CN115957385A - Preparation method and application of a multifunctional coating of metal polyphenol network coupling antimicrobial peptide - Google Patents

Preparation method and application of a multifunctional coating of metal polyphenol network coupling antimicrobial peptideDownload PDFInfo

- Publication number

- CN115957385A CN115957385ACN202211610012.7ACN202211610012ACN115957385ACN 115957385 ACN115957385 ACN 115957385ACN 202211610012 ACN202211610012 ACN 202211610012ACN 115957385 ACN115957385 ACN 115957385A

- Authority

- CN

- China

- Prior art keywords

- titanium

- solution

- metal

- polyphenol

- parts

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 235000013824polyphenolsNutrition0.000titleclaimsabstractdescription61

- 150000008442polyphenolic compoundsChemical class0.000titleclaimsabstractdescription60

- 108700042778Antimicrobial PeptidesProteins0.000titleclaimsabstractdescription44

- 102000044503Antimicrobial PeptidesHuman genes0.000titleclaimsabstractdescription44

- 238000000576coating methodMethods0.000titleclaimsabstractdescription40

- 239000011248coating agentSubstances0.000titleclaimsabstractdescription37

- 239000003910polypeptide antibiotic agentSubstances0.000titleclaimsabstractdescription37

- 229910052751metalInorganic materials0.000titleclaimsabstractdescription35

- 239000002184metalSubstances0.000titleclaimsabstractdescription35

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription18

- 230000008878couplingEffects0.000titleclaimsabstractdescription10

- 238000010168coupling processMethods0.000titleclaimsabstractdescription10

- 238000005859coupling reactionMethods0.000titleclaimsabstractdescription10

- 239000010936titaniumSubstances0.000claimsabstractdescription99

- RTAQQCXQSZGOHL-UHFFFAOYSA-NTitaniumChemical compound[Ti]RTAQQCXQSZGOHL-UHFFFAOYSA-N0.000claimsabstractdescription90

- 229910052719titaniumInorganic materials0.000claimsabstractdescription90

- GWEVSGVZZGPLCZ-UHFFFAOYSA-NTitan oxideChemical compoundO=[Ti]=OGWEVSGVZZGPLCZ-UHFFFAOYSA-N0.000claimsabstractdescription62

- 239000004408titanium dioxideSubstances0.000claimsabstractdescription29

- 230000000844anti-bacterial effectEffects0.000claimsabstractdescription22

- 239000007943implantSubstances0.000claimsabstractdescription17

- 239000000243solutionSubstances0.000claimsdescription91

- 239000000463materialSubstances0.000claimsdescription73

- HEMHJVSKTPXQMS-UHFFFAOYSA-MSodium hydroxideChemical compound[OH-].[Na+]HEMHJVSKTPXQMS-UHFFFAOYSA-M0.000claimsdescription48

- 229910021645metal ionInorganic materials0.000claimsdescription24

- QKNYBSVHEMOAJP-UHFFFAOYSA-N2-amino-2-(hydroxymethyl)propane-1,3-diol;hydron;chlorideChemical compoundCl.OCC(N)(CO)COQKNYBSVHEMOAJP-UHFFFAOYSA-N0.000claimsdescription23

- YCIMNLLNPGFGHC-UHFFFAOYSA-NcatecholChemical compoundOC1=CC=CC=C1OYCIMNLLNPGFGHC-UHFFFAOYSA-N0.000claimsdescription20

- 238000006243chemical reactionMethods0.000claimsdescription20

- LNTHITQWFMADLM-UHFFFAOYSA-Ngallic acidChemical compoundOC(=O)C1=CC(O)=C(O)C(O)=C1LNTHITQWFMADLM-UHFFFAOYSA-N0.000claimsdescription18

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterChemical compoundOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsdescription15

- 239000011259mixed solutionSubstances0.000claimsdescription13

- 239000002120nanofilmSubstances0.000claimsdescription13

- TUSDEZXZIZRFGC-UHFFFAOYSA-N1-O-galloyl-3,6-(R)-HHDP-beta-D-glucoseNatural productsOC1C(O2)COC(=O)C3=CC(O)=C(O)C(O)=C3C3=C(O)C(O)=C(O)C=C3C(=O)OC1C(O)C2OC(=O)C1=CC(O)=C(O)C(O)=C1TUSDEZXZIZRFGC-UHFFFAOYSA-N0.000claimsdescription11

- 239000001263FEMA 3042Substances0.000claimsdescription11

- LRBQNJMCXXYXIU-PPKXGCFTSA-NPenta-digallate-beta-D-glucoseNatural productsOC1=C(O)C(O)=CC(C(=O)OC=2C(=C(O)C=C(C=2)C(=O)OC[C@@H]2[C@H]([C@H](OC(=O)C=3C=C(OC(=O)C=4C=C(O)C(O)=C(O)C=4)C(O)=C(O)C=3)[C@@H](OC(=O)C=3C=C(OC(=O)C=4C=C(O)C(O)=C(O)C=4)C(O)=C(O)C=3)[C@H](OC(=O)C=3C=C(OC(=O)C=4C=C(O)C(O)=C(O)C=4)C(O)=C(O)C=3)O2)OC(=O)C=2C=C(OC(=O)C=3C=C(O)C(O)=C(O)C=3)C(O)=C(O)C=2)O)=C1LRBQNJMCXXYXIU-PPKXGCFTSA-N0.000claimsdescription11

- 235000015523tannic acidNutrition0.000claimsdescription11

- LRBQNJMCXXYXIU-NRMVVENXSA-Ntannic acidChemical compoundOC1=C(O)C(O)=CC(C(=O)OC=2C(=C(O)C=C(C=2)C(=O)OC[C@@H]2[C@H]([C@H](OC(=O)C=3C=C(OC(=O)C=4C=C(O)C(O)=C(O)C=4)C(O)=C(O)C=3)[C@@H](OC(=O)C=3C=C(OC(=O)C=4C=C(O)C(O)=C(O)C=4)C(O)=C(O)C=3)[C@@H](OC(=O)C=3C=C(OC(=O)C=4C=C(O)C(O)=C(O)C=4)C(O)=C(O)C=3)O2)OC(=O)C=2C=C(OC(=O)C=3C=C(O)C(O)=C(O)C=3)C(O)=C(O)C=2)O)=C1LRBQNJMCXXYXIU-NRMVVENXSA-N0.000claimsdescription11

- 229940033123tannic acidDrugs0.000claimsdescription11

- 229920002258tannic acidPolymers0.000claimsdescription11

- WQGWDDDVZFFDIG-UHFFFAOYSA-NpyrogallolChemical compoundOC1=CC=CC(O)=C1OWQGWDDDVZFFDIG-UHFFFAOYSA-N0.000claimsdescription10

- 238000003491arrayMethods0.000claimsdescription9

- 235000004515gallic acidNutrition0.000claimsdescription9

- 229940074391gallic acidDrugs0.000claimsdescription9

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000claimsdescription8

- CSCPPACGZOOCGX-UHFFFAOYSA-NAcetoneChemical compoundCC(C)=OCSCPPACGZOOCGX-UHFFFAOYSA-N0.000claimsdescription6

- 238000010438heat treatmentMethods0.000claimsdescription6

- 108010039918PolylysineProteins0.000claimsdescription5

- 108700022109ropocamptideProteins0.000claimsdescription5

- 239000010935stainless steelSubstances0.000claimsdescription5

- 229910001220stainless steelInorganic materials0.000claimsdescription5

- 230000004048modificationEffects0.000claimsdescription4

- 238000012986modificationMethods0.000claimsdescription4

- 108060003100MagaininProteins0.000claimsdescription3

- 108010053775NisinProteins0.000claimsdescription3

- NVNLLIYOARQCIX-MSHCCFNRSA-NNisinChemical compoundN1C(=O)[C@@H](CC(C)C)NC(=O)C(=C)NC(=O)[C@@H]([C@H](C)CC)NC(=O)[C@@H](NC(=O)C(=C/C)/NC(=O)[C@H](N)[C@H](C)CC)CSC[C@@H]1C(=O)N[C@@H]1C(=O)N2CCC[C@@H]2C(=O)NCC(=O)N[C@@H](C(=O)N[C@H](CCCCN)C(=O)N[C@@H]2C(NCC(=O)N[C@H](C)C(=O)N[C@H](CC(C)C)C(=O)N[C@H](CCSC)C(=O)NCC(=O)N[C@H](CS[C@@H]2C)C(=O)N[C@H](CC(N)=O)C(=O)N[C@H](CCSC)C(=O)N[C@H](CCCCN)C(=O)N[C@@H]2C(N[C@H](C)C(=O)N[C@@H]3C(=O)N[C@@H](C(N[C@H](CC=4NC=NC=4)C(=O)N[C@H](CS[C@@H]3C)C(=O)N[C@H](CO)C(=O)N[C@H]([C@H](C)CC)C(=O)N[C@H](CC=3NC=NC=3)C(=O)N[C@H](C(C)C)C(=O)NC(=C)C(=O)N[C@H](CCCCN)C(O)=O)=O)CS[C@@H]2C)=O)=O)CS[C@@H]1CNVNLLIYOARQCIX-MSHCCFNRSA-N0.000claimsdescription3

- 239000008367deionised waterSubstances0.000claimsdescription3

- 229910021641deionized waterInorganic materials0.000claimsdescription3

- 238000001027hydrothermal synthesisMethods0.000claimsdescription3

- 238000011065in-situ storageMethods0.000claimsdescription3

- 239000002932lusterSubstances0.000claimsdescription3

- 239000004309nisinSubstances0.000claimsdescription3

- 235000010297nisinNutrition0.000claimsdescription3

- 230000002188osteogenic effectEffects0.000claimsdescription3

- 239000002245particleSubstances0.000claimsdescription3

- 238000004506ultrasonic cleaningMethods0.000claimsdescription3

- 238000003260vortexingMethods0.000claimsdescription2

- 229910052588hydroxylapatiteInorganic materials0.000abstractdescription6

- XYJRXVWERLGGKC-UHFFFAOYSA-Dpentacalcium;hydroxide;triphosphateChemical group[OH-].[Ca+2].[Ca+2].[Ca+2].[Ca+2].[Ca+2].[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=OXYJRXVWERLGGKC-UHFFFAOYSA-D0.000abstractdescription6

- 230000008021depositionEffects0.000abstractdescription5

- 239000000126substanceSubstances0.000abstractdescription4

- 230000001737promoting effectEffects0.000abstractdescription2

- 238000013329compoundingMethods0.000abstract1

- ISWSIDIOOBJBQZ-UHFFFAOYSA-Nphenol groupChemical groupC1(=CC=CC=C1)OISWSIDIOOBJBQZ-UHFFFAOYSA-N0.000abstract1

- 238000000034methodMethods0.000description12

- 238000007254oxidation reactionMethods0.000description7

- 238000007626photothermal therapyMethods0.000description7

- 230000001580bacterial effectEffects0.000description6

- 241000894006BacteriaSpecies0.000description5

- 210000000988bone and boneAnatomy0.000description5

- 210000004027cellAnatomy0.000description5

- 230000000694effectsEffects0.000description5

- 238000011160researchMethods0.000description4

- 238000012360testing methodMethods0.000description4

- 210000001519tissueAnatomy0.000description4

- 206010059866Drug resistanceDiseases0.000description3

- 241000588724Escherichia coliSpecies0.000description3

- 238000000445field-emission scanning electron microscopyMethods0.000description3

- 239000012890simulated body fluidSubstances0.000description3

- 230000002195synergetic effectEffects0.000description3

- 206010064687Device related infectionDiseases0.000description2

- 238000000137annealingMethods0.000description2

- 239000003242anti bacterial agentSubstances0.000description2

- 229940088710antibiotic agentDrugs0.000description2

- 230000008859changeEffects0.000description2

- 238000010586diagramMethods0.000description2

- 238000000349field-emission scanning electron micrographMethods0.000description2

- PCHJSUWPFVWCPO-UHFFFAOYSA-NgoldChemical compound[Au]PCHJSUWPFVWCPO-UHFFFAOYSA-N0.000description2

- 239000010931goldSubstances0.000description2

- 229910052737goldInorganic materials0.000description2

- 238000003306harvestingMethods0.000description2

- 238000001727in vivoMethods0.000description2

- 208000015181infectious diseaseDiseases0.000description2

- 239000002609mediumSubstances0.000description2

- 238000013508migrationMethods0.000description2

- 239000002086nanomaterialSubstances0.000description2

- 230000000399orthopedic effectEffects0.000description2

- 238000012546transferMethods0.000description2

- 208000035143Bacterial infectionDiseases0.000description1

- 102000010834Extracellular Matrix ProteinsHuman genes0.000description1

- 108010037362Extracellular Matrix ProteinsProteins0.000description1

- 241000192125FirmicutesSpecies0.000description1

- 239000006142Luria-Bertani AgarSubstances0.000description1

- 238000006845Michael addition reactionMethods0.000description1

- 108091005461Nucleic proteinsProteins0.000description1

- 229910019142PO4Inorganic materials0.000description1

- 229930040373ParaformaldehydeNatural products0.000description1

- 239000002262Schiff baseSubstances0.000description1

- 150000004753Schiff basesChemical class0.000description1

- 241000191967Staphylococcus aureusSpecies0.000description1

- 230000001133accelerationEffects0.000description1

- 230000032683agingEffects0.000description1

- 229910045601alloyInorganic materials0.000description1

- 239000000956alloySubstances0.000description1

- 125000003277amino groupChemical group0.000description1

- 230000002924anti-infective effectEffects0.000description1

- 230000000845anti-microbial effectEffects0.000description1

- 229910052586apatiteInorganic materials0.000description1

- 208000022362bacterial infectious diseaseDiseases0.000description1

- 230000009286beneficial effectEffects0.000description1

- 230000008901benefitEffects0.000description1

- 239000010839body fluidSubstances0.000description1

- 210000001124body fluidAnatomy0.000description1

- 230000004221bone functionEffects0.000description1

- 229910002091carbon monoxideInorganic materials0.000description1

- BVKZGUZCCUSVTD-UHFFFAOYSA-Ncarbonic acidChemical compoundOC(O)=OBVKZGUZCCUSVTD-UHFFFAOYSA-N0.000description1

- 125000003178carboxy groupChemical group[H]OC(*)=O0.000description1

- 230000021164cell adhesionEffects0.000description1

- 230000024245cell differentiationEffects0.000description1

- 230000012292cell migrationEffects0.000description1

- 230000004663cell proliferationEffects0.000description1

- 230000004656cell transportEffects0.000description1

- 238000010668complexation reactionMethods0.000description1

- 238000010276constructionMethods0.000description1

- 230000007797corrosionEffects0.000description1

- 238000005260corrosionMethods0.000description1

- 230000007812deficiencyEffects0.000description1

- 238000013461designMethods0.000description1

- 230000004069differentiationEffects0.000description1

- 238000002474experimental methodMethods0.000description1

- 210000002744extracellular matrixAnatomy0.000description1

- 239000012530fluidSubstances0.000description1

- 125000002887hydroxy groupChemical group[H]O*0.000description1

- 238000002513implantationMethods0.000description1

- 238000000338in vitroMethods0.000description1

- 239000011159matrix materialSubstances0.000description1

- 239000012528membraneSubstances0.000description1

- 230000005012migrationEffects0.000description1

- 230000000877morphologic effectEffects0.000description1

- 239000002071nanotubeSubstances0.000description1

- 230000006911nucleationEffects0.000description1

- 238000010899nucleationMethods0.000description1

- 108020004707nucleic acidsProteins0.000description1

- 102000039446nucleic acidsHuman genes0.000description1

- 150000007523nucleic acidsChemical class0.000description1

- 230000003287optical effectEffects0.000description1

- 238000010883osseointegrationMethods0.000description1

- 210000000963osteoblastAnatomy0.000description1

- 230000002138osteoinductive effectEffects0.000description1

- 229920002866paraformaldehydePolymers0.000description1

- VSIIXMUUUJUKCM-UHFFFAOYSA-Dpentacalcium;fluoride;triphosphateChemical compound[F-].[Ca+2].[Ca+2].[Ca+2].[Ca+2].[Ca+2].[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=OVSIIXMUUUJUKCM-UHFFFAOYSA-D0.000description1

- NBIIXXVUZAFLBC-UHFFFAOYSA-KphosphateChemical compound[O-]P([O-])([O-])=ONBIIXXVUZAFLBC-UHFFFAOYSA-K0.000description1

- 239000010452phosphateSubstances0.000description1

- 239000012221photothermal agentSubstances0.000description1

- 230000008569processEffects0.000description1

- 230000035755proliferationEffects0.000description1

- 102000004169proteins and genesHuman genes0.000description1

- 230000004044responseEffects0.000description1

- 150000003839saltsChemical class0.000description1

- 238000004904shorteningMethods0.000description1

- 239000007787solidSubstances0.000description1

- 239000007921spraySubstances0.000description1

- 239000000725suspensionSubstances0.000description1

Images

Classifications

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A50/00—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE in human health protection, e.g. against extreme weather

- Y02A50/30—Against vector-borne diseases, e.g. mosquito-borne, fly-borne, tick-borne or waterborne diseases whose impact is exacerbated by climate change

Landscapes

- Materials For Medical Uses (AREA)

- Agricultural Chemicals And Associated Chemicals (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于医药化学及材料技术领域,具体涉及一种金属多酚网络偶联抗菌肽的多功能涂层的制备方法及其应用,即在二氧化钛纳米尖结构表面通过金属多酚网络偶联抗菌肽制备多功能钛植入物涂层。The invention belongs to the technical field of medicinal chemistry and materials, and in particular relates to a preparation method and application of a multifunctional coating of a metal polyphenol network coupling antimicrobial peptide, that is, the antimicrobial peptide is coupled on the surface of a titanium dioxide nano-tip structure through a metal polyphenol network Preparation of multifunctional titanium implant coatings.

背景技术Background technique

随着我国人口老龄化的加速,近年来以骨/口腔植入物为代表的硬组织植入医疗器械用量持续增长。钛(Ti)及其合金由于优异的机械性能、良好的耐腐蚀性和生物相容性,在硬组织植入材料中应用广泛,占到骨科植入物的70–80%。然而,钛材固有的生物惰性使其缺乏抗菌性能和骨传导性,从而导致细菌感染和无菌性松动的风险增加,并最终导致手术的失效。因此,通过表面改性,使钛植入物兼具良好的抗菌性能和优异的骨传导性能,具有很好的临床应用前景。目前,针对骨科植入物感染,临床上应用最广泛的抗菌手段仍然是抗生素治疗,但是抗生素的滥用已诱导大量的细菌产生了抗药性,甚至会产生感染无药可治的境地。因此,寻找不易诱发耐药性且具有良好的生物相容性的抗菌方法受到越来越多的关注。光热疗法可以通过非侵入性的光源照射,诱导局部产生高温,破坏生物膜的结构使其活性基质(如核酸和蛋白质)失活,且不易产生耐药性;然而,由于单独使用光热疗法需要引入高功率激光密度和长照射时间,不可避免的对周围健康的组织产生副作用。With the acceleration of my country's population aging, the amount of hard tissue implant medical devices represented by bone/oral implants has continued to grow in recent years. Titanium (Ti) and its alloys are widely used in hard tissue implant materials due to their excellent mechanical properties, good corrosion resistance and biocompatibility, accounting for 70–80% of orthopedic implants. However, the inherent bioinertness of titanium makes it lack antimicrobial properties and osteoconductivity, leading to an increased risk of bacterial infection and aseptic loosening, which ultimately leads to failure of the procedure. Therefore, through surface modification, titanium implants have both good antibacterial properties and excellent bone conduction properties, and have good clinical application prospects. At present, antibiotics are the most widely used clinical antibacterial method for orthopedic implant infection, but the abuse of antibiotics has induced a large number of bacteria to develop drug resistance, and even lead to the situation that the infection has no cure. Therefore, finding an antibacterial method that is not easy to induce drug resistance and has good biocompatibility has received more and more attention. Photothermal therapy can induce local high temperature through non-invasive light source irradiation, destroy the structure of biofilm and inactivate its active matrix (such as nucleic acid and protein), and it is not easy to produce drug resistance; however, due to the use of photothermal therapy alone Need to introduce high power laser density and long irradiation time, inevitably produce side effects on surrounding healthy tissues.

鉴于上述原因,本发明研究团队认为有必要探究一种方法能够解决植入物本体以及植入物内后的抗菌问题。In view of the above reasons, the research team of the present invention believes that it is necessary to explore a method that can solve the antibacterial problem of the implant body and the implant.

发明内容Contents of the invention

本发明的目的在于解决现有技术所存在的不足之处,而提供一种金属多酚网络偶联抗菌肽的多功能涂层的制备方法及其应用。The purpose of the present invention is to solve the deficiencies in the prior art, and provide a preparation method and application of a multifunctional coating of metal polyphenol network coupled antimicrobial peptides.

一种金属多酚网络偶联抗菌肽的多功能涂层的制备方法,其特殊之处在于,包括以下步骤:A method for preparing a multifunctional coating of a metal polyphenol network coupling antimicrobial peptide, which is special in that it includes the following steps:

1)采用水热法在钛材表面原位制备二氧化钛纳米尖阵列(TNS阵列),得到表面具有二氧化钛纳米尖阵列的钛材;即通过高温高压NaOH水热工艺在钛材上制备能够物理穿透细菌并将光转化为热的纳米尖结构,退火之后得到了表面具有二氧化钛纳米尖阵列(TNS阵列)的钛材;1) Titanium dioxide nano-tip arrays (TNS arrays) are prepared in situ on the surface of titanium materials by hydrothermal method, and titanium materials with titanium dioxide nano-tip arrays on the surface are obtained; that is, the titanium materials can be physically penetrated by the high-temperature and high-pressure NaOH hydrothermal process. Bacteria convert light into heat nanotip structures, and after annealing, titanium materials with titanium dioxide nanotip arrays (TNS arrays) on the surface are obtained;

2)在具有二氧化钛纳米尖阵列的钛材表面组装金属多酚纳米膜2) Assembling metal polyphenol nanofilms on the surface of titanium with titania nanotip arrays

2.1)将步骤1)得到的钛材置于反应容器中,然后加入植物多酚溶液和金属离子溶液;2.1) placing the titanium material obtained in step 1) in a reaction vessel, and then adding plant polyphenol solution and metal ion solution;

2.2)将步骤2.1)的混合溶液pH调节至生理pH值(比如:7.4);2.2) Adjust the pH of the mixed solution in step 2.1) to a physiological pH value (for example: 7.4);

2.3)为了使反应和组装更加充分,通过涡旋步骤2.2)调节后的混合溶液,将植物多酚和金属离子形成的金属多酚纳米膜快速组装在二氧化钛纳米尖阵列上,得到具有金属多酚纳米膜的二氧化钛纳米尖阵列的钛材TNS-MPN;2.3) In order to make the reaction and assembly more fully, by vortexing the mixed solution adjusted in step 2.2), the metal polyphenol nanofilm formed by plant polyphenols and metal ions is quickly assembled on the titanium dioxide nanotip array to obtain metal polyphenols with metal polyphenols. Titanium material TNS-MPN of titanium dioxide nanotip array of nanomembrane;

3)制备金属多酚网络偶联抗菌肽的多功能涂层3) Preparation of multifunctional coatings with metal-polyphenol network-coupled antimicrobial peptides

3.1)将步骤2)得到的钛材浸没在溶解有广谱抗菌肽AMP的Tris-HCl溶液中,并置于摇床中进行反应;3.1) Submerge the titanium material obtained in step 2) in a Tris-HCl solution dissolved with broad-spectrum antimicrobial peptide AMP, and place it in a shaker for reaction;

3.2)反应完成后,清洗并干燥钛材,在钛材表面得到金属多酚网络偶联抗菌肽的多功能涂层TNS-MPN-AMP,该涂层具有物理穿刺/光热/化学三元协同带来的抗菌促成骨功能。3.2) After the reaction is completed, the titanium material is cleaned and dried, and a multifunctional coating TNS-MPN-AMP, which is a metal polyphenol network-coupled antibacterial peptide, is obtained on the surface of the titanium material. The coating has physical puncture/photothermal/chemical three-way synergy Brought antibacterial promotes bone function.

进一步地,步骤1)具体为:Further, step 1) is specifically:

1.1)将钛材置于聚四氟乙烯衬里不锈钢高压釜反应器的底部,加入摩尔浓度为0.5-1.5M(优选1M)的NaOH溶液,并密封高压釜反应器;1.1) Place the titanium material at the bottom of a polytetrafluoroethylene-lined stainless steel autoclave reactor, add a NaOH solution with a molar concentration of 0.5-1.5M (preferably 1M), and seal the autoclave reactor;

1.2)将密封的高压釜反应器置于150-300℃的电炉中进行反应3-5h;1.2) Place the sealed autoclave reactor in an electric furnace at 150-300°C for 3-5 hours;

1.3)待反应完成后,将钛材置于400-600℃马弗炉中退火1-3h,得到表面具有二氧化钛纳米尖阵列的钛片。1.3) After the reaction is completed, anneal the titanium material in a muffle furnace at 400-600° C. for 1-3 hours to obtain a titanium sheet with a titanium dioxide nanotip array on its surface.

进一步地,步骤2)中,所述植物多酚溶液中的植物多酚为儿茶酚、焦棓酸、没食子酸或单宁酸;Further, in step 2), the plant polyphenols in the plant polyphenol solution are catechol, pyrogallic acid, gallic acid or tannic acid;

所述金属离子溶液为FeCl3溶液、ZnSO4溶液、CuSO4溶液或AlCl3溶液;The metal ion solution is FeCl3 solution, ZnSO4 solution, CuSO4 solution or AlCl3 solution;

步骤3)中,所述广谱抗菌肽为抗菌肽LL-37、爪蟾素、乳酸链球菌素或ε-多聚赖氨酸;In step 3), the broad-spectrum antimicrobial peptide is antimicrobial peptide LL-37, magainin, nisin or ε-polylysine;

当植物多酚为儿茶酚时,各组分按以下重量份添加:When the plant polyphenol is catechol, each component is added by the following parts by weight:

儿茶酚为4~7份,金属离子为2~5份,溶解在Tris-HCl溶液中的广谱抗菌肽为100~300份;4-7 parts of catechol, 2-5 parts of metal ions, and 100-300 parts of broad-spectrum antimicrobial peptide dissolved in Tris-HCl solution;

当植物多酚为焦棓酸时,各组分按以下重量份添加:When the plant polyphenol is pyrogallic acid, each component is added in the following parts by weight:

焦棓酸为1~4份,金属离子为2~5份,溶解在Tris-HCl溶液中的广谱抗菌肽为100~300份;1-4 parts of pyrogallic acid, 2-5 parts of metal ions, and 100-300 parts of broad-spectrum antimicrobial peptide dissolved in Tris-HCl solution;

当植物多酚为没食子酸时,各组分按以下重量份添加:When the plant polyphenol is gallic acid, each component is added by the following parts by weight:

没食子酸为1~4份,金属离子为2~5份,溶解在Tris-HCl溶液中的AMP为100~300份;1-4 parts of gallic acid, 2-5 parts of metal ions, 100-300 parts of AMP dissolved in Tris-HCl solution;

当植物多酚为单宁酸时,各组分按以下重量份添加:When the plant polyphenol is tannic acid, each component is added by the following parts by weight:

单宁酸为2~5份,金属离子为2~5份,溶解在Tris-HCl溶液中的广谱抗菌肽为100~300份。2-5 parts of tannic acid, 2-5 parts of metal ions, and 100-300 parts of broad-spectrum antimicrobial peptide dissolved in Tris-HCl solution.

为了使浸没钛材的溶液体积适当,可按以下标准配置植物多酚溶液、金属离子溶液以及广谱抗菌肽的Tris-HCl溶液,然后根据前述的重量份量取相应的体积:In order to make the volume of the solution for immersing the titanium material appropriate, the Tris-HCl solution of plant polyphenol solution, metal ion solution and broad-spectrum antimicrobial peptide can be configured according to the following standards, and then take the corresponding volume according to the aforementioned weight parts:

当植物多酚为儿茶酚时,浓度如下:When the plant polyphenol is catechol, the concentration is as follows:

植物多酚溶液中儿茶酚的浓度为0.4~0.7mg mL-1,金属离子溶液中金属离子的浓度为0.2~0.5mg mL-1,溶解在Tris-HCl溶液中的广谱抗菌肽的浓度为0.01~0.03g mL-1;The concentration of catechol in plant polyphenol solution is 0.4~0.7mg mL-1 , the concentration of metal ion in metal ion solution is 0.2~0.5mg mL-1 , the concentration of broad-spectrum antimicrobial peptide dissolved in Tris-HCl solution 0.01~0.03g mL-1 ;

当植物多酚为焦棓酸时,浓度如下:When the plant polyphenol is pyrogallic acid, the concentration is as follows:

植物多酚溶液中焦棓酸的浓度为0.1~0.4mg mL-1,金属离子溶液中金属离子的浓度为0.2~0.5mg mL-1,溶解在Tris-HCl溶液中的广谱抗菌肽的浓度为0.01~0.03g mL-1;The concentration of pyrogallic acid in the plant polyphenol solution is 0.1-0.4 mg mL-1 , the concentration of metal ions in the metal ion solution is 0.2-0.5 mg mL-1 , and the concentration of broad-spectrum antimicrobial peptides dissolved in Tris-HCl solution 0.01~0.03g mL-1 ;

当植物多酚为没食子酸时,浓度如下:When the plant polyphenol is gallic acid, the concentration is as follows:

植物多酚溶液中没食子酸的浓度为0.1~0.4mg mL-1,金属离子溶液中金属离子的浓度为0.2~0.5mg mL-1,溶解在Tris-HCl溶液中的广谱抗菌肽的浓度为0.01~0.03g mL-1;The concentration of gallic acid in the plant polyphenol solution is 0.1-0.4 mg mL-1 , the concentration of metal ions in the metal ion solution is 0.2-0.5 mg mL-1 , and the concentration of the broad-spectrum antimicrobial peptide dissolved in the Tris-HCl solution is 0.01~0.03g mL-1 ;

当植物多酚为单宁酸时,浓度如下:When the plant polyphenol is tannic acid, the concentration is as follows:

植物多酚溶液中单宁酸的浓度为0.2~0.5mg mL-1,金属离子溶液中金属离子的浓度为0.2~0.5mg mL-1,溶解在Tris-HCl溶液中的广谱抗菌肽的浓度为0.01~0.03g mL-1。The concentration of tannic acid in the plant polyphenol solution is 0.2-0.5 mg mL-1 , the concentration of metal ions in the metal ion solution is 0.2-0.5 mg mL-1 , and the concentration of broad-spectrum antimicrobial peptides dissolved in Tris-HCl solution 0.01-0.03g mL-1 .

进一步地,步骤1.3)中,为了安全且高效的实现对TNS的退火,升温速率设定为10℃/min;Further, in step 1.3), in order to realize the annealing of TNS safely and efficiently, the heating rate is set to 10°C/min;

步骤2.2)中,利用NaOH溶液调节步骤2.1)的混合溶液pH;In step 2.2), use NaOH solution to adjust the pH of the mixed solution in step 2.1);

步骤2.3)中,涡旋时长为30-90s,为了提高反应效率,且确保充分反应、组装完全,优选60s;In step 2.3), the vortex time is 30-90s, in order to improve the reaction efficiency, and ensure full reaction and complete assembly, preferably 60s;

步骤3.1)中,室温下反应6-12h。In step 3.1), react at room temperature for 6-12h.

进一步地,在步骤1)之前还包括对钛材的预处理,具体为:Further, before step 1), the pretreatment to titanium material is also included, specifically:

将纯钛材切割为所需尺寸,并用粒度为#400、#800、#1200至#2000的SiC砂纸依次抛光至镜面光泽,使用去离子水冲洗磨屑,之后依次用丙酮、乙醇和水进行超声清洗,去除表面的油污,烘干之后备用。Cut the pure titanium material to the required size, and use SiC sandpaper with a particle size of #400, #800, #1200 to #2000 to polish it to a mirror luster in sequence, use deionized water to rinse the abrasive debris, and then use acetone, ethanol and water in sequence Ultrasonic cleaning to remove the oil on the surface, and dry it for later use.

同时,本发明还提供了采用上述方法制备的金属多酚网络偶联抗菌肽的多功能涂层,以及该多功能涂层在对钛材进行抗菌促成骨改性中的应用。At the same time, the present invention also provides the multifunctional coating of the metal polyphenol network coupling antibacterial peptide prepared by the above method, and the application of the multifunctional coating in antibacterial and bone-promoting modification of titanium materials.

此外,基于上述应用,本发明还提供了一种钛改性材料,其特殊之处在于,在钛材表面上按照上述方法制备金属多酚网络偶联抗菌肽的多功能涂层。以及,上述钛改性材料在制备抗菌促成骨钛植入物中的应用和钛植入。In addition, based on the above application, the present invention also provides a titanium modified material, which is special in that a multifunctional coating of metal polyphenol network coupled antimicrobial peptides is prepared on the surface of the titanium material according to the above method. And, the application of the above-mentioned titanium modified material in the preparation of antibacterial and bone-promoting titanium implants and titanium implantation.

本发明的构思及原理:Design and principle of the present invention:

本发明研究团队考虑到纯钛具有生物惰性,不具备抗菌和骨诱导能力,拟通过在钛表面构建各种微/纳米结构,比如:纳米管、纳米尖、纳米孔、纳米叶等,以提高钛植入物的生物活性。其中的二氧化钛纳米尖结构不仅能够模拟天然细胞外基质,促进流体流动,促进分子和细胞运输,以及激发成骨信号,促进更好的细胞粘附、迁移、增殖和分化,还可以物理破坏细菌膜并泄漏细胞内容物来杀死细菌,更重要的是,二氧化钛纳米尖结构能够通过改善钛表面的光捕获性能和抗反射效率,在近红外(NIR)光照射的辅助下产生良好的光热转换效率,因此,研究团队认为在钛表面构建二氧化钛纳米尖结构可以针对感染部位使用非侵入性的光热疗法来应对植入物感染。此外,将金属多酚网络修饰在钛表面,通过多酚和抗菌肽(AMP)之间的迈克尔加成/希夫碱反应,将其偶联在涂层表面,从而为钛植入物赋予抗菌能力和促成骨生物活性。Considering that pure titanium is biologically inert and does not have antibacterial and osteoinductive capabilities, the research team of the present invention intends to build various micro/nano structures on the titanium surface, such as: nanotubes, nanotips, nanopores, nanoleaf, etc., to improve Bioactivity of titanium implants. The titanium dioxide nanotip structure can not only simulate the natural extracellular matrix, promote fluid flow, promote molecular and cell transport, and stimulate osteogenic signals, promote better cell adhesion, migration, proliferation and differentiation, but also physically destroy bacterial membranes and leak the cell contents to kill bacteria, more importantly, the titanium dioxide nanotip structure can produce good photothermal conversion assisted by near-infrared (NIR) light irradiation by improving the light-harvesting performance and anti-reflection efficiency of the titanium surface Efficiency, therefore, the research team believes that the construction of titanium dioxide nanotip structures on the titanium surface can target the infection site using non-invasive photothermal therapy to deal with implant infection. In addition, the metal polyphenol network was modified on the titanium surface, and it was coupled on the coating surface through the Michael addition/Schiff base reaction between polyphenols and antimicrobial peptides (AMPs), thus conferring antibacterial properties to titanium implants. capacity and contribute to bone bioactivity.

综上,本发明研究团队通过构建光热疗法协同的多元方式,实现降低光热疗法的功率密度和缩短照射时间,同时赋予钛植入材料良好的抗菌促成骨性能和良好生物相容性。To sum up, the research team of the present invention realizes reducing the power density and shortening the irradiation time of photothermal therapy by constructing a synergistic multiple way of photothermal therapy, and at the same time endows titanium implant materials with good antibacterial and osteogenic properties and good biocompatibility.

本发明的优点是:The advantages of the present invention are:

1.本发明方法无需引入光热剂,通过在钛材表面原位构建二氧化钛纳米尖形貌的微/纳结构。该结构改善了钛材表面的光捕获性能和抗反射效率,使其在近红外(NIR)光照射的辅助下产生良好的光热转换效率,适用于光热疗法治疗。1. The method of the present invention does not need to introduce a photothermal agent, and builds a micro/nano structure of titanium dioxide nano-tip morphology on the surface of the titanium material in situ. This structure improves the light-harvesting performance and anti-reflection efficiency of the titanium surface, making it produce good photothermal conversion efficiency with the assistance of near-infrared (NIR) light irradiation, which is suitable for photothermal therapy treatment.

2.本发明方法通过植物多酚和金属离子的络合作用,形成了一层金属多酚网络MPN,该网络具有良好的粘附性,可以快速在TNS上成膜,且成本低廉,生物安全性好,反应时长短。2. The method of the present invention forms a layer of metal polyphenol network MPN through the complexation of plant polyphenols and metal ions. The network has good adhesion, can quickly form a film on TNS, and is low in cost and biologically safe. Good sex, short response time.

3.本发明中制备的TNS-MPN-AMP涂层,相比于纯钛,引入了丰富的生物活性基团如羟基、羧基和氨基等,可以更多的吸引体液中的磷酸盐和碳酸盐至涂层表面,促进体内羟基磷灰石(HAp)成核,进一步促进骨整合。3. Compared with pure titanium, the TNS-MPN-AMP coating prepared in the present invention introduces abundant biologically active groups such as hydroxyl, carboxyl and amino groups, which can attract more phosphate and carbonic acid in body fluids Salt to the surface of the coating promotes the nucleation of hydroxyapatite (HAp) in vivo and further promotes osseointegration.

4.本发明中,通过将物理穿刺/光热/化学三元协同抗菌作用整合到钛植入物表面,实现了高效的杀菌效果,其中,体外抗菌率超过99.99%,体内抗菌率超过95%。同时,相比于单一的光热疗法,能够降低所使用光源的功率激密度并缩短照射时间,在治疗时有效遏制对周围健康组织产生的副作用。4. In the present invention, by integrating physical puncture/photothermal/chemical ternary synergistic antibacterial effect on the surface of the titanium implant, a highly efficient bactericidal effect is achieved, wherein the antibacterial rate in vitro exceeds 99.99%, and the antibacterial rate in vivo exceeds 95% . At the same time, compared with single photothermal therapy, it can reduce the power intensity of the light source used and shorten the irradiation time, effectively curbing the side effects on surrounding healthy tissues during treatment.

5.本发明涂层的制备方法简单、高效、低成本且生物安全性高。5. The preparation method of the coating of the present invention is simple, efficient, low-cost and high in biological safety.

附图说明Description of drawings

图1是本发明通过实施例1所得TNS-MPN-AMP的制备流程示意图;Fig. 1 is a schematic diagram of the preparation process of the TNS-MPN-AMP obtained in Example 1 of the present invention;

图2是本发明实施例1使用的Ti,以及得到的TNS、TNS-MPN和TNS-MPN-AMP的FE-SEM图;Fig. 2 is the Ti used in Example 1 of the present invention, and the FE-SEM figure of TNS, TNS-MPN and TNS-MPN-AMP obtained;

图3是本发明实施例2使用的Ti,以及得到的TNS、TNS-MPN和TNS-MPN-AMP的WCA图;Fig. 3 is the Ti that the embodiment of the present invention 2 uses, and the WCA figure of TNS, TNS-MPN and TNS-MPN-AMP that obtains;

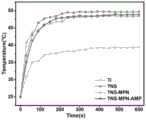

图4是本发明实施例3使用的Ti,以及得到的TNS、TNS-MPN和TNS-MPN-AMP的温度变化曲线;Fig. 4 is the Ti that the embodiment of the present invention 3 uses, and the temperature change curve of TNS, TNS-MPN and TNS-MPN-AMP that obtains;

图5是本发明实施例1使用的Ti,以及得到的TNS、TNS-MPN和TNS-MPN-AMP对于革兰氏阴性菌E.coli和革兰氏阳性菌S.aureus的杀菌涂板照片;Fig. 5 is the Ti used in Example 1 of the present invention, and the obtained TNS, TNS-MPN and TNS-MPN-AMP are for gram-negative bacterium E.coli and gram-positive bacterium S.aureus bactericidal plate photo;

图6是本发明实施例1得到的TNS-MPN-AMP表面MC3T3-E1成骨细胞形态的FE-SEM图像;Fig. 6 is the FE-SEM image of the MC3T3-E1 osteoblast morphology on the TNS-MPN-AMP surface obtained in Example 1 of the present invention;

图7是本发明实施例6使用的Ti,以及得到的TNS-MPN-AMP表面HAp的沉积情况。FIG. 7 shows Ti used in Example 6 of the present invention and the deposition of HAp on the surface of the obtained TNS-MPN-AMP.

具体实施方式Detailed ways

以下结合附图和具体实施例对本发明的内容作进一步的详细描述:Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

实施例1Example 1

一种钛改性材料的制备方法,制备流程示意图如图1所示,包括以下步骤:A preparation method of a titanium modified material, the preparation flow diagram is shown in Figure 1, comprising the following steps:

1)将纯钛材切割成1×1cm2的尺寸(也可以是其他需要的尺寸),并用粒度为#400、#800、#1200至#2000的SiC砂纸依次抛光至镜面光泽,用去离子水冲洗磨屑,然后依次用丙酮、乙醇、水进行超声清洗,去除表面的油污,烘干之后备用。1) Cut the pure titanium material into a size of 1×1cm2 (other required sizes are also available), and use SiC sandpaper with a particle size of #400, #800, #1200 to #2000 to polish it to a mirror luster in sequence, and use deionized Rinse the wear debris with water, then perform ultrasonic cleaning with acetone, ethanol, and water in sequence to remove the oil on the surface, and dry it for later use.

2)将预处理后的钛材放置在体积为30mL聚四氟乙烯衬里不锈钢高压釜反应器的底部,其中加入10mL摩尔浓度为1.5M的NaOH溶液;然后将密封的高压釜反应器置于300℃的电炉中反应3h;2) Place the pretreated titanium material at the bottom of a 30mL polytetrafluoroethylene-lined stainless steel autoclave reactor, add 10mL of NaOH solution with a molar concentration of 1.5M; then place the sealed autoclave reactor at 300 Reaction in electric furnace at ℃ for 3h;

3)待反应完成后,取出钛材,将其置于马弗炉中以10℃/min的升温速率,在400℃下退火3小时,得到表面具有二氧化钛纳米尖阵列的钛材,记为TNS样品;3) After the reaction is completed, take out the titanium material, place it in a muffle furnace at a heating rate of 10 °C/min, and anneal at 400 °C for 3 hours to obtain a titanium material with a titanium dioxide nanotip array on the surface, which is denoted as TNS sample;

4)取50mL离心管,将TNS样品置于离心管底部,然后加入10mL单宁酸(0.4mg mL-1)溶液和10mL ZnSO4(0.2mg mL-1)溶液,用摩尔浓度为1M的NaOH溶液将混合溶液的pH逐渐调节至7.4,涡旋60s,得到具有组装金属多酚纳米膜的二氧化钛纳米尖阵列的钛材,记为TNS-MPN样品;4) Take a 50mL centrifuge tube, place the TNS sample at the bottom of the centrifuge tube, then add 10mL tannic acid (0.4mg mL-1 ) solution and 10mL ZnSO4 (0.2mg mL-1 ) solution, and use 1M NaOH Solution The pH of the mixed solution was gradually adjusted to 7.4, vortexed for 60s, and a titanium material with a titanium dioxide nanotip array assembled with a metal polyphenol nanofilm was obtained, which was recorded as a TNS-MPN sample;

5)将抗菌肽LL-37溶解在Tris-HCl溶液(pH=8.5,10mM)中,得到0.02g mL-1的浓度;将TNS-MPN样品浸没在10mL上述溶液中置于摇床上在室温下反应12小时。随后,取出样品,用DI水冲洗1分钟,并在室温下干燥,获得具有多功能涂层的钛材,记为TNS-MPN-AMP样品。5) Dissolve the antimicrobial peptide LL-37 in Tris-HCl solution (pH=8.5, 10mM) to obtain a concentration of 0.02g mL-1 ; submerge the TNS-MPN sample in 10mL of the above solution and place it on a shaker at room temperature React for 12 hours. Subsequently, the sample was taken out, rinsed with DI water for 1 minute, and dried at room temperature to obtain a titanium material with a multifunctional coating, which was designated as a TNS-MPN-AMP sample.

利用FE-SEM对钛片表面的形态结构进行了表征。首先将本实施中制得的样品粘贴在导电胶带上,然后喷金50s拍摄成像,结果见图2。由图2可见,TNS、TNS-MPN和TNS-MPN-AMP样品表面均呈现典型的纳米尖结构。The morphological structure of the titanium sheet surface was characterized by FE-SEM. First, paste the sample prepared in this implementation on the conductive tape, and then spray gold for 50 seconds to take an image, and the results are shown in Figure 2. It can be seen from Figure 2 that the surfaces of TNS, TNS-MPN and TNS-MPN-AMP samples all present typical nano-tip structures.

实施例2Example 2

与实施例1的区别在于:The difference with embodiment 1 is:

2)将预处理后的钛材放置在体积为30mL聚四氟乙烯衬里不锈钢高压釜反应器的底部,其中加入10mL摩尔浓度为1M的NaOH溶液;然后将密封的高压釜反应器置于150℃的电炉中反应5h;2) Place the pretreated titanium material at the bottom of a PTFE-lined stainless steel autoclave reactor with a volume of 30mL, and add 10mL of NaOH solution with a molar concentration of 1M; then place the sealed autoclave reactor at 150°C React in an electric furnace for 5h;

3)待反应完成后,取出钛材,将其置于马弗炉中以10℃/min的升温速率,在600℃下退火1小时,得到表面具有二氧化钛纳米尖阵列的钛材,记为TNS样品;3) After the reaction is completed, take out the titanium material, place it in a muffle furnace at a heating rate of 10 °C/min, and anneal at 600 °C for 1 hour to obtain a titanium material with a titanium dioxide nanotip array on the surface, which is denoted as TNS sample;

4)取50mL离心管,将TNS在置于离心管底部,然后加入10mL单宁酸(0.4mg mL-1)溶液和10mL CuSO4(0.2mg mL-1)溶液,用摩尔浓度为0.5M的NaOH溶液将混合溶液的pH逐渐调节至7.4,涡旋60s,得到具有组装金属多酚纳米膜的二氧化钛纳米尖阵列的钛材,记为TNS-MPN样品;4) Take a 50mL centrifuge tube, place TNS at the bottom of the centrifuge tube, then add 10mL tannic acid (0.4mg mL-1 ) solution and 10mL CuSO4 (0.2mg mL-1 ) solution, and use 0.5M molar concentration NaOH solution gradually adjusted the pH of the mixed solution to 7.4, vortexed for 60s, and obtained a titanium material with a titanium dioxide nanotip array assembled with a metal polyphenol nanofilm, which was recorded as a TNS-MPN sample;

5)将抗菌肽LL-37溶解在Tris-HCl溶液(pH=8.5,10mM)中,得到0.02g mL-1的浓度;将TNS-MPN样品浸没在10mL上述溶液中置于摇床上在室温下氧化反应6小时。随后,取出样品,用DI水冲洗1分钟,并在室温下干燥,获得具有多功能涂层的钛材,记为TNS-MPN-AMP样品。5) Dissolve the antimicrobial peptide LL-37 in Tris-HCl solution (pH=8.5, 10mM) to obtain a concentration of 0.02g mL-1 ; submerge the TNS-MPN sample in 10mL of the above solution and place it on a shaker at room temperature Oxidation reaction for 6 hours. Subsequently, the sample was taken out, rinsed with DI water for 1 minute, and dried at room temperature to obtain a titanium material with a multifunctional coating, which was designated as a TNS-MPN-AMP sample.

利用接触角测量仪表征了涂层的接触角的变化过程。选用座滴法,将去离子水缓慢吸入水相针管中,接着把针管端口的液滴转移到待测样品表面,确定液滴的基线,完成液滴的转移,读取并记录测量的接触角。图3结果显示:制备的纳米尖结构接触角相比于纯钛,明显减小,同时,随着MPN和AMP的组装和沉积,材料表面接触角进一步增加,但仍然保持了材料表面的亲水性。The change process of the coating's contact angle was characterized by a contact angle measuring instrument. Select the sessile drop method, slowly inhale deionized water into the aqueous needle tube, then transfer the droplet at the needle port to the surface of the sample to be tested, determine the baseline of the droplet, complete the transfer of the droplet, read and record the measured contact angle . The results in Figure 3 show that the contact angle of the prepared nano-tip structure is significantly reduced compared with that of pure titanium. At the same time, with the assembly and deposition of MPN and AMP, the contact angle of the material surface further increases, but the hydrophilicity of the material surface is still maintained. sex.

实施例3Example 3

与实施例1的区别在于:The difference with embodiment 1 is:

2)将预处理后的钛材放置在体积为30mL聚四氟乙烯衬里不锈钢高压釜反应器的底部,其中加入10mL摩尔浓度为0.5M的NaOH溶液;然后将密封的高压釜反应器置于220℃的电炉中反应4h;2) Place the pretreated titanium material at the bottom of a 30mL polytetrafluoroethylene-lined stainless steel autoclave reactor, add 10mL of NaOH solution with a molar concentration of 0.5M; then place the sealed autoclave reactor at 220 Reaction in electric furnace at ℃ for 4h;

3)待反应完成后,取出钛材,将其置于马弗炉中以10℃/min的升温速率,在550℃下退火2小时,得到表面具有二氧化钛纳米尖阵列的钛材,记为TNS样品;3) After the reaction is completed, take out the titanium material, place it in a muffle furnace at a heating rate of 10 °C/min, and anneal at 550 °C for 2 hours to obtain a titanium material with a titanium dioxide nanotip array on the surface, which is denoted as TNS sample;

4)取50mL离心管,将TNS样品置于离心管底部,然后加入10mL儿茶酚(0.4mg mL-1)溶液和10mL AlCl3(0.2mg mL-1)溶液,用摩尔浓度为1.5M的NaOH溶液将混合溶液的pH逐渐调节至7.4,涡旋60s,得到具有组装金属多酚纳米膜的二氧化钛纳米尖阵列的钛材,记为TNS-MPN样品;4) Take a 50mL centrifuge tube, place the TNS sample at the bottom of the centrifuge tube, then add 10mL catechol (0.4mg mL-1 ) solution and 10mL AlCl3 (0.2mg mL-1 ) solution, and use 1.5M molar concentration NaOH solution gradually adjusted the pH of the mixed solution to 7.4, vortexed for 60s, and obtained a titanium material with a titanium dioxide nanotip array assembled with a metal polyphenol nanofilm, which was recorded as a TNS-MPN sample;

5)将抗菌肽LL-37溶解在Tris-HCl溶液(pH=8.5,10mM)中,得到0.02g mL-1的浓度;将TNS-MPN样品浸没在10mL上述溶液中置于摇床上在室温下氧化反应12小时。随后,取出样品,用DI水冲洗1分钟,并在室温下干燥,获得具有多功能涂层的钛材,记为TNS-MPN-AMP样品。5) Dissolve the antimicrobial peptide LL-37 in Tris-HCl solution (pH=8.5, 10mM) to obtain a concentration of 0.02g mL-1 ; submerge the TNS-MPN sample in 10mL of the above solution and place it on a shaker at room temperature Oxidation reaction for 12 hours. Subsequently, the sample was taken out, rinsed with DI water for 1 minute, and dried at room temperature to obtain a titanium material with a multifunctional coating, which was designated as a TNS-MPN-AMP sample.

利用808nm近红外激光器和热红外成像仪记录了在近红外光照射下,材料的光热升温曲线。图4结果显示:制备的纳米尖结构相比于纯钛,具有良好的光热作用,Ti的温度从25.0℃升高至39.4℃,而TNS的温度从25.0℃显著升高至49.7℃,同时,从图中也可以看出,随着MPN和AMP的组装和沉积,材料仍然保持了其良好光热转换效率。Using 808nm near-infrared laser and thermal infrared imager to record the photothermal heating curve of the material under near-infrared light irradiation. The results in Figure 4 show that compared with pure titanium, the prepared nanotip structure has good photothermal effect, the temperature of Ti increases from 25.0 °C to 39.4 °C, and the temperature of TNS increases significantly from 25.0 °C to 49.7 °C, while , it can also be seen from the figure that with the assembly and deposition of MPN and AMP, the material still maintains its good light-to-heat conversion efficiency.

实施例4Example 4

与实施例1的区别在于:The difference with embodiment 1 is:

4)取50mL离心管,将TNS样品置于离心管底部,然后加入10mL单宁酸(0.4mg mL-1)溶液和10mL FeCl3(0.2mg mL-1)溶液,用摩尔浓度为1M的NaOH溶液将混合溶液的pH逐渐调节至7.4,涡旋60s,得到具有组装金属多酚纳米膜的二氧化钛纳米尖阵列的钛材,记为TNS-MPN样品;4) Take a 50mL centrifuge tube, place the TNS sample at the bottom of the centrifuge tube, then add 10mL tannic acid (0.4mg mL-1 ) solution and 10mL FeCl3 (0.2mg mL-1 ) solution, and use 1M NaOH Solution The pH of the mixed solution was gradually adjusted to 7.4, vortexed for 60s, and a titanium material with a titanium dioxide nanotip array assembled with a metal polyphenol nanofilm was obtained, which was recorded as a TNS-MPN sample;

5)将抗菌肽ε-多聚赖氨酸溶解在Tris-HCl溶液(pH=8.5,10mM)中,得到0.02gmL-1的浓度;将TNS-MPN样品浸没在10mL上述溶液中置于摇床上在室温下氧化反应12小时。随后,取出样品,用DI水冲洗1分钟,并在室温下干燥,获得具有多功能涂层的钛材,记为TNS-MPN-AMP样品。5) Dissolve the antimicrobial peptide ε-polylysine in Tris-HCl solution (pH=8.5, 10mM) to obtain a concentration of 0.02gmL-1 ; immerse the TNS-MPN sample in 10mL of the above solution and place it on a shaker The oxidation reaction was carried out at room temperature for 12 hours. Subsequently, the sample was taken out, rinsed with DI water for 1 minute, and dried at room temperature to obtain a titanium material with a multifunctional coating, which was designated as a TNS-MPN-AMP sample.

实施例5Example 5

与实施例1的区别在于:The difference with embodiment 1 is:

4)取50mL离心管,将TNS样品置于离心管底部,然后加入10mL焦棓酸(0.4mg mL-1)溶液和10mL FeCl3(0.2mg mL-1)溶液,用摩尔浓度为0.5M的NaOH溶液将混合溶液的pH逐渐调节至7.4,涡旋60s,得到具有组装金属多酚纳米膜的二氧化钛纳米尖阵列的钛材,记为TNS-MPN样品;4) Take a 50mL centrifuge tube, place the TNS sample at the bottom of the centrifuge tube, then add 10mL pyrogallic acid (0.4mg mL-1 ) solution and 10mL FeCl3 (0.2mg mL-1 ) solution, and use 0.5M molar concentration NaOH solution gradually adjusted the pH of the mixed solution to 7.4, vortexed for 60s, and obtained a titanium material with a titanium dioxide nanotip array assembled with a metal polyphenol nanofilm, which was recorded as a TNS-MPN sample;

5)将抗菌肽乳酸链球菌素溶解在Tris-HCl溶液(pH=8.5,10mM)中,得到0.02gmL-1的浓度;将TNS-MPN样品浸没在10mL上述溶液中置于摇床上在室温下氧化反应12小时。随后,取出样品,用DI水冲洗1分钟,并在室温下干燥,获得具有多功能涂层的钛材,记为TNS-MPN-AMP样品。5) Dissolve the antimicrobial peptide nisin in Tris-HCl solution (pH=8.5, 10mM) to obtain a concentration of 0.02gmL-1 ; immerse the TNS-MPN sample in 10mL of the above solution and place it on a shaker at room temperature Oxidation reaction for 12 hours. Subsequently, the sample was taken out, rinsed with DI water for 1 minute, and dried at room temperature to obtain a titanium material with a multifunctional coating, which was designated as a TNS-MPN-AMP sample.

实施例6Example 6

与实施例1的区别在于:The difference with embodiment 1 is:

4)取50mL离心管,将TNS在置于离心管底部,然后加入10mL没食子酸(0.4mg mL-1)溶液和10mL ZnSO4(0.2mg mL-1)溶液,用摩尔浓度为1M的NaOH溶液将混合溶液的pH逐渐调节至7.4,涡旋60s,得到具有组装金属多酚纳米膜的二氧化钛纳米尖阵列的钛材,记为TNS-MPN样品;4) Take a 50mL centrifuge tube, place TNS at the bottom of the centrifuge tube, then add 10mL gallic acid (0.4mg mL-1 ) solution and 10mL ZnSO4 (0.2mg mL-1 ) solution, and use 1M NaOH solution The pH of the mixed solution was gradually adjusted to 7.4, and vortexed for 60s to obtain a titanium material with a titanium dioxide nanotip array assembled with a metal polyphenol nanofilm, which was designated as a TNS-MPN sample;

5)将抗菌肽ε-多聚赖氨酸溶解在Tris-HCl溶液(pH=8.5,10mM)中,得到0.02gmL-1的浓度;将TNS-MPN样品浸没在10mL上述溶液中置于摇床上在室温下氧化反应8小时。随后,取出样品,用DI水冲洗1分钟,并在室温下干燥,获得具有多功能涂层的钛材,记为TNS-MPN-AMP样品。5) Dissolve the antimicrobial peptide ε-polylysine in Tris-HCl solution (pH=8.5, 10mM) to obtain a concentration of 0.02gmL-1 ; immerse the TNS-MPN sample in 10mL of the above solution and place it on a shaker The oxidation reaction was carried out at room temperature for 8 hours. Subsequently, the sample was taken out, rinsed with DI water for 1 minute, and dried at room temperature to obtain a titanium material with a multifunctional coating, which was designated as a TNS-MPN-AMP sample.

为了验证本发明所制备的多功能涂层的效果,本发明对实施例1制备的TNS-MPN-AMP涂层进行了抗菌性能、细胞相容性的测试,对实施例6制备的TNS-MPN-AMP涂层进行了促进骨传导性能的测试,具体实验如下:In order to verify the effect of the multifunctional coating prepared by the present invention, the present invention has carried out antibacterial property, cytocompatibility test to the TNS-MPN-AMP coating prepared in embodiment 1, to the TNS-MPN prepared in embodiment 6 -AMP coating was tested to promote bone conduction performance, the specific experiment is as follows:

A.通过测试验证实施例1中材料的杀菌性能:A. verify the bactericidal performance of material in embodiment 1 by test:

所有制备好的样品都提前灭菌,从细菌培养板中挑选革兰氏阴性菌E.coli和革兰氏阳性菌S.aureus的单个菌落,并在LB培养基中培养4-6小时,直到细菌种群生长到对数中期(600nm处的光密度达到0.5)。然后,将1×107CFU mL-1的菌液滴加至实施例1中所制备的样品表面,并在37℃细菌培养箱中共孵育45min,其中,对TNS-MPN-AMP+NIR组样品进行808nm的光照2min,随后,将980μL无菌PBS加入孔中,超声分离附着在每个样品上的细菌,然后将含有样品的每个孔中的100μL细菌悬浮液用L型铺布器铺在固体LB琼脂平板上,并在37℃下培养过夜以进行拍照。图5结果显示:Ti对金黄色葡萄球菌和大肠杆菌的平均抗菌率为0%,TNS为24.07%和45.56%,TNS-MPN为9.64%和35.03%,TNS-MPN-AMP为91.79%和92.80%,TNS-MPN-AMP+NIR均超过99.99%。因此证明了所制备的涂层具有良好的三元协同抗感染作用。All prepared samples were sterilized in advance, and single colonies of Gram-negative bacteria E.coli and Gram-positive bacteria S.aureus were picked from bacterial culture plates and cultured in LB medium for 4-6 hours until Bacterial populations were grown to mid-log phase (optical density at 600 nm reached 0.5). Then, 1×107 CFU mL-1 of the bacterial solution was added dropwise to the surface of the sample prepared in Example 1, and co-incubated in a 37°C bacterial incubator for 45min, wherein, for the TNS-MPN-AMP+NIR group samples Light at 808 nm for 2 min, and then add 980 μL of sterile PBS to the wells, ultrasonically separate the bacteria attached to each sample, and then spread 100 μL of the bacterial suspension in each well containing the samples on the surface with an L-shaped spreader. solid LB agar plates and cultured overnight at 37°C for photographing. The results in Figure 5 show that the average antibacterial rate of Ti to Staphylococcus aureus and Escherichia coli is 0%, TNS is 24.07% and 45.56%, TNS-MPN is 9.64% and 35.03%, TNS-MPN-AMP is 91.79% and 92.80 %, TNS-MPN-AMP+NIR are all over 99.99%. Therefore, it is proved that the prepared coating has good ternary synergistic anti-infection effect.

B.通过测试验证实施例1中材料的细胞相容性:B. verify the cytocompatibility of the material in embodiment 1 by testing:

用含有α-MEM、FBS和双抗的培养基培养MC3T3-E1细胞,之后将TNS-MPN-AMP样品与8×103个细胞共孵育。在37℃、5%CO2的湿润环境中培养24h,之后用4%多聚甲醛固定细胞,用梯度乙醇溶液脱水,喷金后用FE-SEM观察。如图6所示,MC3T3-E1细胞呈现纺锤状形态,处于良好的粘附状态。证明了涂层良好的细胞相容性,有利于后续的增殖、迁移和分化。MC3T3-E1 cells were cultured with medium containing α-MEM, FBS and double antibodies, and then TNS-MPN-AMP samples were co-incubated with 8×103 cells. Cultured at 37°C and 5% CO2 in a humid environment for 24 hours, then fixed the cells with 4% paraformaldehyde, dehydrated with gradient ethanol solution, sprayed gold and observed with FE-SEM. As shown in Figure 6, MC3T3-E1 cells present a spindle-like morphology and are in a good adhesion state. The good cytocompatibility of the coating is proved, which is beneficial to the subsequent proliferation, migration and differentiation.

C.通过测试验证实施例6中材料的骨传导性能:C. verify the bone conduction performance of the material in embodiment 6 by testing:

将Ti和TNS-MPN-AMP样品浸入pH值为7.4的模拟体液(SBF)中,并在37℃下保持14天以诱导磷灰石生长,每隔一天换新的SBF。如图7中的FE-SEM图像所示,TNS-MPN-AMP表面上形成了羟基磷灰石层。Ti and TNS-MPN-AMP samples were immersed in simulated body fluid (SBF) with a pH value of 7.4 and kept at 37 °C for 14 days to induce apatite growth, and replaced with new SBF every other day. As shown in the FE-SEM images in Fig. 7, a layer of hydroxyapatite was formed on the surface of TNS-MPN-AMP.

实施例7Example 7

与实施例1的区别在于:The difference with embodiment 1 is:

4)取50mL离心管,将TNS在置于离心管底部,然后加入10mL儿茶酚(0.7mg mL-1)溶液和10mL ZnSO4(0.5mg mL-1)溶液,用摩尔浓度为1.5M的NaOH溶液将混合溶液的pH逐渐调节至7.4,涡旋90s,得到具有组装金属多酚纳米膜的二氧化钛纳米尖阵列的钛材,记为TNS-MPN样品;4) Take a 50mL centrifuge tube, place TNS at the bottom of the centrifuge tube, then add 10mL catechol (0.7mg mL-1 ) solution and 10mL ZnSO4 (0.5mg mL-1 ) solution, and use 1.5M molar concentration NaOH solution gradually adjusted the pH of the mixed solution to 7.4, vortexed for 90s, and obtained a titanium material with a titanium dioxide nanotip array assembled with a metal polyphenol nanofilm, which was recorded as a TNS-MPN sample;

5)将抗菌肽ε-多聚赖氨酸溶解在Tris-HCl溶液(pH=8.5,10mM)中,得到0.01gmL-1的浓度;将TNS-MPN样品浸没在10mL上述溶液中置于摇床上在室温下氧化反应8小时。随后,取出样品,用DI水冲洗1分钟,并在室温下干燥,获得具有多功能涂层的钛材,记为TNS-MPN-AMP样品。5) Dissolve the antimicrobial peptide ε-polylysine in Tris-HCl solution (pH=8.5, 10mM) to obtain a concentration of 0.01gmL-1 ; immerse the TNS-MPN sample in 10mL of the above solution and place it on a shaker The oxidation reaction was carried out at room temperature for 8 hours. Subsequently, the sample was taken out, rinsed with DI water for 1 minute, and dried at room temperature to obtain a titanium material with a multifunctional coating, which was designated as a TNS-MPN-AMP sample.

实施例8Example 8

与实施例1的区别在于:The difference with embodiment 1 is:

4)取50mL离心管,将TNS在置于离心管底部,然后加入10mL焦棓酸(0.1mg mL-1)溶液和10mL CuSO4(0.3mg mL-1)溶液,用摩尔浓度为1.5M的NaOH溶液将混合溶液的pH逐渐调节至7.4,涡旋90s,得到具有组装金属多酚纳米膜的二氧化钛纳米尖阵列的钛材,记为TNS-MPN样品;4) Take a 50mL centrifuge tube, place TNS at the bottom of the centrifuge tube, then add 10mL pyrogallic acid (0.1mg mL-1 ) solution and 10mL CuSO4 (0.3mg mL-1 ) solution, and use 1.5M molar concentration NaOH solution gradually adjusted the pH of the mixed solution to 7.4, vortexed for 90s, and obtained a titanium material with a titanium dioxide nanotip array assembled with a metal polyphenol nanofilm, which was recorded as a TNS-MPN sample;

5)将抗菌肽爪蟾素溶解在Tris-HCl溶液(pH=8.5,10mM)中,得到0.03g mL-1的浓度;将TNS-MPN样品浸没在10mL上述溶液中置于摇床上在室温下氧化反应10小时。随后,取出样品,用DI水冲洗1分钟,并在室温下干燥,获得具有多功能涂层的钛材,记为TNS-MPN-AMP样品。5) Dissolve the antibacterial peptide magainin in Tris-HCl solution (pH=8.5, 10mM) to obtain a concentration of 0.03g mL-1 ; immerse the TNS-MPN sample in 10mL of the above solution and place it on a shaker at room temperature Oxidation reaction for 10 hours. Subsequently, the sample was taken out, rinsed with DI water for 1 minute, and dried at room temperature to obtain a titanium material with a multifunctional coating, which was designated as a TNS-MPN-AMP sample.

综上,本发明通过二氧化钛纳米尖(TNS)、金属多酚网络(MPN)和抗菌肽(AMP)的复合,构建了一种金属多酚网络偶联抗菌肽的多功能钛植入物涂层,实现了物理穿刺/光热/化学抗菌能力的结合,并通过促进羟基磷灰石的沉积增强了涂层的骨传导性,具有很好的应用前景。In summary, the present invention constructs a metal polyphenol network coupled antimicrobial peptide multifunctional titanium implant coating by combining titanium dioxide nano-tips (TNS), metal polyphenol network (MPN) and antimicrobial peptide (AMP) , realize the combination of physical puncture/photothermal/chemical antibacterial ability, and enhance the osteoconductivity of the coating by promoting the deposition of hydroxyapatite, which has a good application prospect.

以上所述,仅为本发明的具体实施方式,但本发明的保护范围并不局限于此,任何熟悉本技术领域的技术人员在本发明公开的技术范围内,可轻易想到各种等效的修改或替换,这些修改或替换都应涵盖在本发明的保护范围之内。The above is only a specific embodiment of the present invention, but the protection scope of the present invention is not limited thereto. Any person familiar with the technical field can easily think of various equivalents within the technical scope disclosed by the present invention. Modifications or replacements shall all fall within the protection scope of the present invention.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211610012.7ACN115957385B (en) | 2022-12-12 | 2022-12-12 | Preparation method and application of multifunctional coating of metal polyphenol network coupled antibacterial peptide |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211610012.7ACN115957385B (en) | 2022-12-12 | 2022-12-12 | Preparation method and application of multifunctional coating of metal polyphenol network coupled antibacterial peptide |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN115957385Atrue CN115957385A (en) | 2023-04-14 |

| CN115957385B CN115957385B (en) | 2024-09-17 |

Family

ID=87353669

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211610012.7AActiveCN115957385B (en) | 2022-12-12 | 2022-12-12 | Preparation method and application of multifunctional coating of metal polyphenol network coupled antibacterial peptide |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115957385B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117820905A (en)* | 2023-11-16 | 2024-04-05 | 四川农业大学 | Preparation method of fruit and vegetable and fruit and vegetable seed photo-thermal coating material |

Citations (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060019028A1 (en)* | 2004-07-22 | 2006-01-26 | Yeung King L | Novel TiO2 material and the coating methods thereof |

| JP2006131583A (en)* | 2004-11-09 | 2006-05-25 | Marukatsu Sangyo Kk | Antibacterial property imparting agent |

| US20090093881A1 (en)* | 2007-10-05 | 2009-04-09 | Washington State University | Modified metal materials, surface modifications to improve cell interactions and antimicrobial properties, and methods for modifying metal surface properties |

| US20110125263A1 (en)* | 2007-08-24 | 2011-05-26 | Brown University | Method for producing nanostructures on a surface of a medical implant |

| CN102719824A (en)* | 2012-06-12 | 2012-10-10 | 天津大学 | Dopamine-nanosilver composite coating and preparation method thereof |

| CN104194460A (en)* | 2014-08-12 | 2014-12-10 | 西南交通大学 | Preparation method of chelate coating with copper ions capable of controllably catalyzing release of nitrogen monoxide and polyphenol complex |

| CN106512091A (en)* | 2016-12-23 | 2017-03-22 | 大连三生科技发展有限公司 | Preparation method for antimicrobial peptide formula for dental implant |

| CN106770216A (en)* | 2017-02-20 | 2017-05-31 | 济南大学 | A kind of bionics method for preparation in situ of composite titanium dioxide nano material and application |

| CN107022782A (en)* | 2017-03-22 | 2017-08-08 | 浙江科惠医疗器械股份有限公司 | A kind of preparation method of the titania nanotube structure coating with biocompatibility and anti-microbial property |

| CN107115559A (en)* | 2017-05-10 | 2017-09-01 | 厦门大学 | The method for preparing nanometer silver antimicrobial coating on medical metal surface |

| CN108310471A (en)* | 2018-01-04 | 2018-07-24 | 重庆大学 | A kind of good enzyme response antibacterial titanium preparation method of biocompatibility |

| CN108434524A (en)* | 2018-02-06 | 2018-08-24 | 重庆大学 | A kind of antibacterial titanium preparation method with good biocompatibility of surface argentiferous |

| CN110465211A (en)* | 2019-08-23 | 2019-11-19 | 哈尔滨工业大学 | A polyphenol functionalized composite membrane with a "sandwich" sandwich structure separation layer and its preparation method |

| CN111068525A (en)* | 2019-12-11 | 2020-04-28 | 天津科技大学 | Composite membrane with titanium dioxide nanorod array on surface, and preparation method and application thereof |

| CN111110916A (en)* | 2020-01-09 | 2020-05-08 | 西北工业大学 | 3D printing porous titanium surface antibacterial and osteogenesis promoting controllable drug release system and preparation method |

| WO2021008092A1 (en)* | 2019-07-17 | 2021-01-21 | 湖北大学 | Method for preparing near-infrared responsive functional coating on surface of cylindrical titanium nail and application |

| CN113057177A (en)* | 2021-03-31 | 2021-07-02 | 乐山师范学院 | A kind of preparation method of nanometer modified titanium dioxide-chitosan-curcumin antibacterial complex |

| CN114366852A (en)* | 2022-01-13 | 2022-04-19 | 山东大学 | A kind of nano-coating of implanted device and its preparation method and application |

| KR20220052233A (en)* | 2020-10-20 | 2022-04-27 | 재단법인대구경북과학기술원 | Antibacterial nano-coating composition containing caffeine-removed green tea extract, preparation method thereof, and coating method using same |

| CN114908314A (en)* | 2022-05-16 | 2022-08-16 | 浙江飞剑工贸有限公司 | Antibacterial coating capable of releasing metal ions in micro-scale and preparation method thereof |

| US20240001006A1 (en)* | 2022-06-30 | 2024-01-04 | Medos International Sarl | Biomedical Implant Having Conical-Tipped Titania Nanorods |

- 2022

- 2022-12-12CNCN202211610012.7Apatent/CN115957385B/enactiveActive

Patent Citations (21)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20060019028A1 (en)* | 2004-07-22 | 2006-01-26 | Yeung King L | Novel TiO2 material and the coating methods thereof |

| JP2006131583A (en)* | 2004-11-09 | 2006-05-25 | Marukatsu Sangyo Kk | Antibacterial property imparting agent |

| US20110125263A1 (en)* | 2007-08-24 | 2011-05-26 | Brown University | Method for producing nanostructures on a surface of a medical implant |

| US20090093881A1 (en)* | 2007-10-05 | 2009-04-09 | Washington State University | Modified metal materials, surface modifications to improve cell interactions and antimicrobial properties, and methods for modifying metal surface properties |

| CN102719824A (en)* | 2012-06-12 | 2012-10-10 | 天津大学 | Dopamine-nanosilver composite coating and preparation method thereof |

| CN104194460A (en)* | 2014-08-12 | 2014-12-10 | 西南交通大学 | Preparation method of chelate coating with copper ions capable of controllably catalyzing release of nitrogen monoxide and polyphenol complex |

| CN106512091A (en)* | 2016-12-23 | 2017-03-22 | 大连三生科技发展有限公司 | Preparation method for antimicrobial peptide formula for dental implant |

| CN106770216A (en)* | 2017-02-20 | 2017-05-31 | 济南大学 | A kind of bionics method for preparation in situ of composite titanium dioxide nano material and application |

| CN107022782A (en)* | 2017-03-22 | 2017-08-08 | 浙江科惠医疗器械股份有限公司 | A kind of preparation method of the titania nanotube structure coating with biocompatibility and anti-microbial property |

| CN107115559A (en)* | 2017-05-10 | 2017-09-01 | 厦门大学 | The method for preparing nanometer silver antimicrobial coating on medical metal surface |

| CN108310471A (en)* | 2018-01-04 | 2018-07-24 | 重庆大学 | A kind of good enzyme response antibacterial titanium preparation method of biocompatibility |

| CN108434524A (en)* | 2018-02-06 | 2018-08-24 | 重庆大学 | A kind of antibacterial titanium preparation method with good biocompatibility of surface argentiferous |

| WO2021008092A1 (en)* | 2019-07-17 | 2021-01-21 | 湖北大学 | Method for preparing near-infrared responsive functional coating on surface of cylindrical titanium nail and application |

| CN110465211A (en)* | 2019-08-23 | 2019-11-19 | 哈尔滨工业大学 | A polyphenol functionalized composite membrane with a "sandwich" sandwich structure separation layer and its preparation method |

| CN111068525A (en)* | 2019-12-11 | 2020-04-28 | 天津科技大学 | Composite membrane with titanium dioxide nanorod array on surface, and preparation method and application thereof |

| CN111110916A (en)* | 2020-01-09 | 2020-05-08 | 西北工业大学 | 3D printing porous titanium surface antibacterial and osteogenesis promoting controllable drug release system and preparation method |

| KR20220052233A (en)* | 2020-10-20 | 2022-04-27 | 재단법인대구경북과학기술원 | Antibacterial nano-coating composition containing caffeine-removed green tea extract, preparation method thereof, and coating method using same |

| CN113057177A (en)* | 2021-03-31 | 2021-07-02 | 乐山师范学院 | A kind of preparation method of nanometer modified titanium dioxide-chitosan-curcumin antibacterial complex |

| CN114366852A (en)* | 2022-01-13 | 2022-04-19 | 山东大学 | A kind of nano-coating of implanted device and its preparation method and application |

| CN114908314A (en)* | 2022-05-16 | 2022-08-16 | 浙江飞剑工贸有限公司 | Antibacterial coating capable of releasing metal ions in micro-scale and preparation method thereof |

| US20240001006A1 (en)* | 2022-06-30 | 2024-01-04 | Medos International Sarl | Biomedical Implant Having Conical-Tipped Titania Nanorods |

Non-Patent Citations (4)

| Title |

|---|

| JINGJING HUO ET AL: "Metal-Phenolic Networks Assembled on TiO2 Nanospikes for Antimicrobial Peptide Deposition and Osteoconductivity Enhancement in Orthopedic Applications", AMERICAN CHEMICAL SOCIETY, 13 January 2023 (2023-01-13), pages 1238* |

| QIANG GAO ET AL: "Antibacterial and hydroxyapatite-forming coating for biomedical implants based on polypeptidefunctionalized titania nanospikes", THE ROYAL SOCIETY OF CHEMISTRY, 16 October 2019 (2019-10-16), pages 278* |

| YUE LI ET AL: "Recent Advances in the Development and Antimicrobial Applications of Metal–Phenolic Networks", ADVANCED SCIENCE, 25 July 2022 (2022-07-25), pages 1 - 22* |

| 黄建洪: "以纳米TiO2为载体的银抗菌整理剂制备与应用", 印染, 1 June 2006 (2006-06-01), pages 35 - 37* |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117820905A (en)* | 2023-11-16 | 2024-04-05 | 四川农业大学 | Preparation method of fruit and vegetable and fruit and vegetable seed photo-thermal coating material |

Also Published As

| Publication number | Publication date |

|---|---|

| CN115957385B (en) | 2024-09-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Wang et al. | Two-dimensional nanocoating-enabled orthopedic implants for bimodal therapeutic applications | |

| Li et al. | Near-infrared light triggered phototherapy and immunotherapy for elimination of methicillin-resistant Staphylococcus aureus biofilm infection on bone implant | |

| CN102677125B (en) | Preparation method of active antibacterial composite coating on surface of titanium and titanium alloy medical instrument | |

| CN103463675B (en) | Antibacterial and antitumor orthopaedic implantation material and preparation method thereof | |

| CN101511399B (en) | Bioimplant | |

| CN113181431B (en) | Antibacterial and osseointegrated coating formed on substrate surface and method for preparing antibacterial and osseointegrated coating on substrate surface | |

| CN108853604B (en) | A method for rapidly eliminating bacterial biofilms on the surface of bone implants using near-infrared | |

| CN107096068A (en) | A kind of preparation method of dentistry implant and its bioactivity antimicrobial surface | |

| CN102758202A (en) | Method for preparing biomedical titanium and titanium alloy surface antibacterial coatings | |

| KR101461159B1 (en) | Preparation method of implant comprising drug delivery layer and implant compostion for living donor transplantation comprising the same | |

| CN107661544B (en) | Antibacterial and osteopromoting composite functional porous orthopedic implant and preparation method thereof | |

| CN107693843B (en) | Surface modification method of biomedical active titanium and its alloy implant materials | |

| Zhang et al. | Near‐infrared light‐triggered therapy to combat bacterial biofilm infections by MoSe2/TiO2 nanorod arrays on bone implants | |

| Tang et al. | Photoelectrons sequentially regulate antibacterial activity and osseointegration of titanium implants | |

| CN113018507B (en) | Antibacterial hydrogel with photo-thermal performance and preparation method and application thereof | |

| CN105617460A (en) | Method for preparing nontoxic antibacterial coating on surface of medical implant material | |

| Huo et al. | Metal-phenolic networks assembled on TiO2 nanospikes for antimicrobial peptide deposition and osteoconductivity enhancement in orthopedic applications | |

| Ding et al. | Surface modification of titanium implants with micro–nano-topography and NIR photothermal property for treating bacterial infection and promoting osseointegration | |

| CN108355165A (en) | A kind of HA/MoS in titanium alloy surface with photocatalytic activity2The preparation method of biological composite coating | |

| CN115957385A (en) | Preparation method and application of a multifunctional coating of metal polyphenol network coupling antimicrobial peptide | |

| CN110898258B (en) | An antibacterial collagen-based bone repair material | |

| Wang et al. | Cu 2− x S homojunction coatings empower titanium implants with near-infrared-triggered antibacterial and antifouling properties | |

| CN116196469A (en) | A preparation method of photothermal synergistic photodynamic antibacterial antibacterial bone-promoting coating on the surface of titanium implant | |

| CN114949374B (en) | Antibacterial bone-promoting difunctional titanium metal orthopedic implant and preparation method thereof | |

| CN117045864A (en) | Zinc ion synergistic photothermal enhanced antibacterial bone titanium implant material |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |