CN115424941A - A self-adaptive installation method for LGA chip heat sink - Google Patents

A self-adaptive installation method for LGA chip heat sinkDownload PDFInfo

- Publication number

- CN115424941A CN115424941ACN202210996503.3ACN202210996503ACN115424941ACN 115424941 ACN115424941 ACN 115424941ACN 202210996503 ACN202210996503 ACN 202210996503ACN 115424941 ACN115424941 ACN 115424941A

- Authority

- CN

- China

- Prior art keywords

- lga

- heat sink

- chip

- corners

- pressure value

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000009434installationMethods0.000titleclaimsabstractdescription69

- 238000000034methodMethods0.000titleclaimsabstractdescription38

- 230000007246mechanismEffects0.000claimsdescription46

- 230000005540biological transmissionEffects0.000claimsdescription23

- 238000004891communicationMethods0.000claimsdescription7

- 230000003044adaptive effectEffects0.000claimsdescription2

- 238000001816coolingMethods0.000claims3

- 238000003466weldingMethods0.000description12

- 230000008569processEffects0.000description6

- 240000004282Grewia occidentalisSpecies0.000description4

- 230000006870functionEffects0.000description4

- 238000010586diagramMethods0.000description3

- 238000011900installation processMethods0.000description2

- 238000003825pressingMethods0.000description2

- 230000008859changeEffects0.000description1

- 230000017525heat dissipationEffects0.000description1

- 230000006872improvementEffects0.000description1

- 238000011089mechanical engineeringMethods0.000description1

- 230000003287optical effectEffects0.000description1

- 238000004806packaging method and processMethods0.000description1

- 238000006467substitution reactionMethods0.000description1

- 230000009466transformationEffects0.000description1

- 238000000844transformationMethods0.000description1

Images

Classifications

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/50—Assembly of semiconductor devices using processes or apparatus not provided for in a single one of the groups H01L21/18 - H01L21/326 or H10D48/04 - H10D48/07 e.g. sealing of a cap to a base of a container

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L22/00—Testing or measuring during manufacture or treatment; Reliability measurements, i.e. testing of parts without further processing to modify the parts as such; Structural arrangements therefor

- H01L22/10—Measuring as part of the manufacturing process

- H01L22/12—Measuring as part of the manufacturing process for structural parameters, e.g. thickness, line width, refractive index, temperature, warp, bond strength, defects, optical inspection, electrical measurement of structural dimensions, metallurgic measurement of diffusions

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L22/00—Testing or measuring during manufacture or treatment; Reliability measurements, i.e. testing of parts without further processing to modify the parts as such; Structural arrangements therefor

- H01L22/20—Sequence of activities consisting of a plurality of measurements, corrections, marking or sorting steps

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/34—Arrangements for cooling, heating, ventilating or temperature compensation ; Temperature sensing arrangements

- H01L23/40—Mountings or securing means for detachable cooling or heating arrangements ; fixed by friction, plugs or springs

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L23/00—Details of semiconductor or other solid state devices

- H01L23/34—Arrangements for cooling, heating, ventilating or temperature compensation ; Temperature sensing arrangements

- H01L23/40—Mountings or securing means for detachable cooling or heating arrangements ; fixed by friction, plugs or springs

- H01L23/4006—Mountings or securing means for detachable cooling or heating arrangements ; fixed by friction, plugs or springs with bolts or screws

- H01L2023/4075—Mechanical elements

- H01L2023/4087—Mounting accessories, interposers, clamping or screwing parts

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Cooling Or The Like Of Semiconductors Or Solid State Devices (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明公开一种方法,涉及主板设计安装技术领域,具体地说是一种LGA类芯片散热片自适应安装方法。The invention discloses a method, relates to the technical field of motherboard design and installation, in particular to a self-adaptive installation method for heat sinks of LGA chips.

背景技术Background technique

LGA类芯片,封装方式具有特殊性,在安装方式上也与其他芯片不同,它不利用阵脚固定接触安装,而是利用安装架固定,使CPU可以正确压在LGA座的针脚上,并利用芯片散热片和CPU之间的压紧力,达到pin点电连接。但拧紧芯片散热片时,四个角的固定螺钉有一定的拧紧顺序,容易导致CPU无法受力均匀。同时,也因为在PCB板焊接过程中,焊接误差的存在,CPU安装面并不能保证绝对水平,因此拧紧芯片散热片时也使CPU受力不均,降低了CPU的可靠性。本发明的LGA类芯片散热片自适应安装方法可以实现LGA类芯片散热片四角螺钉的同时拧紧并随时单独调整各螺钉的拧紧速度,通过压力传感器反馈压力值补偿由于焊接误差导致的压力差,实现CPU整体均匀受力,提高可靠性。LGA chips have a special packaging method and are different from other chips in the installation method. It does not use the pins to fix the contact installation, but uses the mounting frame to fix it, so that the CPU can be correctly pressed on the pins of the LGA seat, and use the chip The pressing force between the heat sink and the CPU reaches the electrical connection of the pin point. However, when tightening the chip heat sink, the fixing screws at the four corners must be tightened in a certain order, which may easily cause the CPU to be unable to be evenly stressed. At the same time, due to the existence of welding errors in the PCB board welding process, the CPU mounting surface cannot be guaranteed to be absolutely level, so when the chip heat sink is tightened, the CPU will be unevenly stressed, reducing the reliability of the CPU. The self-adaptive installation method of the LGA chip heat sink of the present invention can realize the simultaneous tightening of the four-corner screws of the LGA chip heat sink and individually adjust the tightening speed of each screw at any time, and compensate the pressure difference caused by the welding error through the feedback pressure value of the pressure sensor. The CPU is evenly stressed as a whole to improve reliability.

发明内容Contents of the invention

本发明针对现有技术的问题,提供一种LGA类芯片散热片自适应安装方法,可以实现LGA类芯片散热片四角螺钉的同时拧紧并随时单独调整各螺钉的拧紧速度,通过压力传感器反馈压力值补偿由于焊接误差导致的压力差,实现CPU整体均匀受力,提高可靠性。Aiming at the problems of the prior art, the present invention provides an adaptive installation method for LGA chip heat sinks, which can realize the simultaneous tightening of the four-corner screws of the LGA chip heat sink and individually adjust the tightening speed of each screw at any time, and feedback the pressure value through the pressure sensor Compensate the pressure difference caused by welding errors, realize the overall uniform force of the CPU, and improve reliability.

本发明提出的具体方案是:The concrete scheme that the present invention proposes is:

一种LGA类芯片散热片自适应安装方法,采集LGA类芯片散热片安装结构与主板上LGA类芯片固定座之间四角的压力值,对所述四角的压力值进行分析反馈,根据分析反馈情况,按照LGA类芯片固定座四角预设的标称压力值,自动调节LGA类芯片散热片安装结构与主板上LGA类芯片固定座之间的螺纹连接进行LGA类芯片散热片安装。A method for self-adaptive installation of heat sinks of LGA chips, collecting the pressure values at the four corners between the mounting structure of the heat sinks of the LGA chips and the fixing seat of the LGA chips on the motherboard, analyzing and feeding back the pressure values at the four corners, and analyzing and feeding back the pressure values according to the analysis and feedback , according to the preset nominal pressure value at the four corners of the LGA chip holder, automatically adjust the screw connection between the LGA chip heat sink installation structure and the LGA chip holder on the motherboard to install the LGA chip heat sink.

进一步,所述的一种LGA类芯片散热片自适应安装方法中通过LGA类芯片散热片安装结构与主板上LGA类芯片固定座之间部署压力传感器,采集LGA类芯片散热片安装结构与主板上LGA类芯片固定座之间四角的压力值。Further, in the self-adaptive installation method of a heat sink of an LGA chip, a pressure sensor is deployed between the mounting structure of the heat sink of the LGA chip and the fixing seat of the LGA chip on the main board to collect information on the mounting structure of the heat sink of the LGA chip and the mounting structure of the heat sink on the main board. The pressure value of the four corners between the LGA chip holders.

进一步,所述的一种LGA类芯片散热片自适应安装方法中所述根据分析反馈情况,按照LGA类芯片固定座四角预设的标称压力值,自动调节LGA类芯片散热片安装结构与主板上LGA类芯片固定座之间的螺纹连接,包括:Further, in the self-adaptive installation method of an LGA-type chip heat sink, according to the analysis feedback situation, according to the nominal pressure value preset at the four corners of the LGA-type chip holder, the installation structure of the LGA-type chip heat sink and the motherboard are automatically adjusted. Threaded connections between upper LGA-type chip holders, including:

实时获取所述四角的压力值的分析反馈情况,分别比对所述四角的压力值与四角预设的标称压力值,若某一角的压力值小于对应的标称压力值则继续自动进行LGA类芯片散热片安装结构与主板上LGA类芯片固定座之间的螺纹连接,若某一角的压力值等于对应的标称压力值则停止LGA类芯片散热片安装结构与主板上LGA类芯片固定座之间的螺纹连接,直至LGA类芯片散热片安装结构与主板上LGA类芯片固定座之间四角的压力值均符合预设的标称压力值。Obtain the analysis feedback of the pressure values of the four corners in real time, compare the pressure values of the four corners with the preset nominal pressure values of the four corners, and continue to automatically perform LGA if the pressure value of a certain corner is less than the corresponding nominal pressure value The screw connection between the mounting structure of the chip heat sink and the LGA chip fixing seat on the motherboard, if the pressure value of a certain corner is equal to the corresponding nominal pressure value, the LGA chip heat sink mounting structure and the LGA chip fixing seat on the motherboard will stop until the pressure values at the four corners between the mounting structure of the LGA type chip heat sink and the LGA type chip fixing seat on the main board meet the preset nominal pressure value.

进一步,所述的一种LGA类芯片散热片自适应安装方法中所述LGA类芯片散热片安装结构包括散热片安装机构、LGA类芯片散热片和散热片与安装机构固定架,通过所述散热片与安装机构固定架将所述LGA类芯片散热片固定在所述散热片安装机构上,所述散热片位于散热片安装机构的位置与LGA类芯片固定座之间部署压力传感器,Further, in the self-adaptive installation method for heat sinks of LGA chips, the installation structure of heat sinks for LGA chips includes a heat sink installation mechanism, a heat sink for LGA chips, and a fixing frame for heat sinks and installation mechanisms. The fin and the mounting mechanism fixing frame fix the heat sink of the LGA chip on the heat sink mounting mechanism, and the heat sink is located between the position of the heat sink mounting mechanism and the LGA chip mounting seat to deploy a pressure sensor,

所述散热片安装机构内置控制电路板,控制电路板上留有通信接口,四角分别安装传动电机,每个传动电机底端垂直连接一个螺杆固定柱,每个螺杆固定柱底端连接螺丝刀头,所述散热片安装机构通过通信接口接收四角的压力值的分析反馈情况,利用控制电路板根据分析反馈情况,按照LGA类芯片固定座四角预设的标称压力值,控制传动电机带动螺丝刀头拧紧螺钉完成散热片安装结构与主板上LGA类芯片固定座之间的螺纹连接。The heat sink installation mechanism has a built-in control circuit board, and a communication interface is left on the control circuit board. Transmission motors are respectively installed at the four corners. The bottom end of each transmission motor is vertically connected to a screw fixing column, and the bottom end of each screw fixing column is connected to a screwdriver head. The heat sink installation mechanism receives the analysis feedback of the pressure values of the four corners through the communication interface, and uses the control circuit board to control the transmission motor to drive the screwdriver head to tighten according to the analysis feedback and according to the preset nominal pressure values of the four corners of the LGA chip holder. The screw completes the threaded connection between the heat sink installation structure and the LGA type chip fixing seat on the motherboard.

进一步,所述的一种LGA类芯片散热片自适应安装方法中所述散热片与安装机构固定架包括侧架和底架,侧架与底架固定连接,所述底架连接并承托所述散热片,侧架开设螺孔,散热片安装机构对应开设螺孔,侧架与散热片安装机构利用拧紧螺钉进行螺纹连接。Further, in the self-adaptive installation method for heat sinks of LGA chips, the heat sink and the fixing frame of the installation mechanism include side frames and bottom frames, the side frames are fixedly connected to the bottom frame, and the bottom frame is connected and supports the As for the heat sink, the side frame is provided with screw holes, and the heat sink mounting mechanism is correspondingly provided with screw holes, and the side frame and the heat sink mounting mechanism are threadedly connected by tightening screws.

进一步,所述的一种LGA类芯片散热片自适应安装方法中所述散热片安装机构的通信接口为Type-C接口。Further, the communication interface of the heat sink installation mechanism in the self-adaptive installation method for heat sinks of LGA chips is a Type-C interface.

进一步,所述的一种LGA类芯片散热片自适应安装方法中所述散热片安装机构还包括上盖板和承载板,所述上盖板扣合在所述承载板上,所述上盖板留有Type-C接口的插座,所述承载板四角分别承载和安装传动电机,传动电机上平面连接控制电路板,所述承载板对应传动电机开设孔,便于螺杆固定柱伸出。Further, in the heat sink self-adaptive installation method for LGA chips, the heat sink installation mechanism also includes an upper cover plate and a bearing plate, the upper cover plate is fastened on the bearing plate, and the upper cover There is a Type-C interface socket on the board, and the four corners of the bearing board respectively carry and install the transmission motor, and the upper plane of the transmission motor is connected to the control circuit board, and the bearing board is provided with a hole corresponding to the transmission motor to facilitate the extension of the screw fixing column.

本发明还提供计算机可读介质,所述计算机可读介质上存储有计算机指令,所述计算机指令在被处理器执行时,使所述处理器执行所述的一种LGA类芯片散热片自适应安装方法。The present invention also provides a computer-readable medium, on which computer instructions are stored, and when the computer instructions are executed by a processor, the processor is executed to perform the self-adaptive heat sink of a LGA-type chip. installation method.

本发明的有益之处是:The benefits of the present invention are:

本发明提供一种LGA类芯片散热片自适应安装方法,采集散热片安装机构与芯片固定座之间的压力值,根据压力值分析,及预设压力值能实现散热片的安装,在安装过程中,可同步反馈芯片所受压力值并实时调整,避免了人工安装时造成的过压现象,对于在LGA座焊接过程中造成的焊接误差可实现补偿,同步避免了局部过压问题,极大的提高了芯片的使用寿命,降低了对焊接工艺的依赖性,同时利用安装机构对散热片四角进行同步安装,方便了使用者的操作,符合人机工程,满足使用需求。The invention provides a method for self-adaptive installation of heat sinks for LGA chips, which collects the pressure value between the heat sink installation mechanism and the chip fixing seat, analyzes the pressure value, and presets the pressure value to realize the installation of the heat sink. Among them, the pressure value of the chip can be synchronously fed back and adjusted in real time, avoiding the overpressure phenomenon caused by manual installation, and the welding error caused by the welding process of the LGA seat can be compensated, and the local overvoltage problem can be avoided synchronously, greatly The service life of the chip is greatly improved, and the dependence on the welding process is reduced. At the same time, the installation mechanism is used to simultaneously install the four corners of the heat sink, which is convenient for the user's operation, conforms to ergonomics, and meets the use requirements.

附图说明Description of drawings

图1为本发明方法流程示意图。Fig. 1 is a schematic flow chart of the method of the present invention.

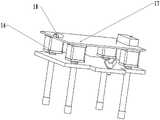

图2为本发明的芯片散热片和压力传感器以及安装机构整体装配示意图。Fig. 2 is a schematic diagram of the overall assembly of the chip heat sink, the pressure sensor and the mounting mechanism of the present invention.

图3为本发明提供的散热片安装机构示意图。Fig. 3 is a schematic diagram of the heat sink installation mechanism provided by the present invention.

图4为本发明提供的散热片安装机构中传动电机位置示意图。Fig. 4 is a schematic diagram of the position of the transmission motor in the heat sink installation mechanism provided by the present invention.

附图标记:1、散热片安装机构,11、电源接口插座,12、上盖板,13、拧紧螺钉,14、承载板,15、螺钉固定柱,16、传动电机,17、控制电路板,18、Type-C插座,2、LGA类芯片散热片,3、螺丝刀头,4、四角压力传感器,5、散热片与安装机构固定架。Reference signs: 1. Heat sink installation mechanism, 11. Power interface socket, 12. Upper cover plate, 13. Tightening screw, 14. Loading plate, 15. Screw fixing column, 16. Transmission motor, 17. Control circuit board, 18. Type-C socket, 2. LGA chip heat sink, 3. Screwdriver head, 4. Four-corner pressure sensor, 5. Heat sink and mounting mechanism fixing frame.

具体实施方式detailed description

下面结合附图和具体实施例对本发明作进一步说明,以使本领域的技术人员可以更好地理解本发明并能予以实施,但所举实施例不作为对本发明的限定。The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

本发明提供一种LGA类芯片散热片自适应安装方法,采集LGA类芯片散热片安装结构与主板上LGA类芯片固定座之间四角的压力值,对所述四角的压力值进行分析反馈,根据分析反馈情况,按照LGA类芯片固定座四角预设的标称压力值,自动调节LGA类芯片散热片安装结构与主板上LGA类芯片固定座之间的螺纹连接进行LGA类芯片散热片安装。The invention provides a method for self-adaptive installation of LGA chip heat sinks, which collects the pressure values at the four corners between the LGA chip heat sink installation structure and the LGA chip fixing seat on the motherboard, and analyzes and feeds back the pressure values at the four corners, according to Analyze the feedback situation, according to the preset nominal pressure value at the four corners of the LGA chip holder, automatically adjust the screw connection between the LGA chip heat sink installation structure and the LGA chip holder on the motherboard to install the LGA chip heat sink.

本发明使用一体式安装机构安装LGA类芯片散热片采集监控并反馈一体式安装机构与芯片固定座之间压力值,差动控制安装结构与芯片固定座之间的螺纹连接,可适应不同的安装环境;在保证安装压紧力的前提下,利用软件反馈并补偿焊接误差,提高了芯片使用寿命,简化了安装程序。The invention uses an integrated installation mechanism to install the LGA chip heat sink to collect, monitor and feed back the pressure value between the integrated installation mechanism and the chip holder, and differentially controls the screw connection between the installation structure and the chip holder, which can adapt to different installations Environment: On the premise of ensuring the installation pressing force, the use of software feedback and compensation of welding errors improves the service life of the chip and simplifies the installation procedure.

具体应用中,在本发明方法的一些实施例中,可以参考图2-4中LGA类芯片散热片安装结构,LGA类芯片散热片安装结构包括散热片安装机构1、LGA类芯片散热片2、螺丝刀头3、压力传感器4和散热片与安装机构固定架5,图2-4中所示的散热片安装机构1为装配形式,散热片安装机构1包括电源接口插座11、上盖板12、拧紧螺钉13、承载板14、螺杆固定柱15、传动电机16、控制电路板17和Type-C插座18,所述上盖板12扣合在所述承载板14上,所述上盖板12留有Type-C插座18,所述承载板14四角分别承载和安装传动电机16,传动电机16上平面连接控制电路板17,每个传动电机16底端垂直连接一个螺杆固定柱,所述承载板14对应传动电机16开设孔,便于螺杆固定柱15伸出,In specific applications, in some embodiments of the method of the present invention, reference can be made to the LGA chip heat sink installation structure in Figures 2-4, the LGA chip heat sink installation structure includes a heat sink installation mechanism 1, an LGA

所述散热片与安装机构固定架5包括侧架和底架,侧架与底架固定连接,所述底架连接并承托所述散热片2,侧架开设螺孔,散热片安装机构1对应开设螺孔,侧架与散热片安装机构1利用拧紧螺钉13进行螺纹连接,The heat sink and mounting mechanism fixing frame 5 includes a side frame and a bottom frame, the side frame and the bottom frame are fixedly connected, the bottom frame is connected and supports the

选择合适的螺丝刀头3与螺杆固定柱15配合,并分别与散热片2的四角螺钉配合,将散热片安装机构1对准LGA类芯片固定座,保证压力传感器4可以压接到芯片四角,电源接口插座11通电后,控制电路板17和与Type-C插座18相连接收控制软件的命令,驱动传动电机16转动并带动螺杆固定柱15旋转,所述承载板14对传动电机16起支撑作用,所述上盖板12对传动机构16起到保护作用,所述压力传感器4通过软件控制,可实现实时读取压力传感器的压力值并进行显示,同时根据压力值驱动四台传动电机16分别转动以便调节螺钉的螺纹连接。Select the

利用上述LGA类芯片散热片安装结构,参考图1执行本LGA类芯片散热片自适应安装流程,首先预设LGA类芯片散热片安装时的标称压力值,利用四角的压力传感器4,在对应控制软件中设定四个相同的压力值;然后将散热片安装机构1和散热片2利用固定架5进行连接,安装合适的螺丝刀头3,通过控制电路板17上的Type-C插座18实现控制软件和安装机构的互联,安装机构通过电源接口插座11上电,根据设定的标称压力值,软件控制传动电机16转动,开始进行四颗固定螺钉的拧紧;所述四角的压力传感器4在受力过程中,将压力值传递到控制软件中进行实时显示,由于焊接误差的存在,四角的压力值有一定差值,当某一角的压力传感器受力达到软件设定值时,通过软件报警反馈,该位置的传动电机16停止转动;其余螺钉的传动电机16仍继续转动,控制软件同步显示各传感器压力值;随着螺钉的陆续拧紧,已完成固定的螺钉压力也可能发生变化,当软件显示的压力值不是标称压力值时,原来停止转动的传动电机16也可以继续运动,直到当各传感器压力值均达到设定值时,控制软件下发停止指令,拆除安装机构,完成散热片2安装。Utilize the installation structure of the above-mentioned LGA type chip heat sink, refer to Figure 1 to execute the self-adaptive installation process of the LGA type chip heat sink, first preset the nominal pressure value when the LGA type chip heat sink is installed, use the pressure sensors 4 at the four corners, Set four identical pressure values in the control software; then connect the heat sink installation mechanism 1 and the

本发明方法中涉及的散热片安装进行软件控制,软件程序选择现有的数控软件程序设置参数即可,无需创造性改进。本发明方法实现散热片的安装,在安装过程中,可同步反馈芯片所受压力值并实时调整,避免了人工安装时造成的过压现象,对于在LGA座焊接过程中造成的焊接误差可实现补偿,同步避免了局部过压问题,极大的提高了芯片的使用寿命,降低了对焊接工艺的依赖性,同时利用安装机构对散热片四角进行同步安装,方便了使用者的操作,符合人机工程,满足使用需求。The heat sink installation involved in the method of the present invention is controlled by software, and the software program can select the existing numerical control software program to set parameters, without creative improvement. The method of the invention realizes the installation of the heat sink. During the installation process, the pressure value of the chip can be synchronously fed back and adjusted in real time, avoiding the overpressure phenomenon caused by manual installation, and the welding error caused in the welding process of the LGA seat can be realized. Compensation and synchronously avoid local overvoltage problems, greatly improve the service life of the chip, reduce the dependence on the welding process, and use the installation mechanism to simultaneously install the four corners of the heat sink, which is convenient for the user's operation and conforms to human Mechanical engineering to meet the needs of use.

本发明还提供计算机可读介质,所述计算机可读介质上存储有计算机指令,所述计算机指令在被处理器执行时,使所述处理器执行所述的一种LGA类芯片散热片自适应安装方法。具体地,可以提供配有存储介质的系统或者装置,在该存储介质上存储着实现上述实施例中任一实施例的功能的软件程序代码,且使该系统或者装置的计算机(或CPU或MPU)读出并执行存储在存储介质中的程序代码。The present invention also provides a computer-readable medium, on which computer instructions are stored, and when the computer instructions are executed by a processor, the processor is executed to perform the self-adaptive heat sink of a LGA-type chip. installation method. Specifically, a system or device equipped with a storage medium may be provided, on which a software program code for realizing the functions of any of the above embodiments is stored, and the computer (or CPU or MPU of the system or device) ) to read and execute the program code stored in the storage medium.

在这种情况下,从存储介质读取的程序代码本身可实现上述实施例中任何一项实施例的功能,因此程序代码和存储程序代码的存储介质构成了本发明的一部分。In this case, the program code itself read from the storage medium can realize the function of any one of the above-mentioned embodiments, so the program code and the storage medium storing the program code constitute a part of the present invention.

用于提供程序代码的存储介质实施例包括软盘、硬盘、磁光盘、光盘(如CD-ROM、CD-R、CD-RW、DVD-ROM、DVD-RAM、DVD-RW、DVD+RW)、磁带、非易失性存储卡和ROM。可选择地,可以由通信网络从服务器计算机上下载程序代码。Examples of storage media for providing program code include floppy disks, hard disks, magneto-optical disks, optical disks (such as CD-ROM, CD-R, CD-RW, DVD-ROM, DVD-RAM, DVD-RW, DVD+RW), Tape, non-volatile memory card, and ROM. Alternatively, the program code can be downloaded from a server computer via a communication network.

此外,应该清楚的是,不仅可以通过执行计算机所读出的程序代码,而且可以通过基于程序代码的指令使计算机上操作的操作系统等来完成部分或者全部的实际操作,从而实现上述实施例中任意一项实施例的功能。In addition, it should be clear that not only by executing the program code read by the computer, but also by making the operating system on the computer complete part or all of the actual operations through instructions based on the program code, so as to realize the function of any one of the embodiments.

此外,可以理解的是,将由存储介质读出的程序代码写到插入计算机内的扩展板中所设置的存储器中或者写到与计算机相连接的扩展单元中设置的存储器中,随后基于程序代码的指令使安装在扩展板或者扩展单元上的CPU等来执行部分和全部实际操作,从而实现上述实施例中任一实施例的功能。In addition, it can be understood that the program code read from the storage medium is written into the memory provided in the expansion board inserted into the computer or written into the memory provided in the expansion unit connected to the computer, and then based on the program code The instruction causes the CPU installed on the expansion board or the expansion unit to perform some or all of the actual operations, so as to realize the functions of any one of the above-mentioned embodiments.

以上所述实施例仅是为充分说明本发明而所举的较佳的实施例,本发明的保护范围不限于此。本技术领域的技术人员在本发明基础上所作的等同替代或变换,均在本发明的保护范围之内。本发明的保护范围以权利要求书为准。The above-mentioned embodiments are only preferred embodiments for fully illustrating the present invention, and the protection scope of the present invention is not limited thereto. Equivalent substitutions or transformations made by those skilled in the art on the basis of the present invention are all within the protection scope of the present invention. The protection scope of the present invention shall be determined by the claims.

Claims (8)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210996503.3ACN115424941A (en) | 2022-08-19 | 2022-08-19 | A self-adaptive installation method for LGA chip heat sink |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210996503.3ACN115424941A (en) | 2022-08-19 | 2022-08-19 | A self-adaptive installation method for LGA chip heat sink |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115424941Atrue CN115424941A (en) | 2022-12-02 |

Family

ID=84198380

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210996503.3APendingCN115424941A (en) | 2022-08-19 | 2022-08-19 | A self-adaptive installation method for LGA chip heat sink |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115424941A (en) |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101026953A (en)* | 2007-03-29 | 2007-08-29 | 杭州华为三康技术有限公司 | Pressure mounting device and pressure mounting method |

| JP2012069632A (en)* | 2010-09-22 | 2012-04-05 | Nec Computertechno Ltd | Overpressure detection mechanism and overpressure detection method and overpressure prevention method for bga solder ball |

| US20120240898A1 (en)* | 2011-03-23 | 2012-09-27 | Visteon Global Technologies, Inc. | Integrated plastic throttle body, electronic control unit, and sensors for small engine |

| CN112382588A (en)* | 2020-11-11 | 2021-02-19 | 海光信息技术股份有限公司 | Chip mounting device and chip mounting method |

| CN114166266A (en)* | 2021-11-19 | 2022-03-11 | 苏州浪潮智能科技有限公司 | A method and device for detecting whether a CPU radiator screw is leaking |

- 2022

- 2022-08-19CNCN202210996503.3Apatent/CN115424941A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101026953A (en)* | 2007-03-29 | 2007-08-29 | 杭州华为三康技术有限公司 | Pressure mounting device and pressure mounting method |

| JP2012069632A (en)* | 2010-09-22 | 2012-04-05 | Nec Computertechno Ltd | Overpressure detection mechanism and overpressure detection method and overpressure prevention method for bga solder ball |

| US20120240898A1 (en)* | 2011-03-23 | 2012-09-27 | Visteon Global Technologies, Inc. | Integrated plastic throttle body, electronic control unit, and sensors for small engine |

| CN112382588A (en)* | 2020-11-11 | 2021-02-19 | 海光信息技术股份有限公司 | Chip mounting device and chip mounting method |

| CN114166266A (en)* | 2021-11-19 | 2022-03-11 | 苏州浪潮智能科技有限公司 | A method and device for detecting whether a CPU radiator screw is leaking |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7755896B2 (en) | Information processing device | |

| JP2000156554A (en) | Module type integrated device | |

| US7185500B2 (en) | Active cooling system for CPU | |

| EP0820098A2 (en) | Switched management of thermal impedance to reduce temperature excursions | |

| EP1909377A1 (en) | Drive circuit of motor and outdoor unit of air conditioner | |

| US20200174534A1 (en) | Heat sink assemblies having removable portions | |

| US20050083660A1 (en) | Power supply without cooling fan | |

| CN1630076A (en) | circuit components | |

| CN101212880A (en) | Heat radiator | |

| CN211959077U (en) | computer power supply components | |

| US6541855B2 (en) | Printed board unit | |

| US20060221576A1 (en) | Radiator device and plug-in unit | |

| CN112020266B (en) | Multipurpose radiator, manufacturing method thereof, board card and multipurpose radiator platform | |

| CN115424941A (en) | A self-adaptive installation method for LGA chip heat sink | |

| JP5062014B2 (en) | Electronic circuit module, power supply device, projector | |

| CN216462881U (en) | Memory bank pressing machine | |

| CN216622603U (en) | A chip power supply circuit test structure and test system | |

| US6349465B1 (en) | Controlled bondline thickness attachment mechanism | |

| CN114325314A (en) | Chip power supply circuit test structure, test method and test system | |

| CN101201775A (en) | Circuit board test fixture | |

| CN101145302A (en) | plasma display module | |

| CN213337910U (en) | Crimping jig device for chip testing | |

| CN218100142U (en) | Host and industrial control system | |

| CN118155670A (en) | Auxiliary heat dissipation device and control method | |

| US6501647B1 (en) | Computer with thermal cooling and a thermal cooling system and method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |