CN115822452A - Horizontal well horizontal section drilling optimization and speed-increasing method for shale gas - Google Patents

Horizontal well horizontal section drilling optimization and speed-increasing method for shale gasDownload PDFInfo

- Publication number

- CN115822452A CN115822452ACN202211417984.4ACN202211417984ACN115822452ACN 115822452 ACN115822452 ACN 115822452ACN 202211417984 ACN202211417984 ACN 202211417984ACN 115822452 ACN115822452 ACN 115822452A

- Authority

- CN

- China

- Prior art keywords

- drilling

- drill bit

- horizontal section

- horizontal

- target box

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Earth Drilling (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及石油、天然气勘探开发领域,特别涉及一种页岩气的水平井水平段钻井优化与提速方法。The invention relates to the field of exploration and development of oil and natural gas, in particular to a method for optimizing and increasing the drilling speed of a horizontal section of a shale gas horizontal well.

背景技术Background technique

随着油气资源勘探开发不断向“深”、“非”、“海”、“低”迈进,非常规油气已成为常规油气的重要接替资源,页岩气属于非常规油气资源,主要指以页岩为主的页岩层系中所包含的天然气资源,其在沉积条件、构造特点、开采方式等方面与常规油气资源存在较大差异。在钻井上仍存在水平段趟钻数高、“一趟钻”比率低、钻井周期长等难题,制约页岩气经济效益开发。As the exploration and development of oil and gas resources continue to move towards "deep", "non", "sea", and "low", unconventional oil and gas have become an important replacement resource for conventional oil and gas. Shale gas belongs to unconventional oil and gas resources, mainly referring to The natural gas resources contained in shale formations dominated by rocks are quite different from conventional oil and gas resources in terms of depositional conditions, structural characteristics, and mining methods. In drilling, there are still problems such as high number of drilling trips in the horizontal section, low "one-trip drilling" ratio, and long drilling cycle, which restrict the economical development of shale gas.

通过对大量完钻井井史统计分析发现,制约现有页岩气水平井水平段“一趟钻”的主要地质工程原因包括:①井下随钻测控工具(包含旋转导向、MWD、LWD等井下随钻测量及控制工具)失效;②PDC钻头破岩机械钻速低;③井下马达失效;④井漏、卡钻等其它井下复杂,其中原因①和原因②在三开水平段起钻原因合计占比达到约80%,是制约页岩气水平段“一趟钻”的主要原因。Through the statistical analysis of a large number of completed drilling wells, it is found that the main geo-engineering reasons restricting the “one-trip drilling” of the horizontal section of existing shale gas horizontal wells include: ① Downhole measurement and control tools (including rotary steerable, MWD, LWD, etc. (drilling measurement and control tool) failure; ②PDC bit rock-breaking mechanical rate of penetration is low; ③Downhole motor failure; ④Other downhole complexities such as lost circulation and drill sticking, among which the

针对水平段井下测控工具频繁失效,钻井工程上攻关配套了旋转阀式MWD、双电池系统、贝克休斯Auto-Track Curve旋转导向、斯伦贝谢Power Drive Archer、Power DriveOrbit旋转导向系统等系列高性能随钻测控工具及系统,一定程度上解决了堵漏材料造成仪器无信号、工具寿命短难题;同时针对水平段PDC钻头机械钻速低难题,基于大量井史数据开展了钻头型号优选、强化钻井参数、制定钻井技术模板等措施,在水平段平均机械钻速及“一趟钻”最长进尺上均有显著提升。In view of the frequent failure of downhole measurement and control tools in the horizontal section, the drilling engineering has been equipped with rotary valve MWD, dual battery system, Baker Hughes Auto-Track Curve rotary steerable, Schlumberger Power Drive Archer, Power DriveOrbit rotary steerable system and other high-tech Performance measurement and control tools and systems while drilling, to a certain extent, solved the problem of no signal of the instrument and short tool life caused by plugging materials; at the same time, in order to solve the problem of low ROP of the PDC bit in the horizontal section, based on a large amount of well history data, the bit model selection and enhancement were carried out. Measures such as drilling parameters and formulation of drilling technology templates have significantly improved the average mechanical penetration rate in the horizontal section and the longest footage of "one-trip drilling".

上述技术措施主要集中在升级装备、优选钻头、强化参数等方面,忽略了水平段钻进过程中因地质条件及工程措施诱发的剧烈井下振动对钻井效率的影响。钻井过程中井下振动主要表现为钻头及钻柱的纵向、横向和扭转(粘滑)振动三种形式,适量的振动在降低井筒摩擦阻力同时也能改善钻头破岩效率、提高机械钻速,但因地层非均质性、井筒摩阻、钻头磨损、钻柱受力不均等因素诱发的剧烈井下振动会对钻井工程带来诸多危害,主要包括:①剧烈振动降低钻头破岩效率,降低钻头机械钻速;②剧烈振动加速钻头磨损,甚至造成钻头切削齿蹦齿、破碎;③剧烈振动增加井下随钻测控工具失效几率、降低工具使用使命;④剧烈振动加速钻具疲劳、甚至诱发断钻具等井下事故复杂。考虑到钻井过程中井下振动无法避免,同时剧烈井下振动会加剧随钻测控工具失效几率,斯伦贝谢、贝克休斯等油服公司在井下随钻测控工具(旋转导向、MWD、LWD等)中广泛配备三轴加速度传感器、转速传感器,随钻过程中实时测量、存储及上传井下不同类型振动强度及不同级别振动强度对应累积时间。基于232套井下振动测量及工具使用情况数据,贝克休斯提出钻井过程中因剧烈井下振动导致MWD/LWD失效占比达到29%,同时提出钻井过程中钻具振动幅度越大、短时间内随钻测控工具失效几率越高。在考虑累积时间下不同级别振动强度内随钻测控工具失效几率基础上,斯伦贝谢也考虑了钻井过程中瞬时剧烈冲击对随钻测控工具稳定性影响,并将随钻测控工具每秒承受剧烈振动冲击强度超过50x9.8m/s2次数(CPS,counts per second)作为随钻测控工具失效风险指标,依据钻进过程中井下随钻测控仪器每秒内、每趟钻内承受剧烈振动冲击强度超过50x9.8m/s2累积次数,将随钻测控工具失效风险划分为低(0)、中(1)、高(2)、极易失效(3)四个风险等级。The above-mentioned technical measures are mainly focused on upgrading equipment, optimizing drill bits, strengthening parameters, etc., ignoring the impact of severe downhole vibration induced by geological conditions and engineering measures on drilling efficiency during horizontal section drilling. During the drilling process, downhole vibration mainly manifests in three forms: longitudinal, lateral and torsional (stick-slip) vibration of the drill bit and drill string. Appropriate vibration can reduce the frictional resistance of the wellbore and improve the rock-breaking efficiency of the drill bit and increase the ROP. Severe downhole vibration induced by factors such as formation heterogeneity, wellbore friction, drill bit wear, and uneven force on the drill string will bring many hazards to drilling engineering, mainly including: ① Severe vibration reduces the rock-breaking efficiency of the drill bit and reduces the mechanical capacity of the drill bit. Drilling speed; ②Severe vibration accelerates the wear of the drill bit, and even causes the cutting teeth of the drill bit to jump and break; ③Severe vibration increases the failure probability of downhole measurement and control tools while drilling, reducing the mission of the tool; ④Severe vibration accelerates drilling tool fatigue, and even induces broken drilling tools Wait for the downhole accident to be complicated. Considering that downhole vibration is unavoidable during drilling, and severe downhole vibration will aggravate the failure probability of MWD tools, Schlumberger, Baker Hughes and other oil service companies have used downhole MWD tools (rotary steerable, MWD, LWD, etc.) It is widely equipped with three-axis acceleration sensors and rotational speed sensors, which can measure, store and upload different types of underground vibration intensities and corresponding accumulation times of different levels of vibration intensities in real time during drilling. Based on 232 sets of downhole vibration measurement and tool usage data, Baker Hughes proposed that MWD/LWD failures due to severe downhole vibration during drilling accounted for 29%. The higher the probability of failure of drilling measurement and control tools. On the basis of considering the failure probability of the MWD tool within different levels of vibration intensity under the accumulated time, Schlumberger also considered the impact of the instantaneous severe impact on the stability of the MWD tool during the drilling process, and made the MWD tool withstand every second The severe vibration and impact intensity exceeding 50x9.8m/s2 times (CPS, counts per second) is used as the failure risk index of the MWD tool, according to the severe vibration and shock that the downhole MWD tool withstands within one second and each trip during the drilling process The intensity exceeds 50x9.8m/s2 cumulative times, and the failure risk of the monitoring and control tool while drilling is divided into four risk levels: low (0), medium (1), high (2), and extremely easy to fail (3).

但是,上述减震措施主要针对北美页岩气与北美页岩气Permian、Eagle Ford、Bakken等均质性储层,对于其它页岩气田,上述措施的效果并不理想。特别对于目的层岩石由石英、斜长石、碳酸盐岩矿物、黏土、黄铁矿等矿物组成,目的层目标箱体厚度分布在1-3m之间的非均质储层,这些非均质储层垂向上储层矿物组分及地层元素含量波动较大,同时因矿物组分波动导致的地层岩石强度变化较大。水平井水平段钻进过程中,井眼轨迹调整由地质导向工程师依据地质需求决定,从后期完井压裂改造角度地质导向工程师更青睐“脆性”更好、更易于压裂裂缝延伸、硅质含量更高或地层碳质含量更加丰富、地层GR数值更高储层,而水平井水平段实钻过程中常因地质建模误差,断层、凹陷、隆起等地质构造,随钻测量工具“零差”等因素常导致井眼轨迹控制出现偏差。当水平段井眼轨迹钻出目标箱体后,地质导向工程师常下发指令,要求现场定向工程师将井眼轨迹再次调整至目标箱体中,而在井眼轨迹调整过程中钻头会在非均质储层中穿越,钻头两侧切削地层岩石强度存在较大差异,易诱发剧烈井下扭转(粘滑)及横向振动,进而导致钻头破岩机械钻速降低、钻头迅速磨损以及井下随钻仪器失效。同一型号PDC钻头在水平段非均质地层中钻进时,钻头破岩机械钻速更低、趟钻进尺更短、磨损程度更高,同时常因井下随钻测控工具(旋转导向、MWD、LWD等)失效导致起钻。However, the above shock-absorbing measures are mainly aimed at North American shale gas and North American shale gas Permian, Eagle Ford, Bakken and other homogeneous reservoirs. For other shale gas fields, the effect of the above measures is not ideal. Especially for the heterogeneous reservoirs where the target layer rocks are composed of quartz, plagioclase, carbonate rock minerals, clay, pyrite and other minerals, and the target box thickness of the target layer is distributed between 1-3m, these heterogeneous reservoirs Vertically, the mineral composition of the reservoir and the element content of the formation fluctuate greatly, and the rock strength of the formation due to the fluctuation of the mineral composition fluctuates greatly. During the drilling of the horizontal section of the horizontal well, the adjustment of the wellbore trajectory is determined by the geosteering engineer based on the geological needs. From the perspective of post-completion and fracturing, the geosteering engineer prefers "brittleness", which is easier to fracture extension, and siliceous However, during the actual drilling process of the horizontal section of the horizontal well, due to geological modeling errors, faults, depressions, uplifts and other geological structures, the measurement-while-drilling tool "hodifference " and other factors often lead to deviations in wellbore trajectory control. When the wellbore trajectory in the horizontal section is drilled out of the target box, geosteering engineers often issue instructions to require the on-site directional engineer to adjust the wellbore trajectory to the target box again. When crossing through the reservoir, there is a large difference in the strength of the cutting formation rock on both sides of the drill bit, which easily induces severe downhole torsion (stick-slip) and lateral vibration, which in turn leads to a decrease in the drilling speed of the drill bit for rock breaking, rapid wear of the drill bit, and failure of downhole tools while drilling . When the same type of PDC bit drills in the heterogeneous formation in the horizontal section, the rock-breaking mechanical speed of the bit is lower, the drilling footage is shorter, and the degree of wear is higher. LWD, etc.) failure leads to tripping.

有鉴于此,本发明人根据多年从事本领域和相关领域的生产设计经验,经过反复试验设计出一种页岩气的水平井水平段钻井优化与提速方法,以期解决现有技术存在的问题。In view of this, based on years of experience in production design in this field and related fields, the inventor has designed a method for optimizing and increasing the drilling speed of the horizontal section of a shale gas horizontal well through repeated tests, in order to solve the problems existing in the prior art.

发明内容Contents of the invention

本发明的目的在于提供一种页岩气的水平井水平段钻井优化与提速方法,能够提高水平段钻进机械钻速、降低趟钻次数及钻井周期。The object of the present invention is to provide a method for optimizing and increasing the drilling speed of the horizontal section of a shale gas horizontal well, which can increase the drilling speed of the horizontal section, reduce the number of drilling trips and the drilling cycle.

为达到上述目的,本发明提出一种页岩气的水平井水平段钻井优化与提速方法,其中,所述水平井水平段钻井优化与提速方法包括:In order to achieve the above purpose, the present invention proposes a method for optimizing and speeding up the horizontal section of a shale gas horizontal well, wherein the method for optimizing and speeding up the horizontal section of a horizontal well includes:

确定水平井的目标箱体并进行钻前水平井水平段的井眼轨迹的优选;Determine the target box of the horizontal well and optimize the wellbore trajectory of the horizontal section of the horizontal well before drilling;

根据所述目标箱体和所述水平井水平段的井眼轨迹钻进水平段并随钻进行水平井水平段钻井参数及工艺措施优化。The horizontal section is drilled according to the target box and the wellbore trajectory of the horizontal section of the horizontal well, and the drilling parameters and technological measures of the horizontal section of the horizontal well are optimized while drilling.

与现有技术相比,本发明具有以下特点和优点:Compared with the prior art, the present invention has the following characteristics and advantages:

本发明提出的页岩气的水平井水平段钻井优化与提速方法,通过钻前优选水平井水平段的井眼轨迹,再结合随钻井参数及工艺措施优化,使得井眼轨迹能够有效规避钻头穿越非均质储层,从而降低穿越非均质储层进尺长度及井下振动强度,最终实现提高水平段钻进机械钻速、降低趟钻次数及钻井周期目的。The drilling optimization and speed-up method for the horizontal section of a shale gas horizontal well proposed by the present invention optimizes the wellbore trajectory of the horizontal section of the horizontal well before drilling, and then optimizes the drilling parameters and process measures, so that the wellbore trajectory can effectively avoid drill bit crossing Heterogeneous reservoirs, thereby reducing the length of footage crossed through heterogeneous reservoirs and the intensity of downhole vibration, and finally achieving the purpose of increasing the ROP of drilling in the horizontal section, reducing the number of drilling trips and the drilling cycle.

附图说明Description of drawings

在此描述的附图仅用于解释目的,而不意图以任何方式来限制本发明公开的范围。另外,图中的各部件的形状和比例尺寸等仅为示意性的,用于帮助对本发明的理解,并不是具体限定本发明各部件的形状和比例尺寸。本领域的技术人员在本发明的教导下,可以根据具体情况选择各种可能的形状和比例尺寸来实施本发明。The drawings described herein are for illustration purposes only and are not intended to limit the scope of the present disclosure in any way. In addition, the shapes and proportional dimensions of the components in the drawings are only schematic and are used to help the understanding of the present invention, and do not specifically limit the shapes and proportional dimensions of the components in the present invention. Under the teaching of the present invention, those skilled in the art can select various possible shapes and proportional dimensions according to specific conditions to implement the present invention.

图1为本发明提出的页岩气的水平井水平段钻井优化与提速方法的流程图;Fig. 1 is the flow chart of the method for drilling optimization and speed-up in the horizontal section of a horizontal well for shale gas proposed by the present invention;

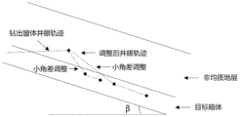

图2为本发明中钻头位于上倾箱体上方井眼轨迹调整示意图;Fig. 2 is a schematic diagram of the adjustment of the wellbore trajectory where the drill bit is located above the up-tilted box in the present invention;

图3为本发明中钻头位于下倾箱体上方井眼轨迹调整示意图;Fig. 3 is a schematic diagram of the adjustment of the wellbore trajectory where the drill bit is located above the down-dipping box in the present invention;

图4为本发明中钻头位于上倾箱体下方井眼轨迹调整示意图;Fig. 4 is a schematic diagram of the adjustment of the wellbore track where the drill bit is located below the up-tilted box in the present invention;

图5为本发明中钻头位于下倾箱体下方井眼轨迹调整示意图;Fig. 5 is a schematic diagram of the adjustment of the wellbore trajectory where the drill bit is located below the down-dipping box in the present invention;

图6为本发明一实施例中导眼井地层岩石强度垂向分布图;Fig. 6 is a vertical distribution diagram of the rock strength of the pilot well formation in an embodiment of the present invention;

图7为本发明一实施例中导眼井地层元素含量垂向分布图;Fig. 7 is a vertical distribution diagram of the element content in the formation of the pilot well in an embodiment of the present invention;

图8为本发明一实施例中水平段井斜角随井深分布图;Fig. 8 is a distribution diagram of the inclination angle of the horizontal section along with the well depth in an embodiment of the present invention;

图9为本发明一实施例中水平段地层主要元素含量占比图;Fig. 9 is a proportion diagram of the content of main elements in the formation of the horizontal section in an embodiment of the present invention;

图10为本发明一实施例中水平段地层岩石抗压强度分布。Fig. 10 shows the distribution of compressive strength of formation rock in the horizontal section in an embodiment of the present invention.

具体实施方式Detailed ways

结合附图和本发明具体实施方式的描述,能够更加清楚地了解本发明的细节。但是,在此描述的本发明的具体实施方式,仅用于解释本发明的目的,而不能以任何方式理解成是对本发明的限制。在本发明的教导下,技术人员可以构想基于本发明的任意可能的变形,这些都应被视为属于本发明的范围。The details of the present invention can be understood more clearly with reference to the accompanying drawings and the description of specific embodiments of the present invention. However, the specific embodiments of the present invention described here are only for the purpose of explaining the present invention, and should not be construed as limiting the present invention in any way. Under the teaching of the present invention, the skilled person can conceive any possible modification based on the present invention, and these should be regarded as belonging to the scope of the present invention.

本发明提出一种页岩气的水平井水平段钻井优化与提速方法,如图1所示,该水平井水平段钻井优化与提速方法包括:The present invention proposes a method for optimizing and increasing the drilling speed of the horizontal section of a shale gas horizontal well. As shown in Figure 1, the method for optimizing and increasing the drilling speed of the horizontal section of the horizontal well includes:

确定水平井的目标箱体并进行钻前水平井水平段的井眼轨迹的优选;Determine the target box of the horizontal well and optimize the wellbore trajectory of the horizontal section of the horizontal well before drilling;

根据目标箱体和水平井水平段的井眼轨迹钻进水平段并随钻进行水平井水平段钻井参数及工艺措施优化。According to the target box and the wellbore trajectory of the horizontal section of the horizontal well, the horizontal section is drilled, and the drilling parameters and technological measures of the horizontal section of the horizontal well are optimized while drilling.

本发明提出的页岩气的水平井水平段钻井优化与提速方法,通过钻前优选水平井水平段的井眼轨迹,再结合随钻井参数及工艺措施优化,使得井眼轨迹能够有效规避钻头穿越非均质储层,从而降低穿越非均质储层进尺长度及井下振动强度,最终实现提高水平段钻进机械钻速、降低趟钻次数及钻井周期目的。The drilling optimization and speed-up method for the horizontal section of a shale gas horizontal well proposed by the present invention optimizes the wellbore trajectory of the horizontal section of the horizontal well before drilling, and then optimizes the drilling parameters and process measures, so that the wellbore trajectory can effectively avoid drill bit crossing Heterogeneous reservoirs, thereby reducing the length of footage crossed through heterogeneous reservoirs and the intensity of downhole vibration, and finally achieving the purpose of increasing the ROP of drilling in the horizontal section, reducing the number of drilling trips and the drilling cycle.

在本发明一个可选的实施方式中,根据水平井所在的钻井平台的岩石矿物组分及岩石强度垂向分布特征及平井的储层的地质构造横向分布规律与特征确定所述目标箱体。In an optional embodiment of the present invention, the target box is determined according to the vertical distribution characteristics of rock mineral composition and rock strength of the drilling platform where the horizontal well is located and the lateral distribution law and characteristics of the geological structure of the reservoir of the flat well.

在该实施方式一个可选的例子中,利用钻井平台其导眼井的岩心及测井数据,获得钻井平台的岩石矿物组份及岩石强度垂向分布特征。In an optional example of this embodiment, the rock mineral composition and rock strength vertical distribution characteristics of the drilling platform are obtained by using the core and logging data of the pilot well of the drilling platform.

需要说明的是,导眼井是钻井平台第一口井先采用直井。It should be noted that the pilot well is the first well on the drilling platform to adopt a vertical well.

在该实施方式一个可选的例子中,利用钻井平台其储层的三维地震数据,完成储层地质建模,确定钻井平台的储层的地质构造横向展布规律与特征。In an optional example of this embodiment, the three-dimensional seismic data of the reservoir of the drilling platform is used to complete the geological modeling of the reservoir, and determine the lateral distribution law and characteristics of the geological structure of the reservoir of the drilling platform.

在本发明一个可选的例子中,钻前水平井水平段井眼轨迹的优选规则为,所述井眼轨迹规避穿越地层矿物组分、地层岩石强度剧烈波动井段。使得井眼轨迹尽可能的经由高硅均质储层穿过。In an optional example of the present invention, the preferred rule for the wellbore trajectory of the horizontal section of the horizontal well before drilling is that the wellbore trajectory avoids well sections passing through formation mineral components and formation rock strength fluctuations. Make the well trajectory pass through the high-silicon homogeneous reservoir as much as possible.

在本发明一个可选的实施方式中,随钻进行水平井水平段钻井参数及工艺措施优化,包括:In an optional embodiment of the present invention, the drilling parameters and technological measures of the horizontal section of the horizontal well are optimized while drilling, including:

在井段钻井过程中判断钻头是否进入水平段的目标箱体;During the drilling process of the well section, it is judged whether the drill bit enters the target box of the horizontal section;

确定钻头进入水平段的目标箱体后,获取当前井深井斜角α、目标箱体地层倾角β;After determining the target box where the drill bit enters the horizontal section, obtain the current well depth well inclination angle α and the target box formation dip angle β;

使钻头在目标箱体内进行水平段钻进,随钻判断钻头位置,根据钻头位置调整井眼轨迹以确保钻头位于目标箱体内。The drill bit is drilled in the horizontal section in the target box, the position of the drill bit is judged while drilling, and the wellbore trajectory is adjusted according to the position of the drill bit to ensure that the drill bit is located in the target box.

在该实施方式一个可选的例子中,若在井段钻井过程中判断钻头尚未进入目标箱体,则调整井眼轨迹继续钻进直至钻头进入目标箱体。In an optional example of this embodiment, if it is judged that the drill bit has not entered the target box during the drilling of the well section, the wellbore trajectory is adjusted and drilling is continued until the drill bit enters the target box.

在一个可选的例子中,在水平段钻进过程中,若判断钻头在目标箱体内,根据钻头的实际垂深及时迭代时深地震数据、更新地质模型,预测水平段地质构造变化,提前调整井眼轨迹,确保钻头在目标箱体内钻进。In an optional example, during the drilling process of the horizontal section, if it is judged that the drill bit is in the target box, the time-deep seismic data is iterated in time according to the actual vertical depth of the drill bit, and the geological model is updated to predict changes in the geological structure of the horizontal section and adjust in advance Borehole trajectory to ensure that the drill bit is drilled within the target casing.

在另一个可选的例子中,在水平段钻进过程中,若判断钻头在目标箱体外,则进行钻井参数调整。In another optional example, during the drilling of the horizontal section, if it is judged that the drill bit is outside the target box, the drilling parameters are adjusted.

进一步的,钻井参数调整的过程包括:Further, the process of drilling parameter adjustment includes:

判断当前泥浆泵泵压是否达到规定安全上限,若未达到则以每0.5L/s步长提高泥浆泵排量直至泥浆泵泵压达到规定安全上限;之后判断当前钻压是否≦80KN,若未达到则以10KN步长不断降低钻压至80KN及以下;之后再判断钻机是否使用顶驱,若使用顶驱则将顶驱转速提高至110-120r/min,若未使用顶驱则将转盘转速调制80r/min以上。Judging whether the current mud pump pressure reaches the specified safety upper limit, if not, increase the displacement of the mud pump in steps of 0.5L/s until the mud pump pressure reaches the specified safety upper limit; then judge whether the current drilling pressure is ≦80KN, if not When it is reached, the WOB will be continuously reduced to 80KN and below in steps of 10KN; after that, it will be judged whether the drilling rig uses top drive. Modulate 80r/min or more.

优选的,完成钻井参数调整后,根据钻头与目标箱体的相对位置,以及钻头的当前井深井斜角α,确定井眼轨迹的调整方法,通过调整方法确保钻头重新钻回目标箱体中。具体的,先确定是使用旋转导向系统还是井下马达,再确定是以增斜方式还是降斜方式进入目标箱体,最后确定进入目标箱体后继续稳斜钻进的井斜角度。通过轨迹调整过程中钻井参数优选及工艺措施的优化,达到降低井下振动强度、减少钻头非均质储层中钻进长度目的,具体实施步骤如下:Preferably, after the adjustment of drilling parameters is completed, according to the relative position of the drill bit and the target box, and the current depth and inclination angle α of the drill bit, the adjustment method of the wellbore trajectory is determined, and the adjustment method is used to ensure that the drill bit is drilled back into the target box. Specifically, first determine whether to use the rotary steerable system or the downhole motor, then determine whether to enter the target box in the way of increasing or decreasing the inclination, and finally determine the inclination angle for continuing to stabilize the drilling after entering the target box. Through the optimization of drilling parameters and process measures during the trajectory adjustment process, the purpose of reducing the downhole vibration intensity and the drilling length of the drill bit in heterogeneous reservoirs is achieved. The specific implementation steps are as follows:

完成钻井参数调整后,判断钻头是否处于目标箱体上方,若是,判断当前井深井斜角α≧90°是否成立,若成立则钻头处于上倾目标箱体上方,判断是否使用旋转导向系统,若是,旋转导向以(90+β-(2~4))°目标井斜角降斜钻进直至钻头重新进入目标箱体,推荐使用大角差调整井眼轨迹以减少非均质地层中钻进进尺长度;若使用井下马达则井下马达以工具面角180°定向降斜钻进0.3~0.5m后复合钻进,判断钻头是否进入目标箱体,若未进入则井下马达重复该过程直至钻头进入目标箱体,当确定钻头进入目标箱体后控制井斜角α≤(90+β±1)°稳斜钻进,见图2。After completing the adjustment of drilling parameters, judge whether the drill bit is above the target box. If so, judge whether the current well depth and inclination angle α≧90° is established. , rotary steerable drilling at (90+β-(2~4))° target inclination angle until the drill bit re-enters the target box, it is recommended to use a large angle difference to adjust the wellbore trajectory to reduce the drilling footage in heterogeneous formations Length; if the downhole motor is used, the downhole motor will drill 0.3~0.5m with a tool face angle of 180° and then compound drilling to judge whether the drill bit has entered the target box. If not, the downhole motor will repeat the process until the drill bit enters the target. Box, when it is determined that the drill bit enters the target box, the well inclination angle α≤(90+β±1)° is controlled to drill steadily, as shown in Figure 2.

若钻头处于目标箱体上方,且当前井斜角α<90°,则钻头处于下倾目标箱体上方,判断是否使用旋转导向系统,若是,旋转导向以(90-β-(2~4))°目标井斜角降斜钻进直至钻头重新进入目标箱体,推荐使用大角差调整井眼轨迹以减少非均质地层中钻进进尺长度;若使用井下马达则井下马达以工具面角180°定向降斜钻进0.3~0.5m后复合钻进,判断钻头是否进入目标箱体,若未进入则井下马达重复该过程直至钻头进入目标箱体,当确定钻头进入目标箱体后控制井斜角α≤(90-β±1)°稳斜钻进,见图3。If the drill bit is above the target box, and the current inclination angle α<90°, then the drill bit is above the down-dipping target box, and it is judged whether to use the rotary steerable system. )° target well inclination angle and drill until the drill bit re-enters the target box. It is recommended to use a large angle difference to adjust the wellbore trajectory to reduce the drilling footage in heterogeneous formations; °Composite drilling after 0.3-0.5m of directional drop-down drilling, judge whether the drill bit enters the target box, if not, the downhole motor repeats the process until the drill bit enters the target box, and controls the well deviation when it is determined that the drill bit enters the target box Angle α≤(90-β±1)°Stable and inclined drilling, see Figure 3.

若判断钻头处于目标箱体下方,判断当前井深井斜角α≧90°是否成立,若成立钻头处于上倾目标箱体下方,判断是否使用旋转导向系统,若是,旋转导向以(90+β+(2~4))°目标井斜角增斜钻进直至钻头重新进入目标箱体,推荐使用大角差调整井眼轨迹以减少非均质地层中钻进进尺长度;若使用井下马达则井下马达以工具面角0°定向增斜钻进0.3~0.5m后复合钻进,判断钻头是否进入目标箱体,若未进入则井下马达重复该过程直至钻头进入目标箱体,当确定钻头进入目标箱体后控制井斜角α≤(90+β±1)°稳斜钻进,见图4。If it is judged that the drill bit is under the target box, judge whether the inclination angle of the current well depth α≧90° is established. If it is established that the drill bit is under the upwardly inclined target box, judge whether to use the rotary steerable system. If so, rotate the steerable with (90+β+ (2~4))° target well inclination angle increase until the drill bit re-enters the target box, it is recommended to use a large angle difference to adjust the wellbore trajectory to reduce the drilling footage in heterogeneous formations; if a downhole motor is used, the downhole motor Drill 0.3 to 0.5m with a tool face angle of 0° and then compound drilling to judge whether the drill bit has entered the target box. If not, the downhole motor will repeat the process until the drill bit enters the target box. The inclination angle α≤(90+β±1)° behind the body is controlled for stable inclination drilling, as shown in Fig. 4.

当钻头处于目标箱体下方,且当前井深井斜角α<90°,则钻头处于下倾目标箱体下方,判断是否使用旋转导向系统,若是,旋转导向以(90-β+(2~4))°目标井斜角增斜钻进直至钻头重新进入目标箱体,推荐使用大角差调整井眼轨迹以减少非均质地层中钻进进尺长度;若使用井下马达则井下马达以工具面角0°定向增斜钻进0.3~0.5m后复合钻进,判断钻头是否进入目标箱体,若未进入则井下马达重复该过程直至钻头进入目标箱体,当确定钻头进入目标箱体后控制井斜角α≤(90-β±1)°稳斜钻进,见图5。When the drill bit is under the target box, and the current well depth and inclination angle α<90°, the drill bit is under the down-dipping target box, and it is judged whether to use the rotary steering system. ))° The target well inclination angle is increased until the drill bit re-enters the target box. It is recommended to use a large angle difference to adjust the wellbore trajectory to reduce the drilling footage in heterogeneous formations; 0° directional augmentation drilling for 0.3-0.5m and compound drilling to judge whether the drill bit has entered the target box, if not, the downhole motor repeats the process until the drill bit enters the target box, when it is determined that the drill bit enters the target box, control the well Angle of inclination α ≤ (90-β ± 1) ° steady inclination drilling, see Figure 5.

请参考图1至图10,现结合一实施例,详细说明本发明提出的页岩气的水平井水平段钻井优化与提速方法。Please refer to FIG. 1 to FIG. 10 , and an embodiment is now used to describe in detail the drilling optimization and speed-up method for the horizontal section of a shale gas horizontal well proposed by the present invention.

本实施例以川南地区(西南油气田)一钻井平台水平井作为模拟实施案例,该钻井平台采用双向布置6-12口水平井(优选8口水平井);利用三维地震数据完成储层地质建模、钻井平台第一口井先采用直井(又称导眼井)钻穿储层段并完成取心作业,取心完成后回填储层直井段后再完成水平井造斜段、水平段钻进作业,具体的:In this embodiment, a horizontal well on a drilling platform in the southern Sichuan area (Southwest oil and gas field) is used as a simulation implementation case. The drilling platform adopts two-way arrangement of 6-12 horizontal wells (8 horizontal wells are preferred); the reservoir geological modeling and drilling are completed using 3D seismic data. The first well on the platform uses a vertical well (also known as a pilot well) to drill through the reservoir section and complete the coring operation. After the coring is completed, the vertical well section of the reservoir is backfilled, and then the horizontal well deflection section and horizontal section drilling operations are completed. specific:

步骤1,钻前水平井水平段井眼轨迹优选;

步骤1-1,利用钻井平台导眼井龙马溪组岩心及测井数据,获得该钻井平台龙马溪组地层岩石矿物组份及岩石强度垂向分布特征;Step 1-1, using the Longmaxi Formation core and logging data of the pilot well of the drilling platform to obtain the vertical distribution characteristics of the rock mineral composition and rock strength of the Longmaxi Formation formation on the drilling platform;

步骤1-2,利用钻井平台储层龙马溪组三维地震数据,完成龙马溪组储层地质建模,确定钻井平台龙马溪组龙一12-龙一11小层垂深,断层、隆起、凹陷等地质构造横向展布规律与特征;Step 1-2: Use the 3D seismic data of the Longmaxi Formation on the drilling platform to complete the geological modeling of the Longmaxi Formation reservoir, and determine the vertical depth, faults, and uplifts of the Longmaxi Formation Long 12 - Long 11 Laws and characteristics of lateral distribution of geological structures such as , sags, etc.;

步骤1-3,结合导眼井龙一12-龙一11组地层岩石矿物组份及岩石强度垂向分布特征,和龙一12-龙一11组小层垂深、地质构造横向展布规律(例如,储层孔隙度、有机碳、含气量曲线分布规律),水平井水平段井眼轨迹优选龙一12-龙一11小层中硅质含量高、岩石强度均质储层作为目标箱体,再结合目标箱体垂深,断层、隆起、凹陷等地质构造横向展布规律与特征,优选水平段井眼轨迹,并且,井眼轨迹规避穿越地层矿物组分、地层岩石强度剧烈波动井段。Steps 1-3, combined with the vertical distribution characteristics of rock mineral composition and rock strength in Longyi 12 -

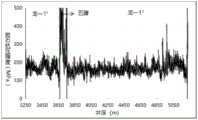

步骤2,随钻水平井水平段钻井参数及工艺措施优化;其中,以该钻井平台威202HHX-Y井水平段作为实施案例,该井目标箱体A点井深3250m,水平段井深区间3250m—5250m,水平段井斜角、地层元素含量百分比、地层岩石强度随井深分布见图7-图9;具体的,

步骤2-1,在井段钻井过程中判断钻头是否进入水平段目标箱体,若未进入则调整轨迹继续钻进直至进入目标箱体,该目标箱体A点井深3250m;Step 2-1, during the drilling process of the well section, it is judged whether the drill bit has entered the target box of the horizontal section, and if not, the trajectory is adjusted to continue drilling until it enters the target box. The depth of point A of the target box is 3250m;

步骤2-2,确定当前井眼轨迹进入水平段目标箱体后,获取当前井深井斜角α、目标箱体地层倾角β,其中,井斜角α=78°,地层倾角β=7°;Step 2-2, after determining that the current wellbore trajectory enters the target box in the horizontal section, obtain the current well depth well inclination α and the target box formation dip β, wherein the well inclination α=78°, and the formation dip β=7°;

步骤2-3,水平段钻头在目标箱体内继续钻进,地质导向工程师根据龙马溪组小层实际垂深及时迭代时深地震数据、更新地质模型,预测水平段地质构造变化,提前调整井眼轨迹,确保钻头在目标箱体内钻进,具体的,钻头水平段继续钻进,井深3250m-3600m井斜角缓慢上升至80°-83°,井眼轨迹一直位于目标箱体内,继续钻进井斜角逐渐降低,井深3666m时井斜角降至80.64°。Step 2-3: The drill bit in the horizontal section continues to drill in the target box, and the geosteering engineer iterates the time-deep seismic data and updates the geological model in time according to the actual vertical depth of the small layer of the Longmaxi Formation, predicts the geological structure changes in the horizontal section, and adjusts the borehole in advance Trajectory, to ensure that the drill bit is drilled in the target box. Specifically, the horizontal section of the drill bit continues to drill, and the inclination angle slowly rises to 80°-83° at a depth of 3250m-3600m. The inclination angle gradually decreases, and the inclination angle drops to 80.64° at the depth of 3666m.

步骤2-4,水平段钻进过程中若判断钻头钻出目标窗体,地质导向工程师会通过旋转导向或井下马达调整井眼轨迹确保钻头重新钻回目标箱体中,考虑到川南页岩气目的层龙一12-龙一11小层矿物组分及岩石强度垂向分布非均质性,因轨迹调整PDC钻头穿越非均质储层过程中会出现剧烈扭转(粘滑)、横向振动,加速钻头磨损同时增加井下随钻测控工具(旋转导向、MWD、LWD等)失效风险,进而导致提前起钻,增加水平段趟钻数及钻井周期。具体的,Steps 2-4, if it is judged that the drill bit has drilled out of the target window during the drilling process of the horizontal section, the geosteering engineer will adjust the wellbore trajectory through the rotary steering or downhole motor to ensure that the drill bit returns to the target box. Considering the shale gas in southern Sichuan The vertical distribution of mineral components and rock strength in the target strata Long-12 -Long-11 is heterogeneous. Due to trajectory adjustment, the PDC drill bit will experience severe torsion (stick-slip) and lateral Vibration accelerates the wear of the drill bit and increases the risk of failure of downhole measurement and control tools (rotary steerable, MWD, LWD, etc.) specific,

当井深3666m时井斜角降至80.64°,地层硅元素百分占比随井斜增加发生显著变化,地质导向判断井眼轨迹钻出目标箱体,进入龙一11小层下部五峰组地层,此时钻头位于下倾目标箱体下方;When the well depth is 3666m, the well inclination angle drops to 80.64°, and the percentage of silicon element in the formation changes significantly with the increase of well inclination. Geosteering judges that the well trajectory drills out of the target box and enters the Wufeng Formation in the lower part of the Longyi11 sublayer , at this time the drill bit is located below the down-tilted target box;

确定钻头钻出目标箱体,且位于下倾目标箱体下方后,地质导向工程师发布井轨迹调整指令,旋转导向以85°(90-β+2,β=7°)目标井斜角增斜钻进;After confirming that the drill bit has drilled out of the target box and is located below the downdipping target box, the geosteering engineer issues a well trajectory adjustment command, and the rotary steering increases the inclination at the target well inclination angle of 85° (90-β+2, β=7°). drill into;

旋转导向增斜钻进至井深3754m,井斜角达到85.2°,结合地层元素含量百分比变化判断钻头已回调至目标箱体,地质导向发布井轨迹调整指令,旋转导向以82°-84°(90-β±1,β=7°)目标井斜角稳斜钻进。完钻后水平段测井数据显示,见图8,钻头穿出目标箱体后回调至目标箱体所钻地层,非均质性强,岩石强度变化幅度大,轨迹调整过程中井下扭转(粘滑)、横向振动剧烈,起钻后钻头切削齿磨损明显。Rotary steering augmented drilling to a well depth of 3754m, and the inclination angle reached 85.2°. Combined with the change in the percentage of formation element content, it was judged that the drill bit had returned to the target box. -β±1, β=7°) Drilling with the target well inclination angle. The logging data of the horizontal section after drilling shows that as shown in Fig. 8, the drill bit passes through the target box and returns to the formation drilled by the target box. The heterogeneity is strong, the rock strength changes greatly, and the downhole torsion (viscosity slippery), severe lateral vibration, and obvious wear of the cutting teeth of the drill bit after pulling out the drill.

接收指令后,旋转导向迅速降斜钻进,井深3789m井斜角降至81.65°,随后3789m-4850m井段稳斜钻进,实钻井斜角控制在80°-83°之间,井眼轨迹始终在龙一11目标箱体内;After receiving the instructions, the rotary steering quickly lowered the inclination and drilled, and the inclination angle dropped to 81.65° at a depth of 3,789m. Then, the drilling was stabilized in the 3,789m-4,850m well section, and the actual drilling inclination angle was controlled between 80°-83°. Always in the

根据龙马溪组龙一11、五峰组小层实际垂深迭代时深地震数据、更新地质模型,预测威202HX-Y水平井井深4950m位置存在微隆起构造,随后地质导向工程师提前发布井眼轨迹调整指令,从4850m开始旋转导向缓慢增斜钻进,钻至井深4950m井斜角增至84.11°,随后发布指令缓慢降斜钻进至完钻井深5250m,井斜角降至80.11°。通过及时更新地质模型,预测水平段地质构造并提前调整井眼轨迹,水平段4950m-5250m井段井斜角虽变化较大,但井眼轨迹始终在目标箱体内。According to the actual vertical depth iteration time-depth seismic data and updated geological model of

本发明提出一种页岩气的水平井水平段钻井优化与提速方法充分地考虑到了川南页岩气龙马溪储层非均质性特征,从兼顾完井压裂改造及钻井优化提速角度,通过钻前优选水平段高硅或高GR储层,结合随钻穿越非均质储层中优化钻井参数以降低井下振动强度,辅助大“角差(井眼轨迹与储层倾角差值)”快速穿越以降低非均质井段钻进进尺,实现水平段井眼轨迹钻遇物性更好储层同时,降低钻头穿越非均质井段长度及井下振动强度,最终实现提高水平段钻进机械钻速、降低趟钻次数及钻井周期目的The present invention proposes a shale gas drilling optimization and speed-up method for the horizontal section of a horizontal well, fully considering the heterogeneity characteristics of the Longmaxi reservoir of shale gas in southern Sichuan. Optimizing high-silicon or high-GR reservoirs in the horizontal section before drilling, combined with optimizing drilling parameters in heterogeneous reservoirs while drilling to reduce downhole vibration intensity, assisting large "angle difference (difference between wellbore trajectory and reservoir inclination angle)" to quickly Crossing to reduce the drilling footage of the heterogeneous well section, realize the drilling of the wellbore trajectory in the horizontal section to meet the reservoir with better physical properties, reduce the length of the drill bit crossing the heterogeneous well section and the downhole vibration intensity, and finally realize the improvement of mechanical drilling in the horizontal section Speed, reduce the number of drilling trips and the purpose of drilling cycle

针对上述各实施方式的详细解释,其目的仅在于对本发明进行解释,以便于能够更好地理解本发明,但是,这些描述不能以任何理由解释成是对本发明的限制,特别是,在不同的实施方式中描述的各个特征也可以相互任意组合,从而组成其他实施方式,除了有明确相反的描述,这些特征应被理解为能够应用于任何一个实施方式中,而并不仅局限于所描述的实施方式。The purpose of the detailed explanations for the above-mentioned embodiments is only to explain the present invention so as to better understand the present invention. However, these descriptions cannot be construed as limiting the present invention for any reason, especially, in different The various features described in the embodiments can also be combined arbitrarily with each other to form other embodiments. Unless there is an explicit description to the contrary, these features should be understood as being applicable to any embodiment and not limited to the described embodiment. Way.

Claims (25)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211417984.4ACN115822452A (en) | 2022-11-14 | 2022-11-14 | Horizontal well horizontal section drilling optimization and speed-increasing method for shale gas |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211417984.4ACN115822452A (en) | 2022-11-14 | 2022-11-14 | Horizontal well horizontal section drilling optimization and speed-increasing method for shale gas |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115822452Atrue CN115822452A (en) | 2023-03-21 |

Family

ID=85527908

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211417984.4APendingCN115822452A (en) | 2022-11-14 | 2022-11-14 | Horizontal well horizontal section drilling optimization and speed-increasing method for shale gas |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115822452A (en) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4854397A (en)* | 1988-09-15 | 1989-08-08 | Amoco Corporation | System for directional drilling and related method of use |

| CN105003245A (en)* | 2015-07-13 | 2015-10-28 | 中国海洋石油总公司 | Dynamic control system and dynamic control method for underground directional power drill tool surface |

| CN105298388A (en)* | 2015-10-30 | 2016-02-03 | 中国石油天然气集团公司 | Horizontal well drilling path guiding method and device |

| US20160341027A1 (en)* | 2014-01-27 | 2016-11-24 | National Oilwell Varco Norway As | Methods and systems for control of wellbore trajectories |

| CN109960897A (en)* | 2019-04-24 | 2019-07-02 | 中国石油大港油田勘探开发研究院 | A kind of shale oil horizontal well path design and live tracking adjustment research method |

| CN113338921A (en)* | 2021-06-22 | 2021-09-03 | 中国地质调查局油气资源调查中心 | Shale oil horizontal well track control method |

- 2022

- 2022-11-14CNCN202211417984.4Apatent/CN115822452A/enactivePending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4854397A (en)* | 1988-09-15 | 1989-08-08 | Amoco Corporation | System for directional drilling and related method of use |

| US20160341027A1 (en)* | 2014-01-27 | 2016-11-24 | National Oilwell Varco Norway As | Methods and systems for control of wellbore trajectories |

| CN105003245A (en)* | 2015-07-13 | 2015-10-28 | 中国海洋石油总公司 | Dynamic control system and dynamic control method for underground directional power drill tool surface |

| CN105298388A (en)* | 2015-10-30 | 2016-02-03 | 中国石油天然气集团公司 | Horizontal well drilling path guiding method and device |

| CN109960897A (en)* | 2019-04-24 | 2019-07-02 | 中国石油大港油田勘探开发研究院 | A kind of shale oil horizontal well path design and live tracking adjustment research method |

| CN113338921A (en)* | 2021-06-22 | 2021-09-03 | 中国地质调查局油气资源调查中心 | Shale oil horizontal well track control method |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| AU2021445202B2 (en) | Segmented fracturing horizontal well coal seam gas extraction method for broken soft low-permeability coal seam roof or floor | |

| Guoxin et al. | Key technologies, engineering management and important suggestions of shale oil/gas development: Case study of a Duvernay shale project in Western Canada Sedimentary Basin | |

| CN103046918B (en) | Method and system for optimizing drilling parameters | |

| CN108561106B (en) | Oil and gas exploitation method for increasing recovery ratio by controlling reserves through artificial seams | |

| CN102272414B (en) | Method for optimizing well production in reservoirs having flow barriers | |

| CN110500034B (en) | Method for establishing neural network model, determining torsional pendulum drill string parameters and directionally drilling | |

| CN104481400B (en) | A kind of three-dimensional horizontal well track control method | |

| CN115324557B (en) | Method for predicting the risk of casing deformation induced by fracturing based on multi-factor analysis | |

| CN115324559B (en) | Multi-factor comprehensive prediction and prevention method for fracturing induced oil-gas casing deformation | |

| Xia et al. | Key technologies for well drilling and completion in ultra-deep sour gas reservoirs, Yuanba Gasfield, Sichuan Basin | |

| CN101701506A (en) | Drilling tool structure with three stabilizers | |

| CN116562079A (en) | A whole-well mechanical specific energy drilling optimization method based on drilling data | |

| CN116877041A (en) | Well drilling completion fracturing transformation method for horizontal seam horizontal well of oil and gas reservoir | |

| Faraj et al. | Wellbore instability analysis using geomechanical model for carbonate reservoir in Zubair oil field, Southern Iraq | |

| CN115822452A (en) | Horizontal well horizontal section drilling optimization and speed-increasing method for shale gas | |

| CN116084838B (en) | A method for determining the horizontal trajectory of a horizontal well in the roof of a surface coal seam | |

| CN201554370U (en) | Four-in-one drilling tool structure with three centralizers | |

| CN108798515B (en) | Directional drilling process for mudstone section | |

| Alam et al. | Investigations on the influence of rock and machine characteristics on coring rates in vertical and mildly inclined exploration drilling in complex coal bearing rock formation | |

| CN1145444A (en) | Method and system of trajectory prediction and control using PDC bits | |

| Jebur | Directional Drilling Tools Assessment and the Impact of Bottom Hole Assembly Configuration on the Well Trajectory and Operation Optimization | |

| Shi et al. | The underground directional drilling technology and equipments for kilometer deep borehole with MWD in coalmine | |

| Курячий et al. | Applying modern technologies when drilling directional wells with long horizontal boreholes | |

| US12196076B1 (en) | Grouting and water blocking method for directional hole with large offset in hard rock stratum | |

| CN109184560A (en) | Method and device for controlling well track of stepped horizontal well |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |