CN115270309A - A fault simulation method, device and storage medium for a vehicle air spring gas circuit - Google Patents

A fault simulation method, device and storage medium for a vehicle air spring gas circuitDownload PDFInfo

- Publication number

- CN115270309A CN115270309ACN202210921724.4ACN202210921724ACN115270309ACN 115270309 ACN115270309 ACN 115270309ACN 202210921724 ACN202210921724 ACN 202210921724ACN 115270309 ACN115270309 ACN 115270309A

- Authority

- CN

- China

- Prior art keywords

- air

- simulation

- air spring

- fault

- sub

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F30/00—Computer-aided design [CAD]

- G06F30/10—Geometric CAD

- G06F30/15—Vehicle, aircraft or watercraft design

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F30/00—Computer-aided design [CAD]

- G06F30/10—Geometric CAD

- G06F30/17—Mechanical parametric or variational design

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F30/00—Computer-aided design [CAD]

- G06F30/20—Design optimisation, verification or simulation

- G06F30/28—Design optimisation, verification or simulation using fluid dynamics, e.g. using Navier-Stokes equations or computational fluid dynamics [CFD]

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F2113/00—Details relating to the application field

- G06F2113/08—Fluids

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F2119/00—Details relating to the type or aim of the analysis or the optimisation

- G06F2119/14—Force analysis or force optimisation, e.g. static or dynamic forces

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Geometry (AREA)

- Theoretical Computer Science (AREA)

- General Physics & Mathematics (AREA)

- Computer Hardware Design (AREA)

- Pure & Applied Mathematics (AREA)

- Mathematical Optimization (AREA)

- Mathematical Analysis (AREA)

- Evolutionary Computation (AREA)

- General Engineering & Computer Science (AREA)

- Computational Mathematics (AREA)

- Algebra (AREA)

- Computing Systems (AREA)

- Fluid Mechanics (AREA)

- Mathematical Physics (AREA)

- Automation & Control Theory (AREA)

- Aviation & Aerospace Engineering (AREA)

- Vehicle Body Suspensions (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本申请涉及车辆空簧气路技术领域,尤其是涉及一种车辆空簧气路的故障模拟方法、装置及存储介质。The present application relates to the technical field of vehicle air spring air circuits, and in particular to a fault simulation method, device and storage medium for vehicle air spring air circuits.

背景技术Background technique

空气悬架系统是以空气弹簧作为弹性元件的悬架总称,由于空气悬架具有良好的道路友好性,任意载荷下能够保持固有振动频率,因此获得了广泛的研究兴趣。而随着我国汽车工业发展,汽车在普通家庭越来越普及,人们对汽车的驾驶舒适性和操控性要求也越来越高,因此越来越多的配有空气悬架系统的汽车被开发生产。The air suspension system is a general term for the suspension with air springs as the elastic components. Because the air suspension has good road friendliness and can maintain the natural vibration frequency under any load, it has gained extensive research interest. With the development of my country's automobile industry, cars are becoming more and more popular in ordinary families, and people have higher and higher requirements for driving comfort and handling of cars. Therefore, more and more cars equipped with air suspension systems are being developed. Production.

目前,空气悬架系统应用广泛,已成功应用于客车、卡车、以及一些高档SUV和轿车上。而空气弹簧气路作为空气悬架系统中的重要组成部分,需要在进行车辆组装完成前,对其可能出现的故障进行确定。现有确定方法,通常是通过软件搭建空簧气路模型,然后模拟气路中的参数确定故障现象。但是这种方式所采用的所有参数均为计算和仿真结果,故存在故障现象判断不准确的问题。At present, the air suspension system is widely used and has been successfully applied to passenger cars, trucks, and some high-end SUVs and cars. As an important part of the air suspension system, the air spring circuit needs to determine its possible failures before the vehicle is assembled. The existing determination method is usually to build an air spring air circuit model through software, and then simulate the parameters in the air circuit to determine the fault phenomenon. However, all parameters used in this method are calculation and simulation results, so there is a problem of inaccurate judgment of fault phenomena.

发明内容Contents of the invention

有鉴于此,本申请的目的在于提供一种车辆空簧气路的故障模拟方法、装置及存储介质,通过软硬件协调配合的方式,可以真实的制造气路故障,从而提高了故障现象判断的准确性。In view of this, the purpose of this application is to provide a fault simulation method, device, and storage medium for a vehicle air spring air circuit. Through the coordination of software and hardware, it is possible to truly manufacture air circuit faults, thereby improving the accuracy of fault phenomenon judgment. accuracy.

本申请实施例提供了一种车辆空簧气路的故障模拟方法,所述故障模拟方法应用于车辆空簧气路的故障模拟装置,所述故障模拟装置分别与上位机和设置于实验台上的空簧模拟气路连接;所述空簧模拟气路包括气泵、组合阀和四个空簧模拟子气路;所述空簧模拟子气路包括第一电磁阀、流量传感器、压力传感器、空气弹簧、第二电磁阀和第三电磁阀;所述第一电磁阀连接到所述流量传感器,所述流量传感器连接到所述压力传感器,所述压力传感器连接到所述空气弹簧,所述空气弹簧连接到所述第二电磁阀,所述第二电磁阀连接到所述第三电磁阀;所述故障模拟方法包括:The embodiment of the present application provides a fault simulation method for a vehicle air spring air circuit. The fault simulation method is applied to a fault simulation device for a vehicle air spring air circuit. The empty spring simulated air circuit connection; the air spring simulated air circuit includes an air pump, a combination valve and four air spring simulated sub-air circuits; the air spring simulated sub-air circuit includes a first solenoid valve, a flow sensor, a pressure sensor, an air spring, a second solenoid valve and a third solenoid valve; the first solenoid valve is connected to the flow sensor, the flow sensor is connected to the pressure sensor, the pressure sensor is connected to the air spring, the The air spring is connected to the second solenoid valve, and the second solenoid valve is connected to the third solenoid valve; the fault simulation method includes:

接收上位机发送的故障模拟指令,响应于所述故障模拟指令中的检测指令,确定所述四个空簧模拟子气路中的每个空簧模拟子气路通过气体后的目标参数是否指示该空簧模拟子气路能够正常工作;Receive the fault simulation command sent by the host computer, respond to the detection command in the fault simulation command, determine whether the target parameter of each air spring simulation sub-gas circuit in the four air spring simulation sub-gas circuits after passing the gas indicates The empty spring simulates the sub-gas circuit to work normally;

若该空簧模拟子气路能够正常工作,则基于所述故障模拟指令中的故障模拟类型,对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障。If the air spring simulation sub-air circuit can work normally, then based on the fault simulation type in the fault simulation instruction, the first solenoid valve, the second solenoid valve and all the air spring simulation sub-air circuits in the air spring simulation sub-air circuit A corresponding one of the third solenoid valves is adjusted to generate a fault corresponding to the fault simulation type.

可选的,所述故障模拟类型包括以下项中的至少一项:气囊爆裂故障、气囊漏气故障和气管堵塞故障。Optionally, the failure simulation type includes at least one of the following items: an airbag burst failure, an airbag leakage failure, and a tracheal blockage failure.

可选的,当所述故障模拟类型包括气囊爆裂故障时,所述对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障,包括:Optionally, when the failure simulation type includes an airbag burst failure, the first solenoid valve, the second solenoid valve and the third solenoid valve in the air spring simulation sub-air circuit The solenoid valves are tuned to generate faults corresponding to the types of fault simulations described, including:

将该空簧模拟子气路中的第二电磁阀的开关状态由闭合状态更改为全开启状态,以使该空簧模拟子气路中的流量传感器测量到的当前气路流量值突变至第一流量阈值,同时使该空簧模拟子气路中的压力传感器测量到的当前气囊压力值突变至第一气压阈值,从而完成气囊爆裂故障模拟生成任务。Change the switch state of the second solenoid valve in the air spring simulation sub-air circuit from the closed state to the fully open state, so that the current air flow rate value measured by the flow sensor in the air spring simulation sub-air circuit changes suddenly to the first A flow threshold, and at the same time make the current airbag pressure value measured by the pressure sensor in the air spring simulation sub-airway suddenly change to the first air pressure threshold, so as to complete the airbag burst fault simulation generation task.

可选的,当所述故障模拟类型包括气囊漏气故障时,所述对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障,包括:Optionally, when the fault simulation type includes an air bag leakage fault, the first electromagnetic valve, the second electromagnetic valve, and the third electromagnetic valve in the air spring simulation sub-air circuit The corresponding solenoid valves are adjusted to generate faults corresponding to the types of fault simulations described, including:

响应于所述故障模拟指令中预设电磁阀开度,将该空簧模拟子气路中的第三电磁阀的开关状态由闭合状态打开所述预设电磁阀开度,以使该空簧模拟子气路中的流量传感器测量到的当前气路流量值逐渐变化至第一流量阈值,同时使该空簧模拟子气路中的压力传感器测量到的当前气囊压力值逐渐变化至第一气压阈值,完成气囊漏气故障模拟生成任务。In response to the preset solenoid valve opening in the fault simulation instruction, the switch state of the third solenoid valve in the empty spring simulation sub-air circuit is opened from the closed state to open the preset solenoid valve opening, so that the empty spring The current flow value of the air path measured by the flow sensor in the simulated sub-air path gradually changes to the first flow threshold, and at the same time, the current airbag pressure value measured by the pressure sensor in the air spring simulated sub-air path gradually changes to the first air pressure Threshold, to complete the airbag leak fault simulation generation task.

可选的,当所述故障模拟类型包括气管堵塞故障时,所述对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障,包括:Optionally, when the failure simulation type includes a trachea blockage failure, the first solenoid valve, the second solenoid valve and the third solenoid valve in the air spring simulation sub-air circuit The solenoid valves are tuned to generate faults corresponding to the types of fault simulations described, including:

将该空簧模拟子气路中的所述第一电磁阀的开关状态由开启状态更改为闭合状态,以使该空簧模拟子气路中的流量传感器测量到的当前气路流量值不变,同时使该空簧模拟子气路中的压力传感器测量到的当前气囊压力值突变至第二气压阈值,完成气管堵塞故障模拟生成任务。Change the switching state of the first electromagnetic valve in the air spring simulation sub-air circuit from the open state to the closed state, so that the current air flow flow value measured by the flow sensor in the air spring simulation sub-air circuit remains unchanged , and at the same time make the current air bag pressure value measured by the pressure sensor in the air spring simulation sub-air circuit suddenly change to the second air pressure threshold value, and complete the task of tracheal blockage fault simulation generation.

可选的,所述确定所述四个空簧模拟子气路中的每个空簧模拟子气路通过气体后的目标参数是否指示该空簧模拟子气路能够正常工作,包括:Optionally, determining whether the target parameter of each air spring simulation sub-air circuit in the four air spring simulation sub-air circuits after passing through the gas indicates that the air spring simulation sub-air circuit can work normally, including:

针对每个空簧模拟子气路,确定该空簧模拟子气路中流量传感器检测到的当前气路流量值是否为第二流量阈值,以及该空簧模拟子气路中气压传感器检测到的当前气囊压力值是否为第三气体压力阈值;For each air spring simulation sub-air circuit, determine whether the current air flow flow value detected by the flow sensor in the air spring simulation sub-air circuit is the second flow threshold value, and whether the air pressure sensor in the air spring simulation sub-air circuit detects the Whether the current airbag pressure value is the third gas pressure threshold;

当两者均为是时,确定该空簧模拟子气路能够正常工作;When both are yes, it is determined that the air spring simulation sub-air circuit can work normally;

当任一者为否时,确定该空簧模拟子气路不能够正常工作。When any one is negative, it is determined that the air spring simulation sub-air circuit cannot work normally.

可选的,在基于所述故障模拟指令中的故障模拟类型,对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障之后,所述故障模拟方法还包括:Optionally, based on the fault simulation type in the fault simulation instruction, simulate the first solenoid valve, the second solenoid valve, and the third solenoid valve in the sub-air circuit for the air spring. After the solenoid valve is adjusted to generate a fault corresponding to the fault simulation type, the fault simulation method further includes:

对基于故障模拟类型更改电磁阀的开关状态后的该空簧模拟子气路通过气体后的目标参数进行识别,根据识别结果确定该空簧模拟子气路中是否产生与所述故障模拟指令中的故障模拟类型相同的故障;其中,每种故障模拟类型均预先设置有与之相对应目标参数;Identify the target parameters of the air spring simulation sub-gas circuit after the air passes through the gas after changing the switching state of the solenoid valve based on the fault simulation type, and determine whether the air spring simulation sub-gas circuit is different from that in the fault simulation command according to the identification result. Faults with the same type of fault simulation; each fault simulation type is preset with corresponding target parameters;

当为是时,控制该空簧模拟子气路中已更改开关状态的电磁阀恢复至更改前的开关状态。When yes, the electromagnetic valve that controls the changed switch state in the air spring analog sub-air circuit returns to the switch state before the change.

可选的,所述目标参数包括以下项中的至少一项:气路流量和气囊压力。Optionally, the target parameters include at least one of the following items: air flow and air bag pressure.

本申请实施例还提供了一种车辆空簧气路的故障模拟装置,所述故障模拟装置分别与上位机和设置于实验台上的空簧模拟气路连接;所述空簧模拟气路包括气泵、组合阀和四个空簧模拟子气路;所述空簧模拟子气路包括第一电磁阀、流量传感器、压力传感器、空气弹簧、第二电磁阀和第三电磁阀;所述第一电磁阀连接到所述流量传感器,所述流量传感器连接到所述压力传感器,所述压力传感器连接到所述空气弹簧,所述空气弹簧连接到所述第二电磁阀,所述第二电磁阀连接到所述第三电磁阀;所述故障模拟装置包括:The embodiment of the present application also provides a fault simulation device for the air spring air circuit of a vehicle, the fault simulation device is respectively connected with the upper computer and the air spring simulation air circuit provided on the test bench; the air spring simulation air circuit includes An air pump, a combination valve and four air spring simulation sub-air circuits; the air spring simulation sub-air circuit includes a first solenoid valve, a flow sensor, a pressure sensor, an air spring, a second solenoid valve and a third solenoid valve; the first solenoid valve A solenoid valve is connected to the flow sensor, the flow sensor is connected to the pressure sensor, the pressure sensor is connected to the air spring, the air spring is connected to the second solenoid valve, the second solenoid valve The valve is connected to the third solenoid valve; the fault simulation device includes:

确定模块,用于接收上位机发送的故障模拟指令,响应于所述故障模拟指令中的检测指令,确定所述四个空簧模拟子气路中的每个空簧模拟子气路通过气体后的目标参数是否指示该空簧模拟子气路能够正常工作;The determination module is used to receive the fault simulation command sent by the host computer, and in response to the detection command in the fault simulation command, determine that each of the four empty spring simulated sub-air circuits passes through the gas. Whether the target parameter indicates that the air spring simulation sub-air circuit can work normally;

调整模块,用于若该空簧模拟子气路能够正常工作,则基于所述故障模拟指令中的故障模拟类型,对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障。The adjustment module is used to, if the air spring simulation sub-air circuit can work normally, based on the fault simulation type in the fault simulation instruction, the first solenoid valve, the second electromagnetic valve, and the second solenoid valve in the air spring simulation sub-air circuit can be operated normally. Corresponding solenoid valves of the second solenoid valve and the third solenoid valve are adjusted to generate a fault corresponding to the fault simulation type.

可选的,所述故障模拟类型包括以下项中的至少一项:气囊爆裂故障、气囊漏气故障和气管堵塞故障。Optionally, the failure simulation type includes at least one of the following items: an airbag burst failure, an airbag leakage failure, and a tracheal blockage failure.

可选的,当所述故障模拟类型包括气囊爆裂故障时,所述调整模块在用于对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障时,所述调整模块用于:Optionally, when the failure simulation type includes an airbag burst failure, the adjustment module is used to simulate the first solenoid valve, the second solenoid valve and the second solenoid valve in the sub-air circuit for the air spring. When the corresponding solenoid valve in the three solenoid valves is adjusted to generate a fault corresponding to the fault simulation type, the adjustment module is used for:

将该空簧模拟子气路中的第二电磁阀的开关状态由闭合状态更改为全开启状态,以使该空簧模拟子气路中的流量传感器测量到的当前气路流量值突变至第一流量阈值,同时使该空簧模拟子气路中的压力传感器测量到的当前气囊压力值突变至第一气压阈值,从而完成气囊爆裂故障模拟生成任务。Change the switch state of the second solenoid valve in the air spring simulation sub-air circuit from the closed state to the fully open state, so that the current air flow rate value measured by the flow sensor in the air spring simulation sub-air circuit changes suddenly to the first A flow threshold, and at the same time make the current airbag pressure value measured by the pressure sensor in the air spring simulation sub-airway suddenly change to the first air pressure threshold, so as to complete the airbag burst fault simulation generation task.

可选的,当所述故障模拟类型包括气囊漏气故障时,所述调整模块在用于对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障时,所述调整模块用于:Optionally, when the fault simulation type includes an air bag leakage fault, the adjustment module is used to simulate the first solenoid valve, the second solenoid valve and the When the corresponding solenoid valve in the third solenoid valve is adjusted to generate a fault corresponding to the fault simulation type, the adjustment module is used for:

响应于所述故障模拟指令中预设电磁阀开度,将该空簧模拟子气路中的第三电磁阀的开关状态由闭合状态打开所述预设电磁阀开度,以使该空簧模拟子气路中的流量传感器测量到的当前气路流量值逐渐变化至第一流量阈值,同时使该空簧模拟子气路中的压力传感器测量到的当前气囊压力值逐渐变化至第一气压阈值,完成气囊漏气故障模拟生成任务。In response to the preset solenoid valve opening in the fault simulation instruction, the switch state of the third solenoid valve in the empty spring simulation sub-air circuit is opened from the closed state to open the preset solenoid valve opening, so that the empty spring The current flow value of the air path measured by the flow sensor in the simulated sub-air path gradually changes to the first flow threshold, and at the same time, the current airbag pressure value measured by the pressure sensor in the air spring simulated sub-air path gradually changes to the first air pressure Threshold, to complete the airbag leak fault simulation generation task.

可选的,当所述故障模拟类型包括气管堵塞故障时,所述调整模块在用于对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障时,所述调整模块用于:Optionally, when the failure simulation type includes a tracheal blockage failure, the adjustment module is used to simulate the first solenoid valve, the second solenoid valve and the second solenoid valve in the sub-air circuit for the air spring. When the corresponding solenoid valve in the three solenoid valves is adjusted to generate a fault corresponding to the fault simulation type, the adjustment module is used for:

将该空簧模拟子气路中的所述第一电磁阀的开关状态由开启状态更改为闭合状态,以使该空簧模拟子气路中的流量传感器测量到的当前气路流量值不变,同时使该空簧模拟子气路中的压力传感器测量到的当前气囊压力值突变至第二气压阈值,完成气管堵塞故障模拟生成任务。Change the switching state of the first electromagnetic valve in the air spring simulation sub-air circuit from the open state to the closed state, so that the current air flow flow value measured by the flow sensor in the air spring simulation sub-air circuit remains unchanged , and at the same time make the current air bag pressure value measured by the pressure sensor in the air spring simulation sub-air circuit suddenly change to the second air pressure threshold value, and complete the task of tracheal blockage fault simulation generation.

可选的,所述确定模块在用于确定所述四个空簧模拟子气路中的每个空簧模拟子气路通过气体后的目标参数是否指示该空簧模拟子气路能够正常工作时,所述确定模块用于:Optionally, the determining module is used to determine whether the target parameter of each of the four air spring simulation sub-air circuits after passing through the gas indicates that the air spring simulation sub-air circuits can work normally When, the determination module is used for:

针对每个空簧模拟子气路,确定该空簧模拟子气路中流量传感器检测到的当前气路流量值是否为第二流量阈值,以及该空簧模拟子气路中气压传感器检测到的当前气囊压力值是否为第三气体压力阈值;For each air spring simulation sub-air circuit, determine whether the current air flow flow value detected by the flow sensor in the air spring simulation sub-air circuit is the second flow threshold value, and whether the air pressure sensor in the air spring simulation sub-air circuit detects the Whether the current airbag pressure value is the third gas pressure threshold;

当两者均为是时,确定该空簧模拟子气路能够正常工作;When both are yes, it is determined that the air spring simulation sub-air circuit can work normally;

当任一者为否时,确定该空簧模拟子气路不能够正常工作。When any one is negative, it is determined that the air spring simulation sub-air circuit cannot work normally.

可选的,所述故障模拟装置还包括恢复模块,所述恢复模块用于:Optionally, the fault simulation device also includes a recovery module, and the recovery module is used for:

对基于故障模拟类型更改电磁阀的开关状态后的该空簧模拟子气路通过气体后的目标参数进行识别,根据识别结果确定该空簧模拟子气路中是否产生与所述故障模拟指令中的故障模拟类型相同的故障;其中,每种故障模拟类型均预先设置有与之相对应目标参数;Identify the target parameters of the air spring simulation sub-gas circuit after the air passes through the gas after changing the switching state of the solenoid valve based on the fault simulation type, and determine whether the air spring simulation sub-gas circuit is different from that in the fault simulation command according to the identification result. Faults with the same type of fault simulation; each fault simulation type is preset with corresponding target parameters;

当为是时,控制该空簧模拟子气路中已更改开关状态的电磁阀恢复至更改前的开关状态。When yes, the electromagnetic valve that controls the changed switch state in the air spring analog sub-air circuit returns to the switch state before the change.

可选的,所述目标参数包括以下项中的至少一项:气路流量和气囊压力。Optionally, the target parameters include at least one of the following items: air flow and air bag pressure.

本申请实施例还提供一种电子设备,包括:处理器、存储器和总线,所述存储器存储有所述处理器可执行的机器可读指令,当电子设备运行时,所述处理器与所述存储器之间通过总线通信,所述机器可读指令被所述处理器执行时执行如上述的故障模拟方法的步骤。The embodiment of the present application also provides an electronic device, including: a processor, a memory, and a bus, the memory stores machine-readable instructions executable by the processor, and when the electronic device is running, the processor and the The memories communicate through the bus, and when the machine-readable instructions are executed by the processor, the steps of the above fault simulation method are executed.

本申请实施例还提供一种计算机可读存储介质,该计算机可读存储介质上存储有计算机程序,该计算机程序被处理器运行时执行如上述的故障模拟方法的步骤。The embodiment of the present application also provides a computer-readable storage medium, on which a computer program is stored, and when the computer program is run by a processor, the steps of the above fault simulation method are executed.

本申请实施例提供的一种车辆空簧气路的故障模拟方法、装置及存储介质,所述故障模拟方法应用于车辆空簧气路的故障模拟装置,所述故障模拟装置分别与上位机和设置于实验台上的空簧模拟气路连接;所述空簧模拟气路包括气泵、组合阀和四个空簧模拟子气路;所述空簧模拟子气路包括第一电磁阀、流量传感器、压力传感器、空气弹簧、第二电磁阀和第三电磁阀;所述第一电磁阀连接到所述流量传感器,所述流量传感器连接到所述压力传感器,所述压力传感器连接到所述空气弹簧,所述空气弹簧连接到所述第二电磁阀,所述第二电磁阀连接到所述第三电磁阀;所述故障模拟方法包括:接收上位机发送的故障模拟指令,响应于所述故障模拟指令中的检测指令,确定所述四个空簧模拟子气路中的每个空簧模拟子气路通过气体后的目标参数是否指示该空簧模拟子气路能够正常工作;若该空簧模拟子气路能够正常工作,则基于所述故障模拟指令中的故障模拟类型,对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障。The embodiment of the present application provides a fault simulation method, device and storage medium of a vehicle air spring air circuit. The fault simulation method is applied to a fault simulation device of a vehicle air spring air circuit, and the fault simulation device is connected with the host computer and the The air spring simulation air circuit connection provided on the test bench; the air spring simulation air circuit includes an air pump, a combination valve and four air spring simulation sub-air circuits; the air spring simulation sub-air circuit includes a first solenoid valve, a flow rate sensor, pressure sensor, air spring, second solenoid valve and third solenoid valve; the first solenoid valve is connected to the flow sensor, the flow sensor is connected to the pressure sensor, and the pressure sensor is connected to the An air spring, the air spring is connected to the second solenoid valve, and the second solenoid valve is connected to the third solenoid valve; the fault simulation method includes: receiving a fault simulation command sent by the host computer, responding to the The detection instruction in the above fault simulation instruction determines whether the target parameter after each air spring simulation sub-air circuit in the four air spring simulation sub-air circuits passes through the gas indicates that the air spring simulation sub-air circuit can work normally; if If the air spring simulation sub-air circuit can work normally, then based on the fault simulation type in the fault simulation instruction, the first solenoid valve, the second solenoid valve and the A corresponding one of the third solenoid valves is adjusted to generate a fault corresponding to the fault simulation type.

这样,通过本申请提供的方法,通过软硬件协调配合的方式,可以在真实的制造气路故障,从而提高了故障现象判断的准确性。并且通过模拟气路故障从而优化软件仿真无法实现的功能。In this way, through the method provided in the present application, through the coordination and cooperation of software and hardware, gas path faults can be actually produced, thereby improving the accuracy of fault phenomenon judgment. And by simulating gas path failures, functions that cannot be realized by software simulation are optimized.

为使本申请的上述目的、特征和优点能更明显易懂,下文特举较佳实施例,并配合所附附图,作详细说明如下。In order to make the above-mentioned purpose, features and advantages of the present application more comprehensible, preferred embodiments will be described in detail below together with the accompanying drawings.

附图说明Description of drawings

为了更清楚地说明本申请实施例的技术方案,下面将对实施例中所需要使用的附图作简单地介绍,应当理解,以下附图仅示出了本申请的某些实施例,因此不应被看作是对范围的限定,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他相关的附图。In order to more clearly illustrate the technical solutions of the embodiments of the present application, the following will briefly introduce the accompanying drawings used in the embodiments. It should be understood that the following drawings only show some embodiments of the present application, so It should be regarded as a limitation on the scope, and those skilled in the art can also obtain other related drawings based on these drawings without creative work.

图1为本申请实施例所提供的一种车辆空簧气路的故障模拟方法的流程图;FIG. 1 is a flow chart of a fault simulation method for a vehicle air spring air circuit provided in an embodiment of the present application;

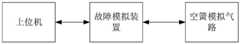

图2为本申请提供的故障模拟装置与上位机及空簧模拟气路连接方式的结构示意图;Fig. 2 is the schematic diagram of the structure of the failure simulation device provided by the application, the upper computer and the air spring simulation air circuit connection mode;

图3为本申请提供的空簧模拟气路的结构示意图;Fig. 3 is the structural representation of the air spring simulation air circuit provided by the present application;

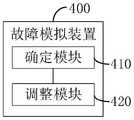

图4为本申请实施例所提供的一种车辆空簧气路的故障模拟装置的结构示意图之一;FIG. 4 is one of the structural schematic diagrams of a fault simulation device for an air spring circuit of a vehicle provided by an embodiment of the present application;

图5为本申请实施例所提供的一种车辆空簧气路的故障模拟装置的结构示意图之二;Fig. 5 is the second structural schematic diagram of a fault simulation device for a vehicle air spring air circuit provided by the embodiment of the present application;

图6为本申请实施例所提供的一种电子设备的结构示意图。FIG. 6 is a schematic structural diagram of an electronic device provided by an embodiment of the present application.

具体实施方式Detailed ways

为使本申请实施例的目的、技术方案和优点更加清楚,下面将结合本申请实施例中附图,对本申请实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本申请一部分实施例,而不是全部的实施例。通常在此处附图中描述和示出的本申请实施例的组件可以以各种不同的配置来布置和设计。因此,以下对在附图中提供的本申请的实施例的详细描述并非旨在限制要求保护的本申请的范围,而是仅仅表示本申请的选定实施例。基于本申请的实施例,本领域技术人员在没有做出创造性劳动的前提下所获得的每个其他实施例,都属于本申请保护的范围。In order to make the purpose, technical solutions and advantages of the embodiments of the present application clearer, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application. Obviously, the described embodiments are only It is a part of the embodiments of this application, not all of them. The components of the embodiments of the application generally described and illustrated in the figures herein may be arranged and designed in a variety of different configurations. Accordingly, the following detailed description of the embodiments of the application provided in the accompanying drawings is not intended to limit the scope of the claimed application, but merely represents selected embodiments of the application. Based on the embodiments of the present application, every other embodiment obtained by those skilled in the art without making creative efforts falls within the protection scope of the present application.

目前,空气悬架系统应用广泛,已成功应用于客车、卡车、以及一些高档SUV和轿车上。而空气弹簧气路作为空气悬架系统中的重要组成部分,需要在进行车辆组装完成前,对其可能出现的故障进行确定。现有确定方法,通常是通过软件搭建空簧气路模型,然后模拟气路中的参数确定故障现象。但是这种方式所采用的所有参数均为计算和仿真结果,故存在故障现象判断不准确的问题。At present, the air suspension system is widely used and has been successfully applied to passenger cars, trucks, and some high-end SUVs and cars. As an important part of the air suspension system, the air spring circuit needs to determine its possible failures before the vehicle is assembled. The existing determination method is usually to build an air spring air circuit model through software, and then simulate the parameters in the air circuit to determine the fault phenomenon. However, all parameters used in this method are calculation and simulation results, so there is a problem of inaccurate judgment of fault phenomena.

基于此,本申请实施例提供了一种车辆空簧气路的故障模拟方法,通过软硬件协调配合的方式,可以在真实的制造气路故障,从而提高了故障现象判断的准确性。Based on this, the embodiment of the present application provides a fault simulation method for the air spring circuit of a vehicle. Through the coordination of software and hardware, the fault of the gas circuit can be actually produced, thereby improving the accuracy of fault phenomenon judgment.

请参阅图1,图1为本申请实施例所提供的一种车辆空簧气路的故障模拟方法的流程图。这里,所述故障模拟方法可应用于车辆空簧气路的故障模拟装置,所述故障模拟装置分别与上位机和设置于实验台上的空簧模拟气路连接;所述空簧模拟气路包括气泵、组合阀和四个空簧模拟子气路;所述空簧模拟子气路包括第一电磁阀、流量传感器、压力传感器、空气弹簧、第二电磁阀和第三电磁阀;所述第一电磁阀连接到所述流量传感器,所述流量传感器连接到所述压力传感器,所述压力传感器连接到所述空气弹簧,所述空气弹簧连接到所述第二电磁阀,所述第二电磁阀连接到所述第三电磁阀;Please refer to FIG. 1 . FIG. 1 is a flow chart of a method for simulating a fault of a vehicle air spring air circuit according to an embodiment of the present application. Here, the fault simulation method can be applied to the fault simulation device of the air spring air circuit of the vehicle, and the fault simulation device is respectively connected with the upper computer and the air spring simulation air circuit arranged on the test bench; the air spring simulation air circuit It includes an air pump, a combination valve and four air spring simulation sub-air circuits; the air spring simulation sub-air circuit includes a first solenoid valve, a flow sensor, a pressure sensor, an air spring, a second solenoid valve and a third solenoid valve; the The first solenoid valve is connected to the flow sensor, the flow sensor is connected to the pressure sensor, the pressure sensor is connected to the air spring, the air spring is connected to the second solenoid valve, the second a solenoid valve connected to the third solenoid valve;

所述车辆空簧气路的故障模拟装置是用于控制、协调所述空簧模拟气路中每个可控器件工作的控制器,控制器具体可以为DSP、单片机等器件。The fault simulation device of the air spring air circuit of the vehicle is a controller for controlling and coordinating the work of each controllable device in the air spring simulated air circuit, and the controller may specifically be a DSP, a single-chip microcomputer and other devices.

所述上位机用于通过故障模拟装置接收空簧模拟气路的运行状态,还用于向故障模拟装置发送控制指令,所发送的控制指令可以包括故障模拟指令。所述空簧模拟气路是在实验台上通过多实体硬件搭建成可用于汽车上的实体气路。The host computer is used to receive the operating status of the air spring simulation air circuit through the fault simulation device, and is also used to send control instructions to the fault simulation device, and the sent control instructions may include fault simulation instructions. The air spring simulated air circuit is built on the test bench through multi-entity hardware to form a physical air circuit that can be used in automobiles.

示例的,请参阅图2,图2为本申请提供的故障模拟装置与上位机及空簧模拟气路连接方式的结构示意图。如图2所示,故障模拟装置可用于对空簧模拟气路的状态进行识别,并将识别到的信息反馈给上位机;所述故障模拟装置还用于接收上位机发送的指令,并根据接收到的指令控制空簧模拟气路中的器件按接收到的指令的要求工作。For an example, please refer to Fig. 2, which is a structural schematic diagram of the fault simulation device provided by the present application, the upper computer and the air spring simulation air circuit connection method. As shown in Figure 2, the fault simulation device can be used to identify the state of the air spring simulation air circuit, and feed back the identified information to the host computer; the fault simulation device is also used to receive instructions sent by the host computer, and according to The received instructions control the devices in the air spring simulation air circuit to work according to the requirements of the received instructions.

这里,所述空簧模拟气路中包括的气泵、组合阀和四个空簧模拟子气路之间的连接方式为:所述气泵连接到所述组合阀,所述组合阀分别与四个空簧模拟子气路。其中,四个空簧模拟子气路中所采用的器件均相同,四个空簧模拟子气路对应于车辆四个轮胎的安装位置。Here, the connection mode between the air pump, the combination valve and the four air spring simulation sub-air circuits included in the air spring simulation air circuit is as follows: the air pump is connected to the combination valve, and the combination valve is connected to the four valves respectively. The empty spring simulates the sub-air path. Among them, the devices used in the four air spring simulation sub-air circuits are the same, and the four air spring simulation sub-air circuits correspond to the installation positions of the four tires of the vehicle.

示例的,请参阅图3,图3为本申请提供的空簧模拟气路的结构示意图。如图3所示,每个虚线框围成的气路为一个空簧模拟子气路,每个空簧模拟子气路均是由第一电磁阀、流量传感器、压力传感器、空气弹簧、第二电磁阀和第三电磁阀互相连接构成,其中图3中a代表第一电磁阀,b代表流量传感器,c代表压力传感器,d代表空气弹簧,e代表第二电磁阀,f代表第三电磁阀。所述组合阀中设置有一个进气端,四个出气端,四个出气端分别与四个空簧模拟子气路连接,用于将气泵输入的气体传输至四个子气路中。For an example, please refer to FIG. 3 , which is a schematic structural diagram of the air spring simulation air circuit provided by the present application. As shown in Figure 3, the air circuit enclosed by each dotted line frame is an air spring simulation sub-air circuit, and each air spring simulation sub-air circuit is composed of the first electromagnetic valve, flow sensor, pressure sensor, air spring, second The two solenoid valves and the third solenoid valve are connected to each other, where in Figure 3, a represents the first solenoid valve, b represents the flow sensor, c represents the pressure sensor, d represents the air spring, e represents the second solenoid valve, and f represents the third solenoid valve. valve. The combined valve is provided with one inlet port, four gas outlet ports, and the four gas outlet ports are respectively connected to four air spring analog sub-air circuits, and are used to transmit the gas input by the air pump to the four sub-air circuits.

如图1中所示,本申请实施例提供的故障模拟方法,包括:As shown in Figure 1, the fault simulation method provided by the embodiment of the present application includes:

S101、接收上位机发送的故障模拟指令,响应于所述故障模拟指令中的检测指令,确定所述四个空簧模拟子气路中的每个空簧模拟子气路通过气体后的目标参数是否指示该空簧模拟子气路能够正常工作。S101. Receive the fault simulation command sent by the host computer, and determine the target parameters of each of the four empty spring simulated sub-gas circuits after passing through the gas in response to the detection command in the fault simulated command Whether it indicates that the air spring analog sub-airway can work normally.

这里,上位机发送的故障模拟指令可由测试人员进行自主设置,并通过上位机将故障模拟指令发送给故障模拟装置。故障模拟装置接收到故障模拟指令后,根据故障模拟指令中的检测指令,分别对四个空簧模拟子气路中的每个空簧模拟子气路通过气体后的目标参数进行识别,根据空簧模拟子气路通过气体后的目标参数确定该空簧模拟子气路是否能够正常工作,这样就可以确定每个空簧模拟子气路是否能够正常工作。Here, the fault simulation command sent by the host computer can be independently set by the tester, and the fault simulation command is sent to the fault simulation device through the host computer. After the fault simulation device receives the fault simulation command, according to the detection command in the fault simulation command, the target parameters of each of the four air spring simulation sub-air circuits after passing through the gas are identified respectively, and according to the air The target parameters after the spring simulation sub-gas circuit passes through the gas determine whether the empty spring simulation sub-gas circuit can work normally, so that it can be determined whether each empty spring simulation sub-gas circuit can work normally.

所述目标参数包括以下项中的至少一项:气路流量和气囊压力。The target parameters include at least one of the following items: gas path flow and air bag pressure.

其中,当任一空簧模拟子气路不能够正常工作时,认为空簧模拟气路不能正常工作,存在故障。空簧模拟气路也就是空气弹簧模拟气路。Wherein, when any air spring simulation sub-air circuit cannot work normally, it is considered that the air spring simulation air circuit cannot work normally and there is a fault. The air spring simulation air circuit is also the air spring simulation air circuit.

在本申请提供的一种实施方式中,所述确定所述四个空簧模拟子气路中的每个空簧模拟子气路通过气体后的目标参数是否指示该空簧模拟子气路能够正常工作,包括:针对每个空簧模拟子气路,确定该空簧模拟子气路中流量传感器检测到的当前气路流量值是否为第二流量阈值,以及该空簧模拟子气路中气压传感器检测到的当前气囊压力值是否为第三气体压力阈值;当两者均为是时,确定该空簧模拟子气路能够正常工作;当任一者为否时,确定该空簧模拟子气路不能够正常工作。In an embodiment provided by the present application, the determination of whether the target parameter after each air spring simulation sub-air passage in the four air spring simulation sub-air passages passes through the gas indicates that the air spring simulation sub-air passages can Normal operation, including: for each air spring simulation sub-air circuit, determine whether the current air flow flow value detected by the flow sensor in the air spring simulation sub-air circuit is the second flow threshold, and determine whether the air spring simulation sub-air circuit Whether the current air bag pressure value detected by the air pressure sensor is the third gas pressure threshold; when both are yes, it is determined that the air spring simulation sub-air circuit can work normally; when either is no, it is determined that the air spring simulation The sub air circuit cannot work normally.

这里,所述第二流量阈值和所述第三气体压力阈值可基于实验需求或者车辆实际的运行状况,预先设定。Here, the second flow threshold and the third gas pressure threshold may be preset based on experimental requirements or actual vehicle operating conditions.

示例的,所述第二流量阈值可设置为0ml/h,所述第三气体压力阈值可设置为6bar。For example, the second flow threshold may be set to 0ml/h, and the third gas pressure threshold may be set to 6bar.

S102、若该空簧模拟子气路能够正常工作,则基于所述故障模拟指令中的故障模拟类型,对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障。S102. If the air spring simulation sub-air circuit can work normally, based on the fault simulation type in the fault simulation instruction, the first solenoid valve and the second solenoid valve in the air spring simulation sub-air circuit Adjusting with a corresponding one of the third solenoid valves to generate a fault corresponding to the fault simulation type.

这里,上位机发送的故障模拟指令可对四个空簧模拟子气路中一个空簧模拟子气路进行故障生成控制,也可以对四个空簧模拟子气路中的多个或全部空簧模拟子气路进行故障生成控制。Here, the fault simulation command sent by the host computer can control the fault generation of one of the four air spring simulation sub-air circuits, or control multiple or all of the four air spring simulation sub-air circuits. The spring simulates the sub-air circuit for fault generation control.

其中,不同故障模拟类型对应控制不同的电磁阀。Among them, different fault simulation types correspond to control different solenoid valves.

所述故障模拟类型包括以下项中的至少一项:气囊爆裂故障、气囊漏气故障和气管堵塞故障。The failure simulation type includes at least one of the following items: an airbag burst failure, an airbag leakage failure and a tracheal blockage failure.

在本申请提供的一种实施方式中,当所述故障模拟类型包括气囊爆裂故障时,所述对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障,包括:将该空簧模拟子气路中的第二电磁阀的开关状态由闭合状态更改为全开启状态,以使该空簧模拟子气路中的流量传感器测量到的当前气路流量值突变至第一流量阈值,同时使该空簧模拟子气路中的压力传感器测量到的当前气囊压力值突变至第一气压阈值,从而完成气囊爆裂故障模拟生成任务。In one embodiment provided by the present application, when the failure simulation type includes an airbag burst failure, the first solenoid valve, the second solenoid valve and the Adjust the corresponding solenoid valve in the third solenoid valve to generate a fault corresponding to the fault simulation type, including: changing the switch state of the second solenoid valve in the air spring simulation sub-air circuit from the closed state to the full state Open state, so that the current air flow value measured by the flow sensor in the air spring simulation sub-air circuit changes to the first flow threshold, and at the same time make the air bag pressure measured by the pressure sensor in the air spring simulation sub-air circuit The value suddenly changes to the first air pressure threshold, so as to complete the airbag burst fault simulation generation task.

这里,所述第一流量阈值和所述第一气压阈值是根据实际实验情况预先设定好的,所述第一气压阈值一般取当前实验条件下的大气压值。Here, the first flow threshold and the first air pressure threshold are preset according to actual experimental conditions, and the first air pressure threshold generally takes the atmospheric pressure value under the current experimental conditions.

其中,在更改第二电磁阀的开关状态前,所述空簧模拟气路是正常工作的,也就是说每个空簧模拟子气路中的流量传感器检测到的当前气路流量值为第二流量阈值,同时气压传感器检测到的当前气囊压力值为第三气体压力阈值。Wherein, before changing the switch state of the second electromagnetic valve, the air spring analog air circuit is working normally, that is to say, the current air flow flow value detected by the flow sensor in each air spring analog sub-air circuit is the first The second flow threshold, and the current airbag pressure value detected by the air pressure sensor is the third gas pressure threshold.

因此,将该空簧模拟子气路中的第二电磁阀的开关状态由闭合状态更改为全开启状态,该空簧模拟子气路中的流量传感器测量到的当前气路流量值由第二流量阈值突变至第一流量阈值,同时该空簧模拟子气路中的压力传感器测量到的当前气囊压力值由第三气体压力阈值突变至第一气压阈值,这样也就完成了气囊爆裂故障模拟生成任务。Therefore, the switch state of the second electromagnetic valve in the air spring simulation sub-air circuit is changed from the closed state to the fully open state, and the current flow value of the air circuit measured by the flow sensor in the air spring simulation sub-air circuit is determined by the second solenoid valve. The flow threshold suddenly changes to the first flow threshold, and at the same time, the current airbag pressure value measured by the pressure sensor in the air spring simulation sub-airway changes from the third gas pressure threshold to the first air pressure threshold, thus completing the airbag burst failure simulation Generate tasks.

示例的,当根据气囊爆裂故障时的指令,将空簧模拟子气路中的第二电磁阀的开关状态由闭合状态更改为全开启状态后,流量传感器示数由默认0值突变到176ml/h以上,压力传感器示数由当前标准弹簧压力值6bar突变为等同大气压力值1bar。For example, when the switch state of the second electromagnetic valve in the air spring simulation sub-air circuit is changed from closed state to fully open state according to the instruction when the air bag bursts, the flow sensor reading changes from the default value of 0 to 176ml/ h and above, the reading of the pressure sensor changes from the current standard spring pressure value of 6 bar to the equivalent atmospheric pressure value of 1 bar.

在本申请提供的另一种实施方式中,当所述故障模拟类型包括气囊漏气故障时,所述对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障,包括:响应于所述故障模拟指令中预设电磁阀开度,将该空簧模拟子气路中的第三电磁阀的开关状态由闭合状态打开所述预设电磁阀开度,以使该空簧模拟子气路中的流量传感器测量到的当前气路流量值逐渐变化至第一流量阈值,同时使该空簧模拟子气路中的压力传感器测量到的当前气囊压力值逐渐变化至第一气压阈值,完成气囊漏气故障模拟生成任务。In another embodiment provided by the present application, when the fault simulation type includes an air bag leakage fault, the first solenoid valve and the second solenoid valve in the air spring simulation sub-air circuit Adjusting the corresponding solenoid valve in the third solenoid valve to generate a fault corresponding to the fault simulation type, including: responding to the preset solenoid valve opening degree in the fault simulation command, the empty spring simulation sub The switching state of the third solenoid valve in the air path is changed from the closed state to open the preset solenoid valve opening, so that the current flow value of the air path measured by the flow sensor in the air spring simulation sub-air path gradually changes to the first At the same time, the current airbag pressure value measured by the pressure sensor in the air spring simulation sub-airway is gradually changed to the first air pressure threshold value to complete the airbag leak fault simulation generation task.

这里,所述第三电磁阀可采用比例电磁阀,这样可根据实际实验要求控制电磁阀的开度,从而实现气囊漏气的故障现象。其中,当发送的故障模拟指令中指令的故障模型类型为气囊漏气故障时,所述故障模拟指令中还携带有控制第三电磁阀开启的电磁阀开度信息,以使故障模拟装置按所述预设电磁阀开度打开第三电磁阀。Here, the third solenoid valve can be a proportional solenoid valve, so that the opening of the solenoid valve can be controlled according to actual experimental requirements, so as to realize the fault phenomenon of air bag leakage. Wherein, when the fault model type of the command sent in the fault simulation command is an air bag leakage fault, the fault simulation command also carries the solenoid valve opening information for controlling the opening of the third solenoid valve, so that the fault simulation device can operate according to the specified The preset solenoid valve opening degree opens the third solenoid valve.

其中,在更改第三电磁阀的开关状态前,所述空簧模拟气路是正常工作的,也就是说每个空簧模拟子气路中的流量传感器检测到的当前气路流量值为第二流量阈值,同时气压传感器检测到的当前气囊压力值为第三气体压力阈值。Wherein, before changing the switch state of the third electromagnetic valve, the air spring analog air circuit is working normally, that is to say, the current air flow flow value detected by the flow sensor in each air spring analog sub-air circuit is the first The second flow threshold, and the current airbag pressure value detected by the air pressure sensor is the third gas pressure threshold.

因此,将该空簧模拟子气路中的第三电磁阀的开关状态由闭合状态打开所述预设电磁阀开度后,该空簧模拟子气路中的流量传感器测量到的当前气路流量值由第二流量阈值逐渐变化至第一流量阈值,同时该空簧模拟子气路中的压力传感器测量到的当前气囊压力值由第三气体压力阈值逐渐变化至第一气压阈值,这样也就完成了气囊漏气故障模拟生成任务。Therefore, after the switch state of the third solenoid valve in the air spring simulation sub-air circuit is opened from the closed state to the preset solenoid valve opening, the air spring simulation sub-air flow sensor in the current air path measured The flow value gradually changes from the second flow threshold to the first flow threshold, and at the same time, the current airbag pressure value measured by the pressure sensor in the air spring simulation sub-airway gradually changes from the third gas pressure threshold to the first air pressure threshold, so that The airbag leakage fault simulation generation task is completed.

示例的,当根据气囊漏气故障时的指令,将空簧模拟子气路中的第三电磁阀的开关状态由闭合状态打开所述预设电磁阀开度后,流量传感器示数由默认0值逐渐变化到176ml/h以上,压力传感器示数由当前标准弹簧压力值6bar逐渐变化为等同大气压力值1bar。For example, when the switch state of the third solenoid valve in the air spring simulation sub-air circuit is changed from the closed state to open the preset solenoid valve opening according to the instruction when the air bag leaks, the flow sensor reading will change from 0 by default. The value gradually changes to above 176ml/h, and the reading of the pressure sensor gradually changes from the current standard spring pressure value of 6bar to the equivalent atmospheric pressure value of 1bar.

在本申请提供的另一种实施方式中,当所述故障模拟类型包括气管堵塞故障时,所述对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障,包括:将该空簧模拟子气路中的所述第一电磁阀的开关状态由开启状态更改为闭合状态,以使该空簧模拟子气路中的流量传感器测量到的当前气路流量值不变,同时使该空簧模拟子气路中的压力传感器测量到的当前气囊压力值突变至第二气压阈值,完成气囊漏气故障模拟生成任务。In another embodiment provided by the present application, when the fault simulation type includes a tracheal blockage fault, the first solenoid valve, the second solenoid valve and the The corresponding solenoid valve in the third solenoid valve is adjusted to generate a fault corresponding to the fault simulation type, including: changing the switch state of the first solenoid valve in the air spring simulation sub-air circuit from an open state to an open state Change to the closed state so that the current air flow rate value measured by the flow sensor in the air spring simulation sub-air circuit remains unchanged, and at the same time make the current air bag pressure value measured by the pressure sensor in the air spring simulation sub-air circuit suddenly change To the second air pressure threshold, the airbag leakage fault simulation generation task is completed.

这里,所述第二气压阈值是根据实际实验情况预先设定好的。其中,在更改第一电磁阀的开关状态前,所述空簧模拟气路是正常工作的,也就是说每个空簧模拟子气路中的流量传感器检测到的当前气路流量值为第二流量阈值,同时气压传感器检测到的当前气囊压力值为第三气体压力阈值。Here, the second air pressure threshold is preset according to actual experimental conditions. Wherein, before changing the switch state of the first electromagnetic valve, the air spring simulation air circuit is working normally, that is to say, the current flow rate of the air circuit detected by the flow sensor in each air spring analog sub-air circuit is the first The second flow threshold, and the current airbag pressure value detected by the air pressure sensor is the third gas pressure threshold.

因此,将该空簧模拟子气路中的第一电磁阀的开关状态由开启状态更改为闭合状态后,该空簧模拟子气路中的流量传感器测量到的当前气路流量值不变,同时该空簧模拟子气路中的压力传感器测量到的当前气囊压力值由第三气体压力阈值突变至第二气压阈值,这样也就完成了气管堵塞故障模拟生成任务。Therefore, after the switching state of the first solenoid valve in the air spring simulation sub-air circuit is changed from the open state to the closed state, the current flow value of the air circuit measured by the flow sensor in the air spring simulation sub-air circuit remains unchanged. At the same time, the current airbag pressure value measured by the pressure sensor in the air spring simulation sub-air circuit changes suddenly from the third gas pressure threshold to the second air pressure threshold, thus completing the task of tracheal blockage fault simulation generation.

示例的,当根据气管堵塞故障时的指令,将空簧模拟子气路中的第一电磁阀的开关状态由开启状态更改为闭合状态后,流量传感器示数不变,压力传感器示数由当前标准弹簧压力值6bar突变为20bar。For example, when the switch state of the first electromagnetic valve in the air spring analog sub-air circuit is changed from the open state to the closed state according to the instruction when the air pipe is blocked, the flow sensor reading remains unchanged, and the pressure sensor reading is changed from the current to the closed state. The standard spring pressure value of 6bar is suddenly changed to 20bar.

在本申请提供的另一种实施方式中,在基于所述故障模拟指令中的故障模拟类型,对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障之后,所述故障模拟方法还包括:对基于故障模拟类型更改电磁阀的开关状态后的该空簧模拟子气路通过气体后的目标参数进行识别,根据识别结果确定该空簧模拟子气路中是否产生与所述故障模拟指令中的故障模拟类型相同的故障;其中,每种故障模拟类型均预先设置有与之相对应目标参数;当为是时,控制该空簧模拟子气路中已更改开关状态的电磁阀恢复至更改前的开关状态。In another embodiment provided by the present application, based on the fault simulation type in the fault simulation instruction, the first solenoid valve, the second solenoid valve and the After the corresponding solenoid valve in the third solenoid valve is adjusted to generate a fault corresponding to the fault simulation type, the fault simulation method further includes: changing the switching state of the solenoid valve based on the fault simulation type for the empty spring The simulated sub-gas path is identified by the target parameters after passing the gas, and it is determined according to the identification result whether the same fault as the fault simulation type in the fault simulation command occurs in the empty spring simulated sub-gas path; wherein, each fault simulation type is The target parameter corresponding to it is set in advance; when yes, the solenoid valve controlling the changed switch state in the air spring simulation sub-air circuit returns to the switch state before the change.

该实施方式为生成故障后解决故障的实施方式,具体来说包括以下几种实现形式:This implementation mode is an implementation mode for solving a fault after a fault is generated, and specifically includes the following implementation forms:

当故障模拟类型为气囊爆裂故障时,该空簧模拟子气路中的流量传感器测量到的当前气路流量值由第二流量阈值突变至第一流量阈值,同时该空簧模拟子气路中的压力传感器测量到的当前气囊压力值由第三气体压力阈值突变至第一气压阈值时,控制该空簧模拟子气路中的第二电磁阀的开关状态由全开启状态恢复至闭合状态;When the fault simulation type is an airbag burst failure, the current flow value of the air path measured by the flow sensor in the air spring simulation sub-air path changes from the second flow threshold to the first flow threshold, and at the same time, the empty spring simulation sub-air path When the current air bag pressure value measured by the pressure sensor changes suddenly from the third gas pressure threshold to the first air pressure threshold, control the switch state of the second electromagnetic valve in the air spring simulation sub-air circuit to return from the fully open state to the closed state;

当故障模拟类型为气囊漏气故障时,该空簧模拟子气路中的流量传感器测量到的当前气路流量值由第二流量阈值逐渐变化至第一流量阈值,同时该空簧模拟子气路中的压力传感器测量到的当前气囊压力值由第三气体压力阈值逐渐变化至第一气压阈值时,控制该空簧模拟子气路中的第三电磁阀的开关状态由当前开度恢复至闭合状态;When the fault simulation type is an air bag leakage fault, the current air path flow value measured by the flow sensor in the air spring simulation sub-air path gradually changes from the second flow threshold to the first flow threshold, and at the same time the air spring simulates the sub-air When the current airbag pressure value measured by the pressure sensor in the circuit gradually changes from the third gas pressure threshold to the first air pressure threshold, control the switching state of the third electromagnetic valve in the air spring simulation sub-air circuit from the current opening to the closed state;

当故障模拟类型为气管堵塞故障时,该空簧模拟子气路中的流量传感器测量到的当前气路流量值不变,同时该空簧模拟子气路中的压力传感器测量到的当前气囊压力值由第三气体压力阈值突变至第二气压阈值时,控制该空簧模拟子气路中的第一电磁阀的开关状态由闭合状态恢复至开启状态。When the fault simulation type is a trachea blockage fault, the current air flow value measured by the flow sensor in the air spring simulation sub-air circuit remains unchanged, and at the same time the current airbag pressure measured by the pressure sensor in the air spring simulation sub-air circuit When the value changes suddenly from the third gas pressure threshold to the second air pressure threshold, the switching state of the first solenoid valve in the air spring analog sub-air circuit is controlled to return from the closed state to the open state.

本申请实施例提供的一种车辆空簧气路的故障模拟方法,所述故障模拟方法应用于车辆空簧气路的故障模拟装置,所述故障模拟装置分别与上位机和设置于实验台上的空簧模拟气路连接;所述空簧模拟气路包括气泵、组合阀和四个空簧模拟子气路;所述空簧模拟子气路包括第一电磁阀、流量传感器、压力传感器、空气弹簧、第二电磁阀和第三电磁阀;所述第一电磁阀连接到所述流量传感器,所述流量传感器连接到所述压力传感器,所述压力传感器连接到所述空气弹簧,所述空气弹簧连接到所述第二电磁阀,所述第二电磁阀连接到所述第三电磁阀;所述故障模拟方法包括:接收上位机发送的故障模拟指令,响应于所述故障模拟指令中的检测指令,确定所述四个空簧模拟子气路中的每个空簧模拟子气路通过气体后的目标参数是否指示该空簧模拟子气路能够正常工作;若该空簧模拟子气路能够正常工作,则基于所述故障模拟指令中的故障模拟类型,对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障。The embodiment of the present application provides a fault simulation method for the air spring circuit of a vehicle. The fault simulation method is applied to a fault simulation device for the air spring circuit of a vehicle. The empty spring simulated air circuit connection; the air spring simulated air circuit includes an air pump, a combination valve and four air spring simulated sub-air circuits; the air spring simulated sub-air circuit includes a first solenoid valve, a flow sensor, a pressure sensor, an air spring, a second solenoid valve and a third solenoid valve; the first solenoid valve is connected to the flow sensor, the flow sensor is connected to the pressure sensor, the pressure sensor is connected to the air spring, the The air spring is connected to the second solenoid valve, and the second solenoid valve is connected to the third solenoid valve; the fault simulation method includes: receiving a fault simulation instruction sent by the host computer, and responding to the fault simulation instruction The detection instruction of determining whether the target parameter of each empty spring analog sub-air circuit in the four air spring analog sub-air circuits passes through the gas indicates that the empty spring analog sub-air circuit can work normally; if the empty spring analog sub-air circuit If the air circuit can work normally, then based on the fault simulation type in the fault simulation instruction, simulate the first solenoid valve, the second solenoid valve and the third solenoid valve in the air spring sub-air circuit The corresponding solenoid valves are adjusted to generate a fault corresponding to the fault simulation type.

这样,通过本申请提供的方法,通过软硬件协调配合的方式,可以在真实的制造气路故障,从而提高了故障现象判断的准确性。并且通过模拟气路故障从而优化软件仿真无法实现的功能。In this way, through the method provided in the present application, through the coordination and cooperation of software and hardware, gas path faults can be actually produced, thereby improving the accuracy of fault phenomenon judgment. And by simulating gas path failures, functions that cannot be realized by software simulation are optimized.

请参阅图4、图5,图4为本申请实施例所提供的一种车辆空簧气路的故障模拟装置的结构示意图之一,图5为本申请实施例所提供的一种车辆空簧气路的故障模拟装置的结构示意图之二。所述故障模拟装置分别与上位机和设置于实验台上的空簧模拟气路连接;所述空簧模拟气路包括气泵、组合阀和四个空簧模拟子气路;所述空簧模拟子气路包括第一电磁阀、流量传感器、压力传感器、空气弹簧、第二电磁阀和第三电磁阀;所述第一电磁阀连接到所述流量传感器,所述流量传感器连接到所述压力传感器,所述压力传感器连接到所述空气弹簧,所述空气弹簧连接到所述第二电磁阀,所述第二电磁阀连接到所述第三电磁阀;如图4中所示,所述故障模拟装置400包括:Please refer to Figure 4 and Figure 5, Figure 4 is one of the structural schematic diagrams of a fault simulation device for a vehicle air spring air circuit provided by the embodiment of the application, Figure 5 is a vehicle air spring provided by the embodiment of the application The second schematic diagram of the structure of the fault simulation device of the gas circuit. The fault simulation device is respectively connected with the upper computer and the air spring simulation air circuit arranged on the test bench; the air spring simulation air circuit includes an air pump, a combination valve and four air spring simulation sub-air circuits; the air spring simulation air circuit The sub-air circuit includes a first solenoid valve, a flow sensor, a pressure sensor, an air spring, a second solenoid valve and a third solenoid valve; the first solenoid valve is connected to the flow sensor, and the flow sensor is connected to the pressure sensor. sensor, the pressure sensor is connected to the air spring, the air spring is connected to the second solenoid valve, and the second solenoid valve is connected to the third solenoid valve; as shown in Figure 4, the The

确定模块410,用于接收上位机发送的故障模拟指令,响应于所述故障模拟指令中的检测指令,确定所述四个空簧模拟子气路中的每个空簧模拟子气路通过气体后的目标参数是否指示该空簧模拟子气路能够正常工作;The determining

调整模块420,用于若该空簧模拟子气路能够正常工作,则基于所述故障模拟指令中的故障模拟类型,对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障。The

可选的,所述故障模拟类型包括以下项中的至少一项:气囊爆裂故障、气囊漏气故障和气管堵塞故障。Optionally, the failure simulation type includes at least one of the following items: an airbag burst failure, an airbag leakage failure, and a tracheal blockage failure.

可选的,当所述故障模拟类型包括气囊爆裂故障时,所述调整模块420在用于对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障时,所述调整模块420用于:Optionally, when the failure simulation type includes an airbag burst failure, the

将该空簧模拟子气路中的第二电磁阀的开关状态由闭合状态更改为全开启状态,以使该空簧模拟子气路中的流量传感器测量到的当前气路流量值突变至第一流量阈值,同时使该空簧模拟子气路中的压力传感器测量到的当前气囊压力值突变至第一气压阈值,从而完成气囊爆裂故障模拟生成任务。Change the switch state of the second solenoid valve in the air spring simulation sub-air circuit from the closed state to the fully open state, so that the current air flow rate value measured by the flow sensor in the air spring simulation sub-air circuit changes suddenly to the first A flow threshold, and at the same time make the current airbag pressure value measured by the pressure sensor in the air spring simulation sub-airway suddenly change to the first air pressure threshold, so as to complete the airbag burst fault simulation generation task.

可选的,当所述故障模拟类型包括气囊漏气故障时,所述调整模块420在用于对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障时,所述调整模块420用于:Optionally, when the fault simulation type includes an air bag leakage fault, the

响应于所述故障模拟指令中预设电磁阀开度,将该空簧模拟子气路中的第三电磁阀的开关状态由闭合状态打开所述预设电磁阀开度,以使该空簧模拟子气路中的流量传感器测量到的当前气路流量值逐渐变化至第一流量阈值,同时使该空簧模拟子气路中的压力传感器测量到的当前气囊压力值逐渐变化至第一气压阈值,完成气囊漏气故障模拟生成任务。In response to the preset solenoid valve opening in the fault simulation instruction, the switch state of the third solenoid valve in the empty spring simulation sub-air circuit is opened from the closed state to open the preset solenoid valve opening, so that the empty spring The current flow value of the air path measured by the flow sensor in the simulated sub-air path gradually changes to the first flow threshold, and at the same time, the current airbag pressure value measured by the pressure sensor in the air spring simulated sub-air path gradually changes to the first air pressure Threshold, to complete the airbag leak fault simulation generation task.

可选的,当所述故障模拟类型包括气管堵塞故障时,所述调整模块420在用于对该空簧模拟子气路中的所述第一电磁阀、所述第二电磁阀和所述第三电磁阀中的对应电磁阀进行调整,以生成与所述故障模拟类型对应的故障时,所述调整模块420用于:Optionally, when the fault simulation type includes a tracheal blockage fault, the

将该空簧模拟子气路中的所述第一电磁阀的开关状态由开启状态更改为闭合状态,以使该空簧模拟子气路中的流量传感器测量到的当前气路流量值不变,同时使该空簧模拟子气路中的压力传感器测量到的当前气囊压力值突变至第二气压阈值,完成气管堵塞故障模拟生成任务。Change the switching state of the first electromagnetic valve in the air spring simulation sub-air circuit from the open state to the closed state, so that the current air flow flow value measured by the flow sensor in the air spring simulation sub-air circuit remains unchanged , and at the same time make the current air bag pressure value measured by the pressure sensor in the air spring simulation sub-air circuit suddenly change to the second air pressure threshold value, and complete the task of tracheal blockage fault simulation generation.

可选的,所述确定模块410在用于确定所述四个空簧模拟子气路中的每个空簧模拟子气路通过气体后的目标参数是否指示该空簧模拟子气路能够正常工作时,所述确定模块410用于:Optionally, the

针对每个空簧模拟子气路,确定该空簧模拟子气路中流量传感器检测到的当前气路流量值是否为第二流量阈值,以及该空簧模拟子气路中气压传感器检测到的当前气囊压力值是否为第三气体压力阈值;For each air spring simulation sub-air circuit, determine whether the current air flow flow value detected by the flow sensor in the air spring simulation sub-air circuit is the second flow threshold value, and whether the air pressure sensor in the air spring simulation sub-air circuit detects the Whether the current airbag pressure value is the third gas pressure threshold;

当两者均为是时,确定该空簧模拟子气路能够正常工作;When both are yes, it is determined that the air spring simulation sub-air circuit can work normally;

当任一者为否时,确定该空簧模拟子气路不能够正常工作。When any one is negative, it is determined that the air spring simulation sub-air circuit cannot work normally.

可选的,如图5所示,所述故障模拟装置400还包括恢复模块430,所述恢复模块430用于:Optionally, as shown in FIG. 5, the

对基于故障模拟类型更改电磁阀的开关状态后的该空簧模拟子气路通过气体后的目标参数进行识别,根据识别结果确定该空簧模拟子气路中是否产生与所述故障模拟指令中的故障模拟类型相同的故障;其中,每种故障模拟类型均预先设置有与之相对应目标参数;Identify the target parameters of the air spring simulation sub-gas circuit after the air passes through the gas after changing the switching state of the solenoid valve based on the fault simulation type, and determine whether the air spring simulation sub-gas circuit is different from that in the fault simulation command according to the identification result. Faults with the same type of fault simulation; each fault simulation type is preset with corresponding target parameters;

当为是时,控制该空簧模拟子气路中已更改开关状态的电磁阀恢复至更改前的开关状态。When yes, the electromagnetic valve that controls the changed switch state in the air spring analog sub-air circuit returns to the switch state before the change.

可选的,所述目标参数包括以下项中的至少一项:气路流量和气囊压力。Optionally, the target parameters include at least one of the following items: air flow and air bag pressure.

请参阅图6,图6为本申请实施例所提供的一种电子设备的结构示意图。如图6中所示,所述电子设备600包括处理器610、存储器620和总线630。Please refer to FIG. 6 . FIG. 6 is a schematic structural diagram of an electronic device provided by an embodiment of the present application. As shown in FIG. 6 , the

所述存储器620存储有所述处理器610可执行的机器可读指令,当电子设备600运行时,所述处理器610与所述存储器620之间通过总线630通信,所述机器可读指令被所述处理器610执行时,可以执行如上述图1所示方法实施例中的步骤,具体实现方式可参见方法实施例,在此不再赘述。The

本申请实施例还提供一种计算机可读存储介质,该计算机可读存储介质上存储有计算机程序,该计算机程序被处理器运行时可以执行如上述图1所示方法实施例中的步骤,具体实现方式可参见方法实施例,在此不再赘述。The embodiment of the present application also provides a computer-readable storage medium, on which a computer program is stored. When the computer program is run by a processor, the steps in the method embodiment shown in FIG. 1 above can be executed, specifically For the implementation manner, reference may be made to the method embodiments, which will not be repeated here.

所属领域的技术人员可以清楚地了解到,为描述的方便和简洁,上述描述的系统、装置和单元的具体工作过程,可以参考前述方法实施例中的对应过程,在此不再赘述。Those skilled in the art can clearly understand that for the convenience and brevity of the description, the specific working process of the above-described system, device and unit can refer to the corresponding process in the foregoing method embodiment, which will not be repeated here.

在本申请所提供的几个实施例中,应该理解到,所揭露的系统、装置和方法,可以通过其它的方式实现。以上所描述的装置实施例仅仅是示意性的,例如,所述单元的划分,仅仅为一种逻辑功能划分,实际实现时可以有另外的划分方式,又例如,多个单元或组件可以结合或者可以集成到另一个系统,或一些特征可以忽略,或不执行。另一点,所显示或讨论的相互之间的耦合或直接耦合或通信连接可以是通过一些通信接口,装置或单元的间接耦合或通信连接,可以是电性,机械或其它的形式。In the several embodiments provided in this application, it should be understood that the disclosed systems, devices and methods may be implemented in other ways. The device embodiments described above are only illustrative. For example, the division of the units is only a logical function division. In actual implementation, there may be other division methods. For example, multiple units or components can be combined or May be integrated into another system, or some features may be ignored, or not implemented. In another point, the mutual coupling or direct coupling or communication connection shown or discussed may be through some communication interfaces, and the indirect coupling or communication connection of devices or units may be in electrical, mechanical or other forms.

所述作为分离部件说明的单元可以是或者也可以不是物理上分开的,作为单元显示的部件可以是或者也可以不是物理单元,即可以位于一个地方,或者也可以分布到多个网络单元上。可以根据实际的需要选择其中的部分或者全部单元来实现本实施例方案的目的。The units described as separate components may or may not be physically separated, and the components shown as units may or may not be physical units, that is, they may be located in one place, or may be distributed to multiple network units. Part or all of the units can be selected according to actual needs to achieve the purpose of the solution of this embodiment.

另外,在本申请各个实施例中的各功能单元可以集成在一个处理单元中,也可以是各个单元单独物理存在,也可以两个或两个以上单元集成在一个单元中。In addition, each functional unit in each embodiment of the present application may be integrated into one processing unit, each unit may exist separately physically, or two or more units may be integrated into one unit.

所述功能如果以软件功能单元的形式实现并作为独立的产品销售或使用时,可以存储在一个处理器可执行的非易失的计算机可读取存储介质中。基于这样的理解,本申请的技术方案本质上或者说对现有技术做出贡献的部分或者该技术方案的部分可以以软件产品的形式体现出来,该计算机软件产品存储在一个存储介质中,包括若干指令用以使得一台计算机设备(可以是个人计算机,服务器,或者网络设备等)执行本申请各个实施例所述方法的全部或部分步骤。而前述的存储介质包括:U盘、移动硬盘、只读存储器(Read-OnlyMemory,ROM)、随机存取存储器(Random Access Memory,RAM)、磁碟或者光盘等各种可以存储程序代码的介质。If the functions are realized in the form of software function units and sold or used as independent products, they can be stored in a non-volatile computer-readable storage medium executable by a processor. Based on this understanding, the technical solution of the present application is essentially or the part that contributes to the prior art or the part of the technical solution can be embodied in the form of a software product, and the computer software product is stored in a storage medium, including Several instructions are used to make a computer device (which may be a personal computer, a server, or a network device, etc.) execute all or part of the steps of the methods described in the various embodiments of the present application. The aforementioned storage medium includes: U disk, mobile hard disk, read-only memory (Read-Only Memory, ROM), random access memory (Random Access Memory, RAM), magnetic disk or optical disk, and other media that can store program codes.

最后应说明的是:以上所述实施例,仅为本申请的具体实施方式,用以说明本申请的技术方案,而非对其限制,本申请的保护范围并不局限于此,尽管参照前述实施例对本申请进行了详细的说明,本领域的普通技术人员应当理解:任何熟悉本技术领域的技术人员在本申请揭露的技术范围内,其依然可以对前述实施例所记载的技术方案进行修改或可轻易想到变化,或者对其中部分技术特征进行等同替换;而这些修改、变化或者替换,并不使相应技术方案的本质脱离本申请实施例技术方案的精神和范围,都应涵盖在本申请的保护范围之内。因此,本申请的保护范围应以权利要求的保护范围为准。Finally, it should be noted that: the above-described embodiments are only specific implementations of the application, used to illustrate the technical solutions of the application, rather than limiting it, and the scope of protection of the application is not limited thereto, although referring to the aforementioned The embodiment has described this application in detail, and those of ordinary skill in the art should understand that any person familiar with this technical field can still modify the technical solutions described in the foregoing embodiments within the technical scope disclosed in this application Changes can be easily imagined, or equivalent replacements can be made to some of the technical features; and these modifications, changes or replacements do not make the essence of the corresponding technical solutions deviate from the spirit and scope of the technical solutions of the embodiments of the application, and should be covered by this application. within the scope of protection. Therefore, the protection scope of the present application should be based on the protection scope of the claims.

Claims (11)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210921724.4ACN115270309A (en) | 2022-08-02 | 2022-08-02 | A fault simulation method, device and storage medium for a vehicle air spring gas circuit |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210921724.4ACN115270309A (en) | 2022-08-02 | 2022-08-02 | A fault simulation method, device and storage medium for a vehicle air spring gas circuit |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115270309Atrue CN115270309A (en) | 2022-11-01 |

Family

ID=83747564

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210921724.4APendingCN115270309A (en) | 2022-08-02 | 2022-08-02 | A fault simulation method, device and storage medium for a vehicle air spring gas circuit |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115270309A (en) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20070076189A (en)* | 2006-01-18 | 2007-07-24 | 주식회사 만도 | Simulation device and method of suspension |

| CN205349921U (en)* | 2016-01-08 | 2016-06-29 | 唐山学院 | Hydraulic system common fault simulation experiment table |

| CN109677227A (en)* | 2019-01-14 | 2019-04-26 | 南京航空航天大学 | A kind of body gesture regulating system and method based on air spring |

| CN110887621A (en)* | 2019-12-13 | 2020-03-17 | 武汉景亚自控设备股份有限公司 | Electromagnetic valve simulation fault detection method |

| CN112764984A (en)* | 2020-12-25 | 2021-05-07 | 际络科技(上海)有限公司 | Automatic driving test system and method, electronic device and storage medium |

| CN114486298A (en)* | 2021-12-01 | 2022-05-13 | 浙江孔辉汽车科技有限公司 | Fault diagnosis simulation system and method for electric control air suspension |

- 2022

- 2022-08-02CNCN202210921724.4Apatent/CN115270309A/enactivePending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20070076189A (en)* | 2006-01-18 | 2007-07-24 | 주식회사 만도 | Simulation device and method of suspension |

| CN205349921U (en)* | 2016-01-08 | 2016-06-29 | 唐山学院 | Hydraulic system common fault simulation experiment table |

| CN109677227A (en)* | 2019-01-14 | 2019-04-26 | 南京航空航天大学 | A kind of body gesture regulating system and method based on air spring |

| CN110887621A (en)* | 2019-12-13 | 2020-03-17 | 武汉景亚自控设备股份有限公司 | Electromagnetic valve simulation fault detection method |

| CN112764984A (en)* | 2020-12-25 | 2021-05-07 | 际络科技(上海)有限公司 | Automatic driving test system and method, electronic device and storage medium |

| CN114486298A (en)* | 2021-12-01 | 2022-05-13 | 浙江孔辉汽车科技有限公司 | Fault diagnosis simulation system and method for electric control air suspension |

Non-Patent Citations (1)

| Title |

|---|

| 单海强: "基于模型的ECAS系统执行器故障诊断与容错控制研究", 中国优秀硕士学位论文全文数据库_工程科技Ⅱ辑, 15 February 2019 (2019-02-15), pages 035 - 551* |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US20220196513A1 (en) | Test device and method for automatic pressure regulating valve of electronic braking system | |

| KR101198997B1 (en) | Testing apparatus for active air suspension system of commercial vehicle based on hils | |

| CN110884315A (en) | An intelligent electronically controlled air suspension system for commercial vehicles | |

| CN110395242B (en) | Air brake pressure control system and brake control method | |

| US8868294B2 (en) | Adjustable hysteresis circuit for control of air suspension | |

| CN103809582B (en) | Control System Imitation method of testing and system and device in semiconductor fabrication process | |

| CN204515372U (en) | Simulation of Brake control module and brake system Integration of Simulation test board | |

| CA2483029A1 (en) | Active adaptation of control algorithms for a central tire inflation system | |

| CN106840547A (en) | A kind of batteries of electric automobile bag air-tightness detection device and detection method | |

| JP7386331B2 (en) | Air pressure control method, device, computer readable storage medium and vehicle | |

| CN114211927B (en) | Solenoid valve control method, device, equipment and storage medium based on air suspension | |

| CN104101504A (en) | Motor car automatic testing method and device | |

| JP2020176531A (en) | Anomaly detection device for fuel vapor emission prevention system | |

| CN115317307A (en) | Passenger body type recognition seat and method based on multipoint massage system | |

| CN115270309A (en) | A fault simulation method, device and storage medium for a vehicle air spring gas circuit | |

| JP3770903B2 (en) | Method and apparatus for verifying proper wiring of brake pressure modulator | |

| CN113285993A (en) | Remote assistant driving access matching method, device and equipment | |

| CN119087979A (en) | Test method, system, device and storage medium for controller used in air suspension | |

| CN105353651A (en) | Microcomputer screen-combining simulation debugging method for locomotive master control system and electric pneumatic breaking system | |

| JP2003149076A (en) | Method and device for air leak test | |

| CN117048271A (en) | Air spring adjusting method, device, equipment and computer readable storage medium | |

| CN115479023A (en) | Method and device for determining fault types of air processing units | |

| CN114486298A (en) | Fault diagnosis simulation system and method for electric control air suspension | |

| CN112765721B (en) | Model control-based entertainment information interaction test method | |

| CN120010444A (en) | Hardware-in-the-loop test system for air spring controller |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| CB02 | Change of applicant information | ||

| CB02 | Change of applicant information | Country or region after:China Address after:313000 No. 18-102 Industrial Road, South Taihu High-tech Industrial Park, Wuxing District, Huzhou City, Zhejiang Province Applicant after:Zhejiang Konghui Automotive Technology Co.,Ltd. Address before:313000 No. 18-102 Industrial Road, South Taihu High-tech Industrial Park, Wuxing District, Huzhou City, Zhejiang Province Applicant before:Zhejiang Kong Hui Automobile Technology Co.,Ltd. Country or region before:China |