min升温速率在10-3Pa真空下快速升温至1100℃时,在1100℃真空烧结5h,随炉冷却。Step 4: Put the obtained green body into a vacuum tube furnace to heat up and sinter in stages, turn on the vacuum pump in the range of 0-200°C, and rapidly raise the temperature at a heating rate of 5°C/min under a vacuum of 10-3 Pa, and dehydrogenate the green body Turn off the vacuum pump at a temperature of 200-800°C and slowly raise the temperature to 800°C at a heating rate of 2°C/min underH2 atmosphere, and keep it at 800°C for 1 hour; then turn on the vacuum pump again at a temperature of 800-1100°C, and heat up at a rate of 5°C/min When the temperature is rapidly raised to 1100°C under 10-3 Pa vacuum, it is sintered in vacuum at 1100°C for 5 hours and cooled with the furnace.

步骤五:所得烧结样品密封在充满Ar气的玻璃管中进行固溶处理,固溶温度为900℃,固溶时间为1h,之后在冰水中快速冷却样品。Step 5: The obtained sintered sample was sealed in a glass tube filled with Ar gas for solution treatment, the solution temperature was 900° C., and the solution time was 1 h, and then the sample was rapidly cooled in ice water.

实施例3:Example 3:

步骤一:在手套箱中将粉末纯度大于99.5%的TiH2、Nb和ZrH2粉按照Ti、Nb和Zr原子比为70:12:18配比进行称取。将称取好的粉末放入等离子放电球磨机上球磨8h,获得均匀混合的TiH2-Nb-ZrH2粉末;将直径为30μm的Mo纤维裁剪成8-10mm。Step 1: Weigh TiH2 , Nb and ZrH2 powders with a powder purity greater than 99.5% in a glove box according to the atomic ratio of Ti, Nb and Zr being 70:12:18. Put the weighed powder into a plasma discharge ball mill and mill it for 8 hours to obtain a uniformly mixed TiH2 -Nb-ZrH2 powder; cut Mo fibers with a diameter of 30 μm to 8-10 mm.

步骤二:将TiH2-Nb-ZrH2混合粉末与碳酸氢铵造孔剂按照造孔剂重量比为45%的比例混合,然后将其放在混粉机上以100r/min的速度混合5min。Step 2: Mix the TiH2 -Nb-ZrH2 mixed powder with the ammonium bicarbonate pore-forming agent at a ratio of 45% by weight of the pore-forming agent, and then put it on a powder mixer and mix for 5 minutes at a speed of 100 r/min.

步骤三:将TiH2-Nb-ZrH2/碳酸氢铵混合粉末与5vol%的裁剪Mo纤维在混粉机上以250r/min的速度混合15min。Step 3: Mix the TiH2 -Nb-ZrH2 /ammonium bicarbonate mixed powder with 5 vol% cut Mo fibers on a powder mixer at a speed of 250 r/min for 15 min.

步骤四:将Mof/TiH2-Nb-ZrH2/碳酸氢铵混合体在液压机上冷压制成生胚,冷压成型压力为300MPa,保压时间5min。Step 4: cold press the mixture of Mof /TiH2 -Nb-ZrH2 /ammonium bicarbonate on a hydraulic press to form green embryos, the cold pressing pressure is 300 MPa, and the holding time is 5 minutes.

步骤五:将所得生坯放入真空管式炉中分段升温和烧结,在0~200℃区间打开真空泵,以5℃/min升温速率在10-3Pa真空下快速升温,在生坯脱氢温度200~800℃区间关闭真空泵并在H2气氛下以2℃/min升温速率缓慢升温至800℃,在800℃保温1h;之后在800~1100℃区间再次打开真空泵,以5℃/min升温速率在10-3Pa真空下快速升温至1100℃时,在1100℃真空烧结5h,随炉冷却。Step 5: Put the obtained green body into a vacuum tube furnace to heat up and sinter in stages, turn on the vacuum pump in the range of 0-200°C, and rapidly raise the temperature at a heating rate of 5°C/min under a vacuum of 10-3 Pa, and dehydrogenate the green body Turn off the vacuum pump at a temperature of 200-800°C and slowly raise the temperature to 800°C at a heating rate of 2°C/min underH2 atmosphere, and keep it at 800°C for 1 hour; then turn on the vacuum pump again at a temperature of 800-1100°C, and heat up at a rate of 5°C/min When the temperature is rapidly raised to 1100°C under 10-3 Pa vacuum, it is sintered in vacuum at 1100°C for 5 hours and cooled with the furnace.

步骤六:所得烧结样品密封在充满Ar气的玻璃管中进行固溶处理,固溶温度为900℃,固溶时间为1h,之后在冰水中快速冷却样品。Step 6: The obtained sintered sample was sealed in a glass tube filled with Ar gas for solution treatment, the solution temperature was 900° C., and the solution time was 1 h, and then the sample was rapidly cooled in ice water.

如上所述,便可较好地实现本发明。As described above, the present invention can be preferably carried out.

本发明的实施方式并不受上述实施例的限制,其他任何未背离本发明的精神实质与原理下所作的改变、修饰、替代、组合、简化,均应为等效的置换方式,都包含在本发明的保护范围之内。The implementation of the present invention is not limited by the above examples, and any other changes, modifications, substitutions, combinations, and simplifications that do not deviate from the spirit and principles of the present invention should be equivalent replacement methods, and are all included in within the protection scope of the present invention.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310313310.8ACN116275022A (en) | 2023-03-28 | 2023-03-28 | Ultrahigh-toughness porous Ti-based memory alloy composite material and preparation method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310313310.8ACN116275022A (en) | 2023-03-28 | 2023-03-28 | Ultrahigh-toughness porous Ti-based memory alloy composite material and preparation method thereof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN116275022Atrue CN116275022A (en) | 2023-06-23 |

Family

ID=86823912

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202310313310.8APendingCN116275022A (en) | 2023-03-28 | 2023-03-28 | Ultrahigh-toughness porous Ti-based memory alloy composite material and preparation method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN116275022A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118951014A (en)* | 2024-10-16 | 2024-11-15 | 中钨稀有金属新材料(湖南)有限公司 | Molybdenum-niobium alloy sintered blank and preparation method thereof, molybdenum-niobium alloy target material and application thereof |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6365092B1 (en)* | 1999-06-23 | 2002-04-02 | Abb Lummus Global, Inc. | Method for producing a sintered porous body |

| CN102796972A (en)* | 2012-09-12 | 2012-11-28 | 哈尔滨工业大学 | Continuous Mo fiber reinforcement TiAl base composite material and method for preparing same |

| CN105817618A (en)* | 2016-03-28 | 2016-08-03 | 佳木斯大学 | Sintering method of porous metal fiber materials with controllable penetrability and porosity |

| CN110588096A (en)* | 2019-09-25 | 2019-12-20 | 哈尔滨工程大学 | A kind of continuous metal Mo wire reinforced Ti/Al3Ti layered composite material and its preparation method |

| CN111876699A (en)* | 2020-06-05 | 2020-11-03 | 华南理工大学 | A SiC fiber reinforced high-porosity Ti-based memory alloy composite and its preparation |

- 2023

- 2023-03-28CNCN202310313310.8Apatent/CN116275022A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6365092B1 (en)* | 1999-06-23 | 2002-04-02 | Abb Lummus Global, Inc. | Method for producing a sintered porous body |

| CN102796972A (en)* | 2012-09-12 | 2012-11-28 | 哈尔滨工业大学 | Continuous Mo fiber reinforcement TiAl base composite material and method for preparing same |

| CN105817618A (en)* | 2016-03-28 | 2016-08-03 | 佳木斯大学 | Sintering method of porous metal fiber materials with controllable penetrability and porosity |

| CN110588096A (en)* | 2019-09-25 | 2019-12-20 | 哈尔滨工程大学 | A kind of continuous metal Mo wire reinforced Ti/Al3Ti layered composite material and its preparation method |

| CN111876699A (en)* | 2020-06-05 | 2020-11-03 | 华南理工大学 | A SiC fiber reinforced high-porosity Ti-based memory alloy composite and its preparation |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118951014A (en)* | 2024-10-16 | 2024-11-15 | 中钨稀有金属新材料(湖南)有限公司 | Molybdenum-niobium alloy sintered blank and preparation method thereof, molybdenum-niobium alloy target material and application thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107190190A (en) | Gradient Porous Magnesium Alloy Materials for Bone Defect Repair | |

| CN108380891B (en) | Preparation method of titanium-based biomedical gradient composite material | |

| CN104313391B (en) | A kind of Ti-Mg alloy material and its preparation method and application | |

| CN102747245A (en) | Preparation method of medical porous titanium and titanium alloy | |

| CN104841009B (en) | A kind of hydroxyapatite activation titanium alloy top layer Biocomposite material and preparation method thereof | |

| CN107142388B (en) | A kind of preparation method of Ti-13Nb-13Zr alloy | |

| CN103540784B (en) | A kind of preparation method of bio-medical porous titanium alloy | |

| CN106756238B (en) | A kind of bio-medical porous titanium alloy and preparation method | |

| CN108273126B (en) | Preparation method of radial gradient medical composite material | |

| CN106521219B (en) | A kind of preparation method of TiC granule intensified titaniums based porous materials | |

| CN113481408B (en) | A kind of dental powder metallurgy Ti-Zr alloy and preparation method thereof | |

| CN102534284A (en) | Method for preparing medical porous NiTi shape memory alloy by microwave sintering | |

| CN104342583A (en) | Ti-Ta alloy as well as preparation method and application thereof | |

| CN106756239B (en) | A kind of medical embedded porous titanium alloy and preparation method | |

| CN102168195A (en) | Method for preparing gradient porous Ti-Mg-based composite material | |

| CN101003868A (en) | Method for preparing shape memory nickel titanium alloy with gradient porosity | |

| CN112143925A (en) | Preparation method of high-strength high-plasticity titanium-magnesium composite material | |

| CN106513681A (en) | Preparation method of graded porous nickel-titanium alloy | |

| CN109971997A (en) | A kind of high-strength high-elasticity titanium alloy and preparation method thereof | |

| CN116275022A (en) | Ultrahigh-toughness porous Ti-based memory alloy composite material and preparation method thereof | |

| Wang et al. | Progress in partially degradable titanium-magnesium composites used as biomedical implants | |

| Sun et al. | Research progress on mechanical properties of 3D printed biomedical titanium alloys | |

| CN109332700B (en) | Preparation method of TiB-reinforced medical porous titanium | |

| CN111876699A (en) | A SiC fiber reinforced high-porosity Ti-based memory alloy composite and its preparation | |

| CN111266592B (en) | Titanium-magnesium composite material with double-communication structure and preparation method and application thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| WD01 | Invention patent application deemed withdrawn after publication | ||

| WD01 | Invention patent application deemed withdrawn after publication | Application publication date:20230623 |