CN115444787A - A kind of compound green tea dendrobium antioxidative essential oil and its processing technology - Google Patents

A kind of compound green tea dendrobium antioxidative essential oil and its processing technologyDownload PDFInfo

- Publication number

- CN115444787A CN115444787ACN202211169041.4ACN202211169041ACN115444787ACN 115444787 ACN115444787 ACN 115444787ACN 202211169041 ACN202211169041 ACN 202211169041ACN 115444787 ACN115444787 ACN 115444787A

- Authority

- CN

- China

- Prior art keywords

- extract

- essential oil

- gauze

- tank

- green tea

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000341volatile oilSubstances0.000titleclaimsabstractdescription35

- 244000269722Thea sinensisSpecies0.000titleclaimsabstractdescription28

- 150000001875compoundsChemical class0.000titleclaimsabstractdescription23

- 235000009569green teaNutrition0.000titleclaimsabstractdescription22

- 230000003078antioxidant effectEffects0.000titleclaimsabstractdescription21

- 241001523681DendrobiumSpecies0.000titleclaimsabstractdescription17

- 238000005516engineering processMethods0.000titleclaimsabstractdescription15

- 239000000284extractSubstances0.000claimsabstractdescription49

- PRAKJMSDJKAYCZ-UHFFFAOYSA-NsqualaneChemical compoundCC(C)CCCC(C)CCCC(C)CCCCC(C)CCCC(C)CCCC(C)CPRAKJMSDJKAYCZ-UHFFFAOYSA-N0.000claimsabstractdescription20

- 239000003963antioxidant agentSubstances0.000claimsabstractdescription12

- JXTPJDDICSTXJX-UHFFFAOYSA-Nn-TriacontaneNatural productsCCCCCCCCCCCCCCCCCCCCCCCCCCCCCCJXTPJDDICSTXJX-UHFFFAOYSA-N0.000claimsabstractdescription10

- 229940032094squalaneDrugs0.000claimsabstractdescription10

- 239000003921oilSubstances0.000claimsabstractdescription9

- 235000004347PerillaNutrition0.000claimsabstractdescription6

- 244000124853Perilla frutescensSpecies0.000claimsabstractdescription6

- 240000008042Zea maysSpecies0.000claimsabstractdescription6

- 235000005824Zea mays ssp. parviglumisNutrition0.000claimsabstractdescription6

- 235000002017Zea mays subsp maysNutrition0.000claimsabstractdescription6

- 235000005822cornNutrition0.000claimsabstractdescription6

- 235000013616teaNutrition0.000claimsabstractdescription6

- 239000010497wheat germ oilSubstances0.000claimsabstractdescription6

- 241001076416Dendrobium tosaenseSpecies0.000claimsabstractdescription4

- 241000222336GanodermaSpecies0.000claimsabstract2

- 244000131316Panax pseudoginsengSpecies0.000claimsabstract2

- 235000003181Panax pseudoginsengNutrition0.000claimsabstract2

- 241000756042PolygonatumSpecies0.000claimsabstract2

- 238000000605extractionMethods0.000claimsdescription64

- 239000000243solutionSubstances0.000claimsdescription40

- 230000007246mechanismEffects0.000claimsdescription38

- 241000411851herbal medicineSpecies0.000claimsdescription37

- 238000002386leachingMethods0.000claimsdescription27

- 238000004898kneadingMethods0.000claimsdescription20

- 230000005540biological transmissionEffects0.000claimsdescription15

- 239000011265semifinished productSubstances0.000claimsdescription15

- 238000003756stirringMethods0.000claimsdescription10

- 239000007788liquidSubstances0.000claimsdescription8

- 238000010924continuous productionMethods0.000claimsdescription5

- 239000000463materialSubstances0.000claimsdescription5

- 239000000203mixtureSubstances0.000claimsdescription5

- 239000000047productSubstances0.000claimsdescription5

- 239000002994raw materialSubstances0.000claimsdescription5

- 238000010438heat treatmentMethods0.000claimsdescription4

- 230000033001locomotionEffects0.000claimsdescription4

- 238000002156mixingMethods0.000claimsdescription4

- 239000000126substanceSubstances0.000claimsdescription4

- 238000011049fillingMethods0.000claimsdescription3

- 230000005389magnetismEffects0.000claimsdescription3

- 239000011259mixed solutionSubstances0.000claimsdescription3

- 239000003814drugSubstances0.000claimsdescription2

- 230000000694effectsEffects0.000abstractdescription6

- 239000002537cosmeticSubstances0.000abstractdescription3

- 230000003020moisturizing effectEffects0.000abstractdescription3

- 230000003647oxidationEffects0.000abstractdescription2

- 238000007254oxidation reactionMethods0.000abstractdescription2

- 238000000034methodMethods0.000description10

- 238000003825pressingMethods0.000description9

- 239000002245particleSubstances0.000description8

- 239000008187granular materialSubstances0.000description6

- 235000005340Asparagus officinalisNutrition0.000description4

- 240000008397Ganoderma lucidumSpecies0.000description4

- 235000001637Ganoderma lucidumNutrition0.000description4

- 239000009277Panax notoginseng extractSubstances0.000description4

- 241001633680Polygonatum odoratumSpecies0.000description4

- 230000000712assemblyEffects0.000description4

- 238000000429assemblyMethods0.000description4

- 241000196324EmbryophytaSpecies0.000description3

- 230000003064anti-oxidating effectEffects0.000description3

- 241000234427AsparagusSpecies0.000description2

- 244000003416Asparagus officinalisSpecies0.000description2

- 241000026010Dendrobium candidumSpecies0.000description2

- 239000004480active ingredientSubstances0.000description2

- 235000006708antioxidantsNutrition0.000description2

- 238000010586diagramMethods0.000description2

- 235000013399edible fruitsNutrition0.000description2

- 235000008216herbsNutrition0.000description2

- 238000007781pre-processingMethods0.000description2

- 230000003716rejuvenationEffects0.000description2

- 230000000630rising effectEffects0.000description2

- 244000183685Citrus aurantiumSpecies0.000description1

- 235000007716Citrus aurantiumNutrition0.000description1

- 238000010521absorption reactionMethods0.000description1

- 238000013019agitationMethods0.000description1

- 230000003712anti-aging effectEffects0.000description1

- 230000009286beneficial effectEffects0.000description1

- 238000004090dissolutionMethods0.000description1

- 238000001125extrusionMethods0.000description1

- 239000004615ingredientSubstances0.000description1

- 238000011068loading methodMethods0.000description1

- 238000004519manufacturing processMethods0.000description1

- 230000001105regulatory effectEffects0.000description1

- 239000011347resinSubstances0.000description1

- 229920005989resinPolymers0.000description1

- 238000000638solvent extractionMethods0.000description1

- 238000001256steam distillationMethods0.000description1

- 230000032258transportEffects0.000description1

- 239000002699waste materialSubstances0.000description1

- 239000002023woodSubstances0.000description1

Images

Classifications

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/92—Oils, fats or waxes; Derivatives thereof, e.g. hydrogenation products thereof

- A61K8/922—Oils, fats or waxes; Derivatives thereof, e.g. hydrogenation products thereof of vegetable origin

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/30—Cosmetics or similar toiletry preparations characterised by the composition containing organic compounds

- A61K8/31—Hydrocarbons

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/96—Cosmetics or similar toiletry preparations characterised by the composition containing materials, or derivatives thereof of undetermined constitution

- A61K8/97—Cosmetics or similar toiletry preparations characterised by the composition containing materials, or derivatives thereof of undetermined constitution from algae, fungi, lichens or plants; from derivatives thereof

- A61K8/9728—Fungi, e.g. yeasts

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/96—Cosmetics or similar toiletry preparations characterised by the composition containing materials, or derivatives thereof of undetermined constitution

- A61K8/97—Cosmetics or similar toiletry preparations characterised by the composition containing materials, or derivatives thereof of undetermined constitution from algae, fungi, lichens or plants; from derivatives thereof

- A61K8/9783—Angiosperms [Magnoliophyta]

- A61K8/9789—Magnoliopsida [dicotyledons]

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K8/00—Cosmetics or similar toiletry preparations

- A61K8/18—Cosmetics or similar toiletry preparations characterised by the composition

- A61K8/96—Cosmetics or similar toiletry preparations characterised by the composition containing materials, or derivatives thereof of undetermined constitution

- A61K8/97—Cosmetics or similar toiletry preparations characterised by the composition containing materials, or derivatives thereof of undetermined constitution from algae, fungi, lichens or plants; from derivatives thereof

- A61K8/9783—Angiosperms [Magnoliophyta]

- A61K8/9794—Liliopsida [monocotyledons]

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61Q—SPECIFIC USE OF COSMETICS OR SIMILAR TOILETRY PREPARATIONS

- A61Q19/00—Preparations for care of the skin

- A61Q19/08—Anti-ageing preparations

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11B—PRODUCING, e.g. BY PRESSING RAW MATERIALS OR BY EXTRACTION FROM WASTE MATERIALS, REFINING OR PRESERVING FATS, FATTY SUBSTANCES, e.g. LANOLIN, FATTY OILS OR WAXES; ESSENTIAL OILS; PERFUMES

- C11B9/00—Essential oils; Perfumes

- C11B9/02—Recovery or refining of essential oils from raw materials

- C11B9/022—Refining

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11B—PRODUCING, e.g. BY PRESSING RAW MATERIALS OR BY EXTRACTION FROM WASTE MATERIALS, REFINING OR PRESERVING FATS, FATTY SUBSTANCES, e.g. LANOLIN, FATTY OILS OR WAXES; ESSENTIAL OILS; PERFUMES

- C11B9/00—Essential oils; Perfumes

- C11B9/02—Recovery or refining of essential oils from raw materials

- C11B9/025—Recovery by solvent extraction

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K2800/00—Properties of cosmetic compositions or active ingredients thereof or formulation aids used therein and process related aspects

- A61K2800/40—Chemical, physico-chemical or functional or structural properties of particular ingredients

- A61K2800/59—Mixtures

- A61K2800/592—Mixtures of compounds complementing their respective functions

- A61K2800/5922—At least two compounds being classified in the same subclass of A61K8/18

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Health & Medical Sciences (AREA)

- Veterinary Medicine (AREA)

- Public Health (AREA)

- General Health & Medical Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Epidemiology (AREA)

- Birds (AREA)

- Mycology (AREA)

- Microbiology (AREA)

- Botany (AREA)

- Biotechnology (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Organic Chemistry (AREA)

- Wood Science & Technology (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Gerontology & Geriatric Medicine (AREA)

- Dermatology (AREA)

- Medicines Containing Plant Substances (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及化妆品加工技术领域,更具体地说,它涉及一种复方绿茶石斛抗氧化精油及加工工艺。The invention relates to the technical field of cosmetic processing, more specifically, it relates to a compound green tea dendrobium anti-oxidation essential oil and a processing technology.

背景技术Background technique

精油是从植物的叶子、花朵、种子、果实、根部、树皮、树脂、木心等部位以水蒸气蒸馏法、冷压榨法、脂吸法和溶剂萃取法提炼出来的,具有高浓度芳香和挥发性的物质。Essential oils are extracted from leaves, flowers, seeds, fruits, roots, bark, resin, wood core and other parts of plants by steam distillation, cold pressing, fat absorption and solvent extraction. volatile substances.

除了植物某一部分可萃取出精油之外,有些植物可在好几个部位萃取出精油,例如,苦橙就可以从花苞、叶子及果实3个部位萃取出精油。现有技术中,对精油的生产设备在使用过程中仍存在一定问题,例如:1、生产精油时无法进行连续化的生产;2、在生产精油时,浸提原料的利用率较低,造成了资源的浪费;同时,现有的护肤精油在使用时,在控油,保湿,抗氧化,嫩肤,紧致,醒肤等方面没有突出的效果,对此我们发明了一种复方绿茶石斛抗氧化精油及加工工艺,以解决此类问题。In addition to extracting essential oils from a certain part of the plant, some plants can extract essential oils from several parts. For example, bitter orange can extract essential oils from three parts: buds, leaves and fruits. In the prior art, there are still certain problems in the use of essential oil production equipment, such as: 1. Continuous production cannot be carried out when producing essential oil; 2. When producing essential oil, the utilization rate of extraction raw materials is low, resulting in At the same time, when the existing skin care essential oils are used, they have no outstanding effects on oil control, moisturizing, anti-oxidation, skin rejuvenation, firming, and refreshing. For this, we have invented a compound green tea Dendrobium anti-aging Oxidation of essential oils and processing technology to solve such problems.

发明内容Contents of the invention

本发明提供一种复方绿茶石斛抗氧化精油重量配方如下:角鲨烷60-70份、玉米胚芽油10-20份、小麦胚芽油15-25份、铁皮石斛提取物0.01-0.1份、茶提取物0.01-0.1份、中国灵芝提取物0.01-0.1份、三七提取物0.01-0.1份、紫苏提取物0.01-0.1份、白鲜根皮提取物0.01-0.1份、玉竹提取物0.01-0.1份、天门冬提取物0.01-0.1份。The invention provides a compound green tea Dendrobium antioxidative essential oil weight formula as follows: 60-70 parts of squalane, 10-20 parts of corn germ oil, 15-25 parts of wheat germ oil, 0.01-0.1 part of Dendrobium officinale extract, tea extract 0.01-0.1 part of Ganoderma lucidum extract, 0.01-0.1 part of Panax notoginseng extract, 0.01-0.1 part of perilla extract, 0.01-0.1 part of white fresh root bark extract, 0.01-0.1 part of Polygonatum odoratum extract , Asparagus extract 0.01-0.1 part.

本发明提供一种复方绿茶石斛抗氧化精油加工工艺流程如下:The invention provides a kind of compound green tea dendrobium antioxidative essential oil processing technological process as follows:

S1:将中草药的干品进行打碎以及混合等预处理;S1: pre-processing the dry product of Chinese herbal medicine by crushing and mixing;

S2:采用加工设备,对粉碎混合之后的草药混合物进行浸提;S2: using processing equipment to extract the crushed and mixed herbal medicine mixture;

将装有草药的纱网放入角鲨烷等混合溶液中,并将溶液加热至设定温度且保持恒温,然后开始浸提;Put the gauze net with herbs into a mixed solution such as squalane, heat the solution to the set temperature and keep it constant, and then start leaching;

S3:浸提之后,将药渣和半成品分离,且对药渣进行多次浸提,将多次浸提的半成品混合;S3: After the extraction, separate the medicinal residues from the semi-finished products, perform multiple extractions on the medicinal residues, and mix the semi-finished products extracted multiple times;

S4:将浸提得到的半成品进行灌装,得到成品。S4: filling the semi-finished product obtained by extraction to obtain a finished product.

本发明提供一种复方绿茶石斛抗氧化精油的加工设备,包括提取液罐、半成品罐、若干个浸提罐以及换药罐,提取液罐、半成品罐以及若干个浸提罐通过管道相连通,浸提罐的进液方式为下进上出,浸提罐的内壁设置有恒温加热板,每组浸提罐的顶端都开设有进料口,每组浸提罐的内部设置有搅拌机构和揉搓机构,搅拌机构用于在进行提取时对罐体内部的物料进行搅拌,揉搓机构用于在进行提取时对被提取进行揉搓,使得内部的有效物质更容易提取出来,浸提罐的上端设置有调度机构,调度机构用于连续生产时的原料调度。The invention provides a processing equipment for the compound green tea dendrobium antioxidative essential oil, which comprises an extraction liquid tank, a semi-finished product tank, several extraction tanks and dressing tanks, and the extraction liquid tank, the semi-finished product tank and several extraction tanks are connected through pipelines, The liquid inlet method of the extraction tank is from the bottom to the top. The inner wall of the extraction tank is equipped with a constant temperature heating plate, and the top of each group of extraction tanks is provided with a feeding port. Kneading mechanism, the stirring mechanism is used to stir the material inside the tank during extraction, and the kneading mechanism is used to knead the extracted material during extraction, making it easier to extract the effective substances inside. The upper end of the extraction tank is set There is a scheduling mechanism, which is used for raw material scheduling during continuous production.

进一步地:搅拌机构包含纱网,纱网的底端固定安装有过滤板,过滤板的边缘位置镶嵌有一号磁环,浸提罐的底部固定安装有套筒,套筒的侧壁开设有孔,套筒的顶端固定安装有二号磁环,套筒的内部设置有扇叶,扇叶固定安装在传动杆上端的侧壁且呈圆周阵列排布,传动杆的下端贯穿浸提罐底部,传动杆的底端与电机的输出端固定连接,纱网、套筒以及传动杆的轴线重合。Further: the stirring mechanism includes gauze, the bottom of the gauze is fixed with a filter plate, the edge of the filter plate is inlaid with a No. 1 magnetic ring, the bottom of the extraction tank is fixed with a sleeve, and the side wall of the sleeve is provided with holes , the top of the sleeve is fixedly installed with the No. 2 magnetic ring, the inside of the sleeve is provided with fan blades, the fan blades are fixedly installed on the side wall of the upper end of the transmission rod and arranged in a circular array, the lower end of the transmission rod runs through the bottom of the extraction tank, The bottom end of the transmission rod is fixedly connected with the output end of the motor, and the axes of the gauze, the sleeve and the transmission rod coincide.

进一步地:一号磁环和二号磁环的磁性相吸,一号磁环和二号磁环之间存在一定间隙。Further: the magnetism of the No. 1 magnetic ring and the No. 2 magnetic ring attracts each other, and there is a certain gap between the No. 1 magnetic ring and the No. 2 magnetic ring.

进一步地:揉搓机构共设两组,且分别位于纱网的两侧,揉搓机构包含压辊,压辊设置有若干个,压辊呈竖直阵列排布,每组压辊内部固定插装有辊轴,每组辊轴的两端皆活动安装在两支架上,两支架之间通过连接杆固定连接,连接杆的外表面套接,连接杆的外表面活动套接有调节杆,扭簧分别与支架和调节杆的侧面固定连接,调节杆上铰接有电动伸缩杆,电动伸缩杆的另一端与浸提罐的内壁转动连接,调节杆的另一端同样与浸提罐的侧壁通过横杆转动连接,每组辊轴的一端皆设有调节组件,调节组件用于调节压辊的横向移动。Further: There are two sets of kneading mechanisms, which are respectively located on both sides of the gauze. The kneading mechanism includes pressing rollers, and there are several pressing rollers arranged in a vertical array. Each set of pressing rollers is fixedly inserted inside Roller shafts, both ends of each group of roller shafts are movably installed on two brackets, and the two brackets are fixedly connected by connecting rods. They are respectively fixedly connected to the side of the bracket and the adjusting rod. The adjusting rod is hinged with an electric telescopic rod. The other end of the electric telescopic rod is connected to the inner wall of the extraction tank in rotation. The rods are rotatably connected, and one end of each set of roller shafts is provided with an adjustment assembly, which is used to adjust the lateral movement of the pressing rollers.

进一步地:调节组件包含竖板和圆盘,竖板固定安装在浸提罐的内壁,竖板的表面开设有凹槽,圆盘固定安装在辊轴的截面,圆盘远离辊轴的一侧固定安装有呈圆周阵列排布的支撑杆,支撑杆的轴线与辊轴的轴线平行,每组支撑杆远离圆盘的一端皆固定安装有球,球与凹槽相对应,圆盘与支架之间设置有弹簧。Further: the adjustment assembly includes a vertical plate and a disc, the vertical plate is fixedly installed on the inner wall of the extraction tank, the surface of the vertical plate is provided with grooves, and the disc is fixedly installed on the section of the roller shaft, and the side of the disc away from the roller shaft The support rods arranged in a circular array are fixedly installed. The axis of the support rods is parallel to the axis of the roller shaft. Balls are fixedly installed on the end of each group of support rods away from the disc. The balls correspond to the grooves. The distance between the disc and the support There are springs between them.

进一步地:调节组件共设两组,两组调节组件分别设置在两组揉捻机构中辊轴的不同两端。Further: there are two sets of adjustment assemblies, and the two sets of adjustment assemblies are respectively arranged at different ends of the roller shafts in the two sets of kneading mechanisms.

调度机构包含支撑柱,支撑柱的顶端侧壁固定安装有安装架,安装架的边缘活动套接有若干滑块,每组滑块的侧壁固定安装有电动卷轴,电动卷轴的内部设有拉绳,拉绳的底端固定连接有顶盖,顶盖的底端固定卡接有纱网。The dispatching mechanism includes a support column, the top side wall of the support column is fixedly installed with a mounting frame, and a number of sliders are movably socketed on the edge of the mounting frame, and the side wall of each group of sliders is fixedly mounted with an electric reel, and the inside of the electric reel is equipped with a pulley. Rope, the bottom end of the pull rope is fixedly connected with the top cover, and the bottom end of the top cover is fixedly clamped with gauze.

本发明的有益效果在于:本发明提出的精油用于化妆品控油,保湿,抗氧化,嫩肤,紧致,该精油在对皮肤的控油,保湿,抗氧化,嫩肤,紧致,醒肤等多方面有着较好的使用效果;The beneficial effects of the present invention are: the essential oil proposed by the present invention is used in cosmetics for oil control, moisturizing, anti-oxidation, skin rejuvenation, and firming. It has a good effect in many aspects;

本发明中提出的加工设备通过设置有多个浸提罐,可以分布组件进行多次浸提操作,可进行精油的连续化生产,且设置对草药进行多次浸提操作,提高了草药的利用率,减少资源浪费,通过在浸提罐内部设置搅拌机构以及揉搓机构,大大提高了草药在提取时的速率以及效果,相比现有技术有更高的实用性。The processing equipment proposed in the present invention is equipped with multiple extraction tanks, which can distribute components for multiple extraction operations, and can carry out continuous production of essential oils, and is set to perform multiple extraction operations on herbal medicines, which improves the utilization of herbal medicines The efficiency and the waste of resources are reduced. By setting the stirring mechanism and the kneading mechanism inside the extraction tank, the speed and effect of herbal medicine extraction are greatly improved, and it has higher practicability than the existing technology.

附图说明Description of drawings

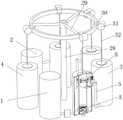

图1是本发明提出的一种复方绿茶石斛抗氧化精油的加工设备结构示意图;Fig. 1 is the processing equipment structural representation of a kind of compound prescription green tea dendrobium antioxidative essential oil that the present invention proposes;

图2是本发明图1中A处结构示意图;Fig. 2 is a schematic diagram of the structure at A in Fig. 1 of the present invention;

图3是本发明图1中B处结构示意图。Fig. 3 is a schematic diagram of the structure at B in Fig. 1 of the present invention.

图中:1、提取液罐;2、半成品罐;3、浸提罐;4、换药罐;5、管道;6、纱网;7、过滤板;8、一号磁环;9、套筒;10、二号磁环;11、扇叶;12、传动杆;13、电机;14、压辊;15、辊轴;16、支架;17、连接杆;18、扭簧;19、调节杆;20、电动伸缩杆;21、横杆;22、竖板;23、圆盘;24、凹槽;25、支撑杆;26、球;27、弹簧;28、支撑柱;29、安装架;30、滑块;31、电动卷轴;32、拉绳;33、顶盖。In the figure: 1. Extraction tank; 2. Semi-finished product tank; 3. Extraction tank; 4. Dressing tank; 5. Pipeline; 6. Gauze; 7. Filter plate; 8. No.1 magnetic ring; 9. Set cylinder; 10, magnetic ring No. 2; 11, fan blade; 12, transmission rod; 13, motor; 14, pressure roller; 15, roller shaft; 16, bracket; 17, connecting rod; 18, torsion spring; 19, adjustment Rod; 20, electric telescopic rod; 21, cross bar; 22, vertical plate; 23, disc; 24, groove; 25, support rod; 26, ball; 27, spring; 28, support column; 29, mounting frame ; 30, slider; 31, electric reel; 32, drawstring; 33, top cover.

具体实施方式detailed description

现在将参考示例实施方式讨论本文描述的主题。应该理解,讨论这些实施方式只是为了使得本领域技术人员能够更好地理解从而实现本文描述的主题,并非是对权利要求书中所阐述的保护范围、适用性或者示例的限制。可以在不脱离本说明书内容的保护范围的情况下,对所讨论的元素的功能和排列进行改变。各个示例可以根据需要,省略、替代或者添加各种过程或组件。另外,相对一些示例所描述的特征在其他例子中也可以进行组合。The subject matter described herein will now be discussed with reference to example implementations. It should be understood that the discussion of these implementations is only to enable those skilled in the art to better understand and realize the subject matter described herein, and is not intended to limit the protection scope, applicability or examples set forth in the claims. Changes may be made in the function and arrangement of elements discussed without departing from the scope of the disclosure. Various examples may omit, substitute, or add various procedures or components as needed. Additionally, features described with respect to some examples may also be combined in other examples.

实施例1Example 1

本实施例提出的一种复方绿茶石斛抗氧化精油的配方如下:The formula of a kind of compound green tea dendrobium antioxidative essential oil proposed by the present embodiment is as follows:

角鲨烷60份、玉米胚芽油10份、小麦胚芽油15份、铁皮石斛提取物0.01份、茶提取物0.01份、中国灵芝提取物0.01份、三七提取物0.01份、紫苏提取物0.01份、白鲜根皮提取物0.01份、玉竹提取物0.01份、天门冬提取物0.01份。60 parts of squalane, 10 parts of corn germ oil, 15 parts of wheat germ oil, 0.01 part of Dendrobium candidum extract, 0.01 part of tea extract, 0.01 part of Chinese Ganoderma lucidum extract, 0.01 part of Panax notoginseng extract, 0.01 part of perilla extract 0.01 part of white fresh root bark extract, 0.01 part of Polygonatum odoratum extract, and 0.01 part of asparagus extract.

实施例2Example 2

本实施例提出的一种复方绿茶石斛抗氧化精油的配方如下:The formula of a kind of compound green tea dendrobium antioxidative essential oil proposed by the present embodiment is as follows:

角鲨烷65份、玉米胚芽油15份、小麦胚芽油20份、铁皮石斛提取物0.05份、茶提取物0.05份、中国灵芝提取物0.05份、三七提取物0.05份、紫苏提取物0.05份、白鲜根皮提取物0.05份、玉竹提取物0.05份、天门冬提取物0.05份。65 parts of squalane, 15 parts of corn germ oil, 20 parts of wheat germ oil, 0.05 parts of Dendrobium candidum extract, 0.05 parts of tea extract, 0.05 parts of Chinese Ganoderma lucidum extract, 0.05 parts of Panax notoginseng extract, 0.05 parts of perilla extract parts, 0.05 parts of white fresh root bark extract, 0.05 parts of Polygonatum odoratum extract, and 0.05 parts of Asparagus extract.

实施例3Example 3

本实施例提出的一种复方绿茶石斛抗氧化精油的配方如下:The formula of a kind of compound green tea dendrobium antioxidative essential oil proposed by the present embodiment is as follows:

角鲨烷70份、玉米胚芽油20份、小麦胚芽油25份、铁皮石斛提取物0.1份、茶提取物0.1份、中国灵芝提取物0.1份、三七提取物0.1份、紫苏提取物0.1份、白鲜根皮提取物0.1份、玉竹提取物0.1份、天门冬提取物0.1份。70 parts of squalane, 20 parts of corn germ oil, 25 parts of wheat germ oil, 0.1 part of Dendrobium officinale extract, 0.1 part of tea extract, 0.1 part of Chinese Ganoderma lucidum extract, 0.1 part of Panax notoginseng extract, 0.1 part of perilla extract 0.1 part of white fresh root bark extract, 0.1 part of Polygonatum odoratum extract, 0.1 part of asparagus extract.

实施例4Example 4

本实施例提出的一种复方绿茶石斛抗氧化精油加工工艺,流程如下:A kind of compound green tea dendrobium antioxidative essential oil processing technology that present embodiment proposes, flow process is as follows:

S1:将中草药的干品进行打碎以及混合等预处理;S1: pre-processing the dry product of Chinese herbal medicine by crushing and mixing;

S2:采用加工设备,对粉碎混合之后的草药混合物进行浸提;S2: using processing equipment to extract the crushed and mixed herbal medicine mixture;

将装有草药的纱网放入角鲨烷等混合溶液中,并将溶液加热至设定温度且保持恒温,然后开始浸提;Put the gauze net with herbs into a mixed solution such as squalane, heat the solution to the set temperature and keep it constant, and then start leaching;

S3:浸提之后,将药渣和半成品分离,且对药渣进行多次浸提,将多次浸提的半成品混合;S3: After the extraction, separate the medicinal residues from the semi-finished products, perform multiple extractions on the medicinal residues, and mix the semi-finished products extracted multiple times;

S4:将浸提得到的半成品进行灌装,得到成品。S4: filling the semi-finished product obtained by extraction to obtain a finished product.

实施例5Example 5

如图1-图3示,在本实施例中提出了一种复方绿茶石斛抗氧化精油加工设备,包括提取液罐1、半成品罐2、若干个浸提罐3以及换药罐4,提取液罐1、半成品罐2以及若干个浸提罐3通过管道5相连通,浸提罐3的进液方式为下进上出,浸提罐3的内壁设置有恒温加热板,每组浸提罐3的顶端都开设有进料口,每组浸提罐3的内部设置有搅拌机构和揉搓机构,搅拌机构用于在进行提取时对罐体内部的物料进行搅拌,揉搓机构用于在进行提取时对被提取进行揉搓,使得内部的有效物质更容易提取出来,浸提罐3的上端设置有调度机构,调度机构用于连续生产时的原料调度。As shown in Figures 1 to 3, a compound green tea dendrobium antioxidant essential oil processing equipment is proposed in this embodiment, including an

搅拌机构包含纱网6,纱网6的底端固定安装有过滤板7,过滤板7的边缘位置镶嵌有一号磁环8,浸提罐3的底部固定安装有套筒9,套筒9的侧壁开设有孔,套筒9的顶端固定安装有二号磁环10,套筒9的内部设置有扇叶11,扇叶11固定安装在传动杆12上端的侧壁且呈圆周阵列排布,传动杆12的下端贯穿浸提罐3底部,传动杆12的底端与电机13的输出端固定连接,纱网6、套筒9以及传动杆12的轴线重合。The stirring mechanism includes a

一号磁环8和二号磁环10的磁性相吸,一号磁环8和二号磁环10之间存在一定间隙。The magnetism of the No. 1

揉搓机构共设两组,且分别位于纱网6的两侧,揉搓机构包含压辊14,压辊14设置有若干个,压辊14呈竖直阵列排布,每组压辊14内部固定插装有辊轴15,每组辊轴15的两端皆活动安装在两支架16上,两支架16之间通过连接杆17固定连接,连接杆17的外表面套接,连接杆17的外表面活动套接有调节杆19,扭簧18分别与支架16和调节杆19的侧面固定连接,调节杆19上铰接有电动伸缩杆20,电动伸缩杆20的另一端与浸提罐3的内壁转动连接,调节杆19的另一端同样与浸提罐3的侧壁通过横杆21转动连接,每组辊轴15的一端皆设有调节组件,调节组件用于调节压辊14的横向移动。There are two groups of kneading mechanisms, which are respectively located on both sides of the

调节组件包含竖板22和圆盘23,竖板22固定安装在浸提罐3的内壁,竖板22的表面开设有凹槽24,圆盘23固定安装在辊轴15的截面,圆盘23远离辊轴15的一侧固定安装有呈圆周阵列排布的支撑杆25,支撑杆25的轴线与辊轴15的轴线平行,每组支撑杆25远离圆盘23的一端皆固定安装有球26,球26与凹槽24相对应,圆盘23与支架16之间设置有弹簧27。The adjustment assembly includes a

调节组件共设两组,两组调节组件分别设置在两组揉捻机构中辊轴15的不同两端。There are two groups of adjustment assemblies, and the two groups of adjustment assemblies are respectively arranged at different ends of the

调度机构包含支撑柱28,支撑柱28的顶端侧壁固定安装有安装架29,安装架29的边缘活动套接有若干滑块30,每组滑块30的侧壁固定安装有电动卷轴31,电动卷轴31的内部设有拉绳32,拉绳32的底端固定连接有顶盖33,顶盖33的底端固定卡接有纱网6。The scheduling mechanism includes a

本实施例提出的一种复方绿茶石斛抗氧化精油的加工设备工作原理如下,首先原料罐中的角鲨烷溶液通过泵传送至各浸提罐3中,并且将溶液预加热至设定温度,首先在上料工位中,将纱网6从顶盖33取下来,将粉碎之后的草药装入在停留在该工位的纱网6中,再将纱网6装配到顶盖33下方;The working principle of a compound green tea dendrobium anti-oxidant essential oil processing equipment proposed in this embodiment is as follows. First, the squalane solution in the raw material tank is sent to each

然后,启动电动卷轴31,将纱网6向下上提,然后,滑块30在安装架29上滑动将该纱网6转移到位于相邻的最后一个浸提罐3上方,电动卷轴31将纱网6下放,使纱网6进入对应的浸提罐3内部;Then, start the

当纱网6下降到一定程度时,顶盖33落在浸提罐3上,将浸提罐3上端盖住,此时纱网6的下方与浸提罐3底面的套筒9顶端存在一定间隔,由于过滤板7的底端和套筒9的顶端设有一号磁环8和二号磁环10,由于磁环产生的吸力,可以使纱网6在溶液中始终保持绷直的状态,与此同时,两揉搓机构相互靠近,将纱网6上端挤压贴靠在一起;When the

启动电机13,电机13带动传动杆12转动,传动杆12转动带动扇叶11转动,扇叶11转动会将溶液从套筒9外部由套筒9侧壁的孔洞吸进入套筒9内部,再通过扇叶11将溶液向纱网6底部输送,大部分溶液便会从过滤板7的孔洞中进入纱网6内部,此时进入的纱网6的流动溶液会带动其内部的草药颗粒在纱网6内部不断地翻腾,使草药颗粒分散开来,增大草药颗粒与提取液的接触面积,从而可以提高提取的速率以及提取效率;Start the

这里需要说明的是,浸提的具体过程为,首先溶液和草药颗粒接触,溶液将草药浸湿,然后慢慢浸入到草药内部,草药有效成分会首先浸入到位于草药颗粒内部以及草药颗粒外部附着的溶液内,然后通过溶液的流动,将富含有草药有效成分的溶液带动,以及通过内外溶液密度差,将草药内部溶液的有效成分析出,实现浸提的效果。What needs to be explained here is that the specific process of extraction is that first the solution is in contact with the herbal medicine particles, the solution soaks the herbal medicine, and then slowly soaks into the inside of the herbal medicine. In the solution, and then through the flow of the solution, the solution rich in the active ingredients of the herbal medicine is driven, and through the density difference between the inner and outer solutions, the effective ingredients of the inner solution of the herbal medicine are separated to achieve the effect of leaching.

扇叶11向纱网6内部输送溶液的同时,由于纱网6底面与套筒9之间存在一定间隔,因此小部分的溶液会从间隙处流出,当溶液从间隙处流出时,由于溶液流动的方向以及流量不均匀,且由于纱网6的底面处于悬浮状态,因此纱网6下端会受到溶液流动的影响发生不规则摆动;When the

与此同时,两揉搓机构能够沿着压辊14长度方向同步往复移动,同时两揉搓机构能够沿着垂直于压辊14长度的水平方向往复移动,实现带动纱网6上端能够朝着不同方向进行摆动;At the same time, the two kneading mechanisms can move back and forth synchronously along the length direction of the

纱网6上下端的摆动复合在一起,能够增大纱网6的摆动频率和幅度;The swinging of the upper and lower ends of the

纱网6的摆动会增加纱网6内部草药颗粒的运动,提升草药颗粒与溶解的接触效率,进一步提升了浸提效率,同时纱网6的摆动还能够对纱网6外部和内部的溶液进行搅动,增加纱网6内部和外部的溶液交换以及进一步促进与溶液与草药颗粒接触的效率,极大地提高浸提的效率;The swing of the

浸提一段之间之后,将纱网6上提,纱网6在上升过程中,带动两侧的压辊14转动,压辊14转动时,可将纱网6内部的溶液进行挤压,将溶液排出纱网6内部,同时压辊14转动的同时会带动辊轴15转动,辊轴15转动便会带动一端的圆盘23转动,圆盘23转动带动支撑杆25以及支撑杆25上的球26围绕圆盘23的轴线转动,同时,球26会在竖版上的凹槽24内滑动,当球26滑出凹槽24时,会带动压辊14向左移动,当球26滑进凹槽24时,在弹簧27的作用下向右回复,再加上两侧的压辊14移动的方向相反,在纱网6上升过程中,两侧的压辊14还会对纱网6内部的草药进行揉搓,两揉搓机构能够沿着垂直于压辊14长度的水平方向往复的运动暂歇,两揉搓机构沿着压辊14长度方向相对移动,纱网6上提的过程中,相对应的压辊14挤压草药颗粒,将草药颗粒内的密度较高的溶液压出,这样,避免了溶液浸入到草药颗粒内部,浸出有效成分之后难以流出的问题,同时,草药颗粒被相对移动的压辊14压碾,实现将浸入到草药颗粒内部的溶液较大程度地挤压出去,纱网6上升到高位之后,揉搓机构将纱网6内草药颗粒内的溶液挤出;After leaching for a period, the

然后,纱网6下降,再次落入到溶液中来,一号磁环8和二号磁环10相吸,将纱网6绷直,扇叶11转动,再次将溶液不断地从向纱网6底部输送,溶液进入纱网6内部之后,将挤压成块或团的草药冲散开来,并且再次与草药颗粒接触,外部溶液浸入草药颗粒内,浸提过程与上述过程相同,同时摆动的纱网6还能够将挤压成块或团的草药抖散开来,提升草药与溶液接触的面积,提升再次浸提的效率;Then, the

重复上述步骤多次之后,纱网6再次上提,揉搓机构将纱网6内部草药中的溶液压出,然后两揉搓机构相互远离,纱网6上提,脱离浸提罐3,然后,纱网6移动到倒数第二个浸提罐3的上方,并下落进入该浸提罐3,与此同时,从上料工位转入到最后一个浸提罐3上方的纱网6,也落入到最后一个浸提罐3内,具体浸提过程如上所述,如此,每个纱网6内草药都能够从最后一个浸提罐3到第一个浸提罐3逐个浸提,当第一个纱网6脱离第一浸提罐3之后,移动到下料工位,将纱网6内的药渣倒出;After repeating the above steps several times, the

需要注意的是,当第一个纱网6脱离第一浸提罐3之后,溶液泵再次启动,向第一浸提罐3不断缓慢注入溶液,溶液在各浸提罐3内的缓慢流动,重复上述步骤,即可连续化的浸提加工处理,草药能够得到多次浸提处理,而且浸提溶液的浓度逐渐降低,实现草药的重复利用,实现能够将草药一次性浸提完全的目的。It should be noted that after the

上面结合附图对本实施例的实施例进行了描述,但是本实施例并不局限于上述的具体实施方式,上述的具体实施方式仅仅是示意性的,而不是限制性的,本领域的普通技术人员在本实施例的启示下,在不脱离本实施例宗旨和权利要求所保护的范围情况下,还可做出很多形式,均属于本实施例的保护之内。The embodiment of this embodiment has been described above in conjunction with the accompanying drawings, but this embodiment is not limited to the above-mentioned specific implementation. The above-mentioned specific implementation is only illustrative, not restrictive. Under the inspiration of this embodiment, people can also make many forms without departing from the purpose of this embodiment and the scope of protection of the claims, all of which belong to the protection of this embodiment.

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211169041.4ACN115444787A (en) | 2022-09-26 | 2022-09-26 | A kind of compound green tea dendrobium antioxidative essential oil and its processing technology |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211169041.4ACN115444787A (en) | 2022-09-26 | 2022-09-26 | A kind of compound green tea dendrobium antioxidative essential oil and its processing technology |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115444787Atrue CN115444787A (en) | 2022-12-09 |

Family

ID=84307839

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211169041.4APendingCN115444787A (en) | 2022-09-26 | 2022-09-26 | A kind of compound green tea dendrobium antioxidative essential oil and its processing technology |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115444787A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116235951A (en)* | 2023-04-20 | 2023-06-09 | 王科超 | Weight-losing meal replacement nutrition powder and processing method thereof |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005044339A2 (en)* | 2003-11-05 | 2005-05-19 | Baxter International Inc. | High convection home hemodialysis/hemofiltration and sorbent system |

| CN207862307U (en)* | 2018-01-13 | 2018-09-14 | 广州碧莲生物科技有限公司 | A kind of cosmetics essential oil production extraction equipment |

| CN208018200U (en)* | 2018-01-16 | 2018-10-30 | 湖南金地生物科技有限公司 | Extractor for honeysuckle extraction |

| CN112316483A (en)* | 2020-10-26 | 2021-02-05 | 宁波鼎科新材料科技有限公司 | Preparation process of cosmetic plant extract |

| CN215691829U (en)* | 2021-09-17 | 2022-02-01 | 邵阳学院 | An efficient extraction device for active components of traditional Chinese medicine |

- 2022

- 2022-09-26CNCN202211169041.4Apatent/CN115444787A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005044339A2 (en)* | 2003-11-05 | 2005-05-19 | Baxter International Inc. | High convection home hemodialysis/hemofiltration and sorbent system |

| CN207862307U (en)* | 2018-01-13 | 2018-09-14 | 广州碧莲生物科技有限公司 | A kind of cosmetics essential oil production extraction equipment |

| CN208018200U (en)* | 2018-01-16 | 2018-10-30 | 湖南金地生物科技有限公司 | Extractor for honeysuckle extraction |

| CN112316483A (en)* | 2020-10-26 | 2021-02-05 | 宁波鼎科新材料科技有限公司 | Preparation process of cosmetic plant extract |

| CN215691829U (en)* | 2021-09-17 | 2022-02-01 | 邵阳学院 | An efficient extraction device for active components of traditional Chinese medicine |

Non-Patent Citations (1)

| Title |

|---|

| 安徽德正堂药业集团有限公司: "太和博士石斛复方精萃油", pages 1, Retrieved from the Internet <URL:https://hzpba.nmpa.gov.cn/gccx/chakan.html?prodId=1073253292475154432&gb=G>* |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116235951A (en)* | 2023-04-20 | 2023-06-09 | 王科超 | Weight-losing meal replacement nutrition powder and processing method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2023133652A1 (en) | Preparation method and device for moringa seed oil | |

| CN109569777B (en) | Automatic high-efficient bruisher is used in type chinese herbal medicine processing | |

| CN206535601U (en) | A kind of Hu shaddock ped reducing mechanism | |

| CN206905459U (en) | A kind of tea processing drying roller | |

| CN110052304B (en) | Triturating device is used in medicinal material processing | |

| CN115444787A (en) | A kind of compound green tea dendrobium antioxidative essential oil and its processing technology | |

| CN104055209B (en) | A kind of process equipment of Japanese Premna Herb jelly food | |

| CN108579865A (en) | A kind of agricultural machining cracking soybeans device | |

| CN114106974A (en) | Brewing process of gordon euryale seed vinegar | |

| CN211798927U (en) | Medicinal extraction element | |

| CN114891595B (en) | A preparation device for antioxidant functional roxburghii fermented liquid | |

| CN208263509U (en) | Oil press is used in a kind of processing of camellia oil | |

| CN216941930U (en) | Peeling walnut kernel continuous cold pressing unit | |

| CN206366318U (en) | A kind of Chinese herbal medicine water dissolving tank | |

| CN216115152U (en) | Drying equipment is used in microcapsule powder production | |

| CN108940548A (en) | A kind of Chinese medicine high-efficient grinding and face mask of traditional Chinese medicine process units | |

| CN108522915A (en) | The processing technology of snow pear juice | |

| CN211298311U (en) | On-spot processingequipment of honey shaddock tea integral type | |

| CN107233840A (en) | A kind of chitin processing agitating device | |

| CN208711882U (en) | A kind of pesticide producing grinding device | |

| CN208390117U (en) | A kind of bean powder production soybean multiple stage crushing milling device | |

| CN214148661U (en) | Drying device is used in herbal pieces-production | |

| CN206260764U (en) | A kind of kudzuvine root starch crushes drying integral machine | |

| CN207927189U (en) | A kind of cane planting covering device that earthing is efficient | |

| CN221752353U (en) | A Chinese herbal medicine extraction device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20221209 |