CN115837387A - Medical waste receiving and processing system - Google Patents

Medical waste receiving and processing systemDownload PDFInfo

- Publication number

- CN115837387A CN115837387ACN202211585070.9ACN202211585070ACN115837387ACN 115837387 ACN115837387 ACN 115837387ACN 202211585070 ACN202211585070 ACN 202211585070ACN 115837387 ACN115837387 ACN 115837387A

- Authority

- CN

- China

- Prior art keywords

- medical waste

- receiving

- processing system

- bucket

- medical

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000002906medical wasteSubstances0.000titleclaimsabstractdescription118

- 238000012545processingMethods0.000titleclaimsabstractdescription20

- 238000004140cleaningMethods0.000claimsabstractdescription32

- 238000003860storageMethods0.000claimsabstractdescription17

- 239000000463materialSubstances0.000claimsdescription10

- 238000012546transferMethods0.000claimsdescription7

- 238000011144upstream manufacturingMethods0.000claimsdescription4

- 238000005303weighingMethods0.000claimsdescription2

- 238000000034methodMethods0.000abstractdescription12

- 230000008569processEffects0.000abstractdescription10

- 230000007306turnoverEffects0.000description4

- 238000013461designMethods0.000description3

- 238000010586diagramMethods0.000description3

- 238000007599dischargingMethods0.000description3

- 230000032258transportEffects0.000description3

- 230000007613environmental effectEffects0.000description2

- 230000009286beneficial effectEffects0.000description1

- 238000010276constructionMethods0.000description1

- 238000001035dryingMethods0.000description1

- 230000006872improvementEffects0.000description1

- 230000010354integrationEffects0.000description1

- 238000007726management methodMethods0.000description1

- 238000004519manufacturing processMethods0.000description1

- 238000005259measurementMethods0.000description1

- 238000005457optimizationMethods0.000description1

- 230000033764rhythmic processEffects0.000description1

- 238000012384transportation and deliveryMethods0.000description1

Images

Classifications

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/10—Waste collection, transportation, transfer or storage, e.g. segregated refuse collecting, electric or hybrid propulsion

Landscapes

- Refuse Collection And Transfer (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于医废处理领域,具体涉及一种医疗废物接收及处理系统。The invention belongs to the field of medical waste treatment, in particular to a system for receiving and treating medical waste.

背景技术Background technique

近年医疗废物激增,随之而来的问题是医疗废物集中处置单位接收、贮存、输送及清洗压力激增,考虑到医疗废物容重较低,正常240L容积周转箱(桶),平均重量只有25kg,占地面积0.42m2,按照一个地级市日产50t医废计算,约有2000箱周转箱。按照HJ/T177及GB18597-2001相关要求,这对医疗废物的接收、贮存、输送及清洗等流程,提出了更高的要求,也是摆在医疗废物集中处置单位面前一个亟需解决的问题。In recent years, medical waste has increased sharply, and the ensuing problem is that the pressure of receiving, storing, transporting and cleaning medical waste centralized disposal units has surged. Considering the low bulk density of medical waste, the average weight of a normal 240L volume turnover box (barrel) is only 25kg, accounting for The land area is 0.42m2 , based on the daily production of 50 tons of medical waste in a prefecture-level city, there are about 2,000 boxes of turnover boxes. According to the relevant requirements of HJ/T177 and GB18597-2001, this puts forward higher requirements for the process of receiving, storing, transporting and cleaning medical waste, and it is also an urgent problem that needs to be solved in front of the centralized disposal of medical waste.

目前国内部分医疗废物集中处置单位,其在建设阶段就开始设计实现自动化接收、暂存、输送及清洗流程,在接收时,其采用人工搬运方式卸货至暂存库内,一部分放置于链条输送线上,另一部分放置于特定区域采用AGV自动搬运车,再分别进行输送至投料口,由机械臂完成投料,后周转桶由自动输送线输送至清洗设备完成清洗。At present, some domestic medical waste centralized disposal units have begun to design and realize the automatic receiving, temporary storage, transportation and cleaning process during the construction stage. When receiving, they use manual handling to unload the goods into the temporary storage, and part of them are placed on the chain conveyor line. On the top, the other part is placed in a specific area using an AGV automatic transfer vehicle, and then transported to the feeding port respectively, and the feeding is completed by the robotic arm, and the turnover barrel is transported to the cleaning equipment by the automatic conveyor line to complete the cleaning.

针对国内部门已建成医废集中处置项目,上述系统存在占地面积大,系统集成效率低,且需在项目设计阶段提前进行设计等缺点,显然不适用于已建成的医废集中处置项目。For the centralized medical waste disposal projects that have been built in the domestic sector, the above-mentioned system has the disadvantages of large footprint, low system integration efficiency, and the need to design in advance at the project design stage, which is obviously not suitable for the centralized medical waste disposal projects that have been built.

随着环保意识的增强、环保法规的健全,国家相关部门对医疗废物在接收、贮存、输送及清洗等流程,要求也越来越严格。With the enhancement of environmental protection awareness and the improvement of environmental protection laws and regulations, the relevant national departments have become more and more strict in the process of receiving, storing, transporting and cleaning medical waste.

发明内容Contents of the invention

本发明提供一种医疗废物接收及处理系统,对医疗废物(即医废)从接收到处理到医废桶的清洗完成自动化流水线处理,提高处理效率。The invention provides a medical waste receiving and processing system, which completes automatic assembly line processing of medical waste (that is, medical waste) from receiving to processing to cleaning of medical waste barrels, thereby improving processing efficiency.

为实现上述目的,本发明采用的是技术方案为:一种医疗废物接收及处理系统,包括用于接收带桶医废的接收平台,其特征在于:接收平台通过输送装置与倒料装置衔接,倒料装置与医废处置装置的医废进料斗衔接,带桶医废从接收平台输送至倒料装置,倒料装置将带桶医废中的医疗废物倒入医废料斗后,医废桶通过输送装置输送至清洗装置,医废桶清洗后的净桶放置在清洗装置旁侧的净桶存放区。In order to achieve the above purpose, the technical solution adopted by the present invention is: a medical waste receiving and processing system, including a receiving platform for receiving medical waste with barrels, characterized in that the receiving platform is connected with the discharging device through a conveying device, The unloading device is connected with the medical waste hopper of the medical waste disposal device, and the medical waste with a bucket is transported from the receiving platform to the unloading device, and the unloading device pours the medical waste in the medical waste with a bucket into the medical waste hopper, and the medical waste The bucket is transported to the cleaning device through the conveying device, and the clean bucket after cleaning the medical waste bucket is placed in the clean bucket storage area next to the cleaning device.

上述技术方案中,带桶的医疗废物(即带桶医废)到厂后,通过人工从收运车卸料至接收平台,或直接送入输送装置的输送线上料口向下游输送,通过倒料装置直接将医疗废物投入医废处置装置,医废桶完成倒料后,输送至清洗装置处完成清洗,整个系统自动完成进厂-医废处置-桶清洗,实现整个流程完全自动化。In the above technical solution, after the medical waste with barrels (that is, medical waste with barrels) arrives at the factory, it is manually unloaded from the collection and transport vehicle to the receiving platform, or directly sent to the material port of the conveyor line of the conveying device to be transported downstream. The unloading device directly puts medical waste into the medical waste disposal device. After the medical waste barrel is finished emptying, it is transported to the cleaning device to complete cleaning. The whole system automatically completes entering the factory - medical waste disposal - barrel cleaning, realizing the complete automation of the entire process.

附图说明Description of drawings

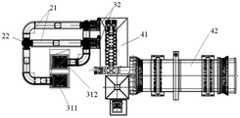

图1、2是本发明实际应用案例布局图,其中图1为底层布局图,图2为倒料装置和医废处置装置高位布局图。Figures 1 and 2 are the layout diagrams of the actual application cases of the present invention, wherein Figure 1 is the bottom layout diagram, and Figure 2 is the high-level layout diagram of the dumping device and the medical waste disposal device.

具体实施方式Detailed ways

一种医疗废物接收及处理系统,包括用于接收带桶医废的接收平台10,其特征在于:接收平台10通过输送装置20与倒料装置30衔接,倒料装置30与医废处置装置40的医废进料斗41衔接,带桶医废从接收平台10输送至倒料装置30,倒料装置30将带桶医废中的医疗废物倒入医废料斗41后,医废桶通过输送装置20输送至清洗装置50,医废桶清洗后的净桶放置在清洗装置50旁侧的净桶存放区60。A medical waste receiving and processing system, comprising a receiving

输送装置20由辊筒输送机21和旋转输送机22构成,直线部分布置辊筒输送机,节点或转弯处设置旋转输送机。The conveying

所述处理系统还包括系统控制软件,包括WMS仓库管理单元、WCS设备控制单元和RFS手持终端,以实现医废的自动化处理。根据医废来料量、医废投料量、医废桶出入库效率以及清洗效率,综合控制各台设备的运行效率、节拍,让整套系统安全高效运行。The processing system also includes system control software, including WMS warehouse management unit, WCS equipment control unit and RFS handheld terminal, so as to realize the automatic processing of medical waste. According to the amount of incoming medical waste, the amount of medical waste fed, the efficiency of entering and exiting the storage of medical waste barrels, and the cleaning efficiency, the operating efficiency and rhythm of each equipment are comprehensively controlled, so that the entire system can operate safely and efficiently.

所述接收平台10邻近处设有用于贮存带桶医废的四向车密集库70,所述四向车密集库70通过输送装置20分别与接收平台10和倒料装置30衔接。当医废集中进厂时,系统不能及时处理,就可以将带桶医废先贮存在密集库中,以免长时间占用接收平台10,影响运输车辆的卸货作业。Near the receiving

所述四向车密集库70内设有相互配合作业的多层货架、四向穿梭车、升降机和机械臂,所述机械臂与输送装置构成取放配合。带桶医废出入库的具体过程如下:The four-way vehicle-

带桶医废入库时,由输送装置20输送至机械臂7处,机械臂7将输送装置20上的带桶医废取下并在托盘上进行码垛,此时托盘放置于顶升移载输送机6上,码垛完毕,托盘分别由链条输送机4、密集库升降机5、顶升移载输送机6提升至对应层高(密集库中货架为多层,哪层空着可以存放带桶医废,就提升至对应的层高),此时四向穿梭车3根据程序指令前来接应,将托盘运送到相应位置,带桶医废完成入库。When medical waste with barrels is put into the warehouse, it is transported to the mechanical arm 7 by the

出库时,通过控制系统指令,四向穿梭车3将托盘送至密集库升降机5处,密集库升降机5将托盘降至地面高度,再由链条升降机4输送至顶升移载输送机6处,此时机械臂7会将托盘上的周转桶放置到输送装置上,带桶医废完成出库。When leaving the warehouse, the four-way shuttle car 3 sends the pallet to the intensive storage elevator 5 through the control system instruction, and the intensive storage elevator 5 lowers the pallet to the ground level, and then is transported by the chain elevator 4 to the jacking transfer conveyor 6 , at this time, the robotic arm 7 will place the turnover barrel on the pallet onto the conveying device, and the medical waste with the barrel will be delivered out of the warehouse.

医废处置装置40包括医废进料斗41和与其衔接的医废焚烧炉42。The medical

所述倒料装置30包括相互配合作业的升降机31、倒料机32和计量称。The material dumping device 30 includes a lifter 31, a

所述倒料装置30包括与上游转运装置20衔接的升降机311和与下游转运装置20衔接的升降机312,升降机311将上游转运来的带桶医废提升至医废进料斗41相适应的高度后,倒料机32将带桶医废中的医疗废物倾倒至医废进料斗41中,再将医废桶置于升降机312上降低至与下游输送装置20的衔接处并向下游清洗装置50输送。The dumping device 30 includes an

所述清洗装置50包括相互配合作业的翻桶机和清洗机。待洗的医废桶通过输送装置输送至清洗装置,此时医废桶是口朝上的状态,翻桶机会将其翻转至口朝下,医废桶在向前移动的过程中,清洗机完成清洗作业,然后再由第二个翻转机将洗干净的医废桶(即净桶)翻转至口朝上,即完成医废桶的清洗,清洗完毕的净桶,自动输送至净桶存放区60处,有序码放,待晾干后即可装车运走。The cleaning device 50 includes a bucket turning machine and a cleaning machine that cooperate with each other. The medical waste barrel to be washed is conveyed to the cleaning device through the conveying device. At this time, the mouth of the medical waste barrel is facing upward. After finishing the cleaning operation, the second overturning machine turns the cleaned medical waste barrel (i.e., the clean barrel) to the mouth upwards, that is, the cleaning of the medical waste barrel is completed, and the cleaned clean barrel is automatically transported to the clean barrel for storage There are 60 places in the area, and they are stacked in an orderly manner, and can be loaded and transported away after drying.

整套流程由控制软件控制,无需人工干预,当出现医疗废物集中回厂时,四向车密集库中的机械臂及提升机等可以设置两套,既可以在医废集中入库时提高入库作业效率,同时两套设备互为备用,当其中一套设备发生故障后,另一套设备也可满足正常出入库作业要求。The entire process is controlled by control software without manual intervention. When medical waste is returned to the factory in a centralized manner, two sets of robotic arms and hoists can be installed in the four-way intensive warehouse, which can improve the storage efficiency when medical waste is intensively stored. At the same time, the two sets of equipment serve as backups for each other. When one set of equipment fails, the other set of equipment can also meet the requirements of normal warehouse entry and exit operations.

当天医疗废物收运结束后,医废接收平台处,便可不在安排工人作业,由系统自动进行出库-输送-倒料-清洗流程。After the medical waste is collected and transported on the same day, at the medical waste receiving platform, there is no need to arrange workers to work, and the system will automatically carry out the warehouse-transportation-dumping-cleaning process.

与现有技术相比,本发明的有益效果在于:本发明综合了四向穿梭车密集库的特点、医疗废物本身及医废桶的特征,经过细节优化,实现了医废贮存场地的高空间利用率,高度自动化贮存及出入库流程,整套系统安全可靠;通过将密集库与输送投料装置的合理配置,不仅实现了医疗废物自动化输送投料,同时使其具备了人工/自动二种模式进料方式,互为备用,切实保障了焚烧系统的正常进料;自动清洗装置通过与上述装置有效衔接,实现了医废桶的自动清洗。上述所述各项功能,经系统控制软件综合控制,得以统一协调配合,同时兼具计量、安全报警等各项功能。Compared with the prior art, the beneficial effect of the present invention is that: the present invention combines the characteristics of the four-way shuttle car dense warehouse, the characteristics of the medical waste itself and the medical waste barrel, and realizes the high space of the medical waste storage site after details optimization Utilization rate, highly automated storage and warehousing process, the whole system is safe and reliable; through the reasonable configuration of intensive storage and conveying and feeding devices, not only the automatic conveying and feeding of medical waste is realized, but also the manual/automatic two modes of feeding The method is mutually backup, which effectively guarantees the normal feeding of the incineration system; the automatic cleaning device realizes the automatic cleaning of medical waste barrels through effective connection with the above-mentioned devices. All the functions mentioned above can be unified and coordinated through the comprehensive control of the system control software, and at the same time, it has various functions such as measurement and safety alarm.

Claims (8)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211585070.9ACN115837387A (en) | 2022-12-09 | 2022-12-09 | Medical waste receiving and processing system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211585070.9ACN115837387A (en) | 2022-12-09 | 2022-12-09 | Medical waste receiving and processing system |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115837387Atrue CN115837387A (en) | 2023-03-24 |

Family

ID=85578423

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211585070.9APendingCN115837387A (en) | 2022-12-09 | 2022-12-09 | Medical waste receiving and processing system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115837387A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117361017A (en)* | 2023-11-22 | 2024-01-09 | 艾信智能环境科技(无锡)有限公司 | Automatic warehouse-in, storage and warehouse-out method for medical waste temporary storage room intensive warehouse |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113636253A (en)* | 2021-09-13 | 2021-11-12 | 广东得友鑫物流系统设备有限公司 | Intelligent automatic dense warehousing system |

| CN113895837A (en)* | 2021-09-30 | 2022-01-07 | 江苏智库智能科技有限公司 | High-efficiency intensive warehousing system based on four-way shuttle-hoister |

| CN115285673A (en)* | 2022-08-22 | 2022-11-04 | 瑞林环境科技有限公司 | A system and method for fully automatic conveying and feeding cleaning and disinfection of medical waste turnover box |

| CN219130237U (en)* | 2022-12-09 | 2023-06-06 | 安徽浩悦环境科技有限责任公司 | Medical waste receiving and processing system |

- 2022

- 2022-12-09CNCN202211585070.9Apatent/CN115837387A/enactivePending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113636253A (en)* | 2021-09-13 | 2021-11-12 | 广东得友鑫物流系统设备有限公司 | Intelligent automatic dense warehousing system |

| CN113895837A (en)* | 2021-09-30 | 2022-01-07 | 江苏智库智能科技有限公司 | High-efficiency intensive warehousing system based on four-way shuttle-hoister |

| CN115285673A (en)* | 2022-08-22 | 2022-11-04 | 瑞林环境科技有限公司 | A system and method for fully automatic conveying and feeding cleaning and disinfection of medical waste turnover box |

| CN219130237U (en)* | 2022-12-09 | 2023-06-06 | 安徽浩悦环境科技有限责任公司 | Medical waste receiving and processing system |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117361017A (en)* | 2023-11-22 | 2024-01-09 | 艾信智能环境科技(无锡)有限公司 | Automatic warehouse-in, storage and warehouse-out method for medical waste temporary storage room intensive warehouse |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111099374B (en) | Automatic storage and sorting system | |

| CN111268382B (en) | Intelligent waste storage and incineration distribution system | |

| CN101863385A (en) | An automatic depalletizing process for cigarettes in storage | |

| CN107416405A (en) | A kind of shuttle plate vertical library | |

| CN212767919U (en) | Automatic production line of bag-shaped material unmanned production workshop | |

| CN115837387A (en) | Medical waste receiving and processing system | |

| CN219130237U (en) | Medical waste receiving and processing system | |

| CN115055496A (en) | Medical waste disposal system and method of use | |

| CN110606307A (en) | An intelligent board warehouse board matching system and board matching method | |

| CN118594939A (en) | Sorting system and sorting method | |

| CN116281283A (en) | Intelligent ton bag feeding system | |

| CN116176939A (en) | Palletizing and conveying equipment for waste aluminum blocks and its conveying process | |

| CN217920121U (en) | Production line is handled with losing in a wretched state, cellar for storing things mud in making wine workshop | |

| CN220717190U (en) | Medical waste full-automatic centralized treatment system | |

| CN111076185A (en) | Intelligent distribution system for incinerated substances based on treatment capacity of incinerator | |

| CN114906526B (en) | Automatic medical waste feeding system and scheduling method thereof | |

| CN107599147B (en) | Automatic feeding device for brick press feeding bin | |

| CN211712125U (en) | Device for transporting materials and automatically discharging materials | |

| CN217458064U (en) | Powdery and granular material collecting, distributing, protecting and supplying system | |

| CN211687436U (en) | Vertical unloading process system for lining bag of container | |

| CN210795088U (en) | Train loading building clout clearance system | |

| CN107363978B (en) | Automatic feeding method of feeding bin of brick press | |

| CN207044381U (en) | Automatic feeding device for brick press feeding bin | |

| KR20140144677A (en) | Shot blast system and control method thereof | |

| JPS6087108A (en) | Automatic storing/delivering apparatus for articles |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |