CN115825759A - Detection method, device and detection equipment for the difference in the health of each battery cell in a battery pack - Google Patents

Detection method, device and detection equipment for the difference in the health of each battery cell in a battery packDownload PDFInfo

- Publication number

- CN115825759A CN115825759ACN202210050856.4ACN202210050856ACN115825759ACN 115825759 ACN115825759 ACN 115825759ACN 202210050856 ACN202210050856 ACN 202210050856ACN 115825759 ACN115825759 ACN 115825759A

- Authority

- CN

- China

- Prior art keywords

- difference

- value

- soc

- cell

- tested

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Landscapes

- Secondary Cells (AREA)

- Charge And Discharge Circuits For Batteries Or The Like (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明实施例涉及电池技术领域,特别是涉及一种电池组各电芯健康度差异的检测方法、装置及检测设备。The embodiments of the present invention relate to the technical field of batteries, and in particular to a detection method, device and detection equipment for the difference in the health of each battery cell in a battery pack.

背景技术Background technique

随着新能源理念的倡导,以锂电池为代表的电池模组的应用越来越广泛,市面上的电池模组由多个电芯组成电池单元,再将多个电池单元通过串并联的方式组成较大的电池模组以使得电池模组能够拥有较大的电池容量。然而,多个电池单元串并联的组合形式也使得电池模组存在较多安全隐患,因此,及时了解各个电芯的健康情况显得尤其重要。With the advocacy of the new energy concept, the application of battery modules represented by lithium batteries is becoming more and more extensive. The battery modules on the market are composed of multiple batteries to form a battery unit, and then multiple battery units are connected in series and parallel. A larger battery module is formed so that the battery module can have a larger battery capacity. However, the series-parallel combination of multiple battery cells also brings more potential safety hazards to the battery module. Therefore, it is particularly important to know the health status of each battery cell in time.

本发明实施例的发明人在实施本发明实施例的过程中,发现:目前,可以通过识别出健康度差异较大的电芯将其判定为不健康电芯,然而,电池模组使用一段时间后,由于各电芯的容量不一致,电芯剩余电量百分比状态不同时,一般的检测结果偏差都比较大。In the process of implementing the embodiment of the present invention, the inventors of the present invention found that: at present, the battery cells with large differences in health can be identified as unhealthy cells. However, after the battery module has been used for a period of time , due to the inconsistency of the capacity of each battery cell, when the percentage of remaining power of the battery cell is different, the deviation of the general test results is relatively large.

发明内容Contents of the invention

本发明实施例主要解决的技术问题是提供一种电池组各电芯健康度差异的检测方法、装置及检测设备,能够消除各电芯的电量容量不一致来对电池组中的各个电芯进行健康度差异的检测,提高检测结果的准确性。The technical problem mainly solved by the embodiments of the present invention is to provide a detection method, device and detection equipment for the difference in the health of each battery cell in a battery pack, which can eliminate the inconsistency of the electric capacity of each battery cell to monitor the health of each battery cell in the battery pack. The degree difference detection can improve the accuracy of the detection results.

为解决上述技术问题,本发明实施例采用的一个技术方案是:提供一种电池组各电芯健康度差异的检测方法,所述检测方法包括:确定所述若干电芯同时处于完全静置状态的M个完全静置时段;获取在各所述完全静置时段内,各所述电芯的SOC值;将所述若干电芯中一电芯确定为参考电芯,以及,将除参考电芯以外的其它电芯确定为待检电芯;获取期望SOC值;计算并确定各所述待检电芯的SOC值与所述参考电芯的SOC值在各所述完全静置时段内的差值为第一差值,以及,所述参考电芯的SOC值和所述期望SOC值在各所述完全静置时段内的差值为第二差值;根据所述第一差值和所述第二差值,构建所述参考电芯和所述待检电芯之间的SOC差异映射模型,以及所述参考电芯和所述待检电芯之间的SOH差异映射模型;根据所述第一差值、所述第二差值以及所述SOC差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOC差异映射值;过滤所述SOC差异映射值,得到SOC差异过滤值;根据所述第一差值、所述第二差值、所述SOC差异过滤值以及所述SOH差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOH差异映射值;根据各所述待检电芯的SOH差异映射值,对所述若干待检电芯进行检测。In order to solve the above technical problems, a technical solution adopted by the embodiment of the present invention is to provide a detection method for the difference in the health of each cell in a battery pack. The detection method includes: determining that the several cells are in a completely static state at the same time M complete quiescence periods; obtain the SOC value of each of the cells in each of the complete quiescence periods; determine one of the plurality of cells as a reference cell, and remove the reference cell The other battery cores other than the core are determined as the battery cores to be tested; the expected SOC value is obtained; the SOC value of each battery core to be tested and the SOC value of the reference battery core are calculated and determined in each of the complete static periods The difference is a first difference, and the difference between the SOC value of the reference cell and the expected SOC value in each of the complete rest periods is a second difference; according to the first difference and The second difference is to construct a SOC difference mapping model between the reference cell and the cell to be inspected, and a SOH difference mapping model between the reference cell and the cell to be inspected; according to The first difference, the second difference, and the SOC difference mapping model are used to calculate the SOC difference mapping value of each of the cells to be tested in each of the complete rest periods; filter the SOC difference mapping value, to obtain the SOC difference filtering value; according to the first difference, the second difference, the SOC difference filtering value and the SOH difference mapping model, calculate each of the batteries to be tested in each of the complete The SOH difference mapping value in the static period; according to the SOH difference mapping value of each of the cells to be inspected, the plurality of cells to be inspected is detected.

可选地,将每一所述完全静置时段内的一所述第一差值和一所述第二差值确定为一差值组,得到M个差值组;从所述第一个差值组开始,依次选取往后相邻N个差值组进行线性回归拟合函数,得到P个拟合函数,其中,P=M-N+1;计算各所述拟合函数的斜率,得到P个拟合斜率;将所述P个拟合斜率按从小到大排序形成斜率队列,并且将位于所述斜率队列中间的斜率确定为最终斜率;根据所述最终斜率和所述M个差值组,构建成所述参考电芯和所述待检电芯之间的SOC差异映射模型。Optionally, determining a first difference and a second difference in each period of complete quiescence as a difference group to obtain M difference groups; from the first At the beginning of the difference group, select successively adjacent N difference groups to carry out the linear regression fitting function, and obtain P fitting functions, wherein, P=M-N+1; calculate the slope of each described fitting function, Obtain P fitting slopes; sort the P fitting slopes from small to large to form a slope queue, and determine the slope located in the middle of the slope queue as the final slope; according to the final slope and the M differences A value group is constructed to form an SOC difference mapping model between the reference cell and the cell to be tested.

可选地,获取一所述待检电芯在一所述完全静置时段的所述SOC差异映射值,以及前后各X个相邻的所述完全静置时段的所述SOC差异映射值,得到Y个所述SOC差异映射值,其中,Y=X+X+1;计算Y个所述SOC差异映射值的平均值;将该所述待检电芯在该所述完全静置时段的所述SOC差异映射值替换为所述平均值,得到该所述待检电芯的SOC差异过滤值。Optionally, acquiring the SOC difference mapping value of the cell to be tested in a complete rest period, and the SOC difference map values of X adjacent complete rest periods before and after each, Obtaining Y said SOC difference mapping values, wherein, Y=X+X+1; calculating the average value of Y said SOC difference mapping values; The SOC difference mapping value is replaced by the average value to obtain the SOC difference filtering value of the cell to be tested.

可选地,所述SOC差异映射模型为:ΔSOC’n,s=ΔSOCn,s+ΔSOCb,s*K,其中,n为电池组中待检电芯的编号,s为电池组中的参考电芯的编号,b为期望SOC值;ΔSOCn,s:第n号待检电芯与参考电芯s在一完全静置时段的SOC差值,ΔSOCb,s:期望SOC值与参考电芯s在该完全静置时段的SOC值之间的SOC差值;ΔSOC’n,s为第n号待检电芯与参考电芯s在该完全静置时段的SOC差异映射值;所述SOH差异映射模型为:ΔSOC”n,s=ΔSOCn,s+ΔSOCb,s*RSOH,其中,n为电池组中待检电芯的编号,s为电池组中的参考电芯的编号,b为期望SOC值;ΔSOCn,s:第n号待检电芯与参考电芯s在一完全静置时段的SOC差值,ΔSOCb,s:期望SOC值与参考电芯s在该完全静置时段的SOC值之间的SOC差值;ΔSOC”n,s为第n号待检电芯与参考电芯s在该完全静置时段的SOC差异过滤值,RSOH为第n号待检电芯与参考电芯s在该完全静置时段的SOH差异映射值。Optionally, the SOC difference mapping model is: ΔSOC'n,s=ΔSOCn,s+ΔSOCb,s*K, wherein, n is the number of the cell to be tested in the battery pack, s is the reference battery in the battery pack The number of the cell, b is the expected SOC value; ΔSOCn,s: the SOC difference between the nth cell to be tested and the reference cell s in a complete static period, ΔSOCb,s: the expected SOC value and the reference cell s at The SOC difference between the SOC values of the complete rest period; ΔSOC'n, s is the SOC difference mapping value of the nth cell to be tested and the reference cell s in the complete rest period; the SOH difference map The model is: ΔSOC"n,s=ΔSOCn,s+ΔSOCb,s*RSOH, where n is the number of cells to be tested in the battery pack, s is the number of reference cells in the battery pack, and b is the expected SOC value ; ΔSOCn,s: the SOC difference between the nth cell to be tested and the reference cell s in a complete rest period, ΔSOCb,s: the difference between the expected SOC value and the SOC value of the reference cell s in the complete rest period ΔSOC”n,s is the filtered value of the SOC difference between the nth cell to be tested and the reference cell s in the complete rest period, RSOH is the nth cell to be tested and the reference cell s The SOH difference map value during this period of complete rest.

可选地,获取所述若干电芯的电流小于预设电流阈值的时间段;获取所述若干电芯位于所述时间段内的电压;将位于所述时间段内的电压拟合成电压函数;判断所述电压函数的斜率是否小于第一预设斜率;若是,则确定所述时间段为所述若干电芯处于完全静置状态的完全静置时段;若否,则确定舍弃所述时间段,并且返回所述获取所述若干电芯的电流小于预设电流阈值的时间段的步骤。Optionally, acquire the time period when the current of the several batteries is less than the preset current threshold; acquire the voltage of the several batteries within the time period; fit the voltage within the time period to a voltage function ; Judging whether the slope of the voltage function is less than the first preset slope; if so, then determining that the time period is a period of complete quiescence in which the plurality of batteries are in a completely quiescent state; if not, then determining to discard the time segment, and return to the step of obtaining the time period during which the current of the plurality of cells is less than the preset current threshold.

可选地,将一所述待检电芯在所述M个完全静置时段对应的M个SOH差异映射值依次排列;依次计算相邻两个SOH差异映射值所在直线的斜率,得到若干个斜率;判断若干个所述斜率是否均在预设斜率范围内;若是,则确定所述待检电芯健康度正常;若否,则确定所述待检电芯健康度异常。Optionally, arrange the M SOH difference mapping values corresponding to the M complete rest periods of the cell to be tested in sequence; calculate the slopes of the straight lines where two adjacent SOH difference mapping values are located, and obtain several Slope: judging whether the plurality of slopes are all within the preset slope range; if yes, determining that the health of the battery to be tested is normal; if not, determining that the health of the battery to be tested is abnormal.

可选地,判断各所述待检电芯在所述M个完全静置时段的SOH差异映射值是否在预设差异映射值范围内;若是,则确定所述电池组中的若干待检电芯健康度正常;若否,则确定SOH差异映射值超出预设差异映射值范围的所述待检电芯健康度异常。Optionally, it is judged whether the SOH difference mapping values of each of the battery cells to be tested in the M complete rest periods are within the preset difference mapping value range; The health of the cell is normal; if not, it is determined that the health of the cell to be checked is abnormal if the SOH difference mapping value exceeds the preset difference mapping value range.

为解决上述技术问题,本发明实施例采用的另一个技术方案是:提供一种电池组各电芯健康度差异的检测装置,所述装置包括:第一确定模块,用于确定所述若干电芯同时处于完全静置状态的M个完全静置时段;第一获取模块,用于获取在各所述完全静置时段内,各所述电芯的SOC值;第二确定模块,用于将所述若干电芯中一电芯确定为参考电芯,以及,将除参考电芯以外的其它电芯确定为待检电芯;第二获取模块,用于获取期望SOC值;第一计算模块,用于计算并确定各所述待检电芯的SOC值与所述参考电芯的SOC值在各所述完全静置时段内的差值为第一差值,以及,所述参考电芯的SOC值和所述期望SOC值在各所述完全静置时段内的差值为第二差值;构建模块,用于根据所述第一差值和所述第二差值,构建所述参考电芯和所述待检电芯之间的SOC差异映射模型,以及所述参考电芯和所述待检电芯之间的SOH差异映射模型;第二计算模块,用于根据所述第一差值、所述第二差值以及所述SOC差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOC差异映射值;过滤模块,用于过滤所述SOC差异映射值,得到SOC差异过滤值;第三计算模块,用于根据所述第一差值、所述第二差值、所述SOC差异过滤值以及所述SOH差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOH差异映射值;检测模块,用于根据各所述待检电芯的SOH差异映射值,对所述若干待检电芯进行检测。In order to solve the above technical problems, another technical solution adopted by the embodiment of the present invention is to provide a detection device for the difference in the health of each battery cell in a battery pack, the device includes: a first determination module, used to determine the The core is in M complete rest periods in a complete rest state at the same time; the first acquisition module is used to obtain the SOC value of each of the batteries in each of the complete rest periods; the second determination module is used to set One of the plurality of batteries is determined as a reference battery, and other batteries except the reference battery are determined as batteries to be tested; the second acquisition module is used to obtain the expected SOC value; the first calculation module , used to calculate and determine that the difference between the SOC value of each of the cells to be tested and the SOC value of the reference cell within each of the complete rest periods is a first difference, and the reference cell The difference between the SOC value of the SOC value and the expected SOC value in each of the complete quiescent periods is a second difference; a building block is used to construct the A SOC difference mapping model between the reference cell and the cell to be inspected, and a SOH difference mapping model between the reference cell and the cell to be inspected; the second calculation module is used for according to the first A difference value, the second difference value, and the SOC difference mapping model, calculating the SOC difference mapping value of each of the cells to be tested in each of the complete rest periods; a filtering module, used to filter the SOC difference mapping value to obtain the SOC difference filtering value; the third calculation module is used to calculate each of the The SOH difference mapping value of the cells to be inspected in each of the complete rest periods; the detection module is used to detect the plurality of cells to be inspected according to the SOH difference mapping values of each of the cells to be inspected.

为解决上述技术问题,本发明实施例采用的再一个技术方案是:提供一种检测设备,包括:控制器,所述控制器包括:至少一个处理器,以及,与所述至少一个处理器通信连接的存储器;其中,所述存储器存储有可被所述至少一个处理器执行的指令,所述指令被所述至少一个处理器执行,以使所述至少一个处理器能够执行如上所述的方法。In order to solve the above technical problems, another technical solution adopted by the embodiment of the present invention is to provide a detection device, including: a controller, the controller includes: at least one processor, and communicates with the at least one processor A connected memory; wherein the memory stores instructions executable by the at least one processor, the instructions are executed by the at least one processor to enable the at least one processor to perform the method as described above .

为解决上述技术问题,本发明实施例采用的还一个技术方案是:提供一种非暂态计算机可读存储介质,所述非暂态计算机可读存储介质存储有计算机可执行指令,所述计算机可执行指令用于使服务器执行如上所述的方法。In order to solve the above technical problems, another technical solution adopted by the embodiment of the present invention is to provide a non-transitory computer-readable storage medium, the non-transitory computer-readable storage medium stores computer-executable instructions, and the computer The executable instructions are used to cause the server to perform the method as described above.

本发明实施例的有益效果是:区别于现有技术的情况,本发明实施例一种电池组各电芯健康度差异的检测方法首先确定所述若干电芯同时处于完全静置状态的M个完全静置时段;获取在各所述完全静置时段内,各所述电芯的SOC值;将所述若干电芯中一电芯确定为参考电芯,以及,将除参考电芯以外的其它电芯确定为待检电芯;获取期望SOC值;计算并确定各所述待检电芯的SOC值与所述参考电芯的SOC值在各所述完全静置时段内的差值为第一差值,以及,所述参考电芯的SOC值和所述期望SOC值在各所述完全静置时段内的差值为第二差值;根据所述第一差值和所述第二差值,构建所述参考电芯和所述待检电芯之间的SOC差异映射模型,以及所述参考电芯和所述待检电芯之间的SOH差异映射模型;根据所述第一差值、所述第二差值以及所述SOC差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOC差异映射值;过滤所述SOC差异映射值,得到SOC差异过滤值;根据所述第一差值、所述第二差值、所述SOC差异过滤值以及所述SOH差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOH差异映射值;根据各所述待检电芯的SOH差异映射值,对所述若干待检电芯进行检测。通过上述步骤,本发明实施例能够消除各电芯的电量容量不一致来对电池组中的各个电芯进行健康度差异的检测,提高检测结果的准确性。The beneficial effect of the embodiment of the present invention is: different from the situation of the prior art, in the embodiment of the present invention, a method for detecting the difference in the health of each battery cell in a battery pack first determines the number of M cells that are in a completely static state at the same time Complete static period; obtain the SOC value of each of the cells in each of the complete static periods; determine one of the plurality of cells as a reference cell, and set the SOC value of each cell other than the reference cell Other batteries are determined as the batteries to be tested; the expected SOC value is obtained; the difference between the SOC value of each battery to be tested and the SOC value of the reference battery in each of the complete rest periods is calculated and determined The first difference, and the difference between the SOC value of the reference cell and the expected SOC value in each of the complete rest periods is a second difference; according to the first difference and the first difference Two difference values, constructing the SOC difference mapping model between the reference cell and the cell to be tested, and the SOH difference mapping model between the reference cell and the cell to be tested; according to the first A difference, the second difference and the SOC difference mapping model, calculate the SOC difference mapping value of each of the batteries to be tested in each of the complete rest periods; filter the SOC difference mapping value to obtain SOC difference filtering value; according to the first difference, the second difference, the SOC difference filtering value and the SOH difference mapping model, calculate each of the cells to be tested in each of the complete rest periods The SOH difference mapping value within; according to the SOH difference mapping value of each of the battery cells to be tested, the plurality of battery cells to be tested is detected. Through the above steps, the embodiment of the present invention can eliminate the inconsistency of the electric capacity of each battery cell to detect the health degree difference of each battery cell in the battery pack, and improve the accuracy of the detection result.

附图说明Description of drawings

为了更清楚地说明本发明具体实施例或现有技术中的技术方案,下面将对具体实施例或现有技术描述中所需要使用的附图作简单地介绍。在所有附图中,类似的元件或部分一般由类似的附图标记标识。附图中,各元件或部分并不一定按照实际的比例绘制。In order to more clearly illustrate the specific embodiments of the present invention or the technical solutions in the prior art, the following will briefly introduce the drawings that need to be used in the description of the specific embodiments or the prior art. Throughout the drawings, similar elements or parts are generally identified by similar reference numerals. In the drawings, elements or parts are not necessarily drawn in actual scale.

图1是本发明实施例电池组各电芯健康度差异的检测方法的应用环境示意图;Fig. 1 is a schematic diagram of the application environment of the detection method for the difference in the health of each battery cell in the battery pack according to the embodiment of the present invention;

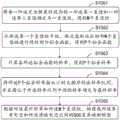

图2是本发明实施例电池组各电芯健康度差异的检测方法的流程图;2 is a flow chart of a method for detecting the difference in health of each battery cell in a battery pack according to an embodiment of the present invention;

图3是本发明实施例电池组各电芯健康度差异的检测方法中步骤S101的流程图;Fig. 3 is a flow chart of step S101 in the method for detecting the difference in the health of each battery cell in the battery pack according to the embodiment of the present invention;

图4是本发明实施例电池组各电芯健康度差异的检测方法中步骤S106的流程图;Fig. 4 is a flow chart of step S106 in the method for detecting the difference in the health of each battery cell in the battery pack according to the embodiment of the present invention;

图5是本发明实施例电池组各电芯健康度差异的检测方法中步骤S108的流程图;Fig. 5 is a flow chart of step S108 in the method for detecting the difference in the health of each battery cell in the battery pack according to the embodiment of the present invention;

图6是本发明实施例电池组各电芯健康度差异的检测方法中步骤S110的流程图;Fig. 6 is a flow chart of step S110 in the method for detecting the difference in the health of each battery cell in the battery pack according to the embodiment of the present invention;

图7是本发明另一实施例电池组各电芯健康度差异的检测方法中步骤S110的流程图;Fig. 7 is a flow chart of step S110 in the method for detecting the difference in the health of each battery cell in a battery pack according to another embodiment of the present invention;

图8是本发明实施例电池组各电芯健康度差异的检测装置的结构框图;Fig. 8 is a structural block diagram of a detection device for the difference in health of each battery cell in a battery pack according to an embodiment of the present invention;

图9是本发明实施例检测设备的示意图。Fig. 9 is a schematic diagram of a detection device according to an embodiment of the present invention.

具体实施方式Detailed ways

为了便于理解本发明,下面结合附图和具体实施例,对本发明进行更详细的说明。需要说明的是,当元件被表述“固定于”另一个元件,它可以直接在另一个元件上、或者其间可以存在一个或多个居中的元件。当一个元件被表述“连接”另一个元件,它可以是直接连接到另一个元件、或者其间可以存在一个或多个居中的元件。本说明书所使用的术语“上”、“下”、“内”、“外”、“垂直的”、“水平的”等指示的方位或位置关系为基于附图所示的方位或位置关系,仅是为了便于描述本发明和简化描述,而不是指示或暗示所指的装置或元件必须具有特定的方位、以特定的方位构造和操作,因此不能理解为对本发明的限制。此外,术语“”、“”等仅用于描述目的,而不能理解为指示或暗示相对重要性。In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that when an element is said to be "fixed" to another element, it may be directly on the other element, or there may be one or more intervening elements therebetween. When an element is referred to as being "connected to" another element, it can be directly connected to the other element or one or more intervening elements may be present therebetween. The orientation or positional relationship indicated by the terms "upper", "lower", "inner", "outer", "vertical", "horizontal" etc. used in this specification is based on the orientation or positional relationship shown in the drawings, It is only for the convenience of describing the present invention and simplifying the description, but does not indicate or imply that the device or element referred to must have a specific orientation, be constructed and operated in a specific orientation, and thus should not be construed as limiting the present invention. Furthermore, the terms "", "", etc. are used for descriptive purposes only and are not to be construed as indicating or implying relative importance.

除非另有定义,本说明书所使用的所有的技术和科学术语与属于本发明的技术领域的技术人员通常理解的含义相同。在本发明的说明书中所使用的术语只是为了描述具体的实施例的目的,不是用于限制本发明。本说明书所使用的术语“和/或”包括一个或多个相关的所列项目的任意的和所有的组合。Unless otherwise defined, all technical and scientific terms used in this specification have the same meaning as commonly understood by one of ordinary skill in the technical field of the invention. Terms used in the description of the present invention are only for the purpose of describing specific embodiments, and are not used to limit the present invention. The term "and/or" used in this specification includes any and all combinations of one or more of the associated listed items.

此外,下面所描述的本发明不同实施例中所涉及的技术特征只要彼此之间未构成冲突就可以相互结合。In addition, the technical features involved in different embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

参阅图1,图1是本发明实施例一种电池组各电芯健康度差异的检测方法的应用环境的示意图,该应用环境包括电动汽车10以及云端设备20,所述电池汽车10包括汽车本体11、电池组12以及数据处理器13。所述电池组12和所述数据处理器13设置于所述汽车本体11,所述电池组12与所述数据处理器13电连接,所述数据处理器13用于收集并且存储电池组12相关数据,所述云端设备20从所述数据处理器13中获取电池组12的相关数据,以便于对所述电池组12进行各电芯健康度差异的检测任务。Referring to FIG. 1, FIG. 1 is a schematic diagram of an application environment of a method for detecting the difference in health of each battery cell of a battery pack according to an embodiment of the present invention. The application environment includes an

图2示出了根据本发明一种电池组各电芯健康度差异的检测方法的流程图,如图2所示,该检测方法包括以下步骤:Fig. 2 shows a flow chart of a method for detecting the difference in health of each battery cell in a battery pack according to the present invention. As shown in Fig. 2, the detection method includes the following steps:

步骤S101,确定所述若干电芯同时处于完全静置状态的M个完全静置时段。Step S101 , determining M complete rest periods during which the plurality of battery cells are in a complete rest state at the same time.

其中M为大于零的自然数。Where M is a natural number greater than zero.

在新能源汽车领域,汽车中配备的储能电源由多个电池组串联、并联以及串并联组成,在本发明实施例中的电池组中的电芯为串联连接。In the field of new energy vehicles, the energy storage power supply equipped in the vehicle is composed of multiple battery packs connected in series, parallel and series-parallel. In the embodiment of the present invention, the batteries in the battery pack are connected in series.

电芯处于完全静置状态是指通过检测电芯的充放电电流,当所述电芯的充放电电流小于预设电流阈值时,就认为该电芯处于完全静置状态,由于电池组中的若干电芯为串联连接,因此,可以认为当其中一个电芯处于完全静置状态时,该电池组中的其他电芯也处于完全静置状态,电芯处于完全静置状态的时间段为完全静置时段,其中,所述电芯的充放电电流是通过电池组中的电流传感器检测采集,所述预设电流阈值为人工设定的电流数值,本发明的一种实施方式中,所述电流阈值一般设预设为3安,当电流传感器采集到电芯的充电电流或者放电电流小于或者等于3安时,则可以认为通过这种小电流的电芯,内部电化学环境趋近于稳态,可以认为电芯处于完全静置状态。The battery cell is in a completely static state means that by detecting the charging and discharging current of the battery cell, when the charging and discharging current of the battery cell is less than the preset current threshold, it is considered that the battery cell is in a completely static state. Several battery cells are connected in series, therefore, it can be considered that when one of the battery cells is in a completely static state, the other battery cells in the battery pack are also in a completely static state, and the time period during which the battery cells are in a completely static state is the complete Standing period, wherein, the charging and discharging current of the battery cell is detected and collected by the current sensor in the battery pack, and the preset current threshold value is a current value set manually. In one embodiment of the present invention, the The current threshold is generally set to 3 amps. When the current sensor collects the charging current or discharging current of the cell is less than or equal to 3 amps, it can be considered that the internal electrochemical environment tends to be stable through such a small current cell. state, it can be considered that the cell is in a completely static state.

在一些实施例中,请参阅图3,步骤S101包括:In some embodiments, referring to FIG. 3, step S101 includes:

步骤S1011,获取所述若干电芯的电流小于预设电流阈值的时间段。Step S1011, acquiring a time period during which the currents of the plurality of cells are less than a preset current threshold.

通过云端获取电动汽车电池组中的若干电芯的数据以及电动汽车里程数据,对所述电芯的数据进行数据清洗,剔除无效信息,其中,所述电芯的数据包括电流数据以及电压数据。Obtain the data of several cells in the electric vehicle battery pack and the mileage data of the electric vehicle through the cloud, and perform data cleaning on the data of the cells to remove invalid information, wherein the data of the cells includes current data and voltage data.

对每个里程的电流进行遍历,当电流小于或等于电流传感器的采样精度的绝对值时,认为该电芯开始静置,记录该时间为静置起始时间。继续向后遍历电流,当电流大于电流传感器精度的绝对值时,认为该电芯结束静置,记录当前时间为静置结束时间,从静置起始时间到静置结束时间定义为完全静置时段。The current of each mileage is traversed. When the current is less than or equal to the absolute value of the sampling accuracy of the current sensor, it is considered that the cell starts to stand still, and the time is recorded as the start time of the standstill. Continue to traverse the current backwards. When the current is greater than the absolute value of the accuracy of the current sensor, it is considered that the cell has ended the rest, and the current time is recorded as the end time of the rest. From the start time of the rest to the end time of the rest is defined as a complete rest time period.

步骤S1012,获取所述若干电芯位于所述时间段内的电压。Step S1012, acquiring voltages of the plurality of battery cells within the time period.

所述电压数据与所述电流一一对应,所述电压为开路电压。The voltage data corresponds to the current one by one, and the voltage is an open circuit voltage.

步骤S1013,将位于所述时间段内的电压拟合成电压函数。Step S1013, fitting the voltage within the time period into a voltage function.

在本发明实施例中,采用指数函数对所述电压数据进行函数拟合,可以理解的是,在其他实施例中,可以采用其他函数进行电压函数拟合,例如对数函数等。In the embodiment of the present invention, an exponential function is used to perform function fitting on the voltage data. It can be understood that in other embodiments, other functions may be used to perform voltage function fitting, such as a logarithmic function.

步骤S1014,判断所述电压函数的斜率是否小于第一预设斜率。Step S1014, judging whether the slope of the voltage function is smaller than a first preset slope.

处于完全静置时段内的电芯的电流依旧处于一个变化的状态,此时与电流对应的电压也处于变化的状态,当拟合的电压函数的斜率小于第一预设斜率时,则当前的电压的变化率足够小,即可以认为当前电芯处于完全静置状态。The current of the battery cell in the completely static period is still in a changing state, and the voltage corresponding to the current is also in a changing state at this time. When the slope of the fitted voltage function is less than the first preset slope, the current The rate of change of the voltage is small enough that it can be considered that the current cell is in a completely static state.

步骤S1015,若是,则确定所述时间段为所述若干电芯处于完全静置状态的完全静置时段。Step S1015, if yes, determine that the time period is a complete rest period when the plurality of battery cells are in a complete rest state.

步骤S1016,若否,则确定舍弃所述时间段,并且返回所述获取所述若干电芯的电流小于预设电流阈值的时间段的步骤。Step S1016, if not, determine to discard the time period, and return to the step of obtaining the time period in which the current of the plurality of cells is less than the preset current threshold.

当电压斜率大于第一预设斜率时,则认为当前时间段内的电芯仍然处于充放电状态,应当舍弃当前时间段,继续遍历电流数据进行完全静置时段的寻找。When the voltage slope is greater than the first preset slope, it is considered that the battery cells in the current time period are still in the charging and discharging state, and the current time period should be discarded, and the current data should be traversed to search for a complete rest period.

步骤S102,获取在各所述完全静置时段内,各所述电芯的SOC值。Step S102, acquiring the SOC value of each battery cell during each period of complete rest.

SOC(state of charge)是指电池剩余电量百分比,即电池剩余电量与该电池当前容量的比值。SOC (state of charge) refers to the percentage of remaining battery power, that is, the ratio of the remaining battery power to the current capacity of the battery.

当拟合电压函数的斜率小于第一预设斜率时,选取拟合电压函数最后一个电压值作为该电芯在当前完全静置时段的开路电压,并且根据OCV-SOC表进行SOC查询,其中,OCV-SOC(Open Circuit Voltage:开路电压)表是指电池开路电压与电池荷电状态一一对应的表格。When the slope of the fitted voltage function is less than the first preset slope, select the last voltage value of the fitted voltage function as the open-circuit voltage of the cell in the current complete rest period, and perform SOC query according to the OCV-SOC table, wherein, The OCV-SOC (Open Circuit Voltage: open circuit voltage) table refers to a one-to-one correspondence table between the open circuit voltage of the battery and the state of charge of the battery.

步骤S103,将所述若干电芯中一电芯确定为参考电芯,以及,将除参考电芯以外的其它电芯确定为待检电芯。In step S103, one battery cell among the plurality of batteries is determined as a reference battery cell, and other batteries except the reference battery cell are determined as battery cells to be tested.

步骤S104,获取期望SOC值。Step S104, obtaining an expected SOC value.

预设一个SOC值为期望SOC值,其中,期望SOC值的作用是:利用SOC差异映射模型将每次静置时参考电芯的SOC值对齐至期望SOC值后,此时所述待检电芯与所述参考电芯之间的SOC差异在不同次静置之间的变化才能够反映出他们之间的自放电差异,其中,期望SOC值一般设置为95%或100%,可根据实际需求进行调整。A preset SOC value is the expected SOC value, wherein the function of the expected SOC value is: after using the SOC difference mapping model to align the SOC value of the reference cell to the expected SOC value at each standstill, the battery to be tested at this time The change of the SOC difference between the cell and the reference cell between different resting times can reflect the self-discharge difference between them, wherein the expected SOC value is generally set to 95% or 100%, which can be determined according to the actual Need to adjust.

步骤S105,计算并确定各所述待检电芯的SOC值与所述参考电芯的SOC值在各所述完全静置时段内的差值为第一差值,以及,所述参考电芯的SOC值和所述期望SOC值在各所述完全静置时段内的差值为第二差值。Step S105, calculating and determining the difference between the SOC value of each cell to be tested and the SOC value of the reference cell in each of the complete rest periods as a first difference, and the reference cell The difference between the SOC value and the expected SOC value in each of the complete rest periods is the second difference.

步骤S106,根据所述第一差值和所述第二差值,构建所述参考电芯和所述待检电芯之间的SOC差异映射模型,以及所述参考电芯和所述待检电芯之间的SOH差异映射模型。Step S106, according to the first difference and the second difference, construct a SOC difference mapping model between the reference cell and the cell to be tested, and the reference cell and the cell to be tested SOH difference mapping model between cells.

所述SOC差异映射模型为:ΔSOC’n,s=ΔSOCn,s+ΔSOCb,s*K,其中,n为电池组中待检电芯的编号,s为电池组中的参考电芯的编号,b为期望SOC值;ΔSOCn,s:第n号待检电芯与参考电芯s在一完全静置时段的SOC差值,ΔSOCb,s:期望SOC值与参考电芯s在该完全静置时段的SOC值之间的SOC差值;ΔSOC’n,s为第n号待检电芯与参考电芯s在该完全静置时段的SOC差异映射值。所述SOC差异映射模型的工作原理为:每次静置时,将参考电芯的SOC补偿ΔSOCb,s之后,参考电芯的SOC对齐至期望SOC。此时,通过比较若干次完全静置时段的第n号待检电芯与参考电芯s的SOC差异映射值(ΔSOC’n,s),可以得出第n号待检电芯与参考电芯s的自放电差异随时间的变化。The SOC difference mapping model is: ΔSOC'n,s=ΔSOCn,s+ΔSOCb,s*K, wherein, n is the number of the cell to be tested in the battery pack, s is the number of the reference cell in the battery pack, b is the expected SOC value; ΔSOCn,s: the SOC difference between the nth cell to be tested and the reference cell s in a complete rest period, ΔSOCb,s: the expected SOC value and the reference cell s in the complete rest period The SOC difference between the SOC values of the period; ΔSOC'n,s is the SOC difference mapping value of the nth cell to be tested and the reference cell s in the completely static period. The working principle of the SOC difference mapping model is as follows: each time the SOC of the reference cell is compensated by ΔSOCb,s, the SOC of the reference cell is aligned to the expected SOC. At this time, by comparing the SOC difference mapping value (ΔSOC'n,s) of the nth cell to be tested and the reference cell s during several periods of complete quiescence, it can be obtained that the nth cell to be tested and the reference cell The self-discharge difference of the core s as a function of time.

SOH(state of health)是指电池健康度,即电池当前的容量与出厂容量的百分比。SOH (state of health) refers to the health of the battery, that is, the percentage of the current capacity of the battery to the factory capacity.

所述SOH差异映射模型为:ΔSOC”n,s=ΔSOCn,s+ΔSOCb,s*RSOH,其中,n为电池组中待检电芯的编号,s为电池组中的参考电芯的编号,b为期望SOC值;ΔSOCn,s:第n号待检电芯与参考电芯s在一完全静置时段的SOC差值,ΔSOCb,s:期望SOC值与参考电芯s在该完全静置时段的SOC值之间的SOC差值;ΔSOC”n,s为第n号待检电芯与参考电芯s在该完全静置时段的SOC差异过滤值,RSOH为第n号待检电芯与参考电芯s在该完全静置时段的SOH差异映射值。所述SOH差异映射模型的工作原理为:每次静置时,将参考电芯的SOC补偿ΔSOCb,s之后,参考电芯的SOC对齐至期望SOC。此时,通过计算可以得出第n号待检电芯与参考电芯s的SOC差异映射值(ΔSOC’n,s),将所述SOC差异映射值进行滑窗滤波操作,可以得到的滤波值,根据所述滤波值可以计算出每次完全静置时段的第n号待检电芯与参考电芯s的健康度差异随时间的变化。The SOH difference mapping model is: ΔSOC"n,s=ΔSOCn,s+ΔSOCb,s*RSOH, wherein, n is the number of the cell to be tested in the battery pack, s is the number of the reference cell in the battery pack, b is the expected SOC value; ΔSOCn,s: the SOC difference between the nth cell to be tested and the reference cell s in a complete rest period, ΔSOCb,s: the expected SOC value and the reference cell s in the complete rest period The SOC difference between the SOC values of the time period; ΔSOC”n,s is the SOC difference filter value of the nth battery cell to be tested and the reference battery s in this completely static period, and RSOH is the nth battery cell to be tested The SOH difference mapping value from the reference cell s during this complete rest period. The working principle of the SOH difference mapping model is: each time the SOC of the reference cell is compensated by ΔSOCb,s, the SOC of the reference cell is aligned to the expected SOC. At this time, the SOC difference mapping value (ΔSOC'n,s) of the nth cell to be tested and the reference cell s can be obtained by calculation, and the sliding window filtering operation is performed on the SOC difference mapping value, and the obtained filtering value, according to the filter value, the change over time of the health degree difference between the nth cell to be tested and the reference cell s can be calculated for each complete rest period.

在一些实施例中,请参阅图4,步骤S106包括:In some embodiments, referring to FIG. 4, step S106 includes:

步骤S1061,将每一所述完全静置时段内的一所述第一差值和一所述第二差值确定为一差值组,得到M个差值组。Step S1061, determining a first difference value and a second difference value in each period of complete quiescence as a difference value group to obtain M difference value groups.

步骤S1062,从所述第一个差值组开始,依次选取往后相邻N个差值组进行线性回归拟合函数,得到P个拟合函数,其中,P=M-N+1。Step S1062, starting from the first difference group, successively select N adjacent difference groups to perform linear regression fitting functions to obtain P fitting functions, where P=M-N+1.

步骤S1063,计算各所述拟合函数的斜率,得到P个拟合斜率。Step S1063, calculating the slopes of each of the fitting functions to obtain P fitting slopes.

步骤S1064,将所述P个拟合斜率按从小到大排序形成斜率队列,并且将位于所述斜率队列中间的斜率确定为最终斜率。Step S1064, sorting the P fitting slopes from small to large to form a slope queue, and determining the slope in the middle of the slope queue as the final slope.

步骤S1065,根据所述最终斜率和所述M个差值组,构建成所述参考电芯和所述待检电芯之间的SOC差异映射模型。Step S1065, constructing a SOC difference mapping model between the reference cell and the cell to be tested according to the final slope and the M difference groups.

步骤S107,根据所述第一差值、所述第二差值以及所述SOC差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOC差异映射值。Step S107 , according to the first difference, the second difference and the SOC difference mapping model, calculate the SOC difference mapping value of each battery cell to be tested in each of the complete rest periods.

将处于某个完全静置时段时其中一个电芯与参考电芯的第一差值以及参考电芯和期望SOC值的第二差值代入SOC差异映射模型中,即可求出在该完全静置时段的该待检电芯与参考电芯之间的SOC差异映射值,同样地,可以求得在该完全静置时段时,电池组中其他待检电芯与参考电芯之间的SOC差异映射值,以及,在选取的M个完全静置时段的各待检电芯与参考电芯的SOC差异映射值。Substituting the first difference between one of the cells and the reference cell and the second difference between the reference cell and the expected SOC value into the SOC difference mapping model during a certain period of complete quiescence, the The SOC difference mapping value between the cell to be tested and the reference cell during the set period, similarly, the SOC between the other cells to be tested and the reference cell in the battery pack can be obtained during the complete rest period. The difference mapping value, and the SOC difference mapping value of each battery cell to be tested and the reference battery cell during the selected M complete rest periods.

步骤S108,过滤所述SOC差异映射值,得到SOC差异过滤值。Step S108, filtering the SOC difference mapping value to obtain the SOC difference filtering value.

在一些实施例中,请参阅图5,步骤S108包括:In some embodiments, referring to FIG. 5, step S108 includes:

步骤S1081,获取一所述待检电芯在一所述完全静置时段的所述SOC差异映射值,以及前后各X个相邻的所述完全静置时段的所述SOC差异映射值,得到Y个所述SOC差异映射值,其中,Y=X+X+1,X和Y均为大于零的自然数。Step S1081, obtaining the SOC difference mapping value of the cell to be tested in a complete resting period, and the SOC difference mapping values of X adjacent complete resting periods before and after each, to obtain Y said SOC difference mapping values, wherein, Y=X+X+1, and both X and Y are natural numbers greater than zero.

步骤S1082,计算Y个所述SOC差异映射值的平均值。Step S1082, calculating the average value of the Y SOC difference mapping values.

步骤S1083,将该所述待检电芯在该所述完全静置时段的所述SOC差异映射值替换为所述平均值,得到该所述待检电芯的SOC差异过滤值。Step S1083, replacing the SOC difference mapping value of the battery cell to be tested in the complete rest period with the average value to obtain the SOC difference filter value of the battery cell to be tested.

为了更方便理解,以下进行举例说明步骤S108的过程,假设共有10个完全静置时段,任意一个待检电芯经过步骤S101至步骤S107,可以得到10个SOC差异映射值,当X=2时,则可以选取5个SOC差异映射值,即第1个完全静置时段至第5个完全静置时段的SOC差异映射值,计算这5个SOC差异映射值的平均值,将所述平均值替换第3个静置时段的SOC差异映射值,此时,第3个静置时段对应的是SOC差异过滤值,完成第一轮替换,接着选取下一轮的5个SOC差异映射值,即第2个完全静置时段至第6个完全静置时段的SOC差异映射值,计算这5个SOC差异映射值的平均值,将所述平均值替换第4个静置时段的SOC差异映射值,此时,第4个静置时段对应的是SOC差异过滤值,完成第二轮替换,依次类推,直至完成所有完全静置时段的SOC差异映射值的替换。For easier understanding, the following is an example to illustrate the process of step S108. Assume that there are 10 complete rest periods, and any cell to be tested can get 10 SOC difference mapping values through steps S101 to S107. When X=2 , then five SOC difference mapping values can be selected, that is, the SOC difference mapping values from the first complete resting period to the fifth complete resting period, and the average value of these five SOC difference mapping values can be calculated, and the average value Replace the SOC difference mapping value of the third static period. At this time, the third static period corresponds to the SOC difference filtering value, complete the first round of replacement, and then select the next round of 5 SOC difference mapping values, namely For the SOC difference mapping value from the second complete rest period to the sixth complete rest period, calculate the average value of these five SOC difference map values, and replace the SOC difference map value of the fourth rest period with the average value , at this time, the fourth resting period corresponds to the SOC difference filtering value, the second round of replacement is completed, and so on, until the replacement of the SOC difference mapping values in all complete resting periods is completed.

步骤S109,根据所述第一差值、所述第二差值、所述SOC差异过滤值以及所述SOH差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOH差异映射值。Step S109, according to the first difference value, the second difference value, the SOC difference filter value and the SOH difference mapping model, calculate the value of each battery cell to be tested in each of the complete rest periods SOH difference map value.

步骤S110,根据各所述待检电芯的SOH差异映射值,对所述若干待检电芯进行检测。Step S110 , inspecting the plurality of cells to be inspected according to the SOH difference mapping value of each cell to be inspected.

在一些实施例中,请参阅图6,步骤S110包括:In some embodiments, referring to FIG. 6, step S110 includes:

步骤S1101,将一所述待检电芯在所述M个完全静置时段对应的M个SOH差异映射值依次排列。Step S1101, arranging the M SOH difference mapping values corresponding to the M complete quiescence periods of a cell to be inspected in sequence.

将SOH差异映射值按照完全静置时段选取顺序依次排列。Arrange the SOH difference mapping values in sequence according to the selection order of the complete rest period.

步骤S1102,依次计算相邻两个SOH差异映射值所在直线的斜率,得到若干个斜率。Step S1102, sequentially calculating the slopes of the straight lines where two adjacent SOH difference mapping values are located, to obtain several slopes.

步骤S1103,判断若干个所述斜率是否均在预设斜率范围内。Step S1103, judging whether the several slopes are all within the preset slope range.

当相邻两个SOH差异映射值所在直线的斜率不在预设斜率范围时,说明该计算斜率过大或者过小,即相邻两个SOH差异映射值差值过大,根据经验可知,SOH差异映射值随时间突然增大的电芯容易成为问题电芯,因此,需要将其检出。When the slope of the straight line where two adjacent SOH difference mapping values are located is not within the preset slope range, it means that the calculated slope is too large or too small, that is, the difference between two adjacent SOH difference mapping values is too large. According to experience, the SOH difference A cell whose mapping value suddenly increases over time is likely to be a problem cell, so it needs to be detected.

步骤S1104,若是,则确定所述待检电芯健康度正常。Step S1104, if yes, determine that the health of the cell to be checked is normal.

步骤S1105,若否,则确定所述待检电芯健康度异常。Step S1105, if not, determine that the health of the cell to be checked is abnormal.

在一些实施例中,请参阅图7,步骤S110还包括:In some embodiments, referring to FIG. 7, step S110 further includes:

步骤S1106,判断各所述待检电芯在所述M个完全静置时段的SOH差异映射值是否在预设差异映射值范围内。Step S1106, judging whether the SOH difference mapping values of each of the battery cells to be inspected during the M complete rest periods are within a preset difference mapping value range.

当某个待测电芯的SOH差异映射值不在预设差异映射值范围内,说明该待检电芯的SOH差异映射值与其他待检电芯的SOH差异映射值存在明显差异,根据经验可知,SOH差异映射值一直大于其他待检电芯的待检电芯容易成为问题电芯,因此,需要将其检出。When the SOH difference mapping value of a cell to be tested is not within the preset difference mapping value range, it means that there is a significant difference between the SOH difference mapping value of the cell to be tested and the SOH difference mapping value of other cells to be tested. According to experience , the cell to be inspected whose SOH difference mapping value is always greater than that of other cells to be inspected is likely to become a problem cell, so it needs to be detected.

步骤S1107,若是,则确定所述电池组中的若干待检电芯健康度正常。Step S1107, if yes, determine that the health of the cells to be checked in the battery pack is normal.

步骤S1108,若否,则确定SOH差异映射值超出预设差异映射值范围的所述待检电芯健康度异常。Step S1108, if not, determine that the health degree of the cell to be checked is abnormal if the SOH difference mapping value exceeds the preset difference mapping value range.

可以理解的是,在一些实施例中,本发明实施例所述的方法不限于云端设备使用,也可以应用于汽车的BMS(Battery Management System:电池管理系统)、储能BMS等电池数据监控平台。It can be understood that, in some embodiments, the methods described in the embodiments of the present invention are not limited to the use of cloud devices, and can also be applied to battery data monitoring platforms such as BMS (Battery Management System: battery management system) and energy storage BMS of automobiles. .

本发明实施例的有益效果是:区别于现有技术的情况,本发明实施例一种电池组各电芯健康度差异的检测方法首先确定所述若干电芯同时处于完全静置状态的M个完全静置时段;获取在各所述完全静置时段内,各所述电芯的SOC值;将所述若干电芯中一电芯确定为参考电芯,以及,将除参考电芯以外的其它电芯确定为待检电芯;获取期望SOC值;计算并确定各所述待检电芯的SOC值与所述参考电芯的SOC值在各所述完全静置时段内的差值为第一差值,以及,所述参考电芯的SOC值和所述期望SOC值在各所述完全静置时段内的差值为第二差值;根据所述第一差值和所述第二差值,构建所述参考电芯和所述待检电芯之间的SOC差异映射模型,以及所述参考电芯和所述待检电芯之间的SOH差异映射模型;根据所述第一差值、所述第二差值以及所述SOC差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOC差异映射值;过滤所述SOC差异映射值,得到SOC差异过滤值;根据所述第一差值、所述第二差值、所述SOC差异过滤值以及所述SOH差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOH差异映射值;根据各所述待检电芯的SOH差异映射值,对所述若干待检电芯进行检测。通过上述步骤,本发明实施例能够消除各电芯的电量容量不一致来对电池组中的各个电芯进行健康度差异的检测,提高检测结果的准确性。The beneficial effect of the embodiment of the present invention is: different from the situation of the prior art, in the embodiment of the present invention, a method for detecting the difference in the health of each battery cell in a battery pack first determines the number of M cells that are in a completely static state at the same time Complete static period; obtain the SOC value of each of the cells in each of the complete static periods; determine one of the plurality of cells as a reference cell, and set the SOC value of each cell other than the reference cell Other batteries are determined as the batteries to be tested; the expected SOC value is obtained; the difference between the SOC value of each battery to be tested and the SOC value of the reference battery in each of the complete rest periods is calculated and determined The first difference, and the difference between the SOC value of the reference cell and the expected SOC value in each of the complete rest periods is a second difference; according to the first difference and the first difference Two difference values, constructing the SOC difference mapping model between the reference cell and the cell to be tested, and the SOH difference mapping model between the reference cell and the cell to be tested; according to the first A difference, the second difference and the SOC difference mapping model, calculate the SOC difference mapping value of each of the batteries to be tested in each of the complete rest periods; filter the SOC difference mapping value to obtain SOC difference filter value; according to the first difference value, the second difference value, the SOC difference filter value and the SOH difference mapping model, calculate each of the cells to be tested in each of the complete rest periods The SOH difference mapping value within; according to the SOH difference mapping value of each of the battery cells to be tested, the plurality of battery cells to be tested is detected. Through the above steps, the embodiment of the present invention can eliminate the inconsistency of the electric capacity of each battery cell to detect the health degree difference of each battery cell in the battery pack, and improve the accuracy of the detection result.

本发明还提供一种电池组各电芯自放电差异的检测装置60实施例,请参阅图8,图8示出了本发明一种电池组各电芯自放电差异的检测装置60的功能框图,所述检测装置60包括第一确定模块601、第一获取模块602、第二确定模块603、第二获取模块604、第一计算模块605、构建模块606、第二计算模块607、过滤模块608、第三计算模块609以及检测模块610。The present invention also provides an embodiment of a detection device 60 for the self-discharge difference of each cell in a battery pack, please refer to FIG. 8 , which shows a functional block diagram of a detection device 60 for the self-discharge difference of each cell in a battery pack according to the present invention. , the detection device 60 includes a first determination module 601, a first acquisition module 602, a second determination module 603, a second acquisition module 604, a first calculation module 605, a construction module 606, a second calculation module 607, and a filter module 608 , a third calculation module 609 and a detection module 610 .

其中,第一确定模块601用于确定所述若干电芯同时处于完全静置状态的M个完全静置时段;第一获取模块602用于获取在各所述完全静置时段内,各所述电芯的SOC值;第二确定模块603用于将所述若干电芯中一电芯确定为参考电芯,以及,将除参考电芯以外的其它电芯确定为待检电芯;第二获取模块604用于获取期望SOC值;第一计算模块605用于计算并确定各所述待检电芯的SOC值与所述参考电芯的SOC值在各所述完全静置时段内的差值为第一差值,以及,所述参考电芯的SOC值和所述期望SOC值在各所述完全静置时段内的差值为第二差值;构建模块606用于根据所述第一差值和所述第二差值,构建所述参考电芯和所述待检电芯之间的SOC差异映射模型,以及所述参考电芯和所述待检电芯之间的SOH差异映射模型;第二计算模块607用于根据所述第一差值、所述第二差值以及所述SOC差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOC差异映射值;过滤模块608用于过滤所述SOC差异映射值,得到SOC差异过滤值;第三计算模块609用于根据所述第一差值、所述第二差值、所述SOC差异过滤值以及所述SOH差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOH差异映射值;检测模块610用于根据各所述待检电芯的SOH差异映射值,对所述若干待检电芯进行检测。Wherein, the first determination module 601 is used to determine the M complete quiescence periods in which the plurality of electric cores are in a complete quiescence state at the same time; the first acquisition module 602 is used to acquire each of the The SOC value of the battery cell; the second determination module 603 is used to determine a battery cell in the plurality of battery cells as a reference battery cell, and determine other batteries except the reference battery cell as the battery cell to be tested; the second The obtaining module 604 is used to obtain the expected SOC value; the first calculation module 605 is used to calculate and determine the difference between the SOC value of each cell to be tested and the SOC value of the reference cell within each of the complete rest periods The value is the first difference, and the difference between the SOC value of the reference cell and the expected SOC value in each of the complete rest periods is the second difference; the construction module 606 is configured to A difference value and the second difference value, constructing a SOC difference mapping model between the reference cell and the cell to be tested, and a SOH difference between the reference cell and the cell to be tested Mapping model; the second calculation module 607 is used to calculate the value of each battery cell to be tested in each of the complete rest periods according to the first difference, the second difference, and the SOC difference mapping model SOC difference mapping value; the filtering module 608 is used to filter the SOC difference mapping value to obtain the SOC difference filtering value; the third calculation module 609 is used to calculate according to the first difference, the second difference, the SOC difference The filtering value and the SOH difference mapping model are used to calculate the SOH difference mapping value of each of the cells to be tested in each of the complete rest periods; the detection module 610 is used to map the SOH differences of each of the cells to be tested value, and detect the plurality of battery cells to be tested.

其中,所述第一确定模块601包括第一获取单元6011、第二获取单元6012、第一拟合单元6013、第一判断单元6014、第一确定单元6015以及第二确定单元6016。其中,第一获取单元6011用于获取所述若干电芯的电流小于预设电流阈值的时间段;第二获取单元6012用于获取所述若干电芯位于所述时间段内的电压;第一拟合单元6013用于将位于所述时间段内的电压拟合成电压函数;第一判断单元6014用于判断所述电压函数的斜率是否小于第一预设斜率;第一确定单元6015用于若是,则确定所述时间段为所述若干电芯处于完全静置状态的完全静置时段;第二确定单元6016用于若否,则舍弃所述时间段,并且返回所述获取所述若干电芯的电流小于预设电流阈值的时间段的步骤。Wherein, the first determining module 601 includes a first acquiring unit 6011 , a second acquiring unit 6012 , a first fitting unit 6013 , a first judging unit 6014 , a first determining unit 6015 and a second determining unit 6016 . Among them, the first acquisition unit 6011 is used to acquire the time period when the current of the several batteries is less than the preset current threshold; the second acquisition unit 6012 is used to acquire the voltage of the several batteries within the time period; the first The fitting unit 6013 is used to fit the voltage within the time period into a voltage function; the first judging unit 6014 is used to judge whether the slope of the voltage function is less than a first preset slope; the first determining unit 6015 is used to If yes, determine that the time period is the complete rest period in which the plurality of battery cells are in a complete rest state; the second determination unit 6016 is configured to discard the time period if not, and return to the method of obtaining the several battery cores. The step of the time period during which the current of the battery cell is less than the preset current threshold.

其中,构建模块606包括第三确定单元6061、第二拟合单元6062、第一计算单元6063、第一排列单元6064以及第一构建单元6065。其中,第三确定单元6061用于将每一所述完全静置时段内的一所述第一差值和一所述第二差值确定为一差值组,得到M个差值组;第二拟合单元6062用于从所述第一个差值组开始,依次选取往后相邻N个差值组进行线性回归拟合函数,得到P个拟合函数,其中,P=M-N+1;第一计算单元6063用于计算各所述拟合函数的斜率,得到P个拟合斜率;第一排列单元6064用于将所述P个拟合斜率按从小到大排序形成斜率队列,并且将位于所述斜率队列中间的斜率确定为最终斜率;第一构建单元6065用于根据所述最终斜率和所述M个差值组,构建成所述参考电芯和所述待检电芯之间的SOC差异映射模型。Wherein, the construction module 606 includes a third determination unit 6061 , a second fitting unit 6062 , a first calculation unit 6063 , a first arrangement unit 6064 and a first construction unit 6065 . Wherein, the third determining unit 6061 is configured to determine a first difference value and a second difference value in each complete rest period as a difference value group to obtain M difference value groups; The second fitting unit 6062 is used to start from the first difference group, sequentially select N adjacent difference groups to perform linear regression fitting functions, and obtain P fitting functions, wherein, P=M-N +1; the first calculation unit 6063 is used to calculate the slope of each of the fitting functions to obtain P fitting slopes; the first arrangement unit 6064 is used to sort the P fitting slopes from small to large to form a slope queue , and determine the slope located in the middle of the slope queue as the final slope; the first construction unit 6065 is configured to construct the reference cell and the battery to be tested according to the final slope and the M difference groups SOC difference mapping model between cores.

其中,过滤模块608包括第三获取单元6081、第二计算单元6082以及第一替换单元6083。其中,第三获取单元6081用于获取一所述待检电芯在一所述完全静置时段的所述SOC差异映射值,以及前后各X个相邻的所述完全静置时段的所述SOC差异映射值,得到Y个所述SOC差异映射值,其中,Y=X+X+1;第二计算单元6082用于计算Y个所述SOC差异映射值的平均值;第一替换单元6083用于将该所述待检电芯在该所述完全静置时段的所述SOC差异映射值替换为所述平均值,得到该所述待检电芯的SOC差异过滤值。Wherein, the filtering module 608 includes a third acquiring unit 6081 , a second calculating unit 6082 and a first replacing unit 6083 . Wherein, the third acquisition unit 6081 is used to acquire the SOC difference mapping value of the cell to be tested in a complete rest period, and the SOC difference mapping values of X adjacent complete rest periods before and after each. SOC difference mapping value, to obtain Y said SOC difference mapping values, wherein, Y=X+X+1; the second calculation unit 6082 is used to calculate the average value of Y said SOC difference mapping values; the first replacement unit 6083 It is used to replace the SOC difference mapping value of the battery cell to be tested in the complete rest period with the average value to obtain the SOC difference filter value of the battery cell to be tested.

其中,检测模块610包括第二排列单元6101、第三计算单元6102、第二判断单元6103、第四确定单元6104、第五确定单元6105、第三判断单元6106、第六确定单元6107以及第七确定单元6108。其中,第二排列单元6101用于将一所述待检电芯在所述M个完全静置时段对应的M个SOH差异映射值依次排列;第三计算单元6102用于依次计算相邻两个SOH差异映射值所在直线的斜率,得到若干个斜率;第二判断单元6103用于判断若干个所述斜率是否均在预设斜率范围内;第四确定单元6104用于若是,则确定所述待检电芯健康度正常;第五确定单元6105用于若否,则确定所述待检电芯健康度异常;第三判断单元6106用于判断各所述待检电芯在所述M个完全静置时段的SOH差异映射值是否在预设差异映射值范围内;第六确定单元6107用于若是,则确定所述电池组中的若干待检电芯健康度正常;第七确定单元6108用于若否,则确定SOH差异映射值超出预设差异映射值范围的所述待检电芯健康度异常。Among them, the detection module 610 includes a second arrangement unit 6101, a third calculation unit 6102, a second judgment unit 6103, a fourth determination unit 6104, a fifth determination unit 6105, a third determination unit 6106, a sixth determination unit 6107, and a seventh determination unit 6107. Determining unit 6108. Wherein, the second arranging unit 6101 is used for arranging the M SOH difference mapping values corresponding to one cell to be tested in the M completely resting periods; the third calculating unit 6102 is used for calculating the two adjacent The slope of the straight line where the SOH difference mapping value is located obtains several slopes; the second judging unit 6103 is used to judge whether the several said slopes are all within the preset slope range; the fourth determining unit 6104 is used to determine the pending The health degree of the cell to be inspected is normal; the fifth determination unit 6105 is used to determine that the health degree of the cell to be inspected is abnormal; Whether the SOH difference mapping value of the static period is within the preset difference mapping value range; the sixth determining unit 6107 is used to determine that the health of several cells to be checked in the battery pack is normal; the seventh determining unit 6108 uses If not, it is determined that the health degree of the cells to be checked is abnormal with the SOH difference mapping value exceeding the preset difference mapping value range.

本发明实施例的有益效果是:区别于现有技术的情况,本发明实施例一种电池组各电芯健康度差异的检测方法首先通过第一确定模块601确定所述若干电芯同时处于完全静置状态的M个完全静置时段;然后通过第一获取模块602获取在各所述完全静置时段内,各所述电芯的SOC值;再通过第二确定模块603将所述若干电芯中一电芯确定为参考电芯,以及,将除参考电芯以外的其它电芯确定为待检电芯;通过第二获取模块604获取期望SOC值;然后通过第一计算模块605计算并确定各所述待检电芯的SOC值与所述参考电芯的SOC值在各所述完全静置时段内的差值为第一差值,以及,所述参考电芯的SOC值和所述期望SOC值在各所述完全静置时段内的差值为第二差值;根据所述第一差值和所述第二差值,通过构建模块606构建所述参考电芯和所述待检电芯之间的SOC差异映射模型,以及所述参考电芯和所述待检电芯之间的SOH差异映射模型;然后通过第二计算模块607根据所述第一差值、所述第二差值以及所述SOC差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOC差异映射值;接着通过过滤模块608过滤所述SOC差异映射值,得到SOC差异过滤值;然后通过第三计算模块609根据所述第一差值、所述第二差值、所述SOC差异过滤值以及所述SOH差异映射模型,计算各所述待检电芯在各所述完全静置时段内的SOH差异映射值;最后通过检测模块610根据各所述待检电芯的SOH差异映射值,对所述若干待检电芯进行检测。通过上述步骤,本发明实施例能够消除各电芯的电量容量不一致来对电池组中的各个电芯进行健康度差异的检测,提高检测结果的准确性。The beneficial effect of the embodiment of the present invention is: different from the situation of the prior art, a method for detecting the difference in the health of each cell in the battery pack in the embodiment of the present invention first determines that the plurality of cells are in full condition at the same time through the first determination module 601 M complete quiescent periods in the quiescent state; then obtain the SOC value of each of the electric cores in each of the complete quiescent periods through the first acquisition module 602; An electric core in the core is determined as the reference electric core, and other electric cores are determined as the electric cores to be checked except the reference electric core; the expected SOC value is obtained by the second acquisition module 604; then calculated by the first calculation module 605 and Determining the difference between the SOC value of each cell to be tested and the SOC value of the reference cell in each of the complete rest periods as a first difference, and the SOC value of the reference cell and the SOC value of the reference cell The difference between the expected SOC value in each of the complete rest periods is a second difference; according to the first difference and the second difference, the construction module 606 is used to construct the reference cell and the The SOC difference mapping model between the battery cells to be tested, and the SOH difference mapping model between the reference battery cell and the battery cell to be tested; and then through the second calculation module 607 according to the first difference, the The second difference value and the SOC difference mapping model calculate the SOC difference mapping value of each of the cells to be tested in each of the complete rest periods; then filter the SOC difference mapping value through the filtering module 608 to obtain the SOC difference filter value; then, according to the first difference value, the second difference value, the SOC difference filter value and the SOH difference mapping model, the third calculation module 609 calculates the The SOH difference mapping value within the complete rest period; finally, the detection module 610 detects the plurality of cells to be inspected according to the SOH difference mapping value of each cell to be inspected. Through the above steps, the embodiment of the present invention can eliminate the inconsistency of the electric capacity of each battery cell to detect the health degree difference of each battery cell in the battery pack, and improve the accuracy of the detection result.

本发明还提供检测设备70的实施例,请参见图9,图9是本发明实施例检测设备70实施例的示意图,所述检测设备70的控制器包括:至少一个处理器701;以及,与所述至少一个处理器701通信连接的存储器702,图9中以其中一个处理器701为例。所述存储器702存储有可被所述至少一个处理器701执行的指令,所述指令被所述至少一个处理器701执行,以使所述至少一个处理器701能够执行上述图2至图7所述的一种电池组各电芯健康度差异的检测方法,以及,执行上述图8所述的一种电池组各电芯健康度差异的检测装置。所述处理器701和所述存储器702可以通过总线或者其他方式连接,图9中以通过总线连接为例。The present invention also provides an embodiment of a detection device 70. Please refer to FIG. 9, which is a schematic diagram of an embodiment of a detection device 70 according to an embodiment of the present invention. The controller of the detection device 70 includes: at least one processor 701; and, The at least one processor 701 is communicatively connected to the memory 702, and one of the processors 701 is taken as an example in FIG. 9 . The memory 702 stores instructions that can be executed by the at least one processor 701, and the instructions are executed by the at least one processor 701, so that the at least one processor 701 can execute the above-mentioned instructions in FIGS. 2 to 7. The method for detecting the difference in the health of each battery cell in a battery pack described above, and the device for detecting the difference in health of each battery cell in the battery pack described above in FIG. 8 . The processor 701 and the memory 702 may be connected through a bus or in other ways. In FIG. 9 , connection through a bus is taken as an example.

存储器702作为一种非易失性计算机可读存储介质,可用于存储非易失性软件程序、非易失性计算机可执行程序以及模块,如本申请实施例中的一种电池组各电芯健康度差异的检测方法对应的程序指令/模块,例如,附图8所示的各个模块。处理器701通过运行存储在存储器702中的非易失性软件程序、指令以及模块,从而执行服务器的各种功能应用以及数据处理,即实现上述方法实施例一种电池组各电芯健康度差异的检测方法。The memory 702, as a non-volatile computer-readable storage medium, can be used to store non-volatile software programs, non-volatile computer-executable programs and modules, such as a battery cell in the embodiment of the present application The program instructions/modules corresponding to the health difference detection method, for example, each module shown in FIG. 8 . The processor 701 executes various functional applications and data processing of the server by running the non-volatile software programs, instructions and modules stored in the memory 702, that is, to realize the above method. detection method.

存储器702可以包括存储程序区和存储数据区,其中,存储程序区可存储操作系统、至少一个功能所需要的应用程序;存储数据区可存储根据一种电池组各电芯健康度差异的检测装置的使用所创建的数据等。此外,存储器702可以包括高速随机存取存储器,还可以包括非易失性存储器,例如至少一个磁盘存储器件、闪存器件、或其他非易失性固态存储器件。在一些实施例中,存储器702可选包括相对于处理器701远程设置的存储器,这些远程存储器可以通过网络连接至一种电池组各电芯健康度差异的检测装置。上述网络的实例包括但不限于互联网、企业内部网、局域网、移动通信网及其组合。The memory 702 may include a program storage area and a data storage area, wherein the program storage area may store an operating system and an application program required by at least one function; use of the created data, etc. In addition, the memory 702 may include a high-speed random access memory, and may also include a non-volatile memory, such as at least one magnetic disk storage device, flash memory device, or other non-volatile solid-state storage devices. In some embodiments, the memory 702 may optionally include a memory set remotely relative to the processor 701, and these remote memories may be connected to a device for detecting the difference in health of each cell of the battery pack through a network. Examples of the aforementioned networks include, but are not limited to, the Internet, intranets, local area networks, mobile communication networks, and combinations thereof.

所述一个或者多个模块存储在所述存储器702中,当被所述一个或者多个处理器701执行时,执行上述任意方法实施例中的一种电池组各电芯健康度差异的检测方法,例如,执行以上描述的图2至图7的方法步骤,以及,执行上述图8所述的一种电池组各电芯健康度差异的检测装置。The one or more modules are stored in the memory 702, and when executed by the one or more processors 701, a method for detecting the difference in health of each battery cell in a battery pack in any of the above method embodiments is executed For example, the above-described method steps in FIG. 2 to FIG. 7 are executed, and the device for detecting the difference in health of each battery cell of the battery pack described in FIG. 8 above is executed.

上述产品可执行本申请实施例所提供的方法,具备执行方法相应的功能模块和有益效果。未在本实施例中详尽描述的技术细节,可参见本申请实施例所提供的方法。The above-mentioned products can execute the method provided by the embodiment of the present application, and have corresponding functional modules and beneficial effects for executing the method. For technical details not described in detail in this embodiment, refer to the method provided in the embodiment of this application.

本申请实施例还提供了一种非易失性计算机可读存储介质,所述计算机可读存储介质存储有计算机可执行指令,该计算机可执行指令被一个或多个处理器执行,例如,执行以上描述的图2至图7的一种电池组各电芯健康度差异的检测方法步骤,以及,执行上述图8所述的一种电池组各电芯健康度差异的检测装置。The embodiment of the present application also provides a non-volatile computer-readable storage medium, the computer-readable storage medium stores computer-executable instructions, and the computer-executable instructions are executed by one or more processors, for example, executing The above-described steps of a method for detecting the difference in health of each battery cell in a battery pack in FIGS. 2 to 7 , and executing the device for detecting the difference in health of each cell in a battery pack described in FIG. 8 above.

本申请实施例还提供了一种计算机程序产品,包括存储在非易失性计算机可读存储介质上的计算程序,所述计算机程序包括程序指令,当所述程序指令被计算机执行时时,使所述计算机执行上述任意方法实施例中的一种电池组各电芯健康度差异的检测方法,例如,执行以上描述的图2至图7的方法步骤,以及,执行上述图8所述的一种电池组各电芯健康度差异的检测装置。The embodiment of the present application also provides a computer program product, including a computer program stored on a non-volatile computer-readable storage medium, the computer program includes program instructions, and when the program instructions are executed by the computer, the The computer executes a method for detecting the difference in the health of each battery cell in a battery pack in any of the above method embodiments, for example, executing the method steps in Fig. 2 to Fig. 7 described above, and executing a method described in Fig. 8 above. A detection device for the difference in the health of each cell in the battery pack.

以上所述仅为本发明的实施例,并非因此限制本发明的专利范围,凡是利用本发明说明书及附图内容所作的等效结构或等效流程变换,或直接或间接运用在其他相关的技术领域,均同理包括在本发明的专利保护范围内。The above is only an embodiment of the present invention, and does not limit the patent scope of the present invention. Any equivalent structure or equivalent process transformation made by using the description of the present invention and the contents of the accompanying drawings, or directly or indirectly used in other related technologies fields, all of which are equally included in the scope of patent protection of the present invention.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210050856.4ACN115825759B (en) | 2022-01-17 | 2022-01-17 | Detection method, device and detection equipment for health degree difference of each battery cell of battery pack |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210050856.4ACN115825759B (en) | 2022-01-17 | 2022-01-17 | Detection method, device and detection equipment for health degree difference of each battery cell of battery pack |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN115825759Atrue CN115825759A (en) | 2023-03-21 |

| CN115825759B CN115825759B (en) | 2025-08-19 |

Family

ID=85522333

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210050856.4AActiveCN115825759B (en) | 2022-01-17 | 2022-01-17 | Detection method, device and detection equipment for health degree difference of each battery cell of battery pack |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115825759B (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117647748A (en)* | 2024-01-30 | 2024-03-05 | 宁德时代新能源科技股份有限公司 | Abnormal cell detection method, device, equipment and storage medium |

| CN119861297A (en)* | 2025-03-25 | 2025-04-22 | 宁德时代新能源科技股份有限公司 | Method, device, storage medium and program product for detecting self-discharge rate of battery cell |

| CN120214625A (en)* | 2025-05-26 | 2025-06-27 | 赣州雄博新能源科技有限公司 | A method and device for detecting loss of lithium battery |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103197257A (en)* | 2013-04-03 | 2013-07-10 | 华为技术有限公司 | Method and device for detecting state of health (SOH) of battery |

| KR20150084354A (en)* | 2014-01-14 | 2015-07-22 | (주)아이비티 | Apparatus of Estimating SOH for Battery |

| CN107271906A (en)* | 2017-05-31 | 2017-10-20 | 宁德时代新能源科技股份有限公司 | Battery pack health degree estimation method and device |

| WO2018126901A1 (en)* | 2017-01-05 | 2018-07-12 | 中兴通讯股份有限公司 | Method and device for testing health status of battery |

| CN109557477A (en)* | 2017-09-25 | 2019-04-02 | 郑州宇通客车股份有限公司 | A kind of battery system health status evaluation method |

| WO2020021888A1 (en)* | 2018-07-25 | 2020-01-30 | パナソニックIpマネジメント株式会社 | Management device and power supply system |

| CN110967645A (en)* | 2019-05-24 | 2020-04-07 | 宁德时代新能源科技股份有限公司 | SOC correction method and device, battery management system and storage medium |

| CN112327176A (en)* | 2020-10-16 | 2021-02-05 | 欣旺达电子股份有限公司 | Battery performance detection method, system and storage medium |

- 2022

- 2022-01-17CNCN202210050856.4Apatent/CN115825759B/enactiveActive

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103197257A (en)* | 2013-04-03 | 2013-07-10 | 华为技术有限公司 | Method and device for detecting state of health (SOH) of battery |

| KR20150084354A (en)* | 2014-01-14 | 2015-07-22 | (주)아이비티 | Apparatus of Estimating SOH for Battery |

| WO2018126901A1 (en)* | 2017-01-05 | 2018-07-12 | 中兴通讯股份有限公司 | Method and device for testing health status of battery |

| CN107271906A (en)* | 2017-05-31 | 2017-10-20 | 宁德时代新能源科技股份有限公司 | Battery pack health degree estimation method and device |

| CN109557477A (en)* | 2017-09-25 | 2019-04-02 | 郑州宇通客车股份有限公司 | A kind of battery system health status evaluation method |

| WO2020021888A1 (en)* | 2018-07-25 | 2020-01-30 | パナソニックIpマネジメント株式会社 | Management device and power supply system |

| CN110967645A (en)* | 2019-05-24 | 2020-04-07 | 宁德时代新能源科技股份有限公司 | SOC correction method and device, battery management system and storage medium |

| CN112327176A (en)* | 2020-10-16 | 2021-02-05 | 欣旺达电子股份有限公司 | Battery performance detection method, system and storage medium |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN117647748A (en)* | 2024-01-30 | 2024-03-05 | 宁德时代新能源科技股份有限公司 | Abnormal cell detection method, device, equipment and storage medium |

| CN117647748B (en)* | 2024-01-30 | 2024-05-28 | 宁德时代新能源科技股份有限公司 | Abnormal battery cell detection method, device, equipment and storage medium |

| CN119861297A (en)* | 2025-03-25 | 2025-04-22 | 宁德时代新能源科技股份有限公司 | Method, device, storage medium and program product for detecting self-discharge rate of battery cell |

| CN120214625A (en)* | 2025-05-26 | 2025-06-27 | 赣州雄博新能源科技有限公司 | A method and device for detecting loss of lithium battery |

Also Published As

| Publication number | Publication date |

|---|---|

| CN115825759B (en) | 2025-08-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN115825759A (en) | Detection method, device and detection equipment for the difference in the health of each battery cell in a battery pack | |

| CN112838631B (en) | Dynamic charge management and control device for power battery and charge diagnosis method for power battery | |

| CN113933732B (en) | New energy automobile power battery health state analysis method, system and storage medium | |

| CN111381178B (en) | Method and system for estimating health state of lithium ion battery | |

| CN104502859B (en) | Method for detecting and diagnosing battery charge and battery health state | |

| CN113109729B (en) | Vehicle power battery SOH evaluation method based on accelerated aging test and real vehicle working condition | |

| CN104977537B (en) | The determination method of battery SOC and the battery management system for using this method | |

| CN111025168A (en) | Battery health state monitoring device and battery state of charge intelligent estimation method | |

| CN110376536B (en) | SOH detection method and device for battery system, computer equipment and storage medium | |

| US9766297B2 (en) | Battery system capacity estimation systems and methods | |

| CN109557477A (en) | A kind of battery system health status evaluation method | |

| CN105793719A (en) | Battery Tester and Battery Registration Tool | |

| KR20230129953A (en) | Method, device, apparatus, and storage medium for evaluating consistency of vehicle battery cell | |

| CN103698713A (en) | Method for assessing SOH (state of health) of lithium ion battery | |

| CN114137428B (en) | Portable power battery safety detection system and device | |

| CN108521155B (en) | A kind of electric vehicle charging early warning method and system | |

| CN110988728B (en) | Method for rapidly diagnosing abnormal internal connection of lithium battery pack | |

| CN115825780B (en) | Method, device and equipment for detecting self-discharge difference of each battery cell of battery pack | |

| CN104237803A (en) | Method for detecting electrical property of battery of electric vehicle on basis of battery working condition simulation | |

| CN110927609B (en) | Decline evaluation method and device for battery energy storage system by utilizing battery in echelon | |

| CN203350421U (en) | System for dynamically evaluating battery uniformity | |

| CN113809809B (en) | Balancing method and system for vehicle battery | |

| CN107632267B (en) | A kind of battery exception monomer localization method and system | |

| DE102013010311A1 (en) | Method for determining the state of individual battery cells of a high-voltage battery and system therefor | |

| CN113759265A (en) | Fault judgment method of power supply system and energy storage system |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |