CN115980077A - Defect detection method, device, screen detection equipment and storage medium - Google Patents

Defect detection method, device, screen detection equipment and storage mediumDownload PDFInfo

- Publication number

- CN115980077A CN115980077ACN202310077161.XACN202310077161ACN115980077ACN 115980077 ACN115980077 ACN 115980077ACN 202310077161 ACN202310077161 ACN 202310077161ACN 115980077 ACN115980077 ACN 115980077A

- Authority

- CN

- China

- Prior art keywords

- wire mesh

- steel wire

- detection

- detected

- defect detection

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P90/00—Enabling technologies with a potential contribution to greenhouse gas [GHG] emissions mitigation

- Y02P90/30—Computing systems specially adapted for manufacturing

Landscapes

- Investigating Materials By The Use Of Optical Means Adapted For Particular Applications (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及缺陷检测技术领域,尤其涉及一种缺陷检测方法、装置、丝网检测设备及存储介质。The invention relates to the technical field of defect detection, in particular to a defect detection method, device, screen detection equipment and storage medium.

背景技术Background technique

钢丝织网指通过不锈钢丝材质包括有镍、无镍、黄铜丝、紫铜丝等各种有色金属丝编制的网状物,多用于煤山、矿山、建筑、养殖、玻璃厂、石油、五金制品、石油化工、建筑机械、防护用网、烧烤网、工艺品用网、食品机械用网、炊具用网、墙体用网、也可用做固体材料的分级筛选、液体和泥浆的过滤等。钢丝织网会存在裂口、漏洞、断线、稀密道、污渍、折痕等多种瑕疵问题。Steel wire mesh refers to the mesh made of stainless steel wire including nickel, nickel-free, brass wire, copper wire and other non-ferrous metal wires. It is mostly used in coal mines, mines, construction, breeding, glass factories, petroleum, and hardware. Products, petrochemical, construction machinery, protective nets, barbecue nets, handicraft nets, food machinery nets, cooker nets, wall nets, can also be used for grading and screening of solid materials, filtration of liquids and mud, etc. Steel wire mesh will have cracks, loopholes, broken lines, dense channels, stains, creases and other defects.

目前,钢丝织网采用人工检测缺陷,存在检测效率低的问题。At present, steel wire mesh is manually detected for defects, which has the problem of low detection efficiency.

发明内容Contents of the invention

本发明提供了一种缺陷检测方法、装置、丝网检测设备及存储介质,以解决钢丝织网缺陷检测效率低的问题。The invention provides a defect detection method, device, wire mesh detection equipment and storage medium to solve the problem of low detection efficiency of steel wire mesh defects.

根据本发明的一方面,提供了一种丝网检测设备,包括:According to an aspect of the present invention, a kind of wire mesh inspection equipment is provided, comprising:

进料机构,包括第一驱动装置和第一驱动辊,所述第一驱动装置驱动所述第一驱动辊转动,以输入待检测钢丝织网;The feeding mechanism includes a first driving device and a first driving roller, and the first driving device drives the first driving roller to rotate so as to input the steel wire mesh to be detected;

检测机构,设置于所述进料机构和出料机构之间,包括相机和检测子设备,所述相机用于采集所述待检测钢丝织网的图像信息;The detection mechanism is arranged between the feeding mechanism and the discharging mechanism, and includes a camera and detection sub-equipment, and the camera is used to collect image information of the steel wire mesh to be detected;

所述检测子设备与所述相机通信连接,所述检测子设备用于接收相机采集的待检测钢丝织网的图像信息,将所述待检测钢丝织网的图像信息输入至预先训练完成的缺陷检测模型,得到钢丝织网缺陷检测结果,所述缺陷检测模型基于钢丝织网样本图像以及所述钢丝织网样本图像对应的标签信息训练得到;The detection sub-device is communicatively connected with the camera, the detection sub-device is used to receive the image information of the steel wire mesh to be detected collected by the camera, and input the image information of the steel wire mesh to be detected into the pre-trained defect A detection model for obtaining a defect detection result of a steel wire mesh, wherein the defect detection model is trained based on a steel wire mesh sample image and label information corresponding to the steel wire mesh sample image;

出料机构,包括第二驱动装置和第二驱动辊,所述第二驱动装置驱动所述第二驱动辊转动,以输出检测完成的钢丝织网并将所述检测完成的钢丝织网收卷。The discharge mechanism includes a second driving device and a second driving roller, the second driving device drives the second driving roller to rotate, so as to output the inspected steel wire mesh and wind up the inspected steel wire mesh .

根据本发明的另一方面,提供了一种缺陷检测方法,由丝网检测设备执行,包括:According to another aspect of the present invention, a defect detection method is provided, performed by a wire mesh detection device, comprising:

获取待检测钢丝织网的图像信息;Obtain the image information of the steel wire mesh to be detected;

将所述待检测钢丝织网的图像信息输入至预先训练完成的缺陷检测模型,得到钢丝织网缺陷检测结果;Inputting the image information of the steel wire mesh to be detected into the pre-trained defect detection model to obtain the defect detection result of the steel wire mesh;

其中,所述缺陷检测模型基于钢丝织网样本图像以及所述钢丝织网样本图像对应的标签信息训练得到。Wherein, the defect detection model is trained based on the steel wire mesh sample image and the label information corresponding to the steel wire mesh sample image.

根据本发明的另一方面,提供了一种缺陷检测装置,由丝网检测设备执行,包括:According to another aspect of the present invention, a defect detection device is provided, performed by a wire mesh detection device, comprising:

图像信息获取模块,用于获取待检测钢丝织网的图像信息;An image information acquisition module, configured to acquire the image information of the steel wire mesh to be detected;

织网缺陷检测模块,用于将所述待检测钢丝织网的图像信息输入至预先训练完成的缺陷检测模型,得到钢丝织网缺陷检测结果;The mesh defect detection module is used to input the image information of the steel wire mesh to be detected into the pre-trained defect detection model to obtain the defect detection result of the steel wire mesh;

其中,所述缺陷检测模型基于钢丝织网样本图像以及所述钢丝织网样本图像对应的标签信息训练得到。Wherein, the defect detection model is trained based on the steel wire mesh sample image and the label information corresponding to the steel wire mesh sample image.

根据本发明的另一方面,提供了一种计算机可读存储介质,所述计算机可读存储介质存储有计算机指令,所述计算机指令用于使处理器执行时实现本发明任一实施例所述的缺陷检测方法。According to another aspect of the present invention, a computer-readable storage medium is provided, the computer-readable storage medium stores computer instructions, and the computer instructions are used to enable a processor to implement any of the embodiments of the present invention when executed. defect detection method.

本发明实施例的技术方案,通过丝网检测设备接采集待检测钢丝织网的图像信息,将待检测钢丝织网的图像信息输入至预先训练完成的缺陷检测模型,得到钢丝织网缺陷检测结果,实现钢丝织网缺陷的自动检测,提高了钢丝织网的检测效率。In the technical solution of the embodiment of the present invention, the image information of the steel wire mesh to be detected is collected through the wire mesh detection equipment, and the image information of the steel wire mesh to be detected is input into the pre-trained defect detection model to obtain the defect detection result of the steel wire mesh , to realize the automatic detection of steel wire mesh defects, and improve the detection efficiency of steel wire mesh.

应当理解,本部分所描述的内容并非旨在标识本发明的实施例的关键或重要特征,也不用于限制本发明的范围。本发明的其它特征将通过以下的说明书而变得容易理解。It should be understood that the content described in this section is not intended to identify key or important features of the embodiments of the present invention, nor is it intended to limit the scope of the present invention. Other features of the present invention will be easily understood from the following description.

附图说明Description of drawings

为了更清楚地说明本发明实施例中的技术方案,下面将对实施例描述中所需要使用的附图作简单地介绍,显而易见地,下面描述中的附图仅仅是本发明的一些实施例,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to more clearly illustrate the technical solutions in the embodiments of the present invention, the drawings that need to be used in the description of the embodiments will be briefly introduced below. Obviously, the drawings in the following description are only some embodiments of the present invention. For those skilled in the art, other drawings can also be obtained based on these drawings without creative effort.

图1是根据本发明实施例一提供的一种丝网检测设备的结构图;FIG. 1 is a structural diagram of a wire mesh detection device provided according to Embodiment 1 of the present invention;

图2是根据本发明实施例二提供的一种缺陷检测方法的流程图;FIG. 2 is a flowchart of a defect detection method provided according to

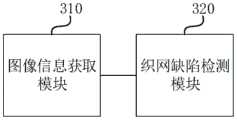

图3是根据本发明实施例三提供的一种缺陷检测装置的结构示意图。FIG. 3 is a schematic structural diagram of a defect detection device provided according to

具体实施方式Detailed ways

为了使本技术领域的人员更好地理解本发明方案,下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分的实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都应当属于本发明保护的范围。In order to enable those skilled in the art to better understand the solutions of the present invention, the following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments are only It is an embodiment of a part of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts shall fall within the protection scope of the present invention.

需要说明的是,本发明的说明书和权利要求书及上述附图中的术语“第一”、“第二”等是用于区别类似的对象,而不必用于描述特定的顺序或先后次序。应该理解这样使用的数据在适当情况下可以互换,以便这里描述的本发明的实施例能够以除了在这里图示或描述的那些以外的顺序实施。此外,术语“包括”和“具有”以及他们的任何变形,意图在于覆盖不排他的包含,例如,包含了一系列步骤或单元的过程、方法、系统、产品或设备不必限于清楚地列出的那些步骤或单元,而是可包括没有清楚地列出的或对于这些过程、方法、产品或设备固有的其它步骤或单元。It should be noted that the terms "first" and "second" in the description and claims of the present invention and the above drawings are used to distinguish similar objects, but not necessarily used to describe a specific sequence or sequence. It is to be understood that the data so used are interchangeable under appropriate circumstances such that the embodiments of the invention described herein can be practiced in sequences other than those illustrated or described herein. Furthermore, the terms "comprising" and "having", as well as any variations thereof, are intended to cover a non-exclusive inclusion, for example, a process, method, system, product or device comprising a sequence of steps or elements is not necessarily limited to the expressly listed instead, may include other steps or elements not explicitly listed or inherent to the process, method, product or apparatus.

实施例一Embodiment one

图1为本发明实施例一提供的一种丝网检测设备,包括:进料机构1,包括第一驱动装置11和第一驱动辊12,第一驱动装置11驱动第一驱动辊12转动,以输入待检测钢丝织网;检测机构2,设置于进料机构1和出料机构3之间,包括相机21和检测子设备22,相机21用于采集待检测钢丝织网的图像信息;检测子设备22与相机21通信连接,检测子设备22用于接收相机21采集的待检测钢丝织网的图像信息,将待检测钢丝织网的图像信息输入至预先训练完成的缺陷检测模型,得到钢丝织网缺陷检测结果,缺陷检测模型基于钢丝织网样本图像以及钢丝织网样本图像对应的标签信息训练得到;出料机构3,包括第二驱动装置31和第二驱动辊32,第二驱动装置31驱动第二驱动辊32转动,以输出检测完成的钢丝织网并将检测完成的钢丝织网收卷。Fig. 1 is a screen inspection device provided by Embodiment 1 of the present invention, including: a feeding mechanism 1, including a first driving device 11 and a

本实施例中,丝网检测设备是指用于钢丝织网缺陷自动检测的设备,并且可以实现放卷和收卷。丝网检测设备包括进料机构1,进料机构1可以将待检测钢丝织网输入至丝网检测设备。具体而言,可以通过进料机构1中的第一驱动装置11驱动第一驱动辊12转动,实现待检测钢丝织网的输入。第一驱动装置11可以为电机等设备。第一驱动装置11与第一驱动辊12可以通过齿轮、皮带或链条等连接。第一驱动装置11和第一驱动辊12可以固定设置在丝网检测设备的支架上。In this embodiment, the wire mesh detection equipment refers to the equipment used for automatic detection of steel wire mesh defects, and can realize unwinding and winding. The wire mesh detection device includes a feeding mechanism 1, which can input the steel wire mesh to be detected into the wire mesh detection device. Specifically, the

检测机构2是指用于检测钢丝织网的机构部分,可以包括相机21和检测子设备22。相机21的数量可以为一个或多个,当相机21的数量为多个时,可以同时采集待检测钢丝织网的图像信息,提升图像采集效率。相机21用于采集待检测钢丝织网的图像信息,待检测钢丝织网的图像信息可以为多张连续的视频帧图像。检测子设备22与相机21通信连接,检测子设备22用于接收相机21采集的待检测钢丝织网的图像信息,将待检测钢丝织网的图像信息输入至预先训练完成的缺陷检测模型,得到钢丝织网缺陷检测结果,缺陷检测模型基于钢丝织网样本图像以及钢丝织网样本图像对应的标签信息训练得到。其中,检测子设备22可以为计算机等终端设备,例如检测子设备22可以为包含显示器的PC柜,可以用于查看钢丝织网缺陷检测结果。钢丝织网缺陷检测结果可以包括瑕疵类型和瑕疵位置信息。示例性的,瑕疵类型可以包括但不限于裂口、漏洞、断线、稀密道、污渍、折痕、粗纱、结头等。The

出料机构3是指输出钢丝织网的机构,包括第二驱动装置31和第二驱动辊32。具体而言,可以通过出料机构3中的第二驱动装置31驱动第二驱动辊32转动,实现待检测钢丝织网的输出,并将检测完成的钢丝织网收卷。第二驱动装置31可以为电机等设备。第二驱动装置31与第二驱动辊32可以通过齿轮、皮带或链条等连接。第二驱动装置31与第二驱动辊32可以固定设置在丝网检测设备的支架上。The

需要说明的是,通过第一驱动辊12和第二驱动辊32可以实现卷对卷输送,使钢丝织网进料前和出料后为卷状,方便运输。It should be noted that the roll-to-roll conveying can be realized through the

可选的,检测子设备22还用于:基于待检测钢丝织网的图像信息确定待检测钢丝织网的织网目数。Optionally, the detection sub-device 22 is further configured to: determine the mesh number of the steel wire mesh to be detected based on the image information of the steel wire mesh to be detected.

示例性的,在得到待检测钢丝织网的图像信息之后,可以将图像二值化,得到二值化丝网图像,获取二值化丝网图像中白色网孔区域的个数,即得到待检测钢丝织网的织网目数。可以理解的是,二值化丝网图像中黑色部分为钢丝部分,白色部分为网孔部分。Exemplarily, after obtaining the image information of the steel wire mesh to be detected, the image can be binarized to obtain a binarized wire mesh image, and the number of white mesh regions in the binarized wire mesh image is obtained, that is, the to-be-detected Detect the mesh number of steel wire mesh. It can be understood that the black part in the binarized silk screen image is the steel wire part, and the white part is the mesh part.

可选的,检测机构2包括检测室,相机21设置在检测室内。Optionally, the

可以理解的是,将相机21设置在检测室内,相机21可以获取检测室范围内的待检测钢丝织网的图像信息,并且可以避免外界干扰。It can be understood that, if the

可选的,丝网检测设备,还包括:张力控制装置4,设置在检测机构2与出料机构3之间,包括升降装置41和张力辊42,升降装置41驱动所述张力辊42纵向往复运动,以实现张力控制。Optionally, the screen detection equipment also includes: a

本实施例中,通过张力控制装置4可以实现辊间的同步,换而言之,可以使第一驱动辊12与第二驱动辊32同步转动,实现放卷和收卷的均匀控制,实现恒张力。第一驱动辊12与第二驱动辊32的转速可以根据检测需求设定,在此不做限定。In this embodiment, the

可选的,升降装置41为气缸、油缸或电动推杆。Optionally, the lifting

示例性的,当升降装置41为气缸时,气缸可以将压缩空气的压力能转换成机械能,驱动张力辊42实现往复直线运动。Exemplarily, when the

可选的,检测机构2,还包括:光源装置23,光源装置23与相机21相对设置,光源装置23用于照亮所述待检测钢丝织网。Optionally, the

本实施例中,通过光源装置23可以照亮待检测钢丝织网,提高相机21获取的图像质量。In this embodiment, the steel wire mesh to be inspected can be illuminated by the light source device 23 to improve the image quality acquired by the

可选的,丝网检测设备,还包括:多个设置在各机构上的从动辊,用于传输钢丝织网。Optionally, the wire mesh detection equipment further includes: a plurality of driven rollers arranged on each mechanism, used for conveying the wire mesh.

本实施例中,钢丝织网可以缠绕在从动辊上,并实现钢丝织网的传输。In this embodiment, the steel wire mesh can be wound on the driven roller to realize the transmission of the steel wire mesh.

本发明实施例的技术方案,通过丝网检测设备接采集待检测钢丝织网的图像信息,将待检测钢丝织网的图像信息输入至预先训练完成的缺陷检测模型,得到钢丝织网缺陷检测结果,实现钢丝织网缺陷的自动检测,提高了钢丝织网的检测效率。In the technical solution of the embodiment of the present invention, the image information of the steel wire mesh to be detected is collected through the wire mesh detection equipment, and the image information of the steel wire mesh to be detected is input into the pre-trained defect detection model to obtain the defect detection result of the steel wire mesh , to realize the automatic detection of steel wire mesh defects, and improve the detection efficiency of steel wire mesh.

实施例二Embodiment two

图2为本发明实施例二提供的一种缺陷检测方法的流程图,本实施例可适用于自动检测钢丝织网缺陷的情况,该方法可以由缺陷检测装置来执行,该缺陷检测装置可以采用硬件和/或软件的形式实现,该缺陷检测装置可配置于丝网检测设备中。如图2所示,该方法包括:Fig. 2 is a flow chart of a defect detection method provided by

S210、获取待检测钢丝织网的图像信息。S210. Obtain image information of the steel wire mesh to be detected.

S220、将所述待检测钢丝织网的图像信息输入至预先训练完成的缺陷检测模型,得到钢丝织网缺陷检测结果。S220. Input the image information of the steel wire mesh to be detected into the pre-trained defect detection model to obtain a defect detection result of the steel wire mesh.

在本实施例中,缺陷检测模型基于钢丝织网样本图像以及所述钢丝织网样本图像对应的标签信息训练得到。In this embodiment, the defect detection model is trained based on the steel wire mesh sample image and the label information corresponding to the steel wire mesh sample image.

其中,缺陷检测模型可以预先通过大量的钢丝织网样本图像以及钢丝织网样本图像对应的标签信息训练得到。在所训练的缺陷检测模型中,会预先对钢丝织网样本图像进行特征提取,并基于提取的特征信息对缺陷检测模型中的模型参数进行训练,并通过不断调整模型参数,使得模型的输出结果与钢丝织网样本图像对应的标签信息之间的距离偏差逐渐减小并趋于稳定,得到训练完成的缺陷检测模型。Wherein, the defect detection model can be trained in advance through a large number of steel wire mesh sample images and label information corresponding to the steel wire mesh sample images. In the trained defect detection model, feature extraction will be performed on the steel wire mesh sample image in advance, and the model parameters in the defect detection model will be trained based on the extracted feature information, and the output result of the model will be improved by continuously adjusting the model parameters. The distance deviation between the label information corresponding to the steel wire mesh sample image gradually decreases and tends to be stable, and the trained defect detection model is obtained.

本实施例中,缺陷检测模型可以为改进的Faster RCNN模型,改进的Faster RCNN模型包括特征提取网络模块、区域候选网络模块、兴趣域池化模块、分类回归网络模块。需要强调的是,特征提取网络模块可以为ResNet50网络,与现有的Faster RCNN模型相比,该特征提取网络模块可以提升缺陷检测模型的检测精度。In this embodiment, the defect detection model may be an improved Faster RCNN model, and the improved Faster RCNN model includes a feature extraction network module, a region candidate network module, an interest domain pooling module, and a classification regression network module. It should be emphasized that the feature extraction network module can be a ResNet50 network. Compared with the existing Faster RCNN model, this feature extraction network module can improve the detection accuracy of the defect detection model.

本发明实施例的技术方案,通过丝网检测设备接采集待检测钢丝织网的图像信息,将待检测钢丝织网的图像信息输入至预先训练完成的缺陷检测模型,得到钢丝织网缺陷检测结果,实现钢丝织网缺陷的自动检测,提高了钢丝织网的检测效率。In the technical solution of the embodiment of the present invention, the image information of the steel wire mesh to be detected is collected through the wire mesh detection equipment, and the image information of the steel wire mesh to be detected is input into the pre-trained defect detection model to obtain the defect detection result of the steel wire mesh , to realize the automatic detection of steel wire mesh defects, and improve the detection efficiency of steel wire mesh.

实施例三Embodiment three

图3为本发明实施例三提供的一种缺陷检测装置的结构示意图。如图3所示,该装置包括:FIG. 3 is a schematic structural diagram of a defect detection device provided by

图像信息获取模块310,用于获取待检测钢丝织网的图像信息;An image

织网缺陷检测模块320,用于将所述待检测钢丝织网的图像信息输入至预先训练完成的缺陷检测模型,得到钢丝织网缺陷检测结果;The mesh

其中,所述缺陷检测模型基于钢丝织网样本图像以及所述钢丝织网样本图像对应的标签信息训练得到。Wherein, the defect detection model is trained based on the steel wire mesh sample image and the label information corresponding to the steel wire mesh sample image.

本发明实施例的技术方案,通过丝网检测设备接采集待检测钢丝织网的图像信息,将待检测钢丝织网的图像信息输入至预先训练完成的缺陷检测模型,得到钢丝织网缺陷检测结果,实现钢丝织网缺陷的自动检测,提高了钢丝织网的检测效率。In the technical solution of the embodiment of the present invention, the image information of the steel wire mesh to be detected is collected through the wire mesh detection equipment, and the image information of the steel wire mesh to be detected is input into the pre-trained defect detection model to obtain the defect detection result of the steel wire mesh , to realize the automatic detection of steel wire mesh defects, and improve the detection efficiency of steel wire mesh.

本发明实施例所提供的缺陷检测装置可执行本发明任意实施例所提供的缺陷检测方法,具备执行方法相应的功能模块和有益效果。The defect detection device provided by the embodiment of the present invention can execute the defect detection method provided by any embodiment of the present invention, and has corresponding functional modules and beneficial effects for executing the method.

实施例四Embodiment Four

本发明实施例还提供了一种计算机可读存储介质,所述计算机可读存储介质存储有计算机指令,所述计算机指令在由计算机处理器执行时用于执行一种缺陷检测方法,该方法包括:An embodiment of the present invention also provides a computer-readable storage medium, the computer-readable storage medium stores computer instructions, and the computer instructions are used to execute a defect detection method when executed by a computer processor. The method includes :

获取待检测钢丝织网的图像信息。Obtain the image information of the steel wire mesh to be detected.

将所述待检测钢丝织网的图像信息输入至预先训练完成的缺陷检测模型,得到钢丝织网缺陷检测结果。The image information of the steel wire mesh to be detected is input to the pre-trained defect detection model to obtain the defect detection result of the steel wire mesh.

其中,所述缺陷检测模型基于钢丝织网样本图像以及所述钢丝织网样本图像对应的标签信息训练得到。Wherein, the defect detection model is trained based on the steel wire mesh sample image and the label information corresponding to the steel wire mesh sample image.

当然,本发明实施例所提供的一种计算机可读存储介质,其计算机指令不限于如上所述的方法操作,还可以执行本发明任意实施例所提供的缺陷检测方法中的相关操作。Of course, the computer-readable storage medium provided by the embodiments of the present invention, the computer instructions thereof are not limited to the operations of the method described above, and can also perform related operations in the defect detection method provided by any embodiment of the present invention.

通过以上关于实施方式的描述,所属领域的技术人员可以清楚地了解到,本发明可借助软件及必需的通用硬件来实现,当然也可以通过硬件实现,但很多情况下前者是更佳的实施方式。基于这样的理解,本发明的技术方案本质上或者说对现有技术做出贡献的部分可以以软件产品的形式体现出来,该计算机软件产品可以存储在计算机可读存储介质中,如计算机的软盘、只读存储器(Read-Only Memory,简称ROM)、随机存取存储器(RandomAccess Memory,简称RAM)、闪存(FLASH)、硬盘或光盘等,包括若干指令用以使得一台计算机设备(可以是个人计算机,服务器,或者网络设备等)执行本发明各个实施例所述的缺陷检测方法。Through the above description about the implementation mode, those skilled in the art can clearly understand that the present invention can be realized by means of software and necessary general-purpose hardware, and of course it can also be realized by hardware, but in many cases the former is a better implementation mode . Based on this understanding, the essence of the technical solution of the present invention or the part that contributes to the prior art can be embodied in the form of a software product, and the computer software product can be stored in a computer-readable storage medium, such as a floppy disk of a computer , read-only memory (Read-Only Memory, referred to as ROM), random access memory (Random Access Memory, referred to as RAM), flash memory (FLASH), hard disk or optical disc, etc., including a number of instructions to make a computer device (which can be a personal A computer, server, or network device, etc.) executes the defect detection method described in various embodiments of the present invention.

值得注意的是,上述缺陷检测装置的实施例中,所包括的各个单元和模块只是按照功能逻辑进行划分的,但并不局限于上述的划分,只要能够实现相应的功能即可;另外,各功能单元的具体名称也只是为了便于相互区分,并不用于限制本发明的保护范围。It is worth noting that, in the above-mentioned embodiment of the defect detection device, the units and modules included are only divided according to functional logic, but are not limited to the above-mentioned division, as long as the corresponding functions can be realized; in addition, each The specific names of the functional units are only for the convenience of distinguishing each other, and are not used to limit the protection scope of the present invention.

应该理解,可以使用上面所示的各种形式的流程,重新排序、增加或删除步骤。例如,本发明中记载的各步骤可以并行地执行也可以顺序地执行也可以不同的次序执行,只要能够实现本发明的技术方案所期望的结果,本文在此不进行限制。It should be understood that steps may be reordered, added or deleted using the various forms of flow shown above. For example, each step described in the present invention may be executed in parallel, sequentially, or in a different order, as long as the desired result of the technical solution of the present invention can be achieved, there is no limitation herein.

上述具体实施方式,并不构成对本发明保护范围的限制。本领域技术人员应该明白的是,根据设计要求和其他因素,可以进行各种修改、组合、子组合和替代。任何在本发明的精神和原则之内所作的修改、等同替换和改进等,均应包含在本发明保护范围之内。The above specific implementation methods do not constitute a limitation to the protection scope of the present invention. It should be apparent to those skilled in the art that various modifications, combinations, sub-combinations and substitutions may be made depending on design requirements and other factors. Any modifications, equivalent replacements and improvements made within the spirit and principles of the present invention shall be included within the protection scope of the present invention.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310077161.XACN115980077A (en) | 2023-01-17 | 2023-01-17 | Defect detection method, device, screen detection equipment and storage medium |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202310077161.XACN115980077A (en) | 2023-01-17 | 2023-01-17 | Defect detection method, device, screen detection equipment and storage medium |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115980077Atrue CN115980077A (en) | 2023-04-18 |

Family

ID=85964921

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202310077161.XAPendingCN115980077A (en) | 2023-01-17 | 2023-01-17 | Defect detection method, device, screen detection equipment and storage medium |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115980077A (en) |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019233166A1 (en)* | 2018-06-04 | 2019-12-12 | 杭州海康威视数字技术股份有限公司 | Surface defect detection method and apparatus, and electronic device |

| CN211225708U (en)* | 2019-12-31 | 2020-08-11 | 瑞安市超扬新材料科技有限公司 | Woven mesh continuous inspection machine |

| CN113129288A (en)* | 2021-04-22 | 2021-07-16 | 安徽大学 | Tablet surface defect detection method based on deep learning image semantic segmentation and automatic processing device thereof |

| CN113205176A (en)* | 2021-04-19 | 2021-08-03 | 重庆创通联达智能技术有限公司 | Method, device and equipment for training defect classification detection model and storage medium |

| CN113469071A (en)* | 2021-07-06 | 2021-10-01 | 西安科技大学 | Video detection method for foreign matters in coal conveying belt for embedded equipment |

| CN113744297A (en)* | 2021-08-31 | 2021-12-03 | 西部超导材料科技股份有限公司 | A kind of MRI superconducting wire braided layer surface defect detection method and detection device |

| CN216978868U (en)* | 2022-03-09 | 2022-07-15 | 临沂鑫润建铜业有限公司 | Surface defect detection device of copper wire |

| US20220270228A1 (en)* | 2020-03-11 | 2022-08-25 | Beijing Baidu Netcom Science And Technology Co., Ltd. | Method and apparatus for obtaining information |

| CN115457017A (en)* | 2022-09-29 | 2022-12-09 | 北京星闪世图科技有限公司 | A wire defect detection method, device, computer equipment and storage medium |

- 2023

- 2023-01-17CNCN202310077161.XApatent/CN115980077A/enactivePending

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2019233166A1 (en)* | 2018-06-04 | 2019-12-12 | 杭州海康威视数字技术股份有限公司 | Surface defect detection method and apparatus, and electronic device |

| CN211225708U (en)* | 2019-12-31 | 2020-08-11 | 瑞安市超扬新材料科技有限公司 | Woven mesh continuous inspection machine |

| US20220270228A1 (en)* | 2020-03-11 | 2022-08-25 | Beijing Baidu Netcom Science And Technology Co., Ltd. | Method and apparatus for obtaining information |

| CN113205176A (en)* | 2021-04-19 | 2021-08-03 | 重庆创通联达智能技术有限公司 | Method, device and equipment for training defect classification detection model and storage medium |

| CN113129288A (en)* | 2021-04-22 | 2021-07-16 | 安徽大学 | Tablet surface defect detection method based on deep learning image semantic segmentation and automatic processing device thereof |

| CN113469071A (en)* | 2021-07-06 | 2021-10-01 | 西安科技大学 | Video detection method for foreign matters in coal conveying belt for embedded equipment |

| CN113744297A (en)* | 2021-08-31 | 2021-12-03 | 西部超导材料科技股份有限公司 | A kind of MRI superconducting wire braided layer surface defect detection method and detection device |

| CN216978868U (en)* | 2022-03-09 | 2022-07-15 | 临沂鑫润建铜业有限公司 | Surface defect detection device of copper wire |

| CN115457017A (en)* | 2022-09-29 | 2022-12-09 | 北京星闪世图科技有限公司 | A wire defect detection method, device, computer equipment and storage medium |

Non-Patent Citations (1)

| Title |

|---|

| 胡正委 等: "基于改进Faster RCNN与Grabcut的商品图像检测", 计算机系统应用, no. 11, 14 November 2018 (2018-11-14)* |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP7391173B2 (en) | Food inspection aid system, food inspection aid device, and computer program | |

| CN111415329A (en) | A detection method for workpiece surface defects based on deep learning | |

| CN103954563B (en) | A kind of fruit and vegetable surfaces damage detection apparatus based on EO-1 hyperion | |

| CN111754470A (en) | Automatic cloth inspection method, device, automatic cloth inspection machine and storage medium | |

| Roseleena et al. | Assessment of palm oil fresh fruit bunches using photogrammetric grading system. | |

| CN104268505A (en) | Automatic cloth defect point detection and recognition device and method based on machine vision | |

| WO2014134880A1 (en) | Detection method and device for backlight module defects | |

| JP2011024485A (en) | Device for analyzing cell image | |

| CN102179374A (en) | Automatic detecting and sorting device for poultry egg quality and method thereof | |

| CN111986195B (en) | Appearance defect detection method and system | |

| CN114037693A (en) | A deep learning-based evaluation method for rock pore-crack and impurity characteristics | |

| US20190188855A1 (en) | Processing digital image to remove unwanted portion | |

| CN110813795A (en) | Device and method for detecting breakage of chemical fiber spindle paper tube on line | |

| CN110743802A (en) | Automatic detection and supervision system for cloth | |

| WO2024055796A1 (en) | Defect detection system, method and apparatus, electronic device, and storage medium | |

| CN113245222B (en) | Visual real-time detection and sorting system and sorting method for foreign matters in panax notoginseng | |

| CN115980077A (en) | Defect detection method, device, screen detection equipment and storage medium | |

| CN117670867A (en) | Industrial defect detection method, device, electronic equipment and storage medium | |

| WO2024037240A1 (en) | Intelligent cloth inspection detection system and method, and computer-readable storage medium and product | |

| JP2022160796A (en) | FOOD INSPECTION SYSTEM, FOOD INSPECTION LEARNING DEVICE, AND FOOD INSPECTION METHOD | |

| Greer et al. | Modular shadowgraph imaging for zooplankton ecological studies in diverse field and mesocosm settings | |

| Mindoro et al. | Automatic visual detection of fresh poultry egg quality inspection using image processing | |

| JP2023115666A (en) | Roasting Degree Inspection System and Roasting Degree Inspection Method Equipped with Roasting Degree Estimating Function for Roasted Coffee Beans | |

| CN115236083A (en) | A kind of image acquisition device and defect detection method of inner surface of cylinder | |

| Lawrence et al. | Modified pressure system for imaging egg cracks |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |