CN115736370A - Electron cigarette ceramic heater - Google Patents

Electron cigarette ceramic heaterDownload PDFInfo

- Publication number

- CN115736370A CN115736370ACN202211456252.6ACN202211456252ACN115736370ACN 115736370 ACN115736370 ACN 115736370ACN 202211456252 ACN202211456252 ACN 202211456252ACN 115736370 ACN115736370 ACN 115736370A

- Authority

- CN

- China

- Prior art keywords

- conductive layer

- ceramic heater

- heater

- pad

- lead

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Resistance Heating (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本申请涉及焊盘加热技术领域,具体涉及一种电子烟陶瓷加热器。The present application relates to the technical field of pad heating, in particular to a ceramic heater for electronic cigarettes.

背景技术Background technique

随着人们对健康的追求,加热不燃烧型电子烟越来越受欢迎,管状加热器作为加热不燃烧电子烟载体,是加热不燃烧型电子烟的核心部件。现有的不燃烧型电子烟的焊盘一般使用锡焊,最高使用温度一般在200℃以下,使用场景十分受限,电连接可靠性也较差;并且,仅使用1个连接孔连接将内部线路与外部焊盘连接,这种焊盘结构在反复加热时容易造成虚弱连接(即虚接或虚焊),电连接可靠性较差;另外,当前的焊盘结构一般通过不同引线颜色管理实现对焊盘引脚功能的管理,操作人员容易将引线颜色对应的焊盘引脚功能搞错,以此容易引发焊接错误的问题,会对器件使用造成不便。With people's pursuit of health, heat-not-burn electronic cigarettes are becoming more and more popular. As the carrier of heat-not-burn electronic cigarettes, tubular heaters are the core components of heat-not-burn electronic cigarettes. The pads of existing non-combustible electronic cigarettes are generally soldered, and the maximum operating temperature is generally below 200°C. The application scenarios are very limited, and the reliability of the electrical connection is also poor; moreover, only one connection hole is used to connect the internal The line is connected to the external pad. This pad structure is likely to cause weak connection (that is, virtual connection or virtual soldering) when heated repeatedly, and the reliability of the electrical connection is poor. In addition, the current pad structure is generally realized through different lead color management. For the management of pad pin functions, operators can easily mistake the pad pin functions corresponding to the color of the lead wires, which can easily lead to soldering errors and cause inconvenience to the use of devices.

发明内容Contents of the invention

鉴于此,本申请提供一种电子烟陶瓷加热器,用以改善现有焊盘结构容易出现虚接以及高温环境下焊盘和引出导线脱落等导致的电连接可靠性较差等问题,还可以改善因缺乏焊盘引脚功能标识导致使用便捷性差的问题。In view of this, the present application provides a ceramic heater for electronic cigarettes, which is used to improve the problems of poor electrical connection reliability caused by the easy occurrence of false connections in the existing pad structure and the falling off of pads and lead wires in high temperature environments. Improve the problem of poor usability due to the lack of pad pin function identification.

本申请提供的一种电子烟陶瓷加热器,包括:An electronic cigarette ceramic heater provided in this application includes:

加热器主体,包括内部线路;heater body, including internal wiring;

焊盘,包括第一导电层、多个金属导体和引出导线;所述第一导电层设置于所述加热器主体外表面;所述加热器主体的位于所述第一导电层和所述内部线路之间的部分设置有多个连接孔,各个所述金属导体设置于对应的各个所述连接孔中,所述金属导体将所述内部线路与所述第一导电层连接;The pad includes a first conductive layer, a plurality of metal conductors and lead wires; the first conductive layer is arranged on the outer surface of the heater body; the heater body is located on the first conductive layer and the inner The part between the lines is provided with a plurality of connection holes, each of the metal conductors is disposed in each of the corresponding connection holes, and the metal conductors connect the internal lines with the first conductive layer;

所述引出导线与所述第一导电层连接并接电。The lead-out wire is connected to the first conductive layer and connected to electricity.

可选地,所述连接孔的直径为R,且0.05mm≦R≦0.2mm,相邻所述连接孔的间距为S2,且S2>0.05mm。Optionally, the diameter of the connection hole is R, and 0.05mm≦R≦0.2mm, and the distance between adjacent connection holes is S2 , and S2 >0.05mm.

可选地,所述电子烟陶瓷加热器包括三个焊盘,为加热电阻输入端、测温电阻输入端和公共接地端。Optionally, the electronic cigarette ceramic heater includes three pads, which are the heating resistor input terminal, the temperature measuring resistor input terminal and the common ground terminal.

可选地,所述加热器主体设置有标识,所述标识邻近设置于对应的焊盘。Optionally, the heater body is provided with a mark, and the mark is adjacent to a corresponding pad.

可选地,所述标识包括文字、字母、数字和数学运算符号的任意组合。Optionally, the identification includes any combination of words, letters, numbers and mathematical operation symbols.

可选地,所述电子烟陶瓷加热器还包括定位框,围设于所述焊盘的外部。Optionally, the electronic cigarette ceramic heater further includes a positioning frame surrounding the pad.

可选地,所述焊盘还包括第二导电层,覆盖第一导电层及所述第一导电层与所述引出导线的连接处。Optionally, the pad further includes a second conductive layer covering the first conductive layer and a connection between the first conductive layer and the lead-out wire.

可选地,所述第二导电层和所述第一导电层的制造材料相同。Optionally, the second conductive layer is made of the same material as the first conductive layer.

可选地,所述引出导线为片状或柱状。Optionally, the lead-out wires are sheet-shaped or column-shaped.

可选地,所述第一导电层的面积为S,且S>0.4mm*0.4mm。Optionally, the area of the first conductive layer is S, and S>0.4mm*0.4mm.

如上所述,本申请设置单个焊盘通过多个连接孔与内部线路连接,增加了电连接可靠性,可降低出现虚接以及高温环境下焊盘和引出导线脱落的风险;并且,第二导电层覆盖第一导电层以及第一导电层与引出导线的连接处,进一步提高了到引出导线与焊盘的连接可靠性以及第一导电层与内部线路的连接可靠性,使得本申请的电子烟陶瓷加热器在最高温度880℃条件下使用而不会出现焊盘和引出导线脱落的问题,适应能力更强、适用场景更广。As mentioned above, the application sets a single pad to be connected to the internal circuit through multiple connection holes, which increases the reliability of the electrical connection and can reduce the risk of false connections and the risk of the pad and the lead wire falling off in a high temperature environment; and, the second conductive The layer covers the first conductive layer and the connection between the first conductive layer and the lead-out wire, which further improves the connection reliability to the lead-out wire and the pad, as well as the connection reliability between the first conductive layer and the internal circuit, so that the electronic cigarette of the present application The ceramic heater can be used at a maximum temperature of 880°C without the problem of pad and lead wire falling off, and has stronger adaptability and wider application scenarios.

另外,焊盘的外围设置有对焊盘引脚功能的标识,例如通过文字、字母、数字和数学运算符号的任意组合来标识加热电阻输入端、测温电阻输入端和公共接地端,便于操作人员直观获知,可提高使用便捷性差。In addition, the periphery of the pad is provided with an identification of the function of the pad pin, such as marking the input terminal of the heating resistor, the input terminal of the temperature measuring resistor and the common ground terminal by any combination of text, letters, numbers and mathematical operation symbols, which is convenient for operation Personnel know intuitively, which can improve the convenience of use.

附图说明Description of drawings

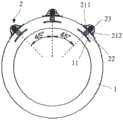

图1是本申请实施例提供的一种电子烟陶瓷加热器的示意图;Fig. 1 is a schematic diagram of an electronic cigarette ceramic heater provided by an embodiment of the present application;

图2是本申请实施例提供的一种电子烟陶瓷加热器的横截面示意图;Fig. 2 is a schematic cross-sectional view of an electronic cigarette ceramic heater provided in an embodiment of the present application;

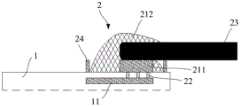

图3是本申请实施例提供的一种电子烟陶瓷加热器沿A-A’方向的剖视图;Fig. 3 is a cross-sectional view along the A-A' direction of an electronic cigarette ceramic heater provided by the embodiment of the present application;

图4是本申请实施例提供的一种焊盘的结构俯视图;Fig. 4 is a structural top view of a pad provided in an embodiment of the present application;

图5是本申请实施例提供的一种单个焊盘的多个连接孔的排布示意图。FIG. 5 is a schematic diagram of an arrangement of multiple connection holes of a single pad provided by an embodiment of the present application.

具体实施方式Detailed ways

现有焊盘结构的电连接可靠性较差,例如容易出现虚接、以及高温环境下焊盘和引出导线脱落,为了改善此问题,本申请的加热焊盘结构设置单个焊盘通过多个连接孔与内部线路连接,增加电连接可靠性。The electrical connection reliability of the existing pad structure is poor, for example, it is prone to false connection, and the pad and lead wire fall off under high temperature environment. In order to improve this problem, the heating pad structure of the present application sets a single pad through multiple connections. The hole is connected with the internal circuit to increase the reliability of the electrical connection.

为使本申请的目的、技术方案和优点更加清楚,下面将结合具体实施例及相应的附图,对本申请的技术方案进行清楚地描述。显然,下文所描述实施例仅是本申请的一部分实施例,而非全部的实施例。在不冲突的情况下,下述各个实施例及其技术特征可相互组合,且亦属于本申请的技术方案。In order to make the purpose, technical solution and advantages of the present application clearer, the technical solution of the present application will be clearly described below in conjunction with specific embodiments and corresponding drawings. Apparently, the embodiments described below are only some of the embodiments of the present application, but not all of them. In the case of no conflict, the following embodiments and technical features thereof can be combined with each other, and also belong to the technical solution of the present application.

在本申请实施例的描述中,术语“中心”、“纵向”、“横向”、“长度”、“宽度”、“厚度”、“上”、“下”、“前”、“后”、“左”、“右”、“竖直”、“水平”、“顶”、“底”、“内”、“外”、“顺时针”、“逆时针”等指示的方位或位置关系为基于附图所示的方位或位置关系,仅为便于描述相应实施例的技术方案,而非指示或暗示装置或元件必须具有特定方位、以特定方位构造和操作,不能理解为对本申请的限制。In the description of the embodiments of the present application, the terms "center", "longitudinal", "transverse", "length", "width", "thickness", "upper", "lower", "front", "rear", The orientation or positional relationship indicated by "left", "right", "vertical", "horizontal", "top", "bottom", "inner", "outer", "clockwise", "counterclockwise" etc. is Based on the orientation or positional relationship shown in the drawings, it is only to facilitate the description of the technical solutions of the corresponding embodiments, but not to indicate or imply that the device or element must have a specific orientation, be constructed and operated in a specific orientation, and should not be construed as limiting the present application.

请一并参阅图1至图5,本申请实施例提供的一种电子烟陶瓷加热器的示意图、以及局部示意图。该电子烟陶瓷加热器包括加热器主体1和焊盘2。Please refer to FIG. 1 to FIG. 5 together, which are schematic diagrams and partial schematic diagrams of a ceramic heater for an electronic cigarette provided by an embodiment of the present application. The electronic cigarette ceramic heater includes a

加热器主体1可视为承载焊盘2的主体,根据电子烟陶瓷加热器所适用的主体器件而定,例如在适用于加热不燃烧型电子烟的场景中,加热器主体1可视为电子烟的盛装烟油以及将烟油电加热雾化的烟油管。加热器主体1的横截面包括但不限于为圆形、矩形、梯形等多边形,在无特殊说明的情况下,本申请默认以圆形的管状加热器主体1为例进行描述。The heater

加热器主体1至少包括内部线路11,该内部线路11与焊盘2连接,并通过焊盘2接电以此产生所需的热量。在图1至图3所示的场景中,内部线路11被示出为片状件或块状件、以及内部线路11在加热器主体1中的相对位置,仅为示例性展示,在实际场景中,内部线路11可具体表现为电极和/或走线等电子元器件的适应组合,内部线路11可以一部分设置于管状加热器主体1的中空腔体内并沿长度方向延伸、另一部分设置于管状主体壁上。The

焊盘2包括第一导电层211、多个金属导体22和引出导线23。The

第一导电层211设置于加热器主体1的外表面。The first

加热器主体1的位于第一导电层211和内部线路11之间的部分设置有多个连接孔12,各个金属导体22设置于对应的各个连接孔12中,这些连接孔12以及设置于对应连接孔12中的金属导体22均被第一导电层211覆盖,各个金属导体22将内部线路11与第一导电层211连接。The part of the

引出导线23与第一导电层211连接并接电,具体地,引出导线23可以为片状或柱状,一端与第一导电层211连接,另一端连接电源。The lead-out

本申请设置单个焊盘2通过多个连接孔12及位于各个连接孔12中的金属导体22与内部线路11连接,即使其中一个或多个连接孔12对应的金属导体22未同时与第一导电层211和引出导线23连接,第一导电层211和引出导线23也可以通过其他连接孔12及对应的金属导体22实现连接,从而增加了第一导电层211和引出导线23之间的电连接可靠性,可降低两者之间出现虚接的风险,以及降低高温环境下焊盘2和引出导线23脱落的风险。In the present application, a

在一些场景中,这些连接孔12的直径和形状等可以对应相同,例如连接孔12可以均为圆形、矩形、梯形等任一多边形;第一导电层211的面积为S,且S>0.4mm*0.4mm;单个连接孔12的直径为R,且0.05mm≦R≦0.2mm,任意相邻两个连接孔12之间的距离相等,均为S2,且S2>0.05mm,在第一导电层211的覆盖范围内设置可以较多的连接孔12和金属导体22,从而有利于保证第一导电层211和引出导线23的连接。In some scenarios, the diameters and shapes of these

请继续参阅图1至图5所示,焊盘2还可以包括第二导电层212,该第二导电层212覆盖第一导电层211、以及覆盖第一导电层211与引出导线23的连接处,进一步提高了到引出导线23与焊盘2的连接可靠性、以及第一导电层211与内部线路11的连接可靠性,使得本申请的电子烟陶瓷加热器在高温(例如最高温度可达880℃)条件下使用而不会出现焊盘2和引出导线23脱落的问题,适应能力更强、适用场景更广。Please continue to refer to FIG. 1 to FIG. 5, the

可选地,第二导电层211和第一导电层211的制造材料可以相同,例如可以为银、铜、铝等金属材料或者适应的合金材料。Optionally, the manufacturing materials of the second

请继续参阅图1至图5,电子烟陶瓷加热器还可以包括定位框24,该定位框24围设于焊盘2的外部,定位框24可用于限定焊盘2的位置及范围,有利于操作人员快速定位焊盘2以便于后续引出导线23与该焊盘2的焊接、以及第二导电层212的覆盖设置。定位框24可以为圆形、矩形、梯形等多边形。Please continue to refer to Figures 1 to 5, the electronic cigarette ceramic heater can also include a

在实际场景中,焊盘2的数量以及位置可以根据实际所需适应性而定,例如,在图1至图5所示的场景中,所述电子烟陶瓷加热器包括三个焊盘2,分别沿管状加热器主体1的圆周方向排布,任意相邻两个焊盘2之间的距离可以相等,对应地,所述电子烟陶瓷加热器包括三条引出导线23,例如图1所示的三条相互平行的引出导线23,各个引出导线23分别连接对应的焊盘2,这三个焊盘2分别可视为加热电阻输入端、测温电阻输入端和公共接地端,焊盘2之间形成的夹角(该夹角以管状加热器主体1的横截面圆心为顶点)可以为45°,但不限于45°。在其他场景中,焊盘2的数量也可以为3到7个之间的任意数量。In actual scenarios, the number and position of

所述加热器主体1可以设置有标识,各个标识邻近设置于对应的焊盘2。可选地,标识包括文字、字母、数字和数学运算符号的任意组合。例如,请参阅图1所示,三个焊盘2分别设置有对应的标识“1”、标识“2”及标识“3”,其中“1”为加热电阻输入端,“2”为测温电阻输入端,“3”为公共接地端,焊盘2的标识不限于“1”、“2”、“3”,例如可标识为“+”、“-”、“GND”等。The

任意两个相邻焊盘2之间的距离可以根据管状加热器主体1的尺寸而定,例如,管状加热器主体1的长度为L,直径为D,所述L和D的取值也可以根据所适用的主体器件而定,例如5mm≦D≦20mm,10mm≦L≦80mm;任意两个相邻焊盘2之间的距离可以至少大于或等于1mm,所述距离可以为相邻焊盘2在管状加热器主体1的横截面上的最小距离;焊盘2与加热器主体1的底部之间的距离为S1,可选地S1≧0.1mm。The distance between any two

以制作10.2mm内径的管状加热器主体1为例,如图4和图5所示,连接孔12设计为9个,单个连接孔12的直径为0.1mm,相邻两个连接孔12的间距为0.07mm。连接孔12上可以涂上一层厚度为0.05mm~0.3mm的银浆,银浆可以流入于各个连接孔12中,于此通过一道高温烧结制程后即可得到第一导电层211和金属导体22。将直径为0.5mm的银质引出导线23安装在第一导电层211上,引出导线23上覆盖一层银浆,并通过高温烧结使银浆与引出导线23及第一导电层211结合在一起,当然引出导线23不限于银质,可使用铜质导线或者镍线。Taking the tubular heater

应理解,以上所述仅为本申请的部分实施例,并非因此限制本申请的专利范围,对于本领域普通技术人员而言,凡是利用本说明书及附图内容所作的等效结构变换,均同理包括在本申请的专利保护范围内。It should be understood that the above descriptions are only part of the embodiments of the application, and are not intended to limit the patent scope of the application. For those of ordinary skill in the art, all equivalent structural transformations made by using the contents of this description and the accompanying drawings are the same as The theory is included in the patent protection scope of the present application.

尽管本文采用术语“第一、第二”等描述各种信息,但这些信息不应限于这些术语。这些术语仅用来将同一类型的信息彼此区分开。另外,单数形式“一”、“一个”和“该”旨在也包括复数形式。术语“或”和“和/或”被解释为包括性的,或意味着任一个或任何组合。仅当元件、功能、步骤或操作的组合在某些方式下内在地互相排斥时,才会出现该定义的例外。Although the terms "first, second", etc. are used herein to describe various information, the information should not be limited to these terms. These terms are only used to distinguish information of the same type from one another. In addition, the singular forms "a", "an" and "the" are intended to include the plural forms as well. The terms "or" and "and/or" are to be construed as inclusive, or to mean either one or any combination. Exceptions to this definition will only arise when combinations of elements, functions, steps or operations are inherently mutually exclusive in some way.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211456252.6ACN115736370A (en) | 2022-11-21 | 2022-11-21 | Electron cigarette ceramic heater |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211456252.6ACN115736370A (en) | 2022-11-21 | 2022-11-21 | Electron cigarette ceramic heater |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115736370Atrue CN115736370A (en) | 2023-03-07 |

Family

ID=85333725

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211456252.6APendingCN115736370A (en) | 2022-11-21 | 2022-11-21 | Electron cigarette ceramic heater |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115736370A (en) |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN203733998U (en)* | 2014-02-26 | 2014-07-23 | 刘秋明 | Electronic cigarette, atomization assembly and electric connecting structure thereof |

| US20150320115A1 (en)* | 2014-05-12 | 2015-11-12 | Kimree Hi-Tech Inc. | Atomizer and electronic cigarette |

| CN207505228U (en)* | 2017-11-21 | 2018-06-15 | 江油星联电子科技有限公司 | A kind of multijunction round circuit board |

| CN108451045A (en)* | 2018-04-26 | 2018-08-28 | 株洲利德英可电子科技有限公司 | A kind of porous ceramics electronic cigarette heater and preparation method thereof and electronic cigarette |

| CN208226122U (en)* | 2018-05-16 | 2018-12-11 | 中山凯旋真空科技股份有限公司 | Electrical equipment and heating installations |

| CN211558817U (en)* | 2019-11-29 | 2020-09-25 | 东莞市国研电热材料有限公司 | Ceramic heating element with ceramic piece for electronic cigarette |

| CN211910538U (en)* | 2020-03-19 | 2020-11-13 | 深圳市湃科集成技术有限公司 | Electronic cigarette control part structure, electronic cigarette and positioning jig thereof |

| CN112137175A (en)* | 2020-10-14 | 2020-12-29 | 深圳市艾溹技术研究有限公司 | Electronic cigarette heating assembly, preparation method thereof and electronic cigarette |

| CN215189459U (en)* | 2021-05-21 | 2021-12-17 | 深圳市新厚泰电子科技有限公司 | SMD electron cigarette controller and electron cigarette |

- 2022

- 2022-11-21CNCN202211456252.6Apatent/CN115736370A/enactivePending

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN203733998U (en)* | 2014-02-26 | 2014-07-23 | 刘秋明 | Electronic cigarette, atomization assembly and electric connecting structure thereof |

| US20150320115A1 (en)* | 2014-05-12 | 2015-11-12 | Kimree Hi-Tech Inc. | Atomizer and electronic cigarette |

| CN207505228U (en)* | 2017-11-21 | 2018-06-15 | 江油星联电子科技有限公司 | A kind of multijunction round circuit board |

| CN108451045A (en)* | 2018-04-26 | 2018-08-28 | 株洲利德英可电子科技有限公司 | A kind of porous ceramics electronic cigarette heater and preparation method thereof and electronic cigarette |

| CN208226122U (en)* | 2018-05-16 | 2018-12-11 | 中山凯旋真空科技股份有限公司 | Electrical equipment and heating installations |

| CN211558817U (en)* | 2019-11-29 | 2020-09-25 | 东莞市国研电热材料有限公司 | Ceramic heating element with ceramic piece for electronic cigarette |

| CN211910538U (en)* | 2020-03-19 | 2020-11-13 | 深圳市湃科集成技术有限公司 | Electronic cigarette control part structure, electronic cigarette and positioning jig thereof |

| CN112137175A (en)* | 2020-10-14 | 2020-12-29 | 深圳市艾溹技术研究有限公司 | Electronic cigarette heating assembly, preparation method thereof and electronic cigarette |

| WO2022078017A1 (en)* | 2020-10-14 | 2022-04-21 | 深圳市艾溹技术研究有限公司 | Heating assembly of electronic cigarette and preparation method therefor, and electronic cigarette |

| CN215189459U (en)* | 2021-05-21 | 2021-12-17 | 深圳市新厚泰电子科技有限公司 | SMD electron cigarette controller and electron cigarette |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2002289407A (en) | Temperature sensor and its manufacturing method | |

| JP3652647B2 (en) | High temperature detector and manufacturing method thereof | |

| JPWO2020075703A1 (en) | Heat exchange unit and cleaning equipment equipped with it | |

| CN115736370A (en) | Electron cigarette ceramic heater | |

| JP5261104B2 (en) | Circuit board and electronic device | |

| JP3886699B2 (en) | Glow plug and manufacturing method thereof | |

| JP6530307B2 (en) | Substrate for gas sensor and gas sensor device | |

| JP2000503485A (en) | Method of fixing electric contact to ceramic layer and resistance element manufactured by the method | |

| US20210257174A1 (en) | Chip-type fuse with a metal wire type fusible element and manufacturing method for the same | |

| KR19980018524A (en) | Method for manufacturing substrates with at least one metal-laminate and printed boards and their application | |

| EP3064834A1 (en) | Heater and glow plug | |

| KR20190082991A (en) | Manufacturing method of solar cell and solar cell | |

| JP2868272B2 (en) | Sensor assembly structure | |

| US20110169592A1 (en) | Planar-Axial Thermistor for Bolometry | |

| JP6829022B2 (en) | heater | |

| CN112133510B (en) | Resistor with signal-noise shielding function and preparation method thereof | |

| JPH09223566A (en) | Surge absorption element | |

| CN208126886U (en) | Fly line and PCB board | |

| CN209929256U (en) | High-current fuse with high-heat-conduction substrate | |

| JP5880583B2 (en) | Temperature sensor and manufacturing method | |

| JP2002353730A (en) | Patch antenna | |

| JP2002141673A (en) | Electronic circuit module | |

| CN218635315U (en) | Integrated heating tube and aerosol generating device | |

| CN215183339U (en) | Flexible lead thick film resistor heating source | |

| CN217407798U (en) | Heating element and low-temperature non-combustion smoking set |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |