CN115440414A - High temperature resistant elastic cable for industrial equipment - Google Patents

High temperature resistant elastic cable for industrial equipmentDownload PDFInfo

- Publication number

- CN115440414A CN115440414ACN202211076968.3ACN202211076968ACN115440414ACN 115440414 ACN115440414 ACN 115440414ACN 202211076968 ACN202211076968 ACN 202211076968ACN 115440414 ACN115440414 ACN 115440414A

- Authority

- CN

- China

- Prior art keywords

- parts

- sheath

- sleeve

- outer side

- high temperature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B3/00—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties

- H01B3/18—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances

- H01B3/28—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances natural or synthetic rubbers

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B3/00—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties

- H01B3/18—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances

- H01B3/30—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances plastics; resins; waxes

- H01B3/42—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances plastics; resins; waxes polyesters; polyethers; polyacetals

- H01B3/421—Polyesters

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B3/00—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties

- H01B3/18—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances

- H01B3/30—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances plastics; resins; waxes

- H01B3/44—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances plastics; resins; waxes vinyl resins; acrylic resins

- H01B3/441—Insulators or insulating bodies characterised by the insulating materials; Selection of materials for their insulating or dielectric properties mainly consisting of organic substances plastics; resins; waxes vinyl resins; acrylic resins from alkenes

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/04—Flexible cables, conductors, or cords, e.g. trailing cables

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/17—Protection against damage caused by external factors, e.g. sheaths or armouring

- H01B7/18—Protection against damage caused by wear, mechanical force or pressure; Sheaths; Armouring

- H01B7/1875—Multi-layer sheaths

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/17—Protection against damage caused by external factors, e.g. sheaths or armouring

- H01B7/18—Protection against damage caused by wear, mechanical force or pressure; Sheaths; Armouring

- H01B7/22—Metal wires or tapes, e.g. made of steel

- H01B7/228—Metal braid

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/17—Protection against damage caused by external factors, e.g. sheaths or armouring

- H01B7/29—Protection against damage caused by extremes of temperature or by flame

- H01B7/292—Protection against damage caused by extremes of temperature or by flame using material resistant to heat

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01B—CABLES; CONDUCTORS; INSULATORS; SELECTION OF MATERIALS FOR THEIR CONDUCTIVE, INSULATING OR DIELECTRIC PROPERTIES

- H01B7/00—Insulated conductors or cables characterised by their form

- H01B7/17—Protection against damage caused by external factors, e.g. sheaths or armouring

- H01B7/29—Protection against damage caused by extremes of temperature or by flame

- H01B7/295—Protection against damage caused by extremes of temperature or by flame using material resistant to flame

Landscapes

- Physics & Mathematics (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Organic Insulating Materials (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及电缆领域,尤其涉及一种工业设备用抗高温弹性电缆。The invention relates to the field of cables, in particular to a high temperature resistant elastic cable for industrial equipment.

背景技术Background technique

工业设备用的电缆,一般随着设备使用的散热,电缆的工作温度较高,相应的,需要电缆能够耐受100℃左右的高温,以保证电缆的正常工作需求,目前普遍的措施是采用含卤塑料护套,来提高电缆的耐高温性能,但是,这样也会产生一些环保问题,含卤材料在燃烧时会释放大量的烟雾和卤化氢气体,造成火灾时的能见度低,给人员的安全疏散和消防带来很大的妨碍。另一方面,工业设备用的电缆,在实际操作中,需要跟随设备行程的运转,这样造成电缆往复弯折,随着使用时间的推移,会造成电缆护套的老化和断裂,进而造成漏电事故。For cables used in industrial equipment, the operating temperature of the cable is generally high with the heat dissipation of the equipment. Correspondingly, the cable needs to be able to withstand a high temperature of about 100°C to ensure the normal operation of the cable. At present, the common measure is to use Halogen plastic sheath is used to improve the high temperature resistance of the cable, but this will also cause some environmental problems. When the halogen-containing material is burned, it will release a large amount of smoke and hydrogen halide gas, resulting in low visibility in the event of a fire and endangering the safety of personnel. Evacuation and firefighting present great hindrances. On the other hand, in actual operation, the cables used for industrial equipment need to follow the operation of the equipment stroke, which will cause the cables to bend back and forth. With the passage of time, the cable sheath will age and break, which will cause leakage accidents .

现在为了避免卤素的使用,而又能提升电缆的耐温性能,通常会在聚合塑料中添加无机耐火材料,例如添加磷类阻燃剂、硼酸锌等无机阻燃剂,来达到阻燃的目的,但是这样会造成电缆的耐弯折性能极大降低,不利于电缆的弯折,在实际使用时会经常断裂。In order to avoid the use of halogens and improve the temperature resistance of cables, inorganic refractory materials are usually added to polymer plastics, such as phosphorus flame retardants, zinc borate and other inorganic flame retardants, to achieve the purpose of flame retardancy , but this will greatly reduce the bending resistance of the cable, which is not conducive to the bending of the cable, and will often break in actual use.

发明内容Contents of the invention

本发明的目的在于针对现有技术的不足而提供一种工业设备用抗高温弹性电缆,具备优异的阻燃性能,同时具备较好的弹性性能,能够适用工业设备上使用。The purpose of the present invention is to provide a high-temperature-resistant elastic cable for industrial equipment, which has excellent flame-retardant performance and good elastic performance, and can be used in industrial equipment.

为达到上述目的,本发明通过以下技术方案来实现。In order to achieve the above object, the present invention is achieved through the following technical solutions.

一种工业设备用抗高温弹性电缆,它包括导电电芯、内护套、屏蔽套、弹性套、过渡套、保护套,所述导电电芯的外侧设置有内护套,所述内护套的外侧设置有屏蔽套,所述屏蔽套的外侧设置有弹性套,所述弹性套的外侧设置有过渡套,所述过渡套的外侧设置有保护套;A high temperature resistant elastic cable for industrial equipment, which includes a conductive electric core, an inner sheath, a shielding sheath, an elastic sheath, a transition sheath, and a protective sheath. The outer side of the conductive electric core is provided with an inner sheath, and the inner sheath A shielding sleeve is provided on the outside of the shielding sleeve, an elastic sleeve is provided on the outside of the shielding sleeve, a transition sleeve is provided on the outside of the elastic sleeve, and a protective sleeve is provided on the outside of the transition sleeve;

所述过渡套为阻燃涂层套,所述过渡套包括内护套、外护套、隔热棉层、隔热涂层,所述内护套、外护套依次设置在弹性套的外侧,所述内护套、外护套之间设置有隔热棉层,所述隔热棉层与内护套、外护套之间填充有隔热涂层。The transition sleeve is a flame retardant coating sleeve, and the transition sleeve includes an inner sheath, an outer sheath, a heat insulation cotton layer, and a heat insulation coating, and the inner sheath and the outer sheath are sequentially arranged on the outside of the elastic sheath , A heat insulating cotton layer is arranged between the inner sheath and the outer sheath, and a heat insulating coating is filled between the heat insulating cotton layer and the inner sheath and the outer sheath.

进一步的,所述内护套为聚乙烯护套。Further, the inner sheath is a polyethylene sheath.

进一步的,所述屏蔽套为镀锡铜丝编制而成的网套。Further, the shielding sleeve is a mesh sleeve made of tinned copper wire.

进一步的,所述弹性套为热塑性聚氨酯橡胶制作。Further, the elastic sleeve is made of thermoplastic polyurethane rubber.

进一步的,所述隔热涂层包括重量份的硅酸盐溶液25-30份、环氧树脂20-25份、纳米空心陶瓷微珠15-18份、钛白粉6-12份、硅酸铝纤维3-5份、氧化镧1-2份、苝四甲酸亚胺1-2份、硬脂酸盐3-5份。Further, the heat-insulating coating includes 25-30 parts by weight of silicate solution, 20-25 parts of epoxy resin, 15-18 parts of nano-hollow ceramic beads, 6-12 parts of titanium dioxide, aluminum silicate 3-5 parts of fiber, 1-2 parts of lanthanum oxide, 1-2 parts of perylene tetracarboxyimide, 3-5 parts of stearate.

进一步的,所述隔热涂层的导热系数小于0.3W/m.K。Further, the thermal conductivity of the thermal insulation coating is less than 0.3W/m.K.

进一步的,所述保护套为改性硅胶制备的保护套,改性硅胶套包括重量份的纳米硅胶30-40份、聚丙烯树脂20-25份、聚氨酯18-26份、酚醛树脂6-10份、三异丙醇胺2-4份、丙烯醇3-5份、硅烷偶联剂5-6份、炭黑粉6-8份、纳米碳化硼3-7份、氧化镧2-3份、聚丙烯酸丁酯1-4份、三异丙醇胺3-6份、偏苯三酸三辛酯2-4份。Further, the protective sheath is a protective sheath made of modified silica gel, and the modified silica gel sheath includes 30-40 parts by weight of nano-silica gel, 20-25 parts of polypropylene resin, 18-26 parts of polyurethane, 6-10 parts of phenolic resin 2-4 parts of triisopropanolamine, 3-5 parts of propenyl alcohol, 5-6 parts of silane coupling agent, 6-8 parts of carbon black powder, 3-7 parts of nano boron carbide, 2-3 parts of lanthanum oxide , 1-4 parts of polybutyl acrylate, 3-6 parts of triisopropanolamine, 2-4 parts of trioctyl trimellitate.

本发明的有益效果:本发明通过对保护套进行稀土改性,并且添加炭黑粉等物质进行性能强化,相较于普通的卤素(聚氯乙烯)护套,耐热温度提升30-50℃,同时使保护套在具备隔热阻燃的性能基础上,还具备一定的弹性和耐磨性能,并且,内部采用复合材料制备的过渡套,在具备优异的隔热性能的同时,还能与保护套连为一体,增强电缆性能,保护电缆内部结构。Beneficial effects of the present invention: the present invention enhances the performance by modifying the protective sheath with rare earth and adding carbon black powder and other substances. Compared with the ordinary halogen (polyvinyl chloride) sheath, the heat-resistant temperature is increased by 30-50°C , and at the same time make the protective cover have a certain degree of elasticity and wear resistance on the basis of heat insulation and flame retardant properties, and the transition sleeve made of composite materials inside has excellent heat insulation performance and can also be used with The protective sleeve is connected as a whole to enhance the performance of the cable and protect the internal structure of the cable.

附图说明Description of drawings

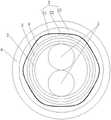

图1为本发明电缆的剖面的结构示意图;Fig. 1 is the structural representation of the section of cable of the present invention;

图中:1、导电电芯;2、内护套;3、屏蔽套;4、弹性套;5、过渡套;6、保护套;51、内护套;52、外护套;53、隔热棉层;54、隔热涂层。In the figure: 1. Conductive cell; 2. Inner sheath; 3. Shielding sheath; 4. Elastic sheath; 5. Transition sheath; 6. Protective sheath; 51. Inner sheath; 52. Outer sheath; 53. Spacer Thermal cotton layer; 54, thermal insulation coating.

具体实施方式detailed description

下面结合实施例对本发明做进一步说明,但不局限于说明书上的内容。The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

如图所示:一种工业设备用抗高温弹性电缆,它包括导电电芯1、内护套2、屏蔽套3、弹性套4、过渡套5、保护套6,导电电芯1的外侧设置有内护套2,内护套2的外侧设置有屏蔽套3,屏蔽套3的外侧设置有弹性套4,弹性套4的外侧设置有过渡套5,过渡套5的外侧设置有保护套6。As shown in the figure: a high temperature resistant elastic cable for industrial equipment, which includes a conductive cell 1, an

导电电芯1用于导电,一般为两根绞合。The conductive cell 1 is used for conducting electricity, generally two strands are twisted.

内护套2为聚乙烯护套,绝缘性好,耐候性能优异,能够很好的保护电缆的导电电芯1。The

屏蔽套3采用镀锡铜丝编制而成的网套,能够屏蔽外界的电磁干扰。The

弹性套4采用热塑性聚氨酯橡胶(TPU)制作,其组成分子基本上是线型的,没有或很少有化学交联,线型聚氨酯分子链之间存在着许多氢键构成的物理交联,氢键对其形态起到强化作用,从而赋予许多优良的性能,如高模量、高强度,优良的耐磨性、耐化学品、耐水解性、耐髙低温和耐霉菌性。同时使得电缆在弯折后,能够很好的回弹性恢复性能,延长电缆的使用寿命。The elastic sleeve 4 is made of thermoplastic polyurethane rubber (TPU), and its constituent molecules are basically linear, with no or little chemical cross-linking. There are many physical cross-links formed by hydrogen bonds between the linear polyurethane molecular chains. The bond strengthens its shape, thus endowing it with many excellent properties, such as high modulus, high strength, excellent abrasion resistance, chemical resistance, hydrolysis resistance, high and low temperature resistance and mold resistance. At the same time, after the cable is bent, it can have good resilience recovery performance and prolong the service life of the cable.

过渡套5为阻燃涂层套,具体的,为了能够保护电缆内部的结构,过渡套5包括内护套51、外护套52、隔热棉层53、隔热涂层54,内护套51、外护套52依次设置在弹性套4的外侧,内护套51、外护套52之间设置有隔热棉层53,隔热棉层53与内护套51、外护套52之间填充有隔热涂层54。内护套51、外护套52采用硅胶制作,韧性强,耐摩擦,同时兼具优异的绝缘性能,耐候性能,设置在隔热涂层54的两侧,一方面可以保护隔热涂层,另一方面,在隔热涂层损坏时,能够避免隔热涂层的材料破坏弹性套4。隔热棉层53可以起到隔热阻燃的作用,具体的,为了增强隔热棉的隔热阻燃性能,可在隔热棉的两侧涂覆隔热涂层,隔热涂层为有机、无机复合隔热涂层,包括重量份的硅酸盐溶液25-30份、环氧树脂20-25份、纳米空心陶瓷微珠15-18份、钛白粉6-12份、硅酸铝纤维3-5份、氧化镧1-2份、苝四甲酸亚胺1-2份、硬脂酸盐3-5份,这样无阻燃涂料,其导热系数小于0.3W/m.K,并且能够与隔热棉很好的结合,相较于无机隔热涂层,不会因为电缆的弯折而破裂,导致隔热阻燃失效。The transition sheath 5 is a flame retardant coating sheath. Specifically, in order to protect the internal structure of the cable, the transition sheath 5 includes an

保护套6为改性硅胶制备的保护套,具体的,改性硅胶套包括重量份的纳米硅胶30-40份、聚丙烯树脂20-25份、聚氨酯18-26份、酚醛树脂6-10份、三异丙醇胺2-4份、丙烯醇3-5份、硅烷偶联剂5-6份、炭黑粉6-8份、纳米碳化硼3-7份、氧化镧2-3份、聚丙烯酸丁酯1-4份、三异丙醇胺3-6份、偏苯三酸三辛酯2-4份,外护套6采用稀土改性,可以增强其耐热性能,耐热温度大于180℃,同时,适当添加聚丙烯树脂、聚氨酯,能够增强保护套的弹性韧性,便于弯折,同时配备适量的炭黑粉、纳米碳化硼,增强保护套的耐磨性能。并且在制备成型时候,通过硅烷偶联剂等助剂的作用,可以使保护套6与过渡套5的外护套52紧密结合,成为一体,有助于提升电缆护套整体的强度性能,避免折损断裂。The

具体的,隔热涂层包括重量份的硅酸盐溶30份、环氧树脂25份、纳米空心陶瓷微珠18份、钛白粉12份、硅酸铝纤维5份、氧化镧2份、苝四甲酸亚胺2份、硬脂酸盐5份;改性硅胶套包括重量份的纳米硅胶40份、聚丙烯树脂25份、聚氨酯26份、酚醛树脂10份、三异丙醇胺4份、丙烯醇5份、硅烷偶联剂6份、炭黑粉8份、纳米碳化硼7份、氧化镧3份、聚丙烯酸丁酯4份、三异丙醇胺6份、偏苯三酸三辛酯4份。Specifically, the thermal insulation coating includes 30 parts by weight of silicate solution, 25 parts of epoxy resin, 18 parts of nano hollow ceramic microspheres, 12 parts of titanium dioxide, 5 parts of aluminum silicate fiber, 2 parts of lanthanum oxide,

具体的,隔热涂层包括重量份的硅酸盐溶液25份、环氧树脂20份、纳米空心陶瓷微珠15份、钛白粉6份、硅酸铝纤维3份、氧化镧1份、苝四甲酸亚胺1份、硬脂酸盐3份;改性硅胶套包括重量份的纳米硅胶30份、聚丙烯树脂20份、聚氨酯18份、酚醛树脂6份、三异丙醇胺2份、丙烯醇3份、硅烷偶联剂5份、炭黑粉6份、纳米碳化硼3份、氧化镧2份、聚丙烯酸丁酯1份、三异丙醇胺3份、偏苯三酸三辛酯2份。Specifically, the thermal insulation coating includes 25 parts by weight of silicate solution, 20 parts of epoxy resin, 15 parts of hollow nano ceramic beads, 6 parts of titanium dioxide, 3 parts of aluminum silicate fiber, 1 part of lanthanum oxide, perylene 1 part of tetraformyl imide, 3 parts of stearate; the modified silica gel cover includes 30 parts by weight of nano silica gel, 20 parts of polypropylene resin, 18 parts of polyurethane, 6 parts of phenolic resin, 2 parts of triisopropanolamine, 3 parts of propenyl alcohol, 5 parts of silane coupling agent, 6 parts of carbon black powder, 3 parts of nano-boron carbide, 2 parts of lanthanum oxide, 1 part of polybutyl acrylate, 3 parts of triisopropanolamine, trioctyl trimellitate 2 parts of ester.

具体的,隔热涂层包括重量份的硅酸盐溶液28份、环氧树脂23份、纳米空心陶瓷微珠16份、钛白粉9份、硅酸铝纤维4份、氧化镧1.5份、苝四甲酸亚胺1.5份、硬脂酸盐4份;改性硅胶套包括重量份的纳米硅胶35份、聚丙烯树脂28份、聚氨酯22份、酚醛树脂8份、三异丙醇胺3份、丙烯醇4份、硅烷偶联剂5.5份、炭黑粉7份、纳米碳化硼5份、氧化镧2.5份、聚丙烯酸丁酯3份、三异丙醇胺5份、偏苯三酸三辛酯3份。Specifically, the thermal insulation coating includes 28 parts by weight of silicate solution, 23 parts of epoxy resin, 16 parts of nano hollow ceramic microspheres, 9 parts of titanium dioxide, 4 parts of aluminum silicate fiber, 1.5 parts of lanthanum oxide, perylene 1.5 parts of tetraformic acid imide, 4 parts of stearate; Modified silica gel cover includes 35 parts of nano-silica gel in parts by weight, 28 parts of polypropylene resin, 22 parts of polyurethane, 8 parts of phenolic resin, 3 parts of triisopropanolamine, 4 parts of propenyl alcohol, 5.5 parts of silane coupling agent, 7 parts of carbon black powder, 5 parts of nano-boron carbide, 2.5 parts of lanthanum oxide, 3 parts of polybutylacrylate, 5 parts of triisopropanolamine, trioctyl trimellitate 3 parts of ester.

本电缆在实际制备中,在导电电芯上依次套装内护套、屏蔽套、弹性套后,制备过渡套,然后以过渡套为基套,制备保护套,成型后套装在弹性套上。In the actual preparation of this cable, after the inner sheath, shielding sheath, and elastic sheath are sequentially fitted on the conductive cell, a transition sheath is prepared, and then the transition sheath is used as the base sheath to prepare a protective sheath, which is put on the elastic sheath after molding.

显然,本发明的上述实施方式仅仅是为清楚地说明本发明所作的举例,而并非是对本发明的实施方式的限定。对于所属领域的普通技术人员来说,在上述说明的基础上还可以做出其它不同形式的变化或变动。这里无法对所有的实施方式予以穷举。凡是属于本发明的技术方案所引伸出的显而易见的变化或变动仍处于本发明的保护范围之列。Apparently, the above-mentioned embodiments of the present invention are only examples for clearly illustrating the present invention, rather than limiting the embodiments of the present invention. For those of ordinary skill in the art, other changes or changes in different forms can be made on the basis of the above description. All the implementation manners cannot be exhaustively listed here. All obvious changes or variations derived from the technical solutions of the present invention are still within the protection scope of the present invention.

Claims (7)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211076968.3ACN115440414A (en) | 2022-09-05 | 2022-09-05 | High temperature resistant elastic cable for industrial equipment |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211076968.3ACN115440414A (en) | 2022-09-05 | 2022-09-05 | High temperature resistant elastic cable for industrial equipment |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115440414Atrue CN115440414A (en) | 2022-12-06 |

Family

ID=84247606

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211076968.3APendingCN115440414A (en) | 2022-09-05 | 2022-09-05 | High temperature resistant elastic cable for industrial equipment |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115440414A (en) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103104784A (en)* | 2013-02-11 | 2013-05-15 | 中国能源建设集团山西省电力勘测设计院 | Sliding support arranged on 150 DEG C heat supply overhead pipeline and used for preventing heat bridge from transferring heat |

| CN106280811A (en)* | 2016-08-31 | 2017-01-04 | 贵州卓霖节能环保科技发展有限公司 | Flame-retardant heat-insulation coating for outer wall and preparation method thereof |

| CN107286519A (en)* | 2017-08-01 | 2017-10-24 | 合肥市大卓电力有限责任公司 | A kind of fire-retardant, ageing-resistant wire cable material and preparation method thereof |

| CN211312895U (en)* | 2019-11-23 | 2020-08-21 | 佛山市广得利新材料有限公司 | Heat preservation and insulation cotton |

| CN112927850A (en)* | 2021-02-01 | 2021-06-08 | 浙江正泰电缆有限公司 | Fireproof flame-retardant cable and preparation method thereof |

| CN213519328U (en)* | 2020-12-12 | 2021-06-22 | 天津德塔线缆有限公司 | Novel photovoltaic cable |

- 2022

- 2022-09-05CNCN202211076968.3Apatent/CN115440414A/enactivePending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103104784A (en)* | 2013-02-11 | 2013-05-15 | 中国能源建设集团山西省电力勘测设计院 | Sliding support arranged on 150 DEG C heat supply overhead pipeline and used for preventing heat bridge from transferring heat |

| CN106280811A (en)* | 2016-08-31 | 2017-01-04 | 贵州卓霖节能环保科技发展有限公司 | Flame-retardant heat-insulation coating for outer wall and preparation method thereof |

| CN107286519A (en)* | 2017-08-01 | 2017-10-24 | 合肥市大卓电力有限责任公司 | A kind of fire-retardant, ageing-resistant wire cable material and preparation method thereof |

| CN211312895U (en)* | 2019-11-23 | 2020-08-21 | 佛山市广得利新材料有限公司 | Heat preservation and insulation cotton |

| CN213519328U (en)* | 2020-12-12 | 2021-06-22 | 天津德塔线缆有限公司 | Novel photovoltaic cable |

| CN112927850A (en)* | 2021-02-01 | 2021-06-08 | 浙江正泰电缆有限公司 | Fireproof flame-retardant cable and preparation method thereof |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN201804582U (en) | A high temperature resistant cable | |

| CN218918476U (en) | Environment-friendly flame-retardant heat-shrinkable tube with antibacterial effect | |

| CN214541663U (en) | High temperature resistant fireproof cable | |

| CN201149782Y (en) | High temperature resistant cables for nuclear power plants | |

| CN115440414A (en) | High temperature resistant elastic cable for industrial equipment | |

| CN220672253U (en) | High flame-retardant insulated wire and cable | |

| CN209912575U (en) | Environment-friendly high-temperature-resistant fireproof control cable | |

| CN219122981U (en) | An extrusion-resistant environment-friendly power cable | |

| CN208141890U (en) | A kind of flexible flame-retardant cable | |

| CN218241398U (en) | Single-core polyvinyl chloride insulated polyvinyl chloride sheathed cable | |

| CN216817943U (en) | A four-core coaxial high-speed data transmission cable for aerospace | |

| CN221529551U (en) | Improved battery connection cable for new energy vehicles | |

| CN208507231U (en) | A kind of mineral insulated cable | |

| CN208400588U (en) | Fireproof cable | |

| CN223193570U (en) | Fireproof isolation wire and cable | |

| CN217933241U (en) | Copper-clad steel grounding wire | |

| CN215643803U (en) | High-temperature-resistant anti-cracking power cable | |

| CN218939300U (en) | High-temperature-resistant bending-resistant cable | |

| CN220509724U (en) | Wire and cable with dampproofing function | |

| CN214505088U (en) | Multi-core stranded conductor fireproof cable | |

| CN219143823U (en) | Crosslinked polyolefin insulating high-service-life environment-friendly wire | |

| CN222167998U (en) | High flame-retardant insulated wire and cable | |

| CN219370650U (en) | Corrosion-resistant environment-friendly cable with copper core | |

| CN215007613U (en) | Waterproof distributed instrument cable for safety explosion-proof circuit | |

| CN221746905U (en) | A high temperature resistant and tensile resistant composite cable |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |