CN116103179A - Preparation method and application of a composite active bacterial agent for treating oily residue - Google Patents

Preparation method and application of a composite active bacterial agent for treating oily residueDownload PDFInfo

- Publication number

- CN116103179A CN116103179ACN202111325258.5ACN202111325258ACN116103179ACN 116103179 ACN116103179 ACN 116103179ACN 202111325258 ACN202111325258 ACN 202111325258ACN 116103179 ACN116103179 ACN 116103179A

- Authority

- CN

- China

- Prior art keywords

- liquid

- active

- preparing

- mass ratio

- composite

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C12—BIOCHEMISTRY; BEER; SPIRITS; WINE; VINEGAR; MICROBIOLOGY; ENZYMOLOGY; MUTATION OR GENETIC ENGINEERING

- C12N—MICROORGANISMS OR ENZYMES; COMPOSITIONS THEREOF; PROPAGATING, PRESERVING, OR MAINTAINING MICROORGANISMS; MUTATION OR GENETIC ENGINEERING; CULTURE MEDIA

- C12N1/00—Microorganisms, e.g. protozoa; Compositions thereof; Processes of propagating, maintaining or preserving microorganisms or compositions thereof; Processes of preparing or isolating a composition containing a microorganism; Culture media therefor

- C12N1/20—Bacteria; Culture media therefor

- B—PERFORMING OPERATIONS; TRANSPORTING

- B09—DISPOSAL OF SOLID WASTE; RECLAMATION OF CONTAMINATED SOIL

- B09B—DISPOSAL OF SOLID WASTE NOT OTHERWISE PROVIDED FOR

- B09B3/00—Destroying solid waste or transforming solid waste into something useful or harmless

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- Genetics & Genomics (AREA)

- Biotechnology (AREA)

- Organic Chemistry (AREA)

- Zoology (AREA)

- Bioinformatics & Cheminformatics (AREA)

- Wood Science & Technology (AREA)

- Medicinal Chemistry (AREA)

- Microbiology (AREA)

- Biomedical Technology (AREA)

- Virology (AREA)

- Biochemistry (AREA)

- General Engineering & Computer Science (AREA)

- General Health & Medical Sciences (AREA)

- Tropical Medicine & Parasitology (AREA)

- Environmental & Geological Engineering (AREA)

- Micro-Organisms Or Cultivation Processes Thereof (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于措施废液残渣处理术领域,特别涉及一种处理含油残渣的复合活性菌剂的制备方法及应用。The invention belongs to the field of waste liquid residue treatment technology, and in particular relates to a preparation method and application of a composite active bacterial agent for treating oily residue.

背景技术Background technique

石油中含有丰富的烃类物质,大部分的烃类对土壤、环境都是有害的,比如芳香烃类物质对人及动物的毒性较大,如果经较长时间较大浓度接触,会引起恶心、头疼、眩晕等症状。此外,石油中的多环芳烃类物质具有强烈的“三致”作用。泄漏的原油等烃类物质如遇明火,会造成火灾事故;如果泄漏的烃类进入受限空间内,VOC达到爆炸下限,极易发生爆炸,甚至造成群死群伤的灾难性事故发生。Petroleum is rich in hydrocarbons, most of which are harmful to the soil and the environment. For example, aromatic hydrocarbons are highly toxic to humans and animals. If they are exposed to large concentrations for a long time, they will cause nausea , headache, dizziness and other symptoms. In addition, polycyclic aromatic hydrocarbons in petroleum have a strong "three-induced" effect. Leaked crude oil and other hydrocarbons will cause a fire accident if exposed to an open flame; if the leaked hydrocarbons enter the confined space, the VOC will reach the lower limit of explosion, and it is very easy to explode, and even cause catastrophic accidents that cause mass death and mass injury.

措施废液是油田石油生产过程中各个工艺环节产生的多种液体废物的混合物,针对这措施废液的处理方式,常用的方式就是将措施废液运输到处理站,进行集中处理,实现油水分离,固液分离,最终得到的固体部分即为油田措施废液残渣。这些措施废液残渣中的烃类物质依然大量存在,属于一类固体危险废弃物。Measure waste liquid is a mixture of various liquid wastes produced in various process links in the oil production process of the oil field. For the treatment method of this measure waste liquid, the common way is to transport the measure waste liquid to the treatment station for centralized treatment to realize oil-water separation , solid-liquid separation, and the final solid part is the waste liquid residue of oilfield measures. The hydrocarbons in the waste liquid residues of these measures still exist in large quantities, which belong to a class of solid hazardous waste.

发明内容Contents of the invention

为了克服现有技术中措施废液残渣中烃类有机物降解效率低的问题,本发明提出了一种处理含油残渣的复合活性菌剂的制备方法及应用,该复合活性菌剂能有针对性的降解油田措施废液残渣的烃类物质,尤其是烯烃和烷烃类,且降解效果好。In order to overcome the problem of low degradation efficiency of hydrocarbon organic matter in waste liquid residues in the prior art, the present invention proposes a preparation method and application of a composite active bacterial agent for treating oily residues. The composite active bacterial agent can be targeted Degradation of hydrocarbons in waste liquid residues of oilfield measures, especially olefins and alkanes, and the degradation effect is good.

本发明采用的技术方案为:The technical scheme adopted in the present invention is:

一种处理含油残渣的复合活性菌剂的制备方法,具体的制备步骤如下:A preparation method of a composite active bacterial agent for treating oily residues, the specific preparation steps are as follows:

步骤1、制备培养基

按比例称取硫酸铵、磷酸二氢钾、牛肉膏、硫酸镁、磷酸氢钠和氯化钙并溶解于蒸馏水中,得到pH值为6.5-7.5的培养基;Weigh ammonium sulfate, potassium dihydrogen phosphate, beef extract, magnesium sulfate, sodium hydrogen phosphate and calcium chloride in proportion and dissolve them in distilled water to obtain a culture medium with a pH value of 6.5-7.5;

步骤2、种子菌液制备

将步骤1中制备的培养基分装于四个瓶中,115-125℃下灭菌25-35min后,对四个瓶中的培养基分别接种动胶菌、微球菌、葡萄球菌以及假单胞菌;接着于35-38℃培养20-25h后,得到动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液;Divide the medium prepared in

步骤3、菌种培养扩大

将步骤2中得到的动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液按比例混合得到混合种子菌液,接着将混合种子菌液接种至步骤1中制备的培养基上,于35-38℃混合培养45-55h后得到复合液体微生物降解菌剂;Mix the Anitoglia seed bacterium liquid, Micrococcus seed bacterium liquid, Staphylococcus seed bacterium liquid and Pseudomonas seed bacterium liquid obtained in

步骤4、制备液体活性乳化剂

将活性乳化剂与酒精按照质量比为4-5:1的比例混合均匀,然后将混合后的液体与蒸馏水按质量比为1-2:1比例进行充分溶解,得到液体活性乳化剂;Mix the active emulsifier and alcohol evenly according to the mass ratio of 4-5:1, and then fully dissolve the mixed liquid and distilled water according to the mass ratio of 1-2:1 to obtain the liquid active emulsifier;

步骤5、制备营养盐溶液

按比例称取硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素溶液溶解于蒸馏水中,搅拌均匀,得到营养盐溶液;Weigh ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, sodium chloride, yeast extract, sodium hydrogen phosphate and trace element solutions in proportion and dissolve them in distilled water, stir evenly to obtain a nutrient salt solution;

步骤6、制备活性辅助剂

将步骤4制备的液体活性乳化剂和步骤5制备的营养盐溶液按照1-1.5:1的体积比混合,得到活性辅助剂;The liquid active emulsifier prepared in

步骤7、载体吸附

将步骤3中得到的复合液体微生物降解菌剂、步骤6中得到的活性辅助剂、以及载体按照7-10:1:9-12质量比混合,静置吸附反应32-45h后于32-45℃烘干至含水率不高于30%,得到复合活性固体菌剂。Mix the composite liquid microbial degradation bacterial agent obtained in

所述的步骤1中,硫酸铵、磷酸二氢钾、牛肉膏、硫酸镁、磷酸氢钠和氯化钙的质量比为1:1:3:0.01:1.2:0.19-0.021。In the

所述的步骤3中,动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液混合质量比为1-1.01:1:1:1-1.01。In the

所述的步骤3中,所述的混合种子菌液的质量占培养基质量的8-12%。In the

所述的步骤4中,活性乳化剂为吐温60、吐温80、斯盘80或斯盘85。In the

所述的步骤4中,活性乳化剂、酒精和蒸馏水的体积比8-12:1:84-94。In described

所述的酒精为质量浓度比为75%-95%酒精。The alcohol is alcohol with a mass concentration ratio of 75%-95%.

所述的步骤5中硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素溶液与蒸馏水的质量比为2.4-2.6:4:4:2:0.5:4:5-5.1:1000;所述的微量元素溶液中Zn2+的质量比为2.3-2.4%;Ca2+的质量比为0.17-0.8%;Cu2+的质量比为2.0%;Fe2+的质量比为0.68-0.70%,其余为水溶液质量。In the described

所述的步骤7中的载体为麸皮或豆粕。The carrier in

一种处理含油残渣的复合活性菌剂的应用,所述的复合活性固体菌剂应用于油田措施废液残渣中烃类的降解。An application of a composite active bacterial agent for treating oily residues. The composite active solid bacterial agent is applied to the degradation of hydrocarbons in waste liquid residues of oil field measures.

本发明的有益效果为:The beneficial effects of the present invention are:

1)本发明提供的一种处理含油残渣的复合活性菌剂的制备方法中复合活性菌剂中的各种微生物菌种采用了分别制备种子菌液的培养模式,有利于复合活性菌剂中各种微生物菌种保持最大菌数比例,避免了复合在一起时,其中某一种占据绝对优势,其他菌种数量被抑制的情况发生。1) In a kind of preparation method of the composite active bacterial agent of processing oily residue provided by the present invention, the various microbial strains in the composite active bacterial agent have adopted the cultivation mode of preparing seed bacterial liquid respectively, are beneficial to each in the composite active bacterial agent The proportion of the maximum number of microorganisms is maintained to avoid the situation that when they are combined together, one of them has an absolute advantage and the number of other bacteria is suppressed.

2)本发明在后期的扩大培养采用混合培养模式,有利于再保证每种微生物均能发挥作用情况下,节省生产成本,减少对生产设备的投入,提高生产过程可操作性。2) The present invention adopts the mixed culture mode in the expanded cultivation in the later stage, which is beneficial to save production cost, reduce investment in production equipment, and improve the operability of the production process while ensuring that each microorganism can play a role.

3)本发明与常规处理菌剂的微生物成分不同,该复合活性菌剂中,除了微生物成分外,还添加了液体活性乳化剂成分,活性乳化剂可以促进处理体系中烃类物质向水相中迁移,增加乳化效果,进而促进微生物对其的催化氧化作用,提高烃类物质的去除效果;该复合活性菌剂与常规处理菌剂不同之处还在于补充添加了营养盐溶液成分。微生物生长过程中会消耗一定量的营养盐,导致处理后期营养盐缺乏,生长缓慢,降解效率降低,添加适量营养盐,保证菌种生长过程中能持续摄取到足够的营养盐。3) The present invention is different from the microbial components of the conventional treatment bacteria agent. In the composite active bacteria agent, in addition to the microbial components, a liquid active emulsifier component is also added, and the active emulsifier can promote the hydrocarbons in the treatment system to the water phase. Migrate, increase the emulsification effect, and then promote the catalytic oxidation of microorganisms to it, and improve the removal effect of hydrocarbons; the difference between this composite active bacterial agent and the conventional treatment bacterial agent is that it is supplemented with nutrient salt solution components. During the growth of microorganisms, a certain amount of nutrient salt will be consumed, resulting in the lack of nutrient salt in the later stage of treatment, slow growth, and reduced degradation efficiency. Add appropriate amount of nutrient salt to ensure that the bacteria can continuously absorb sufficient nutrient salt during the growth process.

以下将结合附图进行进一步的说明。Further description will be made below in conjunction with the accompanying drawings.

附图说明Description of drawings

图1是本发明一种处理含油残渣的复合活性菌剂的制备方法的制备过程示意图;Fig. 1 is a schematic diagram of the preparation process of a preparation method of a composite active microbial agent for processing oily residues of the present invention;

图2是本发明一种处理含油残渣的复合活性菌剂的制备方法实施例1中制备的复合活性固体菌剂得扫描电镜图;Fig. 2 is a scanning electron micrograph of the composite active solid bacterial agent prepared in Example 1 of a preparation method of a composite active bacterial agent for treating oily residues of the present invention;

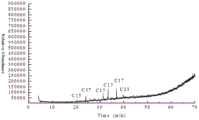

图3是XJ动胶菌、XB芽孢杆菌、W6葡萄球菌对培养基中烷烃降解实验中的空白对照GC-MS图;Fig. 3 is the blank control GC-MS figure in the alkane degradation experiment in the culture medium of XJ Kineticum, XB bacillus, W6 staphylococcus;

图4是XJ动胶菌、XB芽孢杆菌、W6葡萄球菌对培养基中烷烃降解实验中XB芽孢杆菌属降解后的GC-MS图;Fig. 4 is the GC-MS figure after XJ Bacillus, XB Bacillus, W6 staphylococcus are degraded in the alkane degradation experiment in medium;

图5是XJ动胶菌、XB芽孢杆菌、W6葡萄球菌对培养基中烷烃降解实验中XJ动胶菌属降解后的GC-MS图;Fig. 5 is the GC-MS figure after the degradation of XJ Kinetoglia in the experiment of XJ Kinetoglia, XB bacillus, W6 Staphylococcus in the alkane degradation experiment in the medium;

图6是XJ动胶菌、XB芽孢杆菌、W6葡萄球菌对培养基中烷烃降解实验中W6葡萄球菌属降解后的GC-MS图;Fig. 6 is the GC-MS figure after the W6 staphylococcus is degraded in the alkane degradation experiment in the culture medium of XJ kinetobacter, XB bacillus, W6 staphylococcus;

图7是XJ动胶菌、XB芽孢杆菌、W6葡萄球菌对培养基中烷烃降解实验中XH微球菌属、W6葡萄球菌属、W4链球菌属降解后的芳烃GC-MS图;Fig. 7 is the aromatic hydrocarbon GC-MS figure after XH Micrococcus, W6 Staphylococcus, W4 Streptococcus degrades in the alkane degradation experiment in culture medium of XJ Anitoglia, XB Bacillus, W6 Staphylococcus;

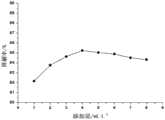

图8是Ba-J1假单胞菌对混合菌群降解率的影响实验效果图;Figure 8 is an experimental effect diagram of the influence of Ba-J1 Pseudomonas on the degradation rate of mixed flora;

图9是Ba-J1假单胞菌的添加量对混合菌群降解率的影响实验效果图。Fig. 9 is an experimental effect diagram of the effect of the addition amount of Ba-J1 Pseudomonas on the degradation rate of the mixed flora.

具体实施方式Detailed ways

实施例1:Example 1:

为了克服现有技术中措施废液残渣中烃类有机物降解效率低的问题,本发明提出了一种处理含油残渣的复合活性菌剂的制备方法及应用,该复合活性菌剂能有针对性的降解油田措施废液残渣的烃类物质,尤其是烯烃和烷烃类,且降解效果好。In order to overcome the problem of low degradation efficiency of hydrocarbon organic matter in waste liquid residues in the prior art, the present invention proposes a preparation method and application of a composite active bacterial agent for treating oily residues. The composite active bacterial agent can be targeted Degradation of hydrocarbons in waste liquid residues of oilfield measures, especially olefins and alkanes, and the degradation effect is good.

一种处理含油残渣的复合活性菌剂的制备方法,具体的制备步骤如下:A preparation method of a composite active bacterial agent for treating oily residues, the specific preparation steps are as follows:

步骤1、制备培养基

按比例称取硫酸铵、磷酸二氢钾、牛肉膏、硫酸镁、磷酸氢钠和氯化钙并溶解于蒸馏水中,得到pH值为6.5-7.5的培养基;Weigh ammonium sulfate, potassium dihydrogen phosphate, beef extract, magnesium sulfate, sodium hydrogen phosphate and calcium chloride in proportion and dissolve them in distilled water to obtain a culture medium with a pH value of 6.5-7.5;

步骤2、种子菌液制备

将步骤1中制备的培养基分装于四个瓶中,115-125℃下灭菌25-35min后,对四个瓶中的培养基分别接种动胶菌、微球菌、葡萄球菌以及假单胞菌;接着于35-38℃培养20-25h后,得到动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液;Divide the medium prepared in

步骤3、菌种培养扩大

将步骤2中得到的动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液按比例混合得到混合种子菌液,接着将混合种子菌液接种至步骤1中制备的培养基上,于35-38℃混合培养45-55h后得到复合液体微生物降解菌剂;Mix the Anitoglia seed bacterium liquid, Micrococcus seed bacterium liquid, Staphylococcus seed bacterium liquid and Pseudomonas seed bacterium liquid obtained in

步骤4、制备液体活性乳化剂

将活性乳化剂与酒精按照质量比为4-5:1的比例混合均匀,然后将混合后的液体与蒸馏水按质量比为1-2:1比例进行充分溶解,得到液体活性乳化剂;Mix the active emulsifier and alcohol evenly according to the mass ratio of 4-5:1, and then fully dissolve the mixed liquid and distilled water according to the mass ratio of 1-2:1 to obtain the liquid active emulsifier;

步骤5、制备营养盐溶液

按比例称取硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素溶液溶解于蒸馏水中,搅拌均匀,得到营养盐溶液;Weigh ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, sodium chloride, yeast extract, sodium hydrogen phosphate and trace element solutions in proportion and dissolve them in distilled water, stir evenly to obtain a nutrient salt solution;

步骤6、制备活性辅助剂

将步骤4制备的液体活性乳化剂和步骤5制备的营养盐溶液按照1-1.5:1的体积比混合,得到活性辅助剂;The liquid active emulsifier prepared in

步骤7、载体吸附

将步骤3中得到的复合液体微生物降解菌剂、步骤6中得到的活性辅助剂、以及载体按照7-10:1:9-12质量比混合,静置吸附反应32-45h后于32-45℃烘干至含水率不高于30%,得到复合活性固体菌剂。Mix the composite liquid microbial degradation bacterial agent obtained in

本发明中,动胶菌、微球菌、葡萄球菌以及假单胞菌均为现有菌种,可直接在市场上购买,购买厂家可以为上海烜雅生物或上海户实医药科技有限公司,本发明中将不再进行进一步的说明。In the present invention, Kinetoglia, Micrococcus, Staphylococcus and Pseudomonas are all existing strains, which can be purchased directly in the market, and the purchaser can be Shanghai Xuanya Biology or Shanghai Hushi Pharmaceutical Technology Co., Ltd. No further description will be given in the invention.

优选的,所述的步骤1中,硫酸铵、磷酸二氢钾、牛肉膏、硫酸镁、磷酸氢钠和氯化钙的质量比为1:1:3:0.01:1.2:0.19-0.021。Preferably, in the

本发明中,瓶为锥形瓶,其锥形结构相对稳定,不易倾倒;瓶身上设有多个刻度,以标示所能盛载的容量。In the present invention, the bottle is an Erlenmeyer bottle with a relatively stable conical structure and is not easy to topple over; there are multiple scales on the body of the bottle to indicate the capacity it can hold.

本发明步骤1中,硫酸铵、磷酸二氢钾、牛肉膏、硫酸镁、磷酸氢钠和氯化钙的质量比优选为1:1:3:0.01:1.2:0.02。制备出的培养基其PH值为6.5-7.5。本发明中,培养基的制备过程为现有技术,本发明中将不再进行进一步的说明。In

优选的,所述的步骤3中,动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液混合质量比为1-1.01:1:1:1-1.01。Preferably, in the

优选的,所述的步骤3中,所述的混合种子菌液的质量占培养基质量的8-12%。Preferably, in the

优选的,所述的步骤4中,活性乳化剂为吐温60、吐温80、斯盘80或斯盘85。Preferably, in the

优选的,所述的步骤4中,活性乳化剂、酒精和蒸馏水的体积比8-12:1:84-94。Preferably, in the

优选的,所述的酒精为质量浓度比为75%-95%酒精。Preferably, the alcohol is alcohol with a mass concentration ratio of 75%-95%.

本发明中,由于斯盘80或斯盘85不溶于水,溶剂选取了酒精,根据需求选取酒精的质量浓度比,其优选为80%、85%、90%。本发发明中,质量浓度比为75%-95%酒精易溶解斯盘80或斯盘85,且溶解效果好。In the present invention, since

优选的,所述的步骤5中硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素溶液与蒸馏水的质量比为2.4-2.6:4:4:2:0.5:4:5-5.1:1000,Preferably, in described

本发明的步骤5中,硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素溶液与蒸馏水的质量比优选为2.5:4:4:2:0.5:4:5:1000。本发明中,制备营养盐溶液的方法为现有技术,本发明中将不再进行进一步的说明。In

优选的,所述的微量元素溶液中Zn2+的质量比为2.3-2.4%;Ca2+的质量比为0.17-0.8%;Cu2+的质量比为2.0%;Fe2+的质量比为0.68-0.70%,其余为水溶液质量。Preferably, the mass ratio of Zn2+ in the trace element solution is 2.3-2.4%; the mass ratio of Ca2+ is 0.17-0.8%; the mass ratio of Cu2+ is 2.0%; the mass ratio of Fe2+ It is 0.68-0.70%, and the rest is the quality of aqueous solution.

本发明中,微量元素至少包括锌、铜、铁、钙,所述的步骤5中的微量元素溶液中Zn2+的质量比优选为2.3%;Ca2+的质量比优选为0.17%;Cu2+的质量比优选为2.0%;Fe2+的质量比优选为0.68%,其余为水溶液质量。In the present invention, trace elements include at least zinc, copper, iron, calcium, and the mass ratio of Zn in the trace element solution in described

优选的,所述的步骤7中的载体为麸皮或豆粕。Preferably, the carrier in

本发明与常规处理菌剂的微生物成分不同,该复合活性菌剂中,除了微生物成分外,还添加了液体活性乳化剂成分,活性乳化剂可以促进处理体系中烃类物质向水相中迁移,增加乳化效果,进而促进微生物对其的催化氧化作用,提高烃类物质的去除效果。本发明中复合活性菌剂中的各种微生物菌种采用了分别制备种子菌液的培养模式,有利于复合活性菌剂中各种微生物菌种保持最大菌数比例,避免了复合在一起时,其中某一种占据绝对优势,其他菌种数量被抑制的情况发生。The present invention is different from the microbial component of the conventional microbial treatment agent. In the composite active bacterial agent, in addition to the microbial component, a liquid active emulsifier component is also added. The active emulsifier can promote the migration of hydrocarbon substances in the treatment system to the water phase. Increase the emulsification effect, and then promote the catalytic oxidation of microorganisms to it, and improve the removal effect of hydrocarbon substances. In the present invention, the various microbial strains in the composite active bacterial agent have adopted the culture mode of separately preparing the seed bacterial liquid, which is conducive to the maintenance of the maximum number of bacteria in the composite active bacterial agent by various microbial strains, and avoids compounding. One of them has an absolute advantage, and the number of other strains is suppressed.

本发明在后期的扩大培养采用混合培养模式,有利于再保证每种微生物均能发挥作用情况下,节省生产成本,减少对生产设备的投入,提高生产过程可操作性。该复合活性菌剂与常规处理菌剂不同之处还在于补充添加了营养盐溶液成分。微生物生长过程中会消耗一定量的营养盐,导致处理后期营养盐缺乏,生长缓慢,降解效率降低,添加适量营养盐,保证菌种生长过程中能持续摄取到足够的营养盐。The present invention adopts a mixed culture mode in the expanded cultivation in the later stage, which is beneficial to save production costs, reduce investment in production equipment, and improve the operability of the production process while ensuring that each microorganism can play a role. The difference between the composite active bacteria agent and the conventional treatment bacteria agent is that the composition of the nutrient salt solution is supplemented. During the growth of microorganisms, a certain amount of nutrient salt will be consumed, resulting in the lack of nutrient salt in the later stage of treatment, slow growth, and reduced degradation efficiency. Add appropriate amount of nutrient salt to ensure that the bacteria can continuously absorb sufficient nutrient salt during the growth process.

本发明通过制备培养基、种子菌液制备、菌种培养扩大、添加液体活性乳化剂、添加营养盐溶液、载体吸附后最终得到含水率不高于30%的复合活性固体菌剂,本发明的复合活性菌剂应用于油田措施废液残渣中烃类的降解,降解效率高,效果好。The present invention finally obtains a composite active solid bacterial agent with a moisture content of not higher than 30% by preparing a culture medium, preparing a seed bacterial liquid, expanding strain culture, adding a liquid active emulsifier, adding a nutrient salt solution, and absorbing a carrier. The composite active bacterial agent is applied to the degradation of hydrocarbons in the waste liquid residue of oil field measures, and the degradation efficiency is high and the effect is good.

实施例2:Example 2:

基于实施例1的基础上,本实施例中,提供一种处理含油残渣的复合活性菌剂的制备方法,具体的制备流程如图1所示,制备步骤如下:Based on Example 1, in this example, a method for preparing a composite active bacterial agent for treating oily residue is provided. The specific preparation process is shown in Figure 1, and the preparation steps are as follows:

步骤1、制备培养基

按1:1:3:0.01:1.2:0.02的质量比称取硫酸铵、磷酸二氢钾、牛肉膏、硫酸镁、磷酸氢钠和氯化钙后溶解于蒸馏水中,得到pH值为7.0的培养基;Weigh ammonium sulfate, potassium dihydrogen phosphate, beef extract, magnesium sulfate, sodium hydrogen phosphate and calcium chloride at a mass ratio of 1:1:3:0.01:1.2:0.02 and dissolve them in distilled water to obtain a pH value of 7.0 Culture medium;

步骤2、种子菌液制备

将步骤1中制备的培养基分装于四个锥形瓶中,115℃下灭菌35min后,分别接种动胶菌、微球菌、葡萄球菌以及假单胞菌,接着于38℃培养20h后,得到动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液;Divide the medium prepared in

步骤3、菌种培养扩大

将步骤2中得到的动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液按1:1:1:1的体积比混合得到混合种子菌液,混合种子菌液按照培养基质量的8%接种至步骤1中制备的培养基上,于38℃混合培养48h后得到复合液体微生物降解菌剂;The Kineticum seed bacterium liquid obtained in

步骤4、制备液体活性乳化剂

称取吐温60并与95%酒精以10:1的体积比混合均匀,接着加入蒸馏水充分溶解,使得95%酒精与蒸馏水的体积比为1:89,得到液体活性乳化剂;Weigh

步骤5、制备营养盐溶液

称取硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素液溶解于蒸馏水中,搅拌均匀,得到营养盐溶液;Weigh ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, sodium chloride, yeast extract, sodium hydrogen phosphate and trace element solutions and dissolve them in distilled water, stir evenly to obtain a nutrient salt solution;

其中,硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素液与蒸馏水的质量比为2.5:4:4:2:0.5:4:5:1000。Among them, the mass ratio of ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, sodium chloride, yeast extract, sodium hydrogen phosphate and trace element liquid to distilled water is 2.5:4:4:2:0.5:4:5:1000.

微量元素液中Zn2+的质量比为2.3%;Ca2+的质量比为0.17%;Cu2+的质量比为2.0%;Fe2+的质量比为0.68%,其余为水溶液质量。The mass ratio of Zn2+ in the trace element solution is 2.3%; the mass ratio of Ca2+ is 0.17%; the mass ratio of Cu2+ is 2.0%; the mass ratio of Fe2+ is 0.68%, and the rest is the mass of the aqueous solution.

步骤6、制备活性辅助剂

将液体活性乳化剂和营养盐溶液按照1:1的体积比混合,得到活性辅助剂;mixing the liquid active emulsifier and the nutrient salt solution according to the volume ratio of 1:1 to obtain the active auxiliary agent;

步骤7、载体吸附

将步骤3中得到的复合液体微生物降解菌剂、步骤6中得到的活性辅助剂、以及麸皮按照7:1:9质量比混合,静置吸附反应36h后于42℃烘干至含水率不高于30%,得到复合活性固体菌剂。Mix the composite liquid microbial degradation bacterial agent obtained in

使用实施例2中制备的该复合活性固体菌剂进行了含油残渣处理的实际应用。向含油残渣中按比例加入上述复合活性固体菌剂,定期检测残渣中含油率变化情况,从而分析该菌剂的应用效果。表1是含油率为3.99%的含油残渣中按比例分别加入0%、1%、2%、3%、4%、5%复合活性固体菌剂,每隔5天检测残渣中的含油率。The practical application of oily residue treatment was carried out using the composite active solid bacterial agent prepared in Example 2. Add the above-mentioned composite active solid bacterial agent to the oily residue in proportion, and regularly detect the change of oil content in the residue, so as to analyze the application effect of the bacterial agent. Table 1 is that 0%, 1%, 2%, 3%, 4%, 5% composite active solid bacterial agents are added in proportion to the oily residue with an oil content of 3.99%, and the oil content in the residue is detected every 5 days.

表1含油率为3.99%含油残渣因不同菌剂添加量的含油率变化Table 1 The oil content is 3.99% The oil content of the oily residue changes due to the addition of different bacterial agents

从表1中可以看出,添加菌剂可以去除含油残渣中的石油烃,降低含油率。5%菌剂添加量处理效果最好,在处理30d后,含油残渣含油率可由3.99%降低至0.70%,提高了82.46%。It can be seen from Table 1 that the addition of bacterial agents can remove petroleum hydrocarbons in oily residues and reduce the oil content. The treatment effect was the best with the addition of 5% bacterial agent. After 30 days of treatment, the oil content of the oily residue could be reduced from 3.99% to 0.70%, an increase of 82.46%.

实施例3:Example 3:

基于实施例1的基础上,本实施例中,一种处理含油残渣的复合活性菌剂的制备方法,具体的制备流程如图1所示,制备步骤如下:Based on Example 1, in this example, a method for preparing a composite active bacterial agent for treating oily residues, the specific preparation process is shown in Figure 1, and the preparation steps are as follows:

步骤1、制备培养基

按1:1:3:0.01:1.2:0.02的质量比称取硫酸铵、磷酸二氢钾、牛肉膏、硫酸镁、磷酸氢钠和氯化钙后溶解于蒸馏水中,得到pH值为7.0的培养基;Weigh ammonium sulfate, potassium dihydrogen phosphate, beef extract, magnesium sulfate, sodium hydrogen phosphate and calcium chloride at a mass ratio of 1:1:3:0.01:1.2:0.02 and dissolve them in distilled water to obtain a pH value of 7.0 Culture medium;

步骤2、种子菌液制备

将步骤1中制备的培养基分装于四个锥形瓶中,125℃下灭菌25min后,分别接种动胶菌、微球菌、葡萄球菌以及假单胞菌,接着于35℃培养25h后,得到动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液;Divide the culture medium prepared in

步骤3、菌种培养扩大

将步骤2中得到的动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液按1:1:1:1的体积比混合得到混合种子菌液,混合种子菌液按照培养基质量的10%接种至步骤1中制备的培养基上,于35℃混合培养55h后得到复合液体微生物降解菌剂;The Kineticum seed bacterium liquid obtained in

步骤4、制备液体活性乳化剂

称取吐温80并与95%酒精以12:1的体积比混合均匀,接着加入蒸馏水充分溶解,使得95%酒精与蒸馏水的体积比为1:84,得到液体活性乳化剂;Weigh

步骤5、制备营养盐溶液

称取硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素液溶解于蒸馏水中,搅拌均匀,得到营养盐溶液;Weigh ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, sodium chloride, yeast extract, sodium hydrogen phosphate and trace element solutions and dissolve them in distilled water, stir evenly to obtain a nutrient salt solution;

其中,硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素液与蒸馏水的质量比为2.5:4:4:2:0.5:4:5:1000。Among them, the mass ratio of ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, sodium chloride, yeast extract, sodium hydrogen phosphate and trace element liquid to distilled water is 2.5:4:4:2:0.5:4:5:1000.

微量元素液中Zn2+的质量比为2.3%;Ca2+的质量比为0.17%;Cu2+的质量比为2.0%;Fe2+的质量比为0.68%,其余为水溶液质量。The mass ratio of Zn2+ in the trace element solution is 2.3%; the mass ratio of Ca2+ is 0.17%; the mass ratio of Cu2+ is 2.0%; the mass ratio of Fe2+ is 0.68%, and the rest is the mass of the aqueous solution.

步骤6、制备活性辅助剂

将液体活性乳化剂和营养盐溶液按照1:1的体积比混合,得到活性辅助剂;mixing the liquid active emulsifier and the nutrient salt solution according to the volume ratio of 1:1 to obtain the active auxiliary agent;

步骤7、载体吸附

将步骤3中得到的复合液体微生物降解菌剂、步骤6中得到的活性辅助剂、以及豆粕按照8:1:10质量比混合,静置吸附反应45h后于32℃烘干至含水率不高于30%,得到复合活性固体菌剂。Mix the composite liquid microbial degradation bacterial agent obtained in

使用实施例3中制备的复合活性固体菌剂进行了含油残渣处理的实际应用。向含油残渣中按比例加入上述复合活性固体菌剂,定期检测残渣中含油率变化情况,从而分析该菌剂的应用效果。表2是含油率为10.59%的含油残渣中按比例分别加入0%、1%、2%、3%、4%、5%复合活性固体菌剂,每隔5天检测残渣中的含油率。The practical application of oily residue treatment was carried out using the composite active solid bacterial agent prepared in Example 3. Add the above-mentioned composite active solid bacterial agent to the oily residue in proportion, and regularly detect the change of oil content in the residue, so as to analyze the application effect of the bacterial agent. Table 2 is that 0%, 1%, 2%, 3%, 4%, 5% composite active solid bacterial agents were added in proportion to the oily residue with an oil content of 10.59%, and the oil content in the residue was detected every 5 days.

表2含油率为10.59%含油残渣因不同菌剂添加量的含油率变化Table 2 The oil content is 10.59% The oil content of the oily residue changes due to the addition of different bacterial agents

从表2中可以看出,添加菌剂可以去除含油残渣中的石油烃,降低含油率。5%菌剂添加量处理效果最好,在处理30d后,含油残渣含油率可由10.59%降低至0.85%。提高了91.97%。It can be seen from Table 2 that the addition of bacterial agents can remove petroleum hydrocarbons in oily residues and reduce the oil content. The treatment effect was the best with the addition of 5% bacterial agent, and the oil content of the oily residue could be reduced from 10.59% to 0.85% after 30 days of treatment. An improvement of 91.97%.

实施例4:Example 4:

基于实施例1的基础上,本实施例中提供一种处理含油残渣的复合活性菌剂的制备方法,具体的制备流程如图1所示,制备步骤如下:Based on Example 1, a method for preparing a composite active bacterial agent for treating oily residue is provided in this example. The specific preparation process is shown in Figure 1, and the preparation steps are as follows:

步骤1、制备培养基

按1:1:3:0.01:1.2:0.02的质量比称取硫酸铵、磷酸二氢钾、牛肉膏、硫酸镁、磷酸氢钠和氯化钙后溶解于蒸馏水中,得到pH值为7.0的培养基;Weigh ammonium sulfate, potassium dihydrogen phosphate, beef extract, magnesium sulfate, sodium hydrogen phosphate and calcium chloride at a mass ratio of 1:1:3:0.01:1.2:0.02 and dissolve them in distilled water to obtain a pH value of 7.0 Culture medium;

步骤2、种子菌液制备

将步骤1中制备的培养基分装于四个锥形瓶中,120℃下灭菌30min后,分别接种动胶菌、微球菌、葡萄球菌以及假单胞菌,接着于36℃培养22h后,得到动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液;Divide the medium prepared in

步骤3、菌种培养扩大

将步骤2中得到的动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液按1:1:1:1的体积比混合得到混合种子菌液,混合种子菌液按照培养基质量的12%接种至步骤1中制备的培养基上,于36℃混合培养48h后得到复合液体微生物降解菌剂;The Kineticum seed bacterium liquid obtained in

步骤4、制备液体活性乳化剂

称取斯盘80并与95%酒精以10:1的体积比混合均匀,接着加入蒸馏水充分溶解,使得95%酒精与蒸馏水的体积比为1:89,得到液体活性乳化剂;Weigh

步骤5、制备营养盐溶液

称取硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素液溶解于蒸馏水中,搅拌均匀,得到营养盐溶液;Weigh ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, sodium chloride, yeast extract, sodium hydrogen phosphate and trace element solutions and dissolve them in distilled water, stir evenly to obtain a nutrient salt solution;

其中,硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素液与蒸馏水的质量比为2.5:4:4:2:0.5:4:5:1000。Among them, the mass ratio of ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, sodium chloride, yeast extract, sodium hydrogen phosphate and trace element liquid to distilled water is 2.5:4:4:2:0.5:4:5:1000.

微量元素液中Zn2+的质量比为2.3%;Ca2+的质量比为0.17%;Cu2+的质量比为2.0%;Fe2+的质量比为0.68%,其余为水溶液质量。The mass ratio of Zn2+ in the trace element solution is 2.3%; the mass ratio of Ca2+ is 0.17%; the mass ratio of Cu2+ is 2.0%; the mass ratio of Fe2+ is 0.68%, and the rest is the mass of the aqueous solution.

步骤6、制备活性辅助剂

将液体活性乳化剂和营养盐溶液按照1:1的体积比混合,得到活性辅助剂;mixing the liquid active emulsifier and the nutrient salt solution according to the volume ratio of 1:1 to obtain the active auxiliary agent;

步骤7、载体吸附

将步骤3中得到的复合液体微生物降解菌剂、步骤6中得到的活性辅助剂、以及麸皮按照10:1:9质量比混合,静置吸附反应40h后于40℃烘干至含水率不高于30%,得到复合活性固体菌剂。Mix the composite liquid microbial degradation bacterial agent obtained in

使用实施例4中制备的复合活性固体菌剂进行了含油残渣处理的实际应用。向含油残渣中按比例加入上述复合活性固体菌剂,定期检测残渣中含油率变化情况,从而分析该菌剂的应用效果。表3是含油率为3.99%的含油残渣中按比例添加5%复合活性固体菌剂与不添加菌剂的对照处理实验。每隔5天检测残渣中的含油率。The practical application of oily residue treatment was carried out using the composite active solid bacterial agent prepared in Example 4. Add the above-mentioned composite active solid bacterial agent to the oily residue in proportion, and regularly detect the change of oil content in the residue, so as to analyze the application effect of the bacterial agent. Table 3 is the control treatment experiment of adding 5% composite active solid bacterial agent and no bacterial agent in proportion to the oily residue with an oil content of 3.99%. Check the oil content in the residue every 5 days.

表3 5%菌剂添加量对含油率为3.99%含油残渣处理效果Table 3 The effect of 5% bacterial agent addition on the treatment of oily residue with an oil content of 3.99%

从表3中可以看出,添加菌剂可以去除含油残渣中的石油烃,降低含油率。5%菌剂添加量处理30d后,含油残渣含油率可由3.99%降低至0.69%。提高了82.70%。It can be seen from Table 3 that the addition of bacterial agents can remove petroleum hydrocarbons in oily residues and reduce the oil content. After 30 days of treatment with 5% bacterial agent addition, the oil content of oily residue can be reduced from 3.99% to 0.69%. An increase of 82.70%.

实施例5:Example 5:

基于实施例1的基础上,本实施例中提供一种处理含油残渣的复合活性菌剂的制备方法,具体的制备流程如图1所示,制备步骤如下:Based on Example 1, a method for preparing a composite active bacterial agent for treating oily residue is provided in this example. The specific preparation process is shown in Figure 1, and the preparation steps are as follows:

步骤1、制备培养基

按1:1:3:0.01:1.2:0.02的质量比称取硫酸铵、磷酸二氢钾、牛肉膏、硫酸镁、磷酸氢钠和氯化钙后溶解于蒸馏水中,得到pH值为7.0的培养基;Weigh ammonium sulfate, potassium dihydrogen phosphate, beef extract, magnesium sulfate, sodium hydrogen phosphate and calcium chloride at a mass ratio of 1:1:3:0.01:1.2:0.02 and dissolve them in distilled water to obtain a pH value of 7.0 Culture medium;

步骤2、种子菌液制备

将步骤1中制备的培养基分装于四个锥形瓶中,122℃下灭菌27min后,分别接种动胶菌、微球菌、葡萄球菌以及假单胞菌,接着于37℃培养21h后,得到动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液;Divide the culture medium prepared in

步骤3、菌种培养扩大

将步骤2中得到的动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液按1:1:1:1的体积比混合得到混合种子菌液,混合种子菌液按照培养基质量的11%接种至步骤1中制备的培养基上,于37℃混合培养45h后得到复合液体微生物降解菌剂;The Kineticum seed bacterium liquid obtained in

步骤4、制备液体活性乳化剂

称取斯盘85并与95%酒精以8:1的体积比混合均匀,接着加入蒸馏水充分溶解,使得95%酒精与蒸馏水的体积比为1:94,得到液体活性乳化剂;Weigh

步骤5、制备营养盐溶液

称取硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素液溶解于蒸馏水中,搅拌均匀,得到营养盐溶液;Weigh ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, sodium chloride, yeast extract, sodium hydrogen phosphate and trace element solutions and dissolve them in distilled water, stir evenly to obtain a nutrient salt solution;

其中,硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素液与蒸馏水的质量比为2.5:4:4:2:0.5:4:5:1000。Among them, the mass ratio of ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, sodium chloride, yeast extract, sodium hydrogen phosphate and trace element liquid to distilled water is 2.5:4:4:2:0.5:4:5:1000.

微量元素液中Zn2+的质量比为2.3%;Ca2+的质量比为0.17%;Cu2+的质量比为2.0%;Fe2+的质量比为0.68%,其余为水溶液质量。The mass ratio of Zn2+ in the trace element solution is 2.3%; the mass ratio of Ca2+ is 0.17%; the mass ratio of Cu2+ is 2.0%; the mass ratio of Fe2+ is 0.68%, and the rest is the mass of the aqueous solution.

步骤6、制备活性辅助剂

将液体活性乳化剂和营养盐溶液按照1:1的体积比混合,得到活性辅助剂;mixing the liquid active emulsifier and the nutrient salt solution according to the volume ratio of 1:1 to obtain the active auxiliary agent;

步骤7、载体吸附

将步骤3中得到的复合液体微生物降解菌剂、步骤6中得到的活性辅助剂、以及豆粕按照7:1:12质量比混合,静置吸附反应32h后于45℃烘干至含水率不高于30%,得到复合活性固体菌剂。Mix the composite liquid microbial degradation bacterial agent obtained in

使用实施例5中制备的复合活性固体菌剂进行了含油残渣处理的实际应用。向含油残渣中按比例加入上述复合活性固体菌剂,定期检测残渣中含油率变化情况,从而分析该菌剂的应用效果。表4是含油率为10.59%的含油残渣中按5%比例添加复合活性固体菌剂和不添加菌剂的处理对比,每隔5天检测残渣中的含油率。The practical application of oily residue treatment was carried out using the composite active solid bacterial agent prepared in Example 5. Add the above-mentioned composite active solid bacterial agent to the oily residue in proportion, and regularly detect the change of oil content in the residue, so as to analyze the application effect of the bacterial agent. Table 4 is a comparison of the treatment of adding composite active solid bacterial agent and no bacterial agent in the oily residue with an oil content of 10.59%, and detecting the oil content in the residue every 5 days.

表4 5%菌剂添加量对含油率为10.59%含油残渣处理效果Table 4 The effect of 5% bacterial agent addition on the treatment of oily residue with an oil content of 10.59%

从表4中可以看出,添加菌剂可以去除含油残渣中的石油烃,降低含油率。5%菌剂添加量处理30d后,含油残渣含油率可由10.59%降低至0.96%。提高了90.93%。It can be seen from Table 4 that the addition of bacterial agents can remove petroleum hydrocarbons in oily residues and reduce the oil content. After 30 days of treatment with 5% bacterial agent addition, the oil content of oily residue can be reduced from 10.59% to 0.96%. An improvement of 90.93%.

实施例6:Embodiment 6:

基于实施例1的基础上,本实施例中提供一种处理含油残渣的复合活性菌剂的制备方法,具体的制备流程如图1所示,制备步骤如下:Based on Example 1, a method for preparing a composite active bacterial agent for treating oily residue is provided in this example. The specific preparation process is shown in Figure 1, and the preparation steps are as follows:

步骤1、制备培养基

按1:1:3:0.01:1.2:0.02的质量比称取硫酸铵、磷酸二氢钾、牛肉膏、硫酸镁、磷酸氢钠和氯化钙后溶解于蒸馏水中,得到pH值为7.0的培养基;Weigh ammonium sulfate, potassium dihydrogen phosphate, beef extract, magnesium sulfate, sodium hydrogen phosphate and calcium chloride at a mass ratio of 1:1:3:0.01:1.2:0.02 and dissolve them in distilled water to obtain a pH value of 7.0 Culture medium;

步骤2、种子菌液制备

将步骤1中制备的培养基分装于四个锥形瓶中,118℃下灭菌33min后,分别接种动胶菌、微球菌、葡萄球菌以及假单胞菌,接着于38℃培养20h后,得到动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液;Divide the medium prepared in

步骤3、菌种培养扩大

将步骤2中得到的动胶菌种子菌液、微球菌种子菌液、葡萄球菌种子菌液以及假单胞菌种子菌液按1:1:1:1的体积比混合得到混合种子菌液,混合种子菌液按照培养基质量的9%接种至步骤1中制备的培养基上,于38℃混合培养45h后得到复合液体微生物降解菌剂;The Kineticum seed bacterium liquid obtained in

步骤4、制备液体活性乳化剂

称取斯盘85并与95%酒精以11:1的体积比混合均匀,接着加入蒸馏水充分溶解,使得95%酒精与蒸馏水的体积比为1:90,得到液体活性乳化剂;Weigh

步骤5、制备营养盐溶液

称取硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素液溶解于蒸馏水中,搅拌均匀,得到营养盐溶液;Weigh ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, sodium chloride, yeast extract, sodium hydrogen phosphate and trace element solutions and dissolve them in distilled water, stir evenly to obtain a nutrient salt solution;

其中,硫酸铵、硫酸镁、磷酸二氢钾、氯化钠、酵母膏、磷酸氢钠以及微量元素液与蒸馏水的质量比为2.5:4:4:2:0.5:4:5:1000。Among them, the mass ratio of ammonium sulfate, magnesium sulfate, potassium dihydrogen phosphate, sodium chloride, yeast extract, sodium hydrogen phosphate and trace element liquid to distilled water is 2.5:4:4:2:0.5:4:5:1000.

微量元素液中Zn2+的质量比为2.3%;Ca2+的质量比为0.17%;Cu2+的质量比为2.0%;Fe2+的质量比为0.68%,其余为水溶液质量。The mass ratio of Zn2+ in the trace element solution is 2.3%; the mass ratio of Ca2+ is 0.17%; the mass ratio of Cu2+ is 2.0%; the mass ratio of Fe2+ is 0.68%, and the rest is the mass of the aqueous solution.

步骤6、制备活性辅助剂

将液体活性乳化剂和营养盐溶液按照1:1的体积比混合,得到活性辅助剂;mixing the liquid active emulsifier and the nutrient salt solution according to the volume ratio of 1:1 to obtain the active auxiliary agent;

步骤7、载体吸附

将步骤3中得到的复合液体微生物降解菌剂、步骤6中得到的活性辅助剂、以及豆粕按照9:1:11质量比混合,静置吸附反应45h后于45℃烘干至含水率不高于30%,得到复合活性固体菌剂。Mix the composite liquid microbial degradation bacterial agent obtained in

使用实施例6中制备的复合活性固体菌剂进行了含油残渣处理的实际应用。向含油残渣中按比例加入上述复合活性固体菌剂,定期检测残渣中含油率变化情况,从而分析该菌剂的应用效果。表5是含油率为3.99%的含油残渣中按比例添加5%复合活性固体菌剂与不添加菌剂的对照处理实验。每隔5d检测残渣中的含油率。The practical application of oily residue treatment was carried out using the composite active solid bacterial agent prepared in Example 6. Add the above-mentioned composite active solid bacterial agent to the oily residue in proportion, and regularly detect the change of oil content in the residue, so as to analyze the application effect of the bacterial agent. Table 5 is the control treatment experiment of adding 5% composite active solid bacterial agent and no bacterial agent in proportion to the oily residue with an oil content of 3.99%. The oil content in the residue was detected every 5 days.

表5 5%菌剂添加量对含油率为3.99%含油残渣处理效果Table 5 The effect of 5% bacterial agent addition on the treatment of oily residue with an oil content of 3.99%

从表5中可以看出,添加菌剂可以去除含油残渣中的石油烃,降低含油率。5%菌剂添加量在处理30d后,含油残渣含油率可由3.99%降低至0.59%。提高了85.21%。It can be seen from Table 5 that the addition of bacterial agents can remove petroleum hydrocarbons in oily residues and reduce the oil content. The oil content of oily residue can be reduced from 3.99% to 0.59% after 30 days of treatment with 5% bacterial agent addition. An increase of 85.21%.

本发明中,图2为上述的实施例2中制备的复合活性固体菌剂得扫描电镜图,由图2可知,该复合活性固体菌剂在扫描电镜下可见菌体形态正常,浓度较高,在载体表面分布较为均匀,吸附稳固。Among the present invention, Fig. 2 is the scanning electron micrograph of the composite active solid bacterial agent prepared in the above-mentioned

本发明的方法中四种菌种选择过程如下:Four kinds of strain selection process are as follows in the method of the present invention:

(1)高效石油降解菌的GC-MS分析(1) GC-MS analysis of efficient petroleum degrading bacteria

a、实验材料a. Experimental materials

菌株:XJ动胶菌属、XH微球菌属、XB芽孢杆菌属、W4链球菌属、W6葡萄球菌属Strains: XJ Kinetobacter, XH Micrococcus, XB Bacillus, W4 Streptococcus, W6 Staphylococcus

原油:采自长庆油田采油一厂Crude oil: extracted from the No. 1 Oil Production Plant of Changqing Oilfield

烷烃、芳烃:分别为原油分离组分Alkanes and aromatics: separate components of crude oil

烷烃降解培养基:硝酸铵2.0g,磷酸氢二钾1.0g,磷酸二氢钾0.5g,无水氯化钙0.02g,七水硫酸镁0.5g,氯化钠5.0g,原油3.0g,蒸馏水1000mL,pH为7Alkane degradation medium: 2.0g ammonium nitrate, 1.0g dipotassium hydrogen phosphate, 0.5g potassium dihydrogen phosphate, 0.02g anhydrous calcium chloride, 0.5g magnesium sulfate heptahydrate, 5.0g sodium chloride, 3.0g crude oil, distilled water 1000mL,

芳烃降解培养基:硝酸铵2.0g,磷酸氢二钾1.0g,磷酸二氢钾0.5g,无水氯化钙0.02g,七水硫酸镁0.5g,氯化钠5.0g,分离芳烃3.0g,蒸馏水1000mL,pH为7Aromatic hydrocarbon degradation medium: ammonium nitrate 2.0g, dipotassium hydrogen phosphate 1.0g, potassium dihydrogen phosphate 0.5g, anhydrous calcium chloride 0.02g, magnesium sulfate heptahydrate 0.5g, sodium chloride 5.0g, separated aromatics 3.0g, Distilled water 1000mL,

b、实验方法b. Experimental method

①XJ动胶菌属、XB芽孢杆菌属、W6葡萄球菌属降解烷烃后GC-MS分析① GC-MS analysis of alkanes degraded by XJ Kinetoglia, XB Bacillus and W6 Staphylococcus

将XJ动胶菌属、XB芽孢杆菌属和W6葡萄球菌属活化培养24h后,制成一定浓度的菌悬液(OD600=0.50),接于灭菌烷烃降解培养基中,30℃,100r/min下恒温震荡培养9d后,加入30mL石油醚萃取降解产物,将菌液离心后,转到分液漏斗,收集上层液,并用石油醚多次洗涤,合并上层液,无水硫酸钠脱水后,于65℃烘箱中烘干,置于干燥器中冷却。将回收得到的残油重新溶解在石油醚(色谱纯)中,取1μL样品进行上样GC-MS分析,同时设不接菌组作为空白对照。After activating and culturing XJ Kinetobacter, XB Bacillus and W6 Staphylococcus for 24 hours, make a certain concentration of bacterial suspension (OD600=0.50), inoculate in sterile alkane degradation medium, 30°C, 100r/ After culturing at constant temperature and shaking for 9 days, add 30mL of petroleum ether to extract the degradation product, centrifuge the bacterial solution, transfer it to a separatory funnel, collect the supernatant, and wash it with petroleum ether for several times, combine the supernatant, and dehydrate it with anhydrous sodium sulfate. Dry in an oven at 65°C and cool in a desiccator. The recovered residual oil was redissolved in petroleum ether (chromatographically pure), and 1 μL sample was taken for GC-MS analysis, and the non-inoculated group was set as a blank control.

GC-MS(HP-5MS,30.0m×250μm×0.25μm)运行条件:检测器温度为300℃,进样口温度为280℃,柱温80℃,恒温5min,以3℃/min升温至290℃,保留10min采用分流进样;载气为He,流速1mL/min。GC-MS (HP-5MS, 30.0m×250μm×0.25μm) operating conditions: detector temperature is 300°C, injection port temperature is 280°C, column temperature is 80°C, constant temperature is 5min, and the temperature is raised to 290°C at 3°C/min ℃, hold for 10 minutes, and use split injection; the carrier gas is He, and the flow rate is 1mL/min.

②XH微球菌属、W4链球菌属、W6葡萄球菌属降解处理后芳烃的GC-MS分析② GC-MS analysis of aromatic hydrocarbons after degradation treatment of XH Micrococcus, W4 Streptococcus and W6 Staphylococcus

分别取W4链球菌属、W6葡萄球菌属、XH微球菌属各1mL稀释后的菌悬液加入到含有100mL芳烃降解培养基的250mL三角瓶中。每4d测一次降解率,降解持续12d,降解剩余底物用相同体积分析纯二氯甲烷萃取2次。二氯甲烷完全挥发后,用色谱纯二氯甲烷复溶,使复溶后浓度在100-500ppm,过0.22μm有机相滤膜后,装入2mL GC-MS自动进样瓶中,用GC-MS检测。不接菌种的培养基作为对照,每个样品做3个平行。Take W4 Streptococcus, W6 Staphylococcus, and XH Micrococcus 1mL diluted bacterial suspensions respectively and add them into 250mL Erlenmeyer flasks containing 100mL aromatics degradation medium. The degradation rate was measured every 4 days, and the degradation lasted for 12 days. The remaining substrate was extracted twice with the same volume of analytically pure dichloromethane. After dichloromethane is completely volatilized, redissolve with chromatographically pure dichloromethane so that the concentration after redissolution is 100-500ppm. After passing through a 0.22μm organic phase filter membrane, put it into a 2mL GC-MS automatic sampling bottle, and use GC-MS MS detection. The culture medium not inoculated with bacteria was used as a control, and three parallels were made for each sample.

c、实验结果c. Experimental results

①XJ动胶菌属、XB芽孢杆菌属、W6葡萄球菌属的烷烃降解后培养液GC-MS分析① GC-MS analysis of the alkane-degraded culture fluid of XJ Kinetoglia, XB Bacillus and W6 Staphylococcus

XJ动胶菌、XB芽孢杆菌、W6葡萄球菌中烷烃降解菌对培养基中烷烃降解的GC-MS变化见图3至图6。The GC-MS changes of the degradation of alkane in the culture medium by the alkane-degrading bacteria in XJ Anitoglia, XB Bacillus, and W6 Staphylococcus are shown in Figures 3 to 6.

由图3可知,实验所用原油中的主要成分为C16-C28的烷烃,约占67.0%,即原油中主要为中长链和长链烷烃,短链烷烃含量相对较少。It can be seen from Figure 3 that the main components of the crude oil used in the experiment are C16-C28 alkanes, accounting for about 67.0%, that is, the crude oil is mainly medium and long chain alkanes, and the content of short chain alkanes is relatively small.

由图4可知,经过菌株XB芽孢杆菌属的降解,可看到长链的C21、C27、C28、C35、C39峰消失,说明菌株XB芽孢杆菌属对于长链烃的降解效果显著。降解后C17明显有所增加,这是长链烃被降解为较短链烃所致。It can be seen from Figure 4 that after the degradation of the strain XB Bacillus, the long-chain C21, C27, C28, C35, and C39 peaks can be seen to disappear, indicating that the strain XB Bacillus has a significant effect on the degradation of long-chain hydrocarbons. After degradation, C17 increased significantly, which was caused by the degradation of long-chain hydrocarbons into shorter-chain hydrocarbons.

由图5所示,经过XJ动胶菌属菌株的降解,不同碳链组分的峰高得到了明显降低,长链烃减少的十分明显,并且它们的降解范围均比XB芽孢杆菌属菌株的降解范围大,峰高的降低程度均优于XB芽孢杆菌属菌株,显示出了较宽的碳链利用范围。As shown in Figure 5, the peak heights of different carbon chain components were significantly reduced after the degradation of the XJ Kinetobacter strain, and the long-chain hydrocarbons were significantly reduced, and their degradation ranges were larger than those of the XB Bacillus strain. The degradation range is large, and the reduction degree of the peak height is better than that of the XB Bacillus strain, showing a wider range of carbon chain utilization.

由图6所示,经过W6葡萄球菌属菌株降解后,各碳链组分的峰高也均得到明显降低,特别是C13、C14、C15、C16、C18峰消失,说明W6葡萄球菌属对短碳链降解效果显著,而C22、C26、C32因为较长链烃被降解而有所增加。W6葡萄球菌属菌株的碳链利用范围最广,但峰高的降低程度不如XB芽孢杆菌属和XJ动胶菌属。As shown in Figure 6, after the degradation of the W6 Staphylococcus strain, the peak heights of each carbon chain component were also significantly reduced, especially the C13, C14, C15, C16, and C18 peaks disappeared, indicating that the W6 Staphylococcus strain is The carbon chain degradation effect is remarkable, while C22, C26, and C32 increase due to the degradation of longer chain hydrocarbons. W6 Staphylococcus strains had the widest range of carbon chain utilization, but the decrease in peak height was not as good as XB Bacillus and XJ Kinetobacter.

综上分析,初选的3株菌,XB芽孢杆菌属、XJ动胶菌属和W6葡萄球菌属均有较宽的碳链利用范围,均有很好的烷烃降解能力。经XB芽孢杆菌属、XJ动胶菌属和W6葡萄球菌属降解后,不同碳链组分的峰高均有不同程度的降低,其中XJ动胶菌属峰高的降低程度均优于XB芽孢杆菌属和W6葡萄球菌属,其次XB芽孢杆菌属峰高的降低程度优于W6葡萄球菌属,说明XJ动胶菌属是一株降解烷烃性能较好的菌株。3株菌降解能力的大小依次为:XJ动胶菌属>XB芽孢杆菌属>W6葡萄球菌属。Based on the above analysis, the three primary strains, XB Bacillus, XJ Anitoglia and W6 Staphylococcus, all had a wide range of carbon chain utilization and good alkane degradation ability. After being degraded by XB Bacillus, XJ Anitoglia and W6 Staphylococcus, the peak heights of different carbon chain components all decreased to varying degrees, and the reduction degree of XJ Anitoglia was better than that of XB Bacillus Bacillus and W6 Staphylococcus, followed by XB Bacillus had a better reduction in peak height than W6 Staphylococcus, indicating that XJ Kinetobacter was a strain with better alkane degradation performance. The order of degradation ability of the three strains was as follows: XJ Anitoglia > XB Bacillus > W6 Staphylococcus.

②XH微球菌属、W4链球菌属、W6葡萄球菌属的芳烃降解后培养液GC-MS分析② GC-MS analysis of the aromatic hydrocarbon degraded culture solution of XH Micrococcus, W4 Streptococcus and W6 Staphylococcus

三株对芳烃有最好降解能力的菌种用于芳烃降解实验研究,培养液中芳烃GC-MS变化情况见图7。Three bacterial strains with the best ability to degrade aromatic hydrocarbons were used in the research on the degradation of aromatic hydrocarbons. The GC-MS changes of aromatic hydrocarbons in the culture solution are shown in Figure 7.

由图7可知,XH微球菌属、W6葡萄球菌属和W4链球菌属降解芳烃后的峰值均低于空白对照组,尤其是XH微球菌属的降解峰值最低,W6葡萄球菌属、W4链球菌属的降解峰值相对较高。图7说明3株菌芳烃降解峰值的高低与其降解率成负相关性,降解峰值越低,降解率越大,同时说明XH微球菌属具有较好的降解芳烃的能力。表明,初选的3株菌均对芳烃有很好的降解能力,降解能力的大小为:XH微球菌属>W6葡萄球菌属>W4链球菌属。It can be seen from Figure 7 that the peak values of aromatic hydrocarbons degraded by XH Micrococcus, W6 Staphylococcus and W4 Streptococcus were lower than those of the blank control group, especially the degradation peak of XH Micrococcus was the lowest, and that of W6 Staphylococcus and W4 Streptococcus The degradation peak of genus is relatively high. Figure 7 shows that the peaks of aromatics degradation of the three strains are negatively correlated with their degradation rates. The lower the degradation peaks, the greater the degradation rate. It also shows that XH Micrococcus has a better ability to degrade aromatics. The results showed that the three primary strains all had good degrading ability to aromatic hydrocarbons, and the degrading ability was as follows: XH Micrococcus > W6 Staphylococcus > W4 Streptococcus.

(2)高效石油降解菌株间的拮抗分析(2) Antagonism analysis among highly efficient oil-degrading strains

将下表6中的3株菌接种于牛肉膏蛋白胨培养基中活化培养24h,吸取培养液按不同梯度稀释后制成菌悬液,在无菌条件下将其中一菌株的菌悬液与冷却至40℃左右的灭菌牛肉膏蛋白胨培养基混合均匀后倒平板,于平板上放置三个牛津杯,然后吸取其他某一菌株的菌悬液加入牛津杯,每组设三个平行实验,30℃培养24h后观察,若出现抑菌圈,则说明两种菌株生长相拮抗,反之则无拮抗。用此方法进行3株降解菌中两两组合的拮抗实验。Inoculate the 3 strains in the following table 6 in the beef extract peptone medium for 24 hours of activation culture, absorb the culture solution and dilute it in different gradients to make a bacterial suspension, and mix the bacterial suspension of one of the bacterial strains with the cooling medium under aseptic conditions. Mix the sterilized beef extract peptone medium at about 40°C evenly, pour it on a plate, place three Oxford cups on the plate, and then draw the bacterial suspension of a certain strain into the Oxford cup, set up three parallel experiments for each group, 30 After culturing at ℃ for 24 hours, if an inhibition zone appears, it means that the growth of the two strains is antagonistic, otherwise there is no antagonistic growth. This method was used to carry out the antagonism experiment of pairwise combinations among the three strains of degrading bacteria.

表6单个菌株之间的拮抗作用分析Antagonism analysis between table 6 single strains

通过3株菌两两组合进行拮抗作用分析可知,只有菌株XB芽孢杆菌属和W4链球菌属之间存在着一定的拮抗作用。可以在平板上观察到直径约为15mm的透明抑菌圈,说明这两种菌在共同培养时一种菌会对另一株菌产生抑制作用的可能,在进行菌种组合的时候,应该考虑将其分开。The antagonism analysis of the pairwise combination of the three strains showed that only the strains XB Bacillus and W4 Streptococcus had certain antagonism. A transparent bacteriostatic zone with a diameter of about 15 mm can be observed on the plate, indicating that when the two bacteria are co-cultivated, one bacterium may have an inhibitory effect on the other strain. When combining bacteria, it should be considered separate it.

XB芽孢杆菌属和W4链球菌属与其他三株菌以及其他三株菌之间均无拮抗作用的现象。又由图7GC-MS分析可知,XJ动胶菌属、XB芽孢杆菌属和W6葡萄球菌属对于烷烃具有较好的降解能力,其中XJ动胶菌属、XB芽孢杆菌属可降解较宽范围的中长链烃和长链烃,而W6葡萄球菌属对短链烃有较好的降解能力,3株菌可互补降解烷烃。XH微球菌属、W6葡萄球菌属、W4链球菌属对于芳烃也有一定的降解效果,其中XH微球菌属的降解效果为最佳,又因为XB芽孢杆菌属和W4链球菌属之间存在拮抗作用。There was no antagonistic effect between XB Bacillus and W4 Streptococcus and the other three strains or between the other three strains. From the GC-MS analysis in Fig. 7, it can be seen that XJ Kinetobacter, XB Bacillus and W6 Staphylococcus have good degradability for alkanes, among which XJ Kinoglia and XB Bacillus can degrade a wide range of alkanes Medium and long-chain hydrocarbons and long-chain hydrocarbons, while Staphylococcus W6 has a better ability to degrade short-chain hydrocarbons, and the three strains can complement each other to degrade alkanes. XH Micrococcus, W6 Staphylococcus, and W4 Streptococcus also have a certain degradation effect on aromatic hydrocarbons, among which XH Micrococcus has the best degradation effect, and because of the antagonistic effect between XB Bacillus and W4 Streptococcus .

综合分析后最终选取XJ动胶菌属、XH微球菌属、W6葡萄球菌属等3株菌用于构建复合菌群。After comprehensive analysis, 3 strains of XJ Kineticum, XH Micrococcus and W6 Staphylococcus were finally selected to construct the composite flora.

(3)假单胞菌与降解菌的拮抗分析(3) Antagonistic analysis of Pseudomonas and degrading bacteria

将保藏的Ba-J1假单胞菌与降油菌株XJ动胶菌属、XH微球菌属、W6葡萄球菌属转接活化后接种至牛肉膏蛋白胨液体培养基中制成菌悬液,按不同浓度梯度稀释至OD600=0.5,在无菌条件下将Ba-J1的菌悬液与冷却至40左右的灭菌牛肉膏蛋白胨培养基混合均匀后倒平板,于平板上放置3个牛津杯,然后吸取其他任一菌株的菌悬液加入牛津杯,每组设三个平行实验,于35℃培养24h后观察。Transfer and activate the preserved Ba-J1 Pseudomonas and the Pseudomonas strains XJ, XH Micrococcus, and W6 Staphylococcus, and then inoculate them into beef extract peptone liquid medium to make a bacterial suspension. Concentration gradient dilution to OD600 = 0.5, under aseptic conditions, mix the Ba-J1 bacterial suspension with the sterilized beef extract peptone medium cooled to about 40 and pour it on the plate,

Ba-J1与各降解菌株的拮抗作用如下表7所示。The antagonism between Ba-J1 and each degrading strain is shown in Table 7 below.

表7 Ba-J1假单胞菌与XJ动胶菌、XH微球菌、W6葡萄球菌之间的拮抗作用分析Table 7 Antagonism analysis between Ba-J1 Pseudomonas and XJ Kinetobacter, XH Micrococcus, W6 Staphylococcus

由表7可知,Ba-J1假单胞菌与降解菌株XJ动胶菌属、XH微球菌属和W6葡萄球菌属均无拮抗作用,因此可考虑由这四种菌组成混合菌群对样品进行降油处理。It can be seen from Table 7 that Ba-J1 Pseudomonas has no antagonistic effect on the degrading strains XJ Anitoglia, XH Micrococcus and W6 Staphylococcus, so it can be considered that a mixed flora composed of these four bacteria can be used to test the samples. Oil reduction treatment.

(4)假单胞菌对混合菌群降解效果的影响(4) Effect of Pseudomonas on the degradation effect of mixed flora

将Ba-J1假单胞菌与XJ动胶菌、XH微球菌、W6葡萄球菌活化后制成菌悬液并稀释至OD600=0.5,在无菌操作下,吸取XJ动胶菌属、XH微球菌属、W6葡萄球菌属各2mL的菌悬液混合至100mL的原油降解培养基中,在另一100mL原油降解培养基中接入4株菌各2%,在30℃、160r/min条件下摇床培养7d后用超声萃取-紫外分光光度法测其降油率。Activate Ba-J1 Pseudomonas, XJ Kinetoglia, XH Micrococcus and W6 Staphylococcus to make a bacterial suspension and dilute to OD600=0.5.

原油降解培养基中仅接种XJ动胶菌属、XH微球菌属、W6葡萄球菌属共3株菌(对照组)Only 3 strains of XJ Kinetobacter, XH Micrococcus and W6 Staphylococcus were inoculated in the crude oil degradation medium (control group)

原油降解培养基中同时接入Ba-J1假单胞菌、XJ动胶菌属、XH微球菌属、W6葡萄球菌属共4株菌(处理组)A total of 4 strains of Ba-J1 Pseudomonas, XJ Kinetobacter, XH Micrococcus, and W6 Staphylococcus were inserted into the crude oil degradation medium at the same time (treatment group)

Ba-J1假单胞菌对混合菌群降解率的影响如图8所示。The effect of Ba-J1 Pseudomonas on the degradation rate of the mixed flora is shown in Figure 8.

由图8可知,加入Ba-J1假单胞菌后的混合菌群降解率为84.22%,明显高于不加假单胞菌Ba-J1的混合菌群降解率75.69%,说明加入含Ba-J1假单胞菌的混合菌群的降解能力明显增强。因为Ba-J1假单胞菌加入后,产生的表面活性剂可乳化样品中的油污成分,并与其他三种菌产生协同作用,使得混合菌群的降油效果明显提高。It can be seen from Figure 8 that the degradation rate of the mixed flora after adding Pseudomonas Ba-J1 was 84.22%, which was significantly higher than that of the mixed flora without adding Pseudomonas Ba-J1, which was 75.69%, indicating that the addition of Pseudomonas containing Ba-J1 The degradation ability of the mixed flora of Pseudomonas J1 was significantly enhanced. After the addition of Ba-J1 Pseudomonas, the surfactant produced can emulsify the oily components in the sample and have a synergistic effect with the other three bacteria, so that the oil-reducing effect of the mixed bacteria group is significantly improved.

Ba-J1假单胞菌的添加量对混合菌群降解率的影响如图4所示:The effect of the amount of Ba-J1 Pseudomonas added on the degradation rate of the mixed flora is shown in Figure 4:

由图9可知,当Ba-J1假单胞菌的添加量小于4mL/L时,混合菌群的降解率随添加量的增加而增大。当Ba-J1假单胞菌的添加量为4mL/L时,混合菌群的降解率达到最大为85.24%,而当Ba-J1假单胞菌的添加量大于4mL/L时,混合菌群的降解率呈平缓下降趋势,这是因为超过最适浓度时,抑制了降解菌群中菌的生长,但菌群中菌的数量足以降解原油组分,从而使得混合菌群降解率缓慢降低。It can be seen from Figure 9 that when the addition amount of Ba-J1 Pseudomonas is less than 4mL/L, the degradation rate of the mixed flora increases with the increase of the addition amount. When the addition of Ba-J1 Pseudomonas was 4mL/L, the degradation rate of the mixed flora reached a maximum of 85.24%, and when the addition of Ba-J1 Pseudomonas was greater than 4mL/L, the The degradation rate showed a gentle downward trend, because the growth of the bacteria in the degrading flora was inhibited when the optimum concentration was exceeded, but the number of bacteria in the flora was sufficient to degrade the crude oil components, so that the degradation rate of the mixed flora decreased slowly.

以上举例仅仅是对本发明的举例说明,并不构成对本发明的保护范围的限制,凡是与本发明相同或相似的设计均属于本发明的保护范围之内。本发明中未详细描述的菌株及其制备方法和试验过程均为现有技术,本发明中将不再进行进一步的说明。The above examples are only illustrations of the present invention, and do not constitute a limitation to the protection scope of the present invention. All designs that are the same as or similar to the present invention fall within the protection scope of the present invention. The bacterial strains not described in detail in the present invention and their preparation methods and test processes are all prior art, and will not be further described in the present invention.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111325258.5ACN116103179A (en) | 2021-11-10 | 2021-11-10 | Preparation method and application of a composite active bacterial agent for treating oily residue |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111325258.5ACN116103179A (en) | 2021-11-10 | 2021-11-10 | Preparation method and application of a composite active bacterial agent for treating oily residue |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN116103179Atrue CN116103179A (en) | 2023-05-12 |

Family

ID=86258468

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202111325258.5APendingCN116103179A (en) | 2021-11-10 | 2021-11-10 | Preparation method and application of a composite active bacterial agent for treating oily residue |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN116103179A (en) |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101234823A (en)* | 2008-03-03 | 2008-08-06 | 暨南大学 | A method for remediating oil pollution of water body |

| CN103045579A (en)* | 2012-12-17 | 2013-04-17 | 南开大学 | Microbial remediation curing adsorbing bacterial preparation applicable to marine environment petroleum pollution as well as preparation method and application of same |

| WO2014006621A1 (en)* | 2012-07-03 | 2014-01-09 | Nanospun Technologies Ltd. | Methods and devices for adsorption and biodegradation of petroleum |

| CN103567220A (en)* | 2013-10-16 | 2014-02-12 | 天津地冠科技有限公司 | In-situ repairing method of microorganisms of petroleum polluted soil |

| CN105753283A (en)* | 2016-03-14 | 2016-07-13 | 北京华纳斯科技有限公司 | Method of utilizing biosurfactant and microbial agent to treat oil-containing sediment |

- 2021

- 2021-11-10CNCN202111325258.5Apatent/CN116103179A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101234823A (en)* | 2008-03-03 | 2008-08-06 | 暨南大学 | A method for remediating oil pollution of water body |

| WO2014006621A1 (en)* | 2012-07-03 | 2014-01-09 | Nanospun Technologies Ltd. | Methods and devices for adsorption and biodegradation of petroleum |

| CN103045579A (en)* | 2012-12-17 | 2013-04-17 | 南开大学 | Microbial remediation curing adsorbing bacterial preparation applicable to marine environment petroleum pollution as well as preparation method and application of same |

| CN103567220A (en)* | 2013-10-16 | 2014-02-12 | 天津地冠科技有限公司 | In-situ repairing method of microorganisms of petroleum polluted soil |

| CN105753283A (en)* | 2016-03-14 | 2016-07-13 | 北京华纳斯科技有限公司 | Method of utilizing biosurfactant and microbial agent to treat oil-containing sediment |

Non-Patent Citations (2)

| Title |

|---|

| 李乐等: "石油降解菌的筛选及复合菌群的构建", 当代化工, vol. 47, no. 04, 30 April 2018 (2018-04-30), pages 672 - 676* |

| 金樑等: "石油降解菌的分离、鉴定及其降解能力的研究", 应用与环境生物学报, vol. 5, no. 1, 31 December 1999 (1999-12-31), pages 127 - 129* |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| An et al. | Hydrocarbon production from secondarily treated piggery wastewater by the green alga Botryococcus braunii | |

| CN104031870A (en) | Microbial compound bacterial agent and soil combined remediation agent prepared from microbial compound bacterial agent and application of microbial compound bacterial agent and soil combined remediation agent | |

| CN103484447B (en) | A kind of preparation method of oil degradation zymin and application | |

| CN108486006B (en) | A kind of preparation method and application of greasy filth oil degradation complex enzyme | |

| CN103045579B (en) | Microbial remediation curing adsorbing bacterial preparation applicable to marine environment petroleum pollution as well as preparation method and application of same | |

| WO2015191582A1 (en) | Microbial compositions for hydrocarbon remediation and methods of use thereof | |

| CN104152388B (en) | One strain activity Thermophilic Bacteria mutant and the application in the displacement of reservoir oil thereof | |

| CN103923659B (en) | The method that NTA and microbial bacterial agent reinforcing Festuca Arundinacea repair irrigating region heavy metal-polluted soil | |

| CN102453678A (en) | Microbial compound microbial inoculum for repairing petroleum-polluted saline-alkali soil | |

| CN104450597A (en) | Preparation method of petroleum degrading bacteria solid inoculant and method for restoring petroleum-polluted soil by using prepared solid inoculant | |

| CN106520604B (en) | One plant of nitrogen-fixing bacteria for producing acc deaminase and its application in soil ecology reparation | |

| CN1223673C (en) | Erythro micrococcus Em and usage for generating biologic emulsifier as well as degrading polycyclic aromatic hydrocarbon | |

| CN106964647A (en) | A kind of method of utilization composite bacteria agent remediating lead-contaminated soil | |

| CN103937731A (en) | Separation, extraction and verification method of air-dried sludge beneficial microorganism components | |

| CN106497810A (en) | A kind of germ oligotrophy unit cell, the microbial inoculum containing the bacterium and its application and the method for degraded diesel oil | |

| CN109794501A (en) | A method of matching the raw-soil using petroleum hydrocarbon contaminated soil preparation | |

| CN102978135B (en) | Crude oil degrading bacterium for producing lipid biosurfactant and application | |

| CN105670956A (en) | Medium thermophilic bacillus licheniformis strain and application thereof in treatment on high-temperature oil-bearing wastewater | |

| CN108865901B (en) | Aspergillus oryzae strain and application thereof in aflatoxin degradation | |

| CN116103179A (en) | Preparation method and application of a composite active bacterial agent for treating oily residue | |

| CN103540540B (en) | One main laminaria degradation bacteria and prepare the method for kelp juice | |

| CN108384777B (en) | Preparation method of porous microbial preparation for soil remediation | |

| CN110699266B (en) | Penicillium MJ51 and application thereof | |

| CN102766580B (en) | A yeast strain producing biosurfactant and its application | |

| CN108570325B (en) | Microbial preparation for high-salinity soil remediation and preparation method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |