CN115430892A - Method for welding tank bottom edge plate of LNG low-temperature storage tank - Google Patents

Method for welding tank bottom edge plate of LNG low-temperature storage tankDownload PDFInfo

- Publication number

- CN115430892A CN115430892ACN202211217729.5ACN202211217729ACN115430892ACN 115430892 ACN115430892 ACN 115430892ACN 202211217729 ACN202211217729 ACN 202211217729ACN 115430892 ACN115430892 ACN 115430892A

- Authority

- CN

- China

- Prior art keywords

- welding

- edge plate

- edge

- plate

- storage tank

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000003466weldingMethods0.000titleclaimsabstractdescription188

- 238000000034methodMethods0.000titleclaimsabstractdescription38

- 238000003860storageMethods0.000titleclaimsabstractdescription21

- 239000000919ceramicSubstances0.000claimsabstractdescription9

- 230000009193crawlingEffects0.000claimsabstractdescription9

- XKRFYHLGVUSROY-UHFFFAOYSA-NArgonChemical compound[Ar]XKRFYHLGVUSROY-UHFFFAOYSA-N0.000claimsdescription34

- 229910052786argonInorganic materials0.000claimsdescription17

- 230000008569processEffects0.000claimsdescription17

- 239000007789gasSubstances0.000claimsdescription12

- 238000004519manufacturing processMethods0.000abstractdescription7

- 238000010276constructionMethods0.000abstractdescription4

- 238000009434installationMethods0.000abstractdescription2

- 238000005498polishingMethods0.000abstract1

- 238000001179sorption measurementMethods0.000abstract1

- 239000003949liquefied natural gasSubstances0.000description13

- 238000005516engineering processMethods0.000description8

- PXHVJJICTQNCMI-UHFFFAOYSA-NnickelSubstances[Ni]PXHVJJICTQNCMI-UHFFFAOYSA-N0.000description6

- 229910000831SteelInorganic materials0.000description5

- 239000011324beadSubstances0.000description5

- 229910052759nickelInorganic materials0.000description5

- 239000010959steelSubstances0.000description5

- 238000004140cleaningMethods0.000description4

- 229910052751metalInorganic materials0.000description4

- 239000002184metalSubstances0.000description4

- 238000010586diagramMethods0.000description3

- 230000004927fusionEffects0.000description3

- 238000000227grindingMethods0.000description3

- 239000000463materialSubstances0.000description3

- 230000007246mechanismEffects0.000description3

- 230000035515penetrationEffects0.000description3

- 238000012360testing methodMethods0.000description3

- 239000000428dustSubstances0.000description2

- 239000001307heliumSubstances0.000description2

- 229910052734heliumInorganic materials0.000description2

- SWQJXJOGLNCZEY-UHFFFAOYSA-Nhelium atomChemical compound[He]SWQJXJOGLNCZEY-UHFFFAOYSA-N0.000description2

- 230000003647oxidationEffects0.000description2

- 238000007254oxidation reactionMethods0.000description2

- 239000000779smokeSubstances0.000description2

- 239000007787solidSubstances0.000description2

- WFKWXMTUELFFGS-UHFFFAOYSA-NtungstenChemical compound[W]WFKWXMTUELFFGS-UHFFFAOYSA-N0.000description2

- 229910052721tungstenInorganic materials0.000description2

- 239000010937tungstenSubstances0.000description2

- 229910000975Carbon steelInorganic materials0.000description1

- 230000009286beneficial effectEffects0.000description1

- 230000015572biosynthetic processEffects0.000description1

- 239000010962carbon steelSubstances0.000description1

- 230000007547defectEffects0.000description1

- 238000013461designMethods0.000description1

- 238000011161developmentMethods0.000description1

- 230000000694effectsEffects0.000description1

- 230000007613environmental effectEffects0.000description1

- 238000002474experimental methodMethods0.000description1

- 239000000945fillerSubstances0.000description1

- 238000005429filling processMethods0.000description1

- 230000036541healthEffects0.000description1

- 239000000203mixtureSubstances0.000description1

- 238000000465mouldingMethods0.000description1

- 239000011148porous materialSubstances0.000description1

- 230000008092positive effectEffects0.000description1

- 238000002360preparation methodMethods0.000description1

- 239000011513prestressed concreteSubstances0.000description1

- 238000012545processingMethods0.000description1

- 238000012797qualificationMethods0.000description1

- 238000011160researchMethods0.000description1

- 238000012827research and developmentMethods0.000description1

- 239000002893slagSubstances0.000description1

- 230000007704transitionEffects0.000description1

- 238000012800visualizationMethods0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/235—Preliminary treatment

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/16—Arc welding or cutting making use of shielding gas

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K9/00—Arc welding or cutting

- B23K9/32—Accessories

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Mechanical Engineering (AREA)

- Butt Welding And Welding Of Specific Article (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及一种LNG低温储罐的焊接方法,特别是一种LNG低温储罐罐底边缘板焊接方法。The invention relates to a welding method for an LNG low-temperature storage tank, in particular to a welding method for a bottom edge plate of an LNG low-temperature storage tank.

背景技术Background technique

随着国内LNG(液化天然气)事业的迅速发展,LNG低温储罐建造迅速发展,国内已建造多个LNG储罐罐群,容积以16万m3、22万m3、27万m3为主。储罐的结构形式一般为自承式拱顶储罐,属于全包容储罐,通常由预应力混凝土外层罐、碳钢外层罐衬里和9%Ni钢内罐组成。LNG储罐内罐底部由边缘板、中幅板构成,罐底边缘板内半径为38000mm,外半径为40085mm,材质9%Ni钢,厚度一般为22mm、25mm和27mm等,整个罐底边缘板共计34道焊口。With the rapid development of the domestic LNG (liquefied natural gas) business, the construction of LNG cryogenic storage tanks has developed rapidly. Many LNG storage tank groups have been built in China, with volumes of 160,000 m3 , 220,000 m3 , and 270,000 m3 . . The structure of the storage tank is generally a self-supporting vault storage tank, which is an all-inclusive storage tank, usually composed of a prestressed concrete outer tank, a carbon steel outer tank lining and a 9% Ni steel inner tank. The bottom of the inner tank of the LNG storage tank is composed of edge plates and medium-width plates. The inner radius of the edge plate of the tank bottom is 38000mm, the outer radius is 40085mm, the material is 9% Ni steel, and the thickness is generally 22mm, 25mm and 27mm. A total of 34 welds.

目前边缘板常用的焊接方法为手工焊条电弧焊,采用此焊接方法焊接存在如下问题:一)手工焊接,焊接生产效率低;二)焊接接头形式为对接焊缝,要求全焊透,正面平焊,反面仰脸焊接,熔敷金属容易下淌,焊道成型不好,仰脸焊接时气体不容易从焊缝溢出,容易产生气孔,是现场焊接一大难题;三)焊接道间需要打磨清理,反面仰脸焊接也需清根处理,打磨工作量大,烟尘大,不利于焊工在罐内密闭空间作业。At present, the commonly used welding method for edge plates is manual arc welding. There are following problems in welding with this welding method: 1) manual welding, and the welding production efficiency is low; 2) the welding joint is in the form of butt weld, which requires full penetration and flat welding , the reverse face is welded with the face up, the deposited metal is easy to drip, the weld bead is not formed well, the gas is not easy to overflow from the weld seam when the face is upside down, and it is easy to produce pores, which is a big problem in on-site welding; 3) The welding pass needs to be polished and cleaned , The welding of the reverse side upside down also needs to be cleaned, the grinding workload is heavy, and the smoke and dust are large, which is not conducive to the welder's work in the confined space of the tank.

目前国内各大工程公司都在开发罐底边缘板机动焊技术,但都存在技术瓶颈,具体如下:第一种自动焊技术方向:采用埋弧焊,还是需要边缘板反面清根,反面再次进行填充焊,由于离地高度只400~500mm,不利于布置自动焊设备。第二种采用药芯焊丝电弧焊(FCAW),目前在-196℃使用工况下,规范不允许采用药芯焊材,故此种方法不被接受。第三种采用熔化极气体保护焊GMAW(实芯),由于9%Ni钢采用镍基焊材,故保护气体需氩气加氦气的混合气,氦气成本特别高昂。第四种热丝氩弧焊技术,此方向是目前LNG储罐机动焊技术研发的主攻方向,但也存在技术瓶颈,一是效率低;二是需正面及反面充氩防止氧化;三是打底技术的攻关,热丝氩弧焊理论可以实现单面焊双面成型,不需要背面清根,但自动热丝氩弧焊焊接边缘板无法实现单面焊双面成型,主要原因是自动焊技术对组对间隙、错边量等组对精度要求较高,22万立、27万立储罐边缘板及壁板焊缝长度为2500mm~3800mm,组对精度很难保证,如果组对间隙大,自动焊接过程特别容易焊穿,如果组对要求不留间隙,整条焊缝不能保证间隙为0,会出现断续未焊透。At present, major domestic engineering companies are developing the motorized welding technology for the edge plate of the tank bottom, but there are technical bottlenecks, as follows: The first automatic welding technology direction: using submerged arc welding, it is still necessary to clean the edge plate from the reverse side, and then proceed again on the reverse side For filling welding, since the height from the ground is only 400-500mm, it is not conducive to the arrangement of automatic welding equipment. The second method uses flux-cored arc welding (FCAW). Currently, under the working condition of -196°C, the code does not allow the use of flux-cored welding materials, so this method is not accepted. The third type uses GMAW (solid core) gas metal shielded welding. Since 9% Ni steel uses nickel-based welding consumables, the shielding gas needs a mixture of argon and helium, and the cost of helium is particularly high. The fourth hot wire argon arc welding technology, this direction is the main research and development direction of LNG storage tank motorized welding technology at present, but there are still technical bottlenecks, one is low efficiency; The research on the bottom technology, hot wire argon arc welding theory can realize single-sided welding and double-sided forming without back cleaning, but automatic hot wire argon arc welding welding edge plate cannot realize single-sided welding and double-sided forming, the main reason is that automatic welding The technology has high requirements on the alignment accuracy such as the alignment gap and the amount of misalignment. The length of the edge plate and wall plate weld of 220,000 liter and 270,000 liter storage tanks is 2500mm-3800mm, and the alignment accuracy is difficult to guarantee. If the alignment gap Large, the automatic welding process is particularly easy to weld through. If the assembly requires no gaps, the entire weld cannot guarantee a gap of 0, and intermittent incomplete penetration will occur.

发明内容Contents of the invention

本发明为解决公知技术中存在的技术问题而提供一种LNG低温储罐罐底边缘板焊接方法,该方法能够实现打底单面焊双面成型,可以避免清根打磨,绿色环保,焊接生产效率高,能够提高焊接质量,降低施工成本。In order to solve the technical problems existing in the known technology, the present invention provides a welding method for the bottom edge plate of LNG low-temperature storage tank. The method can realize single-sided welding and double-sided forming of the bottom, can avoid root cleaning and grinding, and is environmentally friendly and efficient in welding production. The efficiency is high, the welding quality can be improved, and the construction cost can be reduced.

本发明为解决公知技术中存在的技术问题所采取的技术方案是:一种LNG低温储罐罐底边缘板焊接方法,采用以下步骤:The technical solution adopted by the present invention to solve the technical problems existing in the known technology is: a method for welding the bottom edge plate of an LNG low-temperature storage tank, which adopts the following steps:

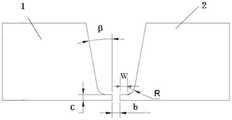

1)开坡口,在边缘板正面开设单面U型窄坡口,底部圆角R为1.5~2mm,钝边C为1~1.5mm,根部钝边宽度W为1.3~1.5mm,坡口角度β为8°;1) Beveling, open a single-sided U-shaped narrow groove on the front of the edge plate, the bottom fillet R is 1.5~2mm, the blunt edge C is 1~1.5mm, the root blunt edge width W is 1.3~1.5mm, the groove Angle β is 8°;

2)焊口及工装组装,采用以下步骤:2) Welding joints and tooling assembly, the following steps are adopted:

2.1)完成边缘板的组对,组对间隙b为1~2mm,在边缘板正面形成单面U型窄焊口,以实现焊口单道焊;2.1) Complete the pairing of the edge plates, the pairing gap b is 1~2mm, and form a single-sided U-shaped narrow weld on the front of the edge plate to realize single-pass welding of the weld;

2.2)将陶瓷衬垫粘贴在焊口下方;2.2) Paste the ceramic liner under the weld;

2.3)在焊口一端加装引弧板,另一端加装熄弧板;2.3) Install an arc striking plate at one end of the welding port, and an arc extinguishing plate at the other end;

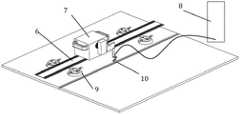

3)安装焊接装备,焊接装备包括轨道、焊接爬行小车、焊机和供气系统,其中轨道安装在焊口一侧,采用真空吸盘吸附在边缘板上,焊接爬行小车安装在轨道上,焊机的焊枪搭载在焊接爬行小车;3) Install welding equipment, welding equipment includes track, welding crawler trolley, welding machine and gas supply system, wherein the track is installed on the side of the welding port, and is adsorbed on the edge plate with a vacuum suction cup, the welding crawler trolley is installed on the track, and the welding machine The welding torch is mounted on the welding crawling trolley;

4)采用脉动热丝氩弧焊焊接工艺在边缘板正面依次完成打底、填充和盖面焊接。4) The pulsating hot wire argon arc welding process is used to complete the bottoming, filling and cover welding on the front side of the edge plate in sequence.

该方法采用焊丝的直径为1.0mm。This method uses a welding wire with a diameter of 1.0 mm.

所述步骤4),在实施打底和填充焊接时,焊枪做角摆动,摆动角设置为30~35°。In the step 4), when performing bottoming and filling welding, the welding torch swings at an angle, and the swing angle is set at 30-35°.

本发明具有的优点和积极效果是:The advantages and positive effects that the present invention has are:

一)焊接在边缘板正面进行,没有反面焊接作业,无需背面充氩,避免了仰脸焊接,避免了气孔缺陷的产生,同时因背面充氩降低了成本。1) Welding is carried out on the front side of the edge plate, there is no reverse welding operation, no need for argon filling on the back, avoiding upward welding, avoiding the occurrence of air hole defects, and reducing the cost due to argon filling on the back.

二)采用自动热丝氩弧焊打底焊时,陶瓷衬垫工装使焊接过程的熔敷金属及热影响与空气隔离,避免了焊口氧化,同时衬垫焊槽使自动热丝氩弧焊打底焊时,熔池金属能通过间隙流入焊槽,避免间隙过大烧穿或间隙过小未焊透产生,从而实现了单面焊双面成型,避免了反面清根,生产环境好,无烟尘、粉尘,绿色、环保,有利于作业人员的身体健康。2) When automatic hot wire argon arc welding is used for bottom welding, the ceramic backing tooling isolates the deposited metal and heat influence from the air during the welding process, avoiding the oxidation of the weld, and at the same time, the liner welding groove enables automatic hot wire argon arc welding During rooting welding, the metal in the molten pool can flow into the welding tank through the gap, avoiding excessive gap burn-through or too small gap without penetration, thus realizing single-sided welding and double-sided molding, avoiding root cleaning on the reverse side, and a good production environment. No smoke, dust, green and environmental protection, which is beneficial to the health of workers.

三)采用U形窄坡口,减少了焊接道数,由原来的每层多道焊变成单道焊,不但提高了焊接生产效率,并且提升了焊接质量,经过试验证实焊接热影响区比焊条电弧焊相比较窄,大大提高热影响区质量,经各类试验及工程应用前的焊接工艺评定测试,焊缝及热影响区的冲击韧性是焊条电弧焊的3倍。3) The U-shaped narrow groove is used to reduce the number of welding passes, and the original multi-pass welding for each layer is changed to single-pass welding, which not only improves the welding production efficiency, but also improves the welding quality. It has been proved by experiments that the heat-affected zone of welding is relatively Electrode arc welding is relatively narrow, which greatly improves the quality of the heat-affected zone. After various tests and welding process qualification tests before engineering application, the impact toughness of the weld and heat-affected zone is three times that of electrode arc welding.

四)U形窄坡口,根部钝边宽度1.3~1.5mm,底部圆角R为1.5~2mm,可以保证组对后的坡口底部宽度至少为6mm,在自动氩弧焊时,焊枪在底部进行角摆动,确保坡口底部两侧的熔合良好,避免由于坡口窄造成根部两侧未熔合,特别采用倒角R设计,保证底部圆弧过渡,避免底部尖端形成,造成焊接死角。4) U-shaped narrow groove, the width of the blunt edge at the root is 1.3-1.5mm, and the fillet R at the bottom is 1.5-2mm, which can ensure that the width of the bottom of the groove after assembly is at least 6mm. During automatic argon arc welding, the welding torch is at the bottom Carry out angular swing to ensure good fusion on both sides of the bottom of the groove, and avoid non-fusion on both sides of the root due to narrow grooves. The chamfer R design is especially used to ensure the arc transition at the bottom and avoid the formation of the bottom tip, resulting in welding dead ends.

五)通过增加引弧板及熄弧板,起弧在引弧板,收弧在熄弧板,保证边缘板焊道的焊接质量,无需手工焊补焊。5) By adding an arc starting plate and an arc extinguishing plate, the arc is started on the arc starting plate and the arc is closed on the arc extinguishing plate to ensure the welding quality of the edge plate weld bead without manual welding.

六)在实施打底和填充焊接时,使焊枪做角摆动,避免了窄坡口焊接,侧壁未熔合的产生。6) When performing backing and filling welding, the welding torch is swung at an angle to avoid narrow groove welding and unfused side walls.

七)脉动热丝氩弧焊无渣产生,减少了焊道打磨,绿色环保,省工省时,焊接生产效率高,能够提高焊接质量,降低施工成本。7) Pulsating hot wire argon arc welding produces no slag, reduces weld bead grinding, is environmentally friendly, saves labor and time, and has high welding production efficiency, which can improve welding quality and reduce construction costs.

附图说明Description of drawings

图1为本发明步骤1)的示意图;Fig. 1 is the schematic diagram of step 1) of the present invention;

图2为本发明步骤2.3)的示意图;Fig. 2 is the schematic diagram of step 2.3) of the present invention;

图3为本发明步骤3)的示意图。Fig. 3 is a schematic diagram of step 3) of the present invention.

图中:1、2、边缘板;3、焊口;4、引弧板;5、熄弧板;6、轨道;7、焊接爬行小车;8、供气系统;9、真空吸盘;10、焊枪。In the figure: 1, 2, edge plate; 3, welding port; 4, arc strike plate; 5, arc extinguishing plate; 6, track; 7, welding crawling trolley; 8, gas supply system; welding torch.

具体实施方式detailed description

为能进一步了解本发明的发明内容、特点及功效,兹例举以下实施例,并配合附图详细说明如下:In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

请参阅图1~图3,一种LNG低温储罐罐底边缘板焊接方法,采用以下步骤:Please refer to Figures 1 to 3, a method for welding the bottom edge plate of an LNG cryogenic storage tank, the following steps are used:

1)开坡口,在边缘板正面开设单面U型窄坡口,底部圆角R为1.5~2mm,钝边C为1~1.5mm,根部钝边宽度W为1.3~1.5mm,坡口角度β为8°;1) Beveling, open a single-sided U-shaped narrow groove on the front of the edge plate, the bottom fillet R is 1.5~2mm, the blunt edge C is 1~1.5mm, the root blunt edge width W is 1.3~1.5mm, the groove Angle β is 8°;

2)焊口及工装组装,采用以下步骤:2) Welding joints and tooling assembly, the following steps are adopted:

2.1)完成边缘板1和2的组对,组对间隙b为1~2mm,在边缘板正面形成单面U型窄焊口3,以实现单道焊,可以满足坡口底部宽度至少为6mm。2.1) Complete the pairing of

2.2)将陶瓷衬垫粘贴在焊口下方;2.2) Paste the ceramic gasket under the weld;

2.3)在焊口3的一端加装引弧板4,另一端加装熄弧板5;2.3) Install an arc

3)安装焊接装备,焊接装备包括轨道6、焊接爬行小车7、焊机和供气系统8,其中轨道6安装在焊口3的一侧,采用真空吸盘9吸附在边缘板1或2上,焊接爬行小车7安装在轨道6上,焊机的焊枪10搭载在焊接爬行小车6,焊接爬行小车7设有驱动系统,是自动行走小车。3) Install the welding equipment, which includes a track 6, a welding crawler 7, a welding machine and a

4)采用脉动热丝氩弧焊焊接工艺在边缘板1和2的正面依次完成打底、填充和盖面焊接。4) The pulsating hot wire argon arc welding process is used to complete the bottoming, filling and cover welding on the front sides of the

在本实施例中,该方法采用焊丝的直径为1.0mm,焊接效率高。所述步骤4),在实施打底和填充焊接时,焊枪做角摆动,摆动角设置为30~35°,可以避免窄坡口焊接时,侧壁未熔合的产生。In this embodiment, the method adopts a welding wire with a diameter of 1.0 mm, and the welding efficiency is high. In step 4), the welding torch swings at an angle during bottoming and filling welding, and the swing angle is set at 30° to 35°, which can avoid the occurrence of unfused side walls during narrow groove welding.

在本发明中,焊接装备以现有热丝氩弧焊设备为基础,增加焊枪角摆机构,采用带真空吸盘的导轨,增加可视化化系统,以满足9%Ni钢厚壁窄间隙焊接。In the present invention, the welding equipment is based on the existing hot wire argon arc welding equipment, adding a welding torch angular swing mechanism, using a guide rail with a vacuum suction cup, and adding a visualization system to meet the needs of 9% Ni steel thick-walled narrow gap welding.

为减少焊接道数,从而减少热输入,提升质量,采用单面窄坡口。为了减少背面氧化,实现单面焊双面成型,在坡口反面粘贴平面型陶瓷焊接衬垫;边缘板的两侧加装引弧板和熄弧板,避免自动焊焊接过程在焊道两端不能满焊而产生小尾巴;坡口正面采用脉动热丝氩弧焊进行打底焊、填充焊、盖面焊,打底及填充增加角摆动工艺,同时增加电弧可视化智能系统,可以更好地观察熔池。通过以上的工艺方法实现了大型储罐边缘板单面焊双面成型的高效自动焊工艺,并成功应用工程实际。In order to reduce the number of welding passes, thereby reducing heat input and improving quality, a narrow bevel on one side is used. In order to reduce oxidation on the back side and realize double-sided forming of single-side welding, a flat ceramic welding pad is pasted on the reverse side of the groove; arc-starting plates and arc-extinguishing plates are installed on both sides of the edge plate to avoid automatic welding process at both ends of the weld bead Small tails cannot be produced due to full welding; the front of the groove adopts pulsating hot wire argon arc welding for bottom welding, filling welding, and cover welding. Observe the molten pool. Through the above process method, the efficient automatic welding process of single-side welding and double-side forming of large storage tank edge plate has been realized, and it has been successfully applied in engineering practice.

本发明采用实芯焊丝,型号为ERNiCrMo-4,直径为1.0mm,陶瓷衬垫的规格为,外宽27mm,焊槽深度1.2.mm,焊槽宽12mm。The present invention adopts solid welding wire, model is ERNiCrMo-4, and diameter is 1.0mm, and the specification of ceramic liner is, outer width 27mm, welding groove depth 1.2.mm, welding groove width 12mm.

本发明的应用实例:Application example of the present invention:

现以16万立LNG储罐边缘板焊接为例,说明上述焊接方法的应用,16万立LNG储罐边缘板厚度为22mm,材质为9Ni%钢,对接焊缝,焊缝长度为2200mm。Now take the welding of the edge plate of the 160,000 liter LNG storage tank as an example to illustrate the application of the above welding method. The thickness of the edge plate of the 160,000 liter LNG storage tank is 22mm, the material is 9Ni% steel, and the length of the butt weld is 2200mm.

S1:坡口加工:将22mm厚度的边缘加工为单面U型窄坡口,其中R为2mm,钝边C为1.5mm,根部钝边宽度W为1.5mm,β为8°;引弧及熄弧工装制作:引弧板及熄弧板的规格为:宽为300mm,长150mm,厚度为22mm,坡口形式为单面U型窄焊口,与边缘板坡口尺寸相同。S1: Groove processing: Process the edge with a thickness of 22mm into a single-sided U-shaped narrow groove, where R is 2mm, blunt edge C is 1.5mm, root blunt edge width W is 1.5mm, and β is 8°; Production of arc extinguishing tooling: The specifications of the arc starting plate and the arc extinguishing plate are: width 300mm, length 150mm, thickness 22mm, the groove form is a single-sided U-shaped narrow weld, which is the same as the edge plate groove size.

S2:清理:坡口组对前,对边缘板及引弧板、熄弧板坡口两侧25mm范围内的氧化层、油污等进行打磨,做好组装前的准备。S2: Cleaning: Before the grooves are aligned, polish the oxide layer and oil stains within 25mm on both sides of the grooves of the edge plates, arc-starting plates, and arc-extinguishing plates to prepare for assembly.

S3:组装:边缘板组对,保证组对间隙为1~2mm。然后将陶瓷衬垫粘贴在边缘板的下方,且保证陶瓷衬垫的坡口中心与边缘板坡口中心保持一致。在边缘板组对完的焊道两端加装引弧板及熄弧板,并保证引弧板与熄弧板坡口中心与边缘板坡口中心一致。S3: Assembling: Assembling edge boards, ensuring that the gap between the pairings is 1-2mm. Then paste the ceramic liner under the edge plate, and ensure that the groove center of the ceramic liner is consistent with the edge plate groove center. Install the arc starting plate and the arc extinguishing plate at both ends of the weld bead after the edge plate group has been aligned, and ensure that the center of the groove of the arc starting plate and the arc extinguishing plate is consistent with the center of the edge plate groove.

S4:焊接装备系统安装:首先进行轨道安装,利用真空吸盘将轨道安装在焊口一侧,并保证轨道距离坡口的距离为300mm以内,启动真空泵,对吸盘抽真空,做好送丝系统、供气系统、焊接电源的线路连接。S4: Welding equipment system installation: first install the track, use the vacuum suction cup to install the track on the side of the weld, and ensure that the distance between the track and the groove is within 300mm, start the vacuum pump, vacuum the suction cup, and complete the wire feeding system. Line connections for gas supply system, welding power source.

S5:焊接前设备准备:焊接装备系统安装完毕,开始准备焊接,首先打开电源开关,热丝脉动送丝机构的开关,焊接小车行走开关,供气装置的开关,同时设置氩弧的流量,在热丝脉动送丝机构设置送丝速度,在控制器上根据之前焊接工艺试验过程的经验工艺参数对将进行的打底焊接、填充焊接、盖面焊接预设焊接电流、电压、摆动方式。S5: Equipment preparation before welding: After the welding equipment system is installed, start to prepare for welding. First, turn on the power switch, the switch of the hot wire pulsating wire feeding mechanism, the switch of the welding trolley, the switch of the gas supply device, and set the flow rate of the argon arc at the same time. The wire feeding speed is set by the hot wire pulsating wire feeding mechanism, and the welding current, voltage, and swing mode are preset on the controller for the bottom welding, filling welding, and cover welding to be performed according to the empirical process parameters of the previous welding process test process.

S6:打底焊接:调整焊枪前端焊丝与钨极的钨针尖距离为3~4mm,焊接操作工通过电弧智能显示屏观察焊接熔池,根据熔池熔合情况可通过编程器上的各参数调节键微调各工艺参数。常用的焊接工艺参数范围为:电流为180~220A,电压10~12V,送丝速度1.4~1.5(m/min),焊丝伸出长度为10~15mm,保护气体流量为20~25L/min,焊枪摆动方式为角摆动。S6: Bottom welding: adjust the distance between the welding wire at the front end of the welding torch and the tungsten tip of the tungsten electrode to 3-4mm, and the welding operator observes the welding pool through the arc intelligent display screen, and can adjust the parameters on the programmer according to the fusion of the pool Fine-tune the process parameters. The commonly used welding process parameters range as follows: current 180-220A, voltage 10-12V, wire feeding speed 1.4-1.5 (m/min), wire extension length 10-15mm, shielding gas flow rate 20-25L/min, The swing mode of the welding torch is angular swing.

S7:填充焊接工艺:S7: Filler welding process:

1)焊接工艺参数:焊接电流:200~230A;电压:10~13A;焊接速度8~13cm/min,焊丝伸出长度为10~15mm,保护气体流量为20~25L/min。1) Welding process parameters: welding current: 200-230A; voltage: 10-13A; welding speed 8-13cm/min, welding wire extension length 10-15mm, shielding gas flow rate 20-25L/min.

2)道间温度小于等于100℃。2) The interpass temperature is less than or equal to 100°C.

3)填充过程焊枪摆动方式选择角摆动。3) During the filling process, the swing mode of the welding torch is selected as angular swing.

S8:盖面焊接:S8: Cover welding:

焊枪摆动方式选选择平摆动;保护气体为氩气的流量为20~25L/min。其他参数与填充相同。The welding torch swing mode is flat swing; the shielding gas is argon and the flow rate is 20-25L/min. Other parameters are the same as padding.

尽管上面结合附图对本发明的优选实施例进行了描述,但是本发明并不局限于上述的具体实施方式,上述的具体实施方式仅仅是示意性的,并不是限制性的,本领域的普通技术人员在本发明的启示下,在不脱离本发明宗旨和权利要求所保护的范围的情况下,还可以做出很多形式,这些均属于本发明的保护范围之内。Although the preferred embodiments of the present invention have been described above in conjunction with the accompanying drawings, the present invention is not limited to the above-mentioned specific embodiments. The above-mentioned specific embodiments are only illustrative and not restrictive. Those of ordinary skill in the art Under the enlightenment of the present invention, people can also make many forms without departing from the purpose of the present invention and the scope of protection of the claims, and these all belong to the protection scope of the present invention.

Claims (3)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211217729.5ACN115430892A (en) | 2022-09-30 | 2022-09-30 | Method for welding tank bottom edge plate of LNG low-temperature storage tank |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211217729.5ACN115430892A (en) | 2022-09-30 | 2022-09-30 | Method for welding tank bottom edge plate of LNG low-temperature storage tank |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115430892Atrue CN115430892A (en) | 2022-12-06 |

Family

ID=84252091

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211217729.5APendingCN115430892A (en) | 2022-09-30 | 2022-09-30 | Method for welding tank bottom edge plate of LNG low-temperature storage tank |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115430892A (en) |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105537737A (en)* | 2015-12-31 | 2016-05-04 | 山东大学 | Narrow gap welding method for vertical weld position of liquified natural gas storage tank |

| CN106425018A (en)* | 2015-08-12 | 2017-02-22 | 中国石油天然气股份有限公司 | Welding method for 9% Ni steel butt welding bead of LNG low-temperature storage tank |

| CN109014507A (en)* | 2018-09-29 | 2018-12-18 | 南京奥特电气股份有限公司 | A kind of solid welding wire gas guarantor vertical-up welding method |

| CN110560843A (en)* | 2019-09-05 | 2019-12-13 | 广州黄船海洋工程有限公司 | One-step forming welding process for Q420 high-strength steel thick plate by electro-gas welding |

- 2022

- 2022-09-30CNCN202211217729.5Apatent/CN115430892A/enactivePending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106425018A (en)* | 2015-08-12 | 2017-02-22 | 中国石油天然气股份有限公司 | Welding method for 9% Ni steel butt welding bead of LNG low-temperature storage tank |

| CN105537737A (en)* | 2015-12-31 | 2016-05-04 | 山东大学 | Narrow gap welding method for vertical weld position of liquified natural gas storage tank |

| CN109014507A (en)* | 2018-09-29 | 2018-12-18 | 南京奥特电气股份有限公司 | A kind of solid welding wire gas guarantor vertical-up welding method |

| CN110560843A (en)* | 2019-09-05 | 2019-12-13 | 广州黄船海洋工程有限公司 | One-step forming welding process for Q420 high-strength steel thick plate by electro-gas welding |

Non-Patent Citations (1)

| Title |

|---|

| 张良锋等: "LNG储罐内罐底板9%Ni 钢的焊接缺陷分析与控制", 《焊接技术》, vol. 49, no. 05, 31 May 2020 (2020-05-31), pages 131* |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN105081520B (en) | The vertical docking FCAW single face welding and double face shaping processes of thin plate in full-automatic 9%Ni steel | |

| CN102009251B (en) | Full-position welding method for pipeline by full-automatic external welding machine | |

| WO2021057307A1 (en) | Welding method for single-sided welding and double-sided forming of mag inverted butt joint | |

| CN105081595A (en) | Fillet weld welding structure for K-type grooves of moderately-thick plate without back chipping and welding technology of fillet weld welding structure | |

| CN111331227B (en) | Flip-chip CO2 automatic welding process and device for storage tanks below 50000m3 | |

| CN102699493B (en) | Carbon dioxide (CO2) gas shielded welding vertical downwards welding method for waste heat boiler heat pipe and connecting plate | |

| CN1994648A (en) | Electrogas arc welding method for vertical line of large-scale floating roof tank reverse construction | |

| CN108856989B (en) | The bottoming method of molten electrode MIG welding in pipeline welding | |

| CN104117762A (en) | Rebar groove welding method | |

| CN203918200U (en) | A kind of copper liner | |

| CN109108437B (en) | Semi-automatic welding method for X90 pipeline steel pipe gas shielded flux-cored wire | |

| WO2021114686A1 (en) | Circular seam welding method for low-alloy steel low temperature pressure vessel tank body | |

| CN106271140A (en) | A kind of plasma MAG complex welding method | |

| CN108890092B (en) | Method of single-sided welding and double-sided forming of molten electrode MAG welding tube sheet | |

| CN104139229A (en) | Welding method for forming T-joints | |

| CN115846809A (en) | Efficient deep-arc welding process method for steel plate butt joint | |

| CN105382384B (en) | A kind of reinforcing bar melts ledge bar welding method | |

| CN115430892A (en) | Method for welding tank bottom edge plate of LNG low-temperature storage tank | |

| CN117600605A (en) | Spherical tank equatorial belt longitudinal weld welding method | |

| CN219787258U (en) | Preheating section feeding U-shaped groove body cracking welding device on electric furnace | |

| CN209614525U (en) | The robot single-side welding double-side forming straight angle and elevation angle weld groove | |

| CN101428373A (en) | Weld mouth structure of steel tube weld | |

| CN110695563A (en) | Welding method for tank wall plate of soil covering tank | |

| CN116571841A (en) | A method to improve the welding efficiency of 9% nickel steel vertical butt joint welding seam | |

| CN110977099A (en) | Steel structure truss column connection method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| WD01 | Invention patent application deemed withdrawn after publication | Application publication date:20221206 | |

| WD01 | Invention patent application deemed withdrawn after publication |