CN116141888A - Double-body all-terrain vehicle pitching control system - Google Patents

Double-body all-terrain vehicle pitching control systemDownload PDFInfo

- Publication number

- CN116141888A CN116141888ACN202310380853.1ACN202310380853ACN116141888ACN 116141888 ACN116141888 ACN 116141888ACN 202310380853 ACN202310380853 ACN 202310380853ACN 116141888 ACN116141888 ACN 116141888A

- Authority

- CN

- China

- Prior art keywords

- valve

- hinged

- vehicle

- car

- pitching

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60D—VEHICLE CONNECTIONS

- B60D1/00—Traction couplings; Hitches; Draw-gear; Towing devices

- B60D1/24—Traction couplings; Hitches; Draw-gear; Towing devices characterised by arrangements for particular functions

Landscapes

- Engineering & Computer Science (AREA)

- Transportation (AREA)

- Mechanical Engineering (AREA)

- Vehicle Body Suspensions (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及一种全地形车的俯仰控制结构及其液压控制系统。The invention relates to a pitch control structure of an all-terrain vehicle and a hydraulic control system thereof.

背景技术Background technique

原双车体全地形车通过中间铰接能够很好地完成多自由度的转向,使车辆能够灵活地在多地面条件行驶,但随着实际使用条件的变化,以及应用场景的拓展,该车辆被应用在面对更多复杂地形的场合,也增加了很多硬性要求。车辆面临跨越更高的垂直障碍、更宽的沟渠沟壑,在野外进行快速检修时需要更短周期,这些条件使双车体全地形车面临更多挑战,需要更加合理的设计和技术应用,解决这些问题。The original double-body all-terrain vehicle can well complete multi-degree-of-freedom steering through the middle hinge, so that the vehicle can flexibly drive on multiple ground conditions, but with the change of actual use conditions and the expansion of application scenarios, the vehicle has been The application in the face of more complex terrain also increases a lot of hard requirements. Vehicles are faced with crossing higher vertical obstacles, wider ditches and gullies, and need a shorter cycle for quick maintenance in the field. These conditions make the dual-body all-terrain vehicles face more challenges, which require more reasonable design and technical applications to solve these questions.

中国专利CN110104061A公开了一种电驱动铰接式全地形履带车的无液压转向铰接机构,通过在前车和后车之间安装俯仰油缸可以实现前车和后车之间的俯仰动作,但是在该技术方案中前车和后车的水平摆动铰点还要额外承受俯仰运动时在竖直面上的分力,铰点处的耳片容易变形。Chinese patent CN110104061A discloses a non-hydraulic steering articulation mechanism of an electrically driven articulated all-terrain crawler vehicle. The pitching action between the front vehicle and the rear vehicle can be realized by installing a pitch cylinder between the front vehicle and the rear vehicle, but in this In the technical solution, the horizontal swing hinges of the front and rear vehicles also bear the force component on the vertical plane during the pitching motion, and the lugs at the hinge points are easily deformed.

发明内容Contents of the invention

本发明所要解决的技术问题:该发明是为解决双车体全地形车俯仰控制问题而设计的一种液压控制系统,实现前车和后车的俯仰动作。The technical problem to be solved by the invention: the invention is a hydraulic control system designed to solve the pitch control problem of the dual-body all-terrain vehicle, so as to realize the pitch action of the front vehicle and the rear vehicle.

为实现上述目的,本发明采用如下技术方案:To achieve the above object, the present invention adopts the following technical solutions:

一种双车体全地形车俯仰控制系统,包括连接前车和后车的铰接装置,铰接装置由前后两个铰装座铰接而成,两个铰装座可以在水平面上摆动,前车和前铰接装置铰接并安装前俯仰油缸,后车和后铰接装置铰接并安装后俯仰油缸,前车或者后车可以在竖直面摆动A pitch control system for a dual-body all-terrain vehicle, including a hinged device connecting the front vehicle and the rear vehicle. The hinged device is composed of two hinged seats at the front and rear. The front hinged device is hinged and the front pitching oil cylinder is installed, the rear car and the rear hinged device are hinged and the rear pitching oil cylinder is installed, the front car or the rear car can swing in the vertical plane

前俯仰油缸铰装在前车和前铰装座之间,前俯仰油缸、前车和铰接装置三者分别两两铰接在三个铰点上,三个铰点所在的平面垂直于车体水平面;后俯仰油缸铰装在后车和铰接装置之间,后俯仰油缸、后车和铰接装置三者分别两两铰接在三个铰点上,三个铰点所在的平面垂直于车体水平面。The front pitching oil cylinder is hinged between the front car and the front hinged seat, and the front pitching oil cylinder, the front car and the hinged device are respectively hinged on three hinge points in pairs, and the plane where the three hinge points are located is perpendicular to the horizontal plane of the car body The rear pitching oil cylinder is hinged between the rear car and the articulated device, and the rear pitching oil cylinder, the rear car and the articulated device are respectively hinged in pairs on three hinge points, and the planes at the three hinge points are perpendicular to the car body level.

铰接装置的前后两个铰装座通过上下两个铰接点实现铰接,上下两个铰接点的连线垂直于车体水平面,两个铰装座可以在车体水平面上左右摆动,设有锁定机构在需要时锁定两个铰装座的相对运动The front and rear hinged seats of the hinged device are hinged through the upper and lower hinge points, and the connection line between the upper and lower hinge points is perpendicular to the horizontal plane of the vehicle body. The two hinged seats can swing left and right on the horizontal plane of the vehicle body, and are equipped with a locking mechanism Lock the relative movement of the two hinged seats when required

前后两个俯仰油缸通过油路依次连接组合阀5、换向阀4、单向阀3、节流阀2和变量泵1。The two front and rear pitch cylinders are sequentially connected to the

变量泵1从液压油箱11吸入液压油,变量泵1出口处的高压液压油经过节流阀2打开单向阀3,流入换向阀4,当车辆未操作俯仰开关时,变量泵1流出的高压油在换向阀4中位截止,当车辆操作俯仰开关时,高压油通过换向阀4流过组合阀5中单向阀流入俯仰油缸,俯仰油缸另一腔回油经组合阀5的安全卸荷阀、换向阀4进入液压油箱11。The variable pump 1 sucks hydraulic oil from the

在两个俯仰油缸和组合阀5之间设置功能阀7,功能阀7可以锁定油路或解除锁定。A

变量泵1输出的高压油经过单向阀5后旁通换向阀8并进入蓄能器9。The high-pressure oil output by the variable displacement pump 1 passes through the

变量泵1出口处旁接安全溢流阀10,安全溢流阀10的出口接入液压油箱11。The outlet of the variable displacement pump 1 is bypassed with a

本发明的有益效果:Beneficial effects of the present invention:

本系统中前后两个俯仰油缸分别铰装在不同的位置,俯仰运动所产生的反作用力对水平方向铰点的的影响很小。In this system, the front and rear pitching oil cylinders are respectively hinged at different positions, and the reaction force generated by the pitching motion has little influence on the hinge point in the horizontal direction.

当车辆需要进行特定障碍通过时、或者进行检修时,可使用俯仰功能进行辅助,充分提高车辆的垂直障碍、水平障碍的通过性能,另外,在检修时,俯仰功能可变换地提高车体的前后端,实现一定程度的模拟举升功能,方便检修人员在车体下部进行快速检修。When the vehicle needs to pass a specific obstacle or when it is overhauled, the pitch function can be used for assistance, which can fully improve the vehicle's passing performance of vertical obstacles and horizontal obstacles. To achieve a certain degree of simulated lifting function, it is convenient for maintenance personnel to perform quick maintenance at the lower part of the car body.

该系统能够很好地控制双车体全地形车俯、仰动作,并可以进行俯仰锁定、解除,同时,在车辆的动力系统停机后,借助蓄能器部件,还可以实现一定次数的俯仰动作,方便车辆的检修。The system can well control the pitching and pitching movements of the dual-body all-terrain vehicle, and can lock and release the pitching. At the same time, after the power system of the vehicle is shut down, it can also achieve a certain number of pitching movements with the help of accumulator components. , to facilitate vehicle maintenance.

附图说明Description of drawings

图1是俯仰油缸整体布局图。Figure 1 is the overall layout of the pitch cylinder.

图2俯仰油缸集成在铰接上的示意图。Figure 2 is a schematic diagram of the pitch cylinder integrated on the hinge.

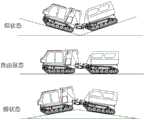

图3双车体全地形车俯仰状态和自由状态下的示意图。Fig. 3 is a schematic diagram of a double-body all-terrain vehicle in a pitch state and a free state.

图4是俯仰控制系统原理图。Figure 4 is a schematic diagram of the pitch control system.

具体实施方式Detailed ways

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述。The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

如图1和图2,铰接装置由前后两个铰装座铰接而成,铰点位于铰接装置中央,两个铰装座可以在车体水平面上摆动,前俯仰油缸铰装在前车和前铰装座之间,前俯仰油缸、前车和铰接装置三者分别两两铰接在三个铰点上,三个铰点所在的平面垂直于车体水平面;后俯仰油缸铰装在后车和铰接装置之间,后俯仰油缸、后车和铰接装置三者分别两两铰接在三个铰点上,前车和前铰接装置铰接的的铰点、前车和前俯仰油缸铰接的铰点、前俯仰油缸和前铰接装置铰接的铰点三者构成一个三角形,该三角形所在的平面垂直于车体的水平面,后车的俯仰铰接结构同理。As shown in Figure 1 and Figure 2, the hinged device is composed of two hinged seats at the front and rear. The hinge point is located in the center of the hinged device. The two hinged seats can swing on the horizontal plane of the car body. Between the hinged seats, the front pitching oil cylinder, the front car and the hinged device are respectively hinged on three hinge points in pairs, and the plane where the three hinge points are located is perpendicular to the horizontal plane of the car body; the rear pitching oil cylinder is hinged on the rear car and the Between the articulation devices, the rear pitching cylinder, the rear car and the articulation device are respectively hinged on three hinge points, the hinge point of the front car and the front articulation device, the hinge point of the front car and the front pitching cylinder, The front pitch oil cylinder and the hinge point of the front hinge device form a triangle, and the plane where the triangle is located is perpendicular to the horizontal plane of the car body, and the pitch hinge structure of the rear car is the same.

铰接装置的前后两个铰装座通过上下两个铰接点实现铰接,上下两个铰接点的连线垂直于车体水平面,两个铰装座可以在车体水平面上左右摆动,设有锁定机构在需要时锁定两个铰装座的相对运动(例如检修时需要提升前车或者后车,这时就要先锁定铰接装置的左右摆动)。铰接装置由前后两个铰装座铰接而成,前后两个铰装座均为C形,上下两个铰点位于铰接装置中央,前车和前铰装座水平铰接,后车和后铰装座水平铰接。前车和前铰接装置铰接,后车和后铰接装置铰接,在前后两个铰装座上有凸起的铰点支座结构,前俯仰油缸前端和前车铰接,缸体铰装在前铰装座的铰点支座结构上;后俯仰油缸铰装在后车和后铰装座的铰点支座结构之间。The front and rear hinged seats of the hinged device are hinged through the upper and lower hinge points, and the connection line between the upper and lower hinge points is perpendicular to the horizontal plane of the vehicle body. The two hinged seats can swing left and right on the horizontal plane of the vehicle body, and are equipped with a locking mechanism When needed, lock the relative movement of the two hinged seats (for example, the front car or the rear car need to be promoted during maintenance, and at this moment the left and right swings of the hinged device will be locked earlier). The hinged device is composed of two hinged seats at the front and rear. The two hinged seats are C-shaped. The upper and lower hinge points are located in the center of the hinged device. The seat is horizontally hinged. The front vehicle is hinged with the front hinged device, and the rear vehicle is hinged with the rear hinged device. There are raised hinge point support structures on the front and rear hinged seats. The front end of the front pitch cylinder is hinged with the front vehicle, and the cylinder body is hinged on the front hinge. On the hinge point support structure of the seat; the rear pitch cylinder is hinged between the rear vehicle and the hinge point support structure of the rear hinge mount.

两个俯仰油缸的俯仰控制系统包括变量泵1、节流阀2、单向阀3、换向阀4、组合阀5、俯仰油缸6、锁定/解除功能阀7、换向阀8、蓄能器9、安全溢流阀10、液压油箱11、液压油路等。如图4所示。The pitch control system of two pitch cylinders includes variable pump 1,

俯仰控制系统工作时的基本回路:变量泵1从液压油箱11吸入液压油,变量泵1出口处的高压液压油经过节流阀2打开单向阀3,流入换向阀4,当车辆未操作俯仰开关时,变量泵1流出的高压油在换向阀4中位截止,当车辆操作俯仰开关时,高压油通过换向阀4流过组合阀5中单向阀流入俯仰油缸,俯仰油缸另一腔回油,回油经组合阀5中安全卸荷阀、换向阀4进入液压油箱。The basic circuit when the pitch control system works: the variable pump 1 sucks hydraulic oil from the

在俯仰开关打开的时,需先使锁定/解除功能阀7通电并换向,使俯仰系统进回油强制断开,才能实现俯仰动作,此时关闭俯仰开关,保持锁定/解除功能阀7通电,则俯仰功能处于锁定状态。当锁定/解除功能阀7断电时,锁定/解除功能阀7恢复初始位置,俯仰油缸6进回油油路旁通,俯仰功能解除,车辆在重力作用下恢复自由状态。When the pitch switch is turned on, it is necessary to energize the lock/

组合阀5中集成单向阀和安全卸荷阀,在主油路有高压油进入时,组合阀5处于正常工作状态,当主油路没有高压油进入或油压过低时,组合阀5为缓冲阀功能,使车辆收到冲击等较大外载荷时,俯仰油缸能够快速卸荷,保障油缸的安全使用。The

变量泵1工作时,变量泵1后高压油经过单向阀5后,旁通换向阀8并进入蓄能器9,使蓄能器充液。在变量泵1停止工作时,在保证车辆通电状态下,可以使用蓄能器9实现变量泵1的功能,使车辆完成俯、仰、锁定、解除等动作。When the variable pump 1 is working, the high-pressure oil behind the variable pump 1 passes through the

旁通换向阀8通电时,蓄能器9泄压,经过泄压后,才可以对蓄能器进行检修、更换,(旁通换向阀8的功能正在于此)。When the bypass reversing valve 8 was energized, the accumulator 9 was depressurized, and after the pressure relief, the accumulator could be overhauled and replaced, (the function of the bypass reversing valve 8 is just here).

节流阀2用于调节俯仰油缸的伸缩速度,保证整车俯仰动作的安全。

单向阀3的作用是,当变量泵1停止工作时,蓄能器9的储存高压油在单向阀3处截止,避免高压油反向冲击主泵。The function of the one-way valve 3 is that when the variable displacement pump 1 stops working, the high-pressure oil stored in the accumulator 9 is cut off at the one-way valve 3, so as to avoid the reverse impact of the high-pressure oil on the main pump.

变量泵1工作时,当泵出口处的高压油超过安全溢流阀10的调定压力时,进行卸荷,避免损坏系统元件。When the variable displacement pump 1 is working, when the high-pressure oil at the outlet of the pump exceeds the set pressure of the

检测口M1用于检测俯仰油缸大腔的压力;检测口M2用于检测俯仰油缸小腔的压力;检测口M3用于检测蓄能器的液压压力。The detection port M1 is used to detect the pressure of the large chamber of the pitching cylinder; the detection port M2 is used to detect the pressure of the small chamber of the pitching cylinder; the detection port M3 is used to detect the hydraulic pressure of the accumulator.

当车辆需要进行特定障碍通过时、或者进行检修时,可使用俯仰功能进行辅助,充分提高车辆的垂直障碍、水平障碍的通过性能,另外,在检修时,俯仰功能可变换地提高车体的前后端,实现一定程度的模拟举升功能,方便检修人员在车体下部进行快速检修。When the vehicle needs to pass a specific obstacle or when it is overhauled, the pitch function can be used for assistance, which can fully improve the vehicle's passing performance of vertical obstacles and horizontal obstacles. To achieve a certain degree of simulated lifting function, it is convenient for maintenance personnel to perform quick maintenance at the lower part of the car body.

Claims (8)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310380853.1ACN116141888A (en) | 2023-04-11 | 2023-04-11 | Double-body all-terrain vehicle pitching control system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310380853.1ACN116141888A (en) | 2023-04-11 | 2023-04-11 | Double-body all-terrain vehicle pitching control system |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN116141888Atrue CN116141888A (en) | 2023-05-23 |

Family

ID=86360340

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202310380853.1APendingCN116141888A (en) | 2023-04-11 | 2023-04-11 | Double-body all-terrain vehicle pitching control system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN116141888A (en) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102358360A (en)* | 2011-07-28 | 2012-02-22 | 贵州詹阳动力重工有限公司 | Crawler-type dual vehicle bodies |

| CN102887177A (en)* | 2011-07-22 | 2013-01-23 | 天津建筑机械厂 | Obstacle surmounting type pitch device |

| US20140129083A1 (en)* | 2012-11-08 | 2014-05-08 | Ford Global Technologies, Llc | Assisted Direct Start And Active Suspension Integration Control |

| CN104563519A (en)* | 2015-01-09 | 2015-04-29 | 湖南五新重型装备有限公司 | Jib of concrete ejecting machine |

| JP2022030062A (en)* | 2020-08-06 | 2022-02-18 | マツダ株式会社 | Vehicle front body structure |

| CN220639424U (en)* | 2023-04-11 | 2024-03-22 | 贵州詹阳动力重工有限公司 | Double-body all-terrain vehicle pitching control system |

- 2023

- 2023-04-11CNCN202310380853.1Apatent/CN116141888A/enactivePending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102887177A (en)* | 2011-07-22 | 2013-01-23 | 天津建筑机械厂 | Obstacle surmounting type pitch device |

| CN102358360A (en)* | 2011-07-28 | 2012-02-22 | 贵州詹阳动力重工有限公司 | Crawler-type dual vehicle bodies |

| US20140129083A1 (en)* | 2012-11-08 | 2014-05-08 | Ford Global Technologies, Llc | Assisted Direct Start And Active Suspension Integration Control |

| CN104563519A (en)* | 2015-01-09 | 2015-04-29 | 湖南五新重型装备有限公司 | Jib of concrete ejecting machine |

| JP2022030062A (en)* | 2020-08-06 | 2022-02-18 | マツダ株式会社 | Vehicle front body structure |

| CN220639424U (en)* | 2023-04-11 | 2024-03-22 | 贵州詹阳动力重工有限公司 | Double-body all-terrain vehicle pitching control system |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR102548286B1 (en) | Active and passive dual mode switchable vehicle suspension system and conversion method thereof | |

| CN105008729B (en) | The energy-regenerating system of engineering machinery | |

| US7908048B2 (en) | Control system for a work machine and method for controlling a hydraulic cylinder | |

| US8726645B2 (en) | Hydraulic control system having energy recovery | |

| CN102971466A (en) | Hybrid construction machine | |

| CN106976425B (en) | Special robot equipment vehicle | |

| US20170241445A1 (en) | Fluid systems for machines with integrated energy recovery circuit | |

| CN105658879B (en) | Boom energy regeneration control loop and control method | |

| JP7478588B2 (en) | Hydraulic Excavator Drive System | |

| CN204956615U (en) | Vehicle and power -assisted steering system thereof | |

| US8561751B2 (en) | System for selectively charging and discharging a steering accumulator | |

| CN220639424U (en) | Double-body all-terrain vehicle pitching control system | |

| CN215436585U (en) | Emergency steering system based on hydraulic bridge circuit and engineering machinery | |

| CN101934819A (en) | Bus chassis articulation system and working method for urban rapid transit system | |

| US20150020511A1 (en) | Method for energy recovery of hydraulic motor | |

| KR102633378B1 (en) | Construction machinery | |

| CN108556910B (en) | All-wheel steering system | |

| CN100467297C (en) | Anti-rollover Safety System for Motor Vehicles | |

| CN116141888A (en) | Double-body all-terrain vehicle pitching control system | |

| CN115744632A (en) | Crane hydraulic control system and crane | |

| CN101370702B (en) | Control system for frame steering of a vehicle and method for controlling two steering cylinders in a frame-steered vehicle | |

| CN212250661U (en) | A kind of aerial work vehicle and its traveling underframe floating oil cylinder balance valve control system | |

| CN112298346B (en) | Vehicle rear wheel steering control system | |

| CN213862408U (en) | Multi-mode steering hydraulic system of multi-shaft semitrailer | |

| CN111775918B (en) | Hydraulic brake system for road-rail dual-purpose vehicle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |