CN115818565A - A device and method for enriching and sorting micro-nano particles - Google Patents

A device and method for enriching and sorting micro-nano particlesDownload PDFInfo

- Publication number

- CN115818565A CN115818565ACN202211438713.7ACN202211438713ACN115818565ACN 115818565 ACN115818565 ACN 115818565ACN 202211438713 ACN202211438713 ACN 202211438713ACN 115818565 ACN115818565 ACN 115818565A

- Authority

- CN

- China

- Prior art keywords

- micro

- nano particles

- chip

- ultrasonic

- enriching

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Physical Or Chemical Processes And Apparatus (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及声学技术领域,具体来说,涉及一种对微纳米颗粒进行富集、分选的装置和方法。The invention relates to the field of acoustic technology, in particular to a device and method for enriching and sorting micro-nano particles.

背景技术Background technique

微纳米颗粒的多功能操控在生物医学和生化应用中不可缺少的工具,其中包括药物递送、细胞操作、用于诊断的样品富集、组织工程和催化反应。粒子操纵的传统技术包括磁性、光电、等离子体、电动和流体动力学。在具体应用中,这些方法虽然各有优势,但也存在一些不足。例如,操纵磁场和电场镊子需要具有电磁物理特性的粒子;光学和等离子镊子提供高精度,但它们通常仅限于操纵相对较少的粒子。流体动力镊子使用流体流动来捕获、聚焦和分类微通道内的颗粒,但它们的可控性较差,并且操纵颗粒的能力有限。声操控技术由于其良好的生物相容性,在生物和生物医学研究领域中被广泛研究,比如生物微纳米颗粒的浓缩富集、分选分析。Multifunctional manipulation of micro/nanoparticles is an indispensable tool in biomedical and biochemical applications, including drug delivery, cell manipulation, sample enrichment for diagnostics, tissue engineering, and catalytic reactions. Traditional techniques for particle manipulation include magnetic, optoelectronic, plasmonic, electrokinetic, and hydrodynamic. In specific applications, although these methods have their own advantages, they also have some shortcomings. For example, manipulating magnetic and electric field tweezers requires particles with electromagnetic physics; optical and plasmonic tweezers offer high precision, but they are usually limited to manipulating relatively few particles. Hydrodynamic tweezers use fluid flow to capture, focus, and sort particles within microchannels, but they are less controllable and have limited ability to manipulate particles. Due to its good biocompatibility, acoustic manipulation technology has been widely studied in the field of biological and biomedical research, such as the enrichment and sorting analysis of biological micro-nanoparticles.

专利公开号为CN103864173A的中国发明公开了一种在多个位置上聚集微纳米颗粒的方法和装置,该发明采用一个长方形腔体,超声励振器,声透过/吸收板,超声励振器振动,在腔室中产生行波声场,从而在水体中产生声学流涡流,分散在流体中的微纳米颗粒会随着涡流流动,聚集到涡流中心位置。The Chinese invention with the patent publication number CN103864173A discloses a method and device for gathering micro-nano particles at multiple locations. The invention uses a rectangular cavity, an ultrasonic exciter, a sound transmission/absorbing plate, and the ultrasonic exciter vibrates. A traveling wave sound field is generated in the chamber, thereby creating an acoustic vortex in the water body, and the micro-nano particles dispersed in the fluid will flow with the vortex and gather at the center of the vortex.

上述发明存在以下不足:腔室中多点对称声涡流场是在较为理想的状态下激发的,需要声波的波长与腔室的尺寸匹配才能激发出涡流场,然后声涡流场聚集流场中的微纳米形成粒子团,然而,当纳米粒子团的直径大于2um时,纳米粒子团的运动由初级声辐射力主导,使得微纳米粒子团远离涡流中心而重新分散开,造成微纳米颗粒无法有效聚集,此外,通过激发固体腔室结构谐振方式激发的流场模式较为单一,无法通过改变外加声场来实现对流体中的微纳米颗粒进行多模式操控,此发明只有简单富集微粒的功能,这种方法的控制能力较弱,并无法对微粒进行分选的操作。因此,亟需一种对微纳米颗粒进行富集、分选的装置和方法来解决上述问题。The above-mentioned invention has the following disadvantages: the multi-point symmetrical acoustic vortex field in the chamber is excited in a relatively ideal state, and the wavelength of the acoustic wave needs to match the size of the chamber to excite the vortex field, and then the acoustic vortex field gathers the Micro-nano particle clusters are formed. However, when the diameter of the nano-particle cluster is greater than 2um, the movement of the nano-particle cluster is dominated by the primary acoustic radiation force, which makes the micro-nano particle cluster far away from the center of the eddy current and redisperses, resulting in the inability to effectively aggregate the micro-nano particles. , in addition, the flow field mode excited by exciting the resonance of the solid cavity structure is relatively single, and it is impossible to achieve multi-mode manipulation of micro-nano particles in the fluid by changing the external sound field. This invention only has the function of simply enriching particles. The control ability of the method is weak, and the operation of sorting the particles cannot be performed. Therefore, there is an urgent need for a device and method for enriching and sorting micro-nano particles to solve the above problems.

发明内容Contents of the invention

针对相关技术中的问题,本发明提出一种对微纳米颗粒进行富集、分选的装置和方法,以克服现有相关技术所存在的上述技术问题。Aiming at the problems in the related technologies, the present invention proposes a device and method for enriching and sorting micro-nano particles, so as to overcome the above-mentioned technical problems in the existing related technologies.

本发明的技术方案是这样实现的:Technical scheme of the present invention is realized like this:

一种对微纳米颗粒进行富集、分选的装置,包括盖板、控制器和设置于所述盖板顶部的超声励振器,所述盖板的底部覆盖有连接片,所述连接片的底部键合有芯片,所述芯片的顶部设置有等距离分布的微孔,所述芯片的底部设置有底板,所述盖板、所述连接片、所述芯片的四侧外壁均设置有侧板,所述超声励振器的顶部设置有连接导线,所述超声励振器通过所述连接导线与所述控制器形成电性连接,所述控制器的一侧外壁设置有开关,所述控制器的顶部设置有调节旋钮。A device for enriching and sorting micro-nano particles, including a cover plate, a controller and an ultrasonic exciter arranged on the top of the cover plate, the bottom of the cover plate is covered with a connecting sheet, and the connecting sheet The bottom is bonded with a chip, the top of the chip is provided with equidistantly distributed micro-holes, the bottom of the chip is provided with a bottom plate, and the cover plate, the connecting piece, and the four-side outer walls of the chip are all provided with side holes. board, the top of the ultrasonic exciter is provided with connecting wires, and the ultrasonic exciter is electrically connected to the controller through the connecting wires, and a switch is arranged on one side of the outer wall of the controller, and the controller There is an adjustment knob on the top.

进一步地,所述超声励振器为压电陶瓷片,所述超声励振器的底部涂抹有超声波耦合剂,所述超声励振器通过超声波耦合剂与所述芯片耦合在一起。Further, the ultrasonic vibrator is a piezoelectric ceramic sheet, the bottom of the ultrasonic vibrator is coated with an ultrasonic coupling agent, and the ultrasonic vibrator is coupled with the chip through the ultrasonic coupling agent.

进一步地,所述芯片和所述底板由ITO玻璃制成,所述芯片顶部开设的等距离所述微孔通过紫外光刻工艺制造。Further, the chip and the bottom plate are made of ITO glass, and the equidistant microholes opened on the top of the chip are manufactured by ultraviolet lithography.

进一步地,所述侧板与所述连接片均由聚二甲基硅氧烷材料制成。Further, both the side plate and the connecting piece are made of polydimethylsiloxane material.

进一步地,所述控制器的底部内壁固定连接有控制电路板,所述控制电路板的顶部分别设置有传感器驱动模块和插座,所述连接导线,所述连接导线的一端设置有插头,所述插头与所述插座相配合,所述控制器的顶部开设有通槽,所述插头从所述通槽的内部穿过。Further, the bottom inner wall of the controller is fixedly connected with a control circuit board, the top of the control circuit board is respectively provided with a sensor drive module and a socket, and the connecting wire is provided with a plug at one end of the connecting wire. The plug matches the socket, and a through slot is opened on the top of the controller, and the plug passes through the inside of the slot.

进一步地,所述控制器的顶部外壁开设有弧形槽,所述弧形槽的与所述通槽相连通。Further, an arc-shaped groove is opened on the top outer wall of the controller, and the arc-shaped groove communicates with the through groove.

进一步地,所述芯片的内部填充有作为流场的声学流动媒介,所述声学流动媒介为水。Further, the interior of the chip is filled with an acoustic flow medium as a flow field, and the acoustic flow medium is water.

进一步地,等距离分布在所述芯片顶部外壁的所述微孔内部捕捉有气泡,所述微孔的直径为15um、深度为5um。Further, air bubbles are trapped inside the micropores equidistantly distributed on the top outer wall of the chip, and the micropores have a diameter of 15 um and a depth of 5 um.

一种对微纳米颗粒进行富集、分选的方法,其采用上述实施例所述的一种对微纳米颗粒进行富集、分选的装置,包括以下步骤:A method for enriching and sorting micro-nano particles, which adopts the device for enriching and sorting micro-nano particles described in the above-mentioned embodiments, comprising the following steps:

S1:工作人员首先打开控制器一侧外壁的开关,此时控制器内部的传感器驱动模块使超声励振器工作,超声励振器产生的超声波辐照在芯片腔室内部的流动媒介中,通过超声空化效应会产生气泡;S1: The staff first turns on the switch on the outer wall of one side of the controller. At this time, the sensor drive module inside the controller makes the ultrasonic exciter work. The chemical effect will produce bubbles;

S2:S1中产生中的气泡在其谐振频率相同的超声波激励下,发生气泡共振诱导的高速声流场,声流场产生的拖拽力Fd把流体中的微纳米颗粒带到气泡附近,气泡附近微纳米颗粒的浓度变高,微纳米颗粒之间的距离也变小,次级声辐射力Fsec变大,使得微纳米颗粒聚集;S2: Under the excitation of the ultrasonic wave with the same resonant frequency, the bubbles generated in S1 generate a high-speed acoustic flow field induced by bubble resonance. The drag force Fd generated by the acoustic flow field brings the micro-nano particles in the fluid to the vicinity of the bubbles, and the bubbles The concentration of nearby micro-nanoparticles becomes higher, the distance between micro-nanoparticles also becomes smaller, and the secondary acoustic radiation force Fsec becomes larger, making the micro-nanoparticles aggregate;

S3:当工作人员施加的声场与气泡谐振频率不同,声波激发气泡振动,不仅可以控制流体中的微纳米颗粒聚集,由于该振荡模式下激发的是围绕气泡的涡流场,声流场产生的拖拽力Fd还可以控制粒子群围绕气泡旋转。S3: When the sound field applied by the staff is different from the resonant frequency of the bubbles, the sound waves excite the bubbles to vibrate, which can not only control the aggregation of micro-nano particles in the fluid, but also because the vortex field around the bubbles is excited in this oscillation mode, the drag generated by the acoustic flow field The drag force Fd can also control the particle group to rotate around the bubble.

本发明的有益效果:Beneficial effects of the present invention:

1、本发明提供的一种对微纳米颗粒进行富集、分选的装置和方法,本装置操控能力增强,与固体结构界面相比,气泡界面自由度高,超声激发气泡阵列振动产生固体结构振动不具备的多模式声流场,微结构和气泡结合,使得气泡能在声场中指定位置振荡,不容易受声场和流场的影响而随意移动,提高流体中微粒的可操控性,可对微孔结构进行程序化设计,在指定位置进行微纳米颗粒的操控。1. The present invention provides a device and method for enriching and sorting micro-nano particles. The device has enhanced control ability. Compared with the solid structure interface, the bubble interface has a higher degree of freedom, and ultrasonically stimulates the vibration of the bubble array to produce a solid structure. The multi-mode acoustic flow field that vibration does not have, the combination of microstructure and bubbles, enables the bubbles to oscillate at specified positions in the sound field, and is not easily affected by the sound field and flow field to move freely, improving the controllability of particles in the fluid, and can control The microporous structure is designed programmatically, and the micro-nano particles are manipulated at the specified position.

2、本发明提供的一种对微纳米颗粒进行富集、分选的装置和方法,本装置灵敏度增强,由于气泡对超声非常敏感,使用很低的声功率就能驱动气泡振荡形成声场操控流体中的微粒;2. The present invention provides a device and method for enriching and sorting micro-nano particles. The sensitivity of the device is enhanced. Since the bubbles are very sensitive to ultrasound, very low sound power can drive the bubbles to oscillate and form a sound field to manipulate the fluid. particles in

同时本装置具备微粒分选的能力,在含有微纳米颗粒的微流通道中布置该结构,可通过改变外加声场的频率,对半径1um以下的微粒进行筛选,这对于从血液中分离出诸如细胞外囊泡(EV)等其他一些小分子具有较大应用价值,且本装置具备小型化,集成化的能力。At the same time, this device has the ability to sort particles. By arranging the structure in the microfluidic channel containing micro-nano particles, the particles with a radius of less than 1um can be screened by changing the frequency of the external sound field, which is very useful for separating such as extracellular particles from blood. Some other small molecules such as vesicles (EV) have great application value, and this device has the ability of miniaturization and integration.

3、本发明提供的一种对微纳米颗粒进行富集、分选的装置和方法,当微纳米颗粒的直径小于2um,初级声辐射力失去对此类微纳米微粒的控制,其在声场中的运动有声流产生的斯托克斯拽力主导,本发明通过使用微孔微阵列芯片结构捕获微气泡结构,形成气泡阵列,相比固体结构界面,气泡界面具有更高的自由度和声敏感性,在微通流体道中,可使用不同频率的超声激发气泡产生不同的振动模式来操控微纳米颗粒聚集,旋转,产生声流和次级声辐射力,对直径2um以下的微粒进行筛选。3. A device and method for enriching and sorting micro-nano particles provided by the present invention, when the diameter of the micro-nano particles is less than 2um, the primary acoustic radiation force loses control over such micro-nano particles, which in the sound field The movement of the acoustic flow is dominated by the Stokes force generated by the acoustic flow. The present invention captures the microbubble structure by using the microporous microarray chip structure to form a bubble array. Compared with the solid structure interface, the bubble interface has a higher degree of freedom and acoustic sensitivity. In the microfluidic channel, ultrasonic excitation of different frequencies can be used to generate different vibration modes to control the aggregation and rotation of micro-nano particles, to generate acoustic flow and secondary acoustic radiation force, and to screen particles with a diameter below 2um.

附图说明Description of drawings

为了更清楚地说明本发明实施例或现有技术中的技术方案,下面将对实施例中所需要使用的附图作简单地介绍,显而易见地,下面描述中的附图仅仅是本发明的一些实施例,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the accompanying drawings required in the embodiments. Obviously, the accompanying drawings in the following description are only some of the present invention. Embodiments, for those of ordinary skill in the art, other drawings can also be obtained based on these drawings without any creative effort.

图1为本发明的整体结构示意图。Figure 1 is a schematic diagram of the overall structure of the present invention.

图2为本发明的盖板、侧板、连接片爆炸结构示意图。Fig. 2 is a schematic diagram of the exploded structure of the cover plate, the side plate and the connecting piece of the present invention.

图3为本发明的控制器整体结构示意图。Fig. 3 is a schematic diagram of the overall structure of the controller of the present invention.

图4为本发明的控制器内部结构示意图。Fig. 4 is a schematic diagram of the internal structure of the controller of the present invention.

图5为本发明的微气泡阵列芯片结构示意图。Fig. 5 is a schematic structural diagram of the microbubble array chip of the present invention.

图6为本发明的微孔和气泡结构示意图。Fig. 6 is a schematic diagram of the structure of micropores and bubbles of the present invention.

图7为本发明微孔阵列中气泡振荡激发的声流场结构示意图。Fig. 7 is a schematic diagram of the structure of the acoustic flow field excited by bubble oscillation in the microhole array of the present invention.

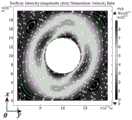

图8为本发明气泡振荡激发的环形声流场示意图。Fig. 8 is a schematic diagram of a circular acoustic flow field excited by bubble oscillation in the present invention.

图中:In the picture:

1、盖板;2、超声励振器;3、侧板;4、开关;5、调节旋钮;6、控制器;7、插头;8、连接导线;9、连接片;10、芯片;11、微孔;12、通槽;13、弧形槽;14、插座;15、传感器驱动模块;16、控制电路板;17、气泡;18、底板。1. Cover plate; 2. Ultrasonic exciter; 3. Side plate; 4. Switch; 5. Adjusting knob; 6. Controller; 7. Plug; 8. Connecting wire; 9. Connecting sheet; 10. Chip; 11. Microhole; 12, through groove; 13, arc groove; 14, socket; 15, sensor drive module; 16, control circuit board; 17, air bubble; 18, bottom plate.

具体实施方式Detailed ways

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员所获得的所有其他实施例,都属于本发明保护的范围。The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. All other embodiments obtained by persons of ordinary skill in the art based on the embodiments of the present invention belong to the protection scope of the present invention.

请参阅图1-图8,一种对微纳米颗粒进行富集、分选的装置,包括盖板1、控制器6和设置于盖板1顶部的超声励振器2,盖板1的底部覆盖有连接片9,连接片9的底部键合有芯片10,芯片10的顶部设置有等距离分布的微孔11,芯片10的底部设置有底板18,盖板1、连接片9、芯片10的四侧外壁均设置有侧板3,超声励振器2的顶部设置有连接导线8,超声励振器2通过连接导线8与控制器6形成电性连接,控制器6的一侧外壁设置有开关4,控制器6的顶部设置有调节旋钮5。Please refer to Figures 1-8, a device for enriching and sorting micro-nano particles, including a

超声励振器2为压电陶瓷片,超声励振器2的底部涂抹有超声波耦合剂,超声励振器2通过超声波耦合剂与芯片10耦合在一起,芯片10和所述底板18由ITO玻璃制成,芯片10顶部开设的等距离微孔11通过紫外光刻工艺制造,侧板3与连接片9均由聚二甲基硅氧烷材料制成。The

控制器6的底部内壁固定连接有控制电路板16,控制电路板16的顶部分别设置有传感器驱动模块15和插座14,连接导线8,连接导线8的一端设置有插头7,插头7与插座14相配合,控制器6的顶部开设有通槽12,插头7从通槽12的内部穿过。The bottom inner wall of the

控制器6的顶部外壁开设有弧形槽13,弧形槽13的与通槽12相连通。The top outer wall of the

芯片10的内部填充有作为流场的声学流动媒介,声学流动媒介为水,等距离分布在芯片10顶部外壁的微孔11内部捕捉有气泡17,微孔11的直径为15um、深度为5um。The interior of the

一种对微纳米颗粒进行富集、分选的方法,其采用上述实施例所述的一种对微纳米颗粒进行富集、分选的装置,包括以下步骤:A method for enriching and sorting micro-nano particles, which adopts the device for enriching and sorting micro-nano particles described in the above-mentioned embodiments, comprising the following steps:

第一步:工作人员首先打开控制器6一侧外壁的开关4,此时控制器6内部的传感器驱动模块15使超声励振器2工作,超声励振器2产生的超声波辐照在芯片10腔室内部的流动媒介中,通过超声空化效应会产生气泡17;Step 1: The staff first turns on the

第二步:第一步中产生中的气泡17在其谐振频率相同的超声波激励下,发生气泡17共振诱导的高速声流场,声流场产生的拖拽力Fd把流体中的微纳米颗粒带到气泡17附近,气泡17附近微纳米颗粒的浓度变高,微纳米颗粒之间的距离也变小,次级声辐射力Fsec变大,使得微纳米颗粒聚集;The second step: the

第三步:当工作人员施加的声场与气泡17谐振频率不同,声波激发气泡17振动,不仅可以控制流体中的微纳米颗粒聚集,由于该振荡模式下激发的是围绕气泡17的涡流场,声流场产生的拖拽力Fd还可以控制粒子群围绕气泡17旋转。Step 3: When the sound field applied by the staff is different from the resonant frequency of the

综上所述,借助于本发明的上述技术方案,工作人员首先打开控制器6一侧外壁的开关4,此时控制器6内部的传感器驱动模块15使超声励振器2工作,超声励振器2产生的超声波辐照在芯片10腔室内部的流动媒介中,通过超声空化效应会产生气泡17,产生中的气泡17在其谐振频率相同的超声波激励下,发生气泡17共振诱导的高速声流场,声流场产生的拖拽力Fd把流体中的微纳米颗粒带到气泡17附近,气泡17附近微纳米颗粒的浓度变高,微纳米颗粒之间的距离也变小,次级声辐射力Fsec变大,使得微纳米颗粒聚集,当工作人员施加的声场与气泡17谐振频率不同,声波激发气泡17振动,不仅可以控制流体中的微纳米颗粒聚集,由于该振荡模式下激发的是围绕气泡17的涡流场,声流场产生的拖拽力Fd还可以控制粒子群围绕气泡17旋转,在微流通道中设置微孔11阵列结构,声场激发微孔11阵列中的气泡17振动,通过公式可知公式中,最大流体拖拽力FdMAX与次级声辐射力Fsec的比值与粒子的半径Rs和角频率w有关,当最大流体拖拽力FdMAX与次级声辐射力Fsec相等时,得到角频率w与临界半径Rc半径的函数关系,可以通过调节角频率大小来筛选不同粒径的微纳米颗粒,从而通过外流场带走未被捕获的微粒。In summary, with the help of the above technical solution of the present invention, the staff first turns on the

以上所述仅为本发明的较佳实施例而已,并不用以限制本发明,凡在本发明的精神和原则之内,所作的任何修改、等同替换、改进等,均应包含在本发明的保护范围之内。The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included in the scope of the present invention. within the scope of protection.

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211438713.7ACN115818565A (en) | 2022-11-17 | 2022-11-17 | A device and method for enriching and sorting micro-nano particles |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211438713.7ACN115818565A (en) | 2022-11-17 | 2022-11-17 | A device and method for enriching and sorting micro-nano particles |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115818565Atrue CN115818565A (en) | 2023-03-21 |

Family

ID=85528703

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211438713.7APendingCN115818565A (en) | 2022-11-17 | 2022-11-17 | A device and method for enriching and sorting micro-nano particles |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115818565A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN119430261A (en)* | 2025-01-13 | 2025-02-14 | 平利县安得利新材料有限公司 | Method and system for preparing uniform nano-barium sulfate particles based on ultrasound |

| CN119747214A (en)* | 2024-12-12 | 2025-04-04 | 北京理工大学 | A device for adjustable control and precision screening of particulate matter based on a vibration structure |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101041467A (en)* | 2007-04-25 | 2007-09-26 | 上海应用技术学院 | Preparation method of wolframic acid mercury nano material |

| US20080271747A1 (en)* | 2007-05-04 | 2008-11-06 | Asml Netherlands B.V. | Cleaning device and a lithographic apparatus cleaning method |

| US20110278457A1 (en)* | 2009-01-08 | 2011-11-17 | Technische Universitaet Wien | Device for ftir absorption spectroscopy |

| CN111319056A (en)* | 2020-03-02 | 2020-06-23 | 河北工业大学 | Method and device for non-destructive transport of micro-nano particles based on controllable micro-scale bubbles |

| CN111774105A (en)* | 2020-06-09 | 2020-10-16 | 南京航空航天大学 | Ultrasonic precision microfluidic chip based on nanomotor array and its realization method |

- 2022

- 2022-11-17CNCN202211438713.7Apatent/CN115818565A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101041467A (en)* | 2007-04-25 | 2007-09-26 | 上海应用技术学院 | Preparation method of wolframic acid mercury nano material |

| US20080271747A1 (en)* | 2007-05-04 | 2008-11-06 | Asml Netherlands B.V. | Cleaning device and a lithographic apparatus cleaning method |

| US20110278457A1 (en)* | 2009-01-08 | 2011-11-17 | Technische Universitaet Wien | Device for ftir absorption spectroscopy |

| CN111319056A (en)* | 2020-03-02 | 2020-06-23 | 河北工业大学 | Method and device for non-destructive transport of micro-nano particles based on controllable micro-scale bubbles |

| CN111774105A (en)* | 2020-06-09 | 2020-10-16 | 南京航空航天大学 | Ultrasonic precision microfluidic chip based on nanomotor array and its realization method |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN119747214A (en)* | 2024-12-12 | 2025-04-04 | 北京理工大学 | A device for adjustable control and precision screening of particulate matter based on a vibration structure |

| CN119430261A (en)* | 2025-01-13 | 2025-02-14 | 平利县安得利新材料有限公司 | Method and system for preparing uniform nano-barium sulfate particles based on ultrasound |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN115818565A (en) | A device and method for enriching and sorting micro-nano particles | |

| JP5642684B2 (en) | Apparatus and method for separating particles from suspension by standing ultrasound | |

| Hammarström et al. | Non-contact acoustic cell trapping in disposable glass capillaries | |

| Yeo et al. | Surface acoustic wave microfluidics | |

| CN111774105B (en) | Ultrasonic precision microfluidic chip based on nanomotor array and its realization method | |

| Destgeer et al. | Recent advances in microfluidic actuation and micro-object manipulation via surface acoustic waves | |

| JP5119848B2 (en) | Microreactor device | |

| Glynne-Jones et al. | Array-controlled ultrasonic manipulation of particles in planar acoustic resonator | |

| EP2838582B1 (en) | Acoustophoretic separation of lipid particles from red blood cells | |

| ES2776524T3 (en) | Fluid apparatus for manipulation of surface acoustic waves of fluid samples, use of fluid apparatus and process for the manufacture of fluid apparatus | |

| CN211784638U (en) | Separating Chip Assemblies and Separating Devices | |

| Araz et al. | Ultrasonic separation in microfluidic capillaries | |

| WO2017059604A1 (en) | Microfluidic system and method of controlling particles based on artificially structured acoustic field | |

| KR20230096955A (en) | Separation device and separation method | |

| CN114308157A (en) | Dynamic adjustable sound tweezer device based on local resonant cavity and use method thereof | |

| CN115468916A (en) | On-chip fluid control module, acoustic fluid chip and analysis device | |

| Zhu et al. | High-throughput acoustofluidic microchannels for single cell rotation | |

| CN115624994B (en) | A non-contact particle shaking device and method | |

| CN112457978A (en) | Blood cell separation chip based on bulk acoustic wave and application | |

| Fuchsluger et al. | Acoustofluidic particle trapping in a structured microchannel using lateral transducer modes | |

| Bai et al. | Acoustohydrodynamic micromixers: Basic mixing principles, programmable mixing prospectives, and biomedical applications | |

| CN111013464B (en) | A kind of contact ultrasonic needle rapid stirring and efficient atomization method | |

| Wang et al. | Skipping the boundary layer: high-speed droplet-based immunoassay using Rayleigh acoustic streaming | |

| CN113198551A (en) | Method for detecting biomolecules by using lamb wave resonator and microfluidic device | |

| CN119793560B (en) | Oscillating microbubble chip, separation system, and acoustic manipulation method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |