CN116197105A - Engineering residue soil screening device and application method thereof - Google Patents

Engineering residue soil screening device and application method thereofDownload PDFInfo

- Publication number

- CN116197105A CN116197105ACN202310228528.3ACN202310228528ACN116197105ACN 116197105 ACN116197105 ACN 116197105ACN 202310228528 ACN202310228528 ACN 202310228528ACN 116197105 ACN116197105 ACN 116197105A

- Authority

- CN

- China

- Prior art keywords

- screening

- feeding

- soil

- lifting

- buffer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/06—Cone or disc shaped screens

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/28—Moving screens not otherwise provided for, e.g. swinging, reciprocating, rocking, tilting or wobbling screens

- B07B1/34—Moving screens not otherwise provided for, e.g. swinging, reciprocating, rocking, tilting or wobbling screens jigging or moving to-and-fro perpendicularly or approximately perpendiculary to the plane of the screen

- B07B1/343—Moving screens not otherwise provided for, e.g. swinging, reciprocating, rocking, tilting or wobbling screens jigging or moving to-and-fro perpendicularly or approximately perpendiculary to the plane of the screen with mechanical drive elements other than electromagnets

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/42—Drive mechanisms, regulating or controlling devices, or balancing devices, specially adapted for screens

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/46—Constructional details of screens in general; Cleaning or heating of screens

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B1/00—Sieving, screening, sifting, or sorting solid materials using networks, gratings, grids, or the like

- B07B1/46—Constructional details of screens in general; Cleaning or heating of screens

- B07B1/4609—Constructional details of screens in general; Cleaning or heating of screens constructional details of screening surfaces or meshes

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G65/00—Loading or unloading

- B65G65/30—Methods or devices for filling or emptying bunkers, hoppers, tanks, or like containers, of interest apart from their use in particular chemical or physical processes or their application in particular machines, e.g. not covered by a single other subclass

- B65G65/32—Filling devices

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G65/00—Loading or unloading

- B65G65/30—Methods or devices for filling or emptying bunkers, hoppers, tanks, or like containers, of interest apart from their use in particular chemical or physical processes or their application in particular machines, e.g. not covered by a single other subclass

- B65G65/34—Emptying devices

- B65G65/40—Devices for emptying otherwise than from the top

- B65G65/46—Devices for emptying otherwise than from the top using screw conveyors

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/50—Reuse, recycling or recovery technologies

- Y02W30/58—Construction or demolition [C&D] waste

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Combined Means For Separation Of Solids (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及工程筛分技术领域,具体是一种工程渣土筛分装置及其使用方法。The invention relates to the technical field of engineering screening, in particular to an engineering dregs screening device and a method for using the same.

背景技术Background technique

渣土只是建筑垃圾的一种,渣土是指建设单位、施工单位新建、改建、扩建和拆除各类建筑物、构筑物、管网等以及居民装饰装修房屋过程中所产生的弃土、弃料及其它废弃物。目前,操作人员在对工程渣土物料进行处理的时候,经常需要使用到筛分机,从而便于操作人员的处理作业,而现有的筛分机在实际使用的过程中,尽管可以实现基本的筛分效果,但是其在对渣土物料进行筛分的时候,大颗粒的渣土物料将会残留在筛分结构的上方,并聚集在筛分结构的外侧,导致筛分结构的外侧筛分速度变慢,从而降低了该装置整体的筛分速率,针对此种问题,现有专利公告号为CN216827184U的专利中公布了一种体是工程渣土物料,该装置通过将过滤网设置成锥形,然后将大颗粒土块向四周堆积,小体积的土块会穿过过滤网,这种改进的好处是使得大体积杂质不会影响过滤面,但是长时间的积累后,过滤网的过滤面仍然会遭受影响,基于此,现在提供一种工程渣土筛分装置及其使用方法,可以消除现有装置存在的弊端。Slag is only a kind of construction waste. Slag refers to the spoils, waste materials and materials produced by construction units, construction units, new construction, reconstruction, expansion and demolition of various buildings, structures, pipe networks, etc., as well as residents' decoration and decoration of houses. other waste. At present, operators often need to use screening machines when processing engineering muck materials, so as to facilitate the processing operations of operators. However, in the actual use of existing screening machines, although basic screening can be achieved effect, but when it sieves the slag material, the large-grained slag material will remain above the screening structure and gather on the outside of the screening structure, resulting in a change in the screening speed outside the screening structure. slow, thereby reducing the overall screening rate of the device. For this problem, the existing patent announcement number is CN216827184U, which discloses a material that is engineering muck. Then pile up the large-grained soil clods around, and the small-sized soil clods will pass through the filter screen. The advantage of this improvement is that the large-volume impurities will not affect the filter surface, but after long-term accumulation, the filter surface of the filter screen is still Will be affected, based on this, now provide an engineering slag screening device and its use method, which can eliminate the disadvantages of the existing device.

发明内容Contents of the invention

本发明的目的在于提供一种工程渣土筛分装置及其使用方法,以解决背景技术中的问题。The object of the present invention is to provide an engineering dregs screening device and its use method to solve the problems in the background technology.

为实现上述目的,本发明提供如下技术方案:To achieve the above object, the present invention provides the following technical solutions:

一种工程渣土筛分装置,包括筛分箱和设置在其下端四个边角位置的支腿,所述筛分箱上端中间位置设有进料口,进料口下端设有下料管,所述进料口上端设有用于加料的加料斗,所述筛分箱内部设有一个可以沿着筛分箱内壁滑动的滑动环,所述滑动环上端设有用于对土块进行筛分的过滤锥板,所述滑动环外侧的筛分箱上设有出料口,出料口所在的筛分箱外侧设有用于收集大颗粒土块的缓存箱,所述缓存箱底部为左低右高的斜面,所述缓存箱上设有用于对大体积土块进行粉碎并送回的回料机构,所述筛分箱下端设有用于将合格土块送出的送料机构。An engineering dregs screening device, comprising a screening box and legs arranged at the four corners of the lower end of the screening box, a feeding port is provided in the middle of the upper end of the screening box, and a feeding pipe is provided at the lower end of the feeding port , the upper end of the feed inlet is provided with a hopper for feeding, the inside of the screening box is provided with a sliding ring that can slide along the inner wall of the screening box, and the upper end of the sliding ring is provided with a The filter cone plate, the screening box outside the sliding ring is provided with a discharge port, and the outside of the screening box where the discharge port is located is provided with a buffer box for collecting large particles of soil. The bottom of the buffer box is left lower On the inclined surface on the right side, the buffer box is provided with a return mechanism for crushing large-volume soil clods and returning them, and the lower end of the screening box is provided with a feeding mechanism for sending out qualified soil clods.

在上述技术方案的基础上,本发明还提供以下可选技术方案:On the basis of the above technical solutions, the present invention also provides the following optional technical solutions:

在一种可选方案中:所述回料机构包括设置在缓存箱左上端的提升筒,所述提升筒下端延伸至缓存箱内部,所述提升筒内部同轴设有一个提升轴,提升轴上端连接用于带动其转动的驱动电机,所述驱动电机安装在提升筒的顶部,提升筒内部的提升轴外侧设有用于推动土块上升的提升叶片,所述提升筒上端出料口通过引导管道与加料斗内壁连通,所述提升轴下端穿出缓存箱底部,位于提升筒外侧的提升轴表面阵列分布有粉碎刀组。In an optional solution: the material return mechanism includes a lifting cylinder arranged at the upper left end of the buffer box, the lower end of the lifting cylinder extends to the inside of the buffer box, a lifting shaft is coaxially arranged inside the lifting cylinder, and the upper end of the lifting shaft Connect the driving motor for driving it to rotate, the driving motor is installed on the top of the lifting cylinder, the lifting shaft inside the lifting cylinder is provided with lifting blades for pushing the soil block up, and the discharge port at the upper end of the lifting cylinder passes through the guide pipe It communicates with the inner wall of the hopper, the lower end of the lifting shaft passes through the bottom of the buffer box, and the surface of the lifting shaft outside the lifting cylinder is distributed with crushing knives in an array.

在一种可选方案中:所述粉碎刀组所在的缓存箱设有排料口,排料口位置设有活动门。In an optional solution: the buffer box where the crushing knife group is located is provided with a discharge port, and a movable door is provided at the discharge port.

在一种可选方案中:所述送料机构包括设置在筛分箱内部的送料通道,所述送料通道为上端开口的半筒体结构,所述送料通道右端延伸出筛分箱右侧,所述筛分箱右侧设有与送料通道相配合的穿口,所述送料通道中同轴设有一个送料轴,所述送料轴左端通过传动件与提升轴传动连接,所述送料通道内部的送料轴表面分布有用于推动物料的送料叶片。In an optional solution: the feeding mechanism includes a feeding channel arranged inside the screening box, the feeding channel is a semi-cylindrical structure with an upper end open, and the right end of the feeding channel extends out of the right side of the screening box, so The right side of the screening box is provided with an opening matching the feeding channel, and a feeding shaft is coaxially provided in the feeding channel, and the left end of the feeding shaft is connected to the lifting shaft through a transmission member. Feeding blades for pushing materials are distributed on the surface of the feeding shaft.

在一种可选方案中:所述送料通道上方设有用于对合格土块进行引导收集的集料斗,所述集料斗上端与滑动块连接,所述集料斗下端口与送料通道接料区域相对应。In an optional solution: a collecting hopper for guiding and collecting qualified soil blocks is provided above the feeding channel, the upper end of the collecting hopper is connected with the sliding block, and the lower port of the collecting hopper is connected to the receiving area of the feeding channel correspond.

在一种可选方案中:所述筛分箱和过滤锥板之间设有缓冲件,通过缓冲件将过滤锥板浮动式设置,使得土块对过滤锥板撞击得以缓冲;所述缓冲件包括设置在滑动块下端的若干个导向杆,所述筛分箱内壁设有一个滑动套,所述滑动套与导向杆滑动设置,所述滑动套与滑动块之间通过缓冲弹簧连接固定。In an optional solution: a buffer is provided between the screening box and the filter cone, and the filter cone is floated through the buffer, so that the impact of the soil block on the filter cone can be buffered; the buffer It includes several guide rods arranged at the lower end of the sliding block, a sliding sleeve is provided on the inner wall of the screening box, the sliding sleeve and the guiding rod are slidably arranged, and the sliding sleeve and the sliding block are connected and fixed by a buffer spring.

在一种可选方案中:所述筛分箱内部还设有用于带动过滤锥板上下抖动以提高筛分效果的抖动件,所述抖动件包括设置在导向杆下端的抵压杆,所述抵压杆侧面转动设有一个抵压轮,所述抵压轮所在的送料轴上设有一个振动盘,所述振动盘外侧分布有若干个用于对抵压杆产生推动力的凸起。In an optional solution: the inside of the screening box is also provided with a shaking part for driving the filter cone to shake up and down to improve the screening effect, and the shaking part includes a pressing rod arranged at the lower end of the guide rod. A pressure roller is provided for the side rotation of the pressure rod, and a vibrating plate is arranged on the feeding shaft where the pressure wheel is located, and several protrusions for generating a driving force for the pressure rod are distributed on the outside of the vibration plate.

在一种可选方案中:所述传动件包括设置在提升轴下端的第一传动轮和设置在送料轴左端的第二传动轮,所述第一传动轮与第二传动轮相互啮合。In an optional solution: the transmission member includes a first transmission wheel arranged at the lower end of the lifting shaft and a second transmission wheel arranged at the left end of the feeding shaft, and the first transmission wheel and the second transmission wheel mesh with each other.

相较于现有技术,本发明的有益效果如下:Compared with the prior art, the beneficial effects of the present invention are as follows:

本申请针对现有装置的弊端进行改进,保留了现有技术中锥形过滤结构的优点,这里通过将在锥形过滤结构四周堆积的大体积土块引导入回料机构中,不仅可以对大体积土块进行粉碎处理,还将粉碎后的土块送回加料斗中,实现了循环筛分,保证了筛分效果。This application improves on the drawbacks of the existing devices, and retains the advantages of the conical filter structure in the prior art. Here, by guiding the large-volume soil clods accumulated around the conical filter structure into the return mechanism, not only can the large The volumetric soil clods are crushed, and the crushed soil clods are sent back to the hopper to realize circular screening and ensure the screening effect.

附图说明Description of drawings

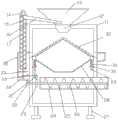

图1为本发明的结构示意图。Fig. 1 is a structural schematic diagram of the present invention.

图2为本发明内部的结构示意图。Fig. 2 is a schematic diagram of the internal structure of the present invention.

图3为本发明的过滤锥板结构示意图。Fig. 3 is a structural schematic diagram of the filter cone plate of the present invention.

图4为本发明的振动盘和抵压轮的结构示意图。Fig. 4 is a structural schematic diagram of the vibrating plate and the pressing wheel of the present invention.

附图标记注释:筛分箱11、下料管12、加料斗13、驱动电机14、提升叶片15、引导管道16、提升筒17、缓存箱18、抵压轮19、第一传动轮20、抵压杆21、第二传动轮22、振动盘23、送料通道24、送料叶片25、送料轴26、支腿27、集料斗28、导向杆29、滑动套30、缓冲弹簧31、过滤锥板32、粉碎刀组33。Notes on reference numerals:

具体实施方式Detailed ways

为了使本发明的目的、技术方案及优点更加清楚明白,以下结合附图及实施例,对本发明进行进一步详细说明。In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

在一个实施例中,如图1-图4所示,一种工程渣土筛分装置,包括筛分箱11和设置在其下端四个边角位置的支腿27,所述筛分箱11上端中间位置设有进料口,进料口下端设有下料管12,所述进料口上端设有用于加料的加料斗13,所述筛分箱11内部设有一个可以沿着筛分箱11内壁滑动的滑动环,所述滑动环上端设有用于对土块进行筛分的过滤锥板32,所述滑动环外侧的筛分箱11上设有出料口,出料口所在的筛分箱11外侧设有用于收集大颗粒土块的缓存箱18,所述缓存箱18底部为左低右高的斜面,所述缓存箱18上设有用于对大体积土块进行粉碎并送回的回料机构,通过回料机构的设置可以将大体积的土块及时处理,并送回筛分,避免出现大体积土块堵塞的问题,所述筛分箱11下端设有用于将合格土块送出的送料机构;In one embodiment, as shown in Figures 1-4, a construction muck screening device includes a

所述回料机构包括设置在缓存箱18左上端的提升筒17,所述提升筒17下端延伸至缓存箱18内部,所述提升筒17内部同轴设有一个提升轴,提升轴上端连接用于带动其转动的驱动电机14,所述驱动电机14安装在提升筒17的顶部,提升筒17内部的提升轴外侧设有用于推动土块上升的提升叶片15,所述提升筒17上端出料口通过引导管道16与加料斗13内壁连通,所述提升轴下端穿出缓存箱18底部,位于提升筒17外侧的提升轴表面阵列分布有粉碎刀组33,在实际使用时,通过驱动电机14带动提升轴转动,提升轴带动提升叶片15转动,从而将土块沿着提升筒17向上输送,土块会沿着引导管道16滑入加料斗13中,从而完成内循环,提升轴外侧的粉碎刀组33会对土块打碎,从而将大体积的土块进行细化处理,避免出现大体积土块的堆积;The material return mechanism includes a

所述送料机构包括设置在筛分箱11内部的送料通道24,所述送料通道24为上端开口的半筒体结构,所述送料通道24右端延伸出筛分箱11右侧,所述筛分箱11右侧设有与送料通道24相配合的穿口,所述送料通道24中同轴设有一个送料轴26,所述送料轴26左端通过传动件与提升轴传动连接,所述送料通道24内部的送料轴26表面分布有用于推动物料的送料叶片25,在传动件的作用下,送料轴26带动送料叶片25转动,送料叶片25会将送料通道24中收集的土块向右推动,最后排出筛分箱11;The feeding mechanism includes a

所述送料通道24上方设有用于对合格土块进行引导收集的集料斗28,所述集料斗28上端与滑动块连接,所述集料斗28下端口与送料通道24接料区域相对应,这样就可以保证土块进入送料通道24中;The top of the

所述筛分箱11和过滤锥板32之间设有缓冲件,通过缓冲件将过滤锥板32浮动式设置,使得土块对过滤锥板32撞击得以缓冲;所述缓冲件包括设置在滑动块下端的若干个导向杆29,所述筛分箱11内壁设有一个滑动套30,所述滑动套30与导向杆29滑动设置,所述滑动套30与滑动块之间通过缓冲弹簧31连接固定,这样就可以使得滑动块沿着导向杆29上下浮动;A buffer is provided between the

所述筛分箱11内部还设有用于带动过滤锥板32上下抖动以提高筛分效果的抖动件,所述抖动件包括设置在导向杆29下端的抵压杆21,所述抵压杆21侧面转动设有一个抵压轮19,所述抵压轮19所在的送料轴26上设有一个振动盘23,所述振动盘23外侧分布有若干个用于对抵压杆21产生推动力的凸起,这样在送料轴26转动时,振动盘23会随着一起转动,振动盘23表面的凸起会对抵压轮19产生推动力,从而使得过滤锥板32可以上下颠簸,提高了对土块的筛分效果;The inside of the

所述传动件包括设置在提升轴下端的第一传动轮20和设置在送料轴2左端的6第二传动轮22,所述第一传动轮20与第二传动轮22相互啮合;The transmission member includes a

上述实施例公布了一种工程渣土筛分装置及其使用方法,在实际上使用时,将废弃的土块倒入加料斗13中,土块沿着下料管12进入过滤锥板32中间位置,然后沿着中间位置下滑,下滑过程中,合格的土块穿过过滤锥板32,然后被送料机构送出筛分箱11,不合格的土块会沿着过滤锥板32下滑,最后进入缓存箱18中,再沿着缓存箱18底部滑动,最后进入回料机构位置,此时通过驱动电机14带动提升轴转动,提升轴外侧的粉碎刀组33会对土块打碎,从而将大体积的土块进行细化处理,避免出现大体积土块的堆积,提升轴带动提升叶片15转动,从而将土块沿着提升筒17向上输送,土块会沿着引导管道16滑入加料斗13中,从而完成内循环。The above-mentioned embodiment discloses a construction dregs screening device and its use method. In actual use, the discarded soil clods are poured into the

以上所述,仅为本公开的具体实施方式,但本公开的保护范围并不局限于此,任何熟悉本技术领域的技术人员在本公开揭露的技术范围内,可轻易想到变化或替换,都应涵盖在本公开的保护范围之内。因此,本公开的保护范围应以权利要求的保护范围为准。The above is only a specific implementation of the present disclosure, but the scope of protection of the present disclosure is not limited thereto. Anyone skilled in the art can easily think of changes or substitutions within the technical scope of the present disclosure. should fall within the protection scope of the present disclosure. Therefore, the protection scope of the present disclosure should be determined by the protection scope of the claims.

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310228528.3ACN116197105A (en) | 2023-03-10 | 2023-03-10 | Engineering residue soil screening device and application method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310228528.3ACN116197105A (en) | 2023-03-10 | 2023-03-10 | Engineering residue soil screening device and application method thereof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN116197105Atrue CN116197105A (en) | 2023-06-02 |

Family

ID=86512782

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202310228528.3APendingCN116197105A (en) | 2023-03-10 | 2023-03-10 | Engineering residue soil screening device and application method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN116197105A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117136688A (en)* | 2023-10-13 | 2023-12-01 | 宁夏师范学院 | Grass seed sowing equipment for pasture restoration |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN210230573U (en)* | 2019-06-19 | 2020-04-03 | 立昌科技(赣州)有限公司 | Powder coating circulation device that sieves |

| CN114798111A (en)* | 2022-04-29 | 2022-07-29 | 毅康科技有限公司 | System and method for accurately controlling adding amount of external carbon source |

- 2023

- 2023-03-10CNCN202310228528.3Apatent/CN116197105A/enactivePending

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN210230573U (en)* | 2019-06-19 | 2020-04-03 | 立昌科技(赣州)有限公司 | Powder coating circulation device that sieves |

| CN114798111A (en)* | 2022-04-29 | 2022-07-29 | 毅康科技有限公司 | System and method for accurately controlling adding amount of external carbon source |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117136688A (en)* | 2023-10-13 | 2023-12-01 | 宁夏师范学院 | Grass seed sowing equipment for pasture restoration |

| CN117136688B (en)* | 2023-10-13 | 2024-11-05 | 宁夏师范学院 | Grass seed sowing equipment for grassland repair |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN116197105A (en) | Engineering residue soil screening device and application method thereof | |

| CN218132425U (en) | Gangue crushing device for green mine | |

| CN115193542B (en) | A garbage disposal device for environmental protection engineering | |

| CN204307663U (en) | The broken gathering-device of a kind of fine earth materials quantitative | |

| CN219505215U (en) | Broken recovery plant | |

| CN216826542U (en) | A reducing mechanism for building grit aggregate | |

| CN218924769U (en) | Construction hydraulic engineering rubble machinery | |

| CN217249229U (en) | Construction site garbage cleaning device | |

| CN217315077U (en) | A waste wood processing apparatus for wood furniture processing | |

| CN217910781U (en) | Fish collagen peptide production shearing mechanism | |

| CN217069038U (en) | Tailing stone crusher capable of separating silt | |

| CN214131881U (en) | Saw mud crushing and decomposing equipment with noise reduction function | |

| CN210045347U (en) | Raw materials reducing mechanism is used in making wine | |

| CN115254330A (en) | An Internet-based intelligent crushing and grinding equipment for Chinese herbal medicine production and processing | |

| CN219424489U (en) | Reducing mechanism with screen cloth structure | |

| CN217450279U (en) | Bio-based asphalt processing breaker | |

| CN222401620U (en) | Raw material screening device for lime soil roadbed construction | |

| CN219441941U (en) | Novel pulverizer for producing disinfection tablets | |

| CN217069210U (en) | Gravel field is with rubble device with screening ejection of compact structure | |

| CN221063053U (en) | Hierarchical processing apparatus is smashed to construction waste | |

| CN220345970U (en) | Rubble equipment for engineering construction | |

| CN218981714U (en) | Rock mass sample breaker for geological exploration | |

| CN221132414U (en) | Sand stone material reducing mechanism | |

| CN216654737U (en) | Gravel aggregate circulating screening and crushing device | |

| CN219341979U (en) | Hydraulic engineering silt processing apparatus |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20230602 | |

| RJ01 | Rejection of invention patent application after publication |