CN115612154A - A surface bone-like apatite coating for polyether ether ketone and its preparation method - Google Patents

A surface bone-like apatite coating for polyether ether ketone and its preparation methodDownload PDFInfo

- Publication number

- CN115612154A CN115612154ACN202211361688.7ACN202211361688ACN115612154ACN 115612154 ACN115612154 ACN 115612154ACN 202211361688 ACN202211361688 ACN 202211361688ACN 115612154 ACN115612154 ACN 115612154A

- Authority

- CN

- China

- Prior art keywords

- peek

- bone

- mineralization

- ether ketone

- polyether ether

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000004696Poly ether ether ketoneSubstances0.000titleclaimsabstractdescription165

- 229920002530polyetherether ketonePolymers0.000titleclaimsabstractdescription165

- 229910052586apatiteInorganic materials0.000titleclaimsabstractdescription54

- VSIIXMUUUJUKCM-UHFFFAOYSA-Dpentacalcium;fluoride;triphosphateChemical compound[F-].[Ca+2].[Ca+2].[Ca+2].[Ca+2].[Ca+2].[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=OVSIIXMUUUJUKCM-UHFFFAOYSA-D0.000titleclaimsabstractdescription54

- 239000011248coating agentSubstances0.000titleclaimsabstractdescription31

- 238000000576coating methodMethods0.000titleclaimsabstractdescription31

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription22

- 230000033558biomineral tissue developmentEffects0.000claimsabstractdescription79

- 238000006277sulfonation reactionMethods0.000claimsabstractdescription21

- 238000004140cleaningMethods0.000claimsabstractdescription14

- 238000000034methodMethods0.000claimsdescription43

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsdescription31

- 239000011575calciumSubstances0.000claimsdescription25

- FAPWRFPIFSIZLT-UHFFFAOYSA-MSodium chlorideChemical compound[Na+].[Cl-]FAPWRFPIFSIZLT-UHFFFAOYSA-M0.000claimsdescription24

- WCUXLLCKKVVCTQ-UHFFFAOYSA-MPotassium chlorideChemical compound[Cl-].[K+]WCUXLLCKKVVCTQ-UHFFFAOYSA-M0.000claimsdescription23

- 239000008367deionised waterSubstances0.000claimsdescription20

- 229910021641deionized waterInorganic materials0.000claimsdescription20

- QAOWNCQODCNURD-UHFFFAOYSA-Nsulfuric acidSubstancesOS(O)(=O)=OQAOWNCQODCNURD-UHFFFAOYSA-N0.000claimsdescription16

- 238000011534incubationMethods0.000claimsdescription15

- CSCPPACGZOOCGX-UHFFFAOYSA-NAcetoneChemical compoundCC(C)=OCSCPPACGZOOCGX-UHFFFAOYSA-N0.000claimsdescription12

- LLSDKQJKOVVTOJ-UHFFFAOYSA-Lcalcium chloride dihydrateChemical compoundO.O.[Cl-].[Cl-].[Ca+2]LLSDKQJKOVVTOJ-UHFFFAOYSA-L0.000claimsdescription12

- 229940052299calcium chloride dihydrateDrugs0.000claimsdescription12

- 229940050906magnesium chloride hexahydrateDrugs0.000claimsdescription12

- DHRRIBDTHFBPNG-UHFFFAOYSA-Lmagnesium dichloride hexahydrateChemical compoundO.O.O.O.O.O.[Mg+2].[Cl-].[Cl-]DHRRIBDTHFBPNG-UHFFFAOYSA-L0.000claimsdescription12

- 229910000403monosodium phosphateInorganic materials0.000claimsdescription12

- 235000019799monosodium phosphateNutrition0.000claimsdescription12

- 239000011780sodium chlorideSubstances0.000claimsdescription12

- AJPJDKMHJJGVTQ-UHFFFAOYSA-Msodium dihydrogen phosphateChemical compound[Na+].OP(O)([O-])=OAJPJDKMHJJGVTQ-UHFFFAOYSA-M0.000claimsdescription12

- 239000011777magnesiumSubstances0.000claimsdescription11

- 239000001103potassium chlorideSubstances0.000claimsdescription11

- 235000011164potassium chlorideNutrition0.000claimsdescription11

- 239000011734sodiumSubstances0.000claimsdescription11

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000claimsdescription8

- 238000009832plasma treatmentMethods0.000claimsdescription7

- 238000003756stirringMethods0.000claimsdescription7

- BDHFUVZGWQCTTF-UHFFFAOYSA-MsulfonateChemical compound[O-]S(=O)=OBDHFUVZGWQCTTF-UHFFFAOYSA-M0.000claimsdescription6

- 229960002816potassium chlorideDrugs0.000claimsdescription5

- 229960002668sodium chlorideDrugs0.000claimsdescription5

- 238000002525ultrasonicationMethods0.000claimsdescription3

- 238000002386leachingMethods0.000claimsdescription2

- 239000007788liquidSubstances0.000abstractdescription17

- 239000011148porous materialSubstances0.000abstractdescription16

- 238000001556precipitationMethods0.000abstractdescription15

- 230000008021depositionEffects0.000abstractdescription6

- 230000003993interactionEffects0.000abstractdescription3

- -1ether ketoneChemical class0.000abstractdescription2

- 239000004721Polyphenylene oxideSubstances0.000abstract1

- RTZKZFJDLAIYFH-UHFFFAOYSA-NetherSubstancesCCOCCRTZKZFJDLAIYFH-UHFFFAOYSA-N0.000abstract1

- 229920000570polyetherPolymers0.000abstract1

- 239000000243solutionSubstances0.000description69

- 239000000463materialSubstances0.000description23

- 229920006508PEEK-MPolymers0.000description19

- 210000004027cellAnatomy0.000description12

- 229940079593drugDrugs0.000description10

- 239000003814drugSubstances0.000description10

- 239000000843powderSubstances0.000description10

- 238000001035dryingMethods0.000description9

- 238000003760magnetic stirringMethods0.000description9

- 239000007943implantSubstances0.000description8

- 238000012360testing methodMethods0.000description8

- 239000012890simulated body fluidSubstances0.000description7

- HECLRDQVFMWTQS-UHFFFAOYSA-NDicyclopentadieneChemical compoundC1C2C3CC=CC3C1C=C2HECLRDQVFMWTQS-UHFFFAOYSA-N0.000description6

- UIIMBOGNXHQVGW-UHFFFAOYSA-MSodium bicarbonateChemical compound[Na+].OC([O-])=OUIIMBOGNXHQVGW-UHFFFAOYSA-M0.000description6

- 210000000988bone and boneAnatomy0.000description6

- LFULEKSKNZEWOE-UHFFFAOYSA-NpropanilChemical compoundCCC(=O)NC1=CC=C(Cl)C(Cl)=C1LFULEKSKNZEWOE-UHFFFAOYSA-N0.000description6

- OYPRJOBELJOOCE-UHFFFAOYSA-NCalciumChemical compound[Ca]OYPRJOBELJOOCE-UHFFFAOYSA-N0.000description4

- 229960005069calciumDrugs0.000description4

- 229910052791calciumInorganic materials0.000description4

- 239000012530fluidSubstances0.000description4

- 230000001089mineralizing effectEffects0.000description4

- 238000001878scanning electron micrographMethods0.000description4

- 230000004071biological effectEffects0.000description3

- 230000015572biosynthetic processEffects0.000description3

- 230000007797corrosionEffects0.000description3

- 238000005260corrosionMethods0.000description3

- 230000000694effectsEffects0.000description3

- PCHJSUWPFVWCPO-UHFFFAOYSA-NgoldChemical compound[Au]PCHJSUWPFVWCPO-UHFFFAOYSA-N0.000description3

- 239000010931goldSubstances0.000description3

- 229910052737goldInorganic materials0.000description3

- 150000002500ionsChemical class0.000description3

- 239000011259mixed solutionSubstances0.000description3

- 230000004048modificationEffects0.000description3

- 238000012986modificationMethods0.000description3

- 150000003017phosphorusChemical class0.000description3

- 235000017557sodium bicarbonateNutrition0.000description3

- 229910000030sodium bicarbonateInorganic materials0.000description3

- 239000000126substanceSubstances0.000description3

- 238000005033Fourier transform infrared spectroscopyMethods0.000description2

- 230000003592biomimetic effectEffects0.000description2

- 238000006243chemical reactionMethods0.000description2

- 230000018044dehydrationEffects0.000description2

- 238000006297dehydration reactionMethods0.000description2

- 238000005516engineering processMethods0.000description2

- 229910052588hydroxylapatiteInorganic materials0.000description2

- 238000002513implantationMethods0.000description2

- 229910052500inorganic mineralInorganic materials0.000description2

- 235000010755mineralNutrition0.000description2

- 239000011707mineralSubstances0.000description2

- 239000000203mixtureSubstances0.000description2

- 238000010883osseointegrationMethods0.000description2

- 230000011164ossificationEffects0.000description2

- 230000002188osteogenic effectEffects0.000description2

- XYJRXVWERLGGKC-UHFFFAOYSA-Dpentacalcium;hydroxide;triphosphateChemical compound[OH-].[Ca+2].[Ca+2].[Ca+2].[Ca+2].[Ca+2].[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=O.[O-]P([O-])([O-])=OXYJRXVWERLGGKC-UHFFFAOYSA-D0.000description2

- 238000007750plasma sprayingMethods0.000description2

- 239000002244precipitateSubstances0.000description2

- 238000010186stainingMethods0.000description2

- FFRBMBIXVSCUFS-UHFFFAOYSA-N2,4-dinitro-1-naphtholChemical compoundC1=CC=C2C(O)=C([N+]([O-])=O)C=C([N+]([O-])=O)C2=C1FFRBMBIXVSCUFS-UHFFFAOYSA-N0.000description1

- VEXZGXHMUGYJMC-UHFFFAOYSA-NHydrochloric acidChemical compoundClVEXZGXHMUGYJMC-UHFFFAOYSA-N0.000description1

- 229930040373ParaformaldehydeNatural products0.000description1

- 239000007983Tris bufferSubstances0.000description1

- 238000010521absorption reactionMethods0.000description1

- 230000002378acidificating effectEffects0.000description1

- 230000009286beneficial effectEffects0.000description1

- 239000010839body fluidSubstances0.000description1

- 210000001124body fluidAnatomy0.000description1

- FUFJGUQYACFECW-UHFFFAOYSA-Lcalcium hydrogenphosphateChemical compound[Ca+2].OP([O-])([O-])=OFUFJGUQYACFECW-UHFFFAOYSA-L0.000description1

- 239000002775capsuleSubstances0.000description1

- 238000003501co-cultureMethods0.000description1

- 239000013078crystalSubstances0.000description1

- 230000003247decreasing effectEffects0.000description1

- 238000005137deposition processMethods0.000description1

- 235000019700dicalcium phosphateNutrition0.000description1

- 230000009977dual effectEffects0.000description1

- 238000002474experimental methodMethods0.000description1

- 239000001963growth mediumSubstances0.000description1

- 230000002209hydrophobic effectEffects0.000description1

- 208000014674injuryDiseases0.000description1

- 238000004519manufacturing processMethods0.000description1

- 239000002609mediumSubstances0.000description1

- 238000002156mixingMethods0.000description1

- 230000006911nucleationEffects0.000description1

- 238000010899nucleationMethods0.000description1

- 230000000399orthopedic effectEffects0.000description1

- 210000000963osteoblastAnatomy0.000description1

- 229920002866paraformaldehydePolymers0.000description1

- 239000002245particleSubstances0.000description1

- 125000002467phosphate groupChemical group[H]OP(=O)(O[H])O[*]0.000description1

- 239000011574phosphorusSubstances0.000description1

- 229910052698phosphorusInorganic materials0.000description1

- 239000002243precursorSubstances0.000description1

- 230000035755proliferationEffects0.000description1

- 210000001243pseudopodiaAnatomy0.000description1

- 238000011160researchMethods0.000description1

- 239000007787solidSubstances0.000description1

- 239000007921spraySubstances0.000description1

- 238000005507sprayingMethods0.000description1

- 239000012192staining solutionSubstances0.000description1

- 125000000542sulfonic acid groupChemical group0.000description1

- 238000000352supercritical dryingMethods0.000description1

- 229920001169thermoplasticPolymers0.000description1

- 210000001519tissueAnatomy0.000description1

- 230000008733traumaEffects0.000description1

- LENZDBCJOHFCAS-UHFFFAOYSA-NtrisChemical compoundOCC(N)(CO)COLENZDBCJOHFCAS-UHFFFAOYSA-N0.000description1

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J7/00—Chemical treatment or coating of shaped articles made of macromolecular substances

- C08J7/04—Coating

- C08J7/06—Coating with compositions not containing macromolecular substances

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2361/00—Characterised by the use of condensation polymers of aldehydes or ketones; Derivatives of such polymers

- C08J2361/04—Condensation polymers of aldehydes or ketones with phenols only

- C08J2361/16—Condensation polymers of aldehydes or ketones with phenols only of ketones with phenols

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/30—Hydrogen technology

- Y02E60/50—Fuel cells

Landscapes

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Materials For Medical Uses (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及涂层制备技术领域,具体涉及一种用于聚醚醚酮的表面类骨磷灰石涂层及制备方法。The invention relates to the technical field of coating preparation, in particular to a surface bone-like apatite coating for polyetheretherketone and a preparation method thereof.

背景技术Background technique

聚醚醚酮(PEEK)是一种高温热塑性聚合物,由于其具有良好的生物相容性、射线可透性和与天然骨相似的机械强度,在骨科、脊柱和创伤植入材料领域得到了广泛的研究和应用。然而,由于PEEK的化学和生物惰性,导致PEEK植入体与宿主骨界面处易形成纤维包囊层,影响其骨整合性和成骨活性,进而导致植入体的松动和失效。Polyetheretherketone (PEEK) is a high-temperature thermoplastic polymer that has gained a lot of attention in the fields of orthopedic, spinal, and trauma implant materials due to its good biocompatibility, radiolucency, and mechanical strength similar to natural bone. Extensive research and application. However, due to the chemical and biological inertness of PEEK, a fibrous capsule layer is easily formed at the interface between the PEEK implant and the host bone, which affects its osseointegration and osteogenic activity, resulting in loosening and failure of the implant.

研究人员为了改善PEEK的生物活性做了很多工作。其中,表面矿化技术能够有效提升PEEK的生物活性并在植入过程中积极诱导新骨的生成。将表面载有类骨磷灰石(碳酸化羟基磷灰石)的PEEK材料植入体内后,在生理环境下PEEK表面的类骨磷灰石会逐渐降解为Ca2+和PO43-,骨组织与PEEK植入物界面处的体液中矿物离子浓度会在一定时间内有所增加,这些矿物离子会重新沉积在人体本身的受损骨骼处并诱导新骨的形成,从而减少PEEK植入物与宿主骨界面的纤维组织层,并增强植入体与宿主骨组织之间的骨整合效果。Researchers have done a lot of work to improve the biological activity of PEEK. Among them, the surface mineralization technology can effectively enhance the biological activity of PEEK and actively induce new bone formation during the implantation process. After the PEEK material loaded with bone-like apatite (carbonated hydroxyapatite) on the surface is implanted in the body, the bone-like apatite on the surface of PEEK will gradually degrade into Ca2+ and PO43- under physiological environment, The concentration of mineral ions in body fluid at the interface between bone tissue and PEEK implants will increase within a certain period of time, and these mineral ions will redeposit on the damaged bones of the human body and induce new bone formation, thereby reducing the risk of PEEK implantation. The fibrous tissue layer at the interface between the implant and the host bone, and enhance the osseointegration effect between the implant and the host bone tissue.

虽然表面负载类骨磷灰石的PEEK具有很好的成骨活性,但是由于PEEK本身的化学惰性,通过传统的模拟体液(SBF)孵育方法在PEEK表面形成类骨磷灰石涂层往往需要7-14天的孵育时间,且形成的磷灰石数量较少、均匀性差、机械稳定性不足,这一方面增加了实际生产中的时间成本,另一方面也难以满足个性化定制颅骨修复体等的快速生产要求。虽然也可使用等离子体喷涂羟基磷灰石涂层技术,但等离子体喷涂过程的高温可能造成PEEK植入物的严重热变形,而且其线性工艺也难以满足复杂形态PEEK植入物表面涂层的均匀性。Although PEEK loaded with bone-like apatite on the surface has good osteogenic activity, due to the chemical inertness of PEEK itself, it often takes 7 hours to form a bone-like apatite coating on the surface of PEEK by the traditional simulated body fluid (SBF) incubation method. -14 days of incubation time, and the amount of apatite formed is small, poor in uniformity, and insufficient in mechanical stability. rapid production requirements. Although plasma spraying hydroxyapatite coating technology can also be used, the high temperature of the plasma spraying process may cause severe thermal deformation of PEEK implants, and its linear process is difficult to meet the surface coating requirements of complex shapes of PEEK implants. Uniformity.

发明内容Contents of the invention

本发明针对现有技术存在的问题提供一种用于聚醚醚酮的表面类骨磷灰石涂层及制备方法。Aiming at the problems existing in the prior art, the invention provides a bone-like apatite coating on the surface of polyetheretherketone and a preparation method thereof.

本发明采用的技术方案是:The technical scheme adopted in the present invention is:

一种用于聚醚醚酮的表面类骨磷灰石涂层制备方法,包括以下步骤:A method for preparing a surface bone-like apatite coating for polyetheretherketone, comprising the following steps:

步骤1:将聚醚醚酮片材清洗后,表面磺化处理得到磺化聚醚醚酮;Step 1: after cleaning the polyether ether ketone sheet, sulfonate the surface to obtain sulfonated polyetheretherketone;

步骤2:将步骤1中得到的磺化聚醚醚酮置于加入析出液的矿化液中,进行类骨磷灰石沉积;Step 2: placing the sulfonated polyetheretherketone obtained in

其中析出液为NaHCO3溶液;矿化液中包括Na+、Cl-、K+、Ca2+、Mg2+和PO43-;其中,Na+浓度为1~1.2mol/L,K+浓度为5~6mmol/L,Ca2+浓度为25~30mmol/L,Mg2+浓度为5~6mmol/L,PO43-浓度为10~12mmol/L,Cl-浓度为1~1.2mol/L;加入析出液的矿化液中,Ca2+、PO43-和CO32-的摩尔比为5:2:3。The eluate is NaHCO3 solution; the mineralization solution includes Na+ , Cl- , K+ , Ca2+ , Mg2+ and PO43- ; the concentration of Na+ is 1-1.2mol/L, and the concentration of K+ The concentration is 5~6mmol/L, the Ca2+ concentration is 25~30mmol/L, the Mg2+ concentration is 5~6mmol/L, the PO43- concentration is 10~12mmol/L, and the Cl- concentration is 1~1.2mol /L; added to the mineralization solution of the eluate, the molar ratio of Ca2+ , PO43- and CO32- is 5:2:3.

进一步的,所述步骤1得到的磺化聚醚醚酮在矿化之前进行空气等离子预处理;等离子处理功率为50~80W,压力为0.3~0.5MPa,处理时间为8~12min。Further, the sulfonated polyetheretherketone obtained in

进一步的,所述矿化液中Na+由氯化钠和磷酸二氢钠提供,K+由氯化钾提供,Ca2+由二水氯化钙提供,Mg2+由六水氯化镁提供,PO43-由磷酸二氢钠提供,Cl-由氯化钠、氯化钾、二水氯化钙和六水氯化镁提供。Further, Na+ in the mineralization solution is provided by sodium chloride and sodium dihydrogen phosphate, K+ is provided by potassium chloride, Ca2+ is provided by calcium chloride dihydrate, Mg2+ is provided by magnesium chloride hexahydrate, PO43- is provided by sodium dihydrogen phosphate, andCl- is provided by sodium chloride, potassium chloride, calcium chloride dihydrate and magnesium chloride hexahydrate.

进一步的,所述矿化液配置方法如下:Further, the mineralization liquid configuration method is as follows:

在搅拌条件下,依次将氯化钠、氯化钾、二水氯化钙、六水氯化镁、磷酸二氢钠溶于水中充分搅拌形成。Under the condition of stirring, sodium chloride, potassium chloride, calcium chloride dihydrate, magnesium chloride hexahydrate, and sodium dihydrogen phosphate are dissolved in water and stirred thoroughly to form.

进一步的,所述步骤2中矿化过程在37~70℃条件下进行,孵育时间为1~2h;重复孵育过程1~2次。Further, the mineralization process in step 2 is carried out at 37-70° C., and the incubation time is 1-2 hours; the incubation process is repeated 1-2 times.

进一步的,所述步骤1中的磺化过程如下:Further, the sulfonation process in the

将聚醚醚酮片材置于浓硫酸中进行磺化,磺化时间为3~5min。The polyether ether ketone sheet is placed in concentrated sulfuric acid for sulfonation, and the sulfonation time is 3-5 minutes.

进一步的,所述磺化过程结束后聚醚醚酮片材置于去离子水中漂洗,被酸蚀部分充分浸出之后超声处理;超声条件为:温度25℃、功率为120W,频率为40KHz,超声时间为15~20min;超声过程中每5min更换去离子水;Further, after the sulfonation process is completed, the polyetheretherketone sheet is rinsed in deionized water, and the etched part is fully leached and then ultrasonically treated; the ultrasonic conditions are: temperature 25°C, power 120W, frequency 40KHz, ultrasonic The time is 15-20min; the deionized water is replaced every 5min during the ultrasonic process;

超声后在60℃条件下,烘干2h。After ultrasonication, dry at 60°C for 2 hours.

进一步的,所述步骤1中片材清洗过程如下:Further, the sheet cleaning process in

依次采用丙酮、无水乙醇和去离子水各超声10min,然后在60℃条件下,烘干1h;超声条件为:温度25℃、功率为120W,频率为40KHz。Acetone, absolute ethanol and deionized water were used in sequence to sonicate for 10 minutes each, and then dried at 60°C for 1 hour; the ultrasonic conditions were: temperature 25°C, power 120W, frequency 40KHz.

本发明的有益效果是:The beneficial effects of the present invention are:

(1)本发明可以在聚醚醚酮表面形成微纳米级互连孔隙结构,并且制备工艺简单;(1) The present invention can form a micro-nano-scale interconnected pore structure on the surface of polyether ether ketone, and the preparation process is simple;

(2)本发明采用空气等离子体预处理,在保留原有孔隙形貌的同时,可以使上表面磺化聚醚醚酮在短时间内具备超亲水性,使得后续矿化处理时矿化液能够快速渗入表面的互连孔中并迅速形核发生矿化;(2) The present invention adopts air plasma pretreatment, while retaining the original pore morphology, the sulfonated polyether ether ketone on the upper surface can be super-hydrophilic in a short time, so that the subsequent mineralization treatment can be mineralized The liquid can quickly penetrate into the interconnected pores on the surface and quickly nucleate and mineralize;

(3)本发明提供一种矿化液和析出液,其中矿化液是非常稳定的体系,可在4℃条件下长期保存;析出液和矿化液混合后发生相互作用,进行快速矿化,形成类骨磷灰石涂层。(3) The present invention provides a mineralization solution and a mineralization solution, wherein the mineralization solution is a very stable system that can be stored for a long time at 4°C; the precipitation solution and the mineralization solution interact after being mixed for rapid mineralization , forming a bone-like apatite coating.

附图说明Description of drawings

图1为本发明实施例1中的聚醚醚酮PEEK、磺化聚醚醚酮PEEK-S和覆盖了涂层的聚醚醚酮PEEK-M的SEM图。Fig. 1 is a SEM image of polyetheretherketone PEEK, sulfonated polyetheretherketone PEEK-S and coated polyetheretherketone PEEK-M in Example 1 of the present invention.

图2为本发明实施例1中的聚醚醚酮PEEK、磺化聚醚醚酮PEEK-S和覆盖了涂层的聚醚醚酮PEEK-M的接触角测试结果。Fig. 2 is the contact angle test results of polyetheretherketone PEEK, sulfonated polyetheretherketone PEEK-S and coated polyetheretherketone PEEK-M in Example 1 of the present invention.

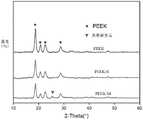

图3为本发明实施例1中的聚醚醚酮PEEK、磺化聚醚醚酮PEEK-S和覆盖了涂层的聚醚醚酮PEEK-M的XRD测试结果。Fig. 3 is the XRD test results of polyetheretherketone PEEK, sulfonated polyetheretherketone PEEK-S and coated polyetheretherketone PEEK-M in Example 1 of the present invention.

图4为本发明实施例1中的聚醚醚酮PEEK、磺化聚醚醚酮PEEK-S和覆盖了涂层的聚醚醚酮PEEK-M的FT-IR测试结果。Fig. 4 shows the FT-IR test results of polyetheretherketone PEEK, sulfonated polyetheretherketone PEEK-S and coated polyetheretherketone PEEK-M in Example 1 of the present invention.

图5为采用现有方法得到的涂层的SEM图。Fig. 5 is the SEM image of the coating obtained by the existing method.

图6为本发明实施例1中的聚醚醚酮PEEK、磺化聚醚醚酮PEEK-S和覆盖了涂层的聚醚醚酮PEEK-M与MC3T3-E1细胞共培养一天后的SEM图。Figure 6 is the SEM image of polyetheretherketone PEEK, sulfonated polyetheretherketone PEEK-S and coated polyetheretherketone PEEK-M in Example 1 of the present invention and MC3T3-E1 cells co-cultured for one day .

图7为本发明实施例1中的聚醚醚酮PEEK、磺化聚醚醚酮PEEK-S和覆盖了涂层的聚醚醚酮PEEK-M与MC3T3-E1细胞共培养1/3/5天后的活死染色结果。Figure 7 shows the co-culture of polyetheretherketone PEEK, sulfonated polyetheretherketone PEEK-S and coated polyetheretherketone PEEK-M with MC3T3-E1 cells in Example 1 of the

具体实施方式detailed description

下面结合附图和具体实施例对本发明做进一步说明。The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

一种用于聚醚醚酮的表面类骨磷灰石涂层制备方法,包括以下步骤:A method for preparing a surface bone-like apatite coating for polyetheretherketone, comprising the following steps:

步骤1:将聚醚醚酮片材清洗后,表面磺化处理得到磺化聚醚醚酮;磺化过程如下:Step 1: After cleaning the PEEK sheet, sulfonate the surface to obtain sulfonated PEEK; the sulfonation process is as follows:

将聚醚醚酮片材置于浓硫酸中进行磺化,磺化时间为3~5min。The polyether ether ketone sheet is placed in concentrated sulfuric acid for sulfonation, and the sulfonation time is 3-5 minutes.

磺化过程结束后聚醚醚酮片材置于去离子水中漂洗,被酸蚀部分充分浸出之后超声处理;超声条件为:温度25℃、功率为120W,频率为40KHz,超声时间为15~20min;超声过程中每5min更换去离子水;After the sulfonation process, the polyether ether ketone sheet is rinsed in deionized water, and the etched part is fully leached and then ultrasonically treated; the ultrasonic conditions are: temperature 25°C, power 120W, frequency 40KHz, ultrasonic time 15-20min ;Replace the deionized water every 5 minutes during the ultrasonic process;

超声后在60℃条件下,烘干2h。After ultrasonication, dry at 60°C for 2 hours.

片材清洗过程如下:The sheet cleaning process is as follows:

依次采用丙酮、无水乙醇和去离子水各超声10min,然后在60℃条件下,烘干1h;超声条件为:温度25℃、功率为120W,频率为40KHz。Acetone, absolute ethanol and deionized water were used in sequence to sonicate for 10 minutes each, and then dried at 60°C for 1 hour; the ultrasonic conditions were: temperature 25°C, power 120W, frequency 40KHz.

磺化聚醚醚酮在矿化之前进行空气等离子预处理;等离子处理功率为50~80W,压力为0.3~0.5MPa,处理时间为8~12min。Sulfonated polyetheretherketone is subjected to air plasma pretreatment before mineralization; the plasma treatment power is 50-80W, the pressure is 0.3-0.5MPa, and the treatment time is 8-12min.

步骤2:将步骤1中得到的磺化聚醚醚酮置于加入析出液的矿化液中,进行类骨磷灰石沉积;Step 2: placing the sulfonated polyetheretherketone obtained in

其中析出液为NaHCO3溶液,浓度为20~25mg/mL;矿化液中包括Na+、Cl-、K+、Ca2+、Mg2+和PO43-;其中,Na+浓度为1~1.2mol/L,K+浓度为5~6mmol/L,Ca2+浓度为25~30mmol/L,Mg2+浓度为5~6mmol/L,PO43-浓度为10~12mmol/L,Cl-浓度为1~1.2mol/L;加入析出液的矿化液中,Ca2+、PO43-和CO32-的摩尔比为5:2:3。The eluate is NaHCO3 solution with a concentration of 20-25 mg/mL; the mineralization solution includes Na+ , Cl- , K+ , Ca2+ , Mg2+ and PO43- ; the concentration of Na+ is 1 ~1.2mol/L, K+ concentration is 5~6mmol/L, Ca2+ concentration is 25~30mmol/L, Mg2+ concentration is 5~6mmol/L, PO43- concentration is 10~12mmol/L, The concentration of Cl- is 1~1.2mol/L; the molar ratio of Ca2+ , PO43- and CO32- is 5:2:3 when it is added to the mineralization solution of the eluate.

矿化液中Na+由氯化钠和磷酸二氢钠提供,K+由氯化钾提供,Ca2+由二水氯化钙提供,Mg2+由六水氯化镁提供,PO43-由磷酸二氢钠提供,Cl-由氯化钠、氯化钾、二水氯化钙和六水氯化镁提供。矿化液配置方法如下:In the mineralization solution, Na+ is provided by sodium chloride and sodium dihydrogen phosphate, K+ is provided by potassium chloride, Ca2+ is provided by calcium chloride dihydrate, Mg2+ is provided by magnesium chloride hexahydrate, PO43- is provided by Sodium dihydrogen phosphate is provided, and Cl- is provided by sodium chloride, potassium chloride, calcium chloride dihydrate and magnesium chloride hexahydrate. The mineralization fluid configuration method is as follows:

在搅拌条件下,依次将氯化钠、氯化钾、二水氯化钙、六水氯化镁、磷酸二氢钠溶于水中充分搅拌形成。Under the condition of stirring, sodium chloride, potassium chloride, calcium chloride dihydrate, magnesium chloride hexahydrate, and sodium dihydrogen phosphate are dissolved in water and stirred thoroughly to form.

矿化过程在所述步骤2中矿化过程在37~70℃条件下进行,孵育时间为1~2h;重复孵育过程1~2次。The mineralization process in the step 2 is carried out at 37-70° C., and the incubation time is 1-2 hours; the incubation process is repeated 1-2 times.

实施例1Example 1

一种用于聚醚醚酮的表面类骨磷灰石涂层制备方法,包括以下步骤:A method for preparing a surface bone-like apatite coating for polyetheretherketone, comprising the following steps:

步骤1:将聚醚醚酮片材清洗后,表面磺化处理得到磺化聚醚醚酮;Step 1: after cleaning the polyether ether ketone sheet, sulfonate the surface to obtain sulfonated polyetheretherketone;

将Φ14×2mm的PEEK片材用400目砂纸进行打磨,并依次用丙酮、无水乙醇和去离子水各超声(温度25℃,超声功率120W,超声频率40KHz)清洗10min后,放置高温干燥箱60℃烘干1h后用于后续表面改性。Grind the Φ14×2mm PEEK sheet with 400-mesh sandpaper, and then use acetone, absolute ethanol and deionized water to clean it ultrasonically (temperature 25°C, ultrasonic power 120W, ultrasonic frequency 40KHz) for 10 minutes, and then place it in a high-temperature drying oven. After drying at 60°C for 1 hour, it is used for subsequent surface modification.

在磁力搅拌下,将PEEK片材置于浓硫酸中进行磺化,磺化时间为3-5min。将磺化后的材料置于去离子水中漂洗,待被酸蚀部分充分浸出之后超声(温度25℃,超声功率120W,超声频率40KHz)15-20min,每5min更换去离子水以充分去除表面孔隙结构中残留的硫酸,将充分清洗后的磺化PEEK置于高温干燥箱60℃烘干2h后得到磺化PEEK(PEEK-S)。Under magnetic stirring, place the PEEK sheet in concentrated sulfuric acid for sulfonation, and the sulfonation time is 3-5min. Rinse the sulfonated material in deionized water. After the acid-etched part is fully leached, ultrasonic (temperature 25°C, ultrasonic power 120W, ultrasonic frequency 40KHz) 15-20min, replace deionized water every 5min to fully remove surface pores For sulfuric acid remaining in the structure, place the fully cleaned sulfonated PEEK in a high-temperature drying oven at 60°C for 2 hours to obtain sulfonated PEEK (PEEK-S).

步骤2:将步骤1中得到的磺化聚醚醚酮置于加入析出液的矿化液中,进行类骨磷灰石沉积;Step 2: placing the sulfonated polyetheretherketone obtained in

快速矿化液的配制:在磁力搅拌下,将58.4430g氯化钠,0.3728g氯化钾,3.6754g二水氯化钙,1.0165g六水氯化镁,1.19g磷酸二氢钠依次溶于1000mL去离子水中,在当前药品完全溶解之后再加入下一种药品。配置完成后将快速矿化液置于4℃冰箱保存,在4℃环境下可以保存至少一个月。Preparation of rapid mineralization solution: under magnetic stirring, dissolve 58.4430g sodium chloride, 0.3728g potassium chloride, 3.6754g calcium chloride dihydrate, 1.0165g magnesium chloride hexahydrate, 1.19g sodium dihydrogen phosphate in 1000mL to In ionized water, add the next drug after the current drug is completely dissolved. After the configuration is complete, store the rapid mineralization solution in a 4°C refrigerator, and it can be stored at 4°C for at least one month.

NaHCO3析出液的配制:在矿化液中加入NaHCO3析出液,加入NaHCO3析出液后,混合溶液中NaHCO3的浓度为15mM。在磁力搅拌下,将0.5g碳酸氢钠溶于20mL去离子水中,待药品充分溶解后将其置于室温保存。每100mL快速矿化液在使用前需加入5mLNaHCO3析出液并快速搅拌均匀。Preparation of NaHCO3 eluate: add NaHCO3 eluate to the mineralization solution, after adding NaHCO3 eluate, the concentration of NaHCO3 in the mixed solution is 15mM. Under magnetic stirring, dissolve 0.5g of sodium bicarbonate in 20mL of deionized water, and store it at room temperature after the drug is fully dissolved. Add 5mL of NaHCO3 eluate to each 100mL rapid mineralization solution before use and stir quickly evenly.

将烘干后的磺化PEEK置于等离子清洗机(功率50-80W,压力0.3-0.5mbar)中进行空气等离子体处理,处理时间为8-12min。The dried sulfonated PEEK is placed in a plasma cleaning machine (power 50-80W, pressure 0.3-0.5mbar) for air plasma treatment, and the treatment time is 8-12min.

将等离子体预处理后的PEEK片材立刻置于50mL刚刚加入NaHCO3析出液并搅拌均匀的快速矿化液中,并置于烘箱中进行类骨磷灰石的沉积。可置于50-70℃烘箱中孵育1h,孵育次数为1-2次。孵育结束后,将PEEK取出并轻轻漂洗以去除未充分沉积的类骨磷灰石以及由于加入析出液而在快速矿化液中析出的钙磷盐,得到矿化PEEK(PEEK-M)。The PEEK sheet after plasma pretreatment was immediately placed in 50 mL of rapid mineralization solution that had just been added with NaHCO3 precipitation solution and stirred evenly, and placed in an oven for bone-like apatite deposition. It can be incubated in an oven at 50-70°C for 1 hour, and the number of incubations is 1-2 times. After the incubation, the PEEK was taken out and gently rinsed to remove insufficiently deposited bone-like apatite and calcium and phosphorus salts precipitated in the rapid mineralization solution due to the addition of the eluate, and mineralized PEEK (PEEK-M) was obtained.

为了观察矿化PEEK表面类骨磷灰石层的均匀性,我们对材料进行了喷金处理。PEEK和PEEK-S均呈现出明显的金黄色,同时在PEEK-S表面还可以观察到浓硫酸的腐蚀痕迹。根据我们的经验,类骨磷灰石在喷金后会明显变黑,由此可以证明PEEK-M表面存在一层均匀的类骨磷灰石涂层。In order to observe the uniformity of the bone-like apatite layer on the surface of mineralized PEEK, we sprayed gold on the material. Both PEEK and PEEK-S exhibited an obvious golden yellow color, and corrosion traces of concentrated sulfuric acid could also be observed on the surface of PEEK-S. According to our experience, bone-like apatite will obviously turn black after spraying gold, which can prove that there is a uniform layer of bone-like apatite coating on the surface of PEEK-M.

图1为实施例1聚醚醚酮PEEK、磺化聚醚醚酮PEEK-S和覆盖了涂层的聚醚醚酮PEEK-M的SEM图。由SEM结果可知,PEEK表面存在一定方向性的划痕,这是因为PEEK在使用前用砂纸进行了打磨;磺化后的PEEK由于在均质环境下受到浓硫酸的腐蚀产生了微纳米级的互连孔隙结构;矿化后的PEEK表面均匀的覆盖了一层类骨磷灰石。Fig. 1 is an SEM image of polyether ether ketone PEEK, sulfonated polyetherether ketone PEEK-S and coated polyetherether ketone PEEK-M in Example 1. It can be seen from the SEM results that there are certain directional scratches on the surface of PEEK, which is because PEEK was polished with sandpaper before use; the sulfonated PEEK produced micro-nano-scale scratches due to the corrosion of concentrated sulfuric acid in a homogeneous environment. Interconnected pore structure; the surface of mineralized PEEK is evenly covered with a layer of bone-like apatite.

图2为实施例1聚醚醚酮PEEK、磺化聚醚醚酮PEEK-S和覆盖了涂层的聚醚醚酮PEEK-M的水接触角测试结果。从图中可以看出纯PEEK本身呈疏水性,其接触角为96.2±1.5°,磺化后的PEEK接触角(88.8±2.4°)相较于纯PEEK略微有所下降并存在显著性差异,矿化后的PEEK呈超亲水性,接触角接近0°,在测试时纯水一经滴落便迅速摊开,没有测得有效的接触角数据Fig. 2 is the water contact angle test results of polyetheretherketone PEEK, sulfonated polyetheretherketone PEEK-S and coated polyetheretherketone PEEK-M in Example 1. It can be seen from the figure that pure PEEK itself is hydrophobic, and its contact angle is 96.2±1.5°. The contact angle of sulfonated PEEK (88.8±2.4°) is slightly lower than that of pure PEEK and there is a significant difference. The mineralized PEEK is super-hydrophilic, and the contact angle is close to 0°. During the test, the pure water spreads out as soon as it drops, and there is no effective contact angle data measured.

图3为实施例1聚醚醚酮PEEK、磺化聚醚醚酮PEEK-S和覆盖了涂层的聚醚醚酮PEEK-M的XRD测试结果。由XRD衍射测试所得数据可知,PEEK和PEEK-S的衍射峰一致,而PEEK-M的衍射峰除了含有PEEK本身的衍射峰之外,在25.4°左右发现具有与类骨磷灰石相似的特征峰,证明PEEK-M表面存在类骨磷灰石。Fig. 3 is the XRD test results of polyetheretherketone PEEK, sulfonated polyetheretherketone PEEK-S and coated polyetheretherketone PEEK-M in Example 1. According to the data obtained from XRD diffraction test, the diffraction peaks of PEEK and PEEK-S are consistent, while the diffraction peaks of PEEK-M are similar to those of bone-like apatite at around 25.4° except for the diffraction peaks of PEEK itself. , proving the presence of bone-like apatite on the surface of PEEK-M.

图4为实施例1中聚醚醚酮PEEK、磺化聚醚醚酮PEEK-S和覆盖了涂层的聚醚醚酮PEEK-M的FT-IR测试结果。从图中可以看出,与PEEK相比,PEEK-S在1050cm-1附近出现了对应S=O官能团的吸收峰,这证明PEEK表面发生了磺化反应并引入了磺酸基团。与PEEK和PEEK-S相比,PEEK-M在1026cm-1出现了对应磷酸基团的强烈特征峰,这意味着类骨磷灰石引入了材料表面。Fig. 4 is the FT-IR test results of polyetheretherketone PEEK, sulfonated polyetheretherketone PEEK-S and coated polyetheretherketone PEEK-M in Example 1. It can be seen from the figure that, compared with PEEK, PEEK-S has an absorption peak corresponding to the S=O functional group around 1050 cm-1 , which proves that a sulfonation reaction has occurred on the surface of PEEK and a sulfonic acid group has been introduced. Compared with PEEK and PEEK-S, PEEK-M has a strong characteristic peak corresponding to the phosphate group at 1026 cm-1 , which means that bone-like apatite has been introduced into the surface of the material.

采用本实施例得到的材料(聚醚醚酮PEEK、磺化聚醚醚酮PEEK-S和覆盖了涂层的聚醚醚酮PEEK-M)分别进行细胞形态观察和增殖实验,采用的细胞为小鼠胚胎成骨细胞前体细胞MC3T3-E1。采用直接培养的方式进行培养,细胞密度为4×104个/孔。The materials obtained in this example (polyether ether ketone PEEK, sulfonated polyetherether ketone PEEK-S and polyetherether ketone PEEK-M covered with coating) were used for cell morphology observation and proliferation experiments, and the cells used were Mouse embryonic osteoblast precursor cells MC3T3-E1. The culture was carried out by direct culture, and the cell density was 4×104 cells/well.

材料与细胞共培养一天后,吸出培养基并用PBS润洗两遍,然后在4℃下用4%多聚甲醛固定过夜。过夜后,用体积浓度为30%、50%、70%、80%、90%、95%和100%的乙醇进行梯度脱水(每种浓度15分钟),脱水后进行临界点干燥,然后喷金进行材料表面细胞形貌的观察。结果如图6所示,从图中可以看出,不同材料表面的MC3T3-E1细胞均向四周伸出伪足并充分在材料表面粘附。One day after the material was co-cultured with the cells, the medium was aspirated and rinsed twice with PBS, and then fixed overnight at 4°C with 4% paraformaldehyde. After overnight, carry out gradient dehydration with ethanol with a volume concentration of 30%, 50%, 70%, 80%, 90%, 95% and 100% (15 minutes for each concentration), perform critical point drying after dehydration, and then spray gold Observation of cell morphology on the surface of the material. The results are shown in Figure 6. It can be seen from the figure that the MC3T3-E1 cells on the surface of different materials protruded pseudopodia and fully adhered to the surface of the material.

采用本实施例得到的材料(聚醚醚酮PEEK、磺化聚醚醚酮PEEK-S和覆盖了涂层的聚醚醚酮PEEK-M)分别与细胞共培养1/3/5天后,吸出培养基并用PBS润洗两遍,然后用0.1%FDA/PI染色液进行染色,染色2分钟后置于激光共聚焦显微镜下进行观察。The materials obtained in this example (polyetheretherketone PEEK, sulfonated polyetheretherketone PEEK-S and coated polyetheretherketone PEEK-M) were co-cultured with cells for 1/3/5 days, and then sucked out The culture medium was rinsed twice with PBS, and then stained with 0.1% FDA/PI staining solution, and observed under a laser confocal microscope after staining for 2 minutes.

如图7所示,从图中可以看出,随着培养时间的增加,不同材料表面的MC3T3-E1在培养中正常增殖且没有出现死细胞,说明改性后的材料具有良好的细胞相容性。As shown in Figure 7, it can be seen from the figure that as the culture time increases, MC3T3-E1 on the surface of different materials proliferates normally in culture and no dead cells appear, indicating that the modified material has good cytocompatibility sex.

实施例2Example 2

一种用于聚醚醚酮的表面类骨磷灰石涂层制备方法,包括以下步骤:A method for preparing a surface bone-like apatite coating for polyetheretherketone, comprising the following steps:

步骤1:将聚醚醚酮片材清洗后,表面磺化处理得到磺化聚醚醚酮;Step 1: after cleaning the polyether ether ketone sheet, sulfonate the surface to obtain sulfonated polyetheretherketone;

将Φ14×2mm的PEEK片材用400目砂纸进行打磨,并依次用丙酮、无水乙醇和去离子水各超声(温度25℃,超声功率120W,超声频率40KHz)清洗10min后,放置高温干燥箱60℃烘干1h后用于后续表面改性。Grind the Φ14×2mm PEEK sheet with 400-mesh sandpaper, and then use acetone, absolute ethanol and deionized water to clean it ultrasonically (temperature 25°C, ultrasonic power 120W, ultrasonic frequency 40KHz) for 10 minutes, and then place it in a high-temperature drying oven. After drying at 60°C for 1 hour, it is used for subsequent surface modification.

在磁力搅拌下,将PEEK片材置于浓硫酸中进行磺化,磺化时间为3-5min。将磺化后的材料置于去离子水中漂洗,待被酸蚀部分充分浸出之后超声(温度25℃,超声功率120W,超声频率40KHz)15-20min,每5min更换去离子水以充分去除表面孔隙结构中残留的硫酸,将充分清洗后的磺化PEEK置于高温干燥箱60℃烘干2h后得到磺化PEEK(PEEK-S)。Under magnetic stirring, place the PEEK sheet in concentrated sulfuric acid for sulfonation, and the sulfonation time is 3-5min. Rinse the sulfonated material in deionized water. After the acid-etched part is fully leached, ultrasonic (temperature 25°C, ultrasonic power 120W, ultrasonic frequency 40KHz) 15-20min, replace deionized water every 5min to fully remove surface pores For sulfuric acid remaining in the structure, place the fully cleaned sulfonated PEEK in a high-temperature drying oven at 60°C for 2 hours to obtain sulfonated PEEK (PEEK-S).

步骤2:将步骤1中得到的磺化聚醚醚酮置于加入析出液的矿化液中,进行类骨磷灰石沉积;Step 2: placing the sulfonated polyetheretherketone obtained in

快速矿化液的配制:在磁力搅拌下,将58.4430g氯化钠,0.3728g氯化钾,3.6754g二水氯化钙,1.0165g六水氯化镁,1.19g磷酸二氢钠依次溶于1000mL去离子水中,在当前药品完全溶解之后再加入下一种药品。配置完成后将快速矿化液置于4℃冰箱保存,在4℃环境下可以保存至少一个月。Preparation of rapid mineralization solution: under magnetic stirring, dissolve 58.4430g sodium chloride, 0.3728g potassium chloride, 3.6754g calcium chloride dihydrate, 1.0165g magnesium chloride hexahydrate, 1.19g sodium dihydrogen phosphate in 1000mL to In ionized water, add the next drug after the current drug is completely dissolved. After the configuration is complete, store the rapid mineralization solution in a 4°C refrigerator, and it can be stored at 4°C for at least one month.

NaHCO3析出液的配制:在矿化液中加入NaHCO3析出液,加入NaHCO3析出液后,混合溶液中NaHCO3的浓度为12mM。在磁力搅拌下,将0.4g碳酸氢钠溶于20mL去离子水中,待药品充分溶解后将其置于室温保存。每100mL快速矿化液在使用前需加入5mL NaHCO3析出液并快速搅拌均匀。Preparation of NaHCO3 eluate: add NaHCO3 eluate to the mineralization solution, after adding NaHCO3 eluate, the concentration of NaHCO3 in the mixed solution is 12mM. Under magnetic stirring, dissolve 0.4g of sodium bicarbonate in 20mL of deionized water, and store it at room temperature after the drug is fully dissolved. Add 5mL of NaHCO3 eluate to every 100mL of rapid mineralization solution and stir quickly before use.

将烘干后的磺化PEEK置于等离子清洗机(功率50-80W,压力0.3-0.5mbar)中进行空气等离子体处理,处理时间为8-12min。The dried sulfonated PEEK is placed in a plasma cleaning machine (power 50-80W, pressure 0.3-0.5mbar) for air plasma treatment, and the treatment time is 8-12min.

将等离子体预处理后的PEEK片材立刻置于50mL刚刚加入NaHCO3析出液并搅拌均匀的快速矿化液中,并置于烘箱中进行类骨磷灰石的沉积。可置于50-70℃烘箱中孵育1.5h,孵育次数为1-2次。孵育结束后,将PEEK取出并轻轻漂洗以去除未充分沉积的类骨磷灰石以及由于加入析出液而在快速矿化液中析出的钙磷盐,得到矿化PEEK(PEEK-M)。The PEEK sheet after plasma pretreatment was immediately placed in 50 mL of rapid mineralization solution that had just been added with NaHCO3 precipitation solution and stirred evenly, and placed in an oven for bone-like apatite deposition. It can be incubated in an oven at 50-70°C for 1.5h, and the number of incubations is 1-2 times. After the incubation, the PEEK was taken out and gently rinsed to remove insufficiently deposited bone-like apatite and calcium and phosphorus salts precipitated in the rapid mineralization solution due to the addition of the eluate, and mineralized PEEK (PEEK-M) was obtained.

实施例3Example 3

一种用于聚醚醚酮的表面类骨磷灰石涂层制备方法,包括以下步骤:A method for preparing a surface bone-like apatite coating for polyetheretherketone, comprising the following steps:

步骤1:将聚醚醚酮片材清洗后,表面磺化处理得到磺化聚醚醚酮;Step 1: after cleaning the polyether ether ketone sheet, sulfonate the surface to obtain sulfonated polyetheretherketone;

将Φ14×2mm的PEEK片材用400目砂纸进行打磨,并依次用丙酮、无水乙醇和去离子水各超声(温度25℃,超声功率120W,超声频率40KHz)清洗10min后,放置高温干燥箱60℃烘干1h后用于后续表面改性。Grind the Φ14×2mm PEEK sheet with 400-mesh sandpaper, and then use acetone, absolute ethanol and deionized water to clean it ultrasonically (temperature 25°C, ultrasonic power 120W, ultrasonic frequency 40KHz) for 10 minutes, and then place it in a high-temperature drying oven. After drying at 60°C for 1 hour, it is used for subsequent surface modification.

在磁力搅拌下,将PEEK片材置于浓硫酸中进行磺化,磺化时间为3-5min。将磺化后的材料置于去离子水中漂洗,待被酸蚀部分充分浸出之后超声(温度25℃,超声功率120W,超声频率40KHz)15-20min,每5min更换去离子水以充分去除表面孔隙结构中残留的硫酸,将充分清洗后的磺化PEEK置于高温干燥箱60℃烘干2h后得到磺化PEEK(PEEK-S)。Under magnetic stirring, place the PEEK sheet in concentrated sulfuric acid for sulfonation, and the sulfonation time is 3-5min. Rinse the sulfonated material in deionized water. After the acid-etched part is fully leached, ultrasonic (temperature 25°C, ultrasonic power 120W, ultrasonic frequency 40KHz) 15-20min, replace deionized water every 5min to fully remove surface pores For sulfuric acid remaining in the structure, place the fully cleaned sulfonated PEEK in a high-temperature drying oven at 60°C for 2 hours to obtain sulfonated PEEK (PEEK-S).

步骤2:将步骤1中得到的磺化聚醚醚酮置于加入析出液的矿化液中,进行类骨磷灰石沉积;Step 2: placing the sulfonated polyetheretherketone obtained in

快速矿化液的配制:在磁力搅拌下,将58.4430g氯化钠,0.3728g氯化钾,3.6754g二水氯化钙,1.0165g六水氯化镁,1.19g磷酸二氢钠依次溶于1000mL去离子水中,在当前药品完全溶解之后再加入下一种药品。配置完成后将快速矿化液置于4℃冰箱保存,在4℃环境下可以保存至少一个月。Preparation of rapid mineralization solution: under magnetic stirring, dissolve 58.4430g sodium chloride, 0.3728g potassium chloride, 3.6754g calcium chloride dihydrate, 1.0165g magnesium chloride hexahydrate, 1.19g sodium dihydrogen phosphate in 1000mL to In ionized water, add the next drug after the current drug is completely dissolved. After the configuration is complete, store the rapid mineralization solution in a 4°C refrigerator, and it can be stored at 4°C for at least one month.

NaHCO3析出液的配制:在矿化液中加入NaHCO3析出液,加入NaHCO3析出液后,混合溶液中NaHCO3的浓度为15mM。在磁力搅拌下,将0.5g碳酸氢钠溶于20mL去离子水中,待药品充分溶解后将其置于室温保存。每100mL快速矿化液在使用前需加入5mL NaHCO3析出液并快速搅拌均匀。Preparation of NaHCO3 eluate: add NaHCO3 eluate to the mineralization solution, after adding NaHCO3 eluate, the concentration of NaHCO3 in the mixed solution is 15mM. Under magnetic stirring, dissolve 0.5g of sodium bicarbonate in 20mL of deionized water, and store it at room temperature after the drug is fully dissolved. Add 5mL of NaHCO3 eluate to every 100mL of rapid mineralization solution and stir quickly before use.

将烘干后的磺化PEEK置于等离子清洗机(功率50-80W,压力0.3-0.5mbar)中进行空气等离子体处理,处理时间为8-12min。The dried sulfonated PEEK is placed in a plasma cleaning machine (power 50-80W, pressure 0.3-0.5mbar) for air plasma treatment, and the treatment time is 8-12min.

将等离子体预处理后的PEEK片材立刻置于50mL刚刚加入NaHCO3析出液并搅拌均匀的快速矿化液中,并置于烘箱中进行类骨磷灰石的沉积。首先在37℃烘箱中孵育1h;然后在60℃烘箱中孵育30min,期间不更换溶液,孵育次数为1次。孵育结束后,将PEEK取出并轻轻漂洗以去除未充分沉积的类骨磷灰石以及由于加入析出液而在快速矿化液中析出的钙磷盐,得到矿化PEEK(PEEK-M)。The PEEK sheet after plasma pretreatment was immediately placed in 50 mL of rapid mineralization solution that had just been added with NaHCO3 precipitation solution and stirred evenly, and placed in an oven for bone-like apatite deposition. First incubate in an oven at 37°C for 1 h; then incubate in an oven at 60°C for 30 min, during which the solution is not replaced, and the number of incubations is 1 time. After the incubation, the PEEK was taken out and gently rinsed to remove insufficiently deposited bone-like apatite and calcium and phosphorus salts precipitated in the rapid mineralization solution due to the addition of the eluate, and mineralized PEEK (PEEK-M) was obtained.

多孔形貌和亲水性有利于类骨磷灰石的沉积并提高涂层的稳定性,多孔形貌可以为类骨磷灰石的形成提供充分的成核位点,而较好的亲水性有利于矿化液与材料表面进行相互作用从而诱导沉积。本发明将化学处理、等离子体处理和仿生矿化沉积工艺进行有机整合,形成一种PEEK表面快速磷灰石涂层制备方法。The porous morphology and hydrophilicity are conducive to the deposition of bone-like apatite and improve the stability of the coating. The porous morphology can provide sufficient nucleation sites for the formation of bone-like apatite, and the better hydrophilic The properties are conducive to the interaction between the mineralizing fluid and the surface of the material to induce deposition. The invention organically integrates chemical treatment, plasma treatment and biomimetic mineralization deposition process to form a rapid apatite coating preparation method on the PEEK surface.

首先通过磺化工艺制备表面多孔聚醚醚酮,由于聚醚醚酮会受到浓硫酸的快速腐蚀,且磺化部分在水中具有溶解性,因此将浸泡过浓硫酸的聚醚醚酮置于水中清洗时,磺化部分会迅速溶解并浸出,由于腐蚀和浸出的双重作用,可以在聚醚醚酮表面形成微纳米级的互连孔隙结构(图1)。为了提高表面孔隙结构与矿化液的相互作用,发明人对磺化聚醚醚酮进行了空气等离子体预处理,在高能粒子的轰击下,在保留原有孔隙形貌的同时,使表面磺化聚醚醚酮在短时间内具备超亲水性,使得后续的矿化处理时矿化液能够快速渗入表面的互连孔中并迅速形核发生矿化。Firstly, surface porous polyether ether ketone was prepared by sulfonation process. Since polyether ether ketone would be corroded rapidly by concentrated sulfuric acid, and the sulfonated part was soluble in water, the polyether ether ketone soaked in concentrated sulfuric acid was placed in water When cleaning, the sulfonated part will dissolve and leach out quickly, and due to the dual effects of corrosion and leaching, a micro-nano-scale interconnected pore structure can be formed on the surface of PEEK (Figure 1). In order to improve the interaction between the surface pore structure and the mineralization fluid, the inventors carried out air plasma pretreatment on the sulfonated polyether ether ketone, under the bombardment of high-energy particles, while retaining the original pore morphology, the surface Polyetheretherketone has super-hydrophilicity in a short period of time, so that the mineralization liquid can quickly penetrate into the interconnected pores on the surface during the subsequent mineralization treatment, and quickly nucleate and mineralize.

为了增加PEEK表面类骨磷灰石的形成速率,提供了一种快速矿化液和析出液配方,快速矿化液由Na+、Cl-、K+、Ca2+、Mg2+和PO43-组成(优选Na+:Cl-:K+:Ca2+:Mg2+:PO43-=202:213:1:5:1:2),析出液由NaHCO3配制而成,快速矿化液是一种非常稳定的体系,可置于4℃冰箱长期保存,在快速矿化液中加入析出液后CO32-会迅速与Ca2+、PO43-等发生相互作用,并生成沉淀,将PEEK片材与加入析出液后的快速矿化液共孵育,可在短时间内于PEEK表面形成类骨磷灰石涂层。In order to increase the formation rate of bone-like apatite on the surface of PEEK, a rapid mineralization solution and precipitation solution formula is provided. The rapid mineralization solution is composed of Na+ , Cl- , K+ , Ca2+ , Mg2+ and PO43- composition (preferably Na+ :Cl- :K+ :Ca2+ :Mg2+ :PO43- = 202:213:1:5:1:2), the eluate is prepared from NaHCO3 , fast The mineralization solution is a very stable system, which can be stored in a 4°C refrigerator for a long time. After adding the eluate to the rapid mineralization solution, CO32- will quickly interact with Ca2+ , PO43- , etc. And to generate precipitation, the PEEK sheet is co-incubated with the rapid mineralization solution after adding the eluate, and a bone-like apatite coating can be formed on the PEEK surface in a short time.

在用SBF或者类似的仿生矿化液进行材料矿化时,有多种因素影响矿化速率。除了材料本身的特性影响矿化效果之外,总的来说,矿化液的体系越不稳定,则钙、磷离子越容易析出并在材料表面发生矿化,矿化速率也越快,但是不稳定的体系同时也会导致整个反应难以控制并降低材料制备的可重复性。在常规的SBF制备过程中,CO32-的加入至关重要,一方面在加入CO32-时,CO32-很容易与溶液中的Ca2+和PO43-相互作用并发生沉淀,同时CO32-的加入还会提高溶液的整体pH值,这同样也会导致溶液体系不稳定。所以一般在配制SBF时,在引入Ca2+这一步需要同时加入稀盐酸来调节pH以防止溶液发生沉淀。在配制10倍SBF时,若按照配制SBF所需药品的10倍用量进行配制则不可能制备出澄清的溶液,过量的CO32-、Ca2+和PO43-之间会相互作用并迅速沉淀,已有的方法是先配制出高浓度的Ca2+和PO43-溶液,但不添加CO32-,这种体系呈弱酸性,非常稳定且能在4°冰箱保存相当长的时间,在使用前加入10mM NaHCO3粉末并溶解均匀,则整个体系由于CO32-的加入和溶液pH值的上升而迅速发生矿化。When using SBF or similar biomimetic mineralization fluids for material mineralization, there are many factors that affect the mineralization rate. In addition to the influence of the characteristics of the material itself on the mineralization effect, in general, the more unstable the system of the mineralization solution, the easier it is for calcium and phosphorus ions to precipitate and mineralize on the surface of the material, and the faster the mineralization rate is, but An unstable system can also lead to difficulty in controlling the overall reaction and reduce the reproducibility of material preparation. In the conventional SBF preparation process, the addition of CO32- is very important. On the one hand, when CO32- is added, CO32- can easily interact with Ca2+ and PO43- in the solution and generate Precipitation, and the addition of CO32- will also increase the overall pH value of the solution, which will also lead to instability of the solution system. Therefore, when preparing SBF, it is necessary to add dilute hydrochloric acid to adjust the pH at the same time as the step of introducing Ca2+ to prevent precipitation of the solution. When preparing 10 times SBF, it is impossible to prepare a clear solution if it is prepared according to 10 times the amount of the drug required for the preparation of SBF, and the excess CO32- , Ca2+ and PO43- will interact and Rapid precipitation, the existing method is to prepare a high concentration of Ca2+ and PO43- solution first, but without adding CO32- , this system is weakly acidic, very stable and can be stored in a 4° refrigerator for a long time Before use, add 10mM NaHCO3 powder and dissolve evenly, then the whole system will rapidly mineralize due to the addition of CO32- and the rise of the pH value of the solution.

但是现有方法在实际操作中存在很大问题:But the existing method has big problems in actual operation:

1)受室温影响大,在冬季和夏季加入NaHCO3粉末后会发现溶液矿化的速率有很大的差异1) It is greatly affected by room temperature. After adding NaHCO3 powder in winter and summer, it will be found that the mineralization rate of the solution is very different

2)受待矿化溶液的体积影响较大,如在50mL矿化液中加入NaHCO3粉末和在500mL矿化液中加入对应量的NaHCO3粉末,两者的矿化速率相差很大,待矿化溶液的体积越大,则矿化速率越快,此时可能尚未加入材料则溶液本身就已经出现大量沉淀了。2) It is greatly affected by the volume of the mineralization solution. For example, adding NaHCO3 powder to 50mL mineralization solution and adding a corresponding amount of NaHCO3 powder to 500mL mineralization solution, the mineralization rate of the two is very different. The larger the volume of the mineralization solution, the faster the mineralization rate. At this time, there may be a large amount of precipitation in the solution itself before adding materials.

3)依照该浓度加入NaHCO3粉末后,除了会在材料表面出现类骨磷灰石相,还会出现大量的DCPD/DCPA(磷酸氢钙)相,表现为巨晶形式(图5),这对于整个涂层的机械稳定性和生物活性存在负面影响。3) After adding NaHCO3 powder according to this concentration, in addition to the bone-like apatite phase appearing on the surface of the material, a large amount of DCPD/DCPA (calcium hydrogen phosphate) phase will also appear in the form of giant crystals (Fig. 5). There is a negative effect on the mechanical stability and biological activity of the entire coating.

在现有技术存在上述问题的前提下对制备方法进行改进;加入NaHCO3粉末后溶液矿化的不稳定性是由于NaHCO3粉末状态导致的。在搅拌状态下加入不同量的NaHCO3粉末基于粉末从固体形式到溶解后的离子形式存在一定的过程,在这个过程中,不同量的NaHCO3粉末可能导致气液界面处局部溶液的CO32-浓度与溶液内部相比存在很大差异,浓度过高可能导致连锁反应并造成体系的过快沉淀。因此我们采用了等浓度的溶液形式的NaHCO3进行添加并矿化,使得整个体系中各处的CO32-在很短时间内达到均衡。The preparation method is improved on the premise of the above-mentioned problems in the prior art; the instability of solution mineralization after adding NaHCO3 powder is caused by the state of NaHCO3 powder. Adding different amounts of NaHCO3 powder in a stirring state is based on the fact that there is a certain process of the powder from solid form to dissolved ion form, and in this process, different amounts of NaHCO3 powder may cause CO32 in the local solution at the gas-liquid interface- There is a big difference in the concentration compared with the inside of the solution, too high a concentration may cause a chain reaction and cause too fast precipitation of the system. Therefore, we used NaHCO3 in the form of an equal concentration solution to add and mineralize, so that the CO32- in the whole system reached equilibrium in a short time.

为了避免DCPD/DCPA相的形成,设置了配比为特定组成的矿化液和析出液;将添加的NaHCO3换为等量的Tris,由于体系的pH值升高,溶液同样发生了沉淀,但由于缺乏CO32-,沉淀仅由DCPD/DCPA相构成;将矿化液和材料的孵育温度由37℃改为60℃,DCPD/DCPA相的比例明显下降;将NaHCO3析出液的浓度由10mM增加至15mM,希望在保证体系稳定的同时Ca2+和PO43-更倾向于与CO32-相互作用从而形成类骨磷灰石。在整个矿化过程中,类骨磷灰石相和DCPD/DCPA相的析出存在一定程度的竞争关系,本发明中特定的参数可以促进类骨磷灰石相的析出,相应的DCPD/DCPA相就会减少甚至不会析出。In order to avoid the formation of the DCPD/DCPA phase, a mineralization solution and a precipitation solution with a specific composition were set; the added NaHCO3 was replaced with an equal amount of Tris, and the solution also precipitated due to the increase in the pH value of the system. However, due to the lack of CO32- , the precipitate was only composed of DCPD/DCPA phase; changing the incubation temperature of mineralization solution and materials from 37°C to 60°C, the ratio of DCPD/DCPA phase decreased significantly; changing the concentration of NaHCO3 eluate Increasing from 10mM to 15mM, it is hoped that Ca2+ and PO43- are more inclined to interact with CO32- to form bone-like apatite while ensuring the stability of the system. During the whole mineralization process, there is a certain degree of competition between the precipitation of bone-like apatite phase and DCPD/DCPA phase. Specific parameters in the present invention can promote the precipitation of bone-like apatite phase, and the corresponding DCPD/DCPA phase It will reduce or even not precipitate.

本发明可以在聚醚醚酮表面形成微纳米级互连孔隙结构,并且制备工艺简单;采用空气等离子体预处理,在保留原有孔隙形貌的同时,可以使上表面磺化聚醚醚酮在短时间内具备超亲水性,使得后续矿化处理时矿化液能够快速渗入表面的互连孔中并迅速形核发生矿化;提供一种矿化液和析出液,其中矿化液是非常稳定的体系,可在4℃条件下长期保存;析出液和矿化液混合后发生相互作用,进行快速矿化,形成类骨磷灰石涂层。The invention can form micro-nano interconnected pore structures on the surface of polyether ether ketone, and the preparation process is simple; air plasma pretreatment is adopted, while retaining the original pore morphology, the upper surface can be sulfonated polyether ether ketone It has super-hydrophilicity in a short period of time, so that the mineralizing liquid can quickly penetrate into the interconnected pores on the surface and quickly nucleate and mineralize during the subsequent mineralization treatment; provide a mineralizing liquid and a precipitated liquid, in which the mineralizing liquid It is a very stable system, which can be stored for a long time at 4°C; the eluate and the mineralization solution interact with each other after mixing, and undergo rapid mineralization to form a bone-like apatite coating.

Claims (9)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211361688.7ACN115612154B (en) | 2022-11-02 | 2022-11-02 | Surface bone-like apatite coating for polyether-ether-ketone and preparation method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211361688.7ACN115612154B (en) | 2022-11-02 | 2022-11-02 | Surface bone-like apatite coating for polyether-ether-ketone and preparation method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN115612154Atrue CN115612154A (en) | 2023-01-17 |

| CN115612154B CN115612154B (en) | 2023-09-05 |

Family

ID=84876238

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211361688.7AActiveCN115612154B (en) | 2022-11-02 | 2022-11-02 | Surface bone-like apatite coating for polyether-ether-ketone and preparation method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115612154B (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116785032A (en)* | 2023-06-26 | 2023-09-22 | 四川大学 | An osteoinductive polyaryl ether ketone intervertebral fusion device and its preparation method |

| CN117659483A (en)* | 2023-12-11 | 2024-03-08 | 四川大学 | Polyaryletherketone with surface having multistage interconnected pore structure, preparation method and application |

| CN119463284A (en)* | 2025-01-10 | 2025-02-18 | 成都大学 | Method for preparing microporous polyetheretherketone biomaterials by 3D metal printing |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101698114A (en)* | 2009-10-21 | 2010-04-28 | 天津大学 | Surface bioactive calcium-phosphate layer of carbon fiber reinforced polyetheretherketone composite material and preparation thereof |

| US20180339082A1 (en)* | 2017-05-23 | 2018-11-29 | Bioalpha Corporation | Polyether ether ketone surface-modified with hydroxyapatite |

| CN109364296A (en)* | 2018-10-23 | 2019-02-22 | 大连理工大学 | Surface-modified polyarylether-based bone implant material containing naphthalenone biphenyl structure and preparation method thereof |

| CN111184913A (en)* | 2020-01-13 | 2020-05-22 | 吉林大学 | Artificial bone composite material based on polyether-ether-ketone and preparation method thereof |

- 2022

- 2022-11-02CNCN202211361688.7Apatent/CN115612154B/enactiveActive

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101698114A (en)* | 2009-10-21 | 2010-04-28 | 天津大学 | Surface bioactive calcium-phosphate layer of carbon fiber reinforced polyetheretherketone composite material and preparation thereof |

| US20180339082A1 (en)* | 2017-05-23 | 2018-11-29 | Bioalpha Corporation | Polyether ether ketone surface-modified with hydroxyapatite |

| CN109364296A (en)* | 2018-10-23 | 2019-02-22 | 大连理工大学 | Surface-modified polyarylether-based bone implant material containing naphthalenone biphenyl structure and preparation method thereof |

| CN111184913A (en)* | 2020-01-13 | 2020-05-22 | 吉林大学 | Artificial bone composite material based on polyether-ether-ketone and preparation method thereof |

Non-Patent Citations (2)

| Title |

|---|

| YUXIANG ZHANG ET AL.: "Enhanced osteogenic activity and antibacterial performance in vitro of polyetheretherketone by plasma-induced graft polymerization of acrylic acid and incorporation of zinc ions", 《JOURNAL OF MATERIALS CHEMISTRY B》, vol. 9, pages 7506 - 7515* |

| 成沁雯 等: "不同磺化及碱处理聚醚醚酮的表面化学组成及体外生物活性评价", 《高等学校化学学报》, vol. 40, no. 8, pages 1757 - 1765* |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116785032A (en)* | 2023-06-26 | 2023-09-22 | 四川大学 | An osteoinductive polyaryl ether ketone intervertebral fusion device and its preparation method |

| CN117659483A (en)* | 2023-12-11 | 2024-03-08 | 四川大学 | Polyaryletherketone with surface having multistage interconnected pore structure, preparation method and application |

| CN119463284A (en)* | 2025-01-10 | 2025-02-18 | 成都大学 | Method for preparing microporous polyetheretherketone biomaterials by 3D metal printing |

Also Published As

| Publication number | Publication date |

|---|---|

| CN115612154B (en) | 2023-09-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN115612154B (en) | Surface bone-like apatite coating for polyether-ether-ketone and preparation method thereof | |

| CN101984144B (en) | Surface mount method of mineralized collagen gradient coating for medical titanium implant | |

| CN101545109A (en) | A kind of titanium or titanium alloy with surface bioactive layer and preparation method thereof | |

| CN106011815B (en) | Preparation method for the hybridization compounding coating that magnesium-based biomaterial surface is modified | |

| CN104888271A (en) | Method for preparing strontium-containing hydroxyapatite coating on surface of biodegradable magnesium alloy | |

| CN105420789A (en) | Hydrophobic composite biological activity coating on surface of pure-magnesium or magnesium alloy and preparation method of hydrophobic composite biological activity coating | |

| CN105536062A (en) | Method for preparing silicon-doped hydroxyapatite nanofiber bioactive coating | |

| CN106958014A (en) | The method for building organic inorganic hybridization function and service coating in pure magnesium surface | |

| CN101949046B (en) | Preparation method of carbonate hydroxyapatite/carbon nano tube composite coating material | |

| CN113616852A (en) | Magnesium powder/calcium phosphate composite bone cement material and preparation method thereof | |

| CN102094227A (en) | Electrochemical method for preparing chitosan/silk fibroin composite coating on surface of titanium implant | |

| CN103498184B (en) | A kind of biological medical magnesium alloy differential of the arc electrophoresis method of modifying | |

| CN109364296A (en) | Surface-modified polyarylether-based bone implant material containing naphthalenone biphenyl structure and preparation method thereof | |

| CN102389588B (en) | Magnesium or magnesium alloy material used for biological implantation and preparation method thereof | |

| CN104746120B (en) | Carbon/carbon compound material containing bioactivity calcium phosphate coating and preparation method thereof | |

| CN105420796B (en) | The modified coating and preparation method of magnesium-based surface carbon nanotubes-hydroxyapatite | |

| CN100430099C (en) | A kind of bioactive coating on titanium or titanium alloy surface and preparation method thereof | |

| CN112126926B (en) | Preparation method of titanium surface-modified nanostructures simultaneously loaded with bioactive zinc ions | |

| CN107338425A (en) | A kind of preparation method of the titanium surface bioactivity conversion film of phosphate containing strontium | |

| CN114848897B (en) | Porous hydroxyapatite-hydrotalcite composite material and preparation method and application thereof | |

| CN103938246A (en) | Electrochemical method for preparing strontium-doped hydroxyapatite ridge rodlike structure coating on titanium surface | |

| CN103628119A (en) | Preparation method for bionic porous octacalcium phosphate/silk fibroin composite film layer | |

| CN104790007B (en) | The preparation method of the mineralized collagen coating of medical metal implant surfaces | |

| CN109646717B (en) | Magnesium alloy surface nano hydroxyapatite coating based on ultrasound and preparation method thereof | |

| CN110819865A (en) | Preparation method of Nb-Ta-Ti-Si biomedical composite material with surface activity |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |