CN115855125A - Decoding circuit and method of dual-channel resolver based on single decoding chip - Google Patents

Decoding circuit and method of dual-channel resolver based on single decoding chipDownload PDFInfo

- Publication number

- CN115855125A CN115855125ACN202211581769.8ACN202211581769ACN115855125ACN 115855125 ACN115855125 ACN 115855125ACN 202211581769 ACN202211581769 ACN 202211581769ACN 115855125 ACN115855125 ACN 115855125A

- Authority

- CN

- China

- Prior art keywords

- decoding

- angle

- chip

- machine

- decoding chip

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000034methodMethods0.000titleclaimsabstractdescription25

- 238000004422calculation algorithmMethods0.000claimsabstractdescription9

- 230000005284excitationEffects0.000claimsdescription16

- 238000004891communicationMethods0.000claimsdescription9

- 238000004364calculation methodMethods0.000claimsdescription7

- 238000003754machiningMethods0.000claims3

- 230000009977dual effectEffects0.000claims1

- 230000005405multipoleEffects0.000description11

- 238000012937correctionMethods0.000description10

- 238000004804windingMethods0.000description6

- 238000006243chemical reactionMethods0.000description4

- 238000013461designMethods0.000description3

- 238000010586diagramMethods0.000description3

- 238000012986modificationMethods0.000description3

- 230000004048modificationEffects0.000description3

- 230000009466transformationEffects0.000description3

- 230000006978adaptationEffects0.000description2

- 230000005540biological transmissionEffects0.000description2

- 230000009286beneficial effectEffects0.000description1

- 238000004590computer programMethods0.000description1

- 230000007423decreaseEffects0.000description1

- 238000001514detection methodMethods0.000description1

- 230000005674electromagnetic inductionEffects0.000description1

- 238000005259measurementMethods0.000description1

- 230000035945sensitivityEffects0.000description1

- 230000035939shockEffects0.000description1

Images

Landscapes

- Transmission And Conversion Of Sensor Element Output (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本申请涉及电子控制领域,具体涉及一种基于单解码芯片的双通道旋转变压器的解码电路及方法。The present application relates to the field of electronic control, in particular to a decoding circuit and method of a dual-channel resolver based on a single decoding chip.

背景技术Background technique

现代军用火炮控制系统工作环境非常苛刻,例如冲击震动和温湿度变化等。在如此苛刻工作条件下,普通类型的角轴位置、速度传感器,例如光电传感器,很容易损坏。旋转变压器由于其坚固耐用,可靠性高的特点,广泛应用在工作环境苛刻的系统之中。The working environment of modern military artillery control systems is very harsh, such as shock vibration and temperature and humidity changes. Under such harsh working conditions, ordinary types of angular axis position and speed sensors, such as photoelectric sensors, are easily damaged. Due to its robustness, durability and high reliability, resolvers are widely used in systems with harsh working environments.

旋转变压器是一种精密角度、位置、速度检测装置,具有灵敏度高、抗干扰能力强等特点,在控制系统中,旋转变压器可作为结算元件,主要用于坐标变换、三角函数运算等。The resolver is a precision angle, position, and speed detection device, which has the characteristics of high sensitivity and strong anti-interference ability. In the control system, the resolver can be used as a settlement component, mainly used for coordinate transformation and trigonometric function operations.

为了提高旋转变压器的解码精度,出现了双通道的旋转变压器,双通道旋转变压器包含粗机和精机两个旋转变压器,通过解码的粗精组合来提高解码的精度,对双通道旋转变压器的解码通常使用两个解码芯片,分别对双通道旋转变压器的粗机和精机进行解码。In order to improve the decoding accuracy of the resolver, a dual-channel resolver has appeared. The dual-channel resolver includes two resolvers, the coarse machine and the fine machine. The decoding accuracy is improved through the combination of coarse and fine decoding. Usually two decoding chips are used to decode the rough machine and fine machine of the dual-channel resolver respectively.

为了节约成本,可采用一个解码芯片同时对双通道旋转变压器的粗机和精机进行解码,但是在解码芯片进行解码的过程中,需要切换粗机和精机发送的信号,此时会产生一个时间较长的阶跃响应,对计算解码角度的精度影响较大。In order to save costs, one decoding chip can be used to decode the rough machine and fine machine of the dual-channel resolver at the same time, but in the process of decoding by the decoding chip, the signals sent by the rough machine and the fine machine need to be switched, and a A longer step response has a greater impact on the accuracy of calculating the decoding angle.

发明内容Contents of the invention

本申请提供一种基于单解码芯片的双通道旋转变压器的解码电路及方法,可以缩短切换粗机和精机时产生的阶跃响应的时长,提升解码角度的精度。The present application provides a decoding circuit and method of a dual-channel resolver based on a single decoding chip, which can shorten the duration of the step response generated when switching between the rough machine and the fine machine, and improve the accuracy of the decoding angle.

在本申请的第一方面提供了一种基于单解码芯片的双通道旋转变压器的解码电路,所述电路包括双通道旋转变压器、单片机、模拟开关以及解码芯片,其中:In the first aspect of the present application, a decoding circuit of a dual-channel rotary transformer based on a single decoding chip is provided, the circuit includes a dual-channel rotary transformer, a single-chip microcomputer, an analog switch, and a decoding chip, wherein:

所述双通道旋转变压器的输入端与所述解码芯片的激励输出端相连接,所述双通道旋转变压器的精机输出端与所述模拟开关的精机输入端相连接,所述双通道旋转变压器的粗机输出端与所述模拟开关的粗机输入端相连接;The input end of the dual-channel resolver is connected to the excitation output end of the decoding chip, the precision output end of the dual-channel resolver is connected to the precision input end of the analog switch, and the dual-channel rotary The rough machine output end of the transformer is connected with the rough machine input end of the analog switch;

所述模拟开关的控制输入端与所述单片机的第一端相连接,所述模拟开关的信号输出端与所述解码芯片的信号输入端相连接;The control input end of the analog switch is connected to the first end of the single-chip microcomputer, and the signal output end of the analog switch is connected to the signal input end of the decoding chip;

所述解码芯片的第一端与所述单片机的第二端相连接。The first terminal of the decoding chip is connected with the second terminal of the single chip microcomputer.

采用上述技术方案,通过单片机控制模拟开关的切换,只需一个解码芯片便能接收到双通道旋转变压器输出的精机信号和粗机信号,相比于现有技术采用两个解码芯片分别对双通道旋转变压器输出的精机信号和粗机信号进行解码,节约了电路成本。With the above technical solution, only one decoder chip is needed to receive the fine machine signal and the rough machine signal output by the dual-channel resolver through the single-chip microcomputer to control the switching of the analog switch. The fine machine signal and the rough machine signal output by the channel resolver are decoded, which saves the circuit cost.

在本申请的第二方面提供了一种基于单解码芯片的双通道旋转变压器的解码方法,所述方法包括:In the second aspect of the present application, a decoding method based on a dual-channel resolver of a single decoding chip is provided, the method comprising:

单片机发送第一控制信号至解码芯片,以使所述解码芯片从第一解码精度降低至第二解码精度;The single-chip microcomputer sends a first control signal to the decoding chip, so that the decoding chip reduces from the first decoding precision to the second decoding precision;

接收所述解码芯片处于第一解码精度时发送的粗机角度;receiving the coarse machine angle sent when the decoding chip is in the first decoding precision;

发送第二控制信号至所述解码芯片,以使所述解码芯片从所述第二解码精度升高至所述第一解码精度;sending a second control signal to the decoding chip, so that the decoding chip increases from the second decoding precision to the first decoding precision;

接收所述解码芯片处于第二解码精度时发送的精机角度;receiving the fine machine angle sent when the decoding chip is in the second decoding precision;

根据组合算法,计算所述粗机角度和所述精机角度,得到编码角度。According to the combined algorithm, the rough machine angle and the fine machine angle are calculated to obtain the encoding angle.

采用上述技术方案,在解码芯片接收粗机反馈信号之前,通过单片机发送第一控制信号至解码芯片,控制解码芯片降低解码精度,当控制模拟开关使得解码芯片接收精机信号之后,通过单片机发送第二控制信号至解码芯片,控制解码芯片升高解码精度。在切换粗机和精机前后,降低解码芯片的解码精度,减少计算量,从而减少了粗机和精机切换时产生的阶跃响应时间,进而提升了解码角度的精度。Using the above technical solution, before the decoding chip receives the rough machine feedback signal, the first control signal is sent to the decoding chip through the single-chip microcomputer, and the decoding chip is controlled to reduce the decoding accuracy. The second control signal is sent to the decoder chip to control the decoder chip to increase the decoding accuracy. Before and after the switch between the rough machine and the fine machine, the decoding accuracy of the decoding chip is reduced and the amount of calculation is reduced, thereby reducing the step response time generated when the rough machine and the fine machine are switched, thereby improving the accuracy of the decoding angle.

可选的,所述发送第一控制信号至解码芯片之前,还包括:Optionally, before sending the first control signal to the decoding chip, it also includes:

所述单片机发送起始信号至所述解码芯片;The single-chip microcomputer sends a start signal to the decoding chip;

所述解码芯片接收所述起始信号,上电作业,产生激励信号,并将所述激励信号发送至所述双通道旋转变压器;The decoding chip receives the start signal, powers on, generates an excitation signal, and sends the excitation signal to the dual-channel resolver;

所述双通道旋转变压器接收所述激励信号,上电作业。The dual-channel rotary transformer receives the excitation signal, and performs power-on operation.

采用上述技术方案,通过单片机发送起始信号至解码芯片,同时为解码芯片提供工作电压,使得解码芯片工作,在解码芯片工作时会产生激励信号传输至双通道旋转变压器中,使得双通道旋转变压器上电作业。Using the above technical solution, the start signal is sent to the decoding chip through the single-chip microcomputer, and the working voltage is provided for the decoding chip at the same time, so that the decoding chip works. Power-on work.

可选的,所述接收所述解码芯片处于第一解码精度时发送的粗机角度之前,还包括:Optionally, before receiving the rough machine angle sent when the decoding chip is in the first decoding precision, it also includes:

所述单片机发送第一开关信号至模拟开关;The single-chip microcomputer sends the first switch signal to the analog switch;

所述模拟开关接收所述第一开关信号,接收粗机反馈信号,并将所述粗机反馈信号传输至所述解码芯片;The analog switch receives the first switch signal, receives a rough machine feedback signal, and transmits the rough machine feedback signal to the decoding chip;

所述解码芯片接收并解码所述粗机反馈信号,得到粗机角度。The decoding chip receives and decodes the rough machine feedback signal to obtain the rough machine angle.

采用上述技术方案,通过单片机发送第一开关信号控制模拟开关接收信号的种类,当模拟开关接收到第一开关信号后,将粗机反馈信号传输至双通道旋转变压器的粗机反馈信号并传输至解码芯片。Using the above technical solution, the type of signal received by the analog switch is controlled by sending the first switch signal through the single-chip microcomputer. When the analog switch receives the first switch signal, the rough machine feedback signal is transmitted to the rough machine feedback signal of the dual-channel resolver and then transmitted to decoding chip.

可选的,所述接收所述解码芯片处于第二解码精度时发送的精机角度之前,还包括:Optionally, before receiving the fine machine angle sent when the decoding chip is in the second decoding precision, it also includes:

所述单片机发送第二开关信号至所述模拟开关;The single-chip microcomputer sends a second switch signal to the analog switch;

所述模拟开关接收所述第二开关信号,接收精机反馈信号,并将所述精机反馈信号传输至所述解码芯片;The analog switch receives the second switch signal, receives a precision machine feedback signal, and transmits the precision machine feedback signal to the decoding chip;

所述解码芯片接收并解码所述精机反馈信号,得到精机角度。The decoding chip receives and decodes the precision machine feedback signal to obtain the precision machine angle.

采用上述技术方案,通过单片机发送第二开关信号控制模拟开关接收信号的种类,当模拟开关接收到第二开关信号后,将精机反馈信号传输至双通道旋转变压器的精机反馈信号并传输至解码芯片。Adopting the above technical solution, the type of signal received by the analog switch is controlled by sending the second switch signal through the single-chip microcomputer. When the analog switch receives the second switch signal, the precision machine feedback signal is transmitted to the precision machine feedback signal of the dual-channel resolver and then transmitted to decoding chip.

可选的,所述根据组合算法,计算所述粗机角度和所述精机角度,得到编码角度之前,还包括:Optionally, before calculating the rough machine angle and the fine machine angle according to the combination algorithm, and obtaining the encoding angle, it also includes:

所述单片机判断是否达到稳定条件;Described single-chip microcomputer judges whether to reach stable condition;

若达到所述稳定条件,则将达到稳定条件之后计算得到的所述编码角度作为最终编码角度。If the stable condition is reached, the encoding angle calculated after reaching the stable condition is used as the final encoding angle.

采用上述技术方案,在稳定条件前的编码角度可能存在精度转换造成的误差,通过判断是否达到稳定条件,将稳定条件之后计算得到的编码角度作为最终编码角度,可以提高结果的准确性。With the above technical solution, the coding angle before the stable condition may have errors caused by precision conversion. By judging whether the stable condition is reached, the coding angle calculated after the stable condition is used as the final coding angle, which can improve the accuracy of the result.

可选的,所述判断是否达到稳定条件,包括:Optionally, the judging whether a stable condition is reached includes:

所述单片机判断接收所述精机角度之后是否达到第一时长;The single-chip microcomputer judges whether the first duration has been reached after receiving the precision machine angle;

若接收所述精机角度之后达到第一时长,确认为达到稳定条件。If the first duration is reached after receiving the precision machine angle, it is determined that a stable condition is reached.

采用上述技术方案,单片机接收到精机角度后,可能还存在精度转换造成的误差,通过判断是否达到第一时长,以此判断是否达到稳定条件,进而将达到稳定条件之后的精机角度,结果更为准确。Using the above technical solution, after the single-chip microcomputer receives the precision angle, there may still be errors caused by precision conversion. By judging whether it has reached the first time length, it can be judged whether it has reached a stable condition, and then the precision angle after reaching the stable condition, the result more accurate.

可选的,所述根据组合算法,计算所述粗机角度和所述精机角度,得到编码角度,包括:Optionally, the calculation of the rough machine angle and the fine machine angle according to the combined algorithm to obtain the encoding angle includes:

所述单片机取所述粗机角度的整数部分以及所述精机角度的小数部分进行组合,得到编码角度。The single-chip microcomputer combines the integer part of the rough machine angle and the fractional part of the fine machine angle to obtain the coded angle.

采用上述技术方案,通过将粗机角度和精机角度结合计算得到编码角度。By adopting the above technical solution, the encoding angle is obtained by combining the rough machine angle and the fine machine angle to calculate.

可选的,所述单片机取所述粗机角度的整数部分以及所述精机角度的小数部分进行组合,得到编码角度之后,还包括:Optionally, the single-chip microcomputer takes the integer part of the rough machine angle and the fractional part of the fine machine angle to combine, and after obtaining the encoding angle, it also includes:

对所述编码角度进行纠错,得到精确的编码角度。Error correction is performed on the encoding angle to obtain an accurate encoding angle.

采用上述技术方案,由于双通道旋转变压器存在传动误差以及轴角变换误差,导致最后计算得到的编码角度不准确,通过对编码角度进行纠错,可进一步提高编码角度的精度。With the above technical solution, due to the transmission error and shaft angle transformation error of the dual-channel resolver, the final calculated encoding angle is inaccurate. By correcting the encoding angle, the accuracy of the encoding angle can be further improved.

在本申请的第三方面提供了一种位置编码器,所述位置编码器包括:基于单解码芯片的双通道旋转变压器的解码和通讯芯片,所述通讯芯片与所述基于单解码芯片的双通道旋转变压器的解码电路相连接。In the third aspect of the present application, a position encoder is provided. The position encoder includes: a decoding and communication chip of a dual-channel rotary transformer based on a single decoding chip, and the communication chip and the dual-channel resolver based on a single decoding chip The decoding circuit of the channel resolver is connected.

综上所述,本申请包括以下至少一种有益效果:In summary, the present application includes at least one of the following beneficial effects:

1、在解码芯片接收粗机反馈信号之前,单片机发送第一控制信号至解码芯片,控制解码芯片降低解码精度,在控制模拟开关使得解码芯片接收精机信号之后,通过单片机发送第二控制信号至解码芯片,控制解码芯片升高解码精度。在切换粗机和精机前后,降低解码芯片的解码精度,减少计算量,从而减少了粗机和精机切换时产生的阶跃响应时间,进而提升了解码角度的精度。1. Before the decoding chip receives the rough machine feedback signal, the single-chip microcomputer sends the first control signal to the decoding chip to control the decoding chip to reduce the decoding accuracy. After controlling the analog switch so that the decoding chip receives the fine machine signal, the single-chip microcomputer sends the second control signal to the Decoding chip, control the decoding chip to increase the decoding accuracy. Before and after the switch between the rough machine and the fine machine, the decoding accuracy of the decoding chip is reduced and the amount of calculation is reduced, thereby reducing the step response time generated when the rough machine and the fine machine are switched, thereby improving the accuracy of the decoding angle.

附图说明Description of drawings

为了更清楚地说明本申请实施例或现有技术中的技术方案,下面将对实施例或现有技术描述中所需要使用的附图作简单地介绍,显而易见地,下面描述中的附图仅仅是本申请的一些实施例,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to more clearly illustrate the technical solutions in the embodiments of the present application or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present application. Those skilled in the art can also obtain other drawings based on these drawings without creative work.

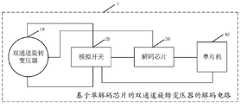

图1是本申请实施例提供的一种基于单解码芯片的双通道旋转变压器的解码电路示意图;FIG. 1 is a schematic diagram of a decoding circuit of a dual-channel resolver based on a single decoding chip provided by an embodiment of the present application;

图2是本申请实施例提供的一种基于单解码芯片的双通道旋转变压器的解码方法的流程示意图;FIG. 2 is a schematic flowchart of a decoding method for a dual-channel resolver based on a single decoding chip provided by an embodiment of the present application;

图3是本申请实施例提供的一种位置编码器的结构示意图;Fig. 3 is a schematic structural diagram of a position encoder provided by an embodiment of the present application;

附图标记说明:1、基于单解码芯片的双通道旋转变压器的解码电路;2、位置编码器;10、双通道旋转变压器;20、模拟开关;30、解码芯片;40、单片机;50、通讯芯片。Explanation of reference signs: 1. Decoding circuit of dual-channel resolver based on single decoding chip; 2. Position encoder; 10. Dual-channel resolver; 20. Analog switch; 30. Decoder chip; 40. Single-chip microcomputer; 50. Communication chip.

具体实施方式Detailed ways

为了使本技术领域的人员更好地理解本说明书中的技术方案,下面将结合本说明书实施例中的附图,对本说明书实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅是本申请一部分实施例,而不是全部的实施例。In order to enable those skilled in the art to better understand the technical solutions in this specification, the technical solutions in the embodiments of this specification will be clearly and completely described below in conjunction with the drawings in the embodiments of this specification. Obviously, the described The embodiments are only some of the embodiments of the present application, but not all of them.

在本申请实施例的描述中,“示性的”、“例如”或者“举例来说”等词用于表示作例子、例证或说明。本申请实施例中被描述为“示性的”、“例如”或者“举例来说”的任何实施例或设计方案不应被解释为比其它实施例或设计方案更优选或更具优势。确切而言,使用“示性的”、“例如”或者“举例来说”等词旨在以具体方式呈现相关概念。In the description of the embodiments of the present application, words such as "exemplary", "for example" or "for example" are used as examples, illustrations or illustrations. Any embodiment or design solution described as "exemplary", "for example" or "for example" in the embodiments of the present application shall not be interpreted as being more preferred or more advantageous than other embodiments or design solutions. Rather, the use of words such as "exemplary", "for example" or "for example" is intended to present the relevant concepts in a concrete manner.

在本申请实施例的描述中,术语“和/或”,仅仅是一种描述关联对象的关联关系,表示可以存在三种关系,例如,A和/或B,可以表示:单独存在A,单独存在B,同时存在A和B这三种情况。另外,除非另有说明,术语“多个”的含义是指两个或两个以上。例如,多个系统是指两个或两个以上的系统,多个屏幕终端是指两个或两个以上的屏幕终端。此外,术语“第一”、“第二”仅用于描述目的,而不能理解为指示或暗示相对重要性或者隐含指明所指示的技术特征。由此,限定有“第一”、“第二”的特征可以明示或者隐含地包括一个或者更多个该特征。术语“包括”、“包含”、“具有”及它们的变形都意味着“包括但不限于”,除非是以其他方式另外特别强调。In the description of the embodiments of the present application, the term "and/or" is only an association relationship describing associated objects, indicating that there may be three relationships, for example, A and/or B may indicate: A exists alone, A exists alone There is B, and there are three cases of A and B at the same time. In addition, unless otherwise specified, the term "plurality" means two or more. For example, multiple systems refer to two or more systems, and multiple screen terminals refer to two or more screen terminals. In addition, the terms "first" and "second" are used for descriptive purposes only, and cannot be understood as indicating or implying relative importance or implicitly specifying indicated technical features. Thus, a feature defined as "first" and "second" may explicitly or implicitly include one or more of these features. The terms "including", "comprising", "having" and variations thereof mean "including but not limited to", unless specifically stated otherwise.

在描述本申请实施例之前,先对旋转变压器进行简单的介绍。Before describing the embodiments of the present application, a brief introduction to the resolver is given first.

旋转变压器是模拟型机电元件,输出的信号时模拟信号,为了能够在数字化伺服系统、测量系统、微机处理机或者微型计算机控制系统中进行应用,就必须要将旋转变压器产生的模拟信号转换成控制系统能够识别的数字信号,而这就要使用解算电路或者是接口电路,而模拟/数字转换器中就包括了旋转变压器的变送器,计算转子轴角并利用上位机来显示结果就是这个元件的主要作用。The resolver is an analog electromechanical component, and the output signal is an analog signal. In order to be able to be applied in a digital servo system, a measurement system, a microcomputer processor or a microcomputer control system, it is necessary to convert the analog signal generated by the resolver into a control The digital signal that the system can recognize, and this requires the use of a solving circuit or an interface circuit, and the analog/digital converter includes a resolver transmitter, which calculates the rotor shaft angle and uses the host computer to display the result. The main function of the component.

双通道旋转变压器指的是一种多极旋转变压器,包括有单对磁极旋转变压器和多对磁极旋转变压器,由于单对磁极旋转变压器具有较低的精度,因此叫做粗机,多对磁极旋转变压器具有较高的精度,因此叫做精机。通常情况下,单极旋转变压器需要与多极旋转变压器一起共同构成一个系统整体,双通道旋转变压器在设计旋转变压器是,将在一套转子、定子铁心中同时涉及多极旋转变压器以及单极旋转变压器,但是多级和单机旋转变压器各种具有对应的多级以及单极绕组。The dual-channel resolver refers to a multi-pole resolver, including a single-pair magnetic pole resolver and a multi-pair magnetic pole resolver. Because the single-pair magnetic pole resolver has low precision, it is called a rough machine, and a multi-pair magnetic pole resolver It has high precision, so it is called precision machine. Usually, a single-pole resolver needs to be combined with a multi-pole resolver to form a whole system. When designing a resolver for a dual-channel resolver, the multi-pole resolver and the single-pole resolver will be involved in a set of rotor and stator cores. transformers, but multistage and single-machine resolvers each have corresponding multistage as well as single-pole windings.

下面将结合本申请实施例中的附图,对本申请实施例中的技术方案进行清楚、完整的描述,显然,所描述的实施例仅仅是本申请一部分实施例,而不是全部的实施例。The technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present application. Obviously, the described embodiments are only some of the embodiments of the present application, not all of them.

请参考图1,在一个实施例中公开了一种基于单解码芯片的双通道旋转变压器的解码电路,如图1所示,一种基于单解码芯片的双通道旋转变压器的解码电路,包括双通道旋转变压器10、单片机40、模拟开关20以及解码芯片30,其中:Please refer to FIG. 1. In one embodiment, a decoding circuit of a dual-channel rotary transformer based on a single decoding chip is disclosed. As shown in FIG. 1, a decoding circuit of a dual-channel rotary transformer based on a single decoding chip includes two

双通道旋转变压器10的输入端与解码芯片30的激励输出端相连接,双通道旋转变压器10的精机输出端与模拟开关20的精机输入端相连接,双通道旋转变压器10的粗机输出端与模拟开关20的粗机输入端相连接;The input end of the dual-

模拟开关20的控制输入端与单片机40的第一端相连接,模拟开关20的信号输出端与解码芯片30的信号输入端相连接;The control input end of

解码芯片30的第一端与单片机40的第二端相连接。The first terminal of the

示例性地,在上电之前,单片机40可发送起始信号至解码芯片30,以使解码芯片30上电。当解码芯片30上电后,会产生一个激励信号,传输至双通道旋转变压器10中,当双通道旋转变压器10接收到激励信号后,便开始工作,读取外部部件的角度信息,并产生精机反馈信号和粗机反馈信号。Exemplarily, before powering on, the single-

进一步地,单片机40可以发送开关信号传输至模拟开关20,用以控制模拟开关20,可根据开关信号,选择性地接收双通道旋转变压器10传输的精机反馈信号或粗机反馈信号。在接受粗机反馈信号前,单片机40发送控制指令至解码芯片30,降低粗机对于粗机反馈信号解码的精度;在需要接受精机反馈信号时,单片机40发送开关信号至模拟开关20,模拟开关20根据开关信号,选择性地接收双通道旋转变压器10传输的精机反馈信号;在接收精机反馈信号之后,解码芯片30需要对精机进行解码,单片机40发送控制信号至解码芯片30,提高解码芯片30的精度。Further, the single-

采用单个解码芯片30对双通道旋转变压器10进行解码,由于解码芯片30在同一时间只能对粗机反馈信号或精机反馈信号其中之一进行解码。故需要在对一个信号解码之后及时对另一个信号解码,由于粗机反馈信号与精机反馈信号存在180度相位差,故在对两个信号进行切换解码的过程中会产生一个180度的阶跃响应,若一直使用高精度对粗机反馈信号进行解码,产生的延迟较长,最后导致编码角度计算的误差较大。由于精机反馈信号的解码精度要求较高,粗机反馈信号的解码精度要求较低,因此,通过上述基于单解码芯片的双通道旋转变压器的解码电路1,在对粗机反馈信号进行解码时,设置较低的解码精度,直到通过模拟开关20切换为对精机反馈信号进行解码时,调高解码的精度对精机反馈信号进行解码,相当于在切换粗机、精机解码的过程中,由于阶跃响应造成的误差,由较低精度进行解码,可缩短阶跃响应的时间,进一步可以提高编码角度计算的准确性。A

在一个实施例中,请参考图2,特提出了一种基于单解码芯片的双通道旋转变压器的解码方法,该方法可依赖于计算机程序实现,可依赖于单片机实现,也可运行与基于冯诺依曼体系的基于单解码芯片的双通道旋转变压器的解码电路1上。该计算机程序可集成在应用中,也可作为独立的工具类应用运行。In one embodiment, please refer to FIG. 2 , a decoding method based on a dual-channel rotary transformer based on a single decoding chip is proposed. On the

步骤101:单片机40发送第一控制信号至解码芯片30,以使解码芯片30从第一解码精度降低至第二解码精度。Step 101: the single-

示例性地,解码芯片30可采用AD2S1210旋转变压器解码芯片30,通常解码芯片30对旋转变压器进行解码时,为了得到较高的精度,通常采用16位精度对旋转变压器传输的粗机反馈信号或精机反馈信号进行解码。由于本申请只采用了一个解码芯片30对粗机反馈信号和精机反馈信号进行解码,若采用16位解码精度对粗机反馈信号和精机反馈信号进行解码,精机解码最高支持的转速为234rpm,从粗机切换到精机,由于相位差最大为180度,因此可能会存在一个位置上的阶跃,产生的阶跃响应可以达到45至66毫秒,在16位解码精度下,以234rpm的转速在45ms下会运行63.18度,远远超过了精机周期,误差较大,无法在实际应用中使用。Exemplarily, the

进一步地,在对粗机反馈信号进行解码之前,单片机40发送第一控制信号至解码芯片30,解码芯片30接收到控制信号后,降低解码的精度,通常解码芯片30精度的最低位数为10位,若以10为精度进行解码,在180度阶跃响应下,10位解码精度进行解码的反应时间只需要1.5至2.2毫秒,在234rpm转速的情况下,2.2毫秒仅仅运行3.089度。通过组合算法计算编码角度的偏差允许在5.625度。Further, before decoding the rough machine feedback signal, the single-

在一种可行的实施方式中,在单片机40发送第一控制信号至解码芯片30之前,还发送起始信号至解码芯片30,在解码信号接收到起始信号后,开始上电工作,并产生激励信号,并将激励信号传输至双通道旋转变压器10中,以使双通道旋转变压器10开始读取外部部件的状态,得到粗机反馈信号和精机反馈信号。In a feasible implementation manner, before the single-

步骤102:接收解码芯片30处于第一解码精度时发送的粗机角度。Step 102: Receive the coarse camera angle sent when the

示例性地,单片机40首先发送第一开关信号至模拟开关20,模拟开关20接收第一开关信号后,只接收双通道旋转变压器10发送的粗机反馈信号,并将粗机反馈信号传输至解码芯片30中,此时的解码芯片30正处于第二解码精度,通过第一解码精度对粗机反馈信号进行解码,得到粗机角度,再发送至单片机40中。Exemplarily, the single-

可选的,在本申请实施例中由于只采用一个解码芯片30对双通道旋转变压器10进行解码,通过模拟开关20可以对双通道旋转变压器10传输的信号进行筛选,模拟开关20可选择SGM3005芯片,SGM3005芯片包括两个常开和两个常闭的可控,可根据单片机40发出的开关信号,将双通道旋转变压器10产生的粗机反馈信号和精机反馈信号择其一筛选至解码芯片30中。模拟开关20也可选用数据选择器等芯片。Optionally, in the embodiment of the present application, since only one

步骤103:发送第二控制信号至解码芯片30,以使解码芯片30从第二解码精度升高至第一解码精度。Step 103: Send a second control signal to the

具体的,当单片机40接收到粗机角度后,发送第二控制信号至解码芯片30,解码芯片30接收到第二控制信号后,将自身的解码精度从第二解码精度提升至第一解码精度,为了保证计算结果的准确性,通常是提高至解码芯片30的最高精度。Specifically, after the single-

步骤104:接收解码芯片30处于第二解码精度时发送的精机角度。Step 104: Receive the fine machine angle sent when the

示例性地,单片机40发送第二开关信号至模拟开关20,模拟开关20接收第二开关信号后,接收双通道旋转变压器10发送的精机反馈信号,并将精机反馈信号传输至解码芯片30中,此时的解码芯片30正处于第一解码精度,通过第一解码精度对精机反馈信号进行解码,得到精机角度,再发送至单片机40中。Exemplarily, the single-

步骤105:根据组合算法,计算粗机角度和精机角度,得到编码角度。Step 105: According to the combined algorithm, calculate the rough machine angle and the fine machine angle to obtain the encoding angle.

示例性地,旋转变压器可以划分为旋变压器以及旋变发送机。对于旋变发送机,通过单向电压相其激励磁绕组进行供电,在转子处于转动状态时,导致励磁绕组与次级输出绕组之间的相对位置出现改变,因此电动势就由次级输出绕组发射电磁感应而生成。并且因为次级输出两相绕组的空间位置关系较为特殊,是正交90度的关系,所以励磁方与输出方对应的电压具有的频率是相同的,仅仅是相位不同,余弦相与正弦相在具有相同的时间相位,但是两者的幅值是以转角为变量进行相应的函数变化。Exemplarily, resolvers can be divided into resolvers and resolver transmitters. For the resolver transmitter, the excitation magnetic winding is powered by the unidirectional voltage phase. When the rotor is in the rotating state, the relative position between the excitation winding and the secondary output winding changes, so the electromotive force is emitted by the secondary output winding. generated by electromagnetic induction. And because the spatial position relationship of the secondary output two-phase winding is quite special, it is a 90-degree orthogonal relationship, so the voltage corresponding to the excitation side and the output side have the same frequency, but the phase is different, and the cosine phase and the sine phase are in the same position. They have the same time phase, but the magnitudes of the two are changed as a function of the rotation angle as a variable.

由于旋转变压器输出的模拟信号中具有精机轴角以及粗机轴角这两个机械角度,并且对于机械角度,计算机并不能直接组合粗机反馈信号与精机反馈信号,因此将组合粗机信号与组合精机信号进行组合,首先就要将机械角度进行数字转换。当多极旋转变压器对应的粗机速度与精机速度比值为1:N时,如果多极旋转变压器对应的粗机轴数字角的周期是360度,那么精机轴数字角的周期为360度/N,即如果粗机轴数字角完成了1圈的转动,那么精机轴数字角则已经完成了N圈的转动。Since the analog signal output by the resolver has two mechanical angles, the shaft angle of the fine machine and the shaft angle of the rough machine, and for the mechanical angle, the computer cannot directly combine the feedback signal of the rough machine and the feedback signal of the fine machine, so the rough machine signal will be combined To combine with combined precision machine signals, the mechanical angle must first be converted to digital. When the ratio of the rough machine speed to the fine machine speed corresponding to the multi-pole resolver is 1:N, if the period of the digital angle of the rough machine shaft corresponding to the multi-pole resolver is 360 degrees, then the period of the digital angle of the fine machine shaft is 360 degrees /N, that is, if the digital angle of the coarse machine axis has completed one rotation, then the digital angle of the fine machine axis has completed N rotations.

具有1:32速比的多极旋转变压器,如果当粗机轴完成了1圈的转动,那么精机轴则完成了32圈的转动,即精机轴完成1圈转动,对应于粗机轴完成1/32圈的转动,也就是11.25度,所以5.6度为精机轴的最高位。若精机数字较与粗机数字角都是12位的,但是精机数字角仅前5位是有效位,这是由于粗机轴后几位的准确度比不上精机轴放大32倍后的数字,在进行组合精机轴角与粗机轴角时,粗机轴数字角的前5位用作高5位,而精机轴数字角则用作低位。所以通常情况下,在进行组合精机、粗机数据时,采用的原则是粗机轴数字角只取整数0部分,精机轴数字角取小数0部分。A multi-pole resolver with a speed ratio of 1:32, if the rough machine shaft completes one revolution, then the fine machine shaft completes 32 revolutions, that is, the fine machine shaft completes one revolution, corresponding to the coarse machine shaft Complete the rotation of 1/32 circle, which is 11.25 degrees, so 5.6 degrees is the highest position of the precision machine shaft. If both the digital angle of the fine machine and the digital angle of the rough machine are 12 digits, but only the first 5 digits of the digital angle of the fine machine are effective digits, this is because the accuracy of the last few digits of the rough machine shaft is not as accurate as that of the fine machine shaft, which is magnified by 32 times The last number, when combining the fine machine shaft angle and the rough machine shaft angle, the first 5 digits of the rough machine shaft digital angle are used as the high 5 digits, while the fine machine shaft digital angle is used as the low order. Therefore, under normal circumstances, when combining fine machine and rough machine data, the principle adopted is that the digital angle of the rough machine shaft only takes the integer 0 part, and the digital angle of the fine machine shaft takes the decimal 0 part.

在组合精机、粗机数据时,必须要保证粗机轴数字角无差错,然而在显示中,多极旋转变压器的误差,传动误差以及轴角变换误差这些因素,将导致在组合精机、粗机轴数据角时,不能达到理想状态,常常使得粗机读数少或者多一个最小单位。所以在组合精机、粗机数据角时,一定要纠错,而在进行纠错时采用通过精机轴数据较对粗机轴数据角进行纠错的原则。When combining the fine machine and rough machine data, it is necessary to ensure that there is no error in the digital angle of the rough machine shaft. However, in the display, the error of the multi-pole resolver, the transmission error and the shaft angle conversion error will cause the combination of fine machine, When the data angle of the rough machine axis is not ideal, it often makes the reading of the rough machine less or more than one minimum unit. Therefore, when combining the data angles of the fine machine and rough machine, it is necessary to correct the error, and the principle of correcting the data angle of the rough machine axis by comparing the data of the fine machine axis is adopted when performing error correction.

在进行纠错时,通常会遇到的情况如下:第一,在精机角度处于第一象限时,出现的情况只能少计粗机角度数字。当进行计数时,如果精机角度数据溢出,则应该进1粗机角度第5位来实施纠错;第二,当精机角度处于第四象限时,出现的情况是只可能多计粗机角度数据,而少计则不可能。在进行计数时,如果精机角度数据还没有计满时,则对于向粗机角度第5位数据不能够实施进位,那么如果出现了粗机角度尾数进位给第5位数据的情况,就必须减1粗机角度第5位来实施纠错;第三,当精机角度处于第二以及第三象限时,那么就没有粗机角度数据进位的情况,所以不可能出现粗机数字角少计或者多计的情况,也就需要纠错。When performing error correction, the following situations are usually encountered: First, when the fine machine angle is in the first quadrant, the rough machine angle can only be undercounted. When counting, if the fine machine angle data overflows, you should enter the 5th digit of the rough machine angle to implement error correction; second, when the fine machine angle is in the fourth quadrant, it is only possible to overcount the rough machine Angular data, while undercounting is not possible. When counting, if the fine machine angle data is not full, the 5th digit data of the rough machine angle cannot be carried, then if the mantissa of the rough machine angle is carried to the 5th data, it must be Subtract 1 from the 5th digit of the rough machine angle to implement error correction; third, when the fine machine angle is in the second and third quadrants, there will be no rounding of the rough machine angle data, so it is impossible for the rough machine digital angle to be undercounted Or in the case of overcounting, error correction is required.

综上所述,当1:32速比的多级旋转变压器在纠错粗机数据以及精机数据时,可通过精通道的高2位以及粗通道的第6位、第7位实现,当精机角度处于一象限进行进位时,如果粗机角度不进位,那么应当对第5位进行加1操作;当精机角度处于四象限时无进位,然而粗机角度则实施了进位,那么应当对第5位进行减1操作;当精机角度在其他情况中或者处于其他象限时,就不需要进位,此时对第5位采用加0操作。To sum up, when the multi-stage resolver with a speed ratio of 1:32 corrects the rough machine data and the fine machine data, it can be realized through the upper 2 bits of the fine channel and the 6th and 7th bits of the coarse channel. When the fine machine angle is in the first quadrant and the carry is carried out, if the rough machine angle does not carry, then the 5th digit should be added by 1; when the fine machine angle is in the four quadrants, there is no carry, but the rough machine angle is carried, then it should be Subtract 1 from the 5th digit; when the precision machine angle is in other situations or in other quadrants, no carry is needed, and add 0 to the 5th digit at this time.

通常情况下,对于普通的多极旋转变压器数字变换系统,可以设计精机数据与粗机数据组合和纠错时需要的双速处理器,并且采用位数相同的精机轴与粗机轴数字角。首先采用同样的位数来表示粗机数据角和精机数据角,如果粗机轴的数字角的位数比精机轴的数字角的位数少,则采用在尾部对粗机数字角进行补零处理,此后,对粗机轴数字角进行速比转换,也就是扩大N倍数,然后采用上述实施例描述的纠错方法实施纠错,也就是使用精机轴的数字角来纠错粗机轴的数字角。在完成纠错后,粗机轴数字角就能够使用精机轴数字角来代替,从而完成组合精机轴与粗机轴对应的数字角,最终就能够获得多极旋转变压器输出对应的数字角。Usually, for a common multi-pole resolver digital transformation system, it is possible to design a two-speed processor required for the combination of fine machine data and rough machine data and error correction, and use the same number of digits for the fine machine shaft and rough machine shaft horn. First, the same number of digits is used to represent the rough machine data angle and the fine machine data angle. If the number of digits of the digital angle of the rough machine axis is less than that of the fine machine axis, the rough machine digital angle is calculated at the end. After that, perform speed ratio conversion on the digital angle of the coarse machine shaft, that is, expand the N multiple, and then use the error correction method described in the above embodiment to implement error correction, that is, use the digital angle of the fine machine shaft to correct the coarse Numeric angle of the machine axis. After the error correction is completed, the digital angle of the coarse machine shaft can be replaced by the digital angle of the fine machine shaft, so as to complete the combination of the digital angle corresponding to the fine machine shaft and the rough machine shaft, and finally obtain the digital angle corresponding to the output of the multi-pole resolver .

通过将粗机数字角位数和精机数字角位数相加,就能够组成多极旋转变压器的粗机数据与精机数据双速处理器的位数。通常来看,精机数字角的位数是通过取真实的精机数据角的位数获得的,然而要求取得粗机数字角的位数要通过多极旋转变压器对应的速比来实现。By adding the digits of the rough machine digital angle and the fine machine digital angle, the digits of the two-speed processor of the rough machine data and the fine machine data of the multi-pole resolver can be formed. Generally speaking, the number of digits of the digital angle of the precision machine is obtained by taking the number of digits of the real data angle of the precision machine, but it is required to obtain the number of digits of the digital angle of the rough machine through the corresponding speed ratio of the multi-pole resolver.

在一种可行的实施方式中,当单片机40上电完成初始化,得到粗机角度后,切换至精机,在精机角度稳定后才可以进行组合。In a feasible implementation manner, when the single-

因此,可以在得到精机反馈信号后,开始计时得到第一时长,在第一时长达到阈值后才开始对精机角度和粗机角度的组合,得到编码角度。由于模拟开关20从粗机切换到精机的响应是非常快的,是微秒级的,通过实验数据,在20毫秒左右,便可达到稳定状态,为了使得最后得到的编码角度准确,通常将第一时长设置为100毫秒,即在100毫秒后必能达到稳定状态。得到初始组合角度后,只需要后续对精机角度不断累加,并到周期值后清零,便可以一直得到绝对角度。Therefore, after obtaining the fine machine feedback signal, start timing to obtain the first time length, and start to combine the fine machine angle and the rough machine angle to obtain the encoding angle after the first time length reaches a threshold. Since the response of the

本施例提供一种位置编码器2,该位置编码器2包括基于单解码芯片的双通道旋转变压器的解码电路1和通讯芯片50,如图3所示,图3为本发明实施例提供的位置编码器2结构示意图,通讯芯片50与单片机40可通过现场总线RS485连接,通讯芯片50可采用ADM2682E型RS232通讯芯片50。This embodiment provides a

以上所述者,仅为本公开的示例性实施例,不能以此限定本公开的范围。即但凡依本公开教导所作的等效变化与修饰,皆仍属本公开涵盖的范围内。本领域技术人员在考虑说明书的公开后,将容易想到本公开的其它实施方案。本申请旨在涵盖本公开的任何变型、用途或者适应性变化,这些变型、用途或者适应性变化遵循本公开的一般性原理并包括本公开未记载的本技术领域中的公知常识或惯用技术手段。What is described above is only an exemplary embodiment of the present disclosure, and should not limit the scope of the present disclosure. That is, all equivalent changes and modifications made according to the teachings of the present disclosure still fall within the scope of the present disclosure. Other embodiments of the present disclosure will readily occur to those skilled in the art upon consideration of the disclosure of the specification. This application is intended to cover any modification, use or adaptation of the present disclosure, and these modifications, uses or adaptations follow the general principles of the present disclosure and include common knowledge or conventional technical means in the technical field not described in the present disclosure .

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211581769.8ACN115855125A (en) | 2022-12-09 | 2022-12-09 | Decoding circuit and method of dual-channel resolver based on single decoding chip |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211581769.8ACN115855125A (en) | 2022-12-09 | 2022-12-09 | Decoding circuit and method of dual-channel resolver based on single decoding chip |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115855125Atrue CN115855125A (en) | 2023-03-28 |

Family

ID=85671654

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211581769.8APendingCN115855125A (en) | 2022-12-09 | 2022-12-09 | Decoding circuit and method of dual-channel resolver based on single decoding chip |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115855125A (en) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4700360A (en)* | 1984-12-19 | 1987-10-13 | Extrema Systems International Corporation | Extrema coding digitizing signal processing method and apparatus |

| CN108551282A (en)* | 2018-03-28 | 2018-09-18 | 北京理工大学 | Two speed resolver resolves bearing calibration, module and electric machine control system |

| US20190296761A1 (en)* | 2018-03-23 | 2019-09-26 | The Boeing Company | System and method for demodulation of resolver outputs |

| CN111102999A (en)* | 2019-12-11 | 2020-05-05 | 哈尔滨新光光电科技股份有限公司 | A resolver for resolver |

| CN112886966A (en)* | 2019-11-29 | 2021-06-01 | 苏州汇川联合动力系统有限公司 | Resolver decoding method, resolver decoding device and computer readable memory |

| CN114323086A (en)* | 2020-09-30 | 2022-04-12 | 叩德自动化(无锡)有限公司 | A dual-channel resolver decoding method, circuit and position encoder |

- 2022

- 2022-12-09CNCN202211581769.8Apatent/CN115855125A/enactivePending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4700360A (en)* | 1984-12-19 | 1987-10-13 | Extrema Systems International Corporation | Extrema coding digitizing signal processing method and apparatus |

| US20190296761A1 (en)* | 2018-03-23 | 2019-09-26 | The Boeing Company | System and method for demodulation of resolver outputs |

| CN108551282A (en)* | 2018-03-28 | 2018-09-18 | 北京理工大学 | Two speed resolver resolves bearing calibration, module and electric machine control system |

| CN112886966A (en)* | 2019-11-29 | 2021-06-01 | 苏州汇川联合动力系统有限公司 | Resolver decoding method, resolver decoding device and computer readable memory |

| CN111102999A (en)* | 2019-12-11 | 2020-05-05 | 哈尔滨新光光电科技股份有限公司 | A resolver for resolver |

| CN114323086A (en)* | 2020-09-30 | 2022-04-12 | 叩德自动化(无锡)有限公司 | A dual-channel resolver decoding method, circuit and position encoder |

Non-Patent Citations (2)

| Title |

|---|

| 张庆 等: "精粗组合轴角解算实验教学装置设计", 《实验技术与管理》, vol. 37, no. 2, 29 February 2020 (2020-02-29), pages 148 - 151* |

| 赵文香 等: "双通道旋转变压器粗精组合轴角转换原理及应用", 《新技术新工艺》, 30 June 2018 (2018-06-30), pages 72 - 76* |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN113489411B (en) | Servo driver absolute position and speed detection method | |

| CN110440846A (en) | A kind of collecting method of encoder, system, terminal and storage medium | |

| CN108375391B (en) | Sin and cosine signal processing method and system | |

| CN111308339A (en) | Servo motor testing method, device and equipment and computer storage medium | |

| CN102494709A (en) | Method for self-calibrating zero position of fine and coarse machine of double-channel multi-polar rotary transformer | |

| CN112033451A (en) | Measuring device and method of encoder and encoder | |

| JP5217766B2 (en) | Angular position detection device and rotation number detection device of rotating body | |

| CN210780430U (en) | Speed reduction motor and robot comprising same | |

| CN114629385A (en) | A brushless DC motor position detection method and system | |

| CN115855125A (en) | Decoding circuit and method of dual-channel resolver based on single decoding chip | |

| CN111106765A (en) | A brushless motor drive system and method | |

| CN117879429B (en) | Rotor initial phase detection method, system, device and readable storage medium | |

| CN117348612B (en) | Industrial grade automatic control system | |

| CN109308275B (en) | System and method for converting orthogonal coding pulse | |

| CN102879017A (en) | Novel double-speed coarse and fine combination system for resolver-to-digital converter | |

| CN115752522A (en) | Decoding circuit, method and position encoder of a dual-channel resolver | |

| WO2007137625A1 (en) | Sin-cos sensor arrangement, integrated circuit and method therefor | |

| CN116222629B (en) | A multi-turn encoder device driven by a sensorless motor and its counting method | |

| CN117411371A (en) | High-precision servo control system | |

| CN116191962B (en) | Position servo control system and method based on double-channel rotary transformer | |

| CN112665531B (en) | Multi-pair-level rotation-transformation coordinate transformation angle solving method | |

| CN210536536U (en) | AD2S 1210-based single-channel rotary transformation and conditioning circuit | |

| CN104682818A (en) | Rotary variable-voltage angle measuring system based on CORDIC (coordinate rotation digital computer) arc tangent algorithm | |

| CN208224851U (en) | Control circuit takes aim at control system with thick | |

| CN113050699B (en) | Control method and device based on magnetic encoder |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |