CN116148315A - Nondestructive and in-situ detection method for predicting elongation change trend of 625 alloy after tensile fracture - Google Patents

Nondestructive and in-situ detection method for predicting elongation change trend of 625 alloy after tensile fractureDownload PDFInfo

- Publication number

- CN116148315A CN116148315ACN202111373938.4ACN202111373938ACN116148315ACN 116148315 ACN116148315 ACN 116148315ACN 202111373938 ACN202111373938 ACN 202111373938ACN 116148315 ACN116148315 ACN 116148315A

- Authority

- CN

- China

- Prior art keywords

- alloy

- elongation

- predicting

- nondestructive

- change trend

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N27/00—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means

- G01N27/02—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means by investigating impedance

- G01N27/04—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means by investigating impedance by investigating resistance

- G01N27/041—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means by investigating impedance by investigating resistance of a solid body

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N27/00—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means

- G01N27/26—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means by investigating electrochemical variables; by using electrolysis or electrophoresis

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E30/00—Energy generation of nuclear origin

- Y02E30/30—Nuclear fission reactors

Landscapes

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Health & Medical Sciences (AREA)

- Biochemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- Physics & Mathematics (AREA)

- Analytical Chemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Molecular Biology (AREA)

- Testing Resistance To Weather, Investigating Materials By Mechanical Methods (AREA)

- Investigating Or Analyzing Materials By The Use Of Electric Means (AREA)

- Investigating Strength Of Materials By Application Of Mechanical Stress (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及625合金电化学测试技术领域,更具体的说,涉及一种预测625合金拉伸断后伸长率变化趋势的方法。The invention relates to the technical field of electrochemical testing of 625 alloys, in particular to a method for predicting the elongation trend of 625 alloys after being stretched and broken.

背景技术Background technique

625合金耐高温氧化,耐腐蚀,抗疲劳,在油气管道、海洋、核工业等领域有着广泛的应用。出于性能或环境的需要,通常要对625合金进行热处理或长期时效处理,高温给元素扩散提供了所需的扩散激活能,溶质原子通过扩散在晶界或位错处偏聚形成析出相并长大。由于析出相的成分晶体结构等与基体存在较大的差异,因此析出相一方面可以通过钉扎位错使得合金强度硬度提高、塑韧性降低,另一方面,由于溶质原子尤其是Cr元素的扩散导致晶界邻近区域耐腐蚀性能降低提高了合金的晶间腐蚀敏感性。对于析出相的研究通常是通过扫描电子显微镜(SEM)及透射电子显微镜(TEM)等方法,这些方法的优点是在微观上可以精确的分析析出相的成分、类型和形态,但局限于微观定性或半定量难以宏观定量的分析析出相,此外,这些方法对设备、样品和实验人员的要求普遍教高,通常只能在科学实验室进行。Alloy 625 is resistant to high temperature oxidation, corrosion, and fatigue, and is widely used in oil and gas pipelines, marine, nuclear industries and other fields. Due to performance or environmental needs, 625 alloys are usually subjected to heat treatment or long-term aging treatment. High temperature provides the required diffusion activation energy for element diffusion, and solute atoms segregate at grain boundaries or dislocations to form precipitates and grow big. Due to the large difference between the composition and crystal structure of the precipitated phase and the matrix, on the one hand, the precipitated phase can increase the strength and hardness of the alloy and reduce the plasticity and toughness by pinning dislocations. On the other hand, due to the diffusion of solute atoms, especially Cr elements The corrosion resistance of the adjacent area of the grain boundary is reduced, which increases the intergranular corrosion susceptibility of the alloy. The study of precipitated phases is usually through scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The advantage of these methods is that the composition, type and morphology of precipitated phases can be accurately analyzed microscopically, but they are limited to microscopic qualitative Or semi-quantitative analysis of precipitated phases is difficult. In addition, these methods generally have high requirements for equipment, samples and experimenters, and usually can only be carried out in scientific laboratories.

发明内容Contents of the invention

本发明的目的在于克服现有技术的不足,提供一种无损且可原位检测的预测625合金(尤其是热处理或长时间时效处理后)拉伸断后伸长率变化趋势的方法。由于析出相在625合金中属于第二相,其结构与成分均与基体存在较大差异,因而腐蚀通常在该区域及其邻近区域优先发生。此外,大量析出的粗化析出相对合金的塑韧性也会产生不利影响,因此利用这一原理,本专利以电化学阻抗技术为基础,提出了一种625合金拉伸断后伸长率变化趋势预测的新指标。The purpose of the present invention is to overcome the deficiencies of the prior art and provide a non-destructive and in-situ detectable method for predicting the elongation trend of 625 alloy (especially after heat treatment or long-term aging treatment) after tensile fracture. Since the precipitated phase belongs to the second phase in the 625 alloy, its structure and composition are quite different from those of the matrix, so corrosion usually occurs preferentially in this area and its adjacent areas. In addition, the coarser precipitation of a large amount of precipitation will also have an adverse effect on the plasticity and toughness of the alloy. Therefore, using this principle, this patent is based on electrochemical impedance technology and proposes a prediction of the change trend of the elongation rate of the 625 alloy after tensile fracture. new indicator of .

一种无损且可原位检测的预测625合金拉伸断后伸长率变化趋势的方法,对625合金试样进行电化学阻抗测试并利用电化学阻抗分析软件建立等效电路对阻抗谱进行拟合,以得到电荷转移电阻Rt作为检测625合金中析出相的指标,电荷转移电阻Rt值越低说明合金中第二相析出越严重,试样的断后伸长率减小的倾向越大。A non-destructive and in-situ detectable method for predicting the elongation trend of 625 alloy after tensile fracture. The electrochemical impedance test is carried out on the 625 alloy sample, and the equivalent circuit is established by using the electrochemical impedance analysis software to fit the impedance spectrum. , the charge transfer resistance Rt is obtained as an indicator for detecting the precipitated phase in the 625 alloy. The lower the value of the charge transfer resistance Rt is, the more serious the precipitation of the second phase in the alloy is, and the greater the tendency of the elongation after fracture of the sample is to decrease.

在上述方法中,进行电化学阻抗测试时,将625合金试样在5wt%H2SO4+0.02wt.%KSCN水溶液中进行电化学阻抗测试。In the above method, when the electrochemical impedance test is performed, the 625 alloy sample is subjected to the electrochemical impedance test in 5 wt% H2 SO4 +0.02 wt.% KSCN aqueous solution.

在上述方法中,将625合金试样表面SiC砂纸由粗到细打磨至2000目并机械抛光,然后用去离子水和无水乙醇洗涤并干燥样品。In the above method, the SiC sandpaper on the surface of the 625 alloy sample was ground from coarse to fine to 2000 mesh and mechanically polished, and then the sample was washed with deionized water and absolute ethanol and dried.

在上述方法中,电化学阻抗测试在稳定的开路电位下进行,测试频率为105-10-2Hz,幅值为10mV。In the above method, the electrochemical impedance test is carried out at a stable open circuit potential, the test frequency is 105 -10-2 Hz, and the amplitude is 10 mV.

在上述方法中,利用电化学阻抗分析软件ZSimpWin建立等效电路对电化学测试得到的阻抗谱进行拟合。In the above method, the electrochemical impedance analysis software ZSimpWin was used to establish an equivalent circuit to fit the impedance spectrum obtained from the electrochemical test.

在本发明的技术方案中,耐蚀合金在介质中的腐蚀总是发生在能量较高的第二相及其邻近区域,所以电荷转移电阻Rt值越低说明合金中第二相析出越严重,试样的断后伸长率减小的倾向越大,当断后伸长率减小到一定程度时需要对材料进行安全防护或替换。In the technical solution of the present invention, the corrosion of the corrosion-resistant alloy in the medium always occurs in the second phase with higher energy and its adjacent region, so the lower the charge transfer resistance Rt value, the more serious the precipitation of the second phase in the alloy , the greater the tendency of the elongation after break of the sample to decrease, when the elongation after break decreases to a certain extent, the material needs to be protected or replaced.

附图说明Description of drawings

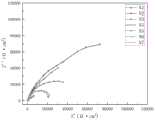

图1是本发明实施例中不同时效温度下的625合金样品的Nyquist图(1)。Fig. 1 is a Nyquist diagram (1) of 625 alloy samples at different aging temperatures in an embodiment of the present invention.

图2是本发明实施例中不同时效温度下的625合金样品的Nyquist图(2)。Fig. 2 is a Nyquist diagram (2) of 625 alloy samples at different aging temperatures in an embodiment of the present invention.

图3是本发明实施例中不同时效温度下的625合金样品的Bode图。Fig. 3 is a Bode diagram of 625 alloy samples at different aging temperatures in the examples of the present invention.

图4是本发明实施例中N1~N4和N7试样的拟合电路图。Fig. 4 is a fitting circuit diagram of N1-N4 and N7 samples in the embodiment of the present invention.

图5是本发明实施例中N5和N6试样的拟合电路图。Fig. 5 is a fitting circuit diagram of N5 and N6 samples in the embodiment of the present invention.

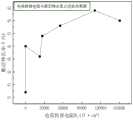

图6是本发明实施例中不同时效温度下的625合金样品的电荷转移电阻与断后伸长率之间的关系图。Fig. 6 is a graph showing the relationship between charge transfer resistance and elongation after fracture of 625 alloy samples at different aging temperatures in an embodiment of the present invention.

具体实施方式Detailed ways

下面结合具体实施例进一步说明本发明的技术方案。The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

将625合金试样在5wt%H2SO4+0.02wt.%KSCN水溶液中进行电化学阻抗测试。所应用的电解质溶液中的SCN-是一种典型的去极化剂,可以将试样表面钝化膜结构薄弱的区域优先破坏,通常这一薄弱区域在第二相邻近区域,而电化学阻抗拟合得到的电荷转移电阻Rt是钝化膜薄弱区电荷转移电阻和完整区电荷转移电阻并联的结果,因此Rt的大小主要受钝化膜薄弱区的控制,因此利用这一原理,本发明将电化学阻抗测试得到的电荷转移电阻Rt作为新指标检测625合金中的析出相,进而评价材料塑韧性尤其是拉伸断后伸长率的变化。该方法可以无损、快速定量的预测625合金拉伸断后伸长率的变化,指导生产安全进行。电化学阻抗测试在稳定的开路电位下进行,测试频率为105-10-2Hz,幅值为10mV。将所得阻抗谱通过拟合软件拟合,得到各项具有物理意义的参数。The 625 alloy sample was subjected to electrochemical impedance test in 5wt% H2 SO4 +0.02wt.% KSCN aqueous solution. TheSCN in the applied electrolyte solution is a typical depolarizer, which can preferentially destroy the weak area of the passivation film structure on the surface of the sample, usually this weak area is in the second phase adjacent area, and the electrochemical The charge transfer resistance Rt obtained by impedance fitting is the result of the parallel connection of the charge transfer resistance in the weak area of the passivation film and the charge transfer resistance in the intact area. Therefore, the size of Rt is mainly controlled by the weak area of the passivation film. Therefore, using this principle, The invention uses the charge transfer resistance Rt obtained by the electrochemical impedance test as a new index to detect the precipitated phase in the 625 alloy, and then evaluates the plastic toughness of the material, especially the change of the elongation after stretching. This method can non-destructively and rapidly quantitatively predict the change of the elongation of the 625 alloy after tensile fracture, so as to guide the safe production. The electrochemical impedance test was carried out at a stable open circuit potential, the test frequency was 105 -10-2 Hz, and the amplitude was 10 mV. The obtained impedance spectrum was fitted by fitting software to obtain various parameters with physical meaning.

具体步骤如下:Specific steps are as follows:

(1)配置5wt.%H2SO4+0.02wt.%KSCN的电解质溶液作为进行电化学再活化测试的介质。(1) Prepare an electrolyte solution of 5wt.% H2 SO4 +0.02wt.% KSCN as the medium for the electrochemical reactivation test.

(2)将待测试样的测试表面的背面接导线封入环氧树脂中并仅暴露测试表面(保证待测试样暴露面积相等)。(2) Encapsulate the back connection wires of the test surface of the test sample in epoxy resin and expose only the test surface (ensure that the exposed area of the test sample is equal).

(3)将样品表面SiC砂纸由粗到细打磨至2000目并机械抛光。然后用去离子水和无水乙醇洗涤并干燥样品。(3) Grind the surface of the sample with SiC sandpaper from coarse to fine to 2000 mesh and mechanically polish it. The samples were then washed with deionized water and absolute ethanol and dried.

(4)将制备好的试样浸泡在配置好的溶液中并测量开路电位,待开路电位稳定后,进行电化学阻抗测试,测试频率为105-10-2Hz,幅值为10mV。(4) Soak the prepared sample in the prepared solution and measure the open circuit potential. After the open circuit potential is stable, perform an electrochemical impedance test with a test frequency of 105 -10-2 Hz and an amplitude of 10 mV.

(8)利用电化学阻抗分析软件ZSimpWin建立等效电路对阻抗谱进行拟合得到各项参数,利用得到的参数Rt结合测试条件进行分析。(8) Use the electrochemical impedance analysis software ZSimpWin to establish an equivalent circuit to fit the impedance spectrum to obtain various parameters, and use the obtained parameter Rt to analyze in combination with the test conditions.

耐蚀合金在介质中的腐蚀总是发生在能量较高的第二相及其邻近区域,所以电荷转移电阻Rt值越低说明合金中第二相析出越严重,试样的断后伸长率减小的倾向越大,当断后伸长率减小到一定程度时需要对材料进行安全防护或替换。The corrosion of corrosion-resistant alloys in the medium always occurs in the second phase with higher energy and its adjacent regions, so the lower the charge transfer resistance Rt value, the more serious the precipitation of the second phase in the alloy, and the elongation after fracture of the sample The greater the tendency to decrease, the material needs to be protected or replaced when the elongation after fracture decreases to a certain extent.

以不同时效温度下的625合金的拉伸断后伸长率变化趋势为例:Take the change trend of elongation after fracture of 625 alloy at different aging temperatures as an example:

表1:625合金的热处理制度(7小时)Table 1: Heat treatment regime for 625 alloy (7 hours)

表2时效处理后625合金的电化学阻抗谱拟合结果Table 2 Fitting results of electrochemical impedance spectroscopy of alloy 625 after aging treatment

在本实验中,图1为各个样品的Nyquist图,图2为图1的左下部的局部放大图,图3为Bode图。In this experiment, Fig. 1 is the Nyquist diagram of each sample, Fig. 2 is the partially enlarged diagram of the lower left part of Fig. 1, and Fig. 3 is the Bode diagram.

从图1和图2可以看到N1~N4和N7试样阻抗弧均较大,而N5和N6试样弧半径远远小于其他试样,结合图3,N5出现了两个时间常数,所以对于阻抗弧度较大的N1~N4和N7试样选择钝化膜完好的电路进行拟合,如图4(阻抗谱拟合电路1),而阻抗弧较小的N5和N6试样则选择局部钝化膜破坏的电路进行拟合,如图5(阻抗谱拟合电路2)。From Figure 1 and Figure 2, it can be seen that the impedance arcs of N1-N4 and N7 samples are relatively large, while the arc radii of N5 and N6 samples are much smaller than other samples. Combined with Figure 3, N5 has two time constants, so For N1-N4 and N7 samples with large impedance arcs, select circuits with intact passivation film for fitting, as shown in Figure 4 (impedance spectrum fitting circuit 1), and for N5 and N6 samples with small impedance arcs, select local The circuit with the damaged passivation film is fitted, as shown in Figure 5 (impedance spectrum fitting circuit 2).

Rt值是由所测得的电化学阻抗谱通过软件ZSimpWin建立如图4和图5的等效电路拟合得到的。在等效电路中,Rs代表对电极到工作电极之间的溶液电阻,Q1为与双电层有关的常相位角元件,弥散系数n是表征常相位角元件接近纯电容的程度,n越接近1,越接近纯电容,Q2为钝化膜电容相关常相位角元件,Rf是钝化膜电阻,Rt是整个测试表面的电荷转移电阻。由图4和图5可以看到,拟合得到的电荷转移电阻Rt是试样表面钝化膜薄弱区域与钝化膜完好区域并联测试的结果,因而Rt值的大小主要取决于钝化膜薄弱区域,即:钝化膜越薄弱,则Rt越小,因而Rt的变化规律可以表明随着时效温度的增加第二相析出导致了局部腐蚀以及钝化膜均匀性的变差。The Rt value is obtained by fitting the measured electrochemical impedance spectrum through the software ZSimpWin to establish the equivalent circuit shown in Figure 4 and Figure 5 . In the equivalent circuit, Rs represents the solution resistance between the counter electrode and the working electrode, Q1 is the constant phase angle element related to the electric double layer, and the diffusion coefficient n is the degree to which the constant phase angle element is close to pure capacitance, n The closer to 1, the closer to pure capacitance,Q2 is the passivation film capacitance related constant phase angle element, Rf is the passivation film resistance, Rt is the charge transfer resistance of the entire test surface. It can be seen from Figure 4 and Figure 5 that the fitted charge transfer resistance Rt is the result of the parallel test of the weak passivation film area on the sample surface and the passivation film intact area, so the value of Rt mainly depends on the passivation film. The area of film weakness, that is, the weaker the passivation film is, the smaller the Rt is, so the change rule of Rt can show that the precipitation of the second phase with the increase of the aging temperature leads to localized corrosion and the deterioration of the uniformity of the passivation film.

从表2、图6可以看到电化学阻抗谱经拟合后,电荷转移电阻Rt较高时(>2.68×104(Ω·cm2))合金断后伸长率有较高的平台,随着Rt值的减小,断后伸长率急剧降低,在本实验的条件下,当Rt值低于2.68×104(Ω·cm2)时,625合金的断后伸长率急剧降低,因此可将该值定义为625合金断后伸长率的警戒值,当Rt值低于该值时,材料的延展性将显著降低有发生脆性断裂风险,需要对零部件进行防护或替换等相应措施。From Table 2 and Figure 6, it can be seen that after fitting the electrochemical impedance spectrum, when the charge transfer resistance Rt is high (>2.68×104 (Ω·cm2 )), the elongation of the alloy after fracture has a higher plateau, As the Rt value decreases, the elongation after fracture decreases sharply. Under the conditions of this experiment, when the Rt value is lower than 2.68×104 (Ω·cm2 ), the elongation after fracture of 625 alloy decreases sharply , so this value can be defined as the warning value of elongation after fracture of 625 alloy. When the Rt value is lower than this value, the ductility of the material will be significantly reduced, and the risk of brittle fracture will be reduced, and parts need to be protected or replaced. corresponding measures.

以上对本发明做了示例性的描述,应该说明的是,在不脱离本发明的核心的情况下,任何简单的变形、修改或者其他本领域技术人员能够不花费创造性劳动的等同替换均落入本发明的保护范围。The present invention has been described as an example above, and it should be noted that, without departing from the core of the present invention, any simple deformation, modification or other equivalent replacements that can be made by those skilled in the art without creative labor all fall within the scope of this invention. protection scope of the invention.

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111373938.4ACN116148315B (en) | 2021-11-19 | 2021-11-19 | Nondestructive and in-situ detection method for predicting elongation change trend of 625 alloy after tensile fracture |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111373938.4ACN116148315B (en) | 2021-11-19 | 2021-11-19 | Nondestructive and in-situ detection method for predicting elongation change trend of 625 alloy after tensile fracture |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN116148315Atrue CN116148315A (en) | 2023-05-23 |

| CN116148315B CN116148315B (en) | 2025-06-24 |

Family

ID=86358672

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202111373938.4AActiveCN116148315B (en) | 2021-11-19 | 2021-11-19 | Nondestructive and in-situ detection method for predicting elongation change trend of 625 alloy after tensile fracture |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN116148315B (en) |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103543180A (en)* | 2013-10-30 | 2014-01-29 | 南京林业大学 | Immune impedance biosensor detection method and device for quick pesticide residue detection |

| US20180143126A1 (en)* | 2016-11-18 | 2018-05-24 | The Boeing Company | Manufacture electrodes for electrochemical monitoring |

| CN109946356A (en)* | 2019-04-19 | 2019-06-28 | 大连海事大学 | A quantitative evaluation method for concrete damage after high temperature and fire |

| US20190277802A1 (en)* | 2016-09-30 | 2019-09-12 | Endress+Hauser Conducta Inc. | Failure analysis of a measuring sensor with an integrated temperature sensor |

| CN110699676A (en)* | 2019-11-20 | 2020-01-17 | 哈尔滨工业大学(深圳) | A kind of high-strength and high-conductivity metallic glass composite material and preparation method thereof |

- 2021

- 2021-11-19CNCN202111373938.4Apatent/CN116148315B/enactiveActive

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103543180A (en)* | 2013-10-30 | 2014-01-29 | 南京林业大学 | Immune impedance biosensor detection method and device for quick pesticide residue detection |

| US20190277802A1 (en)* | 2016-09-30 | 2019-09-12 | Endress+Hauser Conducta Inc. | Failure analysis of a measuring sensor with an integrated temperature sensor |

| US20180143126A1 (en)* | 2016-11-18 | 2018-05-24 | The Boeing Company | Manufacture electrodes for electrochemical monitoring |

| CN109946356A (en)* | 2019-04-19 | 2019-06-28 | 大连海事大学 | A quantitative evaluation method for concrete damage after high temperature and fire |

| CN110699676A (en)* | 2019-11-20 | 2020-01-17 | 哈尔滨工业大学(深圳) | A kind of high-strength and high-conductivity metallic glass composite material and preparation method thereof |

Non-Patent Citations (1)

| Title |

|---|

| 帅铭;郑茂盛;: "变形量对A3钢电化学性能的影响", 化工机械, no. 02, 15 April 2016 (2016-04-15), pages 36 - 39* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN116148315B (en) | 2025-06-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Lu et al. | Pitting and stress corrosion cracking behavior in welded austenitic stainless steel | |

| CN108088741A (en) | A Method of In-Situ Observation of Fatigue Cracks by Laser Confocal Microscope | |

| Toppo et al. | Effect of nitrogen on the intergranular stress corrosion cracking resistance of 316LN stainless steel | |

| Huang et al. | Improvement of stress corrosion cracking resistance by low cycle fatigue of a CrNiMoV steel | |

| Zhang et al. | Unmasking the delamination mechanisms of a defective coating under the co-existence of alternating stress and corrosion | |

| CN112539995B (en) | Method for evaluating hydrogen embrittlement sensitivity of material in cathodic protection process | |

| CN115684161A (en) | Method for judging highest service temperature of high-aluminum ethylene cracking furnace tube | |

| CN116148315A (en) | Nondestructive and in-situ detection method for predicting elongation change trend of 625 alloy after tensile fracture | |

| CN109002628B (en) | A high-temperature strength prediction method for martensitic steel based on microstructure degradation | |

| Zhou et al. | Effect of sensitizing treatment on the microstructure and susceptibility to intergranular corrosion of high-nitrogen austenitic stainless steel | |

| CN118274753B (en) | A method for evaluating the thickness of the oxide layer around high-temperature gas-film holes in nickel-based single crystal alloys | |

| CN114323884A (en) | Preparation method of Super304H austenitic stainless steel coarse grains | |

| CN105510392A (en) | Micro-resistor based waste and old engine valve nondestructive test method | |

| Jiao et al. | Effect of thermal aging on the intergranular stress corrosion cracking susceptibility of type 310S stainless steel | |

| CN114791456B (en) | Nondestructive and in-situ detection method for predicting impact toughness change trend of Cr13 super stainless steel | |

| Zheng et al. | Effect of hydrogen on semiconductor properties and pitting initiation of 2205 duplex stainless steel passivation film | |

| Xu et al. | Creep damage evolution by cavity nucleation and growth considering the cavity closure under cyclic loading conditions | |

| CN110596097A (en) | A Judgment Method for Load Fatigue Failure of Titanium Alloy Based on Fatigue Fracture Analysis | |

| Zhang et al. | Fracture analysis of stainless steel universal joints in power grid equipment: A comparative study of cast and forged structures | |

| Reese et al. | Hydrogen embrittlement of pulse-plated nickel | |

| Khandelwal et al. | Comparative study of basic test and resistance curve methods for fracture toughness evaluation of heat-treated Zr-2.5 Nb alloy | |

| Liu et al. | Research on the correlation between tensile ductility and corrosion behavior of surfacing alloy 625 | |

| CN110940691B (en) | A method for comparing the protective effects of different oxide films on metal substrates and its application | |

| Frenck et al. | Interrelationships of stress-induced martensitic phase transformation and pitting corrosion in iron-based shape memory alloys | |

| Serre et al. | Service behaviour of copper alloy tubes in heat-exchangers |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |