CN115559905A - Two-stage screw compressor and air conditioning unit - Google Patents

Two-stage screw compressor and air conditioning unitDownload PDFInfo

- Publication number

- CN115559905A CN115559905ACN202211311367.6ACN202211311367ACN115559905ACN 115559905 ACN115559905 ACN 115559905ACN 202211311367 ACN202211311367 ACN 202211311367ACN 115559905 ACN115559905 ACN 115559905A

- Authority

- CN

- China

- Prior art keywords

- pressure stage

- pair

- low

- stage

- rotating shaft

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C18/00—Rotary-piston pumps specially adapted for elastic fluids

- F04C18/08—Rotary-piston pumps specially adapted for elastic fluids of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing

- F04C18/12—Rotary-piston pumps specially adapted for elastic fluids of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing of other than internal-axis type

- F04C18/14—Rotary-piston pumps specially adapted for elastic fluids of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing of other than internal-axis type with toothed rotary pistons

- F04C18/16—Rotary-piston pumps specially adapted for elastic fluids of intermeshing-engagement type, i.e. with engagement of co-operating members similar to that of toothed gearing of other than internal-axis type with toothed rotary pistons with helical teeth, e.g. chevron-shaped, screw type

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C23/00—Combinations of two or more pumps, each being of rotary-piston or oscillating-piston type, specially adapted for elastic fluids; Pumping installations specially adapted for elastic fluids; Multi-stage pumps specially adapted for elastic fluids

- F04C23/001—Combinations of two or more pumps, each being of rotary-piston or oscillating-piston type, specially adapted for elastic fluids; Pumping installations specially adapted for elastic fluids; Multi-stage pumps specially adapted for elastic fluids of similar working principle

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C29/00—Component parts, details or accessories of pumps or pumping installations, not provided for in groups F04C18/00 - F04C28/00

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04C—ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT MACHINES FOR LIQUIDS; ROTARY-PISTON, OR OSCILLATING-PISTON, POSITIVE-DISPLACEMENT PUMPS

- F04C2240/00—Components

- F04C2240/80—Other components

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Applications Or Details Of Rotary Compressors (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及空气处理设备技术领域,特别是一种双级螺杆压缩机及空调机组。The invention relates to the technical field of air treatment equipment, in particular to a two-stage screw compressor and an air conditioning unit.

背景技术Background technique

同轴直驱转子是近几年提出的螺杆压缩机新结构。它只通过一对转子实现两级压缩,相比于单机双级压缩机,其结构更加精简,减少了联轴器和轴承的数量,从而降低了压缩机的传动损耗,具有很深远的应用前景。Coaxial direct drive rotor is a new structure of screw compressor proposed in recent years. It only uses a pair of rotors to achieve two-stage compression. Compared with a single two-stage compressor, its structure is more streamlined, reducing the number of couplings and bearings, thereby reducing the transmission loss of the compressor, and has a very far-reaching application prospect. .

同轴直驱螺杆压缩机采用同轴设置的低压级转子对和高压级转子对进行双级压缩,现有技术中采用通过设计参数来控制高压级转子对的排气端面和低压级排气端面的间隙的一致性,然而在生产加工过程中,高压级转子对的排气端面和低压级排气端面的间隙无法进行同时控制,压缩机在工作时,低压级转子对或高压级转子对容易擦伤损坏,造成双级螺杆压缩机工作不可靠的问题。The coaxial direct-drive screw compressor adopts the coaxial low-pressure stage rotor pair and high-pressure stage rotor pair for two-stage compression. In the prior art, the design parameters are used to control the exhaust end face of the high-pressure stage rotor pair and the low-pressure stage exhaust end face. However, in the process of production and processing, the gap between the exhaust end face of the high-pressure stage rotor pair and the discharge end face of the low-pressure stage cannot be controlled simultaneously. When the compressor is working, the low-pressure stage rotor pair or the high-pressure stage rotor pair are easily Scratches and damages cause unreliable operation of the two-stage screw compressor.

发明内容Contents of the invention

为了解决现有技术中压缩机工作不可靠的技术问题,而提供一种低压级转子对和/或高压级转子对可拆卸以实现同时控制间隙的双级螺杆压缩机及空调机组。In order to solve the technical problem of unreliable operation of compressors in the prior art, a two-stage screw compressor and an air conditioner unit are provided in which the low-pressure stage rotor pair and/or the high-pressure stage rotor pair can be disassembled to simultaneously control the gap.

一种双级螺杆压缩机,包括:A two-stage screw compressor comprising:

壳体;case;

间隔板,所述间隔板将所述壳体分隔成相互连通的低压级壳体和高压级壳体,所述间隔板上设置有转轴孔;A partition plate, which separates the housing into a low-pressure stage shell and a high-pressure stage shell that communicate with each other, and a shaft hole is arranged on the partition plate;

转轴对,所述转轴对设置于所述转轴孔处,且部分所述转轴对设置于所述低压级壳体内,部分所述转轴对设置于所述高压级壳体内;A pair of rotating shafts, the pair of rotating shafts is arranged at the hole of the rotating shaft, and some of the pairs of rotating shafts are arranged in the housing of the low-pressure stage, and some of the pairs of rotating shafts are arranged in the casing of the high-pressure stage;

低压级转子对,所述低压级转子对设置于所述低压级壳体内,且所述低压级转子对可拆卸地设置于所述转轴对上;A pair of low-pressure stage rotors, the pair of low-pressure stage rotors is arranged in the low-pressure stage housing, and the pair of low-pressure stage rotors is detachably arranged on the pair of rotating shafts;

和/或,高压级转子对,所述高压级转子对设置于所述高压级壳体上,且所述高压级转子对可拆卸地设置于所述转轴对上。And/or, a pair of high-pressure stage rotors, the pair of high-pressure stage rotors is arranged on the high-pressure stage casing, and the pair of high-pressure stage rotors is detachably arranged on the pair of rotating shafts.

所述转轴对包括第一转轴和第二转轴,所述转轴孔包括第一转轴孔和第二转轴孔,所述第一转轴可转动地设置于所述第一转轴孔处,且部分所述第一转轴位于所述低压级壳体内,部分所述第一转轴位于所述高压级壳体内,所述第二转轴可转动地设置于所述第二转轴孔处,且部分所述第二转轴位于所述低压级壳体内,部分所述第二转轴位于所述高压级壳体内;The pair of rotating shafts includes a first rotating shaft and a second rotating shaft, the rotating shaft hole includes a first rotating shaft hole and a second rotating shaft hole, the first rotating shaft is rotatably arranged at the first rotating shaft hole, and part of the The first rotating shaft is located in the low-pressure stage casing, part of the first rotating shaft is located in the high-pressure stage casing, the second rotating shaft is rotatably arranged at the second rotating shaft hole, and part of the second rotating shaft Located within the low-pressure stage housing, a portion of the second shaft is located within the high-pressure stage housing;

所述低压级转子对包括低压级阳转子和低压级阴转子,所述低压级阳转子可拆卸地套设于所述第一转轴上,所述低压级阴转子可拆卸地套设于所述第二转轴上;The pair of low-pressure stage rotors includes a low-pressure stage male rotor and a low-pressure stage female rotor, the low-pressure stage male rotor is detachably sleeved on the first rotating shaft, and the low-pressure stage female rotor is detachably sleeved on the on the second shaft;

和/或,所述高压级转子对包括高压级阳转子和高压级阴转子,所述高压级阳转子可拆卸地套设于所述第一转轴上,所述高压级阴转子可拆卸地套设于所述第二转轴上。And/or, the pair of high-pressure stage rotors includes a high-pressure stage male rotor and a high-pressure stage female rotor, the high-pressure stage male rotor is detachably sleeved on the first rotating shaft, and the high-pressure stage female rotor is detachably sleeved It is arranged on the second rotating shaft.

所述双级螺杆压缩机还包括轴承座,所述轴承座设置于所述壳体上,且所述轴承座与所述壳体和所述间隔板共同围成所述高压级壳体,所述高压级转子对与所述轴承座之间具有第一间距G1,所述低压级转子对与所述间隔板之间具有第二间距G2,且G1=G2。The two-stage screw compressor also includes a bearing seat, the bearing seat is arranged on the casing, and the bearing seat, the casing and the partition plate together form the high-pressure stage casing, so There is a first distance G1 between the high-pressure stage rotor pair and the bearing seat, and there is a second distance G2 between the low-pressure stage rotor pair and the partition plate, and G1=G2.

所述高压级壳体的长度L1与所述低压级转子对的排气端面至所述高压级转子对的排气端面的距离L2相等。The length L1 of the high-pressure stage housing is equal to the distance L2 from the exhaust end surface of the low-pressure stage rotor pair to the exhaust end surface of the high-pressure stage rotor pair.

所述转轴对上设置有低压级安装结构,所述低压级转子对上设置有第一配合结构,所述第一配合结构与所述低压级安装结构固定配合。The pair of rotating shafts is provided with a low-pressure stage mounting structure, and the pair of low-pressure stage rotors is provided with a first matching structure, and the first matching structure is fixedly matched with the low-pressure stage mounting structure.

所述双级螺杆压缩机还包括调节垫片,所述调节垫片设置于所述低压级转子对和所述低压级安装结构之间。The two-stage screw compressor further includes an adjusting gasket, and the adjusting gasket is arranged between the low-pressure stage rotor pair and the low-pressure stage installation structure.

所述第一配合结构位于所述低压级转子对的排气端处。The first mating structure is located at the discharge end of the low pressure stage rotor pair.

所述转轴对上设置有高压级安装结构,所述高压级转子对上设置有第二配合结构,所述第二配合结构与所述高压级安装结构固定配合。The pair of rotating shafts is provided with a high-pressure stage installation structure, and the pair of high-pressure stage rotors is provided with a second matching structure, and the second matching structure is fixedly matched with the high-pressure stage installation structure.

所述双级螺杆压缩机还包括调节垫片,所述调节垫片设置于所述高压级转子对和所述高压级安装结构之间。The two-stage screw compressor further includes an adjusting gasket, and the adjusting gasket is arranged between the high-pressure stage rotor pair and the high-pressure stage installation structure.

所述第二配合结构位于所述高压级转子对的吸气端处。The second mating structure is located at the suction end of the high pressure stage rotor pair.

一种空调机组,包括上述的双级螺杆压缩机。An air conditioner unit includes the above-mentioned two-stage screw compressor.

本发明提供的双级螺杆压缩机及空调机组,将低压级转子对和/或高压级转子对设置为可拆卸结构,使得低压级转子对的排气端面的间隙和/或高压级转子对的排气端面的间隙可调,确保两个间隙均能控制在设计值范围内,克服现有技术中由于实际加工和/或理论计算存在的误差等原因而造成低压级转子对或高压级转子对容易擦伤损坏的问题,保证压缩机的工作可靠,同时由于低压级转子对和/或高压级转子对可拆卸,可以将间隔板一体设置,避免现有技术中间隔板分体设置而存在加工不一致的问题,避免低压级转子对和/或高压级转子对与间隔板产生干涉,进一步保证压缩机的工作可靠。In the two-stage screw compressor and air-conditioning unit provided by the present invention, the pair of low-stage rotors and/or the pair of high-pressure rotors are set as detachable structures, so that the gap between the exhaust end surfaces of the pair of low-stage rotors and/or the pair of high-pressure rotors The clearance of the exhaust end face can be adjusted to ensure that the two clearances can be controlled within the design value range, so as to overcome the problems caused by the actual machining and/or theoretical calculation errors in the prior art and the low-pressure stage rotor pair or the high-pressure stage rotor pair. The problem of easy scratches and damages ensures the reliable operation of the compressor. At the same time, because the low-pressure stage rotor pair and/or the high-pressure stage rotor pair are detachable, the partition plate can be set in one piece, avoiding the existence of processing in the prior art. The problem of inconsistency can avoid interference between the low-pressure stage rotor pair and/or the high-pressure stage rotor pair and the partition plate, and further ensure the reliable operation of the compressor.

附图说明Description of drawings

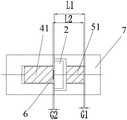

图1为本发明实施例提供的双级螺杆压缩机的结构示意图;Fig. 1 is a schematic structural view of a two-stage screw compressor provided by an embodiment of the present invention;

图2为本发明实施例提供的高压级转子对可拆卸的结构示意图;Fig. 2 is a schematic diagram of the detachable structure of the high-pressure stage rotor pair provided by the embodiment of the present invention;

图3为本发明实施例提供的双级螺杆压缩机的另一结构示意图;Fig. 3 is another structural schematic diagram of the two-stage screw compressor provided by the embodiment of the present invention;

图中:In the picture:

1、壳体;2、间隔板;11、低压级壳体;12、高压级壳体;31、第一转轴;32、第二转轴;41、低压级阳转子;42、低压级阴转子;51、高压级阳转子;52、高压级阴转子;6、调节垫片;7、轴承座。1. Shell; 2. Spacer plate; 11. Low-pressure shell; 12. High-pressure shell; 31. First shaft; 32. Second shaft; 41. Low-pressure male rotor; 42. Low-pressure female rotor; 51. High-pressure male rotor; 52. High-pressure female rotor; 6. Adjusting gasket; 7. Bearing seat.

具体实施方式detailed description

为了使本发明的目的、技术方案及优点更加清楚明白,以下结合附图及实施例对本发明进行进一步详细说明。应当理解,此处所描述的具体实施例仅用于解释本发明,并不用于限定本发明。In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

如图1至图3所示的双级螺杆压缩机,包括:壳体1;间隔板2,所述间隔板2将所述壳体1分隔成相互连通的低压级壳体11和高压级壳体12,所述间隔板2上设置有转轴孔;转轴对,所述转轴对设置于所述转轴孔处,且部分所述转轴对设置于所述低压级壳体11内,部分所述转轴对设置于所述高压级壳体12内;低压级转子对,所述低压级转子对设置于所述低压级壳体11内,且所述低压级转子对可拆卸地设置于所述转轴对上。将低压级转子对设置为可拆卸结构,使得低压级转子对的排气端面的间隙可调,确保两个间隙均能控制在设计值范围内,克服现有技术中由于实际加工和/或理论计算存在的误差等原因而造成低压级转子对容易擦伤损坏的问题,保证压缩机的工作可靠,同时由于低压级转子对可拆卸,可以将间隔板2一体设置,避免现有技术中间隔板2分体设置而存在加工不一致的问题,避免转轴孔偏心或者同轴度低,从而避免低压级转子对和/或高压级转子对与间隔板2产生干涉,进一步保证压缩机的工作可靠。The two-stage screw compressor shown in Figures 1 to 3 includes: a

其中,所述双级螺杆压缩机还包括轴承座,所述轴承座设置于所述壳体1上,且所述轴承座与所述壳体1和所述间隔板2共同围成所述高压级壳体12,低压级转子对的排气端面的间隙是指低压级转子对的排气端面与间隔板2之间的间距,高压级转子对的排气端面的间隙是指高压级转子对的排气端面与轴承座之间的间距。Wherein, the two-stage screw compressor also includes a bearing seat, the bearing seat is arranged on the

具体的,所述转轴对包括第一转轴31和第二转轴32,所述转轴孔包括第一转轴孔和第二转轴孔,所述第一转轴31可转动地设置于所述第一转轴孔处,且部分所述第一转轴31位于所述低压级壳体11内,部分所述第一转轴31位于所述高压级壳体12内,所述第二转轴32可转动地设置于所述第二转轴孔处,且部分所述第二转轴32位于所述低压级壳体11内,部分所述第二转轴32位于所述高压级壳体12内;所述低压级转子对包括低压级阳转子41和低压级阴转子42,所述低压级阳转子41可拆卸地套设于所述第一转轴31上,所述低压级阴转子42可拆卸地套设于所述第二转轴32上。在安装低压级转子对及高压级转子对时,先将低压级阳转子41由第一转轴31上拆下、低压级阴转子42有第二转轴32上拆下,然后将第一转轴31穿过第一转轴孔、第二转轴32穿过第二转轴孔,使得高压级转子对安装到高压级壳体12内,并且使得高压级转子对的排气端的间隙达到设定要求,然后再将低压级阳转子41安装到第一转轴31上、低压级阴转子42安装到第二转轴32上,调节低压级转子对的排气端面的间隙,从而保证低压级转子对的排气端面的间隙和高压级转子对的排气端面的间隙均达到设定要求,保证压缩机的工作可靠,同时间隔板2上直接开设第一转轴孔和第二转轴孔即可,无需将间隔板2分体设置,保证第一转轴孔和第二转轴孔的精度,避免低压级转子对与高压级转子对与间隔板2产生干涉,进一步保证压缩机的工作可靠。Specifically, the shaft pair includes a

所述双级螺杆压缩机还包括轴承座7,所述轴承座7设置于所述壳体1上,且所述轴承座7与所述壳体1和所述间隔板2共同围成所述高压级壳体12,所述高压级转子对与所述轴承座7之间具有第一间距G1,所述低压级转子对与所述间隔板2之间具有第二间距G2,且G1=G2。也即此时第一间距G1和第二间距G2均达到设定要求,从而保证压缩机的压缩效率。The two-stage screw compressor also includes a

可选地,所述高压级壳体12的长度L1与所述低压级转子对的排气端面至所述高压级转子对的排气端面的距离L2相等。Optionally, the length L1 of the high-

所述转轴对上设置有低压级安装结构,所述低压级转子对上设置有第一配合结构,所述第一配合结构与所述低压级安装结构固定配合。此时低压级转子对可以安装在转轴对上,具体的,第一转轴31上设置有第一低压级轴肩,低压级阳转子41的一端处设置有安装槽,第一低压级轴肩抵接在安装槽的槽底,然后在采用锁紧件等由低压级阳转子41的另一端将低压级阳转子41锁紧在第一转轴31上,完成低压级阳转子41的安装,同理,第二转轴32上设置有第二低压级轴肩,低压级阴转子42的一端处设置有安装槽,第二低压级轴肩抵接在安装槽的槽底,然后在采用锁紧件等由低压级阴转子42的另一端将低压级阴转子42锁紧在第二转轴32上,完成低压级阴转子42的安装。The pair of rotating shafts is provided with a low-pressure stage mounting structure, and the pair of low-pressure stage rotors is provided with a first matching structure, and the first matching structure is fixedly matched with the low-pressure stage mounting structure. At this time, the pair of low-pressure stage rotors can be installed on the pair of rotating shafts. Specifically, the first

当需要调节低压级转子对的排气端面的间隙时,所述双级螺杆压缩机还包括调节垫片6,所述调节垫片6设置于所述低压级转子对和所述低压级安装结构之间。利用调节垫片6对低压级转子对和低压级安装结构之间的安装位置进行调节,实现间隙的调节。When it is necessary to adjust the clearance of the exhaust end surface of the low-pressure stage rotor pair, the two-stage screw compressor also includes an adjusting

所述第一配合结构位于所述低压级转子对的排气端处。The first mating structure is located at the discharge end of the low pressure stage rotor pair.

在安装双级螺杆压缩机时,先将轴承座7装配到壳体1上,然后将高压级转子对放入高压级壳体12内,并将高压级转子对的排气端面的间隙调整到设定值,然后测量高压级壳体12的长度,安装间隔板2及低压级转子对,并增加调整垫片使所述高压级壳体12的长度L1与所述低压级转子对的排气端面至所述高压级转子对的排气端面的距离L2相等,然后在安装好压缩机的其他结构,完成安装。When installing a two-stage screw compressor, first assemble the

或者,在安装双级螺杆压缩机时,先将轴承座7装配到壳体1上,然后将高压级转子对放入高压级壳体12内,并将高压级转子对的排气端面的间隙调整到设定值,然后安装间隔板2及低压级转子对,并使低压级转子对与间隔板2紧贴,然后拆卸低压级壳体11,并在安装调节垫片6对低压级转子对的排气端面的间隙进行调整,然后再安装低压级壳体11,完成压缩机的安装。Alternatively, when installing a two-stage screw compressor, first assemble the

作为另一实施方式,与上述实施方式的区别在于,双级螺杆压缩机包括高压级转子对,所述高压级转子对设置于所述高压级壳体12上,且所述高压级转子对可拆卸地设置于所述转轴对上。将高压级转子对设置为可拆卸结构,使得高压级转子对的排气端面的间隙可调,确保两个间隙均能控制在设计值范围内,克服现有技术中由于实际加工和/或理论计算存在的误差等原因而造成低压级转子对容易擦伤损坏的问题,保证压缩机的工作可靠,同时由于低压级转子对可拆卸,可以将间隔板2一体设置,避免现有技术中间隔板2分体设置而存在加工不一致的问题,避免转轴孔偏心或者同轴度低,从而避免低压级转子对和/或高压级转子对与间隔板2产生干涉,进一步保证压缩机的工作可靠。As another embodiment, the difference from the above embodiment is that the two-stage screw compressor includes a high-pressure stage rotor pair, the high-pressure stage rotor pair is arranged on the high-

具体的,所述高压级转子对包括高压级阳转子51和高压级阴转子52,所述高压级阳转子51可拆卸地套设于所述第一转轴31上,所述高压级阴转子52可拆卸地套设于所述第二转轴32上。在安装低压级转子对及高压级转子对时,先将高压级阳转子51由第一转轴31上拆下、高压级阴转子52有第二转轴32上拆下,然后将第一转轴31穿过第一转轴孔、第二转轴32穿过第二转轴孔,使得低压级转子对安装到低压级壳体11内,并且使得低压级转子对的排气端的间隙达到设定要求,然后再将高压级阳转子51安装到第一转轴31上、高压级阴转子52安装到第二转轴32上,调节高压级转子对的排气端面的间隙,从而保证低压级转子对的排气端面的间隙和高压级转子对的排气端面的间隙均达到设定要求,保证压缩机的工作可靠,同时间隔板2上直接开设第一转轴孔和第二转轴孔即可,无需将间隔板2分体设置,保证第一转轴孔和第二转轴孔的精度,避免低压级转子对与高压级转子对与间隔板2产生干涉,进一步保证压缩机的工作可靠。Specifically, the pair of high-pressure stage rotors includes a high-pressure stage

其中,所述双级螺杆压缩机还包括轴承座7,所述轴承座7设置于所述壳体1上,且所述轴承座7与所述壳体1和所述间隔板2共同围成所述高压级壳体12,低压级转子对的排气端面的间隙是指低压级转子对的排气端面与间隔板2之间的间距,高压级转子对的排气端面的间隙是指高压级转子对的排气端面与轴承座7之间的间距。Wherein, the two-stage screw compressor also includes a bearing

所述转轴对上设置有高压级安装结构,所述高压级转子对上设置有第二配合结构,所述第二配合结构与所述高压级安装结构固定配合。具体的,第一转轴31上设置有第一高压级轴肩,高压级阳转子51的一端处设置有安装槽,第一高压级轴肩抵接在安装槽的槽底,然后在采用锁紧件等由高压级阳转子51的另一端将高压级阳转子51锁紧在第一转轴31上,完成高压级阳转子51的安装,同理,第二转轴32上设置有第二高压级轴肩,高压级阴转子52的一端处设置有安装槽,第二高压级轴肩抵接在安装槽的槽底,然后在采用锁紧件等由高压级阴转子52的另一端将高压级阴转子52锁紧在第二转轴32上,完成高压级阴转子52的安装。The pair of rotating shafts is provided with a high-pressure stage installation structure, and the pair of high-pressure stage rotors is provided with a second matching structure, and the second matching structure is fixedly matched with the high-pressure stage installation structure. Specifically, the first

所述双级螺杆压缩机还包括调节垫片6,所述调节垫片6设置于所述高压级转子对和所述高压级安装结构之间。The two-stage screw compressor also includes an adjusting

可选的,轴承座7与壳体1之间设置有调节垫片6,通过调节轴承座7的位置实现调节高压级转子对的排气端面的间隙的调节。Optionally, an adjusting

所述第二配合结构位于所述高压级转子对的吸气端处。The second mating structure is located at the suction end of the high pressure stage rotor pair.

作为另一种实施方式,与上述实施例的区别在于,压缩机包括低压级转子对和高压级转子对,且低压级转子对可拆卸地设置于转轴对上,高压级转子对可拆卸地设置于转轴对上,此时压缩机能够实现上述两个实施例中的有益效果,在此不再赘述。As another implementation mode, the difference from the above embodiment is that the compressor includes a low-pressure stage rotor pair and a high-pressure stage rotor pair, and the low-pressure stage rotor pair is detachably arranged on the shaft pair, and the high-pressure stage rotor pair is detachably arranged On the pair of rotating shafts, the compressor can achieve the beneficial effects of the above two embodiments at this time, and details will not be repeated here.

一种空调机组,包括上述的双级螺杆压缩机。An air conditioner unit includes the above-mentioned two-stage screw compressor.

以上所述实施例仅表达了本发明的几种实施方式,其描述较为具体和详细,但并不能因此而理解为对本发明专利范围的限制。应当指出的是,对于本领域的普通技术人员来说,在不脱离本发明构思的前提下,还可以做出若干变形和改进,这些都属于本发明的保护范围。因此,本发明专利的保护范围应以所附权利要求为准。The above-mentioned embodiments only express several implementation modes of the present invention, and the description thereof is relatively specific and detailed, but should not be construed as limiting the patent scope of the present invention. It should be pointed out that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention. Therefore, the protection scope of the patent for the present invention should be based on the appended claims.

Claims (11)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211311367.6ACN115559905A (en) | 2022-10-25 | 2022-10-25 | Two-stage screw compressor and air conditioning unit |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211311367.6ACN115559905A (en) | 2022-10-25 | 2022-10-25 | Two-stage screw compressor and air conditioning unit |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115559905Atrue CN115559905A (en) | 2023-01-03 |

Family

ID=84746407

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211311367.6APendingCN115559905A (en) | 2022-10-25 | 2022-10-25 | Two-stage screw compressor and air conditioning unit |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115559905A (en) |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1137257A (en)* | 1965-01-13 | 1968-12-18 | Svenska Rotor Maskiner Ab | A meshing-screw rotor machine |

| CN1793654A (en)* | 2005-12-22 | 2006-06-28 | 西安交通大学 | Double-screw compressor for high pressure system |

| CN106704179A (en)* | 2017-03-09 | 2017-05-24 | 上海格什特螺杆科技有限公司 | Novel direct-connected dual-screw compressor |

| CN109751240A (en)* | 2017-11-02 | 2019-05-14 | 开利公司 | Opposed type helical-lobe compressor with non-interference system |

| CN218522805U (en)* | 2022-10-25 | 2023-02-24 | 珠海格力电器股份有限公司 | Two-stage screw compressor and air conditioning unit |

- 2022

- 2022-10-25CNCN202211311367.6Apatent/CN115559905A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB1137257A (en)* | 1965-01-13 | 1968-12-18 | Svenska Rotor Maskiner Ab | A meshing-screw rotor machine |

| CN1793654A (en)* | 2005-12-22 | 2006-06-28 | 西安交通大学 | Double-screw compressor for high pressure system |

| CN106704179A (en)* | 2017-03-09 | 2017-05-24 | 上海格什特螺杆科技有限公司 | Novel direct-connected dual-screw compressor |

| CN109751240A (en)* | 2017-11-02 | 2019-05-14 | 开利公司 | Opposed type helical-lobe compressor with non-interference system |

| CN218522805U (en)* | 2022-10-25 | 2023-02-24 | 珠海格力电器股份有限公司 | Two-stage screw compressor and air conditioning unit |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN203272136U (en) | Single-cylinder multistage compressor | |

| CN109209819B (en) | A piston transmission mechanism and a two-dimensional compressor | |

| WO2019148954A1 (en) | Multi-stage roots dry vacuum pump | |

| JP2012112338A (en) | Screw compressor | |

| CN101072946A (en) | Compressor sound suppression | |

| CN107120274B (en) | Rotary blade type compressor | |

| CN109915377A (en) | A kind of novel two stage rotary-vane vaccum pump | |

| CN202937450U (en) | Intermediate partition board of double-cylinder compressor | |

| CN114320917A (en) | A direct discharge type Roots pump | |

| CN218522805U (en) | Two-stage screw compressor and air conditioning unit | |

| CN115559905A (en) | Two-stage screw compressor and air conditioning unit | |

| WO2023097898A1 (en) | Pump assembly and enthalpy-increasing rotor compressor | |

| WO2020042443A1 (en) | Main shaft of compressor, compressor, and air conditioner | |

| CN114215749A (en) | Screw rotor, compressor and air conditioner | |

| EP4325057A2 (en) | Multi-stage vacuum booster pump rotor | |

| CN111322241A (en) | Pump body subassembly and rotary compressor | |

| CN218816971U (en) | Double-stage coaxial screw compression assembly, compressor and air conditioner with compressor | |

| CN201193614Y (en) | Inlet Mechanism of Rotary Compressor Cylinder | |

| CN216788701U (en) | A screw rotor, compressor and air conditioner | |

| CN104989641A (en) | Vortex dry vacuum pump | |

| CN214617037U (en) | Micro-oil screw vacuum pump | |

| CN216306224U (en) | Compressors and Air Conditioners | |

| CN216306222U (en) | Compressor and air conditioner | |

| CN116292288A (en) | A kind of assembly method of screw vacuum pump | |

| CN105927592B (en) | The spiral case of assembly type compressor and connecting mechanism for gear box, connector |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |