CN116084181A - Flexible stab-resistant and bulletproof textile and manufacturing method thereof - Google Patents

Flexible stab-resistant and bulletproof textile and manufacturing method thereofDownload PDFInfo

- Publication number

- CN116084181A CN116084181ACN202310066918.5ACN202310066918ACN116084181ACN 116084181 ACN116084181 ACN 116084181ACN 202310066918 ACN202310066918 ACN 202310066918ACN 116084181 ACN116084181 ACN 116084181A

- Authority

- CN

- China

- Prior art keywords

- parts

- weight

- nano

- anhydride

- diisocyanate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N3/00—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof

- D06N3/12—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof with macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. gelatine proteins

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F6/00—Monocomponent artificial filaments or the like of synthetic polymers; Manufacture thereof

- D01F6/58—Monocomponent artificial filaments or the like of synthetic polymers; Manufacture thereof from homopolycondensation products

- D01F6/74—Monocomponent artificial filaments or the like of synthetic polymers; Manufacture thereof from homopolycondensation products from polycondensates of cyclic compounds, e.g. polyimides, polybenzimidazoles

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

- D06M11/32—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with oxygen, ozone, ozonides, oxides, hydroxides or percompounds; Salts derived from anions with an amphoteric element-oxygen bond

- D06M11/36—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with oxygen, ozone, ozonides, oxides, hydroxides or percompounds; Salts derived from anions with an amphoteric element-oxygen bond with oxides, hydroxides or mixed oxides; with salts derived from anions with an amphoteric element-oxygen bond

- D06M11/45—Oxides or hydroxides of elements of Groups 3 or 13 of the Periodic Table; Aluminates

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

- D06M11/32—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with oxygen, ozone, ozonides, oxides, hydroxides or percompounds; Salts derived from anions with an amphoteric element-oxygen bond

- D06M11/36—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with oxygen, ozone, ozonides, oxides, hydroxides or percompounds; Salts derived from anions with an amphoteric element-oxygen bond with oxides, hydroxides or mixed oxides; with salts derived from anions with an amphoteric element-oxygen bond

- D06M11/46—Oxides or hydroxides of elements of Groups 4 or 14 of the Periodic Table; Titanates; Zirconates; Stannates; Plumbates

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

- D06M11/73—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with carbon or compounds thereof

- D06M11/74—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with carbon or compounds thereof with carbon or graphite; with carbides; with graphitic acids or their salts

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

- D06M11/77—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with silicon or compounds thereof

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M11/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising

- D06M11/83—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with inorganic substances or complexes thereof; Such treatment combined with mechanical treatment, e.g. mercerising with metals; with metal-generating compounds, e.g. metal carbonyls; Reduction of metal compounds on textiles

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M13/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment

- D06M13/50—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment with organometallic compounds; with organic compounds containing boron, silicon, selenium or tellurium atoms

- D06M13/51—Compounds with at least one carbon-metal or carbon-boron, carbon-silicon, carbon-selenium, or carbon-tellurium bond

- D06M13/513—Compounds with at least one carbon-metal or carbon-boron, carbon-silicon, carbon-selenium, or carbon-tellurium bond with at least one carbon-silicon bond

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/01—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with natural macromolecular compounds or derivatives thereof

- D06M15/03—Polysaccharides or derivatives thereof

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/21—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/356—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds of other unsaturated compounds containing nitrogen, sulfur, silicon or phosphorus atoms

- D06M15/3562—Macromolecular compounds obtained by reactions only involving carbon-to-carbon unsaturated bonds of other unsaturated compounds containing nitrogen, sulfur, silicon or phosphorus atoms containing nitrogen

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/37—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N3/00—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof

- D06N3/0002—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof characterised by the substrate

- D06N3/0015—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof characterised by the substrate using fibres of specified chemical or physical nature, e.g. natural silk

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06N—WALL, FLOOR, OR LIKE COVERING MATERIALS, e.g. LINOLEUM, OILCLOTH, ARTIFICIAL LEATHER, ROOFING FELT, CONSISTING OF A FIBROUS WEB COATED WITH A LAYER OF MACROMOLECULAR MATERIAL; FLEXIBLE SHEET MATERIAL NOT OTHERWISE PROVIDED FOR

- D06N3/00—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof

- D06N3/0043—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof characterised by their foraminous structure; Characteristics of the foamed layer or of cellular layers

- D06N3/005—Artificial leather, oilcloth or other material obtained by covering fibrous webs with macromolecular material, e.g. resins, rubber or derivatives thereof characterised by their foraminous structure; Characteristics of the foamed layer or of cellular layers obtained by blowing or swelling agent

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M2101/00—Chemical constitution of the fibres, threads, yarns, fabrics or fibrous goods made from such materials, to be treated

- D06M2101/16—Synthetic fibres, other than mineral fibres

- D06M2101/30—Synthetic polymers consisting of macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/50—Manufacturing or production processes characterised by the final manufactured product

- Y02P70/62—Manufacturing or production processes characterised by the final manufactured product related technologies for production or treatment of textile or flexible materials or products thereof, including footwear

Landscapes

- Engineering & Computer Science (AREA)

- Textile Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Dispersion Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Organic Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Treatments For Attaching Organic Compounds To Fibrous Goods (AREA)

Abstract

Description

Translated fromChinese技术领域Technical Field

本发明属于功能面料技术领域,具体是一种柔性防刺且防弹的纺织物及其制造方法。The invention belongs to the technical field of functional fabrics, and in particular relates to a flexible stab-proof and bullet-proof textile and a manufacturing method thereof.

背景技术Background Art

防弹的主要机制为吸收或消耗弹头的能量,从而阻止子弹穿透,最终达到保护人体的作用;而防刺的主要机制为阻止锐器继续向前推进。二者有着本质上的不同,前者依靠的是拉伸强度,即提高材料的拉伸强度,有助于吸收或消耗弹头的能量,达到防弹的目的;后者依靠的是剪切强度,即提高材料的剪切强度有助于利器的刃部快速变形,达到防刺的目的。The main mechanism of bulletproof is to absorb or consume the energy of the bullet, thereby preventing the bullet from penetrating and ultimately protecting the human body; while the main mechanism of stab protection is to prevent the sharp weapon from continuing to move forward. The two are essentially different. The former relies on tensile strength, that is, improving the tensile strength of the material helps to absorb or consume the energy of the bullet and achieve the purpose of bulletproof; the latter relies on shear strength, that is, improving the shear strength of the material helps the blade of the sharp weapon to deform quickly and achieve the purpose of stab protection.

目前,软质材料的拉伸断裂强度与剪切强度难以同时兼顾,使得软质材料的防弹与防刺功能难以同时实现,因此有学者提出在面料表面喷涂涂层以待提高面料的拉伸断裂强度与剪切强度。方志强等研究的T26聚脲材料的拉神强度仅为25.4MPa;温喜梅等采用高压湍流分散的方式向自制的聚脲材料中加入了多壁碳纳米管,其拉伸强度为42.5MPa,二者的拉伸强度可适用于防爆领域,但远不满足对防弹性能的要求。改性环氧树脂基复合材料的拉伸强度为440MPa左右,剪切强度为250MPa左右;酚醛树脂基复合材料的拉神强度为420MPa左右,剪切强度为260MPa左右,尽管满足对防刺与防弹的需求,但由于其易受环境和气候的影响,从而改变其分子链结构,失去其原有的防弹防刺性能,缩小了其应用领域以及应用条件。At present, it is difficult to take both the tensile strength and shear strength of soft materials into account at the same time, making it difficult to achieve both the bulletproof and stab-proof functions of soft materials at the same time. Therefore, some scholars have proposed spraying a coating on the surface of the fabric to improve the tensile strength and shear strength of the fabric. The tensile strength of the T26 polyurea material studied by Fang Zhiqiang et al. is only 25.4MPa; Wen Ximei et al. added multi-walled carbon nanotubes to the homemade polyurea material by high-pressure turbulent dispersion, and its tensile strength was 42.5MPa. The tensile strength of the two can be applied to the explosion-proof field, but it is far from meeting the requirements for bulletproof performance. The tensile strength of the modified epoxy resin-based composite material is about 440MPa, and the shear strength is about 250MPa; the tensile strength of the phenolic resin-based composite material is about 420MPa, and the shear strength is about 260MPa. Although it meets the requirements for stab and bullet resistance, it is easily affected by the environment and climate, thus changing its molecular chain structure, losing its original bulletproof and stab-proof performance, and narrowing its application field and application conditions.

发明内容Summary of the invention

针对现有技术存在的不足,本发明的目是提供一种柔性防刺且防弹的纺织物,不仅具有优良的防刺、防弹性能,且柔软透气。In view of the shortcomings of the prior art, the purpose of the present invention is to provide a flexible stab-proof and ballistic-proof textile, which not only has excellent stab-proof and ballistic-proof properties but is also soft and breathable.

为了实现上述目的,本发明采用以下技术方案予以实现:In order to achieve the above object, the present invention adopts the following technical solutions:

一种柔性防刺且防弹的纺织物,由聚酰亚胺纤维织造而成且表面涂覆有聚脲弹性体涂层。A flexible, stab-resistant and ballistic-resistant textile woven from polyimide fibers and coated with a polyurea elastomer coating.

一种柔性防刺且防弹的纺织物的制造方法,包括如下步骤:A method for manufacturing a flexible stab-proof and bullet-proof textile comprises the following steps:

步骤1、将聚酰亚胺纤维织成织物基底;

步骤2、按照重量份将3~3.5份纳米添加剂加入15~20份氨基化合物中并充分搅拌得到混合液,将织物基底置于混合液中并在20~50℃下充分浸泡,取出后将其在30~60℃的温度下烘干,得到表面修饰处理后的织物基底;

步骤3、将聚脲弹性体均匀喷涂在经过表面修饰处理后的织物基底表面,自然晾干后得到柔性防刺且防弹的纺织物。Step 3: spray the polyurea elastomer evenly on the surface of the fabric substrate after surface modification, and obtain a flexible stab-proof and bullet-proof textile after natural drying.

进一步地,所述聚酰亚胺纤维由如下方法制得:Furthermore, the polyimide fiber is prepared by the following method:

按重量份数将40~60份二胺和40~60份二酐溶于酚类溶剂中,并加热至150~250℃,待充分反应后生成聚酰亚胺纺丝浆液,然后利用纺丝工艺得到聚酰亚胺纤维;Dissolving 40-60 parts of diamine and 40-60 parts of dianhydride by weight in a phenolic solvent and heating to 150-250° C. to generate a polyimide spinning slurry after sufficient reaction, and then obtaining polyimide fibers by a spinning process;

所述二胺是2,4-二氨基-3,5-二甲硫基甲苯、3,5-二硝基-1,2-苯二胺、4,5-二氟苯-1,2-二胺、N-(1-萘基)乙二胺二盐酸盐或咖啡酰丁二胺中的一种或多种;The diamine is one or more of 2,4-diamino-3,5-dimethylthiotoluene, 3,5-dinitro-1,2-phenylenediamine, 4,5-difluorobenzene-1,2-diamine, N-(1-naphthyl)ethylenediamine dihydrochloride or caffeoylbutylene diamine;

所述二酐是2,3-吡嗪二酸酐、3-异丁基戊二酸酐、S-乙酰巯基丁二酸酐、甲基丁二酸酐、六氟戊二酸酐、氯桥酸酐或十二烯基丁二酸酐中的一种或多种。The dianhydride is one or more of 2,3-pyrazine dianhydride, 3-isobutyl glutaric anhydride, S-acetylmercaptosuccinic anhydride, methylsuccinic anhydride, hexafluoroglutaric anhydride, chlorohydric anhydride or dodecenylsuccinic anhydride.

进一步地,所述步骤2中的氨基化合物是二乙烯三胺、三乙烯四胺、3-氨丙基三乙氧基硅烷、聚多巴胺、聚烯丙基胺盐酸盐或壳聚糖中的一种或多种。Furthermore, the amino compound in

进一步地,所述步骤2中的纳米添加剂是纳米碳化硼、纳米二氧化钛、纳米碳化硅、氧化石墨烯、纳米氧化铝或纳米银中的一种或多种。Furthermore, the nano-additive in

进一步地,所述步骤2中的浸泡时间为0.5~2.5h。Furthermore, the soaking time in

进一步地,所述步骤3中的聚脲弹性体由如下方法制得:Furthermore, the polyurea elastomer in

按照重量份分别取30-50份二异氰酸酯、0.01-1份催化剂、4-15份增塑剂和0.1-5份发泡剂混合,得到组分A;按照重量份分别取35-50份端氨基聚醚和5-15份扩链剂得到组分B;然后按照重量份将40-60份组分A和40-60份组分B混合并搅拌使其充分反应,得到聚脲弹性体。30-50 parts of diisocyanate, 0.01-1 parts of catalyst, 4-15 parts of plasticizer and 0.1-5 parts of foaming agent are respectively taken by weight to obtain component A; 35-50 parts of amino-terminated polyether and 5-15 parts of chain extender are respectively taken by weight to obtain component B; then 40-60 parts of component A and 40-60 parts of component B are mixed and stirred to fully react, thereby obtaining a polyurea elastomer.

进一步地,所述二异氰酸酯是二苯基甲烷二异氰酸酯、十二烷基苯-2,4-二异氰酸酯、3,3-二氯代联苯4,4-二异氰酸酯、3,3′-二甲氧基-4,4′-联苯二异氰酸酯或α,α,α',α'-四甲基-1,3-苯二甲基二异氰酸酯中的一种或多种;Further, the diisocyanate is one or more of diphenylmethane diisocyanate, dodecylbenzene-2,4-diisocyanate, 3,3-dichlorobiphenyl-4,4-diisocyanate, 3,3′-dimethoxy-4,4′-biphenyl diisocyanate or α,α,α′,α′-tetramethyl-1,3-phenylenedimethyl diisocyanate;

所述催化剂是血根氯铵、地特氯铵、米吡氯铵或甘草酸铵中的一种或多种;The catalyst is one or more of sanguinarium chloride, detemirium chloride, mipyridine chloride or ammonium glycyrrhizinate;

所述增塑剂是柠檬酸三烯丙酯、柠檬酸十八烷醇酯、柠檬酸三甲酯或柠檬酸三丁酯中的一种或多种;The plasticizer is one or more of triallyl citrate, stearyl citrate, trimethyl citrate or tributyl citrate;

所述发泡剂是1-氟-1,1-二氯乙烷、N,N-二甲基十二烷胺-N-氧化物、十二烷基聚氧乙烯醚硫酸钠或十二烷基硫酸钠中的一种或多种;The foaming agent is one or more of 1-fluoro-1,1-dichloroethane, N,N-dimethyldodecylamine-N-oxide, sodium dodecyl polyoxyethylene ether sulfate or sodium dodecyl sulfate;

所述端氨基聚醚是聚醚三元胺或聚醚四元胺中的一种或两种;The amino-terminated polyether is one or both of polyether triamine and polyether tetraamine;

所述扩链剂是灵芝酮三醇、表骨化三醇、六烷基磷三胺或二乙烯三胺五乙酸中的一种或多种。The chain extender is one or more of ganoderma lucidum ketone triol, epicalcitriol, hexaalkylphosphorus triamine or diethylenetriamine pentaacetic acid.

进一步地,所述酚类溶剂由萘酚和对硝基酚按照体积比(2~4):1混合而成本发明与现有技术相比,具有如下技术效果:Furthermore, the phenolic solvent is prepared by mixing naphthol and p-nitrophenol in a volume ratio of (2-4):1. Compared with the prior art, the present invention has the following technical effects:

本发明的柔性防刺且防弹纺织物为双层结构,第一层为聚酰亚胺纤维布组成基底,第二层为聚脲弹性体涂层,聚脲弹性体涂层赋予织物优良的防弹、防刺和透气等性能,具体体现在:一则,聚脲弹性体为连续相,当遇到穿刺和冲击等作用时,化学键的结合力使其内部结构发生弹性变形,使外部冲击力难以对面料造成永久性损伤,从而具有良好的防刺和防弹性能;二则,聚脲弹性体具有良好的柔韧性,作为面料的涂层材料不会影响面料的柔软性;三则,聚脲弹性体富含大量的微孔,不仅使面料具有良好的透气性,而且微孔具有良好的毛细作用,使水分与涂层的接触角大于90°,从而面料具有良好的防水性;四则,聚脲弹性的微孔使其保持电中性,因而不易带电荷,有效防止在穿着过程中面料吸附灰尘。The flexible stab-proof and bullet-proof textile fabric of the present invention has a double-layer structure, wherein the first layer is a polyimide fiber cloth as a base, and the second layer is a polyurea elastomer coating. The polyurea elastomer coating gives the fabric excellent bulletproof, stab-proof and breathable properties, which are specifically embodied in the following aspects: firstly, the polyurea elastomer is a continuous phase, and when encountering puncture and impact, the binding force of the chemical bonds causes its internal structure to undergo elastic deformation, so that it is difficult for the external impact force to cause permanent damage to the fabric, thereby having good stab-proof and bullet-proof properties; secondly, the polyurea elastomer has good flexibility, and as a coating material for the fabric, it will not affect the softness of the fabric; thirdly, the polyurea elastomer is rich in a large number of micropores, which not only makes the fabric have good air permeability, but also the micropores have good capillary action, so that the contact angle between water and the coating is greater than 90 degrees, thereby the fabric has good waterproofness; fourthly, the micropores of the polyurea elastomer keep it electrically neutral, so it is not easy to carry an electric charge, and effectively prevents the fabric from absorbing dust during wearing.

利用含有纳米添加剂的氨基化合物对聚酰亚胺纤维布料基底进行氨基化处理,纳米添加剂带有的功能基团使面料基底表面拥有一定的活性,进而能够增强与聚脲弹性体之间的结合力,使得聚脲弹性体涂料不易在聚酰亚胺纤维布上脱落,能够形成抗冲击强的防刺、防弹纺织物复合材料体系。The polyimide fiber cloth substrate is treated with amino compounds containing nano-additives. The functional groups of the nano-additives make the surface of the fabric substrate have a certain activity, which can enhance the bonding force with the polyurea elastomer, making the polyurea elastomer coating not easy to fall off the polyimide fiber cloth, and forming an impact-resistant, puncture-proof and bullet-proof textile composite material system.

利用二胺和二酐制备聚酰亚胺纤维,由于二胺中苯环的存在,使聚酰亚胺纤维的性能更加稳定,寿命长,且由于N-(1-萘基)乙二胺二盐酸盐和咖啡酰丁二胺均具有较高的熔沸点,使聚酰亚胺纤维面料基底更加耐高温。Polyimide fiber is prepared by using diamine and dianhydride. Due to the presence of benzene ring in diamine, the performance of polyimide fiber is more stable and the service life is longer. In addition, since N-(1-naphthyl)ethylenediamine dihydrochloride and caffeoylbutanediamine both have high melting and boiling points, the polyimide fiber fabric base is more resistant to high temperatures.

加入发泡剂使聚脲弹性体在凝固时部分区域去漆化,从而形成更加丰富的微孔,进一步增强面料的透气性、防水性和防灰作用。The addition of a foaming agent allows the polyurea elastomer to partially de-paint during solidification, thereby forming more abundant micropores, further enhancing the fabric's breathability, waterproofness and dust resistance.

附图说明BRIEF DESCRIPTION OF THE DRAWINGS

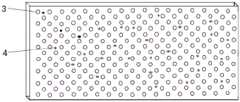

图1:本发明的织物的结构示意图;Figure 1 is a schematic structural diagram of a fabric of the present invention;

图2:本发明的织物基底的放大图;FIG2 is an enlarged view of a fabric substrate of the present invention;

图3:本发明的聚脲弹性体的结构示意图;FIG3 is a schematic structural diagram of a polyurea elastomer of the present invention;

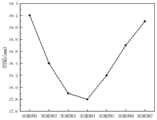

图4:本发明实施例1-实施例7的制造的纺织物中弹后的凹陷程度曲线;FIG4 shows the curves of the degree of depression of the textile fabrics manufactured in Examples 1 to 7 of the present invention after being hit by a bullet;

图5:本发明实施例1-实施例7的制造的纺织物的透气性能曲线;FIG5 : Air permeability curves of textiles manufactured in Examples 1 to 7 of the present invention;

图6:本发明实施例1-实施例7的制造的纺织物在加载速度为4.5mm/min条件下的真应力-应变曲线;Figure 6 shows true stress-strain curves of the textiles manufactured in Examples 1 to 7 of the present invention at a loading speed of 4.5 mm/min;

图中:1、聚脲弹性体涂层;2、聚酰亚胺纤维织物基底;3、网孔、4、纳米添加剂。In the figure: 1. polyurea elastomer coating; 2. polyimide fiber fabric substrate; 3. mesh; 4. nano additive.

具体实施方式DETAILED DESCRIPTION

以下结合实施例对本发明的具体内容做进一步详细解释说明。The specific contents of the present invention are further explained in detail below in conjunction with embodiments.

实施例1Example 1

步骤1、先按照体积比2:1将萘酚和对硝基酚混合,得到酚类溶剂,再按照重量份将55份二胺和45份二酐溶于酚类溶剂中,并加热至150℃,待充分反应后生成聚酰亚胺纺丝浆液,然后利用纺丝工艺得到聚酰亚胺纤维,并将其织成织物基底;

所述二胺是按照重量份将10份2,4-二氨基-3,5-二甲硫基甲苯、10份3,5-二硝基-1,2-苯二胺、10份4,5-二氟苯-1,2-二胺、10份N-(1-萘基)乙二胺二盐酸盐和15份咖啡酰丁二胺混合而成;所述二酐按照重量份将10份2,3-吡嗪二酸酐、10份3-异丁基戊二酸酐、5份S-乙酰巯基丁二酸酐、5份甲基丁二酸酐、5份六氟戊二酸酐、5份氯桥酸酐和5份十二烯基丁二酸酐混合而成;The diamine is prepared by mixing 10 parts of 2,4-diamino-3,5-dimethylthiotoluene, 10 parts of 3,5-dinitro-1,2-phenylenediamine, 10 parts of 4,5-difluorobenzene-1,2-diamine, 10 parts of N-(1-naphthyl)ethylenediamine dihydrochloride and 15 parts of caffeoylbutylene diamine according to weight parts; the dianhydride is prepared by mixing 10 parts of 2,3-pyrazine dianhydride, 10 parts of 3-isobutylglutaric anhydride, 5 parts of S-acetylmercaptosuccinic anhydride, 5 parts of methylsuccinic anhydride, 5 parts of hexafluoroglutaric anhydride, 5 parts of chlorobridged anhydride and 5 parts of dodecenylsuccinic anhydride according to weight parts;

步骤2、先按照重量份取0.5份纳米碳化硼粉末、0.5份纳米二氧化钛粉末、0.5份纳米碳化硅粉末、0.5份氧化石墨烯粉末、0.5份纳米氧化铝粉末和0.5份纳米银粉末混合,得到纳米添加剂混合物;再按照重量份取3份二乙烯三胺、3份三乙烯四胺、3份3-氨丙基三乙氧基硅烷、3份聚多巴胺、3份聚烯丙基胺盐酸盐和3份壳聚糖混合,得到氨基化合物混合物;然后将纳米添加剂混合物加入氨基化合物混合物中并充分搅拌,得到混合液,将织物基底置于混合液中并在20℃下充分浸泡0.5h,取出后将其在30℃的温度下烘干,得到表面修饰处理后的织物基底;

步骤3、按照重量份将60份A组分和40份B组分混合并搅拌使其充分反应,得到聚脲弹性体,将聚脲弹性体喷涂在织物基底表面,自然晾干后得到柔性防刺且防弹的纺织物;

所述A组分是按照重量份将10份二苯基甲烷二异氰酸酯、10份十二烷基苯-2,4-二异氰酸酯、10份3,3-二氯代联苯4,4-二异氰酸酯、10份3,3′-二甲氧基-4,4′-联苯二异氰酸酯、5份α,α,α',α'-四甲基-1,3-苯二甲基二异氰酸酯、0.1份血根氯铵、0.1份地特氯铵、0.1份米吡氯铵、0.2份甘草酸铵、3份柠檬酸三烯丙酯、3份柠檬酸十八烷醇酯、3份柠檬酸三甲酯、3份柠檬酸三丁酯、0.5份1-氟-1,1-二氯乙烷、0.5份N,N-二甲基十二烷胺-N-氧化物、0.5份十二烷基聚氧乙烯醚硫酸钠、1份十二烷基硫酸钠混合而成;The component A is prepared by mixing, by weight, 10 parts of diphenylmethane diisocyanate, 10 parts of dodecylbenzene-2,4-diisocyanate, 10 parts of 3,3-

所述B组分是按照重量份将20份聚醚三元胺、15份聚醚四元胺、1份灵芝酮三醇、1份表骨化三醇、1份六烷基磷三胺和2份二乙烯三胺五乙酸混合而成。The B component is prepared by mixing 20 parts of polyether triamine, 15 parts of polyether tetraamine, 1 part of ganoderma lucidum ketone triol, 1 part of epicalcitriol, 1 part of hexaalkylphosphorus triamine and 2 parts of diethylenetriamine pentaacetic acid according to weight parts.

实施例2Example 2

步骤1、先按照体积比4:1将萘酚和对硝基酚混合,得到酚类溶剂,再按照重量份将50份二胺和50份二酐溶于酚类溶剂中,并加热至250℃,待充分反应后生成聚酰亚胺纺丝浆液,然后利用纺丝工艺得到聚酰亚胺纤维,并将其织成织物基底;

所述二胺是按照重量份将20份2,4-二氨基-3,5-二甲硫基甲苯、10份3,5-二硝基-1,2-苯二胺、10份4,5-二氟苯-1,2-二胺和10份N-(1-萘基)乙二胺二盐酸盐混合而成;所述二酐按照重量份将10份3-异丁基戊二酸酐、10份S-乙酰巯基丁二酸酐、10份甲基丁二酸酐、10份六氟戊二酸酐、5份氯桥酸酐和5份十二烯基丁二酸酐混合而成;The diamine is prepared by mixing 20 parts of 2,4-diamino-3,5-dimethylthiotoluene, 10 parts of 3,5-dinitro-1,2-phenylenediamine, 10 parts of 4,5-difluorobenzene-1,2-diamine and 10 parts of N-(1-naphthyl)ethylenediamine dihydrochloride according to weight parts; the dianhydride is prepared by mixing 10 parts of 3-isobutylglutaric anhydride, 10 parts of S-acetylthiosuccinic anhydride, 10 parts of methylsuccinic anhydride, 10 parts of hexafluoroglutaric anhydride, 5 parts of chlorobridged anhydride and 5 parts of dodecenylsuccinic anhydride according to weight parts;

步骤2、先按照重量份取1份纳米碳化硼粉末、0.5份纳米二氧化钛粉末、0.5份纳米碳化硅粉末、0.5份氧化石墨烯粉末和0.5份纳米氧化铝粉末混合,得到纳米添加剂混合物;再按照重量份取3份三乙烯四胺、8份3-氨丙基三乙氧基硅烷、3份聚多巴胺、3份聚烯丙基胺盐酸盐和3份壳聚糖混合,得到氨基化合物混合物;然后将纳米添加剂混合物加入氨基化合物混合物中并充分搅拌,得到混合液,将织物基底置于混合液中并在30℃下充分浸泡1.5h,取出后将其在60℃的温度下烘干,得到表面修饰处理后的织物基底;

步骤3、按照重量份将50份A组分和50份B组分混合并搅拌使其充分反应,得到聚脲弹性体,将聚脲弹性体喷涂在织物基底表面,自然晾干后得到柔性防刺且防弹的纺织物;

所述A组分是按照重量份将10份十二烷基苯-2,4-二异氰酸酯、10份3,3-二氯代联苯4,4-二异氰酸酯、10份3,3′-二甲氧基-4,4′-联苯二异氰酸酯、10份α,α,α',α'-四甲基-1,3-苯二甲基二异氰酸酯、0.2份地特氯铵、0.2份米吡氯铵、0.6份甘草酸铵、2份柠檬酸十八烷醇酯、3份柠檬酸三甲酯、3份柠檬酸三丁酯、0.5份N,N-二甲基十二烷胺-N-氧化物、0.1份十二烷基聚氧乙烯醚硫酸钠、0.4份十二烷基硫酸钠混合而成;The component A is prepared by mixing, by weight, 10 parts of dodecylbenzene-2,4-diisocyanate, 10 parts of 3,3-

所述B组分是按照重量份将20份聚醚三元胺、20份聚醚四元胺、2份表骨化三醇、2份六烷基磷三胺和6份二乙烯三胺五乙酸混合而成。The B component is prepared by mixing 20 parts of polyether triamine, 20 parts of polyether tetraamine, 2 parts of epicalcitriol, 2 parts of hexaalkylphosphorus triamine and 6 parts of diethylenetriamine pentaacetic acid according to weight parts.

实施例3Example 3

步骤1、先按照体积比3:1将萘酚和对硝基酚混合,得到酚类溶剂,再按照重量份将45份二胺和55份二酐溶于酚类溶剂中,并加热至180℃,待充分反应后生成聚酰亚胺纺丝浆液,然后利用纺丝工艺得到聚酰亚胺纤维,并将其织成织物基底;

所述二胺是按照重量份将10份2,4-二氨基-3,5-二甲硫基甲苯、10份3,5-二硝基-1,2-苯二胺和25份4,5-二氟苯-1,2-二胺混合而成;所述二酐按照重量份将10份S-乙酰巯基丁二酸酐、10份甲基丁二酸酐、10份六氟戊二酸酐、10份氯桥酸酐和15份十二烯基丁二酸酐混合而成;The diamine is prepared by mixing 10 parts of 2,4-diamino-3,5-dimethylthiotoluene, 10 parts of 3,5-dinitro-1,2-phenylenediamine and 25 parts of 4,5-difluorobenzene-1,2-diamine according to weight parts; the dianhydride is prepared by mixing 10 parts of S-acetylmercaptosuccinic anhydride, 10 parts of methylsuccinic anhydride, 10 parts of hexafluoroglutaric anhydride, 10 parts of chlorobridged anhydride and 15 parts of dodecenylsuccinic anhydride according to weight parts;

步骤2、先按照重量份取1份纳米碳化硼粉末、1份纳米二氧化钛粉末、0.5份纳米碳化硅粉末和0.5份氧化石墨烯粉末混合,得到纳米添加剂混合物;再按照重量份取6份3-氨丙基三乙氧基硅烷、6份聚多巴胺、3份聚烯丙基胺盐酸盐和3份壳聚糖混合,得到氨基化合物混合物;然后将纳米添加剂混合物加入氨基化合物混合物中并充分搅拌,得到混合液,将织物基底置于混合液中并在40℃下充分浸泡2h,取出后将其在40℃的温度下烘干,得到表面修饰处理后的织物基底;

步骤3、按照重量份将55份A组分和45份B组分混合并搅拌使其充分反应,得到聚脲弹性体,将聚脲弹性体喷涂在织物基底表面,自然晾干后得到柔性防刺且防弹的纺织物;

所述A组分是按照重量份将20份3,3-二氯代联苯4,4-二异氰酸酯、10份3,3′-二甲氧基-4,4′-联苯二异氰酸酯和10份α,α,α',α'-四甲基-1,3-苯二甲基二异氰酸酯、0.5份米吡氯铵、0.5份甘草酸铵、3份柠檬酸十八烷醇酯、3份柠檬酸三甲酯、4份柠檬酸三丁酯、1份N,N-二甲基十二烷胺-N-氧化物、1份十二烷基聚氧乙烯醚硫酸钠和2份十二烷基硫酸钠混合而成;The component A is prepared by mixing, by weight, 20 parts of 3,3-

所述B组分是按照重量份将20份聚醚三元胺、20份聚醚四元胺、3份六烷基磷三胺和2份二乙烯三胺五乙酸混合而成。The B component is prepared by mixing 20 parts of polyether triamine, 20 parts of polyether tetraamine, 3 parts of hexaalkylphosphorus triamine and 2 parts of diethylenetriamine pentaacetic acid according to weight.

实施例4Example 4

步骤1、先按照体积比2.5:1将萘酚和对硝基酚混合,得到酚类溶剂,再按照重量份将40份二胺和60份二酐溶于酚类溶剂中,并加热至200℃,待充分反应后生成聚酰亚胺纺丝浆液,然后利用纺丝工艺得到聚酰亚胺纤维,并将其织成织物基底;

所述二胺是按照重量份将10份2,4-二氨基-3,5-二甲硫基甲苯和30份3,5-二硝基-1,2-苯二胺混合而成;所述二酐按照重量份将15份甲基丁二酸酐、25份六氟戊二酸酐、10份氯桥酸酐和10份十二烯基丁二酸酐混合而成;The diamine is prepared by mixing 10 parts of 2,4-diamino-3,5-dimethylthiotoluene and 30 parts of 3,5-dinitro-1,2-phenylenediamine in parts by weight; the dianhydride is prepared by mixing 15 parts of methylsuccinic anhydride, 25 parts of hexafluoroglutaric anhydride, 10 parts of chlorobridged anhydride and 10 parts of dodecenylsuccinic anhydride in parts by weight;

步骤2、先按照重量份取2份纳米碳化硼粉末、1份纳米二氧化钛粉末和0.5份纳米碳化硅粉末混合,得到纳米添加剂混合物;再按照重量份取5份聚多巴胺、5份聚烯丙基胺盐酸盐和5份壳聚糖混合,得到氨基化合物混合物;然后将纳米添加剂混合物加入氨基化合物混合物中并充分搅拌,得到混合液,将织物基底置于混合液中并在50℃下充分浸泡2.5h,取出后将其在50℃的温度下烘干,得到表面修饰处理后的织物基底;

步骤3、按照重量份将45份A组分和55份B组分混合并搅拌使其充分反应,得到聚脲弹性体,将聚脲弹性体喷涂在织物基底表面,自然晾干后得到柔性防刺且防弹的纺织物;

所述A组分是按照重量份将10份3,3-二氯代联苯4,4-二异氰酸酯、10份3,3′-二甲氧基-4,4′-联苯二异氰酸酯、20份α,α,α',α'-四甲基-1,3-苯二甲基二异氰酸酯、0.03份米吡氯铵、0.02份甘草酸铵、1份柠檬酸三甲酯、3份柠檬酸三丁酯、0.45份十二烷基聚氧乙烯醚硫酸钠、0.5份十二烷基硫酸钠混合而成;The component A is prepared by mixing, by weight, 10 parts of 3,3-

所述B组分是按照重量份将50份聚醚三元胺、3份六烷基磷三胺和2份二乙烯三胺五乙酸混合而成。The B component is prepared by mixing 50 parts of polyether triamine, 3 parts of hexaalkylphosphorus triamine and 2 parts of diethylenetriamine pentaacetic acid according to weight.

实施例5Example 5

步骤1、先按照体积比3.5:1将萘酚和对硝基酚混合,得到酚类溶剂,再按照重量份将60份二胺和40份二酐溶于酚类溶剂中,并加热至220℃,待充分反应后生成聚酰亚胺纺丝浆液,然后利用纺丝工艺得到聚酰亚胺纤维,并将其织成织物基底;

所述二胺是按照重量份将50份4,5-二氟苯-1,2-二胺和10份3,5-二硝基-1,2-苯二胺混合而成;所述二酐按照重量份将20份氯桥酸酐和20份十二烯基丁二酸酐混合而成;The diamine is prepared by mixing 50 parts of 4,5-difluorobenzene-1,2-diamine and 10 parts of 3,5-dinitro-1,2-phenylenediamine according to weight parts; the dianhydride is prepared by mixing 20 parts of chlorobridgeic anhydride and 20 parts of dodecenylsuccinic anhydride according to weight parts;

步骤2、先按照重量份取2份纳米碳化硼粉末和1.5份纳米二氧化钛粉末混合,得到纳米添加剂混合物;再按照重量份取8份聚多巴胺和8份壳聚糖混合,得到氨基化合物混合物;然后将纳米添加剂混合物加入氨基化合物混合物中并充分搅拌,得到混合液,将织物基底置于混合液中并在25℃下充分浸泡2.5h,取出后将其在60℃的温度下烘干,得到表面修饰处理后的织物基底;

步骤3、按照重量份将40份A组分和60份B组分混合并搅拌使其充分反应,得到聚脲弹性体,将聚脲弹性体喷涂在织物基底表面,自然晾干后得到柔性防刺且防弹的纺织物;

所述A组分是按照重量份将10份3,3-二氯代联苯4,4-二异氰酸酯、20份α,α,α',α'-四甲基-1,3-苯二甲基二异氰酸酯、0.01份米吡氯铵、5份柠檬酸三丁酯、4.99份十二烷基硫酸钠混合而成;The component A is prepared by mixing 10 parts of 3,3-

所述B组分是按照重量份将50份聚醚四元胺和10份二乙烯三胺五乙酸混合而成。The B component is prepared by mixing 50 parts of polyether tetraamine and 10 parts of diethylenetriamine pentaacetic acid according to weight.

实施例6Example 6

步骤1、先按照体积比4:1将萘酚和对硝基酚混合,得到酚类溶剂,再按照重量份将55份二胺和55份二酐溶于酚类溶剂中,并加热至230℃,待充分反应后生成聚酰亚胺纺丝浆液,然后利用纺丝工艺得到聚酰亚胺纤维,并将其织成织物基底;

所述二胺是按照重量份将30份2,4-二氨基-3,5-二甲硫基甲苯、10份3,5-二硝基-1,2-苯二胺和15份咖啡酰丁二胺混合而成;所述二酐按照重量份将20份2,3-吡嗪二酸酐、20份3-异丁基戊二酸酐、5份甲基丁二酸酐、5份六氟戊二酸酐和5份十二烯基丁二酸酐混合而成;The diamine is prepared by mixing 30 parts of 2,4-diamino-3,5-dimethylthiotoluene, 10 parts of 3,5-dinitro-1,2-phenylenediamine and 15 parts of caffeoyl butanediamine according to weight parts; the dianhydride is prepared by mixing 20 parts of 2,3-pyrazine dianhydride, 20 parts of 3-isobutylglutaric anhydride, 5 parts of methylsuccinic anhydride, 5 parts of hexafluoroglutaric anhydride and 5 parts of dodecenylsuccinic anhydride according to weight parts;

步骤2、先按照重量份取3份纳米碳化硼粉末和0.5份纳米碳化硅粉末混合,得到纳米添加剂混合物;再按照重量份取6份二乙烯三胺、2份3-氨丙基三乙氧基硅烷、3份聚烯丙基胺盐酸盐和6份壳聚糖混合,得到氨基化合物混合物;然后将纳米添加剂混合物加入氨基化合物混合物中并充分搅拌,得到混合液,将织物基底置于混合液中并在35℃下充分浸泡2h,取出后将其在35℃的温度下烘干,得到表面修饰处理后的织物基底;

步骤3、按照重量份将55份A组分和55份B组分混合并搅拌使其充分反应,得到聚脲弹性体,将聚脲弹性体喷涂在织物基底表面,自然晾干后得到柔性防刺且防弹的纺织物;

所述A组分是按照重量份将20份二苯基甲烷二异氰酸酯、10份3,3-二氯代联苯4,4-二异氰酸酯和20份α,α,α',α'-四甲基-1,3-苯二甲基二异氰酸酯、0.01份血根氯铵、1份柠檬酸三烯丙酯、3份柠檬酸三丁酯、0.45份1-氟-1,1-二氯乙烷和0.54份N,N-二甲基十二烷胺-N-氧化物混合而成;The component A is prepared by mixing, by weight, 20 parts of diphenylmethane diisocyanate, 10 parts of 3,3-

所述B组分是按照重量份将10份聚醚三元胺、30份聚醚四元胺、5份灵芝酮三醇、5份表骨化三醇和5份二乙烯三胺五乙酸混合而成。The B component is prepared by mixing 10 parts of polyether triamine, 30 parts of polyether tetraamine, 5 parts of ganoderma lucidum triol, 5 parts of epicalcitriol and 5 parts of diethylenetriamine pentaacetic acid according to weight parts.

实施例7Example 7

步骤1、先按照体积比2:1将萘酚和对硝基酚混合,得到酚类溶剂,再按照重量份将60份二胺和60份二酐溶于酚类溶剂中,并加热至160℃,待充分反应后生成聚酰亚胺纺丝浆液,然后利用纺丝工艺得到聚酰亚胺纤维,并将其织成织物基底;

所述二胺是按照重量份将40份2,4-二氨基-3,5-二甲硫基甲苯和20份3,5-二硝基-1,2-苯二胺混合而成;所述二酐按照重量份将20份2,3-吡嗪二酸酐和40份甲基丁二酸酐混合而成;The diamine is prepared by mixing 40 parts of 2,4-diamino-3,5-dimethylthiotoluene and 20 parts of 3,5-dinitro-1,2-phenylenediamine according to weight parts; the dianhydride is prepared by mixing 20 parts of 2,3-pyrazine dianhydride and 40 parts of methylsuccinic anhydride according to weight parts;

步骤2、先按照重量份取1.5份纳米碳化硼粉末和1.5份纳米二氧化钛粉末混合,得到纳米添加剂混合物;再按照重量份取6份二乙烯三胺、6份聚烯丙基胺盐酸盐和7份壳聚糖混合,得到氨基化合物混合物;然后将纳米添加剂混合物加入氨基化合物混合物中并充分搅拌,得到混合液,将织物基底置于混合液中并在45℃下充分浸泡1.5h,取出后将其在45℃的温度下烘干,得到表面修饰处理后的织物基底;

步骤3、按照重量份将60份A组分和60份B组分混合并搅拌使其充分反应,得到聚脲弹性体,将聚脲弹性体喷涂在织物基底表面,自然晾干后得到柔性防刺且防弹的纺织物;

所述A组分是按照重量份将19份二苯基甲烷二异氰酸酯、20份3,3-二氯代联苯4,4-二异氰酸酯、0.5份米吡氯铵、0.5份甘草酸铵、5份柠檬酸十八烷醇酯、5份柠檬酸三甲酯、5份柠檬酸三丁酯和5份N,N-二甲基十二烷胺-N-氧化物混合而成;The component A is prepared by mixing, by weight, 19 parts of diphenylmethane diisocyanate, 20 parts of 3,3-

所述B组分是按照重量份将15份聚醚三元胺、30份聚醚四元胺和15份灵芝酮三醇混合而成。The B component is prepared by mixing 15 parts of polyether triamine, 30 parts of polyether tetraamine and 15 parts of ganoderma lucidum ketone triol according to weight parts.

从图1可以看出聚酰亚胺纤维织物基底2的一侧表面涂覆有聚脲弹性体涂层1;从图2可以看出,聚酰亚胺纤维织物基底2为常规的平纹面料;从图3可以看出聚脲弹性体的表面具有诸多均匀分布的网孔3,且分布有诸多纳米添加剂4。It can be seen from FIG1 that one side surface of the polyimide

从图4可以看出,本发明实施例1~实施例7制备的柔性防刺且防弹的纺织物的凹陷均在19.2mm以内,满足GA141—2010中3级防弹性能测试要求(凹陷小于25mm)。As can be seen from FIG. 4 , the dents of the flexible stab-proof and bullet-proof textiles prepared in Examples 1 to 7 of the present invention are all within 19.2 mm, meeting the requirements of the

从图5可以看出,本发明实施例1~实施例7制备的柔性防刺且防弹的纺织物的透气性均在68%以上,拥有优良的透气性。As can be seen from FIG. 5 , the air permeability of the flexible stab-proof and ballistic-proof textiles prepared in Examples 1 to 7 of the present invention is all above 68%, and has excellent air permeability.

从图6可以看出,本发明实施例1~实施例7制备的柔性防刺且防弹的纺织物的拉伸强度均在470MPa以上,拥有优良的防弹性能。As can be seen from FIG. 6 , the flexible stab-proof and ballistic-proof textiles prepared in Examples 1 to 7 of the present invention all have tensile strengths of more than 470 MPa, and have excellent ballistic-proof properties.

考虑到面料在长期的服役过程中,应用领域的不确定性,尤其是在有些极端环境中的紫外线辐射太强,而有些环境中可能菌类较多,而紫外线与菌类是影响面料性能的两个重要的因素因素,原因在于:1)、当聚脲层受到环境中的紫外线影响时,其分子连段中的某些化学键因吸收能量会发生断裂,使得由大分子链构成的网络结构变成小分子链,从而降低了其拉伸强度与剪切强度,进而丧失了原有的防弹防刺性能。2)、由于在复杂的细菌环境中,有些细菌的分泌物会与聚脲分子链发生化学反应,导致化学键断裂的概率大大提高,直接导致拉伸强度与剪切强度下降的概率提高,从而降低材料的防弹防刺性能,不仅仅是聚脲层,纤维层同样会受到相同的影响。本发明中,面料表面喷涂的聚脲弹性体材料在微观上为交织的网络结构以及纳米添加剂使面料拥有紫外线屏蔽功能(不低于93%)以及抑菌抗菌性能(不低于99.4%)。表1是实施例1~实施例7制备的纺织物的各项性能参数,其中:凹陷指的是面料受到子弹撞击后,产生的凹痕深度;穿透层数指的是将50层厚0.5mm的纺织物叠加在一起进行射击时,子弹共穿透的层数。Considering the uncertainty of the application field of fabrics during long-term service, especially in some extreme environments where ultraviolet radiation is too strong, and in some environments where there may be more fungi, ultraviolet rays and fungi are two important factors that affect the performance of fabrics. The reasons are: 1) When the polyurea layer is affected by ultraviolet rays in the environment, some chemical bonds in its molecular segments will break due to absorption of energy, so that the network structure composed of macromolecular chains becomes small molecular chains, thereby reducing its tensile strength and shear strength, and then losing the original bulletproof and stab-proof performance. 2) Because in a complex bacterial environment, some bacterial secretions will react chemically with the polyurea molecular chain, resulting in a greatly increased probability of chemical bond breakage, which directly leads to an increased probability of tensile strength and shear strength reduction, thereby reducing the bulletproof and stab-proof performance of the material, not only the polyurea layer, but also the fiber layer will be affected in the same way. In the present invention, the polyurea elastomer material sprayed on the surface of the fabric is an interwoven network structure at the microscopic level, and the nano additives enable the fabric to have ultraviolet shielding function (not less than 93%) and antibacterial and antibacterial performance (not less than 99.4%). Table 1 shows the performance parameters of the textiles prepared in Examples 1 to 7, wherein: depression refers to the depth of the dent produced when the fabric is hit by a bullet; the number of penetration layers refers to the number of layers penetrated by the bullet when 50 layers of 0.5 mm thick textiles are stacked together and shot.

表1:实施例1~实施例7的纺织物的各项性能参数Table 1: Performance parameters of textiles of Examples 1 to 7

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310066918.5ACN116084181A (en) | 2023-01-15 | 2023-01-15 | Flexible stab-resistant and bulletproof textile and manufacturing method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310066918.5ACN116084181A (en) | 2023-01-15 | 2023-01-15 | Flexible stab-resistant and bulletproof textile and manufacturing method thereof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN116084181Atrue CN116084181A (en) | 2023-05-09 |

Family

ID=86213689

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202310066918.5APendingCN116084181A (en) | 2023-01-15 | 2023-01-15 | Flexible stab-resistant and bulletproof textile and manufacturing method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN116084181A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024234223A1 (en)* | 2023-05-15 | 2024-11-21 | 福建百宏聚纤科技实业有限公司 | Novel waterproof breathable fabric and preparation method therefor |

| CN119925207A (en)* | 2025-04-09 | 2025-05-06 | 深圳尚诺生物科技有限公司 | A bio-based antibacterial facial mask and preparation method thereof |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0494546A1 (en)* | 1991-01-08 | 1992-07-15 | Huntsman Corporation | Foamed polyurea elastomer |

| CN1382847A (en)* | 2002-06-13 | 2002-12-04 | 东华大学 | Polyimide fibre and its preparing process |

| CN105418881A (en)* | 2015-12-29 | 2016-03-23 | 哈尔滨工业大学 | Polyurea foam material and preparation method thereof |

| CN110103556A (en)* | 2019-05-10 | 2019-08-09 | 山东三达科技发展有限公司 | A kind of flexible ballistic-resistant stab-resistant material and preparation method thereof |

| CN110820349A (en)* | 2019-11-20 | 2020-02-21 | 中国科学院兰州化学物理研究所 | The method of dopamine-polyethyleneimine-nanoparticles combined modification of polytetrafluoroethylene-aramid blended fabric |

| CN113211897A (en)* | 2021-05-19 | 2021-08-06 | 广东电网有限责任公司 | Wrapped flexible fireproof explosion-proof blanket and preparation method and application thereof |

| CN114920975A (en)* | 2022-06-17 | 2022-08-19 | 中国工程物理研究院化工材料研究所 | Polyurea foam material and preparation method thereof |

- 2023

- 2023-01-15CNCN202310066918.5Apatent/CN116084181A/enactivePending

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0494546A1 (en)* | 1991-01-08 | 1992-07-15 | Huntsman Corporation | Foamed polyurea elastomer |

| CN1382847A (en)* | 2002-06-13 | 2002-12-04 | 东华大学 | Polyimide fibre and its preparing process |

| CN105418881A (en)* | 2015-12-29 | 2016-03-23 | 哈尔滨工业大学 | Polyurea foam material and preparation method thereof |

| CN110103556A (en)* | 2019-05-10 | 2019-08-09 | 山东三达科技发展有限公司 | A kind of flexible ballistic-resistant stab-resistant material and preparation method thereof |

| CN110820349A (en)* | 2019-11-20 | 2020-02-21 | 中国科学院兰州化学物理研究所 | The method of dopamine-polyethyleneimine-nanoparticles combined modification of polytetrafluoroethylene-aramid blended fabric |

| CN113211897A (en)* | 2021-05-19 | 2021-08-06 | 广东电网有限责任公司 | Wrapped flexible fireproof explosion-proof blanket and preparation method and application thereof |

| CN114920975A (en)* | 2022-06-17 | 2022-08-19 | 中国工程物理研究院化工材料研究所 | Polyurea foam material and preparation method thereof |

Non-Patent Citations (2)

| Title |

|---|

| CHANG-PIN CHANG ET AL.: "Preparation and Ballistic Performance of a Multi-Layer Armor System Composed of Kevlar/Polyurea Composites and Shear Thickening Fluid (STF)-Filled Paper Honeycomb Panels", 《POLYMERS》, vol. 13, no. 18, 13 September 2021 (2021-09-13), pages 3 - 4* |

| 崔淑玲: "《高技术纤维》", 30 September 2016, 中国纺织出版社, pages: 64* |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024234223A1 (en)* | 2023-05-15 | 2024-11-21 | 福建百宏聚纤科技实业有限公司 | Novel waterproof breathable fabric and preparation method therefor |

| CN119925207A (en)* | 2025-04-09 | 2025-05-06 | 深圳尚诺生物科技有限公司 | A bio-based antibacterial facial mask and preparation method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN116084181A (en) | Flexible stab-resistant and bulletproof textile and manufacturing method thereof | |

| CN103808210B (en) | A kind of Use of Flexible Protective Materials and preparation method thereof | |

| CN112176729A (en) | Nano-reinforced environment-friendly impregnation system for fiber surface treatment, preparation method and impregnation method | |

| Yu et al. | Interfacial and glass transition properties of surface-treated carbon fiber reinforced polymer composites under hygrothermal conditions | |

| CN104558644B (en) | A preparation method of continuous fiber reinforced hybrid multiscale composites | |

| CN101153462B (en) | Method for manufacturing elastic conductive cloth | |

| CN103060779A (en) | Preparation method of copper/modal fiber composite material | |

| CN114507986B (en) | Stab-proof and bulletproof fabric based on shear thickening fluid and preparation method thereof | |

| CN114197205B (en) | Modified carbon fiber and preparation method and application thereof | |

| CN102058188B (en) | Assorted fiber fabric composite material with high nanometer content and preparation method thereof | |

| Mun et al. | Tensile properties and surface treatment of fiber composites with the concentration of polydopamine and buffer solution | |

| CN113106743B (en) | High-performance fiber material with high-strength high-toughness composite performance and preparation method thereof | |

| CN106758136A (en) | The aromatic polymer fiber of composite performance high containing benzimidazole and preparation method thereof | |

| CN119184392A (en) | Outdoor jacket made of cut-resistant antistatic fabric and preparation method thereof | |

| CN118854682A (en) | A preparation method and application of bidirectional braided shear thickening composite material | |

| CN107558170A (en) | A kind of preparation method of fire-retardant UHMWPE fibers | |

| CN115976853A (en) | Polyurea elastomer composite fabric and manufacturing method thereof | |

| CN106084595B (en) | A kind of thermoplasticity bulletproof anti-puncturing material of softness and preparation method thereof | |

| CN107558209A (en) | Utilize supercritical CO2The method that fluid technique carries out aramid fiber organic modification | |

| CN117227288A (en) | High-antistatic non-woven fabric of composite fiber and preparation method thereof | |

| CN114481622B (en) | A kind of moisture-permeable chemical protection fabric and its preparation method and application | |

| CN112962313B (en) | Cotton fabric non-ironing finishing liquid compounded with waterborne polyurethane, preparation method and application thereof | |

| CN105128439A (en) | Flame-retardant polyester ramie composite fabric for vehicles | |

| CN114575151A (en) | Carbon fiber based on biological matrix surface modification, preparation method and composite material | |

| CN114932723A (en) | A method for preparing a lightweight stab-resistant composite material with variable thickness performance gradient |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |