CN115607009A - Air fryer and how it works - Google Patents

Air fryer and how it worksDownload PDFInfo

- Publication number

- CN115607009A CN115607009ACN202211103824.2ACN202211103824ACN115607009ACN 115607009 ACN115607009 ACN 115607009ACN 202211103824 ACN202211103824 ACN 202211103824ACN 115607009 ACN115607009 ACN 115607009A

- Authority

- CN

- China

- Prior art keywords

- air fryer

- weight

- pot body

- cleaning

- heating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J37/00—Baking; Roasting; Grilling; Frying

- A47J37/06—Roasters; Grills; Sandwich grills

- A47J37/0623—Small-size cooking ovens, i.e. defining an at least partially closed cooking cavity

- A47J37/0629—Small-size cooking ovens, i.e. defining an at least partially closed cooking cavity with electric heating elements

- A47J37/0641—Small-size cooking ovens, i.e. defining an at least partially closed cooking cavity with electric heating elements with forced air circulation, e.g. air fryers

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J37/00—Baking; Roasting; Grilling; Frying

- A47J37/06—Roasters; Grills; Sandwich grills

- A47J37/0623—Small-size cooking ovens, i.e. defining an at least partially closed cooking cavity

- A47J37/0664—Accessories

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Frying-Pans Or Fryers (AREA)

- Cookers (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及电器设备相关技术领域,具体而言,涉及一种空气炸锅和空气炸锅的运行方法。The invention relates to the related technical field of electrical equipment, in particular, to an air fryer and an operating method of the air fryer.

背景技术Background technique

空气炸锅是一种新兴烹饪器具,其主要原理是利用发热盘产生的热量,对炸桶里面的食物进行加热。因其体积小,操作简单,受到广大消费者的喜爱。虽然空气炸锅的市场整体反馈较好,但是仍有部分问题需要进一步改进。The air fryer is a new cooking appliance, its main principle is to use the heat generated by the heating plate to heat the food in the frying barrel. Because of its small size and simple operation, it is loved by consumers. Although the overall market feedback of air fryers is good, there are still some problems that need further improvement.

使用空气炸锅烤制食物,食物中的水分受到高温蒸发,食物表面会出现水分流失严重的问题,影响食物外观及口感。When the food is baked in an air fryer, the water in the food is evaporated by high temperature, and serious water loss will occur on the surface of the food, which will affect the appearance and taste of the food.

目前,虽然也有部分空气炸锅采用了加湿器对空气炸锅的内部进行加热处理,但是目前的空气炸锅的加湿装置结构复杂。At present, although some air fryers use a humidifier to heat the inside of the air fryer, the structure of the humidifying device of the current air fryer is complicated.

由上可知,现有技术中的空气炸锅存在结构复杂使用不便的技术问题。It can be seen from the above that the air fryer in the prior art has the technical problem of complex structure and inconvenient use.

发明内容Contents of the invention

本发明的主要目的在于提供一种空气炸锅和空气炸锅的运行方法,以解决现有技术中的空气炸锅存在结构复杂使用不便的问题。The main purpose of the present invention is to provide an air fryer and an operating method of the air fryer, so as to solve the problem that the air fryer in the prior art has a complex structure and is inconvenient to use.

为了实现上述目的,根据本发明的一个方面,提供了一种空气炸锅,空气炸锅包括机体,机体具有容置腔;加热组件,加热组件设置在机体的内部并用于对容置腔内的食物进行加热;加湿组件,加湿组件具有蒸汽发生管,蒸汽发生管位于机体的内部并处于加热组件的热辐射区域内,且加热组件对蒸汽发生管内的液体进行加热以形成蒸汽,蒸汽对容置腔内的食物进行加湿。In order to achieve the above object, according to one aspect of the present invention, an air fryer is provided. The air fryer includes a body with an accommodating cavity; Food heating; humidification component, the humidification component has a steam generating tube, the steam generating tube is located inside the body and in the heat radiation area of the heating component, and the heating component heats the liquid in the steam generating tube to form steam. The food in the cavity is humidified.

进一步地,蒸汽发生管的至少一部分与加热组件贴合设置。Further, at least a part of the steam generating tube is arranged in close contact with the heating component.

进一步地,蒸汽发生管弯曲迂回设置在机体内。Further, the steam generating tube is arranged in the machine body in a meandering manner.

进一步地,蒸汽发生管的至少一段盘绕在加热组件的顶面和/或底面和/或周侧面上。Further, at least one section of the steam generating pipe is coiled on the top surface and/or bottom surface and/or peripheral side of the heating assembly.

进一步地,沿蒸汽发生管的延伸方向具有多个间隔设置的蒸汽口;或者蒸汽发生管具有沿其延伸方向延伸的长条形蒸汽口。Further, there are a plurality of steam ports arranged at intervals along the extending direction of the steam generating tube; or the steam generating tube has elongated steam ports extending along the extending direction thereof.

进一步地,空气炸锅还包括风机组件,风机组件设置在机体内,风机组件设置在加热组件和加湿组件的上方。Further, the air fryer also includes a fan assembly, which is arranged in the body, and the fan assembly is arranged above the heating assembly and the humidification assembly.

进一步地,空气炸锅还包括隔热罩,机体具有电器腔,隔热罩设置在电器腔内以将电器腔分为上部安装区域和下部安装区域,加热组件、加湿组件设置和风机组件的至少一部分设置在下部安装区域的内部。Further, the air fryer also includes a heat shield, the body has an electrical cavity, and the heat shield is arranged in the electrical cavity to divide the electrical cavity into an upper installation area and a lower installation area, and at least A part is provided inside the lower installation area.

进一步地,风机组件包括驱动件,驱动件安装在上部安装区域内部;冷却风叶,驱动件与冷却风叶驱动连接,冷却风叶容置在上部安装区域的内部;加热风叶,驱动件与加热风叶驱动连接,加热风叶容置在下部安装区域的内部。Further, the fan assembly includes a driving part, the driving part is installed inside the upper installation area; the cooling fan blade, the driving part is drivingly connected with the cooling fan blade, and the cooling fan blade is accommodated inside the upper installation area; the heating fan blade, the driving part is connected with the cooling fan blade The heating fan blade is driven and connected, and the heating fan blade is accommodated inside the lower installation area.

进一步地,加湿组件还包括进液管,机体上设置有进液口,进液口与进液管的一端连通;控制阀,进液管的另一端与蒸汽发生管之间通过控制阀连接。Further, the humidification assembly also includes a liquid inlet pipe, the body is provided with a liquid inlet, and the liquid inlet communicates with one end of the liquid inlet pipe; a control valve, the other end of the liquid inlet pipe is connected to the steam generation pipe through the control valve.

进一步地,控制阀至少包括开关阀,空气炸锅还包括稳流结构,稳流结构设置在进液管上并位于开关阀的上游位置处。Further, the control valve includes at least an on-off valve, and the air fryer also includes a flow-stabilizing structure, which is arranged on the liquid inlet pipe and located upstream of the on-off valve.

进一步地,空气炸锅还包括锅体,锅体拆卸地设置在机体上;清洗管,清洗管与进液口和/或进液管连通,清洗管用于向锅体的内部供液;清洁阀,清洁阀设置在清洗管上。Further, the air fryer also includes a pot body, which is detachably arranged on the body; a cleaning pipe, which communicates with the liquid inlet and/or the liquid inlet pipe, and the cleaning pipe is used to supply liquid to the inside of the pot body; the cleaning valve , the cleaning valve is arranged on the cleaning pipe.

进一步地,空气炸锅还包括振动器,振动器安装在机体上,振动器的输出端用于与空气炸锅的锅体抵接,振动器驱动锅体振动。Further, the air fryer further includes a vibrator, the vibrator is installed on the body, the output end of the vibrator is used to abut against the pot body of the air fryer, and the vibrator drives the pot body to vibrate.

进一步地,空气炸锅还包括锅体,锅体拆卸地设置在机体上;重量传感器,重量传感器安装在机体上,重量传感器用于检测锅体的重量;液位传感器,液位传感器安装在机体上,液位传感器用于检测锅体的内部的水位;温度传感器,温度传感器安装在机体上,温度传感器用于检测锅体的内部的水温。Further, the air fryer also includes a pot body, which is detachably arranged on the body; a weight sensor, the weight sensor is installed on the body, and the weight sensor is used to detect the weight of the pot body; a liquid level sensor, the liquid level sensor is installed on the body Above, the liquid level sensor is used to detect the water level inside the pot body; the temperature sensor is installed on the body, and the temperature sensor is used to detect the water temperature inside the pot body.

进一步地,空气炸锅还包括报警器,报警器设置在机体上;控制器,控制器与报警器信号连接,重量传感器、液位传感器、温度传感器、加热组件、空气炸锅的振动器、空气炸锅的加湿组件的控制阀、空气炸锅的清洁阀中的至少一者与控制器信号连接。Further, the air fryer also includes an alarm, the alarm is arranged on the body; a controller, the controller is connected to the alarm signal, a weight sensor, a liquid level sensor, a temperature sensor, a heating component, a vibrator of the air fryer, an air At least one of the control valve of the humidifying assembly of the fryer and the purge valve of the air fryer is signally connected to the controller.

根据本发明的另一方面,提供了一种空气炸锅的运行方法,空气炸锅为为上述的空气炸锅,空气炸锅的运行方法至少包括加湿运行模式和清洗运行模式,根据接收的不同操作指令,选定加湿运行模式或清洗运行模式;其中,在加湿运行模式和清洗运行模式中均根据对空气炸锅的锅体进行称重获取锅体的重量值;将预设时间后获取的重量值与之前获取的重量值进行比较;根据比较结果确定是否执行加湿操作、是否执行清洗操作。According to another aspect of the present invention, an operating method of an air fryer is provided. The air fryer is the above-mentioned air fryer. The operating method of the air fryer at least includes a humidification operation mode and a cleaning operation mode. Operation instruction, select the humidification operation mode or the cleaning operation mode; wherein, in the humidification operation mode and the cleaning operation mode, the weight value of the air fryer is obtained by weighing the pot body of the air fryer; the weight value obtained after the preset time The weight value is compared with the previously obtained weight value; according to the comparison result, it is determined whether to perform a humidification operation and whether to perform a cleaning operation.

进一步地,操作指令包括烹饪指令和清洗指令,当接收烹饪指令时,选定加湿运行模式;当接收清洗指令时,选定清洗运行模式。Further, the operation instruction includes a cooking instruction and a cleaning instruction, when the cooking instruction is received, the humidification operation mode is selected; when the cleaning instruction is received, the cleaning operation mode is selected.

进一步地,在加湿运行模式中,对锅体进行称重获取锅体的初始重量M0;启动烹饪程序;在烹饪的过程中,检测锅体的实际重量M;将实际重量M与初始重量M0进行比较,根据比较结果确定是否执行加湿操作。Further, in the humidification operation mode, the pot is weighed to obtain the initial weight M0 of the pot; the cooking program is started; during the cooking process, the actual weight M of the pot is detected; the actual weight M is compared with the initial weight M0 Compare, and determine whether to perform the humidification operation according to the comparison result.

进一步地,在加湿运行模式中,将实际重量M与初始重量M0的差值与预设的重量损失Mt进行比较;当实际重量M与初始重量M0的差值大于等于重量损失Mt时,启动加湿操作;当实际重量M与初始重量M0的差值小于重量损失Mt时,不启动加湿操作。Further, in the humidification operation mode, compare the difference between the actual weight M and the initial weight M0 with the preset weight loss Mt; when the difference between the actual weight M and the initial weight M0 is greater than or equal to the weight loss Mt, start humidification Operation; when the difference between the actual weight M and the initial weight M0 is less than the weight loss Mt, the humidification operation is not started.

进一步地,在加湿运行模式中,若加湿操作启动后,预设时间T1后,停止加湿。Further, in the humidification operation mode, if the humidification operation is started, the humidification is stopped after a preset time T1.

进一步地,在加湿运行模式中,通过设定的方式调整重量损失Mt的大小;或者根据选定的烹饪模式确定重量损失Mt的大小,在烹饪模式中预设有重量损失Mt的大小。Further, in the humidification operation mode, the weight loss Mt is adjusted by setting; or the weight loss Mt is determined according to the selected cooking mode, and the weight loss Mt is preset in the cooking mode.

进一步地,在加湿运行模式中,重量损失Mt包括损失量绝对值阈值M1和/或损失量百分比判断阈值xM0,其中,x为重量损失系数,损失量百分比判断阈值xM0等于重量损失系数X乘以初始重量M0;其中,当重量损失Mt仅包括损失量绝对值阈值M1时,重量损失Mt等于损失量绝对值阈值M1;当重量损失Mt仅包括损失量百分比判断阈值xM0时,重量损失Mt等于损失量百分比判断阈值xM0;当重量损失Mt包括损失量绝对值阈值M1和损失量百分比判断阈值xM0时,重量损失Mt等于损失量绝对值阈值M1和损失量百分比判断阈值xM0中的最小值。Further, in the humidification operation mode, the weight loss Mt includes the loss absolute value threshold M1 and/or the loss percentage judgment threshold xM0, where x is the weight loss coefficient, and the loss percentage judgment threshold xM0 is equal to the weight loss coefficient X multiplied by Initial weight M0; wherein, when the weight loss Mt only includes the loss absolute value threshold M1, the weight loss Mt is equal to the loss absolute value threshold M1; when the weight loss Mt only includes the loss percentage judgment threshold xM0, the weight loss Mt is equal to the loss Weight percentage judgment threshold xM0; when the weight loss Mt includes the loss absolute value threshold M1 and the loss percentage judgment threshold xM0, the weight loss Mt is equal to the minimum value of the loss absolute value threshold M1 and the loss percentage judgment threshold xM0.

进一步地,在加湿运行模式中,预设时间T1=T0*(M0-M)/T/L0,其中,T为开始加湿的时间,L0为液体流经空气炸锅的开关阀的流速,T0为烹饪时长。Further, in the humidification operation mode, the preset time T1=T0*(M0-M)/T/L0, wherein, T is the time to start humidification, L0 is the flow rate of liquid flowing through the switch valve of the air fryer, T0 for the cooking time.

进一步地,在清洗运行模式中,对锅体进行称重获取锅体的实际重量M;将实际重量M与空载重量M2的差值与预设重量M3进行比较,根据比较结果确定是否执行清洗操作。Further, in the cleaning operation mode, the pot is weighed to obtain the actual weight M of the pot; the difference between the actual weight M and the empty weight M2 is compared with the preset weight M3, and whether to perform cleaning is determined according to the comparison result operate.

进一步地,在清洗运行模式中,当实际重量M与空载重量M2的差值大于预设重量M3时,报警提示;当实际重量M与空载重量M2的差值小于等于预设重量M3时,启动清洗操作。Further, in the cleaning operation mode, when the difference between the actual weight M and the empty weight M2 is greater than the preset weight M3, an alarm prompts; when the difference between the actual weight M and the empty weight M2 is less than or equal to the preset weight M3 , to start the cleaning operation.

进一步地,在清洗操作的过程中,对锅体内注水;启动空气炸锅的加热组件;启动空气炸锅的振动器;直至清洗操作完成。Further, during the cleaning operation, inject water into the pot body; start the heating component of the air fryer; start the vibrator of the air fryer; until the cleaning operation is completed.

进一步地,在清洗操作的过程中,检测液体的实际温度Tw;当液体的实际温度Tw大于等于第一预设温度Tw0时,停止加热组件的工作。Further, during the cleaning operation, the actual temperature Tw of the liquid is detected; when the actual temperature Tw of the liquid is greater than or equal to the first preset temperature Tw0, the heating assembly is stopped.

进一步地,在清洗操作的过程中,检测液体的实际温度Tw;当液体的实际温度Tw大于等于第一预设温度Tw0时,启动振动器。Further, during the cleaning operation, the actual temperature Tw of the liquid is detected; when the actual temperature Tw of the liquid is greater than or equal to the first preset temperature Tw0, the vibrator is started.

进一步地,在清洗操作的过程中,启动振动器后,继续检测液体的实际温度Tw;当液体的实际温度Tw小于第二预设温度Tw1时,停止振动器。Further, during the cleaning operation, after the vibrator is started, the actual temperature Tw of the liquid is continuously detected; when the actual temperature Tw of the liquid is lower than the second preset temperature Tw1, the vibrator is stopped.

应用本发明的技术方案,空气炸锅包括机体、加热组件和加湿组件,机体具有容置腔,加热组件设置在机体的内部并用于对容置腔内的食物进行加热,加湿组件具有蒸汽发生管,蒸汽发生管位于机体的内部并处于加热组件的热辐射区域内,且加热组件对蒸汽发生管内的液体进行加热以形成蒸汽,蒸汽对容置腔内的食物进行加湿。Applying the technical solution of the present invention, the air fryer includes a body, a heating component and a humidification component, the body has a housing cavity, the heating component is arranged inside the body and is used to heat the food in the storage cavity, and the humidification component has a steam generating tube The steam generating tube is located inside the body and in the heat radiation area of the heating component, and the heating component heats the liquid in the steam generating tube to form steam, and the steam humidifies the food in the accommodating cavity.

由上可知,本申请的加热组件不仅能为容置腔的内部的食物进行加热,同时加热组件能将加湿组件的蒸汽发生管内部的液体加热以形成蒸汽,以通过形成的蒸汽为容置腔的内部的食物进行加热,食物的加热和加湿共用一个加热组件有效地提高了加热效率,并且简化了加湿组件的结构。It can be seen from the above that the heating assembly of the present application can not only heat the food inside the storage chamber, but also heat the liquid inside the steam generating tube of the humidification assembly to form steam, and the steam formed by passing through the storage chamber can The food inside is heated, and the heating and humidification of the food share a heating component, which effectively improves the heating efficiency and simplifies the structure of the humidification component.

同时,本申请还提供了一种空气炸锅的运行方法,以实现运行加湿模式和清洗模式,在加湿模式中,采用根据锅体的重量变化控制加湿模式,有效地提高了加湿的精准度。在清洗模式中,采用加热组件和振动器配合的方式实现清洗锅体,有效地提高了清洗效率。At the same time, the application also provides an operation method of the air fryer to realize the operating humidification mode and cleaning mode. In the humidification mode, the humidification mode is controlled according to the weight change of the pot body, which effectively improves the accuracy of humidification. In the cleaning mode, the heating element and the vibrator are used to clean the pot body, which effectively improves the cleaning efficiency.

附图说明Description of drawings

构成本申请的一部分的说明书附图用来提供对本发明的进一步理解,本发明的示意性实施例及其说明用于解释本发明,并不构成对本发明的不当限定。在附图中:The accompanying drawings constituting a part of the present application are used to provide a further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention. In the attached picture:

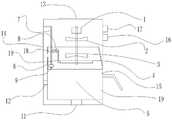

图1示出了本发明的空气炸锅的整体结构示意图;Fig. 1 shows the overall structural representation of air fryer of the present invention;

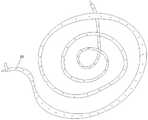

图2示出了本发明的蒸汽发生管的结构示意图;Fig. 2 shows the structural representation of the steam generating tube of the present invention;

图3示出了本发明的加湿运行模式的逻辑框图;Fig. 3 shows the logical block diagram of the humidification operation mode of the present invention;

图4示出了本发明的清洗运行模式的逻辑框图。FIG. 4 shows a logic block diagram of the cleaning operating mode of the present invention.

其中,上述附图包括以下附图标记:Wherein, the above-mentioned accompanying drawings include the following reference signs:

1、驱动件;2、冷却风叶;3、加热风叶;4、加热组件;5、锅体;6、隔热罩;7、进液管;8、控制阀;9、清洁阀;10、蒸汽发生管;11、重量传感器;12、振动器;13、进风口;14、出风口;15、液位传感器;16、温度旋钮;17、定时旋钮;18、稳流结构;19、温度传感器。1. Driving parts; 2. Cooling fan blades; 3. Heating fan blades; 4. Heating components; 5. Pot body; 6. Heat shield; 7. Liquid inlet pipe; 8. Control valve; 9. Cleaning valve; 10 1. Steam generating tube; 11. Weight sensor; 12. Vibrator; 13. Air inlet; 14. Air outlet; 15. Liquid level sensor; 16. Temperature knob; 17. Timing knob; 18. Steady flow structure; 19. Temperature sensor.

具体实施方式detailed description

需要说明的是,在不冲突的情况下,本申请中的实施例及实施例中的特征可以相互组合。下面将参考附图并结合实施例来详细说明本发明。It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

需要指出的是,除非另有指明,本申请使用的所有技术和科学术语具有与本申请所属技术领域的普通技术人员通常理解的相同含义。It should be noted that, unless otherwise specified, all technical and scientific terms used in this application have the same meaning as commonly understood by those of ordinary skill in the art to which this application belongs.

在本发明中,在未作相反说明的情况下,使用的方位词如“上、下、顶、底”通常是针对附图所示的方向而言的,或者是针对部件本身在竖直、垂直或重力方向上而言的;同样地,为便于理解和描述,“内、外”是指相对于各部件本身的轮廓的内、外,但上述方位词并不用于限制本发明。In the present invention, unless stated otherwise, the used orientation words such as "upper, lower, top, bottom" are usually for the directions shown in the drawings, or for the parts themselves in the vertical, In terms of vertical or gravitational direction; similarly, for the convenience of understanding and description, "inner and outer" refer to the inner and outer relative to the outline of each component itself, but the above orientation words are not used to limit the present invention.

实施例一Embodiment one

为了解决现有技术中的空气炸锅存在结构复杂使用不便的问题,本发明提供了一种空气炸锅。In order to solve the problem that the air fryer in the prior art has a complicated structure and is inconvenient to use, the present invention provides an air fryer.

如图1至图2所示,空气炸锅包括机体、加热组件4和加湿组件,机体具有容置腔,加热组件4设置在机体的内部并用于对容置腔内的食物进行加热,加湿组件具有蒸汽发生管10,蒸汽发生管10位于机体的内部并处于加热组件4的热辐射区域内,且加热组件4对蒸汽发生管10内的液体进行加热以形成蒸汽,蒸汽对容置腔内的食物进行加湿。As shown in Figures 1 to 2, the air fryer includes a body, a

具体地,本申请的加热组件4不仅能为容置腔的内部的食物进行加热,同时加热组件4能将加湿组件的蒸汽发生管10内部的液体加热以形成蒸汽,以通过形成的蒸汽为容置腔的内部的食物进行加热,食物的加热和加湿共用一个加热组件4有效地提高了加热效率,并且简化了加湿组件的结构。Specifically, the

进一步地,机体上还设置有与容置腔连通设置的进风口13和出风口14,其中进风口13设置在机体的顶部,出风口14设置在机体的侧部。当然,进风口13和出风口14的位置可以是适应性调整的,例如进风口13和出风口14均设置在顶部,进风口13和出风口14均设置在侧部。Further, the body is also provided with an

在本实施例中,机体上设置有电源插座,以方便进行外接电源,外接电源用于供电。还可以是在机体的内部安装有内置电源,以通过内置电源进行供电。In this embodiment, a power socket is provided on the body to facilitate external power supply, and the external power supply is used for power supply. It is also possible that a built-in power supply is installed inside the body so as to supply power through the built-in power supply.

其中,加热组件4为电加热盘,电加热盘为食物和加湿组件提供热量,当然电加热组件4还可以是电加热丝、电加热棒等具有加热功能的结构件。Wherein, the

进一步地,蒸汽发生管10的至少一部分与加热组件4贴合设置。采用蒸汽发生管10贴设在加热组件4上的方式,即蒸汽发生管10的至少一部分与电加热盘贴合的方式实现将蒸汽发生管10的内部的液体进行蒸发操作。Further, at least a part of the

如图1至图2所示,蒸汽发生管10弯曲迂回设置在机体内。As shown in Fig. 1 to Fig. 2, the

具体地,蒸汽发生管10采用弯曲迂回的结构设置,从而实现增加蒸汽的出气量的技术效果,进而提高了加湿效率。Specifically, the

进一步地,蒸汽发生管10的弯曲迂回的结构形式可以是螺旋形、矩形、回形、口型、角形、多边形或者其他不规则的结构形式,具体以能实现增加蒸汽发生管10与加热组件4之间的接触面积为准。Further, the curved and circuitous structural form of the

在本实施例中,蒸汽发生管10的至少一段可以是盘绕在加热组件4的顶面上的,也可以是设置在加热组件4的底面上的,也可以是设置在加热组件4的周侧面上,以使蒸汽发生管10的至少一部分与加热组件4贴合进行加热并制造蒸汽。当然,蒸汽发生管10的至少一段可以是与加热组件4的顶面、底面和周侧面同时贴合设置的,以增加加热组件4与蒸汽发生管10的接触面积,从而提高蒸汽产生量,提高加湿效率。In this embodiment, at least one section of the

如图1至图2所示,沿蒸汽发生管10的延伸方向具有多个间隔设置的蒸汽口。As shown in FIGS. 1 to 2 , there are a plurality of steam ports arranged at intervals along the extending direction of the

具体地,在蒸汽发生管10上设置多个蒸汽口,当加热组件4对蒸汽发生管10路的内部的液体加热后,蒸汽发生管10路的内部的液体能从多个蒸汽口中散出,以使蒸汽均匀的进入到容置腔的内部,提高了蒸发的扩散的均匀性,有利于提高加湿的效率。Specifically, a plurality of steam outlets are arranged on the

进一步地,多个蒸汽口的设置口径具体可以是根据蒸汽发生管10的尺寸进行适应性调整的。Further, the calibers of the multiple steam ports may be adaptively adjusted according to the size of the

进一步地,各蒸汽口的形状可以是圆形、方形、长条形、多边形等结构。Further, the shape of each steam port can be circular, square, strip-shaped, polygonal and other structures.

在一个未图示的实施方式中,多个蒸汽口配合连通形成沿其蒸汽发生管10延伸方向延伸的长条形蒸汽口,以方便蒸汽发生管10的内部的蒸汽排出。In a non-illustrated embodiment, a plurality of steam ports are matched and communicated to form a strip-shaped steam port extending along the extending direction of the

如图1至图2所示,空气炸锅还包括风机组件,风机组件设置在机体内,风机组件设置在加热组件4和加湿组件的上方。As shown in FIGS. 1 to 2 , the air fryer further includes a fan assembly, which is arranged inside the body, and the fan assembly is arranged above the

具体地,风机组件能提供风力,以实现将加热组件4提供的热空气进行循环流动从而进行加热食物的效果,同时风机组件能将加湿组件提供的蒸汽进行循环流动,从而实现提供加湿的效果。Specifically, the fan assembly can provide wind power to achieve the effect of circulating the hot air provided by the

进一步地,空气炸锅还包括隔热罩6,机体具有电器腔,隔热罩6设置在电器腔内以将电器腔分为上部安装区域和下部安装区域,加热组件4、加湿组件设置和风机组件的至少一部分设置在下部安装区域的内部。采用隔热罩6的进行分割电器腔,以实现下部安装区域的内部的热量不影响上部安装区域的内部的安装的元器件。Further, the air fryer also includes a

其中,下部分安装区域与容置腔连通设置,以实现风机组件能将热空气和蒸汽吹至容置腔的内部食物进行加热和加湿处理。Wherein, the installation area of the lower part is communicated with the accommodating cavity, so that the fan assembly can blow hot air and steam to the food inside the accommodating cavity for heating and humidification.

在本实施例中,风机组件包括驱动件1、冷却风叶2和加热风叶3,驱动件1安装在上部安装区域内部,驱动件1与冷却风叶2驱动连接,冷却风叶2容置在上部安装区域的内部,驱动件1与加热风叶3驱动连接,加热风叶3容置在下部安装区域的内部。In this embodiment, the fan assembly includes a driving part 1, a cooling fan blade 2 and a

需要说明的是,驱动件1为旋转电机或者旋转气缸等结构件,具体以能提供旋转驱动力为准,驱动件1通过驱动轴能驱动冷却风叶2和加热风叶3转动,其中安装在下部安装区域的加热风叶3用于使热空气和蒸汽在容置腔的内部循环,冷却风叶2用于提供散热,防止过热损坏。It should be noted that the driving part 1 is a structural member such as a rotating motor or a rotating cylinder, which is subject to providing a rotating driving force. The driving part 1 can drive the cooling fan blade 2 and the

如图1至图2所示,加湿组件还包括进液管7和控制阀8,机体上设置有进液口,进液口与进液管7的一端连通,进液管7的另一端与蒸汽发生管10之间通过控制阀8连接。As shown in Figures 1 to 2, the humidification assembly also includes a liquid inlet pipe 7 and a

具体地,机体上的进液口可以与外接水源连接并向进液管7供水,以使进液管7的内部的水能向蒸汽发生管10的内部流动,通过设置控制阀8以实现在需要时控制进液管7的内部的水流向蒸汽发生管10,不需要是则控制进液管7的内部的水不流向蒸汽发生管10,提高可控性。Specifically, the liquid inlet on the machine body can be connected with an external water source and supply water to the liquid inlet pipe 7, so that the water inside the liquid inlet pipe 7 can flow to the inside of the

进一步地,控制阀8至少包括开关阀,空气炸锅还包括稳流结构18,稳流结构18设置在进液管7上并位于开关阀的上游位置处。Further, the

其中,开关阀控制进液管7与蒸汽发生管10之间的通断,稳流结构18以保证流入蒸汽发生管10的流速保持稳定。Wherein, the switching valve controls the on-off between the liquid inlet pipe 7 and the

进一步地,稳流结构18为稳压阀。Further, the

如图1至图2所示,空气炸锅还包括锅体5、清洗管和清洁阀9,锅体5拆卸地设置在机体上,清洗管与进液口和/或进液管7连通,清洗管用于向锅体5的内部供液,清洁阀9设置在清洗管上。As shown in Figures 1 to 2, the air fryer also includes a pot body 5, a cleaning pipe and a

具体地,机体的侧壁上设置有与容置腔连通设置的开口结构,通过开口结构将锅体5安装至容置腔的内部或者由容置腔的内部移出,当锅体5安装至容置腔的内部后,锅体5遮挡开口结构。Specifically, the side wall of the machine body is provided with an opening structure communicated with the accommodating cavity, and the pot body 5 is installed into the inside of the accommodating cavity or removed from the inside of the accommodating cavity through the opening structure. After placing inside the cavity, the pot body 5 blocks the opening structure.

进一步地,清洗管能向锅体5的内部供液,以用于清洁锅体5,其中清洁阀9控制清洗管的通断,即通过控制清洁阀9实现控制是否向锅体5供水,清洁阀9为一个开关控制阀8。Further, the cleaning pipe can supply liquid to the inside of the pot body 5 for cleaning the pot body 5, wherein the cleaning

如图1至图2所示,空气炸锅还包括振动器12,振动器12安装在机体上,振动器12的输出端用于与锅体5抵接,振动器12驱动锅体5振动。As shown in FIG. 1 to FIG. 2 , the air fryer further includes a

具体地,通过设置振动器12以实现锅体5能在振动器12的驱动下振动,在烹饪加热食物时,通过振动锅体5能避免食物粘贴在锅体5的表面上,有效地保障了食物的完整性,同时有利于后期进行清洗锅体5。Specifically, by setting the

进一步地,空气炸锅还包括重量传感器11、液位传感器15、温度传感器19、报警器和控制器,重量传感器11安装在机体上,重量传感器11用于检测锅体5的重量,液位传感器15安装在机体上,液位传感器15用于检测锅体5的内部的水位,温度传感器19安装在机体上,温度传感器19用于检测锅体5的内部的水温。Further, the air fryer also includes a

其中,报警器设置在机体上,控制器与报警器信号连接,重量传感器11、液位传感器15、温度传感器19、加热组件4、空气炸锅的振动器12、空气炸锅的加湿组件的控制阀8、空气炸锅的清洁阀9中的至少一者与控制器信号连接,控制阀8能接受重量传感器11、液位传感器15、温度传感器19的信号反馈,同时控制器可以控制加热组件4、振动器12、控制阀8和清洁阀9的使用状态。Wherein, the alarm is arranged on the body, the controller is connected with the signal of the alarm, the control of the

进一步地,液位传感器15检测到锅体5的内部的水位达到预设水位时能通过控制器控制清洁阀9关闭并报警提示;温度传感器19检测到锅体5的内部的水温达到预设温度后并报警提示,控制器能控制加热组件4停止加热,控制器能控制振动器12启停。当然,报不报警可以是是适应性设置的。Further, when the

在本实施例中,空气炸锅还包括温度旋钮16和定时旋钮17,温度旋钮16可转动地设置在机体上,定时旋钮17可转动地设置在机体上,以通过温度旋钮16和定时旋钮17进行温度设置和时间设置。In this embodiment, the air fryer also includes a

实施例二Embodiment two

本实施例提供一种空气炸锅的运行方法,其中空气炸锅为实施例一中的空气炸锅,如图3至图4所示,空气炸锅的运行方法至少包括加湿运行模式和清洗运行模式,根据接收的不同操作指令,选定加湿运行模式或清洗运行模式;其中,在加湿运行模式和清洗运行模式中均根据对空气炸锅的锅体5进行称重获取锅体5的重量值;将预设时间后获取的重量值与之前获取的重量值进行比较;根据比较结果确定是否执行加湿操作、是否执行清洗操作。This embodiment provides an operation method of an air fryer, wherein the air fryer is the air fryer in Embodiment 1, as shown in Figures 3 to 4, the operation method of the air fryer at least includes a humidification operation mode and a cleaning operation mode, according to the different operating instructions received, select the humidification operation mode or the cleaning operation mode; wherein, in both the humidification operation mode and the cleaning operation mode, the weight value of the pot body 5 is obtained by weighing the pot body 5 of the air fryer ;Comparing the weight value obtained after the preset time with the weight value obtained before; determining whether to perform a humidification operation and whether to perform a cleaning operation according to the comparison result.

具体地,操作指令包括烹饪指令和清洗指令,当接收烹饪指令时,选定加湿运行模式;当接收清洗指令时,选定清洗运行模式。Specifically, the operation instruction includes a cooking instruction and a cleaning instruction. When the cooking instruction is received, the humidification operation mode is selected; when the cleaning instruction is received, the cleaning operation mode is selected.

进一步地,在执行烹饪指令时,空气炸锅加热食物,并在加热食物的过程中对食物进行加湿处理;在执行清洗指令以实现对锅体5进行清洗。Further, when the cooking instruction is executed, the air fryer heats the food, and performs humidification treatment on the food during the heating process; when the cleaning instruction is executed, the pot body 5 is cleaned.

如图3至图4所示,在加湿运行模式中,食物装入锅体5中,锅体5放入机体后,重量传感器11会对锅体5进行称重获取锅体5的初始重量M0;启动烹饪程序;在烹饪的过程中,检测锅体5的实际重量M;将实际重量M与初始重量M0进行比较,根据比较结果确定是否执行加湿操作。As shown in Figures 3 to 4, in the humidification operation mode, food is put into the pot body 5, and after the pot body 5 is put into the body, the

具体地,初始重量M0为未加热状态时锅体5和锅体5的内部的食物的总重量,实际重量M是在烹饪过程中的食物和锅体5的总重量,此时由于食物被烹饪导致水分流失因此实际重量M的值小于初始重量M0。Specifically, the initial weight M0 is the total weight of the food inside the pot body 5 and the pot body 5 when the unheated state, and the actual weight M is the total weight of the food and the pot body 5 in the cooking process. Water loss is caused so that the value of the actual weight M is less than the initial weight M0.

进一步地,将实际重量M与初始重量M0的差值与预设的重量损失Mt进行比较;当实际重量M与初始重量M0的差值大于等于重量损失Mt时,启动加湿操作;当实际重量M与初始重量M0的差值小于重量损失Mt时,不启动加湿操作。Further, the difference between the actual weight M and the initial weight M0 is compared with the preset weight loss Mt; when the difference between the actual weight M and the initial weight M0 is greater than or equal to the weight loss Mt, the humidification operation is started; when the actual weight M When the difference from the initial weight M0 is less than the weight loss Mt, the humidification operation is not started.

其中,自行设置的重量损失值为Mt,实际重量M与初始重量M0的差值逐渐增大时,当实际重量M与初始重量M0的差值小于重量损失Mt时,不启动加湿操作,进行持续加热以继续扩大差值,当实际重量M与初始重量M0的差值大于等于重量损失Mt时,启动加湿操作,以进行加湿食物,保障食物的口感。Among them, the weight loss value set by yourself is Mt, and when the difference between the actual weight M and the initial weight M0 gradually increases, when the difference between the actual weight M and the initial weight M0 is less than the weight loss Mt, the humidification operation will not be started, and continuous Heat to continue to expand the difference. When the difference between the actual weight M and the initial weight M0 is greater than or equal to the weight loss Mt, start the humidification operation to humidify the food and ensure the taste of the food.

进一步地,重量损失值为Mt的设置方式可以是用户自行设置,也可以是根据选定的烹饪模式确定重量损失Mt的大小,在烹饪模式中预设有重量损失Mt的大小。具体地设置方式可以是根据需要调整的,当然也可以是同时设置这两种设置方式。Further, the setting method of the weight loss value Mt may be set by the user, or the size of the weight loss Mt may be determined according to the selected cooking mode, and the size of the weight loss Mt is preset in the cooking mode. The specific setting method can be adjusted according to needs, and of course the two setting methods can also be set at the same time.

在本实施例中,重量损失Mt包括损失量绝对值阈值M1和/或损失量百分比判断阈值xM0,其中,x为重量损失系数,损失量百分比判断阈值xM0等于重量损失系数X乘以初始重量M0;其中,当重量损失Mt仅包括损失量绝对值阈值M1时,重量损失Mt等于损失量绝对值阈值M1;当重量损失Mt仅包括损失量百分比判断阈值xM0时,重量损失Mt等于损失量百分比判断阈值xM0;当重量损失Mt包括损失量绝对值阈值M1和损失量百分比判断阈值xM0时,重量损失Mt等于损失量绝对值阈值M1和损失量百分比判断阈值xM0中的最小值。In this embodiment, the weight loss Mt includes a loss absolute value threshold M1 and/or a loss percentage judgment threshold xM0, wherein x is a weight loss coefficient, and the loss percentage judgment threshold xM0 is equal to the weight loss coefficient X multiplied by the initial weight M0 ; Wherein, when the weight loss Mt only includes the loss absolute value threshold M1, the weight loss Mt is equal to the loss absolute value threshold M1; when the weight loss Mt only includes the loss percentage judgment threshold xM0, the weight loss Mt is equal to the loss percentage judgment Threshold xM0; when the weight loss Mt includes the absolute loss threshold M1 and the loss percentage judgment threshold xM0, the weight loss Mt is equal to the minimum value of the loss absolute value threshold M1 and the loss percentage judgment threshold xM0.

进一步地,在加湿运行模式中,加湿操作启动后,预设时间T1后,停止加湿。Further, in the humidification operation mode, after the humidification operation is started, the humidification is stopped after a preset time T1.

其中,预设时间T1=T0*(M0-M)/T/L0,其中,T为开始加湿的时间,L0为液体流经空气炸锅的开关阀的流速在稳流结构18的作用下L0为一个定值,T0为烹饪时长。烹饪时长T0的值是在烹饪前进行设定的,通过温度旋钮16和定时旋钮17进行温度和时间的设定,同时在烹饪前还可以进行预设温度。开始加湿的值T取决于实际重量M与初始重量M0的差值大于等于重量损失Mt的时间。Wherein, the preset time T1=T0*(M0-M)/T/L0, wherein, T is the time to start humidification, L0 is the flow rate of the liquid flowing through the switch valve of the air fryer under the action of the

需要说明的是,预设时间T1=T0*(M0-M)/T/L0可以实现完全补充食物损失的水分,考虑口感等影响因素,可补充部分损失水分,增加补偿系数y,Tjs0=yT0*(M0-M)/T/L0,其中补偿系数y大于0小于等于1,具体地补偿系数y的设置值可根据个人选择适应性设置。It should be noted that the preset time T1=T0*(M0-M)/T/L0 can completely replenish the water lost in the food. Considering the influence factors such as taste, it can replenish part of the lost water and increase the compensation coefficient y, Tjs0=yT0 *(M0-M)/T/L0, where the compensation coefficient y is greater than 0 and less than or equal to 1, specifically the setting value of the compensation coefficient y can be adaptively set according to personal choice.

在加湿运行模式中,加热风叶3在驱动件1的驱动作用下对蒸汽和热空气起到搅动的作用,以实现热空气和蒸汽循环流动以提高加热效率和加湿的效果。In the humidification operation mode, the

如图3至图4所示,在清洗运行模式中,对锅体5进行称重获取锅体5的实际重量M;将实际重量M与空载重量M2的差值与预设重量M3进行比较,根据比较结果确定是否执行清洗操作。As shown in Figures 3 to 4, in the cleaning operation mode, the pot body 5 is weighed to obtain the actual weight M of the pot body 5; the difference between the actual weight M and the empty weight M2 is compared with the preset weight M3 , and determine whether to perform the cleaning operation according to the comparison result.

其中,实际重量M为锅体5与锅体5的内部的残留食物或者锅体5内部的油脂的重量。Wherein, the actual weight M is the weight of the pot body 5 and the residual food inside the pot body 5 or the fat inside the pot body 5 .

具体地,当实际重量M与空载重量M2的差值大于预设重量M3时,报警提示;当实际重量M与空载重量M2的差值小于等于预设重量M3时,启动清洗操作。Specifically, when the difference between the actual weight M and the empty weight M2 is greater than the preset weight M3, an alarm prompts; when the difference between the actual weight M and the empty weight M2 is less than or equal to the preset weight M3, the cleaning operation is started.

其中,预设重量M3为预设值,当实际重量M与空载重量M2的差值大于预设重量M3时,报警器报警以提示用户锅体5的内部仍然存在食物未取出;用户取出锅体5内部的残留食物后,实际重量M与空载重量M2的差值小于等于预设重量M3时,启动清洗操作。Wherein, the preset weight M3 is a preset value, and when the difference between the actual weight M and the empty weight M2 is greater than the preset weight M3, the alarm will alarm to remind the user that there is still food in the pot body 5 that has not been taken out; the user takes out the pot After cleaning the residual food inside the body 5, when the difference between the actual weight M and the empty weight M2 is less than or equal to the preset weight M3, the cleaning operation is started.

进一步地,在清洗操作的过程中,对锅体5内注水;启动空气炸锅的加热组件4;启动空气炸锅的振动器12;直至清洗操作完成。Further, during the cleaning operation, pour water into the pot body 5; start the

其中,控制清洁阀9打开,进液管7经清洗管向锅体5的内部供液,当液体到达预设位置时,液位传感器15向控制器发送信号,控制器控制清洁阀9闭合,并控制加热组件4工作以加热液体。Wherein, the cleaning

进一步地,温度传感器19实时检测液体的温度,在清洗操作的过程中,检测液体的实际温度Tw;当液体的实际温度Tw大于等于第一预设温度Tw0时,停止加热组件4的工作。并且当液体的实际温度Tw大于等于第一预设温度Tw0时,启动振动器12。振动器12启动以实现振动锅体5,通过高速振动及水温,锅体5上残存的少量杂质开始松动、脱落,将强清洗锅体5的效果。Further, the

进一步地,在停止加热组件4的加热效果后液体的温度逐渐降低,并且启动振动器12后,继续检测液体的实际温度Tw;此时的实际温度Tw开始低于第一预设温度Tw0,当液体的实际温度Tw小于第二预设温度Tw1时,停止振动器12。Further, after stopping the heating effect of the

需要说明的是,第一预设温度Tw0大于第二预设温度Tw1,两者具体地设置数值可以是进行适应性调整的。It should be noted that the first preset temperature Tw0 is greater than the second preset temperature Tw1, and the specific values of the two can be adjusted adaptively.

在本实施例中,振动器12停止后,报警器报警以通知用户清洗运行模式结束,用户可以手动将锅体5移出容置腔并将锅体5的内部的液体倒出并冲洗。In this embodiment, after the

从以上的描述中,可以看出,本发明上述的实施例实现了如下技术效果:From the above description, it can be seen that the above-mentioned embodiments of the present invention have achieved the following technical effects:

1、本申请的加热组件4不仅能为容置腔的内部的食物进行加热,同时加热组件4能将加湿组件的蒸汽发生管10内部的液体加热以形成蒸汽,以通过形成的蒸汽为容置腔的内部的食物进行加热,食物的加热和加湿共用一个加热组件4有效地提高了加热效率,并且简化了加湿组件的结构;1. The

2、本申请还提供了一种空气炸锅的运行方法,以实现运行加湿模式和清洗模式,在加湿模式中,采用根据锅体5的重量变化控制加湿模式,有效地提高了加湿的精准度。在清洗模式中,采用加热组件4和振动器12配合的方式实现清洗锅体5,有效地提高了清洗效率。2. This application also provides an operation method of the air fryer to realize the operating humidification mode and cleaning mode. In the humidification mode, the humidification mode is controlled according to the weight change of the pot body 5, which effectively improves the accuracy of humidification . In the cleaning mode, the

显然,上述所描述的实施例仅仅是本发明一部分的实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都应当属于本发明保护的范围。Apparently, the above-described embodiments are only part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts shall fall within the protection scope of the present invention.

需要注意的是,这里所使用的术语仅是为了描述具体实施方式,而非意图限制根据本申请的示例性实施方式。如在这里所使用的,除非上下文另外明确指出,否则单数形式也意图包括复数形式,此外,还应当理解的是,当在本说明书中使用术语“包含”和/或“包括”时,其指明存在特征、步骤、工作、器件、组件和/或它们的组合。It should be noted that the terminology used here is only for describing specific implementations, and is not intended to limit the exemplary implementations according to the present application. As used herein, unless the context clearly dictates otherwise, the singular is intended to include the plural, and it should also be understood that when the terms "comprising" and/or "comprising" are used in this specification, they mean There are features, steps, operations, means, components and/or combinations thereof.

需要说明的是,本申请的说明书和权利要求书及上述附图中的术语“第一”、“第二”等是用于区别类似的对象,而不必用于描述特定的顺序或先后次序。应该理解这样使用的数据在适当情况下可以互换,以便这里描述的本申请的实施方式能够以除了在这里图示或描述的那些以外的顺序实施。It should be noted that the terms "first" and "second" in the description and claims of the present application and the above drawings are used to distinguish similar objects, but not necessarily used to describe a specific sequence or sequence. It is to be understood that the data so used are interchangeable under appropriate circumstances such that the embodiments of the application described herein can be practiced in sequences other than those illustrated or described herein.

以上所述仅为本发明的优选实施例而已,并不用于限制本发明,对于本领域的技术人员来说,本发明可以有各种更改和变化。凡在本发明的精神和原则之内,所作的任何修改、等同替换、改进等,均应包含在本发明的保护范围之内。The above descriptions are only preferred embodiments of the present invention, and are not intended to limit the present invention. For those skilled in the art, the present invention may have various modifications and changes. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included within the protection scope of the present invention.

Claims (28)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211103824.2ACN115607009A (en) | 2022-09-09 | 2022-09-09 | Air fryer and how it works |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211103824.2ACN115607009A (en) | 2022-09-09 | 2022-09-09 | Air fryer and how it works |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115607009Atrue CN115607009A (en) | 2023-01-17 |

Family

ID=84858087

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211103824.2APendingCN115607009A (en) | 2022-09-09 | 2022-09-09 | Air fryer and how it works |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115607009A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD1075406S1 (en) | 2023-08-29 | 2025-05-20 | Sharkninja Operating Llc | Stacked air fryer |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1681422A (en)* | 2002-09-11 | 2005-10-12 | 株式会社日丰制作所 | Fully automatic rice cooking device |

| JP2010136940A (en)* | 2008-12-12 | 2010-06-24 | Osaka Gas Co Ltd | Cooking device |

| CN109213021A (en)* | 2017-06-30 | 2019-01-15 | 佛山市顺德区美的电热电器制造有限公司 | Remind control method, control device and the cooking apparatus for washing pot |

| CN111528699A (en)* | 2020-04-23 | 2020-08-14 | 华帝股份有限公司 | Humidity detection device for cooking equipment and humidity detection method thereof |

| US20200329909A1 (en)* | 2017-10-06 | 2020-10-22 | Omachron Intellectual Property Inc. | Food cooking apparatus and heat storage member |

| CN215305126U (en)* | 2021-02-03 | 2021-12-28 | 浙江天喜厨电股份有限公司 | Cooling system of air fryer and air fryer with cooling system |

| CN215687052U (en)* | 2021-08-02 | 2022-02-01 | 九阳股份有限公司 | Air frying pan |

| CN215777469U (en)* | 2021-05-31 | 2022-02-11 | 深圳市和生创新技术有限公司 | Air frying equipment |

| CN217013672U (en)* | 2022-03-23 | 2022-07-22 | 深圳市和生创新技术有限公司 | Automatic drainage type air fryer with humidifying function |

| CN217365466U (en)* | 2022-01-22 | 2022-09-06 | 中山市鑫能电器制造有限公司 | Air frying cover |

- 2022

- 2022-09-09CNCN202211103824.2Apatent/CN115607009A/enactivePending

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1681422A (en)* | 2002-09-11 | 2005-10-12 | 株式会社日丰制作所 | Fully automatic rice cooking device |

| JP2010136940A (en)* | 2008-12-12 | 2010-06-24 | Osaka Gas Co Ltd | Cooking device |

| CN109213021A (en)* | 2017-06-30 | 2019-01-15 | 佛山市顺德区美的电热电器制造有限公司 | Remind control method, control device and the cooking apparatus for washing pot |

| US20200329909A1 (en)* | 2017-10-06 | 2020-10-22 | Omachron Intellectual Property Inc. | Food cooking apparatus and heat storage member |

| CN111528699A (en)* | 2020-04-23 | 2020-08-14 | 华帝股份有限公司 | Humidity detection device for cooking equipment and humidity detection method thereof |

| CN215305126U (en)* | 2021-02-03 | 2021-12-28 | 浙江天喜厨电股份有限公司 | Cooling system of air fryer and air fryer with cooling system |

| CN215777469U (en)* | 2021-05-31 | 2022-02-11 | 深圳市和生创新技术有限公司 | Air frying equipment |

| CN215687052U (en)* | 2021-08-02 | 2022-02-01 | 九阳股份有限公司 | Air frying pan |

| CN217365466U (en)* | 2022-01-22 | 2022-09-06 | 中山市鑫能电器制造有限公司 | Air frying cover |

| CN217013672U (en)* | 2022-03-23 | 2022-07-22 | 深圳市和生创新技术有限公司 | Automatic drainage type air fryer with humidifying function |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD1075406S1 (en) | 2023-08-29 | 2025-05-20 | Sharkninja Operating Llc | Stacked air fryer |

| USD1083485S1 (en) | 2023-08-29 | 2025-07-15 | Sharkninja Operating Llc | Stacked air fryer |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8695487B2 (en) | Cooking appliance | |

| JP3731816B2 (en) | High-frequency heating apparatus water supply control method and high-frequency heating apparatus | |

| CN109008594A (en) | Cooking appliance and drying control method with steam cooking function | |

| EP1761111A2 (en) | Steam generation system for a household oven | |

| CN101535722A (en) | Device for diluting discharged vapor and cooker with the same | |

| CN115607009A (en) | Air fryer and how it works | |

| TW202220495A (en) | Electrical appliance, controller for use with electrical appliance, method of controlling electrical appliance, electrical heating appliance and electrical device | |

| JP4589825B2 (en) | Cooking equipment | |

| JP2007303816A (en) | Cooker | |

| JP4610530B2 (en) | Cooker | |

| CN207444795U (en) | Electric kettle | |

| CN204394199U (en) | Steam cooking vessel | |

| JP2005249290A (en) | Cooker | |

| WO2020052690A1 (en) | Cooking robot and method for cooking robot to use gyroscope to control cooking process | |

| JP3695658B2 (en) | Cooking device and control method thereof | |

| CN115444271A (en) | Control method, cooking appliance and storage medium | |

| CN114431697A (en) | cooking utensils | |

| KR100691224B1 (en) | Steam cooker and cleaning method | |

| TWM588224U (en) | Circulation heating device | |

| CN219550824U (en) | Mechanical double tank electric water heater | |

| CN215304964U (en) | Cooking utensil | |

| CN217959779U (en) | Oven with Micro Steamer | |

| CN209733661U (en) | cooking machine | |

| JP2015084815A (en) | Dishwasher with thawing function | |

| JP5191909B2 (en) | Heating cooker and steam generator cleaning method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |