CN115590260A - Heating control method, aerosol generating device, and storage medium - Google Patents

Heating control method, aerosol generating device, and storage mediumDownload PDFInfo

- Publication number

- CN115590260A CN115590260ACN202211312420.4ACN202211312420ACN115590260ACN 115590260 ACN115590260 ACN 115590260ACN 202211312420 ACN202211312420 ACN 202211312420ACN 115590260 ACN115590260 ACN 115590260A

- Authority

- CN

- China

- Prior art keywords

- heating

- heating element

- aerosol

- sections

- section

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24F—SMOKERS' REQUISITES; MATCH BOXES; SIMULATED SMOKING DEVICES

- A24F40/00—Electrically operated smoking devices; Component parts thereof; Manufacture thereof; Maintenance or testing thereof; Charging means specially adapted therefor

- A24F40/50—Control or monitoring

- A24F40/57—Temperature control

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24F—SMOKERS' REQUISITES; MATCH BOXES; SIMULATED SMOKING DEVICES

- A24F40/00—Electrically operated smoking devices; Component parts thereof; Manufacture thereof; Maintenance or testing thereof; Charging means specially adapted therefor

- A24F40/40—Constructional details, e.g. connection of cartridges and battery parts

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24F—SMOKERS' REQUISITES; MATCH BOXES; SIMULATED SMOKING DEVICES

- A24F40/00—Electrically operated smoking devices; Component parts thereof; Manufacture thereof; Maintenance or testing thereof; Charging means specially adapted therefor

- A24F40/50—Control or monitoring

- A24F40/51—Arrangement of sensors

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24F—SMOKERS' REQUISITES; MATCH BOXES; SIMULATED SMOKING DEVICES

- A24F47/00—Smokers' requisites not otherwise provided for

Landscapes

- Control Of Resistance Heating (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及气溶胶生成领域,尤其涉及一种发热控制方法、气溶胶生成装置及存储介质。The invention relates to the field of aerosol generation, in particular to a heat generation control method, an aerosol generation device and a storage medium.

背景技术Background technique

传统卷烟燃烧的烟雾中含有焦油等有害物质,用户通常通过点燃的方式抽吸传统卷烟,但长期吸入这些有害物质会对人体产生危害。为了克服传统卷烟燃烧产生有害物质,出现了气溶胶生成装置,其通过加热传统卷烟以产生气溶胶,从而降低有害物质,进而减少对人体的危害。Burning smoke of traditional cigarettes contains tar and other harmful substances. Users usually smoke traditional cigarettes by lighting them, but long-term inhalation of these harmful substances will cause harm to the human body. In order to overcome the harmful substances produced by the burning of traditional cigarettes, an aerosol generating device has emerged, which generates aerosols by heating traditional cigarettes, thereby reducing harmful substances and reducing the harm to the human body.

目前,现有的气溶胶生成装置需要按照固定的预热时间控制发热体进行发热,进而加热传统卷烟产生气溶胶供用户抽吸。然而,按照固定的预热时间控制发热体进行发热存在以下缺陷:用户连续使用气溶胶生成装置加热传统卷烟产生气溶胶进行抽吸时,会出现气溶胶生成装置产生的气溶胶的温度较高,导致气溶胶过热烫嘴的问题,给用户带来不好的体验。At present, the existing aerosol generating device needs to control the heating element to generate heat according to a fixed preheating time, and then heat the traditional cigarette to generate aerosol for the user to smoke. However, controlling the heating element to generate heat according to a fixed preheating time has the following defects: when the user continuously uses the aerosol generating device to heat the traditional cigarette to generate aerosol for smoking, the temperature of the aerosol generated by the aerosol generating device will be relatively high, The problem of causing the aerosol to overheat and burn the mouth brings a bad experience to the user.

发明内容Contents of the invention

本发明实施例提供了一种发热控制方法、气溶胶生成装置及存储介质,旨在解决用户连续使用气溶胶生成装置加热传统卷烟产生气溶胶进行抽吸时,会出现气溶胶生成装置产生的气溶胶的温度较高,导致气溶胶过热烫嘴的问题。Embodiments of the present invention provide a heat generation control method, an aerosol generating device, and a storage medium, aiming at solving the problem of aerosol generated by the aerosol generating device when the user continuously uses the aerosol generating device to heat the traditional cigarette to generate aerosol for smoking. The temperature of the aerosol is high, which leads to the problem that the aerosol is overheated and scalds the mouth.

第一方面,本发明实施例提供一种发热控制方法,应用于气溶胶生成装置,所述气溶胶生成装置包括N段发热体,所述N段发热体,用于对收容于所述气溶胶生成装置中的烟支进行加热以产生气溶胶,N为大于或等于2的整数,所述方法包括:获取所述N段发热体的整体初始温度;获取预设温度控制数据,所述预设温度控制数据包括所述N段发热体在烟支的加热阶段中的不同时间点的目标温度;根据所述整体初始温度,从所述预设温度控制数据中确定所述N段发热体进行发热的起始时间点;根据所述N段发热体进行发热的起始时间点和所述预设温度控制数据,控制所述N段发热体进行发热。In the first aspect, the embodiment of the present invention provides a heating control method, which is applied to an aerosol generating device. The aerosol generating device includes N-section heating elements, and the N-section heating elements are used to control the aerosol The cigarettes in the generation device are heated to generate aerosol, N is an integer greater than or equal to 2, and the method includes: obtaining the overall initial temperature of the heating element in the N section; obtaining preset temperature control data, the preset The temperature control data includes the target temperature of the N-segment heating element at different time points during the heating phase of the cigarette; according to the overall initial temperature, it is determined from the preset temperature control data that the N-segment heating element generates heat The starting time point of the heating element; according to the starting time point of the heating element of the N section and the preset temperature control data, the heating element of the N section is controlled to generate heat.

第二方面,本发明实施例还提供一种气溶胶生成装置,包括气溶胶输出端、烟管、N段发热体和控制器。所述气溶胶输出端用于输出气溶胶;所述烟管用于收容烟支;所述N段发热体,用于对收容于所述烟管中的烟支进行加热以产生气溶胶,第i+1段发热体相比第i段发热体更远离所述气溶胶输出端,所述i为大于等于1且小于N的整数,N为大于或等于2的整数;所述控制器,用于执行如第一方面所述的发热控制方法,以控制所述N段发热体进行发热。In the second aspect, the embodiment of the present invention also provides an aerosol generating device, including an aerosol output terminal, a smoke pipe, N-section heating elements, and a controller. The aerosol output end is used to output aerosol; the smoke tube is used to accommodate cigarettes; the N-section heating element is used to heat the cigarettes stored in the smoke tube to generate aerosol, the i The +1 heating element is farther away from the aerosol output than the i-th heating element, the i is an integer greater than or equal to 1 and less than N, and N is an integer greater than or equal to 2; the controller is used to Executing the heating control method as described in the first aspect to control the N-section heating element to generate heat.

第三方面,本发明实施例还提供一种存储介质,用于计算机可读存储,所述存储介质存储有一个或者多个程序,所述一个或者多个程序可被一个或者多个处理器执行,以实现如第一方面所述的发热控制方法。In the third aspect, the embodiment of the present invention also provides a storage medium for computer-readable storage, the storage medium stores one or more programs, and the one or more programs can be executed by one or more processors , so as to realize the heat generation control method as described in the first aspect.

本发明实施例提供的发热控制方法、气溶胶生成装置及存储介质,通过获取N段发热体的整体初始温度以及获取预设温度控制数据,基于整体初始温度能够在预设温度控制数据中自适应地确定N段发热体进行发热的起始时间点,而后根据N段发热体进行发热的起始时间点和预设温度控制数据,控制N段发热体进行发热,从而实现了基于整体初始温度自适应调整N段发热体的发热时间,避免连续使用气溶胶生成装置加热传统卷烟时对传统卷烟过度加热,从而解决了用户连续使用气溶胶生成装置加热传统卷烟产生气溶胶进行抽吸时,会出现气溶胶生成装置产生的气溶胶的温度较高,导致气溶胶过热烫嘴的问题。The heating control method, aerosol generating device, and storage medium provided by the embodiments of the present invention can adapt to the preset temperature control data based on the overall initial temperature by acquiring the overall initial temperature of the N-section heating element and the preset temperature control data. accurately determine the starting time point of heating of the N-section heating element, and then control the N-section heating element to generate heat according to the starting time point of the N-section heating element and the preset temperature control data, thereby realizing automatic heating based on the overall initial temperature. Adapt to adjust the heating time of the N-section heating element, avoid overheating the traditional cigarettes when the aerosol generating device is continuously used to heat the traditional cigarette, thus solving the problem that occurs when the user continuously uses the aerosol generating device to heat the traditional cigarette to generate aerosol for smoking The temperature of the aerosol generated by the aerosol generating device is relatively high, which leads to the problem that the aerosol is overheated and scalds the mouth.

附图说明Description of drawings

为了更清楚地说明本申请实施例技术方案,下面将对实施例描述中所需要使用的附图作简单地介绍,显而易见地,下面描述中的附图是本申请的一些实施例,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to illustrate the technical solutions of the embodiments of the present application more clearly, the drawings that need to be used in the description of the embodiments will be briefly introduced below. Obviously, the drawings in the following description are some embodiments of the present application. Ordinary technicians can also obtain other drawings based on these drawings on the premise of not paying creative work.

图1是本发明实施例中的气溶胶生成装置的简单结构示意图;Fig. 1 is a simple structural schematic diagram of an aerosol generating device in an embodiment of the present invention;

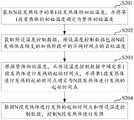

图2是本发明实施例提供的一种发热控制方法的流程示意图;Fig. 2 is a schematic flow chart of a heating control method provided by an embodiment of the present invention;

图3是图2中的发热控制方法的子步骤流程示意图;Fig. 3 is a schematic flow chart of the sub-steps of the heating control method in Fig. 2;

图4是本发明实施例中用于控制4段发热体进行发热的目标温度曲线示意图;Fig. 4 is a schematic diagram of the target temperature curve used to control the 4-stage heating element to generate heat in the embodiment of the present invention;

图5是图2中的发热控制方法的另一子步骤流程示意图;Fig. 5 is a schematic flowchart of another sub-step of the heating control method in Fig. 2;

图6是本发明实施例提供的另一种发热控制方法的流程示意图;Fig. 6 is a schematic flowchart of another heat generation control method provided by an embodiment of the present invention;

图7是本发明实施例提供的一种气溶胶生成装置的结构示意框图。Fig. 7 is a schematic block diagram of the structure of an aerosol generating device provided by an embodiment of the present invention.

具体实施方式detailed description

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

附图中所示的流程图仅是示例说明,不是必须包括所有的内容和操作/步骤,也不是必须按所描述的顺序执行。例如,有的操作/步骤还可以分解、组合或部分合并,因此实际执行的顺序有可能根据实际情况改变。The flow charts shown in the drawings are just illustrations, and do not necessarily include all contents and operations/steps, nor must they be performed in the order described. For example, some operations/steps can be decomposed, combined or partly combined, so the actual order of execution may be changed according to the actual situation.

应当理解,在此本发明说明书中所使用的术语仅仅是出于描述特定实施例的目的而并不意在限制本发明。如在本发明说明书和所附权利要求书中所使用的那样,除非上下文清楚地指明其它情况,否则单数形式的“一”、“一个”及“该”意在包括复数形式。It should be understood that the terminology used in the description of the present invention is for the purpose of describing particular embodiments only and is not intended to be limiting of the present invention. As used in this specification and the appended claims, the singular forms "a", "an" and "the" are intended to include plural referents unless the context clearly dictates otherwise.

下面结合附图,对本发明的一些实施例作详细说明。在不冲突的情况下,下述的实施例及实施例中的特征可以相互组合。Some embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. In the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

请参阅图1,图1是本发明实施例中的气溶胶生成装置的简单结构示意图。如图1所示,所述气溶胶生成装置100包括气溶胶输出端10、N段发热体20、烟管30。所述烟管30用于收容烟支Y1,烟支可以是传统卷烟,也可以是特制烟弹。所述N段发热体20围绕于所述烟管30的外表面上,且所述N段发热体20间隔设置。其中,所述N段发热体20包括第1段发热体201至第N段发热体20N,第1段发热体201至第N段发热体20N沿着逐渐远离所述气溶胶输出端10的方向依次排列。所述第i+1段发热体20i+1相比所述第i段发热体20i更远离所述气溶胶生成装置100的气溶胶输出端10。其中,所述气溶胶输出端10为所述气溶胶生成装置100输出气溶胶而供用户吸食的端口,例如,所述气溶胶输出端10可为滤嘴端。Please refer to FIG. 1 . FIG. 1 is a schematic structural diagram of an aerosol generating device in an embodiment of the present invention. As shown in FIG. 1 , the

所述气溶胶生成装置100还包括雾化组件40,所述雾化组件40与所述烟管30邻近设置,且与所述烟管30沿着逐渐远离所述气溶胶输出端10的方向排列。所述烟管30的延伸方向与所述雾化组件40及所述烟管30的排列方向相同,所述烟管30相比所述雾化组件40更远离所述气溶胶输出端10。The

在一实施例中,所述雾化组件40中设有精油,其中,在进行烟支吸食时,当发热体20通过所述烟管30对收容于烟管30中的烟支Y1加热而产生烟气时,所述精油也被加热而雾化/汽化形成雾化气,所述烟气通过烟管30到达所述雾化组件40,而与所述雾化气混合得到混合气溶胶,然后所述混合气溶胶再到达所述气溶胶输出端10,从而供用户吸食。其中,所述雾化组件40中的精油可以被到达所述雾化组件40的所述烟气雾化。In one embodiment, the

在一实施例中,如图1所示,所述气溶胶生成装置100还可包括冷却通道50,所述冷却通道50位于所述气溶胶输出端10与所述雾化组件40之间。其中,刚从所述雾化组件40出来的混合有雾化气的混合气溶胶温度较高,因此,所述气溶胶和所述雾化气混合后,通过所述冷却通道50进行冷却后,再到达所述气溶胶输出端10,以供用户吸食。在其它实施例中,气溶胶生成装置也可以没有雾化组件和精油,即气溶胶没有雾化气只有烟气,气溶胶经冷却通道冷却后到达气溶胶输出端10。In an embodiment, as shown in FIG. 1 , the

需知,图1中的气溶胶生成装置的结构仅仅是与本发明实施例方案相关的部分结构的框图,并不构成对本发明实施例方案所应用于其上的气溶胶生成装置的限定,具体的气溶胶生成装置可以包括比图中所示更多或更少的部件,或者组合某些部件,或者具有不同的部件布置。例如,在一些实施例中,气溶胶生成装置的雾化组件中的精油也可以是固态香料;在一些实施例中,气溶胶生成装置也可以没有雾化组件和精油;在一些实施例中,N段发热体也可以设于烟管的内部。It should be known that the structure of the aerosol generating device in Figure 1 is only a block diagram of a part of the structure related to the embodiment of the present invention, and does not constitute a limitation on the aerosol generating device to which the embodiment of the present invention is applied. The aerosol-generating device may include more or fewer components than shown in the figures, or combine certain components, or have a different arrangement of components. For example, in some embodiments, the essential oil in the atomization component of the aerosol generating device can also be a solid fragrance; in some embodiments, the aerosol generating device can also have no atomization component and essential oil; in some embodiments, The N section heating element can also be arranged inside the smoke pipe.

以下,将结合图1中的气溶胶生成装置对本发明的实施例提供的发热控制方法进行详细介绍。Hereinafter, the heat generation control method provided by the embodiment of the present invention will be described in detail with reference to the aerosol generating device shown in FIG. 1 .

请参阅图2,图2是本发明实施例提供的一种发热控制方法的流程示意图。Please refer to FIG. 2 . FIG. 2 is a schematic flowchart of a heating control method provided by an embodiment of the present invention.

如图2所示,该发热控制方法包括步骤S101至步骤S104。As shown in FIG. 2 , the heating control method includes steps S101 to S104.

步骤S101、获取N段发热体的整体初始温度;Step S101, obtaining the overall initial temperature of the N-section heating element;

步骤S102、获取预设温度控制数据,预设温度控制数据包括N段发热体在烟支的加热阶段中的不同时间点的目标温度;Step S102. Acquiring preset temperature control data, the preset temperature control data includes the target temperatures of the N-segment heating elements at different time points during the heating phase of the cigarette;

步骤S103、根据整体初始温度,从预设温度控制数据中确定N段发热体进行发热的起始时间点;Step S103, according to the overall initial temperature, determine the starting time point for heating of the heating element in N sections from the preset temperature control data;

步骤S104、根据N段发热体进行发热的起始时间点和预设温度控制数据,控制N段发热体进行发热。Step S104 , according to the starting time point of heating of the heating elements of the N sections and the preset temperature control data, control the heating elements of the N sections to generate heat.

本发明实施例中,通过获取N段发热体的整体初始温度以及获取预设温度控制数据,基于整体初始温度能够在预设温度控制数据中自适应地确定N段发热体进行发热的起始时间点,而后根据N段发热体进行发热的起始时间点和预设温度控制数据,控制N段发热体进行发热,从而实现了基于整体初始温度自适应调整发热体的发热时间,避免连续使用气溶胶生成装置加热传统卷烟时对传统卷烟过度加热,解决了用户连续使用气溶胶生成装置加热传统卷烟产生气溶胶进行抽吸时,会出现气溶胶生成装置产生的气溶胶的温度较高,导致气溶胶过热烫嘴的问题。In the embodiment of the present invention, by acquiring the overall initial temperature of the N-segment heating element and obtaining the preset temperature control data, the starting time for the N-segment heating element to generate heat can be adaptively determined based on the overall initial temperature in the preset temperature control data point, and then according to the starting time point of the heating element in the N section and the preset temperature control data, the heating element in the N section is controlled to generate heat, so that the heating time of the heating element can be adaptively adjusted based on the overall initial temperature, and the continuous use of gas can be avoided. When the aerosol generating device heats the traditional cigarette, it overheats the traditional cigarette, which solves the problem that when the user continuously uses the aerosol generating device to heat the traditional cigarette to generate aerosol for smoking, the temperature of the aerosol generated by the aerosol generating device will be high, resulting in aerosol The problem of overheating and scalding the mouth of the sol.

可以理解的是,由于预设温度控制数据中烟支的加热阶段的截止时间点是固定的,N段发热体的整体初始温度越高,则N段发热体在预设温度控制数据中进行发热的起始时间点越靠后,这样N段发热体进行发热的时间就越短。同样的,N段发热体的整体初始温度越低,N段发热体在预设温度控制数据中进行发热的起始时间点越靠前,这样N段发热体进行发热的时间就越长,从而实现了基于整体初始温度自适应调整N段发热体的发热时间。It can be understood that since the cut-off time point of the heating phase of the cigarette in the preset temperature control data is fixed, the higher the overall initial temperature of the N-section heating element, the N-section heating element will generate heat in the preset temperature control data. The later the starting time point of the N-section heating element is, the shorter the heating time is. Similarly, the lower the overall initial temperature of the N-section heating element is, the earlier the N-section heating element starts heating in the preset temperature control data, so the N-section heating element takes longer to generate heat, thus The heating time of the N-section heating element is adaptively adjusted based on the overall initial temperature.

在一实施例中,响应用户对气溶胶生成装置的开启按键的触发操作,获取N段发热体的整体初始温度;获取预设温度控制数据;根据整体初始温度,从预设温度控制数据中确定N段发热体进行发热的起始时间点;根据该N段发热体进行发热的起始时间点和预设温度控制数据,控制该N段发热体进行发热。通过在侦测到用户按压气溶胶生成装置的开启按键时,基于N段发热体的整体初始温度,可以在预设温度控制数据自适应确定N段发热体进行发热的起始时间点,这样根据N段发热体进行发热的起始时间点和预设温度控制数据,控制N段发热体进行发热后,能够解决用户连续使用气溶胶生成装置加热传统卷烟产生气溶胶进行抽吸时,会出现气溶胶生成装置产生的气溶胶的温度较高,导致气溶胶过热烫嘴的问题。In one embodiment, in response to the user's trigger operation on the start button of the aerosol generating device, the overall initial temperature of the N-section heating element is obtained; the preset temperature control data is obtained; according to the overall initial temperature, it is determined from the preset temperature control data The starting time point of heating of the N-segment heating element; according to the starting time point of the heating of the N-segment heating element and the preset temperature control data, the N-segment heating element is controlled to generate heat. When it is detected that the user presses the start button of the aerosol generating device, based on the overall initial temperature of the heating element in the N section, the starting time point for the heating of the heating element in the N section can be determined adaptively based on the preset temperature control data, so that according to The starting time point and preset temperature control data of the heating element in the N section. After controlling the heating element in the N section, it can solve the problem of aerosol when the user continuously uses the aerosol generating device to heat the traditional cigarette to generate aerosol for smoking. The temperature of the aerosol generated by the sol generating device is relatively high, which leads to the problem that the aerosol is overheated and scalds the mouth.

在一实施例中,N段发热体的整体初始温度可以是在侦测到用户按压气溶胶生成装置的开启按键时,通过温度传感器采集到的,也可以是在侦测到用户按压气溶胶生成装置的开启按键时,根据N段发热体的当前温度确定的。例如,响应用户对气溶胶生成装置的开启按键的触发操作,获取温度传感器采集到的温度,并将温度传感器采集到的温度确定为N段发热体的整体初始温度。In one embodiment, the overall initial temperature of the N-section heating element can be collected by the temperature sensor when it is detected that the user presses the start button of the aerosol generating device, or it can be detected when the user presses the aerosol generating device. When the device is turned on, it is determined according to the current temperature of the N-section heating element. For example, in response to the user's trigger operation of the start button of the aerosol generating device, the temperature collected by the temperature sensor is obtained, and the temperature collected by the temperature sensor is determined as the overall initial temperature of the N-section heating element.

在一实施例中,如图3所示,步骤S101包括子步骤S1011至S1012。In one embodiment, as shown in FIG. 3 , step S101 includes sub-steps S1011 to S1012.

子步骤S1011、获取各段发热体各自对应的初始温度;Sub-step S1011, obtaining the corresponding initial temperature of each heating element;

子步骤S1012、根据各段发热体各自对应的初始温度确定N段发热体的整体初始温度。Sub-step S1012: Determine the overall initial temperature of the heating elements in the N sections according to the corresponding initial temperatures of the heating elements in each section.

本发明实施例中,通过各段发热体各自对应的初始温度,可以综合计算得到N段发热体的整体初始温度,提高整体初始温度的准确性。其中,各段发热体各自对应的初始温度为在侦测到用户按压气溶胶生成装置的开启按键时,各段发热体各自对应的当前温度。In the embodiment of the present invention, the overall initial temperature of the N-section heating elements can be comprehensively calculated through the corresponding initial temperatures of the heating elements in each section, thereby improving the accuracy of the overall initial temperature. Wherein, the initial temperature corresponding to each segment of the heating element is the current temperature corresponding to each segment of the heating element when it is detected that the user presses the start button of the aerosol generating device.

在一实施例中,N段发热体均为热敏电阻,获取发热体对应的初始温度的方式可以为:响应用户对气溶胶生成装置的开启按键的触发操作,获取发热体的当前电阻值;根据预设的发热体的电阻值与温度的对应关系,得到当前电阻值对应的温度,并将当前电阻值对应的温度确定为发热体的初始温度。其中,热敏电阻可为具有正相关的电阻温度系数(temperature coefficient of resistance,TCR)的热敏电阻,即电阻值与温度呈正相关关系,根据热敏电阻固有的电阻值与温度的正相关关系,可以预先得出发热体的电阻值与温度的对应关系。In one embodiment, the heating elements in the N sections are all thermistors, and the way to obtain the initial temperature corresponding to the heating element may be: responding to the user's trigger operation on the opening button of the aerosol generating device, obtaining the current resistance value of the heating element; According to the preset correspondence between the resistance value and temperature of the heating element, the temperature corresponding to the current resistance value is obtained, and the temperature corresponding to the current resistance value is determined as the initial temperature of the heating element. Wherein, the thermistor can be a thermistor with a positively correlated temperature coefficient of resistance (temperature coefficient of resistance, TCR), that is, the resistance value is positively correlated with temperature, and according to the inherent positive correlation relationship between the resistance value and temperature of the thermistor , the corresponding relationship between the resistance value of the heating element and the temperature can be obtained in advance.

可以理解的是,发热体的当前电阻值可以通过电阻测量电路直接测量得到,也可以通过施加至发热体的电压以及经过发热体的电流计算得到,本发明实施例对此不做具体限定。可以理解的是,在其他实施例中,也可以通过温度传感器等直接测量得到发热体的初始温度。It can be understood that the current resistance value of the heating element can be directly measured by the resistance measuring circuit, or can be obtained by calculating the voltage applied to the heating element and the current passing through the heating element, which is not specifically limited in this embodiment of the present invention. It can be understood that, in other embodiments, the initial temperature of the heating element can also be directly measured by a temperature sensor or the like.

在一实施例中,根据各段发热体各自对应的初始温度确定N段发热体的整体初始温度的方式可以为:获取各段发热体各自对应的加权系数;对于每一段发热体,计算发热体的初始温度与发热体对应的加权系数之间的乘积,得到各段发热体的加权温度;对各段发热体的加权温度进行累加,得到N段发热体的整体初始温度。通过对各段发热体各自对应的初始温度进行加权求和,可以得到准确的整体初始温度。In an embodiment, the method of determining the overall initial temperature of the heating elements in N sections according to the corresponding initial temperatures of each section of heating elements may be as follows: obtaining the weighting coefficients corresponding to each section of heating elements; for each section of heating elements, calculating the heating element The product of the initial temperature of the heating element and the weighting coefficient corresponding to the heating element is used to obtain the weighted temperature of each section of heating element; the weighted temperature of each section of heating element is accumulated to obtain the overall initial temperature of N section heating elements. The accurate overall initial temperature can be obtained by weighting and summing the corresponding initial temperatures of each segment of the heating elements.

在一实施例中,发热体的加权系数与目标距离呈负相关关系,目标距离为发热体与气溶胶生成装置的气溶胶输出端之间的距离。可以理解的是,发热体与气溶胶生成装置的气溶胶输出端之间的距离越近,发热体对应的加权系数越大,发热体与气溶胶生成装置的气溶胶输出端之间的距离越远,发热体对应的加权系数越小。其中,各段发热体各自对应的加权系数可以基于实际情况进行设置,本发明实施例对此不做具体限定。In one embodiment, the weighting coefficient of the heating element has a negative correlation with the target distance, and the target distance is the distance between the heating element and the aerosol output end of the aerosol generating device. It can be understood that the closer the distance between the heating element and the aerosol output end of the aerosol generating device, the greater the weighting coefficient corresponding to the heating element, and the closer the distance between the heating element and the aerosol output end of the aerosol generating device. The farther away, the smaller the weighting coefficient corresponding to the heating element. Wherein, the weighting coefficients corresponding to each section of heating elements may be set based on actual conditions, which is not specifically limited in this embodiment of the present invention.

在一实施例中,N段发热体的整体初始温度T=T1*β1+T2*β2+....+TN*βN,其中,T为N段发热体的整体初始温度,T1为第1段发热体的初始温度,β1为第1段发热体对应的加权系数,T2为第2段发热体的初始温度,β2为第2段发热体对应的加权系数,TN为第N段发热体的初始温度,βN为第2段发热体对应的加权系数。例如,以N=4,即气溶胶生成装置包括4段发热体为例,则按照上述公式可以计算得到4段发热体的整体初始温度T=T1*β1+T2*β2+T3*β3+T4*β4,设β1=0.8、β2=0.4、β3=0.2和β4=0.2,则T=T1*0.8+T2*0.4+T3*0.2+T4*0.2,设T1=160、T2=180、T3=200和T4=200,则T=160*0.8+180*0.4+200*0.2+200*0.2=280摄氏度。In one embodiment, the overall initial temperature of the N-section heating element T=T1 *β1 +T2 *β2 +....+TN *βN , where T is the overall initial temperature of the N-section heating element Temperature, T1 is the initial temperature of the heating element in the first stage, β1 is the weighting coefficient corresponding to the heating element in the first stage, T2 is the initial temperature of the heating element in the second stage, and β2 is the weighting coefficient corresponding to the heating element in the second stage Coefficient, TN is the initial temperature of the heating element in the Nth section, and βN is the weighting coefficient corresponding to the heating element in the second section. For example, taking N=4, that is, the aerosol generating device includes 4 heating elements as an example, then the overall initial temperature of the 4 heating elements can be calculated according to the above formula T=T1 *β1 +T2 *β2 +T3 *β3 +T4 *β4 , assuming β1 =0.8, β2 =0.4, β3 =0.2 and β4 =0.2, then T=T1 *0.8+T2 *0.4+T3 *0.2+ T4 *0.2, assuming T1 =160, T2 =180, T3 =200 and T4 =200, then T=160*0.8+180*0.4+200*0.2+200*0.2=280 degrees Celsius.

在一实施例中,各段发热体各自对应的加权系数之和等于1。例如,设β1=0.7、β2=0.1、β3=0.1和β4=0.1,且T1=200、T2=220、T3=240和T4=280,则整体初始温度T=200*0.7+220*0.1+240*0.1+280*0.1=214摄氏度。又例如,设β1=0.6、β2=0.2、β3=0.1和β4=0.1,且T1=200、T2=220、T3=240和T4=280,则4段发热体的整体初始温度T=200*0.6+220*0.2+240*0.1+280*0.1=216摄氏度。In an embodiment, the sum of the weighting coefficients corresponding to each segment of the heating element is equal to 1. For example, if β1 =0.7, β2 =0.1, β3 =0.1 and β4 =0.1, and T1 =200, T2 =220, T3 =240 and T4 =280, then the overall initial temperature T= 200*0.7+220*0.1+240*0.1+280*0.1=214 degrees Celsius. For another example, if β1 =0.6, β2 =0.2, β3 =0.1, and β4 =0.1, and T1 =200, T2 =220, T3 =240, and T4 =280, then the four heating elements The overall initial temperature T = 200*0.6+220*0.2+240*0.1+280*0.1=216 degrees Celsius.

在一实施例中,预设温度控制数据包括N段发热体在烟支的加热阶段中的不同时间点的目标温度,也即预设温度控制数据包括第i段发热体至第N段发热体中的各段发热体在烟支的加热阶段中的不同时间点的目标温度。可以理解的是,预设温度控制数据可以为表格形式或者曲线形式。例如,N=4,预设温度控制数据包括第1段发热体、第2段发热体、第3段发热体和第4段发热体在烟支的加热阶段中的不同时间点的目标温度。In one embodiment, the preset temperature control data includes the target temperatures of the heating elements of the N sections at different time points during the heating phase of the cigarette, that is, the preset temperature control data includes the i-th heating element to the N-th heating element The target temperature of each segment of the heating element in different time points in the heating stage of the cigarette. It can be understood that the preset temperature control data can be in the form of a table or a curve. For example, N=4, the preset temperature control data includes target temperatures at different time points of the heating element in the first stage, the heating element in the second stage, the heating element in the third stage and the heating element in the fourth stage during the heating phase of the cigarette.

请参阅图4,图4是本发明实施例中用于控制4段发热体进行发热的目标温度曲线示意图。图4中示意出了4条目标温度曲线C1-C4。如图4所示,设4条目标温度曲线C1-C4分别定义了第1段发热体、第2段发热体、第3段发热体和第4段发热体在烟支的加热阶段中的不同时间点的目标温度。其中,本发明实施例中的时间点可以是时间片,图4中的横坐标为时间片,每个时间片对应2秒时间,图4中的纵坐标为温度。Please refer to FIG. 4 . FIG. 4 is a schematic diagram of a target temperature curve for controlling the heating elements in four sections to generate heat in an embodiment of the present invention. Figure 4 schematically shows four target temperature curves C1-C4. As shown in Figure 4, set 4 target temperature curves C1-C4 to define the differences in the heating stage of the cigarette branch in the first section of heating element, the second section of heating element, the third section of heating element and the fourth section of heating element The target temperature at the point in time. Wherein, the time point in the embodiment of the present invention may be a time slice, the abscissa in FIG. 4 is a time slice, and each time slice corresponds to 2 seconds, and the ordinate in FIG. 4 is a temperature.

在一实施例中,预设温度控制数据包括烟支的加热阶段所对应的M个时间点和各段发热体在第1个时间点至第M个时间点中的各时间点的目标温度,M为大于等于2的整数,根据整体初始温度,从预设温度控制数据中确定N段发热体进行发热的起始时间点的方式可以包括:按照第1个时间点到第j个时间点的顺序,依次将N段发热体中的各段发热体在各时间点的目标温度与整体初始温度进行比较,j小于M;在目标温度大于或等于整体初始温度时,将当前进行比较的时间点确定为N段发热体进行发热的起始时间点。其中,第1个时间点为烟支的加热阶段的起始时间点,第j个时间点为烟支的加热阶段中烟支预热完成的的截止时间点。按照从早到晚的顺序,依次将N段发热体中的各段在各时间点对应的目标温度与整体初始温度进行比较,可以准确地确定N段发热体进行发热的起始时间点。In one embodiment, the preset temperature control data includes M time points corresponding to the heating phase of the cigarette and the target temperature of each heating element at each time point from the first time point to the Mth time point, M is an integer greater than or equal to 2. According to the overall initial temperature, the method of determining the starting time point of heating of the N-section heating element from the preset temperature control data may include: according to the first time point to the jth time point Sequentially, compare the target temperature of each segment of the heating elements in the N segment heating elements at each time point with the overall initial temperature, j is less than M; when the target temperature is greater than or equal to the overall initial temperature, the current comparison time point It is determined as the starting time point for the N-segment heating element to generate heat. Wherein, the first time point is the starting time point of the heating phase of the cigarette, and the jth time point is the cut-off time point of completion of the preheating of the cigarette in the heating phase of the cigarette. In order from early to late, the target temperature corresponding to each segment of the N-segment heating element at each time point is compared with the overall initial temperature, and the starting time point for the N-segment heating element to generate heat can be accurately determined.

在一实施例中,根据整体初始温度,从预设温度控制数据中确定N段发热体进行发热的起始时间点的方式可以包括:按照第1个时间点到第j个时间点的顺序,依次将N段发热体中的各段发热体在各时间点的目标温度与整体初始温度进行比较;在进行比较的每个时间点的目标温度均小于整体初始温度时,将第j-k个时间点确定为N段发热体进行发热的起始时间点,k为大于等于0,且小于等于j/3的整数。In an embodiment, according to the overall initial temperature, the method of determining the starting time point of heating of N segments of heating elements from the preset temperature control data may include: in the order of the first time point to the jth time point, Sequentially compare the target temperature of each heating element in the N sections of heating elements at each time point with the overall initial temperature; when the target temperature at each time point for comparison is lower than the overall initial temperature, the j-kth time point It is determined as the starting time point when the N-segment heating element generates heat, and k is an integer greater than or equal to 0 and less than or equal to j/3.

可以理解的是,在k=0时,N段发热体中的各段发热体在各时间点的目标温度均小于整体初始温度的情况下,该N段发热体进行发热的起始时间点为预设温度控制数据中的第j个时间点,也即N段发热体在烟支的加热阶段中的预热阶段不需要发热。在k为1、2、3、4或5时,N段发热体中的各段发热体在各时间点的目标温度均小于整体初始温度的情况下,该N段发热体进行发热的起始时间点为预设温度控制数据中的第j-1、第j-2、第j-3、第j-4或第j-5个时间点,这样可以避免N段发热体跳过烟支的加热阶段中的预热阶段,能够解决由于N段发热体跳过烟支的预热阶段带来的生成的气溶胶不充足的问题。It can be understood that when k=0, when the target temperature of each heating element in the N-segment heating element is lower than the overall initial temperature at each time point, the starting time point for the N-segment heating element to generate heat is The jth time point in the preset temperature control data, that is, the heating element of the N segment does not need to generate heat in the preheating stage of the heating stage of the cigarette. When k is 1, 2, 3, 4 or 5, when the target temperature of each heating element in the N-segment heating element at each time point is lower than the overall initial temperature, the N-segment heating element starts to generate heat The time point is the j-1, j-2, j-3, j-4, or j-5 time point in the preset temperature control data, which can prevent the N segment heating element from skipping the cigarette. The preheating stage in the heating stage can solve the problem of insufficient aerosol generated due to the N-section heating element skipping the preheating stage of the cigarette.

例如,j=15,如图4所示,烟支的加热阶段中烟支预热完成的的截止时间点为第15个时间片,也即烟支的加热阶段中的第1个时间片至第15个时间片为烟支的预热阶段,第15时间片以后的阶段为烟支的抽吸阶段,烟支的预热阶段的持续时长为30秒。设整体初始温度T=30摄氏度,如图4所示,按照第1个时间片至第15个时间片的顺序,依次将第1段发热体、第2段发热体、第3段发热体和第4段发热体在各时间片的目标温度与整体初始温度进行比较,由于第1段发热体在第1个时间片的目标温度为40摄氏度,大于30摄氏度,因此,将第1个时间片确定为这4段发热体的起始时间点。For example, j=15, as shown in Figure 4, the cut-off time point for completion of cigarette preheating in the heating phase of cigarettes is the 15th time slice, that is, the first time slice in the heating phase of cigarettes to The 15th time slice is the preheating phase of the cigarette, and the phase after the 15th time slice is the smoking phase of the cigarette, and the duration of the preheating phase of the cigarette is 30 seconds. Assuming the overall initial temperature T = 30 degrees Celsius, as shown in Figure 4, according to the order of the first time slice to the 15th time slice, the first section of heating element, the second section of heating element, the third section of heating element and The target temperature of the heating element in the fourth stage in each time slice is compared with the overall initial temperature. Since the target temperature of the heating element in the first stage in the first time slice is 40 degrees Celsius, which is greater than 30 degrees Celsius, the first time slice It is determined as the starting time point of these 4 sections of heating elements.

又例如,设4段发热体的整体初始温度T=240摄氏度,按照第1个时间片至第15个时间片的顺序,依次将第1段发热体、第2段发热体、第3段发热体和第4段发热体在各时间片的目标温度与整体初始温度进行比较,由于第1段发热体在第7个时间片的目标温度为240摄氏度,与整体初始温度T=240摄氏度相同,且第2段发热体、第3段发热体和第4段发热体第7个时间片的目标温度为零,因此,将第7个时间片确定为这4段发热体的起始时间点。As another example, assume that the overall initial temperature T of the 4-stage heating element is 240 degrees Celsius. According to the sequence from the first time slice to the 15th time slice, the first-stage heating element, the second-stage heating element, and the third-stage heating element are successively heated. The target temperature of the heating element and the heating element in the fourth section in each time slice is compared with the overall initial temperature. Since the target temperature of the heating element in the first section in the seventh time slice is 240 degrees Celsius, it is the same as the overall initial temperature T=240 degrees Celsius. And the target temperature of the 2nd heating element, the 3rd heating element and the 4th heating element in the 7th time slice is zero, therefore, the 7th time slice is determined as the starting time point of these 4 heating elements.

又例如,假设目标温度曲线C1定义了第2段发热体的在烟支的加热阶段中的不同时间点的目标温度,目标温度曲线C2-C4分别定义了第1段发热体第3段发热体和第4段发热体在烟支的加热阶段中的不同时间点的目标温度,设4段发热体的整体初始温度T=240摄氏度,如图4所示,按照第1个时间片至第15个时间片的顺序,依次将第1段发热体、第2段发热体、第3段发热体和第4段发热体在各时间片的目标温度与整体初始温度进行比较,由于第2段发热体在第7个时间片的目标温度为240摄氏度,与整体初始温度T=240摄氏度相同,且第1段发热体、第3段发热体和第4段发热体第7个时间片的目标温度为零,因此,将第7个时间片确定为这4段发热体的起始时间点。For another example, assume that the target temperature curve C1 defines the target temperature of the second-stage heating element at different time points during the heating phase of the cigarette, and the target temperature curves C2-C4 respectively define the first-stage heating element and the third-stage heating element and the target temperature of the heating element in the fourth section at different time points in the heating phase of the cigarette, assuming that the overall initial temperature of the heating element in the fourth section is T=240 degrees Celsius, as shown in Figure 4, according to the first time slice to the fifteenth In the order of each time slice, compare the target temperature of the first heating element, the second heating element, the third heating element, and the fourth heating element in each time slice with the overall initial temperature. The target temperature of the body in the 7th time slice is 240 degrees Celsius, which is the same as the overall initial temperature T=240 degrees Celsius, and the target temperature of the 1st heating element, the 3rd heating element and the 4th heating element in the 7th time slice is zero, therefore, the seventh time slice is determined as the starting time point of the four heating elements.

例如,设整体初始温度T=320摄氏度,k=0,且j=15,如图4所示,按照第1个时间片至第15个时间片的顺序,依次将第1段发热体、第2段发热体、第3段发热体和第4段发热体在各时间片的目标温度与整体初始温度进行比较,由于第1段发热体、第2段发热体、第3段发热体和第4段发热体在各时间片的目标温度均小于320摄氏度,因此将第15个时间片确定为4段发热体进行发热的起始时间点,这样后续在按照第15个时间片以及第15个时间片以后的目标温度控制4段发热体进行发热的过程中,第1段发热体、第2段发热体、第3段发热体和第4段发热体在烟支的预热阶段不需要发热,也即4段发热体均跳过烟支的预热阶段。For example, assuming that the overall initial temperature T=320 degrees Celsius, k=0, and j=15, as shown in Figure 4, according to the order of the first time slice to the 15th time slice, the first heating element, the second The target temperature of the 2nd stage heating element, the 3rd stage heating element and the 4th stage heating element in each time slice are compared with the overall initial temperature, because the 1st stage heating element, the 2nd stage heating element, the 3rd stage heating element and the The target temperature of the 4-segment heating element in each time slice is less than 320 degrees Celsius, so the 15th time slice is determined as the starting time point for the 4-segment heating element to generate heat, so that the follow-up will follow the 15th time slice and the 15th time slice The target temperature after the time slice controls the heating process of the 4 heating elements, the 1st heating element, the 2nd heating element, the 3rd heating element and the 4th heating element do not need to generate heat during the preheating stage of the cigarette , That is to say, the four sections of heating elements all skip the preheating stage of the cigarette.

又例如,设整体初始温度T=320摄氏度,k=4,且j=15,如图4所示,如图4所示,按照第1个时间片至第15个时间片的顺序,依次将第1段发热体、第2段发热体、第3段发热体和第4段发热体在各时间片的目标温度与整体初始温度进行比较,由于第1段发热体、第2段发热体、第3段发热体和第4段发热体在各时间片的目标温度均小于320摄氏度,因此将第11个时间片确定4段发热体进行发热的起始时间点,这样后续在按照第11个时间片以及第11个时间片以后的目标温度控制4段发热体进行发热的过程中,4段发热体跳过了第1个时间片至第10个时间片,使得气溶胶生成装置对烟支的预热时长由30秒调整为10秒。For another example, assume that the overall initial temperature T=320 degrees Celsius, k=4, and j=15, as shown in Figure 4, as shown in Figure 4, according to the order of the first time slice to the 15th time slice, sequentially The target temperature of the first stage heating element, the second stage heating element, the third stage heating element and the fourth stage heating element in each time slice are compared with the overall initial temperature, because the first stage heating element, the second stage heating element, The target temperature of the heating element in the third section and the heating element in the fourth section is less than 320 degrees Celsius in each time slice. Therefore, the starting time point for the heating element in the 4th section is determined in the 11th time slot. During the time slice and after the 11th time slice, the target temperature controls the 4-stage heating element to generate heat, and the 4-stage heating element skips the first time slice to the 10th time slice, making the aerosol generating device Adjusted the warm-up time from 30 seconds to 10 seconds.

在一实施例中,如图5所示,步骤S104包括子步骤S1041至子步骤S1042。In one embodiment, as shown in FIG. 5 , step S104 includes sub-steps S1041 to sub-steps S1042.

子步骤S1041、根据N段发热体进行发热的起始时间点,从预设温度控制数据中确定目标温度控制数据;Sub-step S1041. Determine the target temperature control data from the preset temperature control data according to the starting time point of heating by the N-segment heating elements;

子步骤S1042、根据目标温度控制数据,控制N段发热体进行发热。Sub-step S1042 , according to the target temperature control data, control the heating elements of the N sections to generate heat.

本发明实施例中,现有的气溶胶生成装置在侦测到用户对气溶胶生成装置的开启按键的触发操作时,使用预设温度控制数据控制N段发热体进行发热,以对收容于烟管中的烟支进行加热,并在N段发热体发热的时长达到预设的烟支预热时长后,提示用户烟支预热完成,可以进行抽吸,但在用户连续使用气溶胶生成装置加热传统卷烟产生气溶胶进行抽吸时,发热体的温度较高,而按照预设温度控制数据控制发热体进行发热,并在发热的时长达到预设的烟支预热时长后,提示用户烟支预热完成,这样会导致烟支过度加热,气溶胶的温度较高,存在气溶胶过热烫嘴的问题。通过本发明实施例提供的发热方法,实现了基于整体初始温度自适应调整N段发热体的发热时间,避免连续使用气溶胶生成装置加热传统卷烟时对传统卷烟过度加热,解决了用户连续使用气溶胶生成装置加热传统卷烟产生气溶胶进行抽吸时,会出现气溶胶生成装置产生的气溶胶的温度较高,导致气溶胶过热烫嘴的问题。In the embodiment of the present invention, when the existing aerosol generating device detects the user's trigger operation on the opening button of the aerosol generating device, it uses the preset temperature control data to control the heating elements of the N sections to generate heat, so as to control the heating elements contained in the cigarette. The cigarettes in the tube are heated, and when the heating time of the heating element in the N section reaches the preset cigarette preheating time, the user is prompted that the cigarettes are preheated and can be smoked, but when the user continues to use the aerosol generating device When heating traditional cigarettes to generate aerosol for smoking, the temperature of the heating element is relatively high, and the heating element is controlled to generate heat according to the preset temperature control data, and when the heating time reaches the preset cigarette warm-up time, the user is prompted to smoke. The preheating of cigarettes is completed, which will lead to overheating of cigarettes, the temperature of aerosol is relatively high, and there is a problem that the aerosol is overheated and burns the mouth. Through the heating method provided by the embodiment of the present invention, the heating time of N-section heating elements can be adaptively adjusted based on the overall initial temperature, avoiding overheating of traditional cigarettes when the aerosol generating device is continuously used to heat traditional cigarettes, and solving the problem of continuous use of aerosol generators by users. When the aerosol generating device heats the traditional cigarette to generate aerosol for smoking, the temperature of the aerosol generated by the aerosol generating device will be relatively high, resulting in the problem of overheating of the aerosol and scalding the mouth.

其中,目标温度控制数据包括N段发热体在该起始时间点至截止时间点中的各时间点的目标温度。例如,如图4所示,设第1段发热体、第2段发热体、第3段发热体和第4段发热体这4段发热体进行发热的起始时间点为第7时间片,则目标温度控制数据包括第1段发热体、第2段发热体、第3段发热体和第4段发热体在图4中的第7个时间片以及第7个时间片以后的各时间片的目标温度,这样气溶胶生成装置按照第1段发热体、第2段发热体、第3段发热体和第4段发热体在图4中的第7个时间片以后的各时间片的目标温度,分别控制第1段发热体、第2段发热体、第3段发热体和第4段发热体进行发热,由于这4段发热体跳过了第1个时间片至第6个时间片,使得气溶胶生成装置对烟支的预热时长由30秒调整为了18秒。Wherein, the target temperature control data includes the target temperature of the N-segment heating element at each time point from the start time point to the end time point. For example, as shown in Figure 4, it is assumed that the starting time point of heating of the four heating elements of the first heating element, the second heating element, the third heating element and the fourth heating element is the seventh time slice, Then the target temperature control data includes the 7th time slice of the 1st heating element, the 2nd heating element, the 3rd heating element and the 4th heating element in Figure 4 and each time slice after the 7th time slice In this way, the aerosol generating device follows the target temperature of the first heating element, the second heating element, the third heating element and the fourth heating element in each time slice after the 7th time slice in Figure 4 Temperature, respectively control the heating element in the first section, the heating element in the second section, the heating element in the third section and the heating element in the fourth section to generate heat, because these four heating elements skip the first time slice to the sixth time slice , so that the preheating time of the aerosol generating device for cigarettes is adjusted from 30 seconds to 18 seconds.

例如,用户使用气溶胶生成装置吸食第一根烟支时,按照现有的技术方案,不考虑4段发热体的整体初始温度,而是使用预设温度控制数据控制4段发热体进行发热,也即气溶胶生成装置从第1个时间片开始控制4段发热体进行发热,并在4段发热体发热30秒后,气溶胶生成装置完成对烟支的预热,提示用户可以使用气溶胶生成装置抽吸烟支。用户使用气溶胶生成装置吸食完第一根烟支后的较短时间内,用户又使用气溶胶生成装置吸食第二根烟支,设4段发热体此时的整体初始温度T=240摄氏度,按照现有的技术方案,需要控制4段发热体仍然发热30秒后,溶胶生成装置完成对烟支的预热,提示用户可以使用气溶胶生成装置抽吸烟支,而由于4段发热体的整体初始温度已经较高,而控制4段发热体仍然发热30秒就会出现气溶胶生成装置产生的气溶胶的温度较高,导致气溶胶过热烫嘴的问题。For example, when the user uses the aerosol generating device to smoke the first cigarette, according to the existing technical scheme, the overall initial temperature of the 4-stage heating element is not considered, but the preset temperature control data is used to control the 4-stage heating element to generate heat. That is to say, the aerosol generating device starts to control the 4-stage heating element to generate heat from the first time slice, and after the 4-stage heating element heats up for 30 seconds, the aerosol generating device completes the preheating of the cigarette and prompts the user to use the aerosol Generate means to smoke a cigarette. In a relatively short period of time after the user smokes the first cigarette with the aerosol generating device, the user uses the aerosol generating device to smoke the second cigarette. Assuming that the overall initial temperature T of the 4-stage heating element at this time is 240 degrees Celsius, According to the existing technical scheme, it is necessary to control the 4-stage heating element to still generate heat for 30 seconds. The initial temperature is already high, but the temperature of the aerosol generated by the aerosol generating device will be relatively high if the 4-stage heating element is still heated for 30 seconds, causing the aerosol to overheat and scald the mouth.

而采用本发明实施例提供的发热控制方法,在4段发热体的整体初始温度T=240摄氏度的情况下,如图4所示,按照第1个时间片至第15个时间片的顺序,依次将第1段发热体、第2段发热体、第3段发热体和第4段发热体在各时间片的目标温度与整体初始温度进行比较,由于第1段发热体在第7个时间片的目标温度为240摄氏度,与整体初始温度T=240摄氏度相同,因此将第7个时间片确定为4段发热体进行发热的起始时间点,这样根据4段发热体在第7个时间片以及第7个时间片以后的各时间片的目标温度,控制4段发热体进行发热,4段发热体发热18秒后,气溶胶生成装置完成对烟支的预热,提示用户可以使用气溶胶生成装置抽吸烟支,从而避免了用户连续使用气溶胶生成装置加热传统卷烟产生气溶胶进行抽吸时,会出现气溶胶生成装置产生的气溶胶的温度较高,导致气溶胶过热烫嘴的问题。However, using the heat generation control method provided by the embodiment of the present invention, under the condition that the overall initial temperature T of the 4-stage heating element is 240 degrees Celsius, as shown in FIG. 4 , according to the sequence from the first time slice to the fifteenth time slice, Compare the target temperature of the heating element in the first stage, the heating element in the second stage, the heating element in the third stage, and the heating element in the fourth stage in sequence with the overall initial temperature. The target temperature of the slice is 240 degrees Celsius, which is the same as the overall initial temperature T=240 degrees Celsius, so the seventh time slice is determined as the starting time point for the 4-stage heating element to generate heat, so that according to the 4-stage heating element at the seventh time Control the target temperature of each time slice after the 7th time slice and the 4th heating element to generate heat. After the 4th heating element heats up for 18 seconds, the aerosol generating device completes the preheating of the cigarette and prompts the user to use the gas. The aerosol generating device smokes cigarettes, thereby avoiding the aerosol generated by the aerosol generating device when the user continuously uses the aerosol generating device to heat the traditional cigarette to generate aerosol for smoking, which will cause the aerosol to overheat and burn the mouth. question.

在一实施例中,根据目标温度控制数据,控制N段发热体进行发热的方式可以为:根据目标温度控制数据控制第i段发热体进行发热,第i段发热体的发热过程包括依次进行的第一阶段、第二阶段以及第三阶段,i大于等于1且小于N,N大于或等于2;在第i段发热体处于第二阶段或第三阶段时,根据目标温度控制数据控制第i+1段发热体进行发热。其中,第i+1段发热体相比第i段发热体更远离气溶胶生成装置的气溶胶输出端。通过控制第i段发热体的发热过程包括依次进行的第一阶段、第二阶段以及第三阶段,且在第i段发热体处于第二阶段或第三阶段时,再控制第i+1段发热体进行发热,能够在解决用户连续使用气溶胶生成装置加热传统卷烟产生气溶胶进行抽吸时,会出现气溶胶生成装置产生的气溶胶的温度较高,导致气溶胶过热烫嘴的问题的同时,实现气溶胶均匀地输出。In an embodiment, according to the target temperature control data, the method of controlling the heating elements of the N sections to generate heat may be: according to the target temperature control data, the heating elements of the i section are controlled to generate heat, and the heating process of the i section heating elements includes sequential steps. In the first stage, the second stage, and the third stage, i is greater than or equal to 1 and less than N, and N is greater than or equal to 2; when the heating element in the i-stage is in the second stage or the third stage, control the i-th stage according to the target temperature control data +1 section of heating element to generate heat. Wherein, the heating element in the i+1 section is farther from the aerosol output end of the aerosol generating device than the heating element in the i section. By controlling the heating process of the heating element in the i section, it includes the first stage, the second stage and the third stage in sequence, and when the heating element in the i section is in the second stage or the third stage, then control the i+1 section The heat generated by the heating element can solve the problem that when the user continuously uses the aerosol generating device to heat the traditional cigarette to generate aerosol for smoking, the aerosol generated by the aerosol generating device will have a higher temperature, which will cause the aerosol to overheat and burn the mouth. At the same time, the aerosol can be evenly output.

例如,如图4所示,设目标温度控制数据包括第1段发热体、第2段发热体、第3段发热体和第4段发热体在图4中的第7个时间片以及第7个时间片以后的各时间片的目标温度。也即第1段发热体进行发热的起始时间点为第7个时间片,因此,在侦测到用户按压气溶胶生成装置的开启按键时,使用第1段发热体在第7到19个时间片中的各时间片的目标温度,开始控制第1段发热体在第一阶段的发热,也即第1段发热体的第一阶段对应的时间段为0-26S(在侦测到用户按压气溶胶生成装置的开启按键时,开始计时)。使用第1段发热体在第19到28个时间片中的各时间片的目标温度,控制第1段发热体在第二阶段的发热,也即第1段发热体的第二阶段对应的时间段为26-44S。使用第1段发热体在第28个时间片到最终结束的时间片中的各时间片的目标温度,控制第1段发热体在第三阶段的发热,也即第1段发热体的第三阶段对应的时间段为44S直到结束的时间段。For example, as shown in Figure 4, it is assumed that the target temperature control data includes the 1st section heating element, the 2nd section heating element, the 3rd section heating element and the 4th section heating element in the 7th time slice and the 7th section in Figure 4 The target temperature for each time slice after the first time slice. That is to say, the starting time of the heating element in the first stage is the seventh time slice. Therefore, when it is detected that the user presses the start button of the aerosol generating device, the heating element in the first stage is used in the 7th to 19th time slots. The target temperature of each time slice in the time slice starts to control the heating of the first stage of the heating element in the first stage, that is, the time period corresponding to the first stage of the first stage of the heating element is 0-26S (when the user is detected When the start button of the aerosol generating device is pressed, the timer starts). Use the target temperature of the first-stage heating element in each time slice from the 19th to the 28th time slice to control the heat generation of the first-stage heating element in the second stage, that is, the time corresponding to the second stage of the first-stage heating element The segment is 26-44S. Use the target temperature of the first-stage heating element in each time slice from the 28th time slice to the final time slice to control the heating of the first-stage heating element in the third stage, that is, the third stage of the first-stage heating element. The time period corresponding to the phase is the time period from 44S to the end.

如目标温度曲线C2所示,对于第2段发热体,在侦测到用户按压气溶胶生成装置的开启按键时,在第7个时间片至第28个时间片期间,第2段发热体不发热,之后使用第28个到37个时间片中的各时间片的目标温度,开始控制第2段发热体在第一阶段的发热,也即第2段发热体的第一阶段对应的时间段为44-62S。使用第37个到57个时间片中的各时间片的目标温度,开始控制第2段发热体在第二阶段的发热,也即第2段发热体的第二阶段对应的时间段为62-102S。使用第37个时间片到最终结束的时间片中的各时间片的目标温度,开始控制第2段发热体在第三阶段的发热,也即第2段发热体的第三阶段对应的时间段为102S直到结束的时间段。As shown in the target temperature curve C2, for the second segment of the heating element, when it is detected that the user presses the start button of the aerosol generating device, during the period from the 7th time slice to the 28th time slice, the second segment of the heating element does not After heating, use the target temperature of each time slice in the 28th to 37th time slices to start controlling the heat generation of the second stage heating element in the first stage, that is, the time period corresponding to the first stage of the second stage heating element For 44-62S. Use the target temperature of each time slice in the 37th to 57th time slices to start controlling the heat generation of the second heating element in the second stage, that is, the time period corresponding to the second stage of the second heating element is 62- 102S. Use the target temperature of each time slice from the 37th time slice to the final end time slice to start controlling the heat generation of the second-stage heating element in the third stage, that is, the time period corresponding to the third stage of the second-stage heating element It is the time period from 102S until the end.

如目标温度曲线C3所示,对于第3段发热体,在侦测到用户按压气溶胶生成装置的开启按键时,在第7个时间片至第50个时间片期间,第3段发热体不发热,之后使用第50个到62个时间片中的各时间片的目标温度,开始控制第3段发热体在第一阶段的发热,也即第3段发热体的第一阶段对应的时间段为88-112S。使用第62个到83个时间片中的各时间片的目标温度,开始控制第3段发热体在第二阶段的发热,也即第3段发热体的第二阶段对应的时间段为112-154S。使用第83个时间片到最终结束的时间片中的各时间片的目标温度,开始控制第3段发热体在第三阶段的发热,也即第3段发热体的第三阶段对应的时间段为154S直到结束的时间段。As shown in the target temperature curve C3, for the heating element in the third section, when it is detected that the user presses the start button of the aerosol generating device, the heating element in the third section does not stop during the period from the 7th time slice to the 50th time slice. Generate heat, and then use the target temperature of each time slice in the 50th to 62nd time slices to start controlling the heating of the third-stage heating element in the first stage, that is, the time period corresponding to the first stage of the third-stage heating element For 88-112S. Use the target temperature of each time slice in the 62nd to 83rd time slices to start controlling the heat generation of the third stage heating element in the second stage, that is, the time period corresponding to the second stage of the third stage heating element is 112- 154S. Use the target temperature of each time slice from the 83rd time slice to the final time slice to start controlling the heat generation of the third stage heating element in the third stage, that is, the time period corresponding to the third stage of the third stage heating element It is the time period from 154S until the end.

在一实施例中,当第i+1段为第N段时,第i+1发热体的发热过程包括依次进行的第一阶段及第二阶段。其中,当第i+1段发热体为第N段发热体,即最后一段发热体时,第i+1发热体的发热过程可仅包括依次进行的第一阶段及第二阶段。例如,如目标温度曲线C4所示,对于第4段发热体,在侦测到用户按压气溶胶生成装置的开启按键时,在第7个时间片至第75个时间片期间,第4段发热体不发热,之后使用第75个到85个时间片中的各时间片的目标温度,开始控制第4段发热体在第一阶段的发热,也即第4段发热体的第一阶段对应的时间段为138-158S。使用第85个时间片到最终结束的时间片中的各时间片的目标温度,开始控制第3段发热体在第二阶段的发热,也即第3段发热体的第二阶段对应的时间段为158S直到结束的时间段。In one embodiment, when the (i+1)th stage is the Nth stage, the heating process of the (i+1)th heating element includes a first stage and a second stage which are carried out in sequence. Wherein, when the i+1th heating element is the Nth heating element, that is, the last heating element, the heating process of the i+1th heating element may only include the first stage and the second stage in sequence. For example, as shown in the target temperature curve C4, for the heating element in the fourth segment, when it is detected that the user presses the start button of the aerosol generating device, during the period from the 7th time slice to the 75th time slice, the fourth segment generates heat The body does not generate heat, and then use the target temperature of each time slice in the 75th to 85th time slices to start controlling the heating of the fourth heating element in the first stage, that is, the corresponding temperature of the first stage of the fourth heating element. The time period is 138-158S. Use the target temperature of each time slice from the 85th time slice to the final time slice to start controlling the heat generation of the third stage heating element in the second stage, that is, the time period corresponding to the second stage of the third stage heating element It is the time period from 158S until the end.

在一实施例中,本发明的气溶胶生成装置100还包括电源模块,所述电源模块与第1至N段发热体电连接,用于提供电能至第1-N段发热体。其中,前述任一实施例中的控制各段发热体进行发热中,对于任意一段发热体来说,具体的温度控制过程可包括:侦测对应发热体的温度;将发热体的温度与发热体在当前时间片所要达到的目标温度进行比较;根据比较结果控制施加至发热体的电能,从而使得发热体在当前时间片的温度达到对应的目标温度。In one embodiment, the

在一实施例中,根据比较结果控制施加至发热体的电能,从而使得发热体在当前时间点的温度达到对应的目标温度的方式可以包括:在比较结果为发热体的温度高于发热体在当前时间点所要达到的目标温度时,控制降低施加至发热体的电能或者停止施加电能至发热体,在比较结果为发热体的温度低于发热体在当前时间点所要达到的目标温度时,控制增大施加至发热体的电能或者维持施加至发热体的电能。In an embodiment, the method of controlling the electric energy applied to the heating element according to the comparison result, so that the temperature of the heating element at the current time point reaches the corresponding target temperature may include: when the comparison result shows that the temperature of the heating element is higher than that of the heating element at When the target temperature to be reached at the current time point, the control reduces the electric energy applied to the heating element or stops the application of electric energy to the heating element. Increase the power applied to the heat generating body or maintain the power applied to the heat generating body.

在一实施例中,在控制N段发热体进行发热的过程中,获取N段发热体的已发热时长和烟支预热时长,烟支预热时长是根据N段发热体进行发热的起始时间点确定的;在已发热时长达到烟支预热时长时,输出烟支预热完成提示信息。其中,输出烟支预热完成提示信息的方式可以包括:控制呼吸灯闪烁或者控制振动器按照预设频率振动。通过在基于整体初始温度自适应调整烟支预热时长后,在发热体的已发热时长达到调整后的烟支预热时长时,输出烟支预热完成提示信息,可以准确地提示用户烟支的预热完成,便于用户吸食加热烟支产生的气溶胶。In one embodiment, in the process of controlling the N-segment heating element to generate heat, the heating time of the N-segment heating element and the preheating time of the cigarette are obtained. The time point is determined; when the heating time reaches the cigarette preheating time, a prompt message that the cigarette preheating is completed is output. Wherein, the manner of outputting the prompt message of completion of cigarette preheating may include: controlling the breathing light to blink or controlling the vibrator to vibrate according to a preset frequency. After adaptively adjusting the preheating time of cigarettes based on the overall initial temperature, when the heating time of the heating element reaches the adjusted preheating time of cigarettes, output the prompt information of the completion of preheating of cigarettes, which can accurately prompt the user of cigarettes The preheating is completed, which is convenient for the user to inhale the aerosol generated by the heated cigarette.

例如,如图4所示,第1段发热体、第2段发热体、第3段发热体和第4段发热体这4段发热体进行发热的起点时间点为第7个时间片,则烟支预热时长为第7个时间片至第15个时间片之间的持续时长,即为18秒,也即在控制4段发热体18秒后,输出烟支预热完成提示信息,以提示用户可以使用气溶胶生成装置抽吸烟支。For example, as shown in Figure 4, the starting point of time when the four heating elements of the first section heating element, the second section heating element, the third section heating element and the fourth section heating element are generating heat is the seventh time slice, then The preheating time of the cigarette is the duration between the 7th time slice and the 15th time slice, which is 18 seconds, that is, after controlling the 4-stage heating element for 18 seconds, the prompt message of the completion of the cigarette preheating is output to Remind users that cigarettes can be smoked with an aerosol-generating device.

在一实施例中,根据烟支预热时长和已发热时长,确定烟支预热进度信息,并输出烟支预热进度信息。例如,计算已发热时长与烟支预热时长之间的比值,得到烟支预热进度信息。其中,气溶胶生成装置可以将烟支预热进度信息输出至与气溶胶生成装置连接的手机进行显示。通过在基于整体初始温度自适应调整烟支预热时长后,基于已发热时长和调整后的烟支预热时长,自适应地调整烟支预热进度信息,并输出烟支预热进度信息,使得用户能够及时地知晓烟支的预热进度。In one embodiment, the cigarette preheating progress information is determined according to the cigarette preheating time and the heated time, and the cigarette preheating progress information is output. For example, the ratio between the heating time and the preheating time of the cigarette is calculated to obtain the progress information of the cigarette preheating. Wherein, the aerosol generating device can output the cigarette preheating progress information to the mobile phone connected with the aerosol generating device for display. After adaptively adjusting the preheating time of the cigarette based on the overall initial temperature, based on the heated time and the adjusted preheating time of the cigarette, adaptively adjust the preheating progress information of the cigarette, and output the preheating progress information of the cigarette, The user can know the preheating progress of the cigarette in time.

请参阅图6,图6是本发明实施例提供的另一种发热控制方法的流程示意图。Please refer to FIG. 6 . FIG. 6 is a schematic flowchart of another heating control method provided by an embodiment of the present invention.

如图6所示,该发热控制方法包括步骤S201至S204。As shown in FIG. 6, the heating control method includes steps S201 to S204.

步骤S201、获取N段发热体中的第1段发热体的初始温度,并将第1段发热体的初始温度确定为整体初始温度;Step S201, obtaining the initial temperature of the first heating element in the N heating elements, and determining the initial temperature of the first heating element as the overall initial temperature;

步骤S202、获取预设温度控制数据,预设温度控制数据包括N段发热体在烟支的加热阶段中的不同时间点的目标温度;Step S202. Acquiring preset temperature control data, the preset temperature control data includes the target temperatures of the N-segment heating elements at different time points during the heating phase of the cigarette;

步骤S203、根据整体初始温度,从预设温度控制数据中确定第1段发热体进行发热的起始时间点,并将第1段发热体进行发热的起始时间点确定为N段发热体进行发热的起始时间点;Step S203, according to the overall initial temperature, determine the starting time point of heating of the first heating element from the preset temperature control data, and determine the starting time point of heating of the first heating element as the starting time of heating of the N heating element. The onset time of fever;

步骤S204、根据N段发热体进行发热的起始时间点和预设温度控制数据,控制N段发热体进行发热。Step S204 , according to the start time point of heating of the heating elements of the N sections and the preset temperature control data, control the heating elements of the N sections to generate heat.

本发明实施例中,由于第1段发热体相比其余发热体更靠近气溶胶生成装置的气溶胶输出端,因此在对收容于烟管中的烟支进行加热前期阶段,主要是通过控制第1段发热体进行发热来对烟支进行预热,这样通过获取第1段发热体的初始温度,并将第1段发热体的初始温度确定为N段发热体的整体初始温度,根据整体初始温度,从预设温度控制数据中确定第1段发热体进行发热的起始时间点,并将第1段发热体进行发热的起始时间点确定为N段发热体进行发热的起始时间点,根据N段发热体进行发热的起始时间点和预设温度控制数据,控制N段发热体进行发热,实现了基于第1段发热体的初始温度自适应调整N段发热体的发热时间,避免连续使用气溶胶生成装置加热传统卷烟时对传统卷烟过度加热,从而解决了用户连续使用气溶胶生成装置加热传统卷烟产生气溶胶进行抽吸时,会出现气溶胶生成装置产生的气溶胶的温度较高,导致气溶胶过热烫嘴的问题。In the embodiment of the present invention, since the first-stage heating element is closer to the aerosol output end of the aerosol generating device than the rest of the heating elements, in the early stage of heating the cigarettes stored in the cigarette pipe, mainly by controlling the first heating element The heating element in the first section heats up to preheat the cigarettes. In this way, by obtaining the initial temperature of the heating element in the first section, and determining the initial temperature of the heating element in the first section as the overall initial temperature of the heating element in the N section, according to the overall initial temperature Temperature, from the preset temperature control data, determine the starting time point of heating of the first heating element, and determine the starting time of heating of the first heating element as the starting time of heating of the N heating element , according to the starting time point of heating of the N-segment heating element and the preset temperature control data, the N-segment heating element is controlled to generate heat, and the heating time of the N-segment heating element is adaptively adjusted based on the initial temperature of the first-segment heating element. Avoid overheating the traditional cigarettes when the aerosol generating device is used continuously to heat the traditional cigarettes, thereby solving the problem of the temperature of the aerosol generated by the aerosol generating device when the user continuously uses the aerosol generating device to heat the traditional cigarette to generate aerosol for smoking Higher, causing the aerosol to overheat and scald the mouth.

例如,以N=4,即气溶胶生成装置包括4段发热体为例,第1段发热体的初始温度为140摄氏度,则4段发热体的整体初始温度T=140摄氏度,如图4所示,按照第1个时间片至第15个时间片的顺序,依次将第1段发热体、第2段发热体、第3段发热体和第4段发热体在各时间片的目标温度与整体初始温度进行比较,这样可以得到第1段发热体在第5个时间片的目标温度为150摄氏度,大于第1段发热体的初始温度140摄氏度(即4段发热体的整体初始温度),因此将第5个时间片确定为这4段发热体进行发热的起始时间点。For example, taking N=4, that is, the aerosol generating device includes four heating elements as an example, the initial temperature of the first heating element is 140 degrees Celsius, and the overall initial temperature T of the four heating elements is 140 degrees Celsius, as shown in Figure 4 Shown, according to the sequence from the 1st time slice to the 15th time slice, sequentially compare the target temperature and Compared with the overall initial temperature, it can be obtained that the target temperature of the heating element in the first section in the fifth time slice is 150 degrees Celsius, which is higher than the initial temperature of the heating element in the first section of 140 degrees Celsius (that is, the overall initial temperature of the heating element in the fourth section), Therefore, the fifth time slice is determined as the starting time point for these four heating elements to generate heat.

请参阅图7,图7是本发明实施例提供的一种气溶胶生成装置的结构示意性框图。如图7所示,气溶胶生成装置100包括气溶胶输出端10、N段发热体20、烟管30、控制器101和存储器102。气溶胶输出端10用于输出气溶胶,当气溶胶混合有精油雾化气时,气溶胶输出端10为用于输出混合有精油雾化气的气溶胶。气溶胶输出端10为气溶胶生成装置100输出气溶胶而供用户吸食的端口,例如,气溶胶输出端10可为滤嘴端。烟管30用于收容烟支,N段发热体20用于对收容于烟管30中的烟支进行加热以产生气溶胶,第i+1段发热体相比第i段发热体更远离气溶胶输出端10,i为大于等于1且小于N的整数,N为大于或等于2的整数。存储器102用于存储预设温度控制数据、各段发热体各自对应的加权系数等。Please refer to FIG. 7 . FIG. 7 is a schematic structural block diagram of an aerosol generating device provided by an embodiment of the present invention. As shown in FIG. 7 , the

在一实施例中,控制器101用于实现以下步骤:获取所述N段发热体的整体初始温度;获取预设温度控制数据,所述预设温度控制数据包括所述N段发热体在烟支的加热阶段中的不同时间点的目标温度;根据所述整体初始温度,从所述预设温度控制数据中确定所述N段发热体进行发热的起始时间点;根据所述N段发热体进行发热的起始时间点和所述预设温度控制数据,控制所述N段发热体进行发热。In one embodiment, the

在一实施例中,控制器101在实现获取所述N段发热体的整体初始温度时,用于实现:获取各段所述发热体各自对应的初始温度;根据各段所述发热体各自对应的初始温度确定所述N段发热体的整体初始温度。In one embodiment, the

在一实施例中,控制器101在实现根据各段所述发热体各自对应的初始温度确定所述N段发热体的整体初始温度时,用于实现:获取各段所述发热体各自对应的加权系数;对于每一段所述发热体,计算所述发热体的初始温度与所述发热体对应的所述加权系数之间的乘积,得到各段所述发热体的加权温度;对各段所述发热体的所述加权温度进行累加,得到所述N段发热体的整体初始温度。In an embodiment, when the

在一实施例中,所述发热体的所述加权系数与目标距离呈负相关关系,所述目标距离为所述发热体与所述气溶胶生成装置的气溶胶输出端之间的距离。In one embodiment, the weighting coefficient of the heating element has a negative correlation with a target distance, and the target distance is the distance between the heating element and the aerosol output end of the aerosol generating device.

在一实施例中,控制器101还用于实现:获取所述N段发热体中的第1段发热体的初始温度,并将所述第1段发热体的初始温度确定为所述整体初始温度;获取预设温度控制数据,所述预设温度控制数据包括所述N段发热体在烟支的加热阶段中的不同时间点的目标温度;根据所述整体初始温度,从所述预设温度控制数据中确定所述第1段发热体进行发热的起始时间点,并将所述第1段发热体进行发热的起始时间点确定为所述N段发热体进行发热的起始时间点;根据所述N段发热体进行发热的起始时间点和所述预设温度控制数据,控制所述N段发热体进行发热。In an embodiment, the

在一实施例中,所述预设温度控制数据包括烟支的加热阶段所对应的M个时间点和各段所述发热体在第1个时间点至第M个时间点中的各时间点的目标温度,M为大于等于2的整数,控制器101在实现根据所述整体初始温度,从所述预设温度控制数据中确定所述N段发热体进行发热的起始时间点时,用于实现:按照所述第1个时间点到第j个时间点的顺序,依次将各段所述发热体在各所述时间点的目标温度与所述整体初始温度进行比较,所述j小于所述M;在所述目标温度大于或等于所述整体初始温度时,将当前进行比较的所述时间点确定为所述N段发热体进行发热的起始时间点。In one embodiment, the preset temperature control data includes M time points corresponding to the heating stage of cigarettes and each time point of each segment of the heating element from the first time point to the Mth time point target temperature, M is an integer greater than or equal to 2, and the

在一实施例中,控制器101在实现按照所述第1个时间点到第j个时间点的顺序,依次将各段所述发热体在各所述时间点的目标温度与所述整体初始温度进行比较之后,还用于实现:在进行比较的每个所述时间点的目标温度均小于所述整体初始温度时,将第j-k个时间点确定为所述N段发热体进行发热的起始时间点,k为大于等于0,且小于等于j/3的整数。In one embodiment, the

在一实施例中,控制器101在实现根据N段所述发热体进行发热的起始时间点和所述预设温度控制数据,控制N段所述发热体进行发热时,用于实现:根据所述N段发热体进行发热的起始时间点,从所述预设温度控制数据中确定目标温度控制数据;根据所述目标温度控制数据,控制所述N段发热体进行发热。In an embodiment, when the

在一实施例中,控制器101还用于实现以下步骤:在控制所述N段发热体进行发热的过程中,获取所述N段发热体的已发热时长和烟支预热时长,所述烟支预热时长是根据所述N段发热体进行发热的起始时间点确定的;在所述已发热时长达到所述烟支预热时长时,输出烟支预热完成提示信息。In an embodiment, the

在一实施例中,控制器101在实现获取N段所述发热体的已发热时长和烟支预热时长之后,还用于实现:根据所述烟支预热时长和所述已发热时长,确定烟支预热进度信息,并输出所述烟支预热进度信息。In an embodiment, after the

在一实施例中,所述烟支包括传统卷烟和特制烟弹。In one embodiment, the cigarettes include traditional cigarettes and special cartridges.

需要说明的是,所属领域的技术人员可以清楚地了解到,为了描述的方便和简洁,上述描述的气溶胶生成装置的具体工作过程,可以参考前述发热控制方法实施例中的对应过程,在此不再赘述。It should be noted that those skilled in the art can clearly understand that for the convenience and brevity of the description, the specific working process of the aerosol generating device described above can refer to the corresponding process in the above-mentioned heat generation control method embodiment, here No longer.

本发明实施例还提供一种存储介质,用于计算机可读存储,所述存储介质存储有一个或者多个程序,所述一个或者多个程序可被一个或者多个处理器执行,以实现如本发明实施例说明书提供的任一项发热控制方法。An embodiment of the present invention also provides a storage medium for computer-readable storage, the storage medium stores one or more programs, and the one or more programs can be executed by one or more processors to implement the following: Any one of the heating control methods provided in the description of the embodiments of the present invention.

其中,所述存储介质可以是前述实施例所述的气溶胶生成装置的内部存储单元,例如所述气溶胶生成装置的硬盘或内存。所述存储介质也可以是所述气溶胶生成装置的外部存储设备,例如所述气溶胶生成装置上配备的插接式硬盘,智能存储卡(Smart MediaCard,SMC),安全数字(Secure Digital,SD)卡,闪存卡(Flash Card)等。Wherein, the storage medium may be an internal storage unit of the aerosol generating device described in the foregoing embodiments, such as a hard disk or a memory of the aerosol generating device. The storage medium can also be an external storage device of the aerosol generating device, such as a plug-in hard disk equipped on the aerosol generating device, a smart memory card (Smart MediaCard, SMC), a secure digital (Secure Digital, SD ) card, flash memory card (Flash Card), etc.

本领域普通技术人员可以理解,上文中所公开方法中的全部或某些步骤、系统、装置中的功能模块/单元可以被实施为软件、固件、硬件及其适当的组合。在硬件实施例中,在以上描述中提及的功能模块/单元之间的划分不一定对应于物理组件的划分;例如,一个物理组件可以具有多个功能,或者一个功能或步骤可以由若干物理组件合作执行。某些物理组件或所有物理组件可以被实施为由处理器,如中央处理器、数字信号处理器或微处理器执行的软件,或者被实施为硬件,或者被实施为集成电路,如专用集成电路。这样的软件可以分布在计算机可读介质上,计算机可读介质可以包括计算机存储介质(或非暂时性介质)和通信介质(或暂时性介质)。如本领域普通技术人员公知的,术语计算机存储介质包括在用于存储信息(诸如计算机可读指令、数据结构、程序模块或其他数据)的任何方法或技术中实施的易失性和非易失性、可移除和不可移除介质。计算机存储介质包括但不限于RAM、ROM、EEPROM、闪存或其他存储器技术、CD-ROM、数字多功能盘(DVD)或其他光盘存储、磁盒、磁带、磁盘存储或其他磁存储装置、或者可以用于存储期望的信息并且可以被计算机访问的任何其他的介质。此外,本领域普通技术人员公知的是,通信介质通常包含计算机可读指令、数据结构、程序模块或者诸如载波或其他传输机制之类的调制数据信号中的其他数据,并且可包括任何信息递送介质。Those of ordinary skill in the art can understand that all or some of the steps in the methods disclosed above, the functional modules/units in the system, and the device can be implemented as software, firmware, hardware, and an appropriate combination thereof. In hardware embodiments, the division between functional modules/units mentioned in the above description does not necessarily correspond to the division of physical components; for example, one physical component may have multiple functions, or one function or step may be composed of several physical components. Components cooperate to execute. Some or all of the physical components may be implemented as software executed by a processor, such as a central processing unit, digital signal processor, or microprocessor, or as hardware, or as an integrated circuit, such as an application-specific integrated circuit . Such software may be distributed on computer readable media, which may include computer storage media (or non-transitory media) and communication media (or transitory media). As known to those of ordinary skill in the art, the term computer storage media includes both volatile and nonvolatile media implemented in any method or technology for storage of information, such as computer readable instructions, data structures, program modules, or other data. permanent, removable and non-removable media. Computer storage media includes, but is not limited to, RAM, ROM, EEPROM, flash memory or other memory technology, CD-ROM, digital versatile disk (DVD) or other optical disk storage, magnetic cartridges, tape, magnetic disk storage or other magnetic storage devices, or can Any other medium used to store desired information and which can be accessed by a computer. In addition, as is well known to those of ordinary skill in the art, communication media typically embodies computer readable instructions, data structures, program modules, or other data in a modulated data signal such as a carrier wave or other transport mechanism, and may include any information delivery media .

应当理解,在本发明说明书和所附权利要求书中使用的术语“和/或”是指相关联列出的项中的一个或多个的任何组合以及所有可能组合,并且包括这些组合。需要说明的是,在本文中,术语“包括”、“包含”或者其任何其他变体意在涵盖非排他性的包含,从而使得包括一系列要素的过程、方法、物品或者系统不仅包括那些要素,而且还包括没有明确列出的其他要素,或者是还包括为这种过程、方法、物品或者系统所固有的要素。在没有更多限制的情况下,由语句“包括一个……”限定的要素,并不排除在包括该要素的过程、方法、物品或者系统中还存在另外的相同要素。It should be understood that the term "and/or" used in the description of the present invention and the appended claims refers to any combination and all possible combinations of one or more of the associated listed items, and includes these combinations. It should be noted that, as used herein, the term "comprises", "comprises" or any other variation thereof is intended to cover a non-exclusive inclusion such that a process, method, article or system comprising a set of elements includes not only those elements, It also includes other elements not expressly listed, or elements inherent in the process, method, article, or system. Without further limitations, an element defined by the phrase "comprising a..." does not preclude the presence of additional identical elements in the process, method, article or system comprising that element.

上述本发明实施例序号仅仅为了描述,不代表实施例的优劣。以上所述,仅为本发明的具体实施例,但本发明的保护范围并不局限于此,任何熟悉本技术领域的技术人员在本发明揭露的技术范围内,可轻易想到各种等效的修改或替换,这些修改或替换都应涵盖在本发明的保护范围之内。因此,本发明的保护范围应以权利要求的保护范围为准。The serial numbers of the above embodiments of the present invention are for description only, and do not represent the advantages and disadvantages of the embodiments. The above are only specific embodiments of the present invention, but the protection scope of the present invention is not limited thereto. Any person familiar with the technical field can easily think of various equivalents within the technical scope disclosed in the present invention. Modifications or replacements shall all fall within the protection scope of the present invention. Therefore, the protection scope of the present invention should be based on the protection scope of the claims.

Claims (13)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211312420.4ACN115590260A (en) | 2022-10-25 | 2022-10-25 | Heating control method, aerosol generating device, and storage medium |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211312420.4ACN115590260A (en) | 2022-10-25 | 2022-10-25 | Heating control method, aerosol generating device, and storage medium |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115590260Atrue CN115590260A (en) | 2023-01-13 |

Family

ID=84848814

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211312420.4APendingCN115590260A (en) | 2022-10-25 | 2022-10-25 | Heating control method, aerosol generating device, and storage medium |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115590260A (en) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110946338A (en)* | 2019-12-18 | 2020-04-03 | 惠州市沛格斯科技有限公司 | Heating method and device of electronic smoking set, storage medium and electronic smoking set |

| CN112841752A (en)* | 2019-11-12 | 2021-05-28 | 深圳市合元科技有限公司 | Aerosol generating device and control method thereof |

| CN113439881A (en)* | 2020-03-28 | 2021-09-28 | 深圳市合元科技有限公司 | Aerosol generating device and control method thereof |

| US20220248769A1 (en)* | 2019-07-15 | 2022-08-11 | Shanghai New Tobacco Product Research Institute Co., Ltd. | Temperature control method, aerosol generation apparatus and aerosol generation system |

- 2022

- 2022-10-25CNCN202211312420.4Apatent/CN115590260A/enactivePending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20220248769A1 (en)* | 2019-07-15 | 2022-08-11 | Shanghai New Tobacco Product Research Institute Co., Ltd. | Temperature control method, aerosol generation apparatus and aerosol generation system |

| CN112841752A (en)* | 2019-11-12 | 2021-05-28 | 深圳市合元科技有限公司 | Aerosol generating device and control method thereof |