CN116087798A - Power battery detection method - Google Patents

Power battery detection methodDownload PDFInfo

- Publication number

- CN116087798A CN116087798ACN202310342516.3ACN202310342516ACN116087798ACN 116087798 ACN116087798 ACN 116087798ACN 202310342516 ACN202310342516 ACN 202310342516ACN 116087798 ACN116087798 ACN 116087798A

- Authority

- CN

- China

- Prior art keywords

- temperature

- power battery

- power

- data processing

- processing unit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000001514detection methodMethods0.000titleclaimsabstractdescription191

- 238000001816coolingMethods0.000claimsabstractdescription93

- 230000008859changeEffects0.000claimsabstractdescription75

- 239000000284extractSubstances0.000claimsabstractdescription13

- 238000012544monitoring processMethods0.000claimsabstractdescription10

- 238000012545processingMethods0.000claimsdescription118

- 238000000034methodMethods0.000claimsdescription35

- 230000008569processEffects0.000claimsdescription26

- 238000004458analytical methodMethods0.000claimsdescription21

- 238000011084recoveryMethods0.000claimsdescription5

- 108700041286deltaProteins0.000claims1

- 238000007689inspectionMethods0.000claims1

- 238000010586diagramMethods0.000abstractdescription22

- 238000012360testing methodMethods0.000description8

- 238000010187selection methodMethods0.000description6

- 238000007726management methodMethods0.000description5

- 239000000446fuelSubstances0.000description4

- UFHFLCQGNIYNRP-UHFFFAOYSA-NHydrogenChemical compound[H][H]UFHFLCQGNIYNRP-UHFFFAOYSA-N0.000description3

- 230000000694effectsEffects0.000description3

- 238000005516engineering processMethods0.000description3

- 238000010438heat treatmentMethods0.000description3

- 229910052739hydrogenInorganic materials0.000description3

- 239000001257hydrogenSubstances0.000description3

- 239000000243solutionSubstances0.000description3

- 230000004913activationEffects0.000description2

- 238000013499data modelMethods0.000description2

- 230000005611electricityEffects0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 238000006467substitution reactionMethods0.000description2

- 230000009286beneficial effectEffects0.000description1

- 238000004891communicationMethods0.000description1

- 238000007599dischargingMethods0.000description1

- 238000005265energy consumptionMethods0.000description1

- 238000002474experimental methodMethods0.000description1

- 230000017525heat dissipationEffects0.000description1

- 238000002347injectionMethods0.000description1

- 239000007924injectionSubstances0.000description1

- 238000009434installationMethods0.000description1

- 239000007788liquidSubstances0.000description1

- 239000000463materialSubstances0.000description1

- 238000005259measurementMethods0.000description1

- NJPPVKZQTLUDBO-UHFFFAOYSA-NnovaluronChemical compoundC1=C(Cl)C(OC(F)(F)C(OC(F)(F)F)F)=CC=C1NC(=O)NC(=O)C1=C(F)C=CC=C1FNJPPVKZQTLUDBO-UHFFFAOYSA-N0.000description1

- 238000004088simulationMethods0.000description1

- 238000010998test methodMethods0.000description1

Images

Classifications

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/61—Types of temperature control

- H01M10/613—Cooling or keeping cold

- G—PHYSICS

- G01—MEASURING; TESTING

- G01R—MEASURING ELECTRIC VARIABLES; MEASURING MAGNETIC VARIABLES

- G01R31/00—Arrangements for testing electric properties; Arrangements for locating electric faults; Arrangements for electrical testing characterised by what is being tested not provided for elsewhere

- G01R31/36—Arrangements for testing, measuring or monitoring the electrical condition of accumulators or electric batteries, e.g. capacity or state of charge [SoC]

- G01R31/382—Arrangements for monitoring battery or accumulator variables, e.g. SoC

- G—PHYSICS

- G01—MEASURING; TESTING

- G01R—MEASURING ELECTRIC VARIABLES; MEASURING MAGNETIC VARIABLES

- G01R31/00—Arrangements for testing electric properties; Arrangements for locating electric faults; Arrangements for electrical testing characterised by what is being tested not provided for elsewhere

- G01R31/36—Arrangements for testing, measuring or monitoring the electrical condition of accumulators or electric batteries, e.g. capacity or state of charge [SoC]

- G01R31/396—Acquisition or processing of data for testing or for monitoring individual cells or groups of cells within a battery

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/62—Heating or cooling; Temperature control specially adapted for specific applications

- H01M10/625—Vehicles

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/60—Heating or cooling; Temperature control

- H01M10/63—Control systems

- H01M10/635—Control systems based on ambient temperature

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Automation & Control Theory (AREA)

- Charge And Discharge Circuits For Batteries Or The Like (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及动力电池检测领域,尤其涉及一种动力电池检测方法。The invention relates to the field of power battery detection, in particular to a power battery detection method.

背景技术Background technique

动力电池即为工具提供动力来源的电源,多指为电动汽车、电动列车、电动自行车、高尔夫球车提供动力的蓄电池。从成本、散热效果及加工工艺、材料选择等方面综合比较,液体冷却综合优势较为明显,现已被广泛应用于电动汽车领域。但是目前针对动力电池的检测技术对动力电池电能和冷却系统的结合检测考虑的并不多,因此,如何检测动力电池的在高温情况下电池电量与冷却系统功率的关系并生成更优的冷却策略是人们亟待解决的问题。The power battery is the power source that provides the power source for the tool, and mostly refers to the battery that provides power for electric vehicles, electric trains, electric bicycles, and golf carts. From a comprehensive comparison of cost, heat dissipation effect, processing technology, and material selection, the comprehensive advantages of liquid cooling are more obvious, and it has been widely used in the field of electric vehicles. However, the current detection technology for power batteries does not consider the combined detection of power battery power and cooling system. Therefore, how to detect the relationship between the power of the power battery and the power of the cooling system under high temperature conditions and generate a better cooling strategy It is a problem that people urgently need to solve.

中国专利公开号CN111366854A公布了一种燃料电池动力系统测试平台测试方法及装置,包括:提取一份氢燃料电池汽车实际路况下长时间行驶的电能消耗数据,根据现有测试模型搭建电耗数据模型;将电能消耗数据与电耗数据模型进行数据拟合,得到氢燃料电池汽车在各测试模型下所需的等比例测试时长;基于氢燃料电池电电混合动力系统搭建动力系统测试平台装置等;中国专利公开号CN113552485A公布了一种新能源汽车热管理功能测试系统及方法,包括过将整车布置在转毂台架上行驶,HIL控制柜对热管理系统进行故障注入、IO信号模;用转毂台架调节驱动电机、发动机、动力电池的工作负载。HIL控制柜操作车辆台架行驶挡位、车速、油门和制动踏板深度;控制板卡模拟热管理IO信号;调节车载空调挡位、电池冷却\加热、发动机冷却\加热、驱动电机冷却\加热;控制充电\放电负载对车进行充电\放电;分析测试采集的数据,验证整车热管理功能、传感器故障的影响。由此可见:上述技术方案未结合考虑电能与冷却系统对动力电池温度的影响,导致动力电池冷却系统的工作参数可行性差以及动力电池冷却系统的效率低。Chinese Patent Publication No. CN111366854A discloses a test method and device for a fuel cell power system test platform, including: extracting a piece of power consumption data of a hydrogen fuel cell vehicle traveling under actual road conditions for a long time, and building a power consumption data model based on the existing test model ; Data fitting of the electric energy consumption data and the electric consumption data model is carried out to obtain the proportional test duration required by the hydrogen fuel cell vehicle under each test model; a power system test platform device is built based on the hydrogen fuel cell electric-electric hybrid system; Chinese Patent Publication No. CN113552485A discloses a new energy vehicle thermal management function testing system and method, including arranging the whole vehicle on a rotating hub platform for driving, and the HIL control cabinet performs fault injection and IO signal simulation on the thermal management system; The rotating hub pedestal adjusts the working load of the drive motor, engine and power battery. The HIL control cabinet operates the driving gear, vehicle speed, accelerator and brake pedal depth of the vehicle bench; the control board simulates the thermal management IO signal; adjusts the gear of the vehicle air conditioner, battery cooling/heating, engine cooling/heating, and drive motor cooling/heating ;Control the charging/discharging load to charge/discharge the car; analyze the data collected by the test, and verify the impact of the vehicle's thermal management function and sensor failure. It can be seen that the above technical solution does not consider the influence of electric energy and cooling system on the temperature of the power battery, resulting in poor feasibility of the working parameters of the power battery cooling system and low efficiency of the power battery cooling system.

发明内容Contents of the invention

为此,本发明提供一种动力电池检测方法,用以克服现有技术中动力电池的冷却系统高温条件下热管理系统的冷却策略效率差的问题。For this reason, the present invention provides a detection method for a power battery, which is used to overcome the problem of poor efficiency of the cooling strategy of the thermal management system in the prior art under the high temperature condition of the cooling system of the power battery.

为实现上述目的,本发明提供一种动力电池检测方法,包括:In order to achieve the above purpose, the present invention provides a power battery detection method, including:

S1,输入动力电池的目标使用地区的影响气温并根据其与预设温度标准的比对结果判定放电检测单元的检测温度;S1, input the influence air temperature of the target use area of the power battery and determine the detection temperature of the discharge detection unit according to the comparison result with the preset temperature standard;

S2,数据处理单元控制放电检测单元对所述动力电池进行一次放电检测且在放电过程中监测记录动力电池的温度以及电量,并控制图像生成单元根据放电检测过程监测记录的动力电池的温度数据和电量数据生成动力电池温度变化图以及耗电量变化图;S2, the data processing unit controls the discharge detection unit to perform a discharge detection on the power battery and monitors and records the temperature and power of the power battery during the discharge process, and controls the image generation unit to monitor and record the temperature data of the power battery according to the discharge detection process and The power data generates the power battery temperature change graph and the power consumption change graph;

S3,通过预设选取方式选取所述动力电池的温度变化图内若干待测点;S3, selecting a number of points to be measured in the temperature change graph of the power battery by a preset selection method;

S4,数据处理单元依次计算各待测点的纵坐标差值并将其与预设纵坐标差值进行比对以判定该纵坐标差值是否为有效差值,并且在有效差值的数量符合预设阈值时确定与有效差值对应的待测点为温度变化有效点;S4, the data processing unit sequentially calculates the ordinate difference of each point to be measured and compares it with the preset ordinate difference to determine whether the ordinate difference is an effective difference, and when the number of effective differences meets When the threshold is preset, it is determined that the point to be measured corresponding to the effective difference is the effective point of temperature change;

S5,选取纵坐标温度最小的温度变化有效点对应的温度为动力电池冷却系统的一次关闭温度,并且将除去与一次关闭温度对应的温度变化有效点以外的温度变化有效点记为功率调节点;S5, select the temperature corresponding to the effective point of temperature change with the smallest ordinate temperature as the primary shutdown temperature of the power battery cooling system, and record the effective temperature change points other than the effective point of temperature change corresponding to the primary shutdown temperature as power adjustment points;

S6,由横坐标轴正方向依次提取各功率调节点在所述耗电量变化图中对应的动力电池电量并与预设耗电量进行比对以确定功率调节点对应的冷却系统功率调节系数;S6, sequentially extract the power battery power corresponding to each power adjustment point in the power consumption change diagram from the positive direction of the abscissa axis, and compare it with the preset power consumption to determine the cooling system power adjustment coefficient corresponding to the power adjustment point ;

S7,将生成的冷却策略通过显示单元传送至用户端。S7, sending the generated cooling strategy to the user terminal through the display unit.

进一步地,放电检测单元,其包括用以对动力电池放电检测过程中电池电量进行监测的电量监测模块以及用以对动力电池放电检测过程中动力电池温度进行检测的温度检测模块;Further, the discharge detection unit includes a power monitoring module for monitoring the battery power during the power battery discharge detection process and a temperature detection module for detecting the power battery temperature during the power battery discharge detection process;

图像生成单元,其与所述放电检测单元相连,用以接收并记录所述温度检测模块以及所述电量检测模块所传递的动力电池的温度信息以及电量信息,并且分别生成反应动力电池电量与放电检测时间变化关系的耗电量变化关系图以及反应动力电池温度与放电检测时间变化关系的温度变化关系图;An image generation unit, which is connected to the discharge detection unit, is used to receive and record the temperature information and power information of the power battery transmitted by the temperature detection module and the power detection module, and generate the power battery power and discharge power respectively. The power consumption change relationship diagram of the detection time variation relationship and the temperature variation relationship diagram reflecting the power battery temperature and the discharge detection time variation relationship;

数据处理单元,其与所述放电检测单元以及所述图像生成单元相连;a data processing unit connected to the discharge detection unit and the image generation unit;

其中,所述温度检测模块包括一壳体,壳体内壁上设有若干圆环型的电子滑槽,每个电子滑槽上对应安装有温度传感器,用以对动力电池的温度进行检测。Wherein, the temperature detection module includes a housing, and the inner wall of the housing is provided with a plurality of ring-shaped electronic chutes, and each electronic chute is correspondingly installed with a temperature sensor for detecting the temperature of the power battery.

进一步地,所述数据处理单元在第一检测条件下提取所述存储模块中储存的所述动力电池的目标使用地区的影响气温T并将T与预设温度标准进行比对以判定对针对该动力电池进行放电检测时放电检测单元的检测温度,设定,其中, Tu为目标使用地区的全年内第u日大于预设气温的最高气温,u=1,2,3,……,umax,umax为目标使用地区全年内大于预设气温的最高气温的天数,所述数据处理单元设有第一预设温度标准T1、第二预设温度标准T2以及预设气温Tmax,其中,0<T1<T2,0<Tmax,Further, the data processing unit extracts the affected air temperature T of the target usage area of the power battery stored in the storage module under the first detection condition, and compares T with the preset temperature standard to determine whether it is suitable for the power battery. The detection temperature of the discharge detection unit during the discharge detection of the power battery, set , among them, Tu is the maximum temperature greater than the preset temperature on the uth day of the year in the target use area, u=1, 2, 3, ..., umax, umax is the maximum temperature greater than the preset temperature in the year in the target use area The number of days, the data processing unit is provided with a first preset temperature standard T1, a second preset temperature standard T2 and a preset temperature Tmax, wherein, 0<T1<T2, 0<Tmax,

若0<T≤T1,所述数据处理单元判定放电检测单元的检测温度为Tz,设定Tz=T0,其中,T0为预设标准检测温度,T0>0;If 0<T≤T1, the data processing unit determines that the detection temperature of the discharge detection unit is Tz, and sets Tz=T0, wherein T0 is a preset standard detection temperature, and T0>0;

若T1<T≤T2,所述数据处理单元判定放电检测单元的检测温度为Tz,设定Tz=T0×α1;If T1<T≤T2, the data processing unit determines that the detection temperature of the discharge detection unit is Tz, and sets Tz=T0×α1;

若T2<T,所述数据处理单元判定放电检测单元的检测温度为Tz,设定Tz=T0×α2;If T2<T, the data processing unit determines that the detection temperature of the discharge detection unit is Tz, and sets Tz=T0×α2;

其中,α1为第一温度调节系数,α2为第二温度调节系数,其中,1<α1<α2,第一检测条件为待测的动力电池置于放电检测单元并且放电检测单元通电开启。Wherein, α1 is the first temperature adjustment coefficient, α2 is the second temperature adjustment coefficient, where 1<α1<α2, and the first detection condition is that the power battery to be tested is placed in the discharge detection unit and the discharge detection unit is powered on.

进一步地,所述数据处理单元在第二检测条件下将放电检测单元的温度调节至Tz并控制放电检测单元对所述动力电池进行一次放电检测且在放电过程中监测记录动力电池的温度以及电量,其中,动力电池放电功率设置为第一放电功率,数据处理单元在放电检测完成时控制图像生成单元根据放电检测过程监测记录的动力电池的温度数据以及电量数据生成动力电池温度变化图以及耗电量变化图,其中,所述温度变化图为动力电池在放电检测过程中放电检测时间与动力电池温度的第一函数关系曲线,所述第一函数关系曲线呈现为坐标系形式,横坐标变量为放电检测时间t,纵坐标变量为动力电池温度,所述耗电量变化图为动力电池在放电检测过程中放电检测时间与动力电池电量的第二函数关系曲线,所述第二函数关系曲线呈现为坐标系形式,横坐标变量为放电检测时间t,纵坐标变量为动力电池电量Q;Further, the data processing unit adjusts the temperature of the discharge detection unit to Tz under the second detection condition and controls the discharge detection unit to perform a discharge detection on the power battery and monitor and record the temperature and power of the power battery during the discharge process. , wherein the discharge power of the power battery is set as the first discharge power, and the data processing unit controls the image generation unit to generate a power battery temperature change map and power consumption data according to the temperature data and power data of the power battery that are monitored and recorded during the discharge detection process when the discharge detection is completed. Quantity change graph, wherein, the temperature change graph is the first functional relationship curve between the discharge detection time and the power battery temperature during the discharge detection process of the power battery, the first functional relationship curve is presented in the form of a coordinate system, and the abscissa variable is The discharge detection time t, the ordinate variable is the temperature of the power battery, and the power consumption change graph is the second function relationship curve between the discharge detection time and the power battery power of the power battery during the discharge detection process, and the second function relationship curve presents In the form of a coordinate system, the abscissa variable is the discharge detection time t, and the ordinate variable is the power battery Q;

其中,所述第二检测条件为所述数据处理单元对动力电池检测环境的温度判定完成。Wherein, the second detection condition is that the temperature determination of the power battery detection environment by the data processing unit is completed.

进一步地,所述数据处理单元在第一分析条件下通过预设选取方式选取所述动力电池的温度变化图内若干待测点,数据处理单元依次计算第i个待测点的纵坐标差值△Hi并将△Hi与预设纵坐标差值进行比对以判定该纵坐标差值是否为有效差值,设定△Hi=(Hi+1-Hi),其中,Hi为第i个待测点的纵坐标温度值,Hi+1为第i+1个待测点的纵坐标温度值,i=1,2,3,……,n,其中,n+1为待测点的总数量,所述数据处理单元设有第一预设有效差值△H0,其中,0<△H0,Further, the data processing unit selects a number of points to be measured in the temperature change diagram of the power battery by a preset selection method under the first analysis condition, and the data processing unit sequentially calculates the ordinate difference of the i-th point to be measured △Hi and compare △Hi with the preset ordinate difference to determine whether the ordinate difference is a valid difference, set △Hi = (Hi+1 -Hi ), where, Hi is the ordinate temperature value of the i-th point to be measured, Hi+1 is the ordinate temperature value of the i+1th point to be measured, i=1, 2, 3,..., n, wherein, n+ 1 is the total number of points to be measured, and the data processing unit is provided with a first preset effective difference ΔH0, wherein, 0<ΔH0,

若△Hi≤△H0,所述数据处理单元判定该纵坐标差值不是有效差值;If △Hi≦△H0, the data processing unit determines that the ordinate difference is not a valid difference;

若△H0<△Hi,所述数据处理单元判定该纵坐标差值为有效差值;If ΔH0<ΔHi, the data processing unit determines that the ordinate difference is an effective difference;

所述预设选取方式为所述数据处理单元针对温度变化图由横轴放电检测时间t=0开始,将每个选取周期的开始时刻在函数关系曲线上对应的坐标点作为待测点,所述选取周期为r,设定r=1000s,所述第一分析条件为所述图像生成单元针对所述动力电池的温度变化图生成结束。The preset selection method is that the data processing unit starts from the horizontal axis discharge detection time t=0 for the temperature change diagram, and uses the corresponding coordinate points on the function relationship curve at the beginning of each selection cycle as the points to be measured, so The selection period is r, and r=1000s is set, and the first analysis condition is that the generation of the temperature change map of the power battery by the image generation unit is completed.

进一步地,所述数据处理单元在第二分析条件下统计所有纵坐标差值中有效差值的数量N并将N与预设有效差值数量进行比对以判定是否对选取周期r进行调节,所述数据处理单元设有第一预设周期调节系数β1以及第二预设周期调节系数β2,其中,0<β1<β2<1,Further, the data processing unit counts the number N of valid differences among all ordinate differences under the second analysis condition, and compares N with the preset number of valid differences to determine whether to adjust the selection cycle r, The data processing unit is provided with a first preset period adjustment coefficient β1 and a second preset period adjustment coefficient β2, wherein 0<β1<β2<1,

若N=0,所述数据处理单元判定使用β1将选取周期r调节为r’,设定r’=r×β1;If N=0, the data processing unit determines to use β1 to adjust the selection period r to r', and set r'=r×β1;

若N=1,所述数据处理单元判定使用β2将选取周期r调节为r’,设定r’=r×β2;If N=1, the data processing unit judges to use β2 to adjust the selection cycle r to r', and set r'=r×β2;

若N>1,所述数据处理单元判定无需对选取周期r进行调节,所述数据处理单元计算各有效差值的有效中间值Hi’并将函数关系曲线上横坐标与Hi’的横坐标距离最近的待测点记为温度变化有效点,设定Hi’=(Hi+1-Hi)/2;If N>1, the data processing unit determines that there is no need to adjust the selected period r, and the data processing unit calculates the effective intermediate value Hi ' of each effective difference and compares the abscissa on the function relationship curve with the abscissa of Hi ' The point to be measured with the closest coordinate distance is recorded as the effective point of temperature change, and Hi '=(Hi+1 -Hi )/2;

所述第二分析条件为所述数据处理单元对各纵坐标差值是否为有效差值的判定完成。The second analysis condition is that the data processing unit completes the determination of whether each ordinate difference is a valid difference.

进一步地,所述数据处理单元在第三分析条件下提取各温度变化有效点中对应的纵坐标温度最小的温度变化有效点记为Pmin,数据处理单元将Pmin对应的纵坐标温度值Hmin记为动力电池冷却系统的一次关闭温度并将Hmin与Tz进行比对以判定动力电池冷却系统的一次关闭时长,所述数据处理单元设有第一预设时长调节系数θ1、第二时长调节系数θ2以及第三预设时长调节系数θ3,其中,0<θ3<θ2<θ1<2,Further, under the third analysis condition, the data processing unit extracts the effective point of temperature change corresponding to the smallest ordinate temperature among the effective points of temperature change under the third analysis condition, which is marked as Pmin, and the data processing unit records the ordinate temperature value Hmin corresponding to Pmin as The primary shutdown temperature of the power battery cooling system is compared with Hmin and Tz to determine the primary shutdown duration of the power battery cooling system. The data processing unit is provided with a first preset duration adjustment coefficient θ1, a second duration adjustment coefficient θ2 and The third preset duration adjustment coefficient θ3, where 0<θ3<θ2<θ1<2,

若Hmin≤0.8Tz,所述数据处理单元判定动力电池冷却系统的一次关闭时长为tg,设定tg=tg0×Hmin/H0×θ1;If Hmin≤0.8Tz, the data processing unit determines that the power battery cooling system shuts down once for tg, and sets tg=tg0×Hmin/H0×θ1;

若0.8Tz<Hmin≤0.9Tz,所述数据处理单元判定动力电池冷却系统的一次关闭时长为tg,设定tg=tg0×Hmin/H0×θ2;If 0.8Tz<Hmin≤0.9Tz, the data processing unit determines that the power battery cooling system shuts down once for tg, and sets tg=tg0×Hmin/H0×θ2;

若0.9Tz<Hmin,所述数据处理单元判定动力电池冷却系统的一次关闭时长为tg,设定tg=tg0×Hmin/H0×θ3;If 0.9Tz<Hmin, the data processing unit determines that the power battery cooling system shuts down once for tg, and sets tg=tg0×Hmin/H0×θ3;

其中,tg0为预设一次关闭时长基值,H0为预设关闭温度,0<tg0,0<H0,所述第三分析条件为所述数据处理单元判定N>1。Wherein, tg0 is the base value of the preset shutdown time, H0 is the preset shutdown temperature, 0<tg0, 0<H0, and the third analysis condition is that the data processing unit determines that N>1.

进一步地,所述数据处理单元在第三检测条件下将除Pmin以外的温度变化有效点记为功率调节点Pe,并分别提取第e个功率调节点Pe在所述耗电量变化图中第二关系曲线上对应的动力电池电量,e=1,2,3,……,emax,其中,emax=N-1,数据处理单元将P1对应的动力电池温度记为动力电池冷却系统的一次开启温度并且数据处理单元分别计算除P1外的第e个功率调节点的耗电量差值△Qe,设定△Qe=Qe-Qe-1,e=2,3,……,emax-1,数据处理单元将第e个功率调节点的△Qe与预设耗电量差值标准进行比对以判定第e个功率调节点对应的冷却系统功率调节系数,所述数据处理单元设有第一预设耗电量差值△Q01、第二预设耗电量差值△Q02、第一功率确定系数δ1以及第二功率确定系数δ2,其中,0<△Q01<△Q02,0<δ2<δ1,Further, under the third detection condition, the data processing unit records the effective point of temperature change other than Pmin as the power adjustment point Pe, and respectively extracts the eth power adjustment point Pe in the power consumption variation diagram. The corresponding power battery power on the two relationship curves, e=1, 2, 3, ..., emax, wherein, emax=N-1, the data processing unit records the temperature of the power battery corresponding to P1 as an opening of the power battery cooling system The temperature and data processing unit respectively calculates the power consumption difference △Qe of the eth power adjustment point except P1, and sets △Qe=Qe-Qe-1, e=2, 3,..., emax-1, The data processing unit compares the △Qe of the eth power adjustment point with the preset power consumption difference standard to determine the power adjustment coefficient of the cooling system corresponding to the eth power adjustment point. The data processing unit has a first The preset power consumption difference △Q01, the second preset power consumption difference △Q02, the first power determination coefficient δ1 and the second power determination coefficient δ2, wherein, 0<△Q01<△Q02, 0<δ2< δ1,

若△Qe≤△Q01,所述放电检测单元判定冷却系统功率调节系数为ζ,设定ζ=ζ0-△Qe×δ1;If △Qe≤△Q01, the discharge detection unit determines that the power adjustment coefficient of the cooling system is ζ, and sets ζ=ζ0-△Qe×δ1;

若△Q01<△Qe≤△Q02,所述放电检测单元判定压缩机功率为ζ,设定ζ=ζ0-△Qe×δ2;If △Q01<△Qe≤△Q02, the discharge detection unit determines that the power of the compressor is ζ, and sets ζ=ζ0-△Qe×δ2;

若△Q02<△Qe,所述放电检测单元判定该功率调节点为功率调节停止点并且无需对压缩机功率进行调节;If △Q02<△Qe, the discharge detection unit determines that the power adjustment point is the power adjustment stop point and there is no need to adjust the power of the compressor;

其中,P1为冷却系统恢复开启点,ζ0为预设功率调节基值,ζ0>0,所述第三检测条件为动力电池冷却系统的一次关闭时长判定完成。Wherein, P1 is the recovery start point of the cooling system, ζ0 is the preset power adjustment base value, ζ0>0, and the third detection condition is that the power battery cooling system has been shut down for one time.

进一步地,所述数据处理单元生成的冷却策略包括:动力电池初始温度为Tz±5°时且动力电池工作过程中温动力电池温度为Hmin时关闭冷却系统,并在动力电池温度达到冷却系统恢复开启点P1对应的温度时重新开启冷却系统,并在重新开启冷却系统后每当电池温度达到功率调节点的温度时使用ζ调节冷却系统的压缩机的功率为C,设定C=C0×ζ,其中,C0为初始压缩机功率,0<C0;Further, the cooling strategy generated by the data processing unit includes: when the initial temperature of the power battery is Tz±5° and the temperature of the power battery during the working process of the power battery is Hmin, the cooling system is turned off, and the cooling system is turned on again when the temperature of the power battery reaches Restart the cooling system at the temperature corresponding to point P1, and use ζ to adjust the power of the compressor of the cooling system to C whenever the battery temperature reaches the temperature of the power adjustment point after restarting the cooling system, and set C=C0×ζ, Among them, C0 is the initial compressor power, 0<C0;

其中,若在重新开启冷却系统后电池温度在预设监测时间内始终未达到功率调节点的温度,启动冷却系统的间接开启策略。Wherein, if the battery temperature has not reached the temperature of the power adjustment point within the preset monitoring time after the cooling system is restarted, the indirect activation strategy of the cooling system is activated.

进一步地,所述间接开启策略为冷却系统每运行B秒时转为关闭状态,并且在关闭状态时长达到b秒时重新转为开启状态,其中,B>0,b>0。Further, the indirect opening strategy is that the cooling system turns off every B seconds, and turns on again when the off state reaches b seconds, wherein, B>0, b>0.

与现有技术相比,本发明的有益效果在于,本发明通过对动力电池进行放电检测以生成反应动力电池电量与放电检测时间变化关系的耗电量变化关系图以及反应动力电池温度与放电检测时间变化关系的温度变化关系图,并将动力电池的耗电量与动力电池温度相结合,确定动力电池的冷却系统的一次关闭温度,冷却系统的一次关闭时长,冷却系统恢复开启点以及冷却系统的功率调节点,相比于现有的技术同一型号动力电池采用统一的冷却策略,本发明所生成的冷却策略更加符合动力电池的实际工作情况并且避免了加工过程中导致的同一型号各电池之间的差异性。Compared with the prior art, the beneficial effect of the present invention lies in that the present invention generates a power consumption change relationship diagram reflecting the relationship between power battery power and discharge detection time by performing discharge detection on the power battery, as well as a graph reflecting power battery temperature and discharge detection time. The temperature change relationship diagram of the time-varying relationship, and combines the power consumption of the power battery with the temperature of the power battery to determine the temperature of the cooling system of the power battery, the length of the cooling system's first shutdown, the recovery of the cooling system and the cooling system. Compared with the unified cooling strategy of the same type of power battery in the existing technology, the cooling strategy generated by the present invention is more in line with the actual working conditions of the power battery and avoids the gap between the same type of batteries caused by the processing process. difference between.

进一步地,所述温度检测模块包括一壳体,壳体内壁上设有若干圆环型的电子滑槽,每个电子滑槽上对应安装有温度传感器,用以对动力电池的温度进行检测,避免了动力电池温度分布不均匀导致的检测到的信息具有偏差。Further, the temperature detection module includes a housing, and the inner wall of the housing is provided with several circular electronic chutes, and each electronic chute is correspondingly equipped with a temperature sensor to detect the temperature of the power battery. It avoids the deviation of the detected information caused by the uneven temperature distribution of the power battery.

进一步地,所述数据处理单元在第一检测条件下提取所述存储模块中储存的所述动力电池的目标使用地区的影响气温T并将T与预设温度标准进行比对以判定对针对该动力电池进行放电检测时放电检测单元的检测温度,相比于现有技术,使得测量环境温度更加符合实际,提高了检测的准确性。Further, the data processing unit extracts the affected air temperature T of the target usage area of the power battery stored in the storage module under the first detection condition, and compares T with the preset temperature standard to determine whether it is suitable for the power battery. Compared with the prior art, the detection temperature of the discharge detection unit during the discharge detection of the power battery makes the measurement of the ambient temperature more realistic and improves the accuracy of detection.

进一步地,所述数据处理单元在第二分析条件下统计所有纵坐标差值中有效差值的数量N并将N与预设有效差值数量进行比对以判定是否对选取周期r进行调节,避免了由于选取范围过大导致的信息误差,进而提高了本发明的准确性。Further, the data processing unit counts the number N of valid differences among all ordinate differences under the second analysis condition, and compares N with the preset number of valid differences to determine whether to adjust the selection cycle r, The information error caused by too large selection range is avoided, thereby improving the accuracy of the present invention.

进一步地,数据处理单元将Pmin对应的纵坐标温度值Hmin记为动力电池冷却系统的一次关闭温度并将Hmin与Tz进行比对以判定动力电池冷却系统的一次关闭时长,使得冷却系统在动力电池的降温效果符合标准时关闭以节省动力电池的损耗。Further, the data processing unit records the ordinate temperature value Hmin corresponding to Pmin as the primary shutdown temperature of the power battery cooling system, and compares Hmin with Tz to determine the duration of the primary shutdown of the power battery cooling system, so that the cooling system is in the power battery. When the cooling effect meets the standard, it is turned off to save power battery loss.

进一步地,数据处理单元将第e个功率调节点的△Qe与预设耗电量差值标准进行比对以判定第e个功率调节点对应的冷却系统功率调节系数,使得冷却系统的压缩机功率不在是根据温度线性变化,而是根据压缩机不同记录有效的调节点,以节省动力电池的电量。Further, the data processing unit compares the △Qe of the eth power adjustment point with the preset power consumption difference standard to determine the power adjustment coefficient of the cooling system corresponding to the eth power adjustment point, so that the compressor of the cooling system The power is no longer linearly changed according to the temperature, but the effective adjustment point is recorded according to the different compressors to save the power of the power battery.

附图说明Description of drawings

图1为本发明实施例所述动力电池检测方法的示意图;Fig. 1 is a schematic diagram of a power battery detection method according to an embodiment of the present invention;

图2为本发明实施例所述动力电池进行放电检测时的示意图;Fig. 2 is a schematic diagram of the power battery described in the embodiment of the present invention when performing discharge detection;

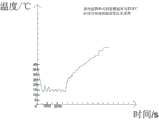

图3为本发明实施例所述放电检测单元的检测温度为37.5℃时动力电池的温度变化关系图;Fig. 3 is a graph showing the relationship between the temperature change of the power battery when the detection temperature of the discharge detection unit according to the embodiment of the present invention is 37.5°C;

图4为本发明实施例所述放电检测单元的检测温度为20℃时动力电池的温度变化关系图。Fig. 4 is a diagram showing the temperature variation relationship of the power battery when the detection temperature of the discharge detection unit according to the embodiment of the present invention is 20°C.

具体实施方式Detailed ways

为了使本发明的目的和优点更加清楚明白,下面结合实施例对本发明作进一步描述;应当理解,此处所描述的具体实施例仅仅用于解释本发明,并不用于限定本发明。In order to make the objects and advantages of the present invention clearer, the present invention will be further described below in conjunction with the examples; it should be understood that the specific examples described here are only for explaining the present invention, and are not intended to limit the present invention.

下面参照附图来描述本发明的优选实施方式。本领域技术人员应当理解的是,这些实施方式仅仅用于解释本发明的技术原理,并非在限制本发明的保护范围。Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principle of the present invention, and are not intended to limit the protection scope of the present invention.

需要说明的是,在本发明的描述中,术语“上”、“下”、“左”、“右”、“内”、“外”等指示的方向或位置关系的术语是基于附图所示的方向或位置关系,这仅仅是为了便于描述,而不是指示或暗示所述装置或元件必须具有特定的方位、以特定的方位构造和操作,因此不能理解为对本发明的限制。It should be noted that, in the description of the present invention, terms such as "upper", "lower", "left", "right", "inner", "outer" and other indicated directions or positional relationships are based on the terms shown in the accompanying drawings. The direction or positional relationship shown is only for convenience of description, and does not indicate or imply that the device or element must have a specific orientation, be constructed and operated in a specific orientation, and thus should not be construed as limiting the present invention.

此外,还需要说明的是,在本发明的描述中,除非另有明确的规定和限定,术语“安装”、“相连”、“连接”应做广义理解,例如,可以是固定连接,也可以是可拆卸连接,或一体地连接;可以是机械连接,也可以是电连接;可以是直接相连,也可以通过中间媒介间接相连,可以是两个元件内部的连通。对于本领域技术人员而言,可根据具体情况理解上述术语在本发明中的具体含义。In addition, it should be noted that, in the description of the present invention, unless otherwise clearly stipulated and limited, the terms "installation", "connection" and "connection" should be understood in a broad sense, for example, it can be a fixed connection or a It is a detachable connection or an integral connection; it may be a mechanical connection or an electrical connection; it may be a direct connection or an indirect connection through an intermediary, and it may be the internal communication of two components. Those skilled in the art can understand the specific meanings of the above terms in the present invention according to specific situations.

请参阅图1至图2所示,提供一种动力电池检测方法,包括:Please refer to Figure 1 to Figure 2, a power battery detection method is provided, including:

S1,输入动力电池的目标使用地区的影响气温并根据其与预设温度标准的比对结果判定放电检测单元的检测温度;S1, input the influence air temperature of the target use area of the power battery and determine the detection temperature of the discharge detection unit according to the comparison result with the preset temperature standard;

S2,数据处理单元控制放电检测单元对所述动力电池进行一次放电检测且在放电过程中监测记录动力电池的温度以及电量,并控制图像生成单元根据放电检测过程监测记录的动力电池的温度数据和电量数据生成动力电池温度变化图以及耗电量变化图;S2, the data processing unit controls the discharge detection unit to perform a discharge detection on the power battery and monitors and records the temperature and power of the power battery during the discharge process, and controls the image generation unit to monitor and record the temperature data of the power battery according to the discharge detection process and The power data generates the power battery temperature change graph and the power consumption change graph;

S3,通过预设选取方式选取所述动力电池的温度变化图内若干待测点,数据处理单元依次计算各待测点的纵坐标差值并将其与预设纵坐标差值进行比对以判定该纵坐标差值是否为有效差值,并且在有效差值的数量符合预设阈值时确定与有效差值对应的待测点为温度变化有效点;S3, select a number of points to be measured in the temperature change map of the power battery by a preset selection method, and the data processing unit sequentially calculates the ordinate difference of each point to be measured and compares it with the preset ordinate difference to obtain Determine whether the ordinate difference is an effective difference, and determine that the point to be measured corresponding to the effective difference is an effective temperature change point when the number of effective differences meets the preset threshold;

S4,选取纵坐标温度最小的温度变化有效点对应的温度为动力电池冷却系统的一次关闭温度,并且将除去与一次关闭温度对应的温度变化有效点以外的温度变化有效点记为功率调节点;S4, select the temperature corresponding to the effective point of temperature change with the smallest ordinate temperature as the primary shutdown temperature of the power battery cooling system, and record the effective temperature change points other than the effective point of temperature change corresponding to the primary shutdown temperature as power adjustment points;

S5,由横坐标轴正方向依次提取各功率调节点在所述耗电量变化图中对应的动力电池电量并与预设耗电量进行比对以确定功率调节点对应的冷却系统功率调节系数,将生成的冷却策略通过显示单元传送至用户端。S5, sequentially extract the power battery power corresponding to each power adjustment point in the power consumption change diagram from the positive direction of the abscissa axis, and compare it with the preset power consumption to determine the power adjustment coefficient of the cooling system corresponding to the power adjustment point , and transmit the generated cooling strategy to the user terminal through the display unit.

具体而言,放电检测单元,其包括用以对动力电池放电检测过程中电池电量进行监测的电量监测模块以及用以对动力电池放电检测过程中动力电池温度进行检测的温度检测模块;Specifically, the discharge detection unit includes a power monitoring module for monitoring the battery power during the power battery discharge detection process and a temperature detection module for detecting the power battery temperature during the power battery discharge detection process;

图像生成单元,其与所述放电检测单元相连,用以接收并记录所述温度检测模块以及所述电量检测模块所传递的动力电池的温度信息以及电量信息,并且分别生成反应动力电池电量与放电检测时间变化关系的耗电量变化关系图以及反应动力电池温度与放电检测时间变化关系的温度变化关系图;An image generation unit, which is connected to the discharge detection unit, is used to receive and record the temperature information and power information of the power battery transmitted by the temperature detection module and the power detection module, and generate the power battery power and discharge power respectively. The power consumption change relationship diagram of the detection time variation relationship and the temperature variation relationship diagram reflecting the power battery temperature and the discharge detection time variation relationship;

数据处理单元,其与所述放电检测单元以及所述图像生成单元相连;a data processing unit connected to the discharge detection unit and the image generation unit;

其中,所述温度检测模块包括一壳体,壳体内壁上设有若干圆环型的电子滑槽,每个电子滑槽上对应安装有温度传感器,用以对动力电池的温度进行检测。Wherein, the temperature detection module includes a housing, and the inner wall of the housing is provided with a plurality of ring-shaped electronic chutes, and each electronic chute is correspondingly installed with a temperature sensor for detecting the temperature of the power battery.

具体而言,所述数据处理单元在第一检测条件下提取所述动力电池的目标使用地区的影响气温T并将T与预设温度标准进行比对以判定对针对该动力电池进行放电检测时放电检测单元的检测温度,设定,其中, Tu为目标使用地区的全年内第u日大于预设气温的最高气温,u=1,2,3,……,umax,umax为目标使用地区全年内大于预设气温的最高气温的天数,所述数据处理单元设有第一预设温度标准T1、第二预设温度标准T2以及预设气温Tmax,其中,T1=25℃,T2=35℃,Tmax=20℃,Specifically, the data processing unit extracts the affected air temperature T of the target usage area of the power battery under the first detection condition, and compares T with the preset temperature standard to determine whether it is necessary to perform discharge detection on the power battery. The detection temperature of the discharge detection unit is set , among them, Tu is the maximum temperature greater than the preset temperature on the uth day of the year in the target use area, u=1, 2, 3, ..., umax, umax is the maximum temperature greater than the preset temperature in the year in the target use area The number of days, the data processing unit is provided with a first preset temperature standard T1, a second preset temperature standard T2 and a preset temperature Tmax, wherein, T1=25°C, T2=35°C, Tmax=20°C,

若0<T≤T1,所述数据处理单元判定放电检测单元的检测温度为Tz,设定Tz=T0,其中,T0为预设标准检测温度,T0=20℃;If 0<T≤T1, the data processing unit determines that the detection temperature of the discharge detection unit is Tz, and sets Tz=T0, wherein T0 is a preset standard detection temperature, and T0=20°C;

若T1<T≤T2,所述数据处理单元判定放电检测单元的检测温度为Tz,设定Tz=T0×α1;If T1<T≤T2, the data processing unit determines that the detection temperature of the discharge detection unit is Tz, and sets Tz=T0×α1;

若T2<T,所述数据处理单元判定放电检测单元的检测温度为Tz,设定Tz=T0×α2;If T2<T, the data processing unit determines that the detection temperature of the discharge detection unit is Tz, and sets Tz=T0×α2;

其中,α1为第一温度调节系数,α2为第二温度调节系数,其中,α1=1.2,α2=1.5,第一检测条件为待测的动力电池置于放电检测单元并且放电检测单元通电开启。Among them, α1 is the first temperature adjustment coefficient, α2 is the second temperature adjustment coefficient, where α1=1.2, α2=1.5, and the first detection condition is that the power battery to be tested is placed in the discharge detection unit and the discharge detection unit is powered on.

具体而言,作为可实行的实施方式,用户能够通过显示单元对T1,T2以及Tmax的数值进行设置,但是T1应为动力电池工作适宜温度,T2以及Tmax应为对动力电池工作产生负影响的温度。Specifically, as a feasible implementation, the user can set the values of T1, T2, and Tmax through the display unit, but T1 should be the temperature suitable for the operation of the power battery, and T2 and Tmax should be the temperature that has a negative impact on the operation of the power battery. temperature.

具体而言,所述数据处理单元在第二检测条件下将放电检测单元的温度调节至Tz并控制放电检测单元对所述动力电池进行一次放电检测且在放电过程中监测记录动力电池的温度以及电量,其中,动力电池放电功率设置为第一放电功率,数据处理单元在放电检测完成时控制图像生成单元根据放电检测过程监测记录的动力电池的温度数据以及电量数据生成动力电池温度变化图以及耗电量变化图,其中,所述温度变化图为动力电池在放电检测过程中放电检测时间与动力电池温度的第一函数关系曲线,所述第一函数关系曲线呈现为坐标系形式,横坐标变量为放电检测时间t,纵坐标变量为动力电池温度,所述耗电量变化图为动力电池在放电检测过程中放电检测时间与动力电池电量的第二函数关系曲线,所述第二函数关系曲线呈现为坐标系形式,横坐标变量为放电检测时间t,纵坐标变量为动力电池电量Q;Specifically, the data processing unit adjusts the temperature of the discharge detection unit to Tz under the second detection condition and controls the discharge detection unit to perform a discharge detection on the power battery and monitor and record the temperature of the power battery during the discharge process and Electricity, wherein, the discharge power of the power battery is set as the first discharge power, and the data processing unit controls the image generation unit to generate the power battery temperature change map and power consumption data according to the temperature data and power data of the power battery that are monitored and recorded during the discharge detection process when the discharge detection is completed. Electricity change graph, wherein, the temperature change graph is the first functional relationship curve between the discharge detection time and the power battery temperature during the discharge detection process of the power battery, the first functional relationship curve is in the form of a coordinate system, and the abscissa variable is the discharge detection time t, the ordinate variable is the temperature of the power battery, and the power consumption change diagram is the second function relationship curve between the discharge detection time and the power battery power of the power battery during the discharge detection process, and the second function relationship curve Presented in the form of a coordinate system, the abscissa variable is the discharge detection time t, and the ordinate variable is the power battery Q;

其中,所述第二检测条件为所述数据处理单元对动力电池检测环境的温度判定完成。Wherein, the second detection condition is that the temperature determination of the power battery detection environment by the data processing unit is completed.

具体而言,所述数据处理单元在第一分析条件下通过预设选取方式选取所述动力电池的温度变化图内若干待测点,数据处理单元依次计算第i个待测点的纵坐标差值△Hi并将△Hi与预设纵坐标差值进行比对以判定该纵坐标差值是否为有效差值,设定△Hi=(Hi+1-Hi),其中,Hi为第i个待测点的纵坐标温度值,Hi+1为第i+1个待测点的纵坐标温度值,i=1,2,3,……,n,其中,n+1为待测点的总数量,所述数据处理单元设有第一预设有效差值△H0,其中,△H0=5℃,Specifically, under the first analysis condition, the data processing unit selects several points to be measured in the temperature change diagram of the power battery through a preset selection method, and the data processing unit sequentially calculates the difference in ordinates of the i-th point to be measured Value △Hi and compare △Hi with the preset ordinate difference to determine whether the ordinate difference is a valid difference, set △Hi = (Hi+1 -Hi ), where, Hi is the ordinate temperature value of the i-th point to be measured, Hi+1 is the ordinate temperature value of the i+1-th point to be measured, i=1, 2, 3,..., n, where, n +1 is the total number of points to be measured, and the data processing unit is provided with a first preset effective difference ΔH0, wherein, ΔH0=5°C,

若△Hi≤△H0,所述数据处理单元判定该纵坐标差值不是有效差值;If △Hi≦△H0, the data processing unit determines that the ordinate difference is not a valid difference;

若△H0<△Hi,所述数据处理单元判定该纵坐标差值为有效差值;If ΔH0<ΔHi, the data processing unit determines that the ordinate difference is an effective difference;

所述预设选取方式为所述数据处理单元针对温度变化图由横轴放电检测时间t=0开始,将每个选取周期的开始时刻在函数关系曲线上对应的坐标点作为待测点,所述选取周期为r,设定r=1000s,所述第一分析条件为所述图像生成单元针对所述动力电池的温度变化图生成结束。The preset selection method is that the data processing unit starts from the horizontal axis discharge detection time t=0 for the temperature change diagram, and uses the corresponding coordinate points on the function relationship curve at the beginning of each selection cycle as the points to be measured, so The selection period is r, and r=1000s is set, and the first analysis condition is that the generation of the temperature change map of the power battery by the image generation unit is completed.

具体而言,所述数据处理单元在第二分析条件下统计所有纵坐标差值中有效差值的数量N并将N与预设有效差值数量进行比对以判定是否对选取周期r进行调节,所述数据处理单元设有第一预设周期调节系数β1以及第二预设周期调节系数β2,其中,β1=0.7,β2=0.8<1,Specifically, the data processing unit counts the number N of valid differences among all ordinate differences under the second analysis condition and compares N with the preset number of valid differences to determine whether to adjust the selected period r , the data processing unit is provided with a first preset period adjustment coefficient β1 and a second preset period adjustment coefficient β2, wherein, β1=0.7, β2=0.8<1,

若N=0,所述数据处理单元判定使用β1将选取周期r调节为r’,设定r’=r×β1;If N=0, the data processing unit determines to use β1 to adjust the selection period r to r', and set r'=r×β1;

若N=1,所述数据处理单元判定使用β2将选取周期r调节为r’,设定r’=r×β2;If N=1, the data processing unit judges to use β2 to adjust the selection cycle r to r', and set r'=r×β2;

若N>1,所述数据处理单元判定无需对选取周期r进行调节,所述数据处理单元计算各有效差值的有效中间值Hi’并将函数关系曲线上横坐标与Hi’的横坐标距离最近的待测点记为温度变化有效点,设定Hi’=(Hi+1-Hi)/2;If N>1, the data processing unit determines that there is no need to adjust the selected period r, and the data processing unit calculates the effective intermediate value Hi ' of each effective difference and compares the abscissa on the function relationship curve with the abscissa of Hi ' The point to be measured with the closest coordinate distance is recorded as the effective point of temperature change, and Hi '=(Hi+1 -Hi )/2;

所述第二分析条件为所述数据处理单元对各纵坐标差值是否为有效差值的判定完成。The second analysis condition is that the data processing unit completes the determination of whether each ordinate difference is a valid difference.

具体而言,所述数据处理单元在第三分析条件下提取各温度变化有效点中对应的纵坐标温度最小的温度变化有效点记为Pmin,数据处理单元将Pmin对应的纵坐标温度值Hmin记为动力电池冷却系统的一次关闭温度并将Hmin与Tz进行比对以判定动力电池冷却系统的一次关闭时长,所述数据处理单元设有第一预设时长调节系数θ1、第二时长调节系数θ2以及第三预设时长调节系数θ3,其中,θ3=0.8,θ2=1,θ1=1.2,Specifically, under the third analysis condition, the data processing unit extracts the effective point of temperature change corresponding to the minimum temperature on the ordinate temperature among the effective points of temperature change under the third analysis condition and marks it as Pmin, and the data processing unit records the temperature value Hmin on the ordinate corresponding to Pmin as It is the primary shutdown temperature of the power battery cooling system and compares Hmin with Tz to determine the primary shutdown duration of the power battery cooling system. The data processing unit is provided with a first preset duration adjustment coefficient θ1 and a second duration adjustment coefficient θ2 And the third preset duration adjustment coefficient θ3, wherein, θ3=0.8, θ2=1, θ1=1.2,

若Hmin≤0.8Tz,所述数据处理单元判定动力电池冷却系统的一次关闭时长为tg,设定tg=tg0××θ1;If Hmin≤0.8Tz, the data processing unit determines that the power battery cooling system shuts down once for tg, and sets tg=tg0××θ1;

若0.8Tz<Hmin≤0.9Tz,所述数据处理单元判定动力电池冷却系统的一次关闭时长为tg,设定tg=tg0××θ2;If 0.8Tz<Hmin≤0.9Tz, the data processing unit determines that the power battery cooling system shuts down once for tg, and sets tg=tg0××θ2;

若0.9Tz<Hmin,所述数据处理单元判定动力电池冷却系统的一次关闭时长为tg,设定tg=tg0××θ3;If 0.9Tz<Hmin, the data processing unit determines that the power battery cooling system shuts down once for tg, and sets tg=tg0××θ3;

其中,tg0为预设一次关闭时长基值,tg0=5min,=30℃,所述第三分析条件为所述数据处理单元判定N>1。Wherein, tg0 is a preset base value of one time off time, tg0=5min,=30°C, and the third analysis condition is that the data processing unit judges that N>1.

其中,预设阈值以及第一预设时长调节系数θ1、第二时长调节系数θ2以及第三预设时长调节系数θ3通过多次试验得出,作为可选择的一种实施方式,用户能够根据对动力电池的需求通过显示单元设定第一预设时长调节系数θ1、第二时长调节系数θ2以及第三预设时长调节系数θ3的数值,但是应满足的是,若Hmin≤0.8Tz,将一次关闭时长调小,若0.8Tz<Hmin≤0.9Tz,对一次关闭时长的调节无需调节,若0.9Tz<Hmin,将一次关闭时长调大。Among them, the preset threshold value and the first preset duration adjustment coefficient θ1, the second duration adjustment coefficient θ2 and the third preset duration adjustment coefficient θ3 are obtained through multiple experiments. As an optional implementation mode, the user can The demand of the power battery sets the values of the first preset time length adjustment coefficient θ1, the second time length adjustment coefficient θ2 and the third preset time length adjustment coefficient θ3 through the display unit, but it should be satisfied that if Hmin≤0.8Tz, one time Turn down the closing time. If 0.8Tz<Hmin≤0.9Tz, there is no need to adjust the closing time. If 0.9Tz<Hmin, increase the closing time.

具体而言,所述数据处理单元在第三检测条件下将除Pmin以外的温度变化有效点记为功率调节点Pe,并由横坐标轴正方向依次提取第e个功率调节点Pe在所述耗电量变化图中第二关系曲线上对应的动力电池电量,e=1,2,3,……,emax,其中,emax=N-1,数据处理单元将P1对应的动力电池温度记为动力电池冷却系统的一次开启温度并且数据处理单元分别计算除P1外的第e个功率调节点的耗电量差值△Qe,设定△Qe=Qe-Qe-1,e=2,3,……,emax-1,数据处理单元将第e个功率调节点的△Qe与预设耗电量差值标准进行比对以判定第e个功率调节点对应的冷却系统功率调节系数,所述数据处理单元设有第一预设耗电量差值△Q01、第二预设耗电量差值△Q02、第一功率确定系数δ1以及第二功率确定系数δ2,其中,△Q01=15VAN,△Q02=25VAN,δ1=0.01,δ2=0.02,Specifically, under the third detection condition, the data processing unit records the effective point of temperature change except Pmin as the power adjustment point Pe, and sequentially extracts the e-th power adjustment point Pe from the positive direction of the abscissa axis in the The power battery power corresponding to the second relationship curve in the power consumption change graph, e=1, 2, 3, ..., emax, wherein, emax=N-1, the data processing unit records the temperature of the power battery corresponding to P1 as The primary start-up temperature of the power battery cooling system and the data processing unit respectively calculate the power consumption difference △Qe of the eth power adjustment point except P1, set △Qe=Qe-Qe-1, e=2, 3, ..., emax-1, the data processing unit compares the △Qe of the eth power adjustment point with the preset power consumption difference standard to determine the cooling system power adjustment coefficient corresponding to the eth power adjustment point, said The data processing unit is provided with a first preset power consumption difference ΔQ01, a second preset power consumption difference ΔQ02, a first power determination coefficient δ1, and a second power determination coefficient δ2, where ΔQ01=15VAN, △Q02=25VAN, δ1=0.01, δ2=0.02,

若△Qe≤△Q01,所述放电检测单元判定冷却系统功率调节系数为ζ,设定ζ=ζ0-△Qe×δ1;If △Qe≤△Q01, the discharge detection unit determines that the power adjustment coefficient of the cooling system is ζ, and sets ζ=ζ0-△Qe×δ1;

若△Q01<△Qe≤△Q02,所述放电检测单元判定压缩机功率为ζ,设定ζ=ζ0-△Qe×δ2;If △Q01<△Qe≤△Q02, the discharge detection unit determines that the power of the compressor is ζ, and sets ζ=ζ0-△Qe×δ2;

若△Q02<△Qe,所述放电检测单元判定该功率调节点为功率调节停止点并且无需对压缩机功率进行调节;If △Q02<△Qe, the discharge detection unit determines that the power adjustment point is the power adjustment stop point and there is no need to adjust the power of the compressor;

其中,P1为冷却系统恢复开启点,ζ0为预设功率调节基值,ζ0>0,所述第三检测条件为动力电池冷却系统的一次关闭时长判定完成。Wherein, P1 is the recovery start point of the cooling system, ζ0 is the preset power adjustment base value, ζ0>0, and the third detection condition is that the power battery cooling system has been shut down for one time.

其中,用户能够依据动力电池的续航能力为标准对δ1,δ2的数值进行设定,本实施方式中δ1,δ2根据多次试验数据得出,但是并不限于所提供的数值。Wherein, the user can set the values of δ1 and δ2 according to the endurance capacity of the power battery as a standard. In this embodiment, δ1 and δ2 are obtained based on multiple test data, but are not limited to the provided values.

具体而言,所述数据处理单元生成的冷却策略包括:动力电池初始温度为Tz±5°时且动力电池工作过程中温动力电池温度为Hmin时关闭冷却系统,并在动力电池温度达到冷却系统恢复开启点P1对应的温度时重新开启冷却系统,并在重新开启冷却系统后每当电池温度达到功率调节点的温度时使用ζ调节冷却系统的压缩机的功率为C,设定C=C0×ζ,其中,C0为初始压缩机功率,C0=50W;Specifically, the cooling strategy generated by the data processing unit includes: when the initial temperature of the power battery is Tz±5° and the temperature of the power battery is Hmin during the working process of the power battery, the cooling system is turned off, and the cooling system is restored when the temperature of the power battery reaches Turn on the cooling system again when the temperature corresponding to the opening point P1 is turned on, and use ζ to adjust the power of the compressor of the cooling system to C when the battery temperature reaches the temperature of the power adjustment point after restarting the cooling system, and set C=C0×ζ , where C0 is the initial compressor power, C0=50W;

其中,若在重新开启冷却系统后电池温度在预设监测时间内始终未达到功率调节点的温度,启动冷却系统的间接开启策略。Wherein, if the battery temperature has not reached the temperature of the power adjustment point within the preset monitoring time after the cooling system is restarted, the indirect activation strategy of the cooling system is activated.

具体而言,所述间接开启策略为冷却系统每运行B秒时转为关闭状态,并且在关闭状态时长达到b秒时重新转为开启状态,其中,B>0,b>0,作为一种可实施方式,B与b的取值应以动力电池使用时长为参考依据,用户能够通过显示单元在不影响动力电池工作的且B>b的前提下对B与b的取值进行设置,本发明提供一种B与b的取值,B=2000s,b=1000s。Specifically, the indirect opening strategy is that the cooling system turns off every B seconds, and turns on again when the off state reaches b seconds, wherein, B>0, b>0, as a Possible implementation methods, the values of B and b should be based on the service life of the power battery, and the user can set the values of B and b through the display unit without affecting the work of the power battery and under the premise of B>b. The invention provides a value of B and b, B=2000s, b=1000s.

请参阅图3至图4所示,在本实施例中,动力电池的目标使用地区的影响气温T=40℃,此时T2<T,所述数据处理单元判定放电检测单元的检测温度为Tz,设定Tz=25×1.5=37.5℃,图3为放电检测单元的检测温度为37.5℃时动力电池的温度变化关系图,该温度变化关系图为放电检测单元的检测温度在37.5℃时,动力电池在放电检测过程中放电检测时间与动力电池温度的第一函数关系曲线,横坐标变量为放电检测时间t,其单位为秒,纵坐标变量为动力电池温度,其单位为摄氏度,在另一实施例中,动力电池的目标使用地区的影响气温T=23℃,此时0<T<T1,所述数据处理单元判定放电检测单元的检测温度为Tz,设定Tz=T0=20℃,图4为放电检测单元的检测温度为20℃时动力电池的温度变化关系图,该温度变化关系图为放电检测单元的检测温度在20℃时,动力电池在放电检测过程中放电检测时间与动力电池温度的第一函数关系曲线,横坐标变量为放电检测时间t,其单位为秒,纵坐标变量为动力电池温度,其单位为摄氏度,可见不同的环境温度对于动力电池的温度影响不同。Please refer to Fig. 3 to Fig. 4, in this embodiment, the temperature T=40°C in the target area of use of the power battery, at this time T2<T, the data processing unit determines that the detection temperature of the discharge detection unit is Tz , set Tz=25×1.5=37.5°C, and Fig. 3 is the temperature change relation diagram of the power battery when the detection temperature of the discharge detection unit is 37.5°C, the temperature change relation diagram is when the detection temperature of the discharge detection unit is 37.5°C, The first functional relationship curve between the discharge detection time and the power battery temperature during the discharge detection process of the power battery. In one embodiment, the temperature affected by the target usage area of the power battery is T=23°C, at this

至此,已经结合附图所示的优选实施方式描述了本发明的技术方案,但是,本领域技术人员容易理解的是,本发明的保护范围显然不局限于这些具体实施方式。在不偏离本发明的原理的前提下,本领域技术人员可以对相关技术特征做出等同的更改或替换,这些更改或替换之后的技术方案都将落入本发明的保护范围之内。So far, the technical solutions of the present invention have been described in conjunction with the preferred embodiments shown in the accompanying drawings, but those skilled in the art will easily understand that the protection scope of the present invention is obviously not limited to these specific embodiments. Without departing from the principles of the present invention, those skilled in the art can make equivalent changes or substitutions to related technical features, and the technical solutions after these changes or substitutions will all fall within the protection scope of the present invention.

以上所述仅为本发明的优选实施例,并不用于限制本发明;对于本领域的技术人员来说,本发明可以有各种更改和变化。凡在本发明的精神和原则之内,所作的任何修改、等同替换、改进等,均应包含在本发明的保护范围之内。The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention; for those skilled in the art, the present invention may have various modifications and changes. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included within the protection scope of the present invention.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310342516.3ACN116087798B (en) | 2023-04-03 | 2023-04-03 | A kind of detection method of power battery |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310342516.3ACN116087798B (en) | 2023-04-03 | 2023-04-03 | A kind of detection method of power battery |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN116087798Atrue CN116087798A (en) | 2023-05-09 |

| CN116087798B CN116087798B (en) | 2023-07-18 |

Family

ID=86210474

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202310342516.3AActiveCN116087798B (en) | 2023-04-03 | 2023-04-03 | A kind of detection method of power battery |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN116087798B (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116995340A (en)* | 2023-09-26 | 2023-11-03 | 北京电科汇能检测技术有限公司 | Multipolar self-switching detection device and detection method for energy storage battery box |

| CN117465297A (en)* | 2023-12-14 | 2024-01-30 | 嘉丰盛精密电子科技(孝感)有限公司 | Intelligent cooling system based on electric automobile |

| CN117491054A (en)* | 2023-12-18 | 2024-02-02 | 嘉丰盛精密电子科技(孝感)有限公司 | An adaptive heat exchanger performance monitoring method and system |

Citations (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012104458A (en)* | 2010-11-15 | 2012-05-31 | Honda Motor Co Ltd | Battery cooling system and cooling method |

| WO2015078652A1 (en)* | 2013-11-26 | 2015-06-04 | Siemens Aktiengesellschaft | Method and apparatus for operating a battery cooling system for cooling a battery |

| CN107293821A (en)* | 2017-05-23 | 2017-10-24 | 北京新能源汽车股份有限公司 | Power battery heat treatment method and device and electric automobile |

| JP2018107923A (en)* | 2016-12-27 | 2018-07-05 | ダイムラー・アクチェンゲゼルシャフトDaimler AG | Battery cooling device |

| CN109599632A (en)* | 2017-09-30 | 2019-04-09 | 比亚迪股份有限公司 | The temperature control method and humidity control system of on-vehicle battery |

| US20190237826A1 (en)* | 2016-07-01 | 2019-08-01 | Mitsubishi Electric Corporation | Storage battery cooling control device and storage battery cooling control method |

| CN110137619A (en)* | 2019-04-15 | 2019-08-16 | 华为技术有限公司 | Energy storage device temprature control method and device |

| CN111251939A (en)* | 2018-11-30 | 2020-06-09 | 比亚迪股份有限公司 | Vehicle, reservation management system thereof, reservation system thereof, and reservation management method thereof |

| CN111460664A (en)* | 2020-04-01 | 2020-07-28 | 吉林大学 | A nonlinear cooling optimization method for new energy vehicle power battery |

| CN111509331A (en)* | 2019-01-31 | 2020-08-07 | 北京新能源汽车股份有限公司 | Control method and device for cooling power battery and electric vehicle |

| CN111791755A (en)* | 2019-04-09 | 2020-10-20 | 微宏动力系统(湖州)有限公司 | Battery thermal management method |

| KR20210007247A (en)* | 2019-07-10 | 2021-01-20 | 주식회사 엘지화학 | Apparatus and method for diagnosing cooling requirement for battery module |

| CN112455287A (en)* | 2019-09-06 | 2021-03-09 | 比亚迪股份有限公司 | Vehicle and cooling method and device of power battery of vehicle |

| CN112519635A (en)* | 2019-09-17 | 2021-03-19 | 深圳市英维克科技股份有限公司 | Control method and related device for battery thermal management |

| CN113410537A (en)* | 2021-04-27 | 2021-09-17 | 浙江合众新能源汽车有限公司 | Power battery charging thermal management control method and system |

| CN113851757A (en)* | 2021-09-24 | 2021-12-28 | 经纬恒润(天津)研究开发有限公司 | Power battery thermal management method and device |

| WO2022094893A1 (en)* | 2020-11-05 | 2022-05-12 | 江苏洋口港港务有限公司 | Temperature management control system for power battery of electric vehicle |

| CN114572058A (en)* | 2022-03-09 | 2022-06-03 | 重庆金康赛力斯新能源汽车设计院有限公司 | Method and device for controlling temperature of battery system and electronic equipment |

| CN114590171A (en)* | 2020-12-03 | 2022-06-07 | 观致汽车有限公司 | Control method of thermal management system, thermal management system, and vehicle |

| CN114590169A (en)* | 2022-02-23 | 2022-06-07 | 北京罗克维尔斯科技有限公司 | Battery cooling method, device, electronic equipment and storage medium |

| CN114628818A (en)* | 2022-01-30 | 2022-06-14 | 南京理工大学 | A battery pack cooling method that considers aging and inconsistency |

| CN114628805A (en)* | 2022-03-28 | 2022-06-14 | 重庆金康赛力斯新能源汽车设计院有限公司 | Battery cooling method, management system and vehicle-mounted terminal |

| CN114927803A (en)* | 2022-05-27 | 2022-08-19 | 中国第一汽车股份有限公司 | Battery temperature adjusting method and device, storage medium and vehicle |

| CN114919466A (en)* | 2022-06-07 | 2022-08-19 | 中国第一汽车股份有限公司 | Thermal management control method and device, vehicle control unit and medium |

| CN115503554A (en)* | 2022-08-09 | 2022-12-23 | 岚图汽车科技有限公司 | Electric vehicle smart battery thermal management control method and system |

| CN115716431A (en)* | 2022-12-28 | 2023-02-28 | 广州巨湾技研有限公司 | Thermal management control method, system, medium, equipment and vehicle for vehicle precooling |

| CN115771432A (en)* | 2022-12-02 | 2023-03-10 | 吉利汽车研究院(宁波)有限公司 | A battery management control method, device, equipment, vehicle and medium |

- 2023

- 2023-04-03CNCN202310342516.3Apatent/CN116087798B/enactiveActive

Patent Citations (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012104458A (en)* | 2010-11-15 | 2012-05-31 | Honda Motor Co Ltd | Battery cooling system and cooling method |

| WO2015078652A1 (en)* | 2013-11-26 | 2015-06-04 | Siemens Aktiengesellschaft | Method and apparatus for operating a battery cooling system for cooling a battery |

| US20190237826A1 (en)* | 2016-07-01 | 2019-08-01 | Mitsubishi Electric Corporation | Storage battery cooling control device and storage battery cooling control method |

| JP2018107923A (en)* | 2016-12-27 | 2018-07-05 | ダイムラー・アクチェンゲゼルシャフトDaimler AG | Battery cooling device |

| CN107293821A (en)* | 2017-05-23 | 2017-10-24 | 北京新能源汽车股份有限公司 | Power battery heat treatment method and device and electric automobile |

| CN109599632A (en)* | 2017-09-30 | 2019-04-09 | 比亚迪股份有限公司 | The temperature control method and humidity control system of on-vehicle battery |

| CN111251939A (en)* | 2018-11-30 | 2020-06-09 | 比亚迪股份有限公司 | Vehicle, reservation management system thereof, reservation system thereof, and reservation management method thereof |

| CN111509331A (en)* | 2019-01-31 | 2020-08-07 | 北京新能源汽车股份有限公司 | Control method and device for cooling power battery and electric vehicle |

| CN111791755A (en)* | 2019-04-09 | 2020-10-20 | 微宏动力系统(湖州)有限公司 | Battery thermal management method |

| CN110137619A (en)* | 2019-04-15 | 2019-08-16 | 华为技术有限公司 | Energy storage device temprature control method and device |

| KR20210007247A (en)* | 2019-07-10 | 2021-01-20 | 주식회사 엘지화학 | Apparatus and method for diagnosing cooling requirement for battery module |

| CN112455287A (en)* | 2019-09-06 | 2021-03-09 | 比亚迪股份有限公司 | Vehicle and cooling method and device of power battery of vehicle |

| CN112519635A (en)* | 2019-09-17 | 2021-03-19 | 深圳市英维克科技股份有限公司 | Control method and related device for battery thermal management |

| CN111460664A (en)* | 2020-04-01 | 2020-07-28 | 吉林大学 | A nonlinear cooling optimization method for new energy vehicle power battery |

| WO2022094893A1 (en)* | 2020-11-05 | 2022-05-12 | 江苏洋口港港务有限公司 | Temperature management control system for power battery of electric vehicle |

| CN114590171A (en)* | 2020-12-03 | 2022-06-07 | 观致汽车有限公司 | Control method of thermal management system, thermal management system, and vehicle |

| CN113410537A (en)* | 2021-04-27 | 2021-09-17 | 浙江合众新能源汽车有限公司 | Power battery charging thermal management control method and system |

| CN113851757A (en)* | 2021-09-24 | 2021-12-28 | 经纬恒润(天津)研究开发有限公司 | Power battery thermal management method and device |

| CN114628818A (en)* | 2022-01-30 | 2022-06-14 | 南京理工大学 | A battery pack cooling method that considers aging and inconsistency |

| CN114590169A (en)* | 2022-02-23 | 2022-06-07 | 北京罗克维尔斯科技有限公司 | Battery cooling method, device, electronic equipment and storage medium |

| CN114572058A (en)* | 2022-03-09 | 2022-06-03 | 重庆金康赛力斯新能源汽车设计院有限公司 | Method and device for controlling temperature of battery system and electronic equipment |

| CN114628805A (en)* | 2022-03-28 | 2022-06-14 | 重庆金康赛力斯新能源汽车设计院有限公司 | Battery cooling method, management system and vehicle-mounted terminal |

| CN114927803A (en)* | 2022-05-27 | 2022-08-19 | 中国第一汽车股份有限公司 | Battery temperature adjusting method and device, storage medium and vehicle |

| CN114919466A (en)* | 2022-06-07 | 2022-08-19 | 中国第一汽车股份有限公司 | Thermal management control method and device, vehicle control unit and medium |

| CN115503554A (en)* | 2022-08-09 | 2022-12-23 | 岚图汽车科技有限公司 | Electric vehicle smart battery thermal management control method and system |

| CN115771432A (en)* | 2022-12-02 | 2023-03-10 | 吉利汽车研究院(宁波)有限公司 | A battery management control method, device, equipment, vehicle and medium |

| CN115716431A (en)* | 2022-12-28 | 2023-02-28 | 广州巨湾技研有限公司 | Thermal management control method, system, medium, equipment and vehicle for vehicle precooling |

Non-Patent Citations (6)

| Title |

|---|

| LARRANAGA-EZEIZA.M 等: "A novel direct liquid cooling strategy for electric vehicles focused on pouch type battery cells", APPLIED THERMAL ENGINEERING* |

| XIJIN KUANG 等: "Research on Control Strategy for a Battery Thermal Management System for Electric Vehicles Based on Secondary Loop Cooling", IEEE ACCESS* |

| 吴凡: "基于BMS的锂离子电池组热管理技术研究", 中国优秀硕士学位论文全文数据库 工程科技Ⅱ辑* |

| 孙一钊: "全气候工况动力电池组热管理系统性能研究", 中国优秀硕士学位论文全文数据库工程科技Ⅱ辑* |

| 彭影;黄瑞;俞小莉;许建青;: "电动汽车锂离子动力电池冷却方案的对比研究", 机电工程, no. 04* |

| 胡远志: "车用锂离子电池冷却技术研究进展", 重庆理工大学学报(自然科学)* |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116995340A (en)* | 2023-09-26 | 2023-11-03 | 北京电科汇能检测技术有限公司 | Multipolar self-switching detection device and detection method for energy storage battery box |

| CN116995340B (en)* | 2023-09-26 | 2023-12-15 | 北京电科汇能检测技术有限公司 | Multipolar self-switching detection device and detection method for energy storage battery box |

| CN117465297A (en)* | 2023-12-14 | 2024-01-30 | 嘉丰盛精密电子科技(孝感)有限公司 | Intelligent cooling system based on electric automobile |

| CN117491054A (en)* | 2023-12-18 | 2024-02-02 | 嘉丰盛精密电子科技(孝感)有限公司 | An adaptive heat exchanger performance monitoring method and system |

Also Published As

| Publication number | Publication date |

|---|---|

| CN116087798B (en) | 2023-07-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN116087798B (en) | A kind of detection method of power battery | |

| CN108172930B (en) | Battery pack cooling control method and device and battery pack | |

| CN111055722B (en) | Method, device and storage medium for estimating charging time | |

| CN105958138B (en) | Thermal management method of lithium battery management system | |

| TWI704738B (en) | Super capacitor protection device and protection method of vehicle power supply system | |

| JP2020092091A (en) | Method and device for optimizing life of power storage system | |

| CN109935867A (en) | For diagnosing the method and system of the temperature sensor fault of fuel cell | |

| CN105048021A (en) | Battery temperature estimation system | |

| CN108152742B (en) | A kind of vehicle generator efficiency test method | |

| JP2015505955A (en) | Battery remaining capacity estimation apparatus and method | |

| CN103337669B (en) | Reutilization method of power battery of electric automobile | |

| CN111342089A (en) | Thermal management testing device and method for fuel cell vehicle | |

| CN213986650U (en) | Thermal management performance evaluation testing device for power battery system | |

| CN110350259B (en) | A low-temperature charging method for lithium-ion batteries | |

| CN104881550A (en) | Self-adaptive prediction method for running temperature of power battery | |

| CN109752659A (en) | PACK test system and method for liquid-cooled battery | |

| US20130158913A1 (en) | System and method for determining charging and discharging power levels for a battery pack | |

| CN119298400B (en) | Intelligent monitoring type photovoltaic power generation system | |

| CN117848627B (en) | Air tightness detection method, air tightness detection device, storage medium, battery system and electricity utilization device | |

| TW201427851A (en) | Power management system of range extended electric vehicle and method of power control thereof | |

| CN112060927A (en) | Temperature protection method and control equipment for electromechanical and thermal integrated system of new energy automobile | |

| CN116500465A (en) | Method and system for realizing battery monitoring based on automobile battery parameters | |

| KR20200134009A (en) | Method and apparatus for charging battery for vehicle | |

| CN115993256A (en) | Method and system for testing vehicle cruising range | |

| CN108068648A (en) | A kind of centralization cell management system of electric automobile |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| PE01 | Entry into force of the registration of the contract for pledge of patent right | ||

| PE01 | Entry into force of the registration of the contract for pledge of patent right | Denomination of invention:A method for detecting power batteries Granted publication date:20230718 Pledgee:Jining Jiaxiang sub branch of Rizhao Bank Co.,Ltd. Pledgor:Zhongbei runliang new energy (Jining) Co.,Ltd. Registration number:Y2024980054565 | |

| CP03 | Change of name, title or address | ||

| CP03 | Change of name, title or address | Address after:272400 South Automobile Industrial Park, the intersection of Chengxiang Avenue and Jiamei Road, Jining economic and Technological Development Zone, Jining City, Shandong Province Patentee after:Xiaolu Lithium Battery New Energy (Shandong) Co.,Ltd. Country or region after:China Address before:272400 South Automobile Industrial Park, the intersection of Chengxiang Avenue and Jiamei Road, Jining economic and Technological Development Zone, Jining City, Shandong Province Patentee before:Zhongbei runliang new energy (Jining) Co.,Ltd. Country or region before:China |