CN115602143A - Novel underwater sound absorption material and preparation method thereof - Google Patents

Novel underwater sound absorption material and preparation method thereofDownload PDFInfo

- Publication number

- CN115602143A CN115602143ACN202211265228.4ACN202211265228ACN115602143ACN 115602143 ACN115602143 ACN 115602143ACN 202211265228 ACN202211265228 ACN 202211265228ACN 115602143 ACN115602143 ACN 115602143A

- Authority

- CN

- China

- Prior art keywords

- sound

- sound absorption

- absorbing

- hydrogel matrix

- matrix material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10K—SOUND-PRODUCING DEVICES; METHODS OR DEVICES FOR PROTECTING AGAINST, OR FOR DAMPING, NOISE OR OTHER ACOUSTIC WAVES IN GENERAL; ACOUSTICS NOT OTHERWISE PROVIDED FOR

- G10K11/00—Methods or devices for transmitting, conducting or directing sound in general; Methods or devices for protecting against, or for damping, noise or other acoustic waves in general

- G10K11/16—Methods or devices for protecting against, or for damping, noise or other acoustic waves in general

- G10K11/162—Selection of materials

- G10K11/168—Plural layers of different materials, e.g. sandwiches

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Acoustics & Sound (AREA)

- Multimedia (AREA)

- Soundproofing, Sound Blocking, And Sound Damping (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于水下吸声材料技术领域,具体涉及一种新型水下吸声材料及制备方法。The invention belongs to the technical field of underwater sound-absorbing materials, and in particular relates to a novel underwater sound-absorbing material and a preparation method.

背景技术Background technique

与空气环境下的吸声结构相比,由于水中深度较大以及水粘性较小等原因,水下吸声一直是一个比较困难的问题。目前的水下吸声材料的基体大多为橡胶或聚氨酯,吸声机制主要以声波在材料内部引起的分子内摩擦以及声波在不同介质界面上的耗能机制为基础,但在低频范围内会失效。为了增强对低频声波的吸收,可以在基体材料内部设置一些特定形状的空腔结构制成共振式结构,但是随着水压增大,空腔并不能维持原有形状,使得整个材料与水的阻抗失配,空腔固有频率发生改变,导致吸声性能下降,而且压力的增大会使橡胶或聚氨酯失去弹性,进而失去吸收振动与噪音的功能。Compared with the sound-absorbing structure in the air environment, underwater sound absorption has always been a more difficult problem due to the greater depth in water and the lower viscosity of water. The matrix of the current underwater sound-absorbing materials is mostly rubber or polyurethane. The sound-absorbing mechanism is mainly based on the intramolecular friction caused by the sound wave inside the material and the energy dissipation mechanism of the sound wave on the interface of different media, but it will fail in the low frequency range. . In order to enhance the absorption of low-frequency sound waves, some specific-shaped cavity structures can be set inside the matrix material to form a resonant structure, but as the water pressure increases, the cavity cannot maintain the original shape, making the entire material and water. Impedance mismatch, the natural frequency of the cavity changes, resulting in a decrease in sound absorption performance, and the increase in pressure will cause the rubber or polyurethane to lose its elasticity, thereby losing the function of absorbing vibration and noise.

此外,水下吸声材料实际工作时需粘贴在水下装备的钢制外壳上,随着在海底长时间的航行,温度、压力、盐蚀等会对其造成损耗,需要定期进行更换,制备成本高。故寻找一种宽频吸声性能好、耐压、制备工艺简单、应用方便、价格低廉的水下吸声材料是非常有意义和应用价值的。In addition, underwater sound-absorbing materials need to be pasted on the steel shell of underwater equipment during actual work. With long-term navigation on the seabed, temperature, pressure, salt corrosion, etc. will cause wear and tear on them, and they need to be replaced regularly. high cost. Therefore, it is of great significance and application value to find an underwater sound-absorbing material with good broadband sound-absorbing performance, pressure resistance, simple preparation process, convenient application and low price.

发明内容Contents of the invention

本发明所要解决的技术问题在于针对现有技术中的不足,提供一种新型水下吸声材料,通过结构的合理设计解决了宽频吸声性能差、不耐压、制备工艺复杂、制备成本较高的难题。The technical problem to be solved by the present invention is to provide a new type of underwater sound-absorbing material for the deficiencies in the prior art, which solves the problems of poor broadband sound-absorbing performance, pressure resistance, complicated preparation process, and relatively high preparation cost through rational design of the structure. High puzzle.

为解决上述技术问题达到相应的目的,本发明提供一种新型水下吸声材料及制备方法,技术方案如下:In order to solve the above technical problems and achieve corresponding goals, the present invention provides a new type of underwater sound-absorbing material and its preparation method. The technical scheme is as follows:

一种新型水下吸声材料包括包覆材料、水凝胶基体材料、吸声散射体。水凝胶基体材料作为载体,具有良好的耐压性,保护其中的吸声散射体载高静水压下,仍保持设定的形状和结构固定在其中,同时其声阻抗与水相近,使声波几乎无反射地进入,被其中的吸声散射体损耗,从而具有优良的的吸声性能。A novel underwater sound-absorbing material includes a cladding material, a hydrogel matrix material, and a sound-absorbing scatterer. As a carrier, the hydrogel matrix material has good pressure resistance, and protects the sound-absorbing scatterer in it under high hydrostatic pressure, and still maintains the set shape and structure fixed in it. At the same time, its acoustic impedance is similar to that of water, so that the sound wave is almost It enters without reflection and is lost by the sound-absorbing scatterer, so it has excellent sound-absorbing performance.

所述包覆材料包覆所述水凝胶基体材料及吸声散射体,遇水后,所述水凝胶基体材料自发吸水膨胀成包覆材料所束缚的形状,所述吸声散射体在水凝胶基体材料中呈三维分布结构。The coating material covers the hydrogel matrix material and the sound-absorbing scatterer. After encountering water, the hydrogel matrix material spontaneously absorbs water and swells into a shape bound by the coating material. The sound-absorbing scatterer is There is a three-dimensional distribution structure in the hydrogel matrix material.

进一步的,所述的吸声散射体占水凝胶基体材料体积分数的5%-50%,优选10%-40%,进一步优选15-30%。Further, the sound-absorbing scatterers account for 5%-50% of the volume fraction of the hydrogel matrix material, preferably 10%-40%, more preferably 15-30%.

进一步的,所述的吸声散射体的尺寸为13μm-40mm,优选30-700μm、2-40mm,进一步优选60-400μm、10-30mm。Further, the size of the sound-absorbing scatterer is 13 μm-40 mm, preferably 30-700 μm, 2-40 mm, more preferably 60-400 μm, 10-30 mm.

进一步的,所述的吸声散射体在水凝胶基体材料厚度方向上,以梯度或连续渐变阻抗结构形式排布。Further, the sound-absorbing scatterers are arranged in the form of a gradient or continuous gradient impedance structure in the thickness direction of the hydrogel matrix material.

进一步的,所述的水凝胶基体材料厚度为2-15cm。Further, the thickness of the hydrogel matrix material is 2-15cm.

具体的,所述的包覆材料为聚乙烯、聚氯乙烯、聚酯、塑料、尼龙、纤维、芳纶、钢中的一种或两种以上为原料加工而成。Specifically, the cladding material is processed from one or two or more of polyethylene, polyvinyl chloride, polyester, plastic, nylon, fiber, aramid, and steel.

具体的,所述的水凝胶基体材料为明胶、琼脂、聚丙烯酸钠、聚丙烯酰胺、海藻酸钠中的一种或两种以上的混合物。Specifically, the hydrogel matrix material is one or a mixture of two or more of gelatin, agar, sodium polyacrylate, polyacrylamide, and sodium alginate.

具体的,所述的吸声散射体为云母、蛭石、玻璃、金属、金属氧化物、橡胶、聚氨酯、塑料、纤维、多孔陶瓷中的一种或两种以上。Specifically, the sound-absorbing scatterer is one or more of mica, vermiculite, glass, metal, metal oxide, rubber, polyurethane, plastic, fiber, and porous ceramic.

进一步的,所述的吸声散射体的形状为球体、圆柱体、长方体或锥体。Further, the shape of the sound-absorbing scatterer is a sphere, a cylinder, a cuboid or a cone.

进一步的,所述的吸声散射体的结构为实心、空心或核壳结构。Further, the structure of the sound-absorbing scatterer is solid, hollow or core-shell.

进一步的,所述的新型水下吸声材料的制备方法为将吸声散射体与水凝胶基体材料混合或使用粘合剂粘合,装入包覆材料中或与包覆材料粘合。Further, the preparation method of the novel underwater sound-absorbing material is to mix the sound-absorbing scatterer with the hydrogel matrix material or use an adhesive to bond them, and pack them into or bond them to the cladding material.

具体的,所述的粘合剂为羧甲基纤维素、糊精、合成树脂、合成橡胶、聚氨酯、塑料中的一种或两种以上为原料加工而成。Specifically, the binder is processed from one or two or more of carboxymethyl cellulose, dextrin, synthetic resin, synthetic rubber, polyurethane, and plastic.

本发明与现有的水下吸声材料相比,具有以下优势:Compared with existing underwater sound-absorbing materials, the present invention has the following advantages:

1、本发明具有良好的耐压性。结构支撑单元为水凝胶是一种兼有固体和液体的性质、具有三维网络结构的新型功能高分子材料,它在水中吸收大量水分显著溶胀,内部90%以上都是水,有很强的“类水”性质,在水下具有良好的耐压性,特性阻抗与水相近,可以使入射声波几乎无反射地进入。1. The present invention has good pressure resistance. The structural support unit is hydrogel, which is a new type of functional polymer material with both solid and liquid properties and a three-dimensional network structure. It absorbs a large amount of water in water and swells significantly. More than 90% of the interior is water, which has a strong The "water-like" property has good pressure resistance under water, and the characteristic impedance is similar to that of water, which can make the incident sound wave enter with almost no reflection.

2、本发明具有优异的宽频吸声性能。功能响应单元为吸声散射体,对超声波造成吸收衰减、波形转换和散射衰减,空腔的引入增加了声波在材料中的传播路径,声波与空腔产生谐振,剪切变形损耗能力变强,不仅增加了低频段的声吸收,也提高了其它频段上的吸声效果,同时也进一步增大了整体水下吸声材料的耐压性。在厚度方向上,各层吸声材料按一定规律变化呈阻抗梯度排布,介质的两临界面呈阻抗匹配状态,并且内部各层的阻抗梯度渐变,声波传播中减少了反射,材料吸声性能增大,使其具有优异的宽频吸声性能。2. The present invention has excellent broadband sound absorption performance. The functional response unit is a sound-absorbing scatterer, which causes absorption attenuation, waveform conversion, and scattering attenuation for ultrasonic waves. The introduction of the cavity increases the propagation path of the sound wave in the material, and the sound wave and the cavity resonate, and the shear deformation loss capability becomes stronger. It not only increases the sound absorption in the low frequency band, but also improves the sound absorption effect in other frequency bands, and further increases the pressure resistance of the overall underwater sound-absorbing material. In the thickness direction, each layer of sound-absorbing material changes according to a certain rule and is arranged in an impedance gradient. The two critical surfaces of the medium are in an impedance matching state, and the impedance gradient of each internal layer changes gradually. The reflection is reduced in the sound wave propagation, and the sound absorption performance of the material is improved. Increase, so that it has excellent broadband sound absorption performance.

3、本发明具有更多的可调参数和变量。本发明中的吸声散射体种类、形状、结构、吸声层厚度等均为可调参数,可以根据具体的使用场景,如对声学性能的要求合理的进行选择调整。3. The present invention has more adjustable parameters and variables. The type, shape, structure, and thickness of the sound-absorbing layer of the sound-absorbing scatterers in the present invention are all adjustable parameters, which can be reasonably selected and adjusted according to specific usage scenarios, such as requirements for acoustic performance.

4、本发明具有良好的生物相容性、化学稳定性、热稳定性、自修复性。水凝胶在水中溶胀之后仍能够继续保持原有结构而不被溶解,具有良好的生物相容性、化学稳定性、热稳定性、自修复性。4. The present invention has good biocompatibility, chemical stability, thermal stability and self-healing property. After being swollen in water, the hydrogel can continue to maintain the original structure without being dissolved, and has good biocompatibility, chemical stability, thermal stability, and self-healing property.

5、本发明结构简单,易于制备,可以贴覆于刚制外壳上或附在水下装备四周,并且制备成本较低,更加适用于实际工程应用。5. The present invention has a simple structure and is easy to prepare. It can be pasted on the steel casing or attached to the surroundings of underwater equipment, and the preparation cost is relatively low, so it is more suitable for practical engineering applications.

附图说明Description of drawings

图1为本发明实施例1的结构示意图;Fig. 1 is the structural representation of

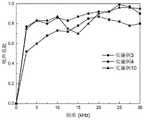

图2为本发明实施例3、4、5的吸声系数示意图。Fig. 2 is a schematic diagram of sound absorption coefficients of Examples 3, 4, and 5 of the present invention.

具体实施方式detailed description

下面结合实施例,对本发明进一步说明;下述实施案例是说明性的,不是限定性的,不能以下述实施例来限定本发明的保护范围。Below in conjunction with embodiment, the present invention is further described; The following embodiments are illustrative, not limiting, and cannot limit the protection scope of the present invention with the following embodiments.

实施例1Example 1

实施例用材料:Examples of materials:

包覆材料为聚酯纤维:其特征是带有网孔的束缚网。The covering material is polyester fiber: it is characterized by a bondage net with mesh.

水凝胶基体材料为聚丙烯酸钠水凝胶:其特征是粒径为0.15-0.60mm,吸水倍率为280g·g-1,密度为1.66g·cm-3。The hydrogel matrix material is sodium polyacrylate hydrogel: the characteristic is that the particle size is 0.15-0.60 mm, the water absorption rate is 280 g·g-1 , and the density is 1.66 g·cm-3 .

吸声散射体为中空玻璃微珠和蛭石粉的混合物,比例为1:1,其特征是:中空玻璃微珠是一种中空的圆球形粉末,主要成分为硼硅酸盐,壁厚在1-2μm之间,粒径为13.73-89.68μm,密度为0.17g·cm-3;蛭石粉是一种由云母在高温下(1200℃)膨胀形成的层状颗粒,含有大小不同的气孔,粒径为0.60-0.85mm,密度为3.4g·cm-3。The sound-absorbing scatterer is a mixture of hollow glass microspheres and vermiculite powder, with a ratio of 1:1. Its characteristics are: hollow glass microspheres are a hollow spherical powder, the main component is borosilicate, and the wall thickness is 1 Between -2μm, the particle size is 13.73-89.68μm, and the density is 0.17g·cm-3 ; The diameter is 0.60-0.85mm, and the density is 3.4g·cm-3 .

其制备过程包括以下步骤:Its preparation process comprises the following steps:

第一步,按比例称取聚丙烯酸钠水凝胶、中空玻璃微珠和蛭石粉,其中中空玻璃微珠和蛭石粉占聚丙烯酸钠水凝胶体积分数的10%;The first step, weighing sodium polyacrylate hydrogel, hollow glass microspheres and vermiculite powder in proportion, wherein hollow glass microspheres and vermiculite powder account for 10% of the volume fraction of sodium polyacrylate hydrogel;

第二步,倒入束缚网中,厚度为0.5mm左右;The second step is to pour it into the bondage net, with a thickness of about 0.5mm;

第三步,投入水中后,水凝胶吸附渗入的水快速膨胀,形成厚度为4cm的新型水下吸声材料,中空玻璃微珠和蛭石粉均匀地分布在水凝胶内部,样品结构示意图请参阅附图1。In the third step, after being put into the water, the hydrogel absorbs the infiltrated water and rapidly expands to form a new underwater sound-absorbing material with a thickness of 4cm. Hollow glass microspheres and vermiculite powder are evenly distributed inside the hydrogel. Please refer to the schematic diagram of the sample structure. Refer to accompanying

性能测试:Performance Testing:

依据GB/T14369-2011标准,采用脉冲声管测试系统在2-12kHz频率范围内,测量试样的声透射系数和声压反射系数,并计算得到吸声系数。平均吸声系数达到0.85,具有优良的吸声效果,尤其在8-10kHz范围内平均吸声系数可达0.99,相较其它频段,具有更好的吸声效果。部分数据见表1:According to the GB/T14369-2011 standard, the sound transmission coefficient and the sound pressure reflection coefficient of the sample are measured in the frequency range of 2-12kHz by the pulse sound tube test system, and the sound absorption coefficient is calculated. The average sound absorption coefficient reaches 0.85, which has excellent sound absorption effect, especially in the range of 8-10kHz, the average sound absorption coefficient can reach 0.99, which has better sound absorption effect than other frequency bands. Part of the data is shown in Table 1:

表1Table 1

实施例2Example 2

实施例用材料:Examples of materials:

包覆材料为尼龙:其特征是带有网孔的束缚网。The covering material is nylon: it is characterized by a bondage net with mesh.

水凝胶基体材料为聚丙烯酰胺水凝胶:其特征是粒径为0.18-0.40mm,吸水倍率为420g·g-1,密度为1.32g·cm-3。The hydrogel matrix material is polyacrylamide hydrogel: the characteristic is that the particle size is 0.18-0.40mm, the water absorption rate is 420g·g-1 , and the density is 1.32g·cm-3 .

吸声散射体为聚丙烯和多孔陶瓷的混合物,比例为1:1:其特征是聚丙烯是粒径为2-8mm的实心球,密度为0.92g·cm-3;多孔陶瓷球是粒径为2-8mm的多孔球,主要成分是二氧化硅,密度为2.70g·cm-3。The sound-absorbing scatterer is a mixture of polypropylene and porous ceramics, the ratio is 1:1: the characteristic is that the polypropylene is a solid ball with a particle size of 2-8mm, and the density is 0.92g cm-3 ; the porous ceramic ball is a particle size It is a porous ball with a diameter of 2-8mm, the main component is silicon dioxide, and the density is 2.70g·cm-3 .

粘合剂为PP塑料胶水:其特征是高强度、高韧性、防水、速干。The adhesive is PP plastic glue: it is characterized by high strength, high toughness, waterproof and quick drying.

其制备过程包括以下步骤:Its preparation process comprises the following steps:

第一步,在聚丙烯球和多孔陶瓷球外部涂上粘合剂,放入聚丙烯酰胺水凝胶中,使它们外部均匀粘上一层水凝胶;In the first step, apply adhesive on the outside of polypropylene balls and porous ceramic balls, put them into polyacrylamide hydrogel, so that they are uniformly adhered to a layer of hydrogel;

第二步,将粘有水凝胶的聚丙烯球和陶瓷球按照粒径2-8mm水平排列,然后使用粘合剂粘结;The second step is to arrange the polypropylene balls and ceramic balls glued with hydrogel horizontally according to the particle size of 2-8mm, and then bond them with an adhesive;

第三步,将两列吸声散射体水平排列,将粒径8mm的两个球体粘结,装入束缚网中,厚度为3.6cm;The third step is to arrange two rows of sound-absorbing scatterers horizontally, bond two spheres with a particle size of 8mm, and put them into a bondage net with a thickness of 3.6cm;

第四步,投入水中,水凝胶在水中自发吸水膨胀,形成厚度为7cm的新型水下吸声材料。The fourth step is to put it into the water, and the hydrogel will spontaneously absorb water and expand in the water to form a new type of underwater sound-absorbing material with a thickness of 7cm.

性能测试:Performance Testing:

将新型吸声材料置于超声波探伤仪反射超声波探头和接收超声波探头之间,通过接收声波的波幅计算在0.5-3MHz频率范围内的吸声系数。平均吸声系数达到0.84,具有优良的吸声效果,尤其在0.5-1MHz范围内平均吸声系数可达0.99,相较其它频段,具有更好的吸声效果。部分数据见表2。The new sound-absorbing material is placed between the reflecting ultrasonic probe and the receiving ultrasonic probe of the ultrasonic flaw detector, and the sound absorption coefficient in the frequency range of 0.5-3MHz is calculated by the amplitude of the received sound wave. The average sound absorption coefficient reaches 0.84, which has excellent sound absorption effect, especially in the range of 0.5-1MHz, the average sound absorption coefficient can reach 0.99, which has better sound absorption effect than other frequency bands. See Table 2 for some data.

表2Table 2

实施例3Example 3

实施例用材料:Examples of materials:

包覆材料为聚乙烯:其特征是带有网孔的束缚网。The covering material is polyethylene: it is characterized by a restraint net with mesh.

水凝胶基体材料为海藻酸钠和聚丙烯酸钠的混合物,海藻酸钠质量分数为30%:其特征是粒径为0.15-0.60mm,吸水倍率为250g·g-1,密度为1.63g·cm-3。The hydrogel matrix material is a mixture of sodium alginate and sodium polyacrylate, and the mass fraction of sodium alginate is 30%. Its characteristics are that the particle size is 0.15-0.60mm, the water absorption rate is 250g·g-1 , and the density is 1.63g· cm-3 .

吸声散射体为铁粉:其特征是粒径为80目,性状为深灰色不规则或类球形粉末,气雾化为球形或类球形粉末。The sound-absorbing scatterer is iron powder: its characteristic is that the particle size is 80 mesh, and its properties are dark gray irregular or spherical powder, which can be atomized into spherical or spherical powder.

粘结剂为聚氨酯胶水:其特征是高弹性、快速固化、粘结强度高。The binder is polyurethane glue: it is characterized by high elasticity, fast curing and high bonding strength.

其制备过程包括以下步骤:Its preparation process comprises the following steps:

第一步,称取水凝胶分别和占其体积分数10%、20%、30%、40%的铁粉混合均匀,分别装入4个束缚网中;In the first step, the hydrogel is weighed and mixed evenly with iron powder accounting for 10%, 20%, 30%, and 40% of its volume fraction, respectively, and loaded into four restraint nets;

第二步,按照铁粉体积分数从小到大的顺序将4个束缚网粘结;The second step is to bond the 4 bondage nets in order of iron powder volume fraction from small to large;

第三步,投入水中,水凝胶在水中自发吸水膨胀,形成厚度为4cm的水下吸声材料。The third step is to put it into the water, and the hydrogel will spontaneously absorb water and expand in the water to form an underwater sound-absorbing material with a thickness of 4cm.

根据改变水凝胶中的铁粉比例,制备了阻抗渐变多层复合吸声材料。By changing the proportion of iron powder in the hydrogel, a multilayer composite sound-absorbing material with gradient impedance was prepared.

性能测试:Performance Testing:

依据GB/T14369-2011标准,采用脉冲声管测试系统在3-30kHz频率范围内,测量试样的声透射系数和声压反射系数,并计算得到吸声系数。平均吸声系数达到0.75,具有优良的吸声效果,尤其在15-30kHz范围内平均吸声系数可达0.82,相较其它频段,具有更好的吸声效果。请参阅附图2。According to the GB/T14369-2011 standard, the sound transmission coefficient and sound pressure reflection coefficient of the sample are measured by the pulse sound tube test system in the frequency range of 3-30kHz, and the sound absorption coefficient is calculated. The average sound absorption coefficient reaches 0.75, which has excellent sound absorption effect, especially in the range of 15-30kHz, the average sound absorption coefficient can reach 0.82, which has better sound absorption effect than other frequency bands. Please refer to attached picture 2.

实施例4Example 4

实施例用材料:Examples of materials:

包覆材料为聚乙烯和涤纶:其特征是带有网孔的束缚网。Wrapping material is polyethylene and polyester: characterized by a bondage net with mesh.

水凝胶基体材料为明胶和聚丙烯酰胺的混合物,明胶质量分数为30%:其特征是粒径为0.18-0.50mm,吸水倍率为360g·g-1,密度为1.28g·cm-3。The hydrogel matrix material is a mixture of gelatin and polyacrylamide, and the mass fraction of gelatin is 30%. It is characterized in that the particle size is 0.18-0.50mm, the water absorption rate is 360g·g-1 , and the density is 1.28g·cm-3 .

吸声散射体为中空玻璃微珠和聚甲醛的混合物:其特征是中空玻璃微珠是中空的圆球形粉末,主要成分为硼硅酸盐,壁厚在1-2μm之间,粒径为13.73-89.68μm,密度为0.17g·cm-3;聚甲醛是壁厚为1mm,底面直径为10mm的空心圆柱体,高度为11mm。The sound-absorbing scatterer is a mixture of hollow glass microspheres and polyoxymethylene: the characteristic is that the hollow glass microspheres are hollow spherical powders, the main component is borosilicate, the wall thickness is between 1-2μm, and the particle size is 13.73 -89.68μm, density 0.17g·cm-3 ; polyoxymethylene is a hollow cylinder with a wall thickness of 1mm, a bottom diameter of 10mm, and a height of 11mm.

粘合剂为PVC胶水:其特征是耐热耐寒、防水、速干。The adhesive is PVC glue: it is characterized by heat and cold resistance, waterproof and quick drying.

其制备过程包括以下步骤:Its preparation process comprises the following steps:

第一步,使用粘合剂将聚甲醛空心圆柱体均匀粘结在束缚网底部;In the first step, use an adhesive to evenly bond the polyoxymethylene hollow cylinder to the bottom of the restraint net;

第二步,将中空玻璃微珠与水凝胶混合均匀倒入束缚网中,中空玻璃微珠占水凝胶体积分数的15%;In the second step, the hollow glass microspheres are evenly mixed with the hydrogel and poured into the bondage net, and the hollow glass microspheres account for 15% of the volume fraction of the hydrogel;

第三步,投入水中,水凝胶自发吸水膨胀,形成厚度为4cm的新型水下吸声材料。The third step is to put it into water, and the hydrogel will spontaneously absorb water and expand to form a new underwater sound-absorbing material with a thickness of 4cm.

性能测试:Performance Testing:

依据GB/T14369-2011标准,采用脉冲声管测试系统在2-30kHz频率范围内,测量试样的声透射系数和声压反射系数,并计算得到吸声系数。平均吸声系数达到0.75,具有优良的吸声效果,尤其在15-30kHz范围内平均吸声系数可达0.82,相较其它频段,具有更好的吸声效果。请参阅附图2。According to the GB/T14369-2011 standard, the sound transmission coefficient and sound pressure reflection coefficient of the sample are measured by the pulse sound tube test system in the frequency range of 2-30kHz, and the sound absorption coefficient is calculated. The average sound absorption coefficient reaches 0.75, which has excellent sound absorption effect, especially in the range of 15-30kHz, the average sound absorption coefficient can reach 0.82, which has better sound absorption effect than other frequency bands. Please refer to attached picture 2.

实施例5Example 5

包覆材料为尼龙:其特征是带有网孔的束缚网。The covering material is nylon: it is characterized by a bondage net with mesh.

水凝胶基体材料为聚丙烯酰胺水凝胶:其特征是粒径为0.18-0.40mm,吸水倍率为420g·g-1,密度为1.32g·cm-3。The hydrogel matrix material is polyacrylamide hydrogel: the characteristic is that the particle size is 0.18-0.40mm, the water absorption rate is 420g·g-1 , and the density is 1.32g·cm-3 .

吸声散射体为中空玻璃微珠、聚氨酯和聚甲醛:其特征是中空玻璃微珠是一种中空的圆球形粉末,主要成分为硼硅酸盐,壁厚在1-2μm之间,粒径为13.73-89.68μm,密度为0.17g·cm-3;聚氨酯是壁厚为1mm,上下半径分别为3mm、12.1mm的空心圆台,高度9mm;聚甲醛是壁厚为1mm,底面直径为10mm、高度为11mm的实心圆柱体。The sound-absorbing scatterers are hollow glass microspheres, polyurethane and polyoxymethylene: the characteristic is that the hollow glass microspheres are a hollow spherical powder, the main component is borosilicate, the wall thickness is between 1-2μm, and the particle size is 13.73-89.68μm, density 0.17g·cm-3 ; polyurethane is a hollow circular table with a wall thickness of 1mm, upper and lower radii of 3mm and 12.1mm respectively, and a height of 9mm; polyoxymethylene has a wall thickness of 1mm and a bottom diameter of 10mm, Solid cylinder with a height of 11mm.

粘合剂为硅胶胶水,其特征是耐高低温、防水、速干。The adhesive is silicone glue, which is characterized by high and low temperature resistance, waterproof and quick drying.

其制备过程包括以下步骤:Its preparation process comprises the following steps:

第一步,使用粘合剂将聚氨酯空心圆台粘结在束缚网1底部,称取水凝胶和占其体积分数15%的中空玻璃微珠混合均匀加入网中;In the first step, use an adhesive to bond the polyurethane hollow round platform to the bottom of the

第二步,使用粘合剂将聚甲醛实心圆柱粘结在束缚网2底部,称取干水凝胶和占其体积分数20%的中空玻璃微珠混合均匀加入网中;In the second step, use an adhesive to bond the polyoxymethylene solid cylinder to the bottom of the bondage net 2, weigh the dry hydrogel and the hollow glass microspheres accounting for 20% of its volume fraction and mix them evenly into the net;

第三步,使用粘合剂将聚氨酯空心圆台粘结在束缚网3底部,称取干水凝胶和占其体积分数25%的中空玻璃微珠混合均匀加入网中;The third step is to use an adhesive to bond the polyurethane hollow round platform to the bottom of the bondage net 3, weigh the dry hydrogel and the hollow glass microspheres accounting for 25% of its volume fraction and mix them evenly into the net;

第四步,使用粘合剂将聚甲醛实心圆柱粘结在束缚网4底部,称取干水凝胶和占其体积分数30%的中空玻璃微珠混合均匀加入网中;The fourth step is to use an adhesive to bond the polyoxymethylene solid cylinder to the bottom of the bondage net 4, weigh the dry hydrogel and the hollow glass microspheres accounting for 30% of its volume fraction and mix them evenly into the net;

第五步,将4个束缚网按照中空玻璃微珠体积分数从小到大的顺序依次粘结;The fifth step is to bond the four restraint nets sequentially according to the volume fraction of hollow glass microspheres from small to large;

第六步,投入水中,水凝胶自发吸水膨胀,形成厚度为4cm的新型水下吸声材料。The sixth step is to put it into the water, and the hydrogel will spontaneously absorb water and expand to form a new underwater sound-absorbing material with a thickness of 4cm.

粘合剂为PVC胶水,其特征是耐热耐寒、防水、速干。The adhesive is PVC glue, which is characterized by heat and cold resistance, waterproof and quick drying.

性能测试:Performance Testing:

依据GB/T14369-2011标准,采用脉冲声管测试系统在2-30kHz频率范围内,测量试样的声透射系数和声压反射系数,并计算得到吸声系数。平均吸声系数达到0.85以上,具有优良的吸声效果,尤其在20-30kHz范围内吸声系数达0.90以上,可实现宽频段的吸声。请参阅附图2。According to the GB/T14369-2011 standard, the sound transmission coefficient and sound pressure reflection coefficient of the sample are measured by the pulse sound tube test system in the frequency range of 2-30kHz, and the sound absorption coefficient is calculated. The average sound absorption coefficient reaches above 0.85, which has excellent sound absorption effect, especially in the range of 20-30kHz, the sound absorption coefficient reaches above 0.90, which can realize wide-band sound absorption. Please refer to attached picture 2.

实施例6Example 6

包覆材料为聚乙烯和涤纶:其特征是带有网孔的束缚网。Wrapping material is polyethylene and polyester: characterized by a bondage net with mesh.

水凝胶基体材料为聚丙烯酸钠水凝胶:其特征是粒径为0.15-0.60mm,吸水倍率为280g·g-1,密度为1.66g·cm-3。The hydrogel matrix material is sodium polyacrylate hydrogel: the characteristic is that the particle size is 0.15-0.60 mm, the water absorption rate is 280 g·g-1 , and the density is 1.66 g·cm-3 .

吸声散射体为铁粉和聚氨酯的混合物:其特征是铁粉粒径为80目,性状为深灰色不规则或类球形粉末,气雾化为球形或类球形粉末;聚氨酯壁厚为1mm,上下半径分别为3mm、12.1mm的空心圆台,高度为9mm。The sound-absorbing scatterer is a mixture of iron powder and polyurethane: its characteristic is that the particle size of the iron powder is 80 mesh, its properties are dark gray irregular or spherical powder, and it is aerosolized into spherical or spherical powder; the polyurethane wall thickness is 1mm, A hollow circular table with upper and lower radii of 3mm and 12.1mm respectively, and a height of 9mm.

粘合剂为PVC胶水:其特征是耐热耐寒、防水、速干。The adhesive is PVC glue: it is characterized by heat and cold resistance, waterproof and quick drying.

其制备过程包括以下步骤:Its preparation process comprises the following steps:

第一步,使用粘合剂将聚氨酯空心圆台粘结在束缚网底部,共制备4份;In the first step, use an adhesive to bond the polyurethane hollow round platform to the bottom of the bondage net, and prepare 4 parts in total;

第二步,称取水凝胶分别和占其体积分数10%、20%、30%、40%的铁粉混合均匀,分别装入上述4个束缚网中;In the second step, the hydrogel is weighed and mixed evenly with the iron powder accounting for 10%, 20%, 30%, and 40% of its volume fraction, respectively, and loaded into the above-mentioned 4 restraining nets;

第三步,按照铁粉体积分数从小到大的顺序,将4个束缚网粘结;The third step is to bond the 4 bondage nets according to the order of iron powder volume fraction from small to large;

第四步,投入水中,水凝胶自发吸水膨胀,形成厚度为12cm的新型水下吸声材料。The fourth step is to put it into the water, and the hydrogel will spontaneously absorb water and expand to form a new underwater sound-absorbing material with a thickness of 12cm.

性能测试:Performance Testing:

依据GB/T18696.22002标准,采用阻抗管测试系统在0.1-6kHz频率范围内进行吸声系数测试,平均吸声系数达到0.74,具有良好的吸声效果,在低频0.5kHz的吸声系数在0.60以上,具有良好的低频吸声效果,最高吸声系数可达到0.82,在4-6kHz范围内出现第二吸收峰,可实现多频段的吸声,部分数据见表3:According to the GB/T18696.22002 standard, the impedance tube test system is used to test the sound absorption coefficient in the frequency range of 0.1-6kHz. The average sound absorption coefficient reaches 0.74, which has a good sound absorption effect. The sound absorption coefficient at low frequency 0.5kHz is 0.60 Above, it has a good low-frequency sound absorption effect, the highest sound absorption coefficient can reach 0.82, and the second absorption peak appears in the range of 4-6kHz, which can realize multi-band sound absorption. Some data are shown in Table 3:

表3table 3

实施例7Example 7

包覆材料为聚乙烯:其特征是带有网孔的束缚网。The covering material is polyethylene: it is characterized by a restraint net with mesh.

水凝胶基体材料为海藻酸钠和聚丙烯酸钠的混合物,其中海藻酸钠质量分数为30%:其特征是粒径为0.15-0.60mm,吸水倍率为250g·g-1,密度为1.63g·cm-3。The hydrogel matrix material is a mixture of sodium alginate and sodium polyacrylate, wherein the mass fraction of sodium alginate is 30%: it is characterized by a particle size of 0.15-0.60 mm, a water absorption rate of 250 g·g-1 , and a density of 1.63 g • cm−3 .

吸声散射体为蛭石粉和聚甲醛:其特征是蛭石粉是一种由云母在高温下(1200℃)膨胀形成的层状颗粒,含有大小不同的气孔,粒径为0.60-0.85mm,密度为3.4g·cm-3。聚甲醛是壁厚为1mm,底面直径为10mm、高度为11mm的空心圆柱体和壁厚为1mm,上下半径分别为3mm、12.1mm、高度为9mm的空心圆台。The sound-absorbing scatterers are vermiculite powder and polyoxymethylene: it is characterized in that vermiculite powder is a layered particle formed by the expansion of mica at high temperature (1200°C), containing pores of different sizes, with a particle size of 0.60-0.85mm and a density of It is 3.4g·cm-3 . POM is a hollow cylinder with a wall thickness of 1mm, a bottom diameter of 10mm, and a height of 11mm, and a hollow circular platform with a wall thickness of 1mm, upper and lower radii of 3mm, 12.1mm, and a height of 9mm.

粘合剂为聚氨酯胶水:其特征为高弹性、快速固化、粘结强度高。The adhesive is polyurethane glue: it is characterized by high elasticity, fast curing and high bond strength.

其制备过程包括以下步骤:Its preparation process comprises the following steps:

第一步,使用粘合剂将聚甲醛空心圆柱和空心圆台粘结在束缚网底部;In the first step, use an adhesive to bond the polyoxymethylene hollow cylinder and the hollow circular table to the bottom of the restraint net;

第二步,将占水凝胶体积分数为20%的蛭石粉与水凝胶混合均匀倒入束缚网中;In the second step, the vermiculite powder accounting for 20% of the hydrogel volume fraction is mixed with the hydrogel evenly and poured into the bondage net;

第三步,投入水中,水凝胶自发吸水膨胀,形成厚度为4cm的新型水下吸声材料。The third step is to put it into water, and the hydrogel will spontaneously absorb water and expand to form a new underwater sound-absorbing material with a thickness of 4cm.

性能测试:Performance Testing:

依据GB/T18696.22002标准,采用阻抗管测试系统在0.1-6kHz频率范围内进行吸声系数测试,平均吸声系数达到0.73,具有良好的吸声效果,在低频0.5kHz的吸声系数在0.60,具有良好的低频吸声效果,最高吸声系数可达到0.83,在4-6kHz范围内出现第二吸收峰,可实现多频段的吸声,部分数据见表4:According to the GB/T18696.22002 standard, the impedance tube test system is used to test the sound absorption coefficient in the frequency range of 0.1-6kHz. The average sound absorption coefficient reaches 0.73, which has a good sound absorption effect. The sound absorption coefficient at low frequency 0.5kHz is 0.60 , has a good low-frequency sound absorption effect, the highest sound absorption coefficient can reach 0.83, and the second absorption peak appears in the range of 4-6kHz, which can realize multi-band sound absorption. Some data are shown in Table 4:

表4Table 4

实施例8Example 8

包覆材料为尼龙:其特征是带有网孔的束缚网。The covering material is nylon: it is characterized by a bondage net with mesh.

水凝胶基体材料为聚丙烯酰胺水凝胶:其特征是粒径为0.18-0.40mm,吸水倍率为420g·g-1,密度为1.32g·cm-3。The hydrogel matrix material is polyacrylamide hydrogel: the characteristic is that the particle size is 0.18-0.40mm, the water absorption rate is 420g·g-1 , and the density is 1.32g·cm-3 .

吸声散射体为铁粉、聚氨酯和聚甲醛:其特征是铁粉粒径为80目,性状为深灰色不规则或类球形粉末,气雾化为球形或类球形粉末;为聚氨酯壁厚为1mm,上下半径分别为3mm、12.1mm的空心圆台,高度9mm。聚甲醛是是壁厚为1mm,底面直径为10mm、高度为11mm的空心圆柱体。The sound-absorbing scatterers are iron powder, polyurethane and polyoxymethylene: the characteristic is that the particle size of the iron powder is 80 mesh, and the properties are dark gray irregular or spherical powder, which is aerosolized into spherical or spherical powder; the wall thickness of polyurethane is 1mm, a hollow circular table with upper and lower radii of 3mm and 12.1mm respectively, and a height of 9mm. POM is a hollow cylinder with a wall thickness of 1 mm, a bottom diameter of 10 mm, and a height of 11 mm.

粘合剂为硅胶胶水,其特征是耐高低温、防水、速干。The adhesive is silicone glue, which is characterized by high and low temperature resistance, waterproof and quick drying.

其制备过程包括以下步骤:Its preparation process comprises the following steps:

第一步,使用粘合剂将聚氨酯空心圆台粘结在束缚网1底部,称取水凝胶和占其体积分数10%的铁粉混合均匀加入网中;In the first step, use an adhesive to bond the polyurethane hollow round platform to the bottom of the

第二步,使用粘合剂将聚甲醛空心圆柱粘结在束缚网2底部,称取水凝胶和占其体积分数20%的铁粉混合均匀加入网中;In the second step, use an adhesive to bond the polyoxymethylene hollow cylinder to the bottom of the bondage net 2, weigh the hydrogel and iron powder accounting for 20% of its volume fraction and mix them evenly into the net;

第三步,使用粘合剂将聚氨酯空心圆台粘结在束缚网3底部,称取水凝胶和占其体积分数30%的铁粉混合均匀加入网中;The third step is to use an adhesive to bond the polyurethane hollow round table to the bottom of the bondage net 3, weigh the hydrogel and iron powder accounting for 30% of its volume fraction and mix them evenly into the net;

第四步,使用粘合剂将聚甲醛空心圆柱粘结在束缚网4底部,称取水凝胶和占其体积分数40%的铁粉混合均匀加入网中;The fourth step is to use an adhesive to bond the polyoxymethylene hollow cylinder to the bottom of the bondage net 4, weigh the hydrogel and iron powder accounting for 40% of its volume fraction and mix them evenly into the net;

第五步,使用粘合剂将4个束缚网按照铁粉体积分数从小到大的顺序依次粘结;The fifth step is to use an adhesive to bond the four bondage nets in order of iron powder volume fraction from small to large;

第六步,投入水中,水凝胶自发吸水膨胀,形成厚度为6cm的新型水下吸声材料。The sixth step is to put it into water, and the hydrogel will spontaneously absorb water and expand to form a new underwater sound-absorbing material with a thickness of 6cm.

粘合剂为PVC胶水,其特征是耐热耐寒、防水、速干。The adhesive is PVC glue, which is characterized by heat and cold resistance, waterproof and quick drying.

性能测试:Performance Testing:

依据GB/T18696.22002标准,采用阻抗管测试系统在0.1-6kHz频率范围内进行吸声系数测试,平均吸声系数达到0.76,具有良好的吸声效果,在低频0.5kHz的吸声系数在0.60以上,具有良好的低频吸声效果,最高吸声系数可达到0.82,部分数据见表5:According to the GB/T18696.22002 standard, the impedance tube test system is used to test the sound absorption coefficient in the frequency range of 0.1-6kHz. The average sound absorption coefficient reaches 0.76, which has a good sound absorption effect. The sound absorption coefficient at low frequency 0.5kHz is 0.60 Above, it has a good low-frequency sound absorption effect, and the highest sound absorption coefficient can reach 0.82. Some data are shown in Table 5:

表5table 5

实施例9Example 9

包覆材料为聚乙烯:其特征带有网孔的束缚网。The covering material is polyethylene: it is characterized by a bondage net with mesh.

水凝胶基体材料为海藻酸钠和聚丙烯酸钠的混合物,其中海藻酸钠质量分数为30%:其特征是粒径为0.15-0.60mm,吸水倍率为250g·g-1,密度为1.63g·cm-3。The hydrogel matrix material is a mixture of sodium alginate and sodium polyacrylate, wherein the mass fraction of sodium alginate is 30%: it is characterized by a particle size of 0.15-0.60 mm, a water absorption rate of 250 g·g-1 , and a density of 1.63 g • cm−3 .

吸声散射体为蛭石粉、聚丙烯和聚氨酯:其特征是蛭石粉是一种由云母在高温下(1200℃)膨胀形成的层状颗粒,含有大小不同的气孔,粒径为0.60-0.85mm,密度为3.4g·cm-3;聚丙烯是粒径为9mm的实心球,密度为0.92g·cm-3,具有较高的耐冲击性、耐多种有机溶剂和酸碱腐蚀;聚氨酯是壁厚为1mm,上下半径分别为3mm、12.1mm的空心圆台,高度9mm。The sound-absorbing scatterers are vermiculite powder, polypropylene and polyurethane: the characteristic is that vermiculite powder is a layered particle formed by the expansion of mica at high temperature (1200°C), containing pores of different sizes, and the particle size is 0.60-0.85mm , with a density of 3.4g·cm-3 ; polypropylene is a solid ball with a particle size of 9mm and a density of 0.92g·cm-3 , which has high impact resistance, resistance to various organic solvents and acid-base corrosion; polyurethane is A hollow circular platform with a wall thickness of 1mm, a radius of 3mm and 12.1mm for the upper and lower sides, and a height of 9mm.

粘合剂为聚氨酯胶水,其特征为高弹性、快速固化、粘结强度高。The adhesive is polyurethane glue, which is characterized by high elasticity, fast curing and high bond strength.

其制备过程包括以下步骤:Its preparation process comprises the following steps:

第一步,使用粘合剂聚丙烯球粘结在束缚网1底部,称取水凝胶和占其体积分数10%的蛭石粉混合均匀加入网中;In the first step, adhesive polypropylene balls are used to bond the bottom of the

第二步,使用粘合剂将聚氨酯空心圆台粘结在束缚网2底部,称取水凝胶和占其体积分数20%的蛭石粉混合均匀加入网中;In the second step, use an adhesive to bond the polyurethane hollow round platform to the bottom of the bondage net 2, weigh the hydrogel and the vermiculite powder accounting for 20% of its volume fraction and mix them evenly into the net;

第三步,使用粘合剂聚丙烯球粘结在圆柱体束缚网3底部,称取水凝胶和占其体积分数30%的蛭石粉混合均匀加入网中;The third step is to use adhesive polypropylene balls to bond to the bottom of the cylindrical restraint net 3, weigh the hydrogel and the vermiculite powder accounting for 30% of its volume fraction and mix them evenly into the net;

第四步,使用粘合剂将聚氨酯空心圆台粘结在束缚网4底部,称取水凝胶和占其体积分数为40%的云母混合均匀加入网中;The fourth step is to use an adhesive to bond the polyurethane hollow round platform to the bottom of the bondage net 4, weigh the hydrogel and 40% of the mica by volume and mix them evenly into the net;

第五步,使用粘合剂将4个束缚网按照蛭石粉体积分数从小到大的顺序依次粘结;The fifth step is to use an adhesive to bond the 4 bondage nets sequentially according to the volume fraction of vermiculite powder in ascending order;

第五步,投入水中,水凝胶自发吸水膨胀,形成厚度为6cm的新型水下吸声材料。The fifth step is to put it into water, and the hydrogel will spontaneously absorb water and expand to form a new underwater sound-absorbing material with a thickness of 6cm.

性能测试:Performance Testing:

依据GB/T14369-2011标准,采用脉冲声管测试系统在2-12kHz频率范围内,测量试样的声透射系数和声压反射系数,并计算得到吸声系数。平均吸声系数达到0.87,具有优良的吸声效果,尤其在8-12kHz范围内平均吸声系数可达0.93,相较其它频段,具有更好的吸声效果。部分数据见表6:According to the GB/T14369-2011 standard, the sound transmission coefficient and the sound pressure reflection coefficient of the sample are measured in the frequency range of 2-12kHz by the pulse sound tube test system, and the sound absorption coefficient is calculated. The average sound absorption coefficient reaches 0.87, which has excellent sound absorption effect, especially in the range of 8-12kHz, the average sound absorption coefficient can reach 0.93, which has better sound absorption effect than other frequency bands. Some data are shown in Table 6:

表6Table 6

实施例10Example 10

包覆材料为聚乙烯和涤纶:其特征是带有网孔的束缚网。Wrapping material is polyethylene and polyester: characterized by a bondage net with mesh.

水凝胶基体材料为明胶和聚丙烯酰胺的混合物,明胶质量分数为30%:其特征是粒径为0.18-0.50mm,吸水倍率为360g·g-1,密度为1.28g·cm-3。The hydrogel matrix material is a mixture of gelatin and polyacrylamide, and the mass fraction of gelatin is 30%. It is characterized in that the particle size is 0.18-0.50mm, the water absorption rate is 360g·g-1 , and the density is 1.28g·cm-3 .

吸声散射体为中空玻璃微珠、蛭石粉和铁粉:其特征是中空玻璃微珠是一种中空的圆球形粉末,主要成分为硼硅酸盐,壁厚在1-2μm之间,粒径为13.73-89.68μm,密度为0.17g·cm-3;蛭石粉是一种由云母在高温下(1200℃)膨胀形成的层状颗粒,含有大小不同的气孔,粒径为0.60-0.85mm,密度为3.4g·cm-3;铁粉是粒径为80目的高纯铁粉,性状为深灰色不规则或类球形粉末,气雾化为球形或类球形粉末。The sound-absorbing scatterers are hollow glass microspheres, vermiculite powder and iron powder: the characteristic is that the hollow glass microspheres are a hollow spherical powder, the main component is borosilicate, and the wall thickness is between 1-2μm. The diameter is 13.73-89.68μm, and the density is 0.17g·cm-3 ; vermiculite powder is a layered particle formed by the expansion of mica at high temperature (1200°C), which contains pores of different sizes, and the particle size is 0.60-0.85mm , with a density of 3.4g·cm-3 ; the iron powder is a high-purity iron powder with a particle size of 80 mesh, and its properties are dark gray irregular or spherical powder, which can be atomized into a spherical or spherical powder.

粘合剂为PVC胶水,其特征是耐热耐寒、防水、速干。The adhesive is PVC glue, which is characterized by heat and cold resistance, waterproof and quick drying.

其制备过程包括以下步骤:Its preparation process comprises the following steps:

第一步,将水凝胶和占其体积分数15%的中空玻璃微珠混合均匀倒入束缚网1中;In the first step, the hydrogel and hollow glass microspheres accounting for 15% of its volume fraction are evenly mixed and poured into the

第二步,将水凝胶和占其体积分数15%的蛭石粉混合均匀倒入束缚网2中;In the second step, the hydrogel and the vermiculite powder accounting for 15% of its volume fraction are evenly mixed and poured into the bondage net 2;

第三步,将水凝胶和占其体积分数15%的铁粉混合均匀倒入束缚网3中;The third step is to mix the hydrogel with iron powder accounting for 15% of its volume fraction and pour it into the bondage net 3 evenly;

第四步,使用粘合剂将三个束缚网粘结,投入水中,水凝胶自发吸水膨胀,形成厚度为4cm的新型水下吸声材料。The fourth step is to use an adhesive to bond the three bondage nets, put them into the water, and the hydrogel will spontaneously absorb water and expand to form a new underwater sound-absorbing material with a thickness of 4cm.

性能测试:Performance Testing:

依据GB/T14369-2011标准,采用脉冲声管测试系统在2-12kHz频率范围内,测量试样的声透射系数和声压反射系数,并计算得到吸声系数。平均吸声系数达到0.81,具有优良的吸声效果,尤其在8-12kHz范围内平均吸声系数可达0.90,相较其它频段,具有更好的吸声效果。部分数据见表7:According to the GB/T14369-2011 standard, the sound transmission coefficient and the sound pressure reflection coefficient of the sample are measured in the frequency range of 2-12kHz by the pulse sound tube test system, and the sound absorption coefficient is calculated. The average sound absorption coefficient reaches 0.81, which has excellent sound absorption effect, especially in the range of 8-12kHz, the average sound absorption coefficient can reach 0.90, which has better sound absorption effect than other frequency bands. Some data are shown in Table 7:

表7Table 7

对比例1Comparative example 1

称取聚丙烯酸钠水凝胶倒入聚乙烯束缚网中,厚度为0.5mm左右,投入水中后,水凝胶吸附渗入的水快速膨胀,形成厚度为4cm的水下吸声材料。Weigh the sodium polyacrylate hydrogel and pour it into the polyethylene bondage net with a thickness of about 0.5mm. After being put into the water, the hydrogel absorbs the infiltrated water and expands rapidly to form an underwater sound-absorbing material with a thickness of 4cm.

性能测试:Performance Testing:

依据GB/T14369-2011标准,采用脉冲声管测试系统在2-12kHz频率范围内,测量试样的声透射系数和声压反射系数,并计算得到吸声系数。水凝胶在吸水溶胀时,平均吸声系数为0.5,待水凝胶充分吸水溶胀后,几乎没有造成吸声。According to the GB/T14369-2011 standard, the sound transmission coefficient and the sound pressure reflection coefficient of the sample are measured in the frequency range of 2-12kHz by the pulse sound tube test system, and the sound absorption coefficient is calculated. When the hydrogel swells with water, the average sound absorption coefficient is 0.5. After the hydrogel is fully swollen with water, there is almost no sound absorption.

对比例2Comparative example 2

称取中空玻璃微珠倒入聚乙烯束缚网中,形成厚度为4cm的水下吸声材料。Weigh the hollow glass microspheres and pour them into the polyethylene tethering net to form an underwater sound-absorbing material with a thickness of 4 cm.

性能测试:Performance Testing:

依据GB/T14369-2011标准,采用脉冲声管测试系统在2-12kHz频率范围内,测量试样的声透射系数和声压反射系数,并计算得到吸声系数。平均系数为0.34,吸声性能不佳,该材料与水的声阻抗不匹配,其平均声压反射系数随着频率的增大而增大。According to the GB/T14369-2011 standard, the sound transmission coefficient and the sound pressure reflection coefficient of the sample are measured in the frequency range of 2-12kHz by the pulse sound tube test system, and the sound absorption coefficient is calculated. The average coefficient is 0.34, and the sound absorption performance is not good. The acoustic impedance of the material does not match the water, and its average sound pressure reflection coefficient increases with the increase of frequency.

对比例3Comparative example 3

将丁苯橡胶与炭黑混合,加入体积分数为15%的中空玻璃微珠与其它配合剂混炼均匀,制得厚4cm的复合材料。Mix styrene-butadiene rubber and carbon black, add hollow glass microspheres with a volume fraction of 15% and mix evenly with other compounding ingredients to prepare a composite material with a thickness of 4 cm.

性能测试:Performance Testing:

依据GB/T14369-2011标准,采用脉冲声管测试系统在2-12kHz频率范围内,测量试样的声透射系数和声压反射系数,并计算得到吸声系数。平均吸声系数为0.58,吸声效果不佳,尤其在2-4kHz范围内吸声系数小于0.60,低频吸声效果差,在高频8-12kHz范围内平均吸声系数为0.63,吸声效果不佳。部分数据见表8:According to the GB/T14369-2011 standard, the sound transmission coefficient and the sound pressure reflection coefficient of the sample are measured in the frequency range of 2-12kHz by the pulse sound tube test system, and the sound absorption coefficient is calculated. The average sound absorption coefficient is 0.58, the sound absorption effect is not good, especially in the range of 2-4kHz, the sound absorption coefficient is less than 0.60, the low-frequency sound absorption effect is poor, the average sound absorption coefficient is 0.63 in the high-frequency range of 8-12kHz, the sound absorption effect bad. Part of the data is shown in Table 8:

表8Table 8

以上所述的仅是本发明的优选实施方式,应当指出,对于本领域的普通技术人员来说,在不脱离发明构思的前提下,还可以做出若干变形和改进,这些都属于本发明的保护范围。What has been described above is only a preferred embodiment of the present invention. It should be pointed out that for those of ordinary skill in the art, some modifications and improvements can be made without departing from the inventive concept, and these all belong to the scope of the present invention. protected range.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211265228.4ACN115602143A (en) | 2022-10-17 | 2022-10-17 | Novel underwater sound absorption material and preparation method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211265228.4ACN115602143A (en) | 2022-10-17 | 2022-10-17 | Novel underwater sound absorption material and preparation method thereof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115602143Atrue CN115602143A (en) | 2023-01-13 |

Family

ID=84847417

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211265228.4APendingCN115602143A (en) | 2022-10-17 | 2022-10-17 | Novel underwater sound absorption material and preparation method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115602143A (en) |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3972328A (en)* | 1975-07-28 | 1976-08-03 | E. R. Squibb & Sons, Inc. | Surgical bandage |

| US4127547A (en)* | 1974-12-23 | 1978-11-28 | Union Carbide Corporation | Hydrogel dough composition for fabrication of foamed articles |

| US4367259A (en)* | 1981-07-27 | 1983-01-04 | W. R. Grace & Co. | Sound deadening material |

| US20060246272A1 (en)* | 2005-04-29 | 2006-11-02 | Zhang Xiaomin X | Thermoplastic foam composite |

| US20090189111A1 (en)* | 2006-08-16 | 2009-07-30 | Hitachi Chemical Co., Ltd. | Composites for sound control applications |

| CN110534083A (en)* | 2019-08-29 | 2019-12-03 | 西安工程大学 | A kind of three-phase composite structure sound-absorbing material and its preparation method and application |

| CN113954468A (en)* | 2021-10-20 | 2022-01-21 | 西安工程大学 | Laminated impedance change composite structure sound absorbing material and preparation method and application thereof |

- 2022

- 2022-10-17CNCN202211265228.4Apatent/CN115602143A/enactivePending

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4127547A (en)* | 1974-12-23 | 1978-11-28 | Union Carbide Corporation | Hydrogel dough composition for fabrication of foamed articles |

| US3972328A (en)* | 1975-07-28 | 1976-08-03 | E. R. Squibb & Sons, Inc. | Surgical bandage |

| US4367259A (en)* | 1981-07-27 | 1983-01-04 | W. R. Grace & Co. | Sound deadening material |

| US20060246272A1 (en)* | 2005-04-29 | 2006-11-02 | Zhang Xiaomin X | Thermoplastic foam composite |

| US20090189111A1 (en)* | 2006-08-16 | 2009-07-30 | Hitachi Chemical Co., Ltd. | Composites for sound control applications |

| CN110534083A (en)* | 2019-08-29 | 2019-12-03 | 西安工程大学 | A kind of three-phase composite structure sound-absorbing material and its preparation method and application |

| CN113954468A (en)* | 2021-10-20 | 2022-01-21 | 西安工程大学 | Laminated impedance change composite structure sound absorbing material and preparation method and application thereof |

Non-Patent Citations (3)

| Title |

|---|

| ERQIAN DONG ET AL.: "《Bioinspired metagel with broadband tunable impedance matching》", 《SCIENCE ADVANCES》, vol. 6, no. 4, 30 October 2020 (2020-10-30), pages 1 - 9* |

| 吕杰等编著: "《生物医用材料导论》", vol. 978, 31 October 2016, 《同济大学出版社》, pages: 112 - 113* |

| 陈文等: "《材料物理性能》", vol. 978, 31 January 2010, 《武汉理工大学出版社》, pages: 279 - 280* |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Chen et al. | The effects of various additive components on the sound absorption performances of polyurethane foams | |

| CN106475296A (en) | A kind of thickness mode piezoelectricity sky coupling transducer based on double coupling Rotating fields | |

| He et al. | Enhanced sound absorption properties of porous ceramics modified by graphene oxide films | |

| CN115602143A (en) | Novel underwater sound absorption material and preparation method thereof | |

| CN111849048B (en) | A metal powder-rubber particle composite phononic material, preparation method and application | |

| CN115806412B (en) | A kind of multi-solid waste base polymer wave-absorbing concrete material and its preparation method | |

| Yu et al. | Acoustic properties of polyurethane composite with both millimeter-scale closed cavity and nanometer-scale semi closed cavity | |

| CN103275529A (en) | 0.6-18GHz-frequency-band wave-absorbing powder/inorganic silicate anti-electromagnetic interference coating material and preparation method thereof | |

| CN116453493A (en) | Pressure-resistant sound absorption structure with supporting structure | |

| Zhang et al. | Study on viscoelasticity and damping properties of OSA/PAAM hydrogel | |

| Jiang et al. | Acoustic/mechanical properties of polyurethane composites with syntactic hollow spheres | |

| Chen et al. | Preparation of lamellar-structured carboxymethyl cellulose aerogels for efficient sound absorption | |

| MB et al. | Acoustic characterization of natural areca catechu fiber‐reinforced flexible polyurethane foam composites | |

| US20210217397A1 (en) | Sound Insulation Element | |

| CN102155870B (en) | High-absorption camouflage net and manufacturing method thereof | |

| CN112194962B (en) | A kind of high ultrasonic reflection unmanned vehicle coating composition and its application | |

| CN202032947U (en) | Highly-absorbing camouflage net | |

| CN109081637B (en) | Wave-absorbing conical body for anechoic chamber | |

| CN102702724B (en) | Multiphase composite decoupling material and preparation method thereof | |

| CN110342852A (en) | A kind of multi-functional photocatalyst aeroge wall covering and preparation method thereof | |

| CN202031277U (en) | Wave-absorbing ceiling for electromagnetic protection | |

| CN115011076B (en) | Fiber embedded wave-absorbing composite hollow sphere and preparation method thereof | |

| CN211199025U (en) | Hollow porous glass bead | |

| CN102993684A (en) | Polyurethane material of glass flake as well as preparation method and application thereof | |

| CN102168477A (en) | Wave-absorbing hang ceiling for electromagnetic protection and preparation method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |