CN115770883A - A method of phase transfer through surface modification of inorganic nanomaterials - Google Patents

A method of phase transfer through surface modification of inorganic nanomaterialsDownload PDFInfo

- Publication number

- CN115770883A CN115770883ACN202111039342.0ACN202111039342ACN115770883ACN 115770883 ACN115770883 ACN 115770883ACN 202111039342 ACN202111039342 ACN 202111039342ACN 115770883 ACN115770883 ACN 115770883A

- Authority

- CN

- China

- Prior art keywords

- gold

- solution

- silver

- phase transfer

- room temperature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/50—Improvements relating to the production of bulk chemicals

- Y02P20/54—Improvements relating to the production of bulk chemicals using solvents, e.g. supercritical solvents or ionic liquids

Landscapes

- Pigments, Carbon Blacks, Or Wood Stains (AREA)

- Manufacture Of Metal Powder And Suspensions Thereof (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉一种无机纳米材料合成领域,尤其是通过表面改性对无机纳米材料进行相转移。The invention relates to the field of synthesis of inorganic nanometer materials, in particular to phase transfer of inorganic nanometer materials through surface modification.

背景技术Background technique

随着纳米合成技术的进步,如今在实验室中可以合成各种形貌的纳米颗粒。但是发展纳米技术不单单是为了合成各种形态的纳米颗粒,而是希望纳米技术能在生产实践中有更广泛的应用。聚合物有许多优秀的性质,比如高强度的机械性能、优秀的光学性质以及高延展性、耐腐蚀性等。聚合物可以作为无机纳米材料的优秀载体,而无机纳米材料负载到聚合物中是其发挥物理化学性质的重要方式,无机纳米材料的掺杂能够增强聚合物强度或赋予其导电性、光学、磁性或渗透性等功能。高分子材料与不同无机纳米材料的这种组合通常称为聚合物无机纳米复合材料。With the advancement of nanosynthesis technology, nanoparticles with various shapes can be synthesized in the laboratory. However, the development of nanotechnology is not only for the synthesis of various forms of nanoparticles, but also for the wider application of nanotechnology in production practice. Polymers have many excellent properties, such as high-strength mechanical properties, excellent optical properties, high ductility, and corrosion resistance. Polymers can be used as excellent carriers of inorganic nanomaterials, and the loading of inorganic nanomaterials into polymers is an important way for them to exert their physical and chemical properties. The doping of inorganic nanomaterials can enhance the strength of polymers or endow them with electrical conductivity, optics, and magnetic properties. Or permeability and other functions. Such combinations of polymer materials and different inorganic nanomaterials are generally called polymer inorganic nanocomposites.

无机纳米复合材料制备方法有两种,一种是无机纳米材料自己在聚合物载体中原位合成,即,在聚合物载体中加入纳米材料前驱体,在光照或者加热的条件下,合成聚合物无机纳米材料,但是,这种方法合成的纳米材料无法控制其尺寸、形貌等,这不能很好地发挥无机纳米材料的结构性质。另一种方法是,先合成均一的纳米材料,再将其分散到聚合物中。但是,如何保证无机纳米材料在聚合物中的分散性是一个亟需解决的关键问题,其原因是,无机纳米颗粒通常在水相中合成,而聚合物或者聚合物单体溶液多是有机相的,这就使得无机纳米颗粒很难在聚合物或者聚合物单体溶液中均一稳定地分散。There are two methods for preparing inorganic nanocomposites. One is the in-situ synthesis of inorganic nanomaterials in the polymer carrier, that is, adding nanomaterial precursors to the polymer carrier, and synthesizing polymer inorganic materials under the condition of light or heating. Nanomaterials, however, the nanomaterials synthesized by this method cannot control their size, shape, etc., which cannot give full play to the structural properties of inorganic nanomaterials. Another approach is to synthesize uniform nanomaterials and then disperse them in polymers. However, how to ensure the dispersion of inorganic nanomaterials in polymers is a key problem that needs to be solved urgently. The reason is that inorganic nanoparticles are usually synthesized in aqueous phase, while polymers or polymer monomer solutions are mostly organic phases. Yes, this makes it difficult for inorganic nanoparticles to disperse uniformly and stably in polymer or polymer monomer solutions.

对无机纳米材料表面改性,使其能够在有机相中均一稳定地分散,是解决相转移问题的一个理想方案,截止目前,金属纳米颗粒的表面改性方法已包含聚合物包覆、表面接枝聚合物刷、烷基醇或烷基胺的配体交换及离子液体萃取等方式。但此类表面改性方式均存在各项缺陷,例如表面改性周期长、过程复杂、转移率低、普适性差等缺陷。Modifying the surface of inorganic nanomaterials so that they can be uniformly and stably dispersed in the organic phase is an ideal solution to the problem of phase transfer. Up to now, the surface modification methods of metal nanoparticles have included polymer coating, surface contact Branched polymer brushes, ligand exchange with alkyl alcohols or alkylamines, and ionic liquid extraction. However, these surface modification methods have various defects, such as long surface modification period, complicated process, low transfer rate, and poor universality.

因此寻找一种简单、有效、普适的相转移方法,对无机金属纳米复合材料的制备具有重要的意义。Therefore, it is of great significance to find a simple, effective and universal phase transfer method for the preparation of inorganic metal nanocomposites.

发明内容Contents of the invention

本发明解决的技术问题是:提出一种通过表面改性可以使无机纳米颗粒均一稳定地分在有机溶剂的方法,该方法简单普适,相转移的方法解决了水相合成的无机纳米颗粒不能在聚合物单体溶液中均匀稳定分散的问题,使得无机纳米粒子与聚合物结合更加容易。The technical problem to be solved by the present invention is: to propose a method for uniformly and stably distributing inorganic nanoparticles in organic solvents through surface modification. The problem of uniform and stable dispersion in the polymer monomer solution makes it easier to combine inorganic nanoparticles with polymers.

为了解决上述技术问题,本发明提出的技术方案是:一种通过表面改性无机纳米材料相转移的方法,制备步骤如下In order to solve the above technical problems, the technical solution proposed by the present invention is: a method for phase transfer through surface modification of inorganic nanomaterials, the preparation steps are as follows

步骤(1):合成金纳米棒、金颗粒、金纳米锥、银纳米颗粒、或金-银二聚体;Step (1): Synthesizing gold nanorods, gold particles, gold nanocones, silver nanoparticles, or gold-silver dimers;

步骤(2):将金纳米棒、金颗粒、金纳米锥、银纳米颗粒、或金-银二聚体之一离心提纯后分散在0.5-1.5倍原体积的含有配体的N,N-二甲基甲酰胺(DMF)溶液中,配体为聚乙烯吡咯烷酮(PVP),PVP浓度为12mg/ml;Step (2): Centrifuge and purify one of gold nanorods, gold particles, gold nanocones, silver nanoparticles, or gold-silver dimers, and disperse them in 0.5-1.5 times the original volume of N,N- In the dimethylformamide (DMF) solution, the ligand is polyvinylpyrrolidone (PVP), and the PVP concentration is 12mg/ml;

步骤(3):将步骤(2)所述的纳米材料离心提纯,使用不超过纳米材料的初始体积的含有配体的二氯甲烷(DCM)溶液中分散,配体为PVP,PVP浓度为6-12mg/ml。Step (3): The nanomaterial described in step (2) is centrifugally purified, dispersed in a dichloromethane (DCM) solution containing a ligand not exceeding the initial volume of the nanomaterial, the ligand is PVP, and the PVP concentration is 6 -12 mg/ml.

优选的,步骤(1)中的金纳米棒合成方法如下:首先在20mL的小反应瓶中制备金纳米颗粒种子:将硼氢化钠(NaBH4,10mM,0.3mL)在搅拌条件下加入至四氯金酸(HAuCl4,0.125mL,10mM)和十六烷基三甲基溴化铵(CTAB,5mL,0.1M)的混合物中,在剧烈摇晃下,溶液颜色瞬间从金黄色变为棕色,表明形成金纳米颗粒种子,保持涡流状态10分钟使得HAuCl4被充分还原;将准备好的种子溶液在室温静置2小时后用于制备金纳米棒;将95mL的CTAB(0.1M),1mL的硝酸银(AgNO3,10mM)和5mL HAuCl4(10mM)溶液依次添加至250mL的锥形瓶中。然后,向混合物中加入0.55mL L-抗坏血酸(L-AA,0.1M)溶液,缓慢摇动烧瓶直至溶液变为无色;最后,在轻轻混合下将0.12mL种子溶液加入至上述混合液中;所得的混合液在室温下静止过夜后得到金纳米棒;金纳米棒通过离心进一步纯化,并稳定于100mL的CTAB溶液中(0.1M)以供进一步使用。Preferably, the synthesis method of gold nanorods in step (1) is as follows: first prepare gold nanoparticle seeds in a 20mL small reaction vial: add sodium borohydride (NaBH4 , 10mM, 0.3mL) to four In a mixture of chloroauric acid (HAuCl4 , 0.125mL, 10mM) and cetyltrimethylammonium bromide (CTAB, 5mL, 0.1M), under vigorous shaking, the color of the solution instantly changed from golden yellow to brown, Show to form gold nanoparticle seed, keep the vortex state for 10 minutes so that HAuCl4 is fully reduced; The prepared seed solution is used to prepare gold nanorods after standing for 2 hours at room temperature; 95mL of CTAB (0.1M), 1mL of Silver nitrate (AgNO3 , 10 mM) and 5 mL HAuCl4 (10 mM) solutions were sequentially added to a 250 mL Erlenmeyer flask. Then, 0.55 mL of L-ascorbic acid (L-AA, 0.1 M) solution was added to the mixture, and the flask was slowly shaken until the solution became colorless; finally, 0.12 mL of the seed solution was added to the above mixture with gentle mixing; The resulting mixture was left standing overnight at room temperature to obtain gold nanorods; the gold nanorods were further purified by centrifugation and stabilized in 100 mL of CTAB solution (0.1 M) for further use.

优选的,步骤(1)中的金纳米颗粒合成方法如下:合成15nm的金纳米颗粒。首先将100mL HAuCl4(0.1mg/mL)水溶液放入在250mL的两口圆底烧瓶中,然后将其放置于130℃的油浴中回流加热搅拌,待HAuCl4水溶液沸腾后向其中快速加入3mL柠檬酸钠(1wt%)水溶液,混合溶液颜色在短时间内经历无色、紫色、紫红色最终稳定于酒红色的转变,酒红色的出现表明15nm的金颗粒已经形成,继续加热沸腾30分钟后将其冷却至室温。随后,取45mL去离子水和10mL上述已制备好的15nm金纳米颗粒溶液混合于250mL两口圆底烧瓶中,将其放置于125℃的油浴中加热回流并搅拌,待溶液沸腾后向其中依次快速加入0.25mL柠檬酸钠(1wt%)水溶液和0.3mL HAuCl4(10mg/mL)水溶液,将混合物加热30分钟以完全还原HAuCl4使其在种子表面上形成金层;重复此步骤两次,最后再次加入1mL柠檬酸钠水溶液并回流10分钟以稳定合成的金纳米颗粒,冷却至室温储存。Preferably, the method for synthesizing gold nanoparticles in step (1) is as follows: synthesizing 15nm gold nanoparticles. First, put 100mL of HAuCl4 (0.1mg/mL) aqueous solution into a 250mL two-neck round bottom flask, then place it in an oil bath at 130°C and heat and stir under reflux. After the HAuCl4 aqueous solution boils, quickly add 3mL of lemon sodium bicarbonate (1wt%) aqueous solution, the color of the mixed solution experiences a colorless, purple, purplish red transition in a short period of time and is finally stable in wine red, and the appearance of wine red shows that the gold particles of 15nm have formed, continue to heat and boil after 30 minutes It was cooled to room temperature. Subsequently, take 45mL of deionized water and 10mL of the prepared 15nm gold nanoparticle solution and mix them in a 250mL two-necked round-bottomed flask, place it in an oil bath at 125°C, heat to reflux and stir, and pour the solution into it successively after boiling. 0.25 mL of sodium citrate (1 wt%) aqueous solution and 0.3 mL ofHAuCl4 (10 mg/mL) aqueous solution were quickly added, and the mixture was heated for 30 min to completely reduceHAuCl4 to form a gold layer on the seed surface; repeat this step twice, Finally, 1 mL of sodium citrate aqueous solution was added again and refluxed for 10 minutes to stabilize the synthesized gold nanoparticles, then cooled to room temperature for storage.

优选的,步骤(1)中的金纳米锥合成方法如下:首先在20mL的小样品瓶中制备金种,在室温剧烈搅拌的条件下,将新鲜冰水配置的NaBH4(0.25mL,25mM)、十六烷基三甲基氯化铵水溶液(CTAC,50mM,最终浓度)配置的柠檬酸钠的溶液(9.75mL,5.128mM)和HAuCl4水溶液(0.25mL,10mM)迅速混合;混合溶液颜色由浅黄色转变为褐色,表明金种的形成;持续搅拌2分钟后,将种子溶液转移至80℃的油浴中,温和搅拌持续加热90分钟,溶液颜色呈现由棕色到红色的逐渐转变;最后,将热处理后的种子溶液从油浴中取出并在室温下储存;在100mL的锥形瓶中依次加入CTAB(50mL,100mM),HAuCl4(2.5mL,10mM),AgNO3(0.5mL,10mM)的水溶液,随后再加入HCl(1mL,1M)和L-AA(0.4mL,100mM),搅拌2分钟后加入0.125mL上述合成的金种子溶液。最后将生长液在30℃环境中静置10小时。Preferably, the synthesis method of gold nanocones in step (1) is as follows: first prepare gold species in a 20mL small sample bottle, and under vigorous stirring at room temperature, NaBH4 (0.25mL, 25mM) prepared with fresh ice water , cetyltrimethylammonium chloride aqueous solution (CTAC, 50mM, final concentration) the solution of sodium citrate (9.75mL, 5.128mM) and HAuCl4 aqueous solution (0.25mL, 10mM) mix rapidly; Mixed solution color The change from light yellow to brown indicates the formation of gold seeds; after continuous stirring for 2 minutes, the seed solution was transferred to an oil bath at 80°C, and heated with gentle stirring for 90 minutes, the color of the solution showed a gradual change from brown to red; finally , the heat-treated seed solution was taken out from the oil bath and stored at room temperature; CTAB (50mL, 100mM), HAuCl4 (2.5mL, 10mM), AgNO3 (0.5mL, 10mM ) aqueous solution, then added HCl (1 mL, 1M) and L-AA (0.4 mL, 100 mM), stirred for 2 minutes and added 0.125 mL of the gold seed solution synthesized above. Finally, the growth solution was left to stand in an environment of 30°C for 10 hours.

优选的,步骤(1)中的银纳米颗粒合成方法如下:将10mL 15nm的金纳米颗粒和50mL去离子水加入到圆底烧瓶中。在130℃的油浴中加热回流,待溶液被加热至沸腾后,在剧烈搅拌下快速加入0.5mL柠檬酸钠(1wt%)和0.5mL AgNO3(10mg/mL),将所得溶液加热30分钟,溶液颜色由红色变为橙色。30分钟后,再次加入相同量的柠檬酸钠和AgNO3并继续加热30分钟。在第三轮中,加入0.48mL柠檬酸钠和0.48mL AgNO3,将所得溶液加热1小时后冷却至室温。最后向溶液中再加入21.9mL水,避光室温储存。Preferably, the synthesis method of silver nanoparticles in step (1) is as follows: 10 mL of 15 nm gold nanoparticles and 50 mL of deionized water are added to a round bottom flask. Heat to reflux in an oil bath at 130°C. After the solution is heated to boiling, quickly add 0.5mL sodium citrate (1wt%) and 0.5mL AgNO3 (10mg/mL) under vigorous stirring, and heat the resulting solution for 30 minutes , the solution color changed from red to orange. After 30 min, the same amount of sodium citrate andAgNO were added again and heating was continued for 30 min. In a third round, 0.48 mL of sodium citrate and 0.48 mL ofAgNO3 were added, and the resulting solution was heated for 1 hour and then cooled to room temperature. Finally, 21.9 mL of water was added to the solution, and stored in the dark at room temperature.

优选的,步骤(1)中的金-银二聚体合成方法如下:向1mL 3中合成的金颗粒溶液中加入20μL MBIA配体(1mM,乙醇配置),然后将溶液静置于60℃下2小时。冷却至室温后,将60μL对苯二酚(10mM水溶液)和60μL AgNO3(10mM水溶液)依次快速加入至上述溶液中,混合溶液在室温条件中静置不低于2小时,使得AgNO3被充分还原,最终得到金-银二聚体结构的纳米颗粒。Preferably, the gold-silver dimer synthesis method in step (1) is as follows: add 20 μL of MBIA ligand (1 mM, ethanol configuration) to 1 mL of the gold particle solution synthesized in 3, and then place the solution at 60° C. 2 hours. After cooling to room temperature, 60 μL hydroquinone (10 mM aqueous solution) and 60 μL AgNO3 (10 mM aqueous solution) were quickly added to the above solution in turn, and the mixed solution was left standing at room temperature for not less than 2 hours, so that AgNO3 was fully After reduction, the nanoparticles with gold-silver dimer structure are finally obtained.

优选的,步骤(2)中的金纳米棒体积为40ml,离心转速为5500rpm,离心时间15min;离心去除上清液后,使用40ml PVP-DMF溶液分散,PVP的浓度为12mg/ml,PVP的分子量为40000。Preferably, the volume of gold nanorods in step (2) is 40ml, the centrifugation speed is 5500rpm, and the centrifugation time is 15min; after centrifugation to remove the supernatant, 40ml PVP-DMF solution is used to disperse, the concentration of PVP is 12mg/ml, and the concentration of PVP The molecular weight is 40000.

优选的,步骤(3)中使用的离心转速为4600rpm,离心时间15min;去除上清液后,使用300μl PVP-DCM溶液进行分散,PVP的浓度为6mg/ml。Preferably, the centrifugation speed used in step (3) is 4600 rpm, and the centrifugation time is 15 min; after removing the supernatant, 300 μl of PVP-DCM solution is used for dispersion, and the concentration of PVP is 6 mg/ml.

优选的,将金纳米棒、金颗粒、金纳米锥、银纳米颗粒、或金-银二聚体之一离心提纯后分散在同体积的含有配体的N,N-二甲基甲酰胺(DMF)溶液中。Preferably, one of gold nanorods, gold particles, gold nanocones, silver nanoparticles, or gold-silver dimers is centrifugally purified and dispersed in the same volume of N,N-dimethylformamide ( DMF) solution.

通过表面改性无机纳米材料相转移的方法,包括一下步骤:The method for phase transfer by surface modification of inorganic nanomaterials comprises the following steps:

(1)金纳米棒合成方法:首先在20mL的小反应瓶中制备金纳米颗粒种子:将硼氢化钠(NaBH4,10mM,0.3mL)在搅拌条件下加入至四氯金酸(HAuCl4,0.125mL,10mM)和十六烷基三甲基溴化铵(CTAB,5mL,0.1M)的混合物中,在剧烈摇晃下,溶液颜色瞬间从金黄色变为棕色,表明形成金纳米颗粒种子,保持涡流状态10分钟使得HAuCl4被充分还原。将准备好的种子溶液在室温静置2小时后用于制备金纳米棒。将95mL的CTAB(0.1M),1mL的硝酸银(AgNO3,10mM)和5mL HAuCl4(10mM)溶液依次添加至250mL的锥形瓶中。然后,向混合物中加入0.55mL L-抗坏血酸(L-AA,0.1M)溶液,缓慢摇动烧瓶直至溶液变为无色。最后,在轻轻混合下将0.12mL种子溶液加入至上述混合液中。所得的混合液在室温下静止过夜后得到金纳米棒。金纳米棒通过离心进一步纯化,并稳定于100mL的CTAB溶液中(0.1M)以供进一步使用。(1) Synthesis method of gold nanorods: first prepare gold nanoparticle seeds in a 20mL small reaction vial: add sodium borohydride (NaBH4 , 10mM, 0.3mL) to tetrachloroauric acid (HAuCl4 , 0.125mL, 10mM) and cetyltrimethylammonium bromide (CTAB, 5mL, 0.1M), under vigorous shaking, the solution color instantly changed from golden yellow to brown, indicating the formation of gold nanoparticle seeds, Keep vortexing for 10 minutes to fully reduce the HAuCl4 . The prepared seed solution was used to prepare gold nanorods after standing at room temperature for 2 hours. A solution of 95 mL of CTAB (0.1 M), 1 mL of silver nitrate (AgNO3 , 10 mM) and 5 mL of HAuCl4 (10 mM) was sequentially added to a 250 mL Erlenmeyer flask. Then, 0.55 mL of L-ascorbic acid (L-AA, 0.1 M) solution was added to the mixture, and the flask was shaken slowly until the solution became colorless. Finally, 0.12 mL of the seed solution was added to the above mixture with gentle mixing. The resulting mixture was left to stand overnight at room temperature to obtain gold nanorods. The gold nanorods were further purified by centrifugation and stabilized in 100 mL of CTAB solution (0.1 M) for further use.

(2)将水相的金纳米棒转移到有机相中。取40ml金纳米棒,5500rpm离心15min,去除上清液。使用40ml 12mg/ml的PVP-DMF溶液重新分散,再次5500rpm离心15min,去除上清液。使用300μl 6mg/ml的PVP-DCM溶液重新分散,至此,金纳米棒便由水相转移到了有机相中。(2) Transfer the gold nanorods from the aqueous phase to the organic phase. Take 40ml of gold nanorods, centrifuge at 5500rpm for 15min, and remove the supernatant. Use 40ml of 12mg/ml PVP-DMF solution to redisperse, centrifuge again at 5500rpm for 15min, and remove the supernatant. 300 μl of 6 mg/ml PVP-DCM solution was used to redisperse the gold nanorods from the aqueous phase to the organic phase.

本发明的有益效果:Beneficial effects of the present invention:

(1)该方法简单普适(1) The method is simple and universal

(2)相转移的方法解决了水相合成的无机纳米颗粒不能在聚合物单体溶液中均匀稳定分散的问题,使得无机纳米粒子与聚合物结合更加容易。(2) The method of phase transfer solves the problem that the inorganic nanoparticles synthesized in the aqueous phase cannot be uniformly and stably dispersed in the polymer monomer solution, making it easier to combine the inorganic nanoparticles with the polymer.

(3)选用的两亲性表面活性剂PVP可以通过其氨基与金属纳米粒子表面形成配位作用,在DMF中快速进行配体交换,使纳米颗粒表面具有两亲性。(3) The selected amphiphilic surfactant PVP can form coordination with the surface of metal nanoparticles through its amino groups, and quickly perform ligand exchange in DMF, making the surface of nanoparticles amphiphilic.

(4)该配体交换方法简单迅速,与传统的方法相比,不需要加热、不需要长时间的孵育,在离心过程中就可进行配体交换。(4) The ligand exchange method is simple and rapid. Compared with the traditional method, it does not require heating and long-term incubation, and the ligand exchange can be performed during the centrifugation process.

(5)该方法选用了与水互溶的有机溶剂DMF作为相转移的过度溶剂,利用DMF的吸水性进一步除去了残留的水分。(5) The method selects the water-miscible organic solvent DMF as an excessive solvent for phase transfer, and utilizes the water absorption of DMF to further remove residual moisture.

(6)聚合物无机纳米复合材料在光学器件、传感器、光催化、生物医疗等方面具有非常大的应用价值。(6) Polymer-inorganic nanocomposites have great application value in optical devices, sensors, photocatalysis, and biomedicine.

(7)金纳米棒、金颗粒、金纳米锥、银纳米颗粒、和金-银二聚体都可以用该相转移的方法从水相转移到有机相。(7) Gold nanorods, gold particles, gold nanocones, silver nanoparticles, and gold-silver dimers can all be transferred from the aqueous phase to the organic phase by this phase transfer method.

(8)理论上PVP的浓度越高相转移后纳米粒子越稳定,但是残留过多的PVP可能会对后续应用产生干扰,综合考虑我们选用PVP-DMF溶液中PVP的浓度为12mg/ml,PVP-DCM中PVP的浓度为6mg/ml。(8) In theory, the higher the concentration of PVP, the more stable the nanoparticles after phase transfer, but too much residual PVP may interfere with subsequent applications. Considering that we choose the concentration of PVP in the PVP-DMF solution as 12mg/ml, PVP - The concentration of PVP in DCM is 6 mg/ml.

(9)步骤2中PVP浓度为12mg/ml,如果浓度低于12mg/ml,相转移的时候金棒容易聚集,如果浓度高于12mg/ml,浓度太大会影响到下一步的操作。(9) The PVP concentration in step 2 is 12mg/ml. If the concentration is lower than 12mg/ml, the gold rods are easy to aggregate during phase transfer. If the concentration is higher than 12mg/ml, the concentration will affect the next step if the concentration is too high.

附图说明Description of drawings

下面结合附图对本发明的作进一步说明。The present invention will be further described below in conjunction with accompanying drawing.

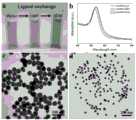

图1是金纳米棒的表面改性。(a)证明相转移过程中金纳米棒稳定性的光学照片。(b)分散在不同介质中的金纳米棒的紫外可见近红外吸收光谱。金纳米棒分别在(c)水溶液和(d)二氯甲烷中稳定的透射电子显微镜图像。Figure 1 shows the surface modification of gold nanorods. (a) Optical photographs demonstrating the stability of gold nanorods during phase transfer. (b) UV-vis-NIR absorption spectra of gold nanorods dispersed in different media. TEM images of gold nanorods stabilized in (c) aqueous solution and (d) dichloromethane, respectively.

图2是金纳米颗粒的表面改性。(a)证明相转移过程中金纳米颗粒稳定性的光学照片。(b)分散在不同介质中的金纳米颗粒的紫外可见近红外吸收光谱。金纳米颗粒别在(c)水溶液和(d)二氯甲烷中稳定的透射电子显微镜图像。Figure 2 is the surface modification of gold nanoparticles. (a) Optical photographs demonstrating the stability of gold nanoparticles during phase transfer. (b) UV-Vis-NIR absorption spectra of gold nanoparticles dispersed in different media. TEM images of gold nanoparticles stabilized in (c) aqueous solution and (d) dichloromethane.

图3是金纳米锥的表面改性。(a)证明相转移过程中金纳米锥稳定性的光学照片。(b)分散在不同介质中的金纳米锥的紫外可见近红外吸收光谱。金纳米锥分别在(c)水溶液和(d)二氯甲烷中稳定的透射电子显微镜图像。Figure 3 is the surface modification of gold nanocones. (a) Optical photographs demonstrating the stability of gold nanocones during phase transfer. (b) UV-vis-NIR absorption spectra of gold nanocones dispersed in different media. TEM images of gold nanocones stabilized in (c) aqueous solution and (d) dichloromethane, respectively.

图4是银纳米颗粒的表面改性。(a)证明相转移过程中银纳米颗粒稳定性的光学照片。(b)分散在不同介质中的银纳米颗粒的紫外可见近红外吸收光谱。银纳米颗粒分别在(c)水溶液和(d)二氯甲烷中稳定的透射电子显微镜图像。Figure 4 is the surface modification of silver nanoparticles. (a) Optical photograph demonstrating the stability of silver nanoparticles during phase transfer. (b) UV-vis-NIR absorption spectra of silver nanoparticles dispersed in different media. Transmission electron microscope images of silver nanoparticles stabilized in (c) aqueous solution and (d) dichloromethane, respectively.

图5是金-银二聚体的表面改性。(a)证明相转移过程中金-银二聚体稳定性的光学照片。(b)分散在不同介质中的金-银二聚体的紫外可见近红外吸收光谱。金-银二聚体分别在(c)水溶液和(d)二氯甲烷中稳定的透射电子显微镜图像。Figure 5 is the surface modification of gold-silver dimer. (a) Optical photograph demonstrating the stability of the gold-silver dimer during phase transfer. (b) UV-Vis-NIR absorption spectra of gold-silver dimers dispersed in different media. Transmission electron microscopy images of gold-silver dimers stabilized in (c) aqueous solution and (d) dichloromethane, respectively.

图6是金纳米棒-PUV圆偏振光学薄膜的CD光谱图Fig. 6 is the CD spectrogram of gold nanorod-PUV circularly polarizing optical film

具体实施方式Detailed ways

实施例1Example 1

(1)金纳米棒合成方法:首先在20mL的小反应瓶中制备金纳米颗粒种子:将硼氢化钠(NaBH4,10mM,0.3mL)在搅拌条件下加入至四氯金酸(HAuCl4,0.125mL,10mM)和十六烷基三甲基溴化铵(CTAB,5mL,0.1M)的混合物中,在剧烈摇晃下,溶液颜色瞬间从金黄色变为棕色,表明形成金纳米颗粒种子,保持涡流状态10分钟使得HAuCl4被充分还原。将准备好的种子溶液在室温静置2小时后用于制备金纳米棒。将95mL的CTAB(0.1M),1mL的硝酸银(AgNO3,10mM)和5mL HAuCl4(10mM)溶液依次添加至250mL的锥形瓶中。然后,向混合物中加入0.55mL L-抗坏血酸(L-AA,0.1M)溶液,缓慢摇动烧瓶直至溶液变为无色。最后,在轻轻混合下将0.12mL种子溶液加入至上述混合液中。所得的混合液在室温下静止过夜后得到金纳米棒。金纳米棒通过离心进一步纯化,并稳定于100mL的CTAB溶液中(0.1M)以供进一步使用。(1) Synthesis method of gold nanorods: first prepare gold nanoparticle seeds in a 20mL small reaction vial: add sodium borohydride (NaBH4 , 10mM, 0.3mL) to tetrachloroauric acid (HAuCl4 , 0.125mL, 10mM) and cetyltrimethylammonium bromide (CTAB, 5mL, 0.1M), under vigorous shaking, the solution color instantly changed from golden yellow to brown, indicating the formation of gold nanoparticle seeds, Keep vortexing for 10 minutes to fully reduce the HAuCl4 . The prepared seed solution was used to prepare gold nanorods after standing at room temperature for 2 hours. A solution of 95 mL of CTAB (0.1 M), 1 mL of silver nitrate (AgNO3 , 10 mM) and 5 mL of HAuCl4 (10 mM) was sequentially added to a 250 mL Erlenmeyer flask. Then, 0.55 mL of L-ascorbic acid (L-AA, 0.1 M) solution was added to the mixture, and the flask was shaken slowly until the solution became colorless. Finally, 0.12 mL of the seed solution was added to the above mixture with gentle mixing. The resulting mixture was left to stand overnight at room temperature to obtain gold nanorods. The gold nanorods were further purified by centrifugation and stabilized in 100 mL of CTAB solution (0.1 M) for further use.

(2)将水相的金纳米棒转移到有机相中。取40ml金纳米棒,5500rpm离心15min,去除上清液。使用40ml 12mg/ml的PVP-DMF溶液重新分散,再次5500rpm离心15min,去除上清液。使用300μl 6mg/ml的PVP-DCM溶液重新分散。至此,金纳米棒便由水相转移到了有机相中。(2) Transfer the gold nanorods from the aqueous phase to the organic phase. Take 40ml of gold nanorods, centrifuge at 5500rpm for 15min, and remove the supernatant. Use 40ml of 12mg/ml PVP-DMF solution to redisperse, centrifuge again at 5500rpm for 15min, and remove the supernatant. Redisperse using 300 μl of 6 mg/ml PVP-DCM solution. At this point, the gold nanorods were transferred from the aqueous phase to the organic phase.

实施例2Example 2

一种通过三步相转移方式将金纳米棒均一稳定地分在聚合物单体溶液中,并将金纳米棒与聚氨酯类Vitrimer结合制备了一种圆偏振光学薄膜及其制备方法。A circularly polarizing optical film is prepared by uniformly and stably distributing gold nanorods in a polymer monomer solution through a three-step phase transfer method, and combining gold nanorods with polyurethane Vitrimer and a preparation method thereof.

步骤1、金纳米棒合成方法:首先在20mL的小反应瓶中制备金纳米颗粒种子:将硼氢化钠(NaBH4,10mM,0.3mL)在搅拌条件下加入至四氯金酸(HAuCl4,0.125mL,10mM)和十六烷基三甲基溴化铵(CTAB,5mL,0.1M)的混合物中,在剧烈摇晃下,溶液颜色瞬间从金黄色变为棕色,表明形成金纳米颗粒种子,保持涡流状态10分钟使得HAuCl4被充分还原。将准备好的种子溶液在室温静置2小时后用于制备金纳米棒。将95mL的CTAB(0.1M),1mL的硝酸银(AgNO3,10mM)和5mL HAuCl4(10mM)溶液依次添加至250mL的锥形瓶中。然后,向混合物中加入0.55mL L-抗坏血酸(L-AA,0.1M)溶液,缓慢摇动烧瓶直至溶液变为无色。最后,在轻轻混合下将0.12mL种子溶液加入至上述混合液中。所得的混合液在室温下静止过夜后得到金纳米棒。金纳米棒通过离心进一步纯化,并稳定于100mL的CTAB溶液中(0.1M)以供进一步使用。Step 1, gold nanorod synthesis method: first prepare gold nanoparticle seeds in a 20mL small reaction vial: add sodium borohydride (NaBH4 , 10mM, 0.3mL) to tetrachloroauric acid (HAuCl4 , 0.125mL, 10mM) and cetyltrimethylammonium bromide (CTAB, 5mL, 0.1M), under vigorous shaking, the solution color instantly changed from golden yellow to brown, indicating the formation of gold nanoparticle seeds, Keep vortexing for 10 minutes to fully reduce the HAuCl4 . The prepared seed solution was used to prepare gold nanorods after standing at room temperature for 2 hours. A solution of 95 mL of CTAB (0.1 M), 1 mL of silver nitrate (AgNO3 , 10 mM) and 5 mL of HAuCl4 (10 mM) was sequentially added to a 250 mL Erlenmeyer flask. Then, 0.55 mL of L-ascorbic acid (L-AA, 0.1 M) solution was added to the mixture, and the flask was shaken slowly until the solution became colorless. Finally, 0.12 mL of the seed solution was added to the above mixture with gentle mixing. The resulting mixture was left to stand overnight at room temperature to obtain gold nanorods. The gold nanorods were further purified by centrifugation and stabilized in 100 mL of CTAB solution (0.1 M) for further use.

步骤2、将水相的金纳米棒转移到有机相中。取40ml金纳米棒,5500rpm离心15min,去除上清液。使用40ml 12mg/ml的PVP-DMF溶液重新分散,再次5500rpm离心15min,去除上清液。使用300μl6mg/ml的PVP-DCM溶液重新分散,以供进一步使用。Step 2, transferring the gold nanorods in the aqueous phase to the organic phase. Take 40ml of gold nanorods, centrifuge at 5500rpm for 15min, and remove the supernatant. Use 40ml of 12mg/ml PVP-DMF solution to redisperse, centrifuge again at 5500rpm for 15min, and remove the supernatant. Use 300 μl of 6 mg/ml PVP-DCM solution to redisperse for further use.

步骤3、称取750mg聚乙二醇、25mg甘油、3.9mg催化剂,80℃加热30min,在其融化后加入500μl四氢呋喃进行稀释。然后在搅拌下依次加入135μl六亚甲基二异氰酸酯和90μl催化剂。最后在搅拌下加入(1)中的金纳米棒,将其倒入模具,60℃固化2小时,然后100℃真空干燥过夜。Step 3. Weigh 750 mg of polyethylene glycol, 25 mg of glycerin, and 3.9 mg of catalyst, heat at 80° C. for 30 min, and add 500 μl of tetrahydrofuran to dilute after melting. Then 135 μl of hexamethylene diisocyanate and 90 μl of catalyst were added successively under stirring. Finally, the gold nanorods in (1) were added under stirring, poured into a mold, cured at 60° C. for 2 hours, and then vacuum-dried at 100° C. overnight.

步骤4、将(3)中金纳米棒-PUV复合材料使用热压机压制成薄膜,温度145℃,压力0.15MPa,压制3min,最终薄膜厚度为0.2-0.4毫米。从图1可以看出金纳米棒在每步相转移后的溶液里紫外可见光谱并没有明显红移,并且在TEM图中也没有看出有聚集情况,说明金纳米棒的相转移是成功的。并且从图6可以看出金纳米棒-PUV薄膜具有很强的圆二色性。Step 4. Press the gold nanorod-PUV composite material in (3) into a film with a hot press at a temperature of 145° C. and a pressure of 0.15 MPa for 3 minutes. The final film thickness is 0.2-0.4 mm. It can be seen from Figure 1 that the UV-visible spectrum of the gold nanorods in the solution after each step of phase transfer has no obvious red shift, and there is no aggregation in the TEM image, indicating that the phase transfer of the gold nanorods is successful. . And it can be seen from Figure 6 that the gold nanorod-PUV film has strong circular dichroism.

对比例1Comparative example 1

与实施例1相比,不同在于,实施例1步骤(2)中的为金纳米颗粒,金纳米颗粒合成步骤如下:合成15nm的金纳米颗粒。首先将100mL HAuCl4(0.1mg/mL)水溶液放入在250mL的两口圆底烧瓶中,然后将其放置于130℃的油浴中回流加热搅拌,待HAuCl4水溶液沸腾后向其中快速加入3mL柠檬酸钠(1wt%)水溶液,混合溶液颜色在短时间内经历无色、紫色、紫红色最终稳定于酒红色的转变,酒红色的出现表明15nm的金颗粒已经形成,继续加热沸腾30分钟后将其冷却至室温。随后,取45mL去离子水和10mL上述已制备好的15nm金纳米颗粒溶液混合于250mL两口圆底烧瓶中,将其放置于125℃的油浴中加热回流并搅拌,待溶液沸腾后向其中依次快速加入0.25mL柠檬酸钠(1wt%)水溶液和0.3mL HAuCl4(10mg/mL)水溶液,将混合物加热30分钟以完全还原HAuCl4使其在种子表面上形成金层。重复此步骤两次,最后再次加入1mL柠檬酸钠水溶液并回流10分钟以稳定合成的金纳米颗粒,冷却至室温储存。Compared with Example 1, the difference is that the gold nanoparticles in step (2) of Example 1 are gold nanoparticles, and the synthesis steps of gold nanoparticles are as follows: Synthesize 15nm gold nanoparticles. First, put 100mL of HAuCl4 (0.1mg/mL) aqueous solution into a 250mL two-neck round bottom flask, then place it in an oil bath at 130°C and heat and stir under reflux. After the HAuCl4 aqueous solution boils, quickly add 3mL of lemon sodium bicarbonate (1wt%) aqueous solution, the color of the mixed solution experiences a colorless, purple, purplish red transition in a short period of time and is finally stable in wine red, and the appearance of wine red shows that the gold particles of 15nm have formed, continue to heat and boil after 30 minutes It was cooled to room temperature. Subsequently, take 45mL of deionized water and 10mL of the prepared 15nm gold nanoparticle solution and mix them in a 250mL two-necked round-bottomed flask, place it in an oil bath at 125°C, heat to reflux and stir, and pour the solution into it successively after boiling. 0.25 mL of sodium citrate (1 wt%) aqueous solution and 0.3 mL ofHAuCl4 (10 mg/mL) aqueous solution were added quickly, and the mixture was heated for 30 minutes to completely reduceHAuCl4 to form a gold layer on the seed surface. Repeat this step twice, and finally add 1 mL of sodium citrate aqueous solution again and reflux for 10 minutes to stabilize the synthesized gold nanoparticles, cool to room temperature for storage.

从图3可以看出金纳米颗粒在每步相转移后的溶液颜色没有变化,紫外可见光谱并没有明显红移,并且在TEM图中也没有看出有聚集情况,说明金纳米颗粒的相转移是成功的。It can be seen from Figure 3 that the color of the gold nanoparticle solution after each step of phase transfer does not change, the ultraviolet-visible spectrum does not have a significant red shift, and there is no aggregation in the TEM image, indicating the phase transfer of gold nanoparticles was successful.

对比例2Comparative example 2

与实施例1相比,不同在于,实施例1步骤(2)中的为金纳米锥,金纳米锥合成步骤如下:首先在20mL的小样品瓶中制备金种,在室温剧烈搅拌的条件下,将新鲜冰水配置的NaBH4(0.25mL,25mM)、十六烷基三甲基氯化铵水溶液(CTAC,50mM,最终浓度)配置的柠檬酸钠的溶液(9.75mL,5.128mM)和HAuCl4水溶液(0.25mL,10mM)迅速混合。混合溶液颜色由浅黄色转变为褐色,表明金种的形成。持续搅拌2分钟后,将种子溶液转移至80℃的油浴中,温和搅拌持续加热90分钟,溶液颜色呈现由棕色到红色的逐渐转变。最后,将热处理后的种子溶液从油浴中取出并在室温下储存。在100mL的锥形瓶中依次加入CTAB(50mL,100mM),HAuCl4(2.5mL,10mM),AgNO3(0.5mL,10mM)的水溶液,随后再加入HCl(1mL,1M)和L-AA(0.4mL,100mM),搅拌2分钟后加入0.125mL上述合成的金种子溶液。最后将生长液在30℃环境中静置10小时。Compared with Example 1, the difference is that in the step (2) of Example 1, it is a gold nanocone, and the synthesis steps of the gold nanocone are as follows: first, the gold species is prepared in a small sample bottle of 20mL, and under the condition of vigorous stirring at room temperature , NaBH4 (0.25mL, 25mM) in fresh ice water, sodium citrate solution (9.75mL, 5.128mM) in cetyltrimethylammonium chloride aqueous solution (CTAC, 50mM, final concentration) and Aqueous HAuCl4 (0.25 mL, 10 mM) was mixed rapidly. The color of the mixed solution changed from light yellow to brown, indicating the formation of gold species. After continuous stirring for 2 minutes, the seed solution was transferred to an oil bath at 80° C., and heated with gentle stirring for 90 minutes. The color of the solution showed a gradual change from brown to red. Finally, the heat-treated seed solution was removed from the oil bath and stored at room temperature. In a 100mL Erlenmeyer flask, CTAB (50mL, 100mM), HAuCl4 (2.5mL, 10mM), AgNO3 (0.5mL, 10mM) aqueous solution were added successively, followed by HCl (1mL, 1M) and L-AA ( 0.4mL, 100mM), and after stirring for 2 minutes, 0.125mL of the gold seed solution synthesized above was added. Finally, the growth solution was left to stand in an environment of 30°C for 10 hours.

从图4可以看出金纳米锥在每步相转移后的溶液颜色没有变化,紫外可见光谱并没有明显红移,并且在TEM图中也没有看出有聚集情况,说明金纳米锥的相转移是成功的。It can be seen from Figure 4 that the color of the gold nanocone solution does not change after each step of phase transfer, and the ultraviolet-visible spectrum does not have a significant red shift, and there is no aggregation in the TEM image, indicating the phase transfer of the gold nanocone was successful.

对比例3Comparative example 3

与实施例1相比,不同在于,实施例1步骤(2)中的为银纳米颗粒,银纳米颗粒合成步骤如下:将10mL 15nm的金纳米颗粒和50mL去离子水加入到圆底烧瓶中。在130℃的油浴中加热回流,待溶液被加热至沸腾后,在剧烈搅拌下快速加入0.5mL柠檬酸钠(1wt%)和0.5mL AgNO3(10mg/mL),将所得溶液加热30分钟,溶液颜色由红色变为橙色。30分钟后,再次加入相同量的柠檬酸钠和AgNO3并继续加热30分钟。在第三轮中,加入0.48mL柠檬酸钠和0.48mL AgNO3,将所得溶液加热1小时后冷却至室温。最后向溶液中再加入21.9mL水,避光室温储存。Compared with Example 1, the difference is that the silver nanoparticles in step (2) of Example 1 are silver nanoparticles, and the synthesis steps of silver nanoparticles are as follows: 10mL of 15nm gold nanoparticles and 50mL of deionized water are added to a round bottom flask. Heat to reflux in an oil bath at 130°C. After the solution is heated to boiling, quickly add 0.5mL sodium citrate (1wt%) and 0.5mL AgNO3 (10mg/mL) under vigorous stirring, and heat the resulting solution for 30 minutes , the solution color changed from red to orange. After 30 min, the same amount of sodium citrate andAgNO were added again and heating was continued for 30 min. In a third round, 0.48 mL of sodium citrate and 0.48 mL ofAgNO3 were added, and the resulting solution was heated for 1 hour and then cooled to room temperature. Finally, 21.9 mL of water was added to the solution, and stored in the dark at room temperature.

从图5中可以看出银纳米颗粒在每步相转移后的溶液颜色没有变化,紫外可见光谱并没有明显红移,并且在TEM图中也没有看出有聚集情况,说明银纳米颗粒的相转移是成功的。It can be seen from Figure 5 that the color of the solution of silver nanoparticles does not change after each step of phase transfer, the ultraviolet-visible spectrum has no obvious red shift, and there is no aggregation in the TEM image, indicating that the phase of silver nanoparticles The transfer was successful.

对比例4Comparative example 4

与实施例1相比,不同在于,实施例1步骤(2)中的为金-银二聚体,金-银二聚体合成步骤如下:向1mL实施例2中合成的金颗粒溶液中加入20μL MBIA配体(1mM,乙醇配置),然后将溶液静置于60℃下2小时。冷却至室温后,将60μL对苯二酚(10mM水溶液)和60μL AgNO3(10mM水溶液)依次快速加入至上述溶液中,混合溶液在室温条件中静置不低于2小时,使得AgNO3被充分还原,最终得到金-银二聚体结构的纳米颗粒。Compared with Example 1, the difference is that the gold-silver dimer in the step (2) of Example 1 is a gold-silver dimer, and the synthesis steps of the gold-silver dimer are as follows: Add 20 μL of MBIA ligand (1 mM, prepared in ethanol), and then the solution was left standing at 60° C. for 2 hours. After cooling to room temperature, 60 μL hydroquinone (10 mM aqueous solution) and 60 μL AgNO3 (10 mM aqueous solution) were quickly added to the above solution in turn, and the mixed solution was left standing at room temperature for not less than 2 hours, so that AgNO3 was fully After reduction, the nanoparticles with gold-silver dimer structure are finally obtained.

从图5中可以看出银纳米颗粒在每步相转移后的溶液颜色没有变化,紫外可见光谱并没有明显红移,并且在TEM图中也没有看出有聚集情况,说明金-银二聚体的相转移是成功的。It can be seen from Figure 5 that the color of the solution of silver nanoparticles does not change after each step of phase transfer, the ultraviolet-visible spectrum does not have a significant red shift, and there is no aggregation in the TEM image, indicating that gold-silver dimerization The phase transfer of the bulk was successful.

本发明的不局限于上述实施例所述的具体技术方案,凡采用等同替换形成的技术方案均为本发明要求的保护范围。The present invention is not limited to the specific technical solutions described in the above embodiments, and all technical solutions formed by equivalent replacement are within the scope of protection required by the present invention.

Claims (9)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111039342.0ACN115770883B (en) | 2021-09-06 | 2021-09-06 | A method for phase transfer of inorganic nanomaterials by surface modification |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111039342.0ACN115770883B (en) | 2021-09-06 | 2021-09-06 | A method for phase transfer of inorganic nanomaterials by surface modification |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN115770883Atrue CN115770883A (en) | 2023-03-10 |

| CN115770883B CN115770883B (en) | 2025-02-25 |

Family

ID=85387367

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202111039342.0AActiveCN115770883B (en) | 2021-09-06 | 2021-09-06 | A method for phase transfer of inorganic nanomaterials by surface modification |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115770883B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN119304178A (en)* | 2024-10-10 | 2025-01-14 | 吉林大学 | A method for preparing rod-shaped and tetrapod-shaped gold nanocapsules |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050165120A1 (en)* | 2004-01-22 | 2005-07-28 | Ashavani Kumar | Process for phase transfer of hydrophobic nanoparticles |

| CN109128152A (en)* | 2018-09-29 | 2019-01-04 | 南京农业大学 | A kind of high activity Venus@gold-silver alloy Raman substrate material and preparation method thereof |

| CN109434133A (en)* | 2018-12-20 | 2019-03-08 | 江苏经贸职业技术学院 | A kind of synthetic method based on phase transfer method Au nano material |

| CN110039068A (en)* | 2019-05-21 | 2019-07-23 | 南京工业大学 | Sea urchin-shaped gold nanoparticles and synthesis method thereof |

- 2021

- 2021-09-06CNCN202111039342.0Apatent/CN115770883B/enactiveActive

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050165120A1 (en)* | 2004-01-22 | 2005-07-28 | Ashavani Kumar | Process for phase transfer of hydrophobic nanoparticles |

| CN109128152A (en)* | 2018-09-29 | 2019-01-04 | 南京农业大学 | A kind of high activity Venus@gold-silver alloy Raman substrate material and preparation method thereof |

| CN109434133A (en)* | 2018-12-20 | 2019-03-08 | 江苏经贸职业技术学院 | A kind of synthetic method based on phase transfer method Au nano material |

| CN110039068A (en)* | 2019-05-21 | 2019-07-23 | 南京工业大学 | Sea urchin-shaped gold nanoparticles and synthesis method thereof |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN119304178A (en)* | 2024-10-10 | 2025-01-14 | 吉林大学 | A method for preparing rod-shaped and tetrapod-shaped gold nanocapsules |

Also Published As

| Publication number | Publication date |

|---|---|

| CN115770883B (en) | 2025-02-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Deng et al. | Multifunctional mesoporous composite microspheres with well-designed nanostructure: a highly integrated catalyst system | |

| Hartlen et al. | Facile preparation of highly monodisperse small silica spheres (15 to> 200 nm) suitable for colloidal templating and formation of ordered arrays | |

| CN103231069B (en) | Preparation method for hollow nano metal | |

| CN101638238B (en) | Preparation method of shape and structure controllable silicon dioxide nano material containing ordered mesoporous pore canal | |

| KR101235873B1 (en) | A process for the preparation of silver nano particles | |

| Park et al. | Heterophase polymer dispersion: A green approach to the synthesis of functional hollow polymer microparticles | |

| Liu et al. | Polyphenol‐mediated synthesis of superparamagnetic magnetite nanoclusters for highly stable magnetically responsive photonic crystals | |

| Lu et al. | Strategies for tailoring the properties of chemically precipitated metal powders | |

| CN108236932B (en) | Superparamagnetic-plasma composite microsphere and preparation method thereof | |

| Ye et al. | Surface morphology changes on silica-coated gold colloids | |

| Grzelczak et al. | A general approach toward polymer-coated plasmonic nanostructures | |

| CN102079840B (en) | Method for preparing Ag/PMMA (polymethyl methacrylate) nano composite material | |

| CN111834074A (en) | A kind of method and application for purifying and synthesizing magnetic nano-stirring bar of Fe3O4 nanoparticles with oleic acid as ligand | |

| Li et al. | Facile synthesis of single crystal Fe 3 O 4 sub-microcubes free of any capping agent and their catalytic performance in p-nitrophenol reduction | |

| Sachdev et al. | Synthesis and assembly of gold and iron oxide particles within an emulsion droplet; facile production of core@ shell particles | |

| CN100556587C (en) | Microwave auxiliary liquid phase reduction method preparing needle-shaped nanometer nickel | |

| Logutenko et al. | A novel method to prepare copper microspheres via chemical reduction route | |

| Carotenuto et al. | Synthesis and characterization of gold-based nanoscopic additives for polymers | |

| CN111747451A (en) | A kind of ferric oxide/mesoporous silica magnetic composite particle and super-assembly method thereof | |

| CN104817776B (en) | A kind of preparation method of the amino polysilsesquioxane ball nano material of load Ag particles | |

| CN102294213A (en) | Preparation method of polymer-coated binary double-functional nano-cluster core-shell microspheres | |

| CN115770883A (en) | A method of phase transfer through surface modification of inorganic nanomaterials | |

| Bae et al. | Synthesis and characterization of silver nanoparticles by a reverse micelle process | |

| Wang et al. | Hollow polymer microspheres containing a gold nanocolloid core adsorbed on the inner surface as a catalytic microreactor | |

| Tan et al. | Iron nanoparticles encapsulated in poly (AAm-co-MAA) microgels for magnetorheological fluids |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |