CN115326656A - Nondestructive measurement method for particle size and grading of loose layer particles of particle materials for traffic civil engineering - Google Patents

Nondestructive measurement method for particle size and grading of loose layer particles of particle materials for traffic civil engineeringDownload PDFInfo

- Publication number

- CN115326656A CN115326656ACN202211257525.4ACN202211257525ACN115326656ACN 115326656 ACN115326656 ACN 115326656ACN 202211257525 ACN202211257525 ACN 202211257525ACN 115326656 ACN115326656 ACN 115326656A

- Authority

- CN

- China

- Prior art keywords

- particle

- civil engineering

- loose layer

- horizontal plane

- point

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000002245particleSubstances0.000titleclaimsabstractdescription112

- 238000000691measurement methodMethods0.000titleclaimsabstractdescription16

- 239000000463materialSubstances0.000titleclaimsabstract7

- 239000008187granular materialSubstances0.000claimsabstractdescription66

- 238000001514detection methodMethods0.000claimsabstractdescription26

- 238000000034methodMethods0.000claimsabstractdescription26

- 230000011218segmentationEffects0.000claimsabstractdescription12

- 238000012876topographyMethods0.000claimsdescription24

- 230000001066destructive effectEffects0.000claimsdescription16

- 238000010276constructionMethods0.000claimsdescription13

- 238000004364calculation methodMethods0.000claimsdescription12

- 238000012937correctionMethods0.000claimsdescription6

- 230000014509gene expressionEffects0.000claimsdescription4

- 230000009466transformationEffects0.000claimsdescription3

- 238000005259measurementMethods0.000abstractdescription6

- 239000011148porous materialSubstances0.000abstractdescription2

- 230000008569processEffects0.000description5

- 239000011362coarse particleSubstances0.000description3

- 238000013461designMethods0.000description3

- 238000012360testing methodMethods0.000description3

- 230000009471actionEffects0.000description2

- 238000010586diagramMethods0.000description2

- 239000000203mixtureSubstances0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 238000012216screeningMethods0.000description2

- 239000010426asphaltSubstances0.000description1

- 238000009412basement excavationMethods0.000description1

- 230000009286beneficial effectEffects0.000description1

- 239000004568cementSubstances0.000description1

- 230000008859changeEffects0.000description1

- 238000012512characterization methodMethods0.000description1

- 238000001035dryingMethods0.000description1

- 238000005516engineering processMethods0.000description1

- 239000010419fine particleSubstances0.000description1

- 239000010881fly ashSubstances0.000description1

- -1graded macadamSubstances0.000description1

- 230000005484gravityEffects0.000description1

- 230000006872improvementEffects0.000description1

- 238000012544monitoring processMethods0.000description1

- 238000003908quality control methodMethods0.000description1

- 238000005204segregationMethods0.000description1

- 238000003756stirringMethods0.000description1

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N15/00—Investigating characteristics of particles; Investigating permeability, pore-volume or surface-area of porous materials

- G01N15/02—Investigating particle size or size distribution

- G01N15/0205—Investigating particle size or size distribution by optical means

- G01N15/0227—Investigating particle size or size distribution by optical means using imaging; using holography

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02W—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO WASTEWATER TREATMENT OR WASTE MANAGEMENT

- Y02W30/00—Technologies for solid waste management

- Y02W30/50—Reuse, recycling or recovery technologies

- Y02W30/91—Use of waste materials as fillers for mortars or concrete

Landscapes

- Chemical & Material Sciences (AREA)

- Dispersion Chemistry (AREA)

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Management, Administration, Business Operations System, And Electronic Commerce (AREA)

- Investigating Or Analyzing Materials By The Use Of Ultrasonic Waves (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及颗粒粒径测量领域,具体是交通土建用颗粒材料松铺层颗粒粒径及级配无损测量方法。The invention relates to the field of particle size measurement, in particular to a non-destructive measurement method for the particle size and gradation of loose layers of granular materials used in traffic civil engineering.

背景技术Background technique

颗粒材料普遍存在于自然界,并广泛应用于工程建设中,尤其是大宗的交通土建工程中。决定颗粒材料工程性能的关键设计参数为颗粒粒径及颗粒组成级配。所谓级配,是指各级粒径颗粒的分布情况。随着交通等级的提高,现有交通土建工程中,如沥青混合料、级配碎石、水泥稳定级配碎石、二灰稳定级配碎石等颗粒材料,均采用厂拌然后运送到施工现场进行摊铺作业模式。虽然,在拌合厂拌和过程可以通过控制传送带速率来精确控制颗粒材料出厂时的级配严格符合设计级配。Granular materials are ubiquitous in nature and are widely used in engineering construction, especially in bulk traffic civil engineering. The key design parameters that determine the engineering performance of granular materials are particle size and particle composition gradation. The so-called gradation refers to the distribution of particle sizes at all levels. With the improvement of traffic level, in the existing traffic civil engineering, granular materials such as asphalt mixture, graded macadam, cement stabilized graded macadam, fly ash stabilized graded macadam and other granular materials are mixed in the factory and then transported to the construction site. On-site paving operation mode. Although, the mixing process in the mixing plant can precisely control the gradation of the granular material when it leaves the factory by controlling the speed of the conveyor belt to strictly comply with the design gradation.

但是,在颗粒材料运输至工程施工现场过程中,在路途颠簸等作用下易造成颗粒材料产生离析现象,即细颗粒在振动及重力共同作用下穿过粗颗粒组成的孔隙,往运输车辆底部汇聚,致使运输车辆中上部颗粒材料级配较粗,但是下部颗粒材料级配偏细,偏离设计级配。更为关键的是,在摊铺机摊铺过程中,螺旋摊铺杆搅拌传送过程时,粗颗粒更易聚集到道路边缘地带,致使其级配偏粗;而道路中央地带的颗粒材料因为损失了粗颗粒,致使其级配偏细。However, during the transportation of granular materials to the construction site, segregation of granular materials is likely to occur under the action of road bumps, that is, fine particles pass through the pores composed of coarse particles under the combined action of vibration and gravity, and gather at the bottom of the transport vehicle , resulting in a coarser gradation of the upper granular material in the transport vehicle, but a finer gradation of the lower granular material, which deviates from the design gradation. More importantly, during the paver paving process, when the spiral paving rod is stirring and conveying, coarse particles are more likely to gather at the edge of the road, resulting in a coarser gradation; and the granular material in the middle of the road is lost due to Coarse particles lead to finer gradation.

因此,如何实时控制摊铺后的交通土建用颗粒材料级配,是控制交通土建用颗粒材料力学性能及变形稳定性的关键。但是,传统交通土建用颗粒材料松铺层颗粒级配测量,通常采用检测点开挖法,即在检测点将松铺颗粒材料挖出,然后运输至实验室烘干筛分,整个过程将持续4到6个小时,测试效率低下,难以实现交通土建用颗粒材料松铺层颗粒级配实时测试需求,且为有损测试,“事后”控制模式。如何如何实时准确测量摊铺后的交通土建用颗粒材料级配,是实现交通土建用颗粒材料“事中”控制的关键。Therefore, how to control the gradation of granular materials for traffic civil engineering after paving in real time is the key to controlling the mechanical properties and deformation stability of granular materials for traffic civil engineering. However, the particle gradation measurement of the loose layer of granular materials used in traditional transportation civil engineering usually adopts the detection point excavation method, that is, the loose layered granular materials are dug out at the detection point, and then transported to the laboratory for drying and screening. The whole process will continue 4 to 6 hours, the test efficiency is low, it is difficult to meet the real-time test requirements for the particle gradation of the loose layer of granular materials for transportation and civil engineering, and it is a destructive test and an "post-event" control mode. How to accurately measure the gradation of granular materials for traffic civil engineering after paving in real time is the key to realize the "in-process" control of granular materials for traffic civil engineering.

鉴于此,本发明创造性地提出了一种交通土建用颗粒材料松铺层颗粒粒径及级配无损测量方法,能够实现实时无损测量交通土建用颗粒材料松铺层颗粒粒径及级配。有望一改传统交通土建用颗粒材料松铺层颗粒级配“事后”控制模式,实现交通土建用颗粒材料松铺层颗粒级配“事中”控制。In view of this, the present invention creatively proposes a non-destructive measurement method for the particle size and gradation of the loose layer of granular materials for transportation and civil engineering, which can realize real-time non-destructive measurement of the particle size and gradation of the loose layer of granular materials for transportation and civil engineering. It is expected to change the traditional "post-event" control mode of the particle gradation of the loose layer of granular materials for transportation and civil engineering, and realize the "in-the-fact" control of the particle gradation of the loose layer of granular materials for transportation and civil engineering.

发明内容Contents of the invention

本发明目的在于提供交通土建用颗粒材料松铺层颗粒粒径及级配无损测量方法,解决了目前交通土建用颗粒材料级配测量效率低下的问题,实现交通土建用颗粒材料级配的高效测量及“事中控制”。The purpose of the present invention is to provide a non-destructive measurement method for the particle size and gradation of the loose layer of granular materials used in traffic civil engineering, which solves the problem of low efficiency in measuring the gradation of granular materials used in traffic civil engineering, and realizes the high-efficiency measurement of the gradation of granular materials used in traffic civil engineering. And "control in the event".

为了解决上述问题,本发明提供了交通土建用颗粒材料松铺层颗粒粒径及级配无损测量方法,对交通土建用颗粒材料施工过程中骨料颗粒形态表征与后续级配控制、调整提供技术基础。In order to solve the above problems, the present invention provides a non-destructive measurement method for the particle size and gradation of the loose layer of granular materials for traffic civil engineering, and provides technology for the characterization of aggregate particle morphology and subsequent gradation control and adjustment during the construction of granular materials for traffic civil engineering Base.

为了实现上述目的,本发明采用的方法是:交通土建用颗粒材料松铺层颗粒粒径及级配无损测量方法,主要用于交通土建用颗粒材料施工质量控制过程中,对于交通土建用颗粒材料松铺层骨料颗粒进行识别,表征骨料颗粒形态与估算骨料颗粒级配,包括以下步骤。In order to achieve the above object, the method adopted in the present invention is: the particle size and gradation non-destructive measurement method of particle size and gradation of granular material for traffic civil engineering, which is mainly used in the construction quality control process of granular material for traffic civil engineering. Identifying the aggregate particles of the loose layer, characterizing the morphology of the aggregate particles and estimating the gradation of the aggregate particles include the following steps.

S1、获取检测点位处交通土建用颗粒材料松铺层表面300mm×300mm范围的多视角数字图像,所述数字图像像素数不小于65536×65536像素点。S1. Obtain a multi-view digital image in the range of 300mm×300mm on the surface of the loose layer of granular materials for traffic civil engineering at the detection point, and the number of pixels in the digital image is not less than 65536×65536 pixels.

S2、运用基于尺度不变特征变换算法(SIFT)提取并匹配S1中所述交通土建用颗粒材料松铺层表面检测点位处的多视角数字图像中的图像特征描述子,然后依次进行松铺层表面数字图像拍摄姿态估计、松铺层表面形貌稀疏点云数字模型构建、松铺层表面形貌稠密点云数字模型构建、松铺层表面形貌点云网格建模及松铺层表面形貌三维矢量数字模型构建,进而得到检测点位处交通土建用颗粒材料松铺层表面三维形貌数字模型。S2. Use the scale-invariant feature transformation algorithm (SIFT) to extract and match the image feature descriptors in the multi-view digital images at the detection points on the surface of the loose layer of granular materials for transportation and civil engineering described in S1, and then perform loose layering in sequence Attitude estimation of layer surface digital image shooting, loose layer surface topography sparse point cloud digital model construction, loose layer surface topography dense point cloud digital model construction, loose layer surface topography point cloud grid modeling and loose layer The three-dimensional vector digital model of the surface topography is constructed, and then the three-dimensional topography digital model of the surface of the loose layer of granular materials for traffic civil engineering at the detection point is obtained.

S3、对S2中所述检测点位处交通土建用颗粒材料松铺层表面三维形貌数字模型,进行倾斜修正与比例修正,得到与实际交通土建用颗粒材料松铺层表面被测点尺寸相同的颗粒材料松铺层表面三维形貌数字模型。S3. Perform inclination correction and scale correction on the digital model of the three-dimensional appearance of the surface of the loose layer of granular materials for traffic civil engineering at the detection point in S2, and obtain the same size as the measured point on the surface of the loose layer of granular materials for traffic civil engineering. A digital model of the 3D surface topography of loosely laid layers of granular materials.

S4、运用所述改进局部区域生长分割法对S3中所述检测点位处交通土建用颗粒材料松铺层表面三维形貌数字模型进行颗粒的识别计算与分割计算,颗粒识别时,首先利用所述插值法对所述检测点位处交通土建用颗粒材料松铺层表面三维形貌数字模型进行网格划分,再使用所述分水岭算法识别所述局部区域极大值点与所述局部区域极小值点,最后使用所述四领域区域生长方式确定区域生长范围,将所述局部区域极大值点作为局部区域生长点及区域生长范围上限,所述局部区域极小值点中的最小值作为区域生长范围的下限;颗粒分割时,将所述网格间距系数设置为0.5,所述高度系数设置为0.4,所述局部区域极大值间距系数设置为50,所述局部区域极小值间距系数设置为10。S4. Use the improved local region growth segmentation method to carry out particle recognition calculation and segmentation calculation on the digital model of the three-dimensional appearance of the surface of the loose layer of granular materials for traffic civil engineering at the detection point in S3. When identifying the particles, first use the The interpolation method meshes the three-dimensional topography digital model of the surface of the loose layer of granular materials used for traffic civil engineering at the detection point, and then uses the watershed algorithm to identify the local area maximum point and the local area extreme point. Small value points, finally use the four-field region growth method to determine the region growth range, use the local region maximum point as the local region growth point and the upper limit of the region growth range, the minimum value of the local region minimum point As the lower limit of the region growth range; during particle segmentation, the grid spacing coefficient is set to 0.5, the height coefficient is set to 0.4, the local area maximum value spacing coefficient is set to 50, and the local area minimum value The spacing factor is set to 10.

S5、获得所述每个颗粒在水平面内的二维投影图像,获得所述每个颗粒外露表面最高点距水平面的垂直距离,计算所述二维投影图像的截面凸度、截面长宽比、圆形度和所述二维投影图像的等效圆直径,计算表达式如下:S5. Obtain the two-dimensional projection image of each particle in the horizontal plane, obtain the vertical distance from the highest point on the exposed surface of each particle to the horizontal plane, and calculate the cross-sectional convexity, cross-sectional aspect ratio, Circularity and the equivalent circle diameter of the two-dimensional projection image, the calculation expression is as follows:

其中,A为截面凸度,SA为颗粒在水平面内二维投影图像的面积,SC为颗粒在水平面内二维投影图像的外切多边形面积,B为截面长宽比,L为颗粒在水平面内二维投影图像等效椭圆的主轴长度,W为颗粒在水平面内二维投影图像等效椭圆的次轴长度,C为圆形度,P为颗粒在水平面内二维投影图像周长,D为颗粒在水平面内二维投影图像的等效圆直径。Among them, A is the cross-sectional convexity, SA is the area of the two-dimensional projection image of the particle in the horizontal plane, SC is the circumscribed polygon area of the two-dimensional projection image of the particle in the horizontal plane, B is the section aspect ratio, and L is the area of the particle in the horizontal plane. The main axis length of the equivalent ellipse of the two-dimensional projection image in the horizontal plane, W is the minor axis length of the equivalent ellipse of the two-dimensional projection image of the particle in the horizontal plane, C is the circularity, and P is the perimeter of the two-dimensional projection image of the particle in the horizontal plane, D is the equivalent circle diameter of the two-dimensional projected image of the particle in the horizontal plane.

S6、运用S5中所述二维投影图像等效圆直径和所述每个颗粒外露表面最高点距水平面的垂直距离,计算所述每个颗粒等效粒径;并根据标准筛孔尺寸范围19mm、16mm、12.5mm、9.5mm、4.75mm,累计得到交通土建用颗粒材料级配曲线。所述每个颗粒等效粒径用下式计算:S6. Using the equivalent circle diameter of the two-dimensional projection image described in S5 and the vertical distance between the highest point on the exposed surface of each particle and the horizontal plane, calculate the equivalent particle diameter of each particle; and according to the standard sieve size range of 19mm . The equivalent particle diameter of each particle is calculated by the following formula:

式中,R为颗粒等效粒径,h为颗粒外露表面最高点距水平面的垂直距离,D为颗粒在水平面内二维投影图像的等效圆直径。In the formula, R is the equivalent particle diameter of the particle, h is the vertical distance from the highest point on the exposed surface of the particle to the horizontal plane, and D is the equivalent circle diameter of the two-dimensional projected image of the particle in the horizontal plane.

本发明实施例带来了以下有益效果。The embodiments of the present invention bring the following beneficial effects.

该发明方法步骤简单,易于实现,基于局部区域生长分割法,提出了更为简单、参数更少的等效球体径计算公式,有效提高了骨料颗粒粒径估算的精确度;该方法不仅可以实现交通土建用颗粒材料松铺层施工过程中颗粒级配检测,还可以根据具体工程具体需要对骨料颗粒形态进行表征,为接下来的颗粒形态筛选以及颗粒级配控制与后续级配调整提供优质的参考数据,为交通土建用颗粒材料松铺层施工过程中级配监测提供了一种新型有效的方法。The inventive method has simple steps and is easy to implement. Based on the local region growth segmentation method, a simpler equivalent sphere diameter calculation formula with fewer parameters is proposed, which effectively improves the accuracy of aggregate particle size estimation; the method can not only Realize particle gradation detection in the construction process of loose pavement of granular materials for transportation and civil engineering, and can also characterize the shape of aggregate particles according to the specific needs of specific projects, providing a basis for the next particle shape screening, particle gradation control and subsequent gradation adjustment. High-quality reference data provide a new and effective method for gradation monitoring during the construction of loose layers of granular materials for transportation civil engineering.

下面结合附图和具体实施方式对本发明做进一步的说明。本发明附加的方面和优点将在下面的描述中部分给出,部分将从下面的描述中变得明显。或通过本发明的实践了解到。The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. Additional aspects and advantages of the invention will be set forth in part, and in part will be apparent from, the description which follows. Or understand through the practice of the present invention.

附图说明Description of drawings

下面结合附图说明和具体实施方式对本发明做进一步详细说明。The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

图1为交通土建用颗粒材料松铺层颗粒粒径及级配无损测量方法流程图。Figure 1 is a flow chart of the non-destructive measurement method for the particle size and gradation of the loose layer of granular materials used in traffic civil engineering.

图2为四领域区域生长方式流程图。Figure 2 is a flow chart of the regional growth method in four domains.

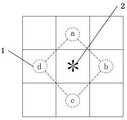

图3为四领域生长方向示意图。Figure 3 is a schematic diagram of the growth direction of the four domains.

图中:1-四领域区域生长方向,2-局部区域生长点。In the figure: 1- the growth direction of the four domains, 2- the growth point of the local area.

具体实施方式Detailed ways

下面结合附图对本发明进行清楚、完整的说明。本领域普通技术人员在基于这些说明的情况下将能够实现本发明。在结合附图对本发明进行说明前,需要特别指出的是,本发明中在包括下述说明在内的各部分中所提供的技术方案和技术特征,在不冲突的情况下,这些技术方案和技术特征可以相互组合。The present invention will be clearly and completely described below in conjunction with the accompanying drawings. Those skilled in the art will be able to implement the present invention based on these descriptions. Before describing the present invention in conjunction with the accompanying drawings, it needs to be particularly pointed out that the technical solutions and technical features provided in each part of the present invention, including the following descriptions, in the case of no conflict, these technical solutions and Technical features can be combined with each other.

此外,下述说明中涉及到的本发明的实施例通常仅是本发明的一部分实施例,而不是全部的实施例。因此,基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动的前提下所获得的所有其他实施例,都应当属于本发明保护的范围。In addition, the embodiments of the present invention referred to in the following descriptions are usually only some of the embodiments of the present invention, not all of the embodiments. Therefore, based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

关于本发明中术语和单位。本发明的说明书和权利要求书及有关的部分中的术语“包括”以及它的任何变形,意图在于覆盖不排他的包含。About terms and units in the present invention. The term "comprise" and any variations thereof in the description and claims of the present invention and related parts are intended to cover non-exclusive inclusion.

交通土建用颗粒材料松铺层颗粒粒径及级配无损测量方法流程图,如图1所示,其实现步骤如下。The flow chart of the non-destructive measurement method for the particle size and gradation of the loose layer of granular materials for transportation and civil engineering is shown in Figure 1, and the implementation steps are as follows.

步骤一、获取检测点位处交通土建用颗粒材料松铺层表面300mm×300mm范围的多视角数字图像,所述数字图像像素数不小于65536×65536像素点。

步骤二、运用基于尺度不变特征变换算法(SIFT)提取并匹配步骤一中所述交通土建用颗粒材料松铺层表面检测点位处的多视角数字图像中的图像特征描述子,然后依次进行松铺层表面数字图像拍摄姿态估计、松铺层表面形貌稀疏点云数字模型构建、松铺层表面形貌稠密点云数字模型构建、松铺层表面形貌点云网格建模及松铺层表面形貌三维矢量数字模型构建,进而得到检测点位处交通土建用颗粒材料松铺层表面三维形貌数字模型。

步骤三、对步骤二中所述检测点位处交通土建用颗粒材料松铺层表面三维形貌数字模型,进行倾斜修正与比例修正,得到与实际交通土建用颗粒材料松铺层表面被测点尺寸相同的颗粒材料松铺层表面三维形貌数字模型。Step 3. Carry out inclination correction and scale correction to the digital model of the three-dimensional topography of the surface of the loose layer of granular materials for traffic civil engineering at the detection point in

步骤四、运用所述改进局部区域生长分割法对步骤三中所述检测点位处交通土建用颗粒材料松铺层表面三维形貌数字模型进行每个颗粒的识别与分割计算。颗粒识别计算时,利用所述插值法对所述检测点位处交通土建用颗粒材料松铺层表面三维形貌数字模型进行网格划分,并使用所述分水岭算法识别所述局部区域极大值点与所述局部区域极小值点;使用所述四领域区域生长方式确定区域生长范围,将所述局部区域极大值点作为局部区域生长点2及区域生长范围上限,所述局部区域极小值点中的最小值作为区域生长范围的下限,所述四领域区域生长方式流程图如图2所示;然后按照四领域区域生长方向1,即a所代表的y轴正向、b所代表的x轴正向、c所代表的y轴负向、d所代表的x轴负向,所述四领域生长方向示意图如图3所示;颗粒分割计算时,将所述网格间距系数设置为0.5,所述高度系数设置为0.4,所述局部区域极大值间距系数设置为50,所述局部区域极小值间距系数设置为10。Step 4: Using the improved local region growth segmentation method to perform identification and segmentation calculation of each particle on the digital model of the three-dimensional appearance of the surface of the loose layer of granular materials for traffic and civil engineering at the detection point in step 3. During the calculation of particle identification, the interpolation method is used to divide the three-dimensional topography digital model of the surface of the loose layer of granular materials for traffic civil engineering at the detection point into grids, and the watershed algorithm is used to identify the maximum value of the local area point and the minimum value point of the local area; use the four-field regional growth method to determine the regional growth range, and use the local area maximum point as the local

步骤五、获得所述每个颗粒在水平面内的二维投影图像,获得所述每个颗粒外露表面最高点距水平面的垂直距离,计算所述二维投影图像的截面凸度、截面长宽比、圆形度和所述二维投影图像的等效圆直径,计算表达式如下:Step 5. Obtain the two-dimensional projection image of each particle in the horizontal plane, obtain the vertical distance from the highest point on the exposed surface of each particle to the horizontal plane, and calculate the cross-sectional convexity and cross-sectional aspect ratio of the two-dimensional projection image , circularity and the equivalent circle diameter of the two-dimensional projection image, the calculation expression is as follows:

其中,A为截面凸度,SA为颗粒在水平面内二维投影图像的面积,SC为颗粒在水平面内二维投影图像的外切多边形面积,B为截面长宽比,L为颗粒在水平面内二维投影图像等效椭圆的主轴长度,W为颗粒在水平面内二维投影图像等效椭圆的次轴长度,C为圆形度,P为颗粒在水平面内二维投影图像周长,D为颗粒在水平面内二维投影图像的等效圆直径。Among them, A is the cross-sectional convexity, SA is the area of the two-dimensional projection image of the particle in the horizontal plane, SC is the circumscribed polygon area of the two-dimensional projection image of the particle in the horizontal plane, B is the section aspect ratio, and L is the area of the particle in the horizontal plane. The main axis length of the equivalent ellipse of the two-dimensional projection image in the horizontal plane, W is the minor axis length of the equivalent ellipse of the two-dimensional projection image of the particle in the horizontal plane, C is the circularity, and P is the perimeter of the two-dimensional projection image of the particle in the horizontal plane, D is the equivalent circle diameter of the two-dimensional projected image of the particle in the horizontal plane.

步骤六、运用S5中所述二维投影图像等效圆直径和所述每个颗粒外露表面最高点距水平面的垂直距离,计算所述每个颗粒等效粒径;并根据标准筛孔尺寸范围19mm、16mm、12.5mm、9.5mm、4.75mm,累计得到交通土建用颗粒材料级配曲线。所述每个颗粒等效粒径用下式计算:Step 6. Calculate the equivalent particle diameter of each particle by using the equivalent circle diameter of the two-dimensional projection image described in S5 and the vertical distance from the highest point on the exposed surface of each particle to the horizontal plane; and according to the standard sieve size range 19mm, 16mm, 12.5mm, 9.5mm, 4.75mm, accumulatively obtained the gradation curve of granular materials for transportation and civil engineering. The equivalent particle diameter of each particle is calculated by the following formula:

式中,R为颗粒等效粒径,h为颗粒外露表面最高点距水平面的垂直距离,D为颗粒在水平面内二维投影图像的等效圆直径。In the formula, R is the equivalent particle diameter of the particle, h is the vertical distance from the highest point on the exposed surface of the particle to the horizontal plane, and D is the equivalent circle diameter of the two-dimensional projected image of the particle in the horizontal plane.

以上所述仅是本发明的优选实施方式,应当理解本发明并非局限于本文所披露的形式,不应看作是对其他实施例的排除,而可用于各种其他组合、修改和环境,并能够在本文所述构想范围内,通过上述教导或相关领域的技术或知识进行改动。而本领域人员所进行的改动和变化不脱离本发明的精神和范围,则都应在本发明所附权利要求的保护范围内。The above descriptions are only preferred embodiments of the present invention. It should be understood that the present invention is not limited to the form disclosed herein, and should not be regarded as excluding other embodiments, but can be used in various other combinations, modifications and environments, and Modifications can be made within the scope of the ideas described herein, by virtue of the above teachings or skill or knowledge in the relevant art. However, changes and changes made by those skilled in the art do not depart from the spirit and scope of the present invention, and should all be within the protection scope of the appended claims of the present invention.

Claims (7)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211257525.4ACN115326656B (en) | 2022-10-14 | 2022-10-14 | Non-destructive measurement method for particle size and gradation of loose layers of granular materials for transportation civil engineering |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211257525.4ACN115326656B (en) | 2022-10-14 | 2022-10-14 | Non-destructive measurement method for particle size and gradation of loose layers of granular materials for transportation civil engineering |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN115326656Atrue CN115326656A (en) | 2022-11-11 |

| CN115326656B CN115326656B (en) | 2022-12-23 |

Family

ID=83913237

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211257525.4AActiveCN115326656B (en) | 2022-10-14 | 2022-10-14 | Non-destructive measurement method for particle size and gradation of loose layers of granular materials for transportation civil engineering |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115326656B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116451305A (en)* | 2023-03-10 | 2023-07-18 | 哈尔滨工业大学 | Coarse aggregate geometric modeling method based on real concrete bridge |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101639947A (en)* | 2009-08-26 | 2010-02-03 | 北京农业信息技术研究中心 | Image-based plant three-dimensional shape measurement and reconstruction method and system |

| CN102288522A (en)* | 2011-06-30 | 2011-12-21 | 河海大学 | Device and method for analyzing sediment grains based on digital image technology |

| CN104008553A (en)* | 2014-06-17 | 2014-08-27 | 武汉武大卓越科技有限责任公司 | Crack detection method with image gradient direction histogram and watershed method conflated |

| US20150212521A1 (en)* | 2013-05-23 | 2015-07-30 | Irobot Corporation | Simultaneous Localization And Mapping For A Mobile Robot |

| CN109801291A (en)* | 2019-03-12 | 2019-05-24 | 西安交通大学 | A kind of acquisition methods moving abrasive grain multi-surface three-dimensional appearance |

| US20190188474A1 (en)* | 2017-12-15 | 2019-06-20 | Magic Leap, Inc. | Enhanced pose determination for display device |

| CN111397541A (en)* | 2020-04-23 | 2020-07-10 | 五邑大学 | Method, device, terminal and medium for measuring slope angle of soil dump |

| US10782220B1 (en)* | 2019-05-20 | 2020-09-22 | Southwest Petroleum University | Cross-scale wide-spectrum particle size plugging formula granularity analysis method |

| CN111724433A (en)* | 2020-06-24 | 2020-09-29 | 广西师范大学 | A method and system for crop phenotypic parameter extraction based on multi-eye vision |

| WO2021021779A1 (en)* | 2019-07-29 | 2021-02-04 | Universal City Studios Llc | Enhanced granular material effects |

| CN112927366A (en)* | 2021-05-10 | 2021-06-08 | 中南大学 | Asphalt pavement structure depth measuring method |

| US20210341989A1 (en)* | 2018-09-28 | 2021-11-04 | Shanghai Cambricon Information Technology Co., Ltd | Signal processing device and related products |

| CN115147401A (en)* | 2022-08-02 | 2022-10-04 | 中国水利水电科学研究院 | An intelligent detection method of earth-rock dam material qualification based on digital image processing |

| US20220316311A1 (en)* | 2014-11-12 | 2022-10-06 | Helmerich & Payne Technologies, Llc | System and method for measuring characteristics of cuttings from drilling operations with computer vision |

- 2022

- 2022-10-14CNCN202211257525.4Apatent/CN115326656B/enactiveActive

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101639947A (en)* | 2009-08-26 | 2010-02-03 | 北京农业信息技术研究中心 | Image-based plant three-dimensional shape measurement and reconstruction method and system |

| CN102288522A (en)* | 2011-06-30 | 2011-12-21 | 河海大学 | Device and method for analyzing sediment grains based on digital image technology |

| US20150212521A1 (en)* | 2013-05-23 | 2015-07-30 | Irobot Corporation | Simultaneous Localization And Mapping For A Mobile Robot |

| CN104008553A (en)* | 2014-06-17 | 2014-08-27 | 武汉武大卓越科技有限责任公司 | Crack detection method with image gradient direction histogram and watershed method conflated |

| US20220316311A1 (en)* | 2014-11-12 | 2022-10-06 | Helmerich & Payne Technologies, Llc | System and method for measuring characteristics of cuttings from drilling operations with computer vision |

| US20190188474A1 (en)* | 2017-12-15 | 2019-06-20 | Magic Leap, Inc. | Enhanced pose determination for display device |

| US20210341989A1 (en)* | 2018-09-28 | 2021-11-04 | Shanghai Cambricon Information Technology Co., Ltd | Signal processing device and related products |

| CN109801291A (en)* | 2019-03-12 | 2019-05-24 | 西安交通大学 | A kind of acquisition methods moving abrasive grain multi-surface three-dimensional appearance |

| US10782220B1 (en)* | 2019-05-20 | 2020-09-22 | Southwest Petroleum University | Cross-scale wide-spectrum particle size plugging formula granularity analysis method |

| WO2021021779A1 (en)* | 2019-07-29 | 2021-02-04 | Universal City Studios Llc | Enhanced granular material effects |

| CN111397541A (en)* | 2020-04-23 | 2020-07-10 | 五邑大学 | Method, device, terminal and medium for measuring slope angle of soil dump |

| CN111724433A (en)* | 2020-06-24 | 2020-09-29 | 广西师范大学 | A method and system for crop phenotypic parameter extraction based on multi-eye vision |

| CN112927366A (en)* | 2021-05-10 | 2021-06-08 | 中南大学 | Asphalt pavement structure depth measuring method |

| CN115147401A (en)* | 2022-08-02 | 2022-10-04 | 中国水利水电科学研究院 | An intelligent detection method of earth-rock dam material qualification based on digital image processing |

Non-Patent Citations (7)

| Title |

|---|

| XIN MING 等: "Robust object tracking by particle filter with scale invariant features", 《NEW TRENDS IN MECHATRONICS AND MATERIALS ENGINEERING》* |

| ZHONG XIN 等: "A robust tracking algorithm of fighter in complex situation", 《ELECTRONICS OPTICS & CONTROL》* |

| ZHU JUN 等: "Size-dependent reaction mechanism and kinetics for propane dehydrogenation over Pt catalysts", 《ACS CATALYSIS》* |

| 张清峰 等: "玄武岩纤维改性透水水泥稳定碎石试验研究", 《铁道工程学报》* |

| 王正东 等: "基于无人机的校园全景地图制作", 《矿山测量》* |

| 石超 等: "含碳颗粒的凝胶推进剂雾化特性实验研究", 《兵工学报》* |

| 石超 等: "基于SIFT算法的含碳 颗粒凝胶推进剂雾化场速度分析", 《推进技术》* |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116451305A (en)* | 2023-03-10 | 2023-07-18 | 哈尔滨工业大学 | Coarse aggregate geometric modeling method based on real concrete bridge |

Also Published As

| Publication number | Publication date |

|---|---|

| CN115326656B (en) | 2022-12-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110458119B (en) | A rapid identification method of concrete aggregate gradation by non-contact measurement | |

| CN105571571B (en) | Accumulation section spatial structural form analysis method based on 3 D laser scanning | |

| CN116448080B (en) | Unmanned aerial vehicle-based oblique photography-assisted earth excavation construction method | |

| CN107679441A (en) | Method based on multi-temporal remote sensing image shadow extraction City Building height | |

| CN105354832B (en) | A method for automatic registration of satellite images of mountainous areas to geographic basemaps | |

| CN108288059A (en) | A kind of building waste monitoring method based on high-definition remote sensing technology | |

| CN113008202B (en) | Ground settlement monitoring method integrating different synthetic aperture radar interferometry | |

| CN112857312B (en) | Fusion method for measuring ground settlement by different time sequence differential interference according to settlement rate | |

| CN110335352A (en) | A dual-element multi-resolution hierarchical filtering method for airborne lidar point clouds | |

| CN115326656B (en) | Non-destructive measurement method for particle size and gradation of loose layers of granular materials for transportation civil engineering | |

| US20240005599A1 (en) | Data normalization of aerial images | |

| CN101916329A (en) | A Modeling Calculation Method for Stockpile Volume | |

| CN110260876A (en) | A kind of road model generation method and system based on oblique photograph and GIS technology | |

| CN108801878A (en) | A kind of method of determining accumulation bulk granular material voidage | |

| JP5658613B2 (en) | Method and system for dividing particle size of granular material | |

| CN107368624A (en) | Aggregate particle model generation algorithm and Inhomogeneous charge material test specimen model generating method | |

| CN115965790A (en) | A point cloud filtering method for oblique photography based on cloth simulation algorithm | |

| CN115797288B (en) | Method for calculating filling and excavating amount based on ground point cloud data | |

| CN118052947B (en) | Method and device for establishing three-dimensional geographic model based on big data | |

| CN109388891A (en) | A kind of virtual extraction of drainage of super-large dimension and confluence method | |

| CN116630558B (en) | Pebble bed surface three-dimensional terrain reconstruction method based on underwater image | |

| CN116051741B (en) | A DEM refinement method based on pixel-level dense matching point cloud | |

| CN104656072B (en) | Optical-microwave common image resolution evaluation bar target and construction method thereof | |

| WO2023223282A1 (en) | Automated elevation adjustments using object identification on aerial images | |

| CN113446992B (en) | Method for optimizing distribution of topographic survey points in topographic survey |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |