CN115263773A - Submersible pump test system - Google Patents

Submersible pump test systemDownload PDFInfo

- Publication number

- CN115263773A CN115263773ACN202210940263.5ACN202210940263ACN115263773ACN 115263773 ACN115263773 ACN 115263773ACN 202210940263 ACN202210940263 ACN 202210940263ACN 115263773 ACN115263773 ACN 115263773A

- Authority

- CN

- China

- Prior art keywords

- water

- sand

- submersible pump

- detection

- gas

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D15/00—Control, e.g. regulation, of pumps, pumping installations or systems

- F04D15/0088—Testing machines

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D13/00—Pumping installations or systems

- F04D13/02—Units comprising pumps and their driving means

- F04D13/06—Units comprising pumps and their driving means the pump being electrically driven

- F04D13/08—Units comprising pumps and their driving means the pump being electrically driven for submerged use

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及潜水泵测试领域,具体而言,涉及一种潜水泵测试系统。The invention relates to the field of submersible pump testing, in particular to a submersible pump testing system.

背景技术Background technique

近年来,矿用潜水泵测试技术得到很大程度的发展,是解决矿用潜水泵异常或故障的重要手段。虽能解决一定的问题,但还是存在一些不足。In recent years, the testing technology of mining submersible pump has been developed to a great extent, and it is an important means to solve the abnormality or failure of mining submersible pump. Although certain problems can be solved, there are still some deficiencies.

由于传统系统的测试环境与真实使用环境存在着较大的差距,因此很难得到全面准确的结果,测试结果较真实情况存在一定差距;传统测试系统虽然能够实时采集和分析采集到的综合参数,为矿用潜水泵的工况诊断提供了更直观的信息和依据,但是关于矿用潜水泵模拟真实使用环境的测试系统的应用目前尚无系统的研究,未形成规范模板。测试分析过程也费时、费力,而且还容易出现较大偏差的情况。Due to the large gap between the test environment of the traditional system and the actual use environment, it is difficult to obtain comprehensive and accurate results, and there is a certain gap between the test results and the real situation; although the traditional test system can collect and analyze the collected comprehensive parameters in real time, It provides more intuitive information and basis for the working condition diagnosis of mining submersible pumps, but there is no systematic research on the application of the test system for mining submersible pumps simulating the real use environment, and no normative template has been formed. The test and analysis process is also time-consuming, laborious, and prone to large deviations.

发明内容Contents of the invention

本发明的主要目的在于提供一种潜水泵测试系统,以解决现有技术中的测试潜水泵的系统的测试结果存在较大偏差的问题。The main purpose of the present invention is to provide a submersible pump testing system to solve the problem of large deviations in the test results of the submersible pump testing system in the prior art.

为了实现上述目的,根据本发明的一个方面,提供了一种潜水泵测试系统,包括:水沙输送结构,包括储水罐、沙箱以及水沙混合罐,储水罐和沙箱均与水沙混合罐连通,以分别向水沙混合罐内通入水和沙,水沙混合罐具有用于与测试井连通的第一输出口;气体输送结构,包括空气压缩机和用于与测试井连通的第二输出口;检测结构,包括分离组件和检测组件,分离组件与位于测试井内的待测试的潜水泵连通,以将潜水泵中流出的流体分离为水、气体和干沙;检测组件用于分别检测分离得出后的水、气体和干沙的重量。In order to achieve the above object, according to one aspect of the present invention, a submersible pump test system is provided, including: a water and sand conveying structure, including a water storage tank, a sand box and a water and sand mixing tank, and the water storage tank and the sand box are all mixed with water and sand The mixing tank is communicated to feed water and sand into the water-sand mixing tank respectively, and the water-sand mixing tank has a first output port for communicating with the test well; the gas delivery structure includes an air compressor and a first outlet for communicating with the test well. Two output ports; the detection structure includes a separation component and a detection component, and the separation component is connected with the submersible pump to be tested in the test well, so as to separate the fluid flowing out of the submersible pump into water, gas and dry sand; the detection component is used for respectively Measure the weight of separated water, gas and dry sand.

进一步地,水沙输送结构还包括:第一输送管道,第一输送管道用于连通储水罐和水沙混合罐;第一开关阀和管道泵,第一开关阀和管道泵均设置在第一输送管道上。Further, the water-sand conveying structure also includes: a first conveying pipeline, which is used to communicate with the water storage tank and the water-sand mixing tank; the first on-off valve and the pipeline pump, both of which are set at the second A delivery pipeline.

进一步地,水沙输送结构还包括:第一流量计,第一流量计设置在第一输送管道上;第一调节阀,第一调节阀设置在第一输送管道上;其中,沿储水罐至水沙混合罐的方向,第一开关阀、管道泵、第一流量计以及第一调节阀依次间隔布置。Further, the water and sand conveying structure also includes: a first flow meter, the first flow meter is arranged on the first conveying pipeline; a first regulating valve, the first regulating valve is arranged on the first conveying pipeline; wherein, along the water storage tank To the direction of the water-sand mixing tank, the first on-off valve, the pipeline pump, the first flow meter and the first regulating valve are arranged at intervals in sequence.

进一步地,水沙输送结构还包括:第二输送管道和第二调节阀,第二输送管道用于连通沙箱和水沙混合罐;第二调节阀设置在第二输送管道上;其中,沙箱位于水沙混合罐的上方。Further, the water-sand conveying structure also includes: a second conveying pipeline and a second regulating valve, the second conveying pipeline is used to communicate with the sand box and the water-sand mixing tank; the second regulating valve is arranged on the second conveying pipeline; wherein, the sand The box is located above the water-sand mixing tank.

进一步地,水沙输送结构还包括:第三输送管道和第二开关阀,第三输送管道的一端与水沙混合罐连通,第三输送管道的另一端形成第一输出口;渣浆泵,渣浆泵设置在第三输送管道上。Further, the water-sand conveying structure also includes: a third conveying pipeline and a second switch valve, one end of the third conveying pipeline communicates with the water-sand mixing tank, and the other end of the third conveying pipeline forms the first output port; a slurry pump, The slurry pump is arranged on the third delivery pipeline.

进一步地,水沙输送结构还包括:第三调节阀、第二流量计以及第一止回阀,第三调节阀、第二流量计以及第一止回阀均设置在第三输送管道上;其中,沿靠近第一输出口的方向,第二开关阀、渣浆泵、第三调节阀、第二流量计以及第一止回阀依次间隔布置。Further, the water and sand conveying structure further includes: a third regulating valve, a second flow meter and a first check valve, and the third regulating valve, the second flow meter and the first check valve are all arranged on the third conveying pipeline; Wherein, along the direction close to the first output port, the second on-off valve, the slurry pump, the third regulating valve, the second flow meter and the first check valve are sequentially arranged at intervals.

进一步地,气体输送结构还包括:第四输送管道,第四输送管道的一端与空气压缩机连通,第四输送管道的另一端形成第二输出口;第四调节阀、第三流量计、第一压力变送器以及第二止回阀,沿靠近第二输出口的方向,第四调节阀、第三流量计、第一压力变送器以及第二止回阀依次间隔地设置在第四输送管道上。Further, the gas delivery structure also includes: a fourth delivery pipeline, one end of the fourth delivery pipeline communicates with the air compressor, and the other end of the fourth delivery pipeline forms a second output port; a fourth regulating valve, a third flow meter, a fourth A pressure transmitter and a second check valve, along the direction close to the second output port, the fourth regulating valve, the third flow meter, the first pressure transmitter and the second check valve are arranged at intervals in the fourth on the delivery pipeline.

进一步地,水沙输送结构还包括:液位传感器,液位传感器与水沙混合罐的腔体连通;和/或搅拌装置,搅拌装置的至少部分可运动地设置在水沙混合罐的腔体;排料管和排料阀,排料管与水沙混合罐的腔体连通,排料阀设置在排料管上。Further, the water-sand conveying structure also includes: a liquid level sensor, which communicates with the cavity of the water-sand mixing tank; and/or a stirring device, at least part of which is movably arranged in the cavity of the water-sand mixing tank ; The discharge pipe and the discharge valve, the discharge pipe is connected with the cavity of the water-sand mixing tank, and the discharge valve is arranged on the discharge pipe.

进一步地,检测结构还包括:输入管道、第二压力变送器以及第一温度传感器,输入管道与潜水泵连通,第二压力变送器和第一温度传感器均设置在输入管道上;和/或第二温度传感器和振动传感器,第二温度传感器和振动传感器均设置在潜水泵上。Further, the detection structure also includes: an input pipeline, a second pressure transmitter and a first temperature sensor, the input pipeline communicates with the submersible pump, and the second pressure transmitter and the first temperature sensor are both arranged on the input pipeline; and/or Or the second temperature sensor and the vibration sensor, both of the second temperature sensor and the vibration sensor are arranged on the submersible pump.

进一步地,检测组件包括用于将潜水泵内流出的流体分离为湿沙和气水混合物的沙分离器,检测结构还包括:第一检测管道,第一检测管道的两端分别与潜水泵和沙分离器连接;第三压力变送器和第五调节阀,第三压力变送器和第五调节阀均设置在第一检测管道上。Further, the detection assembly includes a sand separator for separating the fluid flowing out of the submersible pump into wet sand and air-water mixture, and the detection structure also includes: a first detection pipeline, and the two ends of the first detection pipeline are respectively separated from the submersible pump and the sand The device is connected; the third pressure transmitter and the fifth regulating valve, the third pressure transmitter and the fifth regulating valve are all arranged on the first detection pipeline.

进一步地,分离组件包括:沙分离器,沙分离器的进口与潜水泵连接,以将潜水泵内流出的流体分离为湿沙和气水混合物;水气分离器,水气分离器与沙分离器的气水出口连接,以将沙分离器分离出的气水混合物分离为气体和水。Further, the separation assembly includes: a sand separator, the inlet of the sand separator is connected to the submersible pump, so as to separate the fluid flowing out of the submersible pump into wet sand and air-water mixture; the water-air separator, the water-air separator and the sand separator The gas-water outlet is connected to separate the gas-water mixture separated by the sand separator into gas and water.

进一步地,检测组件还包括:烘干装置和称重装置,烘干装置与水气分离器的湿沙出口连接,以将沙分离器分离出的湿沙烘干为干沙;称重装置与烘干装置配合,以对经烘干装置烘干得出的干沙的重量;和/或第二检测管道和第四流量计,第二检测管道与水气分离器的气出口连接,第四流量计设置在第二检测管道上;和/或第三检测管道和第五流量计,第三检测管道与水气分离器的水出口连接,第五流量计设置在第三检测管道上。Further, the detection component also includes: a drying device and a weighing device, the drying device is connected with the wet sand outlet of the water-air separator to dry the wet sand separated by the sand separator into dry sand; the weighing device and The drying device cooperates to check the weight of the dry sand dried by the drying device; and/or the second detection pipeline and the fourth flow meter, the second detection pipeline is connected with the gas outlet of the water-gas separator, and the fourth The flowmeter is arranged on the second detection pipeline; and/or the third detection pipeline and the fifth flowmeter, the third detection pipeline is connected with the water outlet of the water-gas separator, and the fifth flowmeter is arranged on the third detection pipeline.

应用本发明的技术方案,潜水泵测试系统包括水沙输送结构,包括储水罐、沙箱以及水沙混合罐,储水罐和沙箱均与水沙混合罐连通,以分别向水沙混合罐内通入水和沙,水沙混合罐具有用于与测试井连通的第一输出口;气体输送结构,包括空气压缩机和用于与测试井连通的第二输出口;检测结构,包括分离组件和检测组件,分离组件与位于测试井内的待测试的潜水泵连通,以将潜水泵中流出的流体分离为水、气体和干沙;检测组件用于分别检测分离得出后的水、气体和干沙的重量。采用上述设置,通过被模拟井下真实的环境对矿用潜水泵进行分析,分析出泵的真实性能参数,解决现有技术中的测试潜水泵的系统的测试结果存在较大偏差的问题。Applying the technical scheme of the present invention, the submersible pump test system includes a water-sand conveying structure, including a water storage tank, a sand box, and a water-sand mixing tank, and the water storage tank and the sand box are all communicated with the water-sand mixing tank to feed water and sand to the water-sand mixing tank respectively. Water and sand are passed inside, and the water-sand mixing tank has a first output port for communicating with the test well; a gas delivery structure, including an air compressor and a second output port for communicating with the test well; a detection structure, including a separation component and The detection component, the separation component is in communication with the submersible pump to be tested in the test well, so as to separate the fluid flowing out of the submersible pump into water, gas and dry sand; the detection component is used to detect the separated water, gas and dry sand respectively. sand weight. With the above settings, the mining submersible pump is analyzed through the simulated underground real environment, the real performance parameters of the pump are analyzed, and the problem of large deviations in the test results of the submersible pump testing system in the prior art is solved.

附图说明Description of drawings

构成本申请的一部分的说明书附图用来提供对本发明的进一步理解,本发明的示意性实施例及其说明用于解释本发明,并不构成对本发明的不当限定。在附图中:The accompanying drawings constituting a part of the present application are used to provide a further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention. In the attached picture:

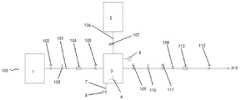

图1示出了根据本发明的潜水泵测试系统的水沙输送结构的结构示意图;Fig. 1 shows the structural representation of the water-sand delivery structure of the submersible pump testing system according to the present invention;

图2示出了本发明的潜水泵测试系统的气体输送结构的结构示意图;Fig. 2 shows the structural representation of the gas delivery structure of the submersible pump test system of the present invention;

图3示出了本发明的潜水泵测试系统的检测结构的结构示意图。Fig. 3 shows a schematic structural diagram of the detection structure of the submersible pump test system of the present invention.

其中,上述附图包括以下附图标记:Wherein, the above-mentioned accompanying drawings include the following reference signs:

100、水沙输送结构;1、储水罐;2、沙箱;3、水沙混合罐;101、第一输送管道;102、第一开关阀;103、管道泵;104、第一流量计;105、第一调节阀;106、第二输送管道;107、第二调节阀;108、第三输送管道;109、第二开关阀;110、渣浆泵;111、第三调节阀;112、第二流量计;113、第一止回阀;100. Water and sand conveying structure; 1. Water storage tank; 2. Sandbox; 3. Water and sand mixing tank; 101. First conveying pipeline; 102. First switch valve; 103. Pipeline pump; 104. First flow meter ; 105, the first regulating valve; 106, the second conveying pipeline; 107, the second regulating valve; 108, the third conveying pipeline; 109, the second switching valve; 110, the slurry pump; 111, the third regulating valve; 112 , the second flow meter; 113, the first check valve;

200、气体输送结构;4、空气压缩机;5、液位传感器;6、搅拌装置;7、排料管;8、排料阀;201、第四输送管道;202、第四调节阀;203、第三流量计;204、第一压力变送器;205、第二止回阀;200. Gas conveying structure; 4. Air compressor; 5. Liquid level sensor; 6. Stirring device; 7. Discharging pipe; 8. Discharging valve; 201. The fourth conveying pipeline; 202. The fourth regulating valve; 203 , the third flow meter; 204, the first pressure transmitter; 205, the second check valve;

301、输入管道;302、第二压力变送器;303、第一温度传感器;304、第二温度传感器;305、振动传感器;306、沙分离器;307、第一检测管道;308、第三压力变送器;309、第五调节阀;310、水气分离器;311、烘干装置;312、称重装置;313、第二检测管道;314、第四流量计;315、第三检测管道;316、第五流量计;301, input pipeline; 302, second pressure transmitter; 303, first temperature sensor; 304, second temperature sensor; 305, vibration sensor; 306, sand separator; 307, first detection pipeline; 308, third Pressure transmitter; 309, fifth regulating valve; 310, water-gas separator; 311, drying device; 312, weighing device; 313, second detection pipeline; 314, fourth flowmeter; 315, third detection pipeline; 316, the fifth flowmeter;

400、潜水泵。400. Submersible pump.

具体实施方式Detailed ways

需要说明的是,在不冲突的情况下,本申请中的实施例及实施例中的特征可以相互组合。下面将参考附图并结合实施例来详细说明本发明。It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

本实施例的潜水泵测试系统,包括:水沙输送结构100,包括储水罐1、沙箱2以及水沙混合罐3,储水罐1和沙箱2均与水沙混合罐3连通,以分别向水沙混合罐3内通入水和沙,水沙混合罐3具有用于与测试井连通的第一输出口;气体输送结构200,包括空气压缩机4和用于与测试井连通的第二输出口;检测结构,包括分离组件和检测组件,分离组件与位于测试井内的待测试的潜水泵400连通,以将潜水泵400中流出的流体分离为水、气体和干沙;检测组件用于分别检测分离得出后的水、气体和干沙的重量。采用上述设置,通过被模拟井下真实的环境对矿用潜水泵进行分析,分析出泵的真实性能参数,解决现有技术中的测试潜水泵的系统的测试结果存在较大偏差的问题。The submersible pump testing system of the present embodiment includes: a water-

在本实施例的潜水泵测试系统中,参见图1至图3,水沙输送结构100还包括:第一输送管道101,第一输送管道101用于连通储水罐1和水沙混合罐3;第一开关阀102和管道泵103,第一开关阀102和管道泵103均设置在第一输送管道101上。In the submersible pump testing system of this embodiment, referring to Fig. 1 to Fig. 3, the water-

参见图1至图3,在本实施例的潜水泵测试系统中,水沙输送结构100还包括:第一流量计104,第一流量计104设置在第一输送管道101上;第一调节阀105,第一调节阀105设置在第一输送管道101上;其中,沿储水罐1至水沙混合罐3的方向,第一开关阀102、管道泵103、第一流量计104以及第一调节阀105依次间隔布置。Referring to Fig. 1 to Fig. 3, in the submersible pump test system of the present embodiment, the water and

在本实施例的潜水泵测试系统中,参见图1至图3,水沙输送结构100还包括:第二输送管道106和第二调节阀107,第二输送管道106用于连通沙箱2和水沙混合罐3;第二调节阀107设置在第二输送管道106上;其中,沙箱2位于水沙混合罐3的上方。In the submersible pump testing system of this embodiment, referring to Fig. 1 to Fig. 3, the water-

参见图1至图3,在本实施例的潜水泵测试系统中,水沙输送结构100还包括:第三输送管道108和第二开关阀109,第三输送管道108的一端与水沙混合罐3连通,第三输送管道108的另一端形成第一输出口;渣浆泵110,渣浆泵110设置在第三输送管道108上。1 to 3, in the submersible pump test system of the present embodiment, the water-

在本实施例的潜水泵测试系统中,参见图1至图3,水沙输送结构100还包括:第三调节阀111、第二流量计112以及第一止回阀113,第三调节阀111、第二流量计112以及第一止回阀113均设置在第三输送管道108上;其中,沿靠近第一输出口的方向,第二开关阀109、渣浆泵110、第三调节阀111、第二流量计112以及第一止回阀113依次间隔布置。In the submersible pump testing system of this embodiment, referring to FIGS. 1 to 3 , the water and

参见图1至图3,在本实施例的潜水泵测试系统中,气体输送结构200还包括:第四输送管道201,第四输送管道201的一端与空气压缩机4连通,第四输送管道201的另一端形成第二输出口;第四调节阀202、第三流量计203、第一压力变送器204以及第二止回阀205,沿靠近第二输出口的方向,第四调节阀202、第三流量计203、第一压力变送器204以及第二止回阀205依次间隔地设置在第四输送管道201上。1 to 3, in the submersible pump test system of this embodiment, the

在本实施例的潜水泵测试系统中,参见图1至图3,水沙输送结构100还包括:液位传感器5,液位传感器5与水沙混合罐3的腔体连通;和/或搅拌装置6,搅拌装置6的至少部分可运动地设置在水沙混合罐3的腔体;排料管7和排料阀8,排料管7与水沙混合罐3的腔体连通,排料阀8设置在排料管7上。In the submersible pump test system of the present embodiment, referring to Fig. 1 to Fig. 3, the water-

参见图1至图3,在本实施例的潜水泵测试系统中,检测结构还包括:输入管道301、第二压力变送器302以及第一温度传感器303,输入管道301与潜水泵400连通,第二压力变送器302和第一温度传感器303均设置在输入管道301上;和/或第二温度传感器304和振动传感器305,第二温度传感器304和振动传感器305均设置在潜水泵400上。Referring to Figures 1 to 3, in the submersible pump test system of this embodiment, the detection structure further includes: an

在本实施例的潜水泵测试系统中,参见图1至图3,检测组件包括用于将潜水泵400内流出的流体分离为湿沙和气水混合物的沙分离器306,检测结构还包括:第一检测管道307,第一检测管道307的两端分别与潜水泵400和沙分离器306连接;第三压力变送器308和第五调节阀309,第三压力变送器308和第五调节阀309均设置在第一检测管道307上。In the submersible pump testing system of this embodiment, referring to Fig. 1 to Fig. 3, the detection assembly includes a

参见图1至图3,在本实施例的潜水泵测试系统中,分离组件包括:沙分离器306,沙分离器306的进口与潜水泵400连接,以将潜水泵400内流出的流体分离为湿沙和气水混合物;水气分离器310,水气分离器310与沙分离器306的气水出口连接,以将沙分离器306分离出的气水混合物分离为气体和水。Referring to Fig. 1 to Fig. 3, in the submersible pump test system of the present embodiment, separation assembly comprises:

在本实施例的潜水泵测试系统中,参见图1至图3,检测组件还包括:烘干装置311和称重装置312,烘干装置311与水气分离器310的湿沙出口连接,以将沙分离器306分离出的湿沙烘干为干沙;称重装置312与烘干装置311配合,以对经烘干装置311烘干得出的干沙的重量;和/或第二检测管道313和第四流量计314,第二检测管道313与水气分离器310的气出口连接,第四流量计314设置在第二检测管道313上;和/或第三检测管道315和第五流量计316,第三检测管道315与水气分离器310的水出口连接,第五流量计316设置在第三检测管道315上。In the submersible pump test system of the present embodiment, referring to Fig. 1 to Fig. 3, the detection assembly also includes: a drying

本实施例的矿用潜水泵环境仿真测试系统,用于测试在不同的井况下矿用潜水泵的气体、泥沙杂质对于矿用潜水泵效率的影响;测试在不同的井况下,不同含量的泥沙等杂质对于矿用潜水泵寿命的影响;检测矿用潜水泵在举升多相流流体的最佳工况点;对改进的矿用潜水泵管柱能够进行测试,验证改进效果。为了能够达到以上的测试目的,矿用潜水泵的测试回路具备以下的功能:The mining submersible pump environmental simulation test system of this embodiment is used to test the influence of gas and sediment impurities of the mining submersible pump on the efficiency of the mining submersible pump under different well conditions; The impact of impurities such as sediment and other impurities on the life of the mine submersible pump; detection of the best working point of the mine submersible pump in lifting multiphase flow fluid; the improved mine submersible pump string can be tested to verify the improvement effect . In order to achieve the above test purposes, the test circuit of the mine submersible pump has the following functions:

本实施例的潜水泵测试系统能够分别控制水、气、砂三相流体的流量。The submersible pump testing system of this embodiment can control the flow of three-phase fluids of water, air and sand respectively.

本实施例的潜水泵测试系统能够实现模拟矿用潜水泵举升的过程。The submersible pump testing system of this embodiment can realize the process of simulating the lifting of the mine submersible pump.

本实施例的潜水泵测试系统能够对矿用潜水泵的工作工况进行检测且能够实时读取检测数据。The submersible pump test system of this embodiment can detect the working conditions of the mine submersible pump and can read the detection data in real time.

本实施例的潜水泵测试系统能够自动调节矿用潜水泵的工况。The submersible pump testing system of this embodiment can automatically adjust the working conditions of the mine submersible pump.

本实施例的潜水泵测试系统能够对举升的三相流体进行地面分离,测量。The submersible pump test system of this embodiment can separate and measure the lifted three-phase fluid on the ground.

本实施例的潜水泵测试系统能够对测试的结果进行拟合、分析。The submersible pump testing system of this embodiment can fit and analyze the test results.

本实施例的潜水泵测试系统目的在于克服上述已有技术的不足,提供一种矿用潜水泵环境仿真测试系统,该系统可通过被模拟井下真实的环境对矿用潜水泵进行分析,并快速分析出泵的真实性能参数。The purpose of the submersible pump test system of this embodiment is to overcome the above-mentioned deficiencies in the prior art, and to provide a mine submersible pump environment simulation test system, which can analyze the mine submersible pump through the simulated underground real environment, and quickly Analyze the real performance parameters of the pump.

为了实现上述目的,本实施例的潜水泵测试系统的测试方法包括如下步骤:In order to achieve the above object, the test method of the submersible pump test system of the present embodiment includes the following steps:

根据矿用潜水泵在井下使用的位置来按比例配置与该环境相近的砂。According to the location where the mine submersible pump is used underground, the sand that is similar to the environment is configured in proportion.

根据矿用潜水泵在井下使用的位置来选择合适的气体加注阀门。Select the appropriate gas filling valve according to the location of the mine submersible pump used in the mine.

根据矿用潜水泵在井下使用环境的不同来调节水、砂、气的混合比例。Adjust the mixing ratio of water, sand and air according to the different environment of the mine submersible pump in the mine.

对矿用潜水泵吐出的混合液体进行分离、并计算出三者的实际数量,分析出矿用潜水泵真实的提升能力。Separate the mixed liquid spit out by the mine submersible pump, and calculate the actual quantity of the three, and analyze the real lifting capacity of the mine submersible pump.

本实施例的潜水泵测试系统的操作过程如下:The operation process of the submersible pump test system of the present embodiment is as follows:

第一开关阀102打开,第一开关阀102处装有手动跟电动两只阀门,手动阀门为检修阀,平常为常开状态,只有当检修或者特殊情况时才用手动阀门关闭进水。启动管道泵103此处采用不锈钢多级供水泵用变频器控制后,第一流量计104显示此时的进水量,系统根据设定的需进水量,自动对第一调节阀105进行控制,第一调节阀105后装有单向止回阀,防止系统意外掉电时含沙的混合液体回流,电磁流量计采集的是水的体积流量,系统自动将体积值换算成质量值,再根据第二调节阀107的进沙量,达到所需要的水沙混合比例;此处采用传送带方式,传送带上有装沙装置,当传送带从沙箱底部经过时便携带了定量的沙子,根据设定传送带的速度来调节进砂量。同时打开搅拌装置6,水沙混合罐中装有双层的搅拌装置,装置用变频器进行控制,系统根据含沙量的大小,可以自动调节不同转速,防止由于搅拌装置转速过快对供水量有影响。液位传感器5(此处的液位传感器为插入式压差液位计)使得系统不会因为水中含沙的原因造成液位计的测量不精确。到达限定液位时,关闭阀门,同时停掉管道泵103。The first on-off

打开第二开关阀109,第二开关阀109处装有手动跟电动两只阀门,手动阀门为检修阀,平常为常开状态,只有当检修或者特殊情况时才用手动阀门关闭进水。启动渣浆泵110,调节第一开关阀102门查看第二流量计112到需要流量。当水沙混合罐上的液位传感器5低于某数值时液位计共有4段设定值,低于最低点设定值时为工频供水,在第2-3点之间时,系统根据液位的高低不同采用变频供水,当液位高于最高点的液位时管道泵0HZ运行。Open the second on-off

启动空气压缩机空压机因为噪声过大,在空压机上根据实验室实际面积选择建隔音房,空压机排气端有稳压罐用来减小气压的波动,查看第三流量计203根据气量的不同可选择不同量程的压差变送器来进行气量的的测量。提高测量的精度。调节高真空调节蝶阀(即第四调节阀202),蝶阀末端装有可更换的气体打散装置,对气量进行精确地细微调节,到所需要的气量。Start the air compressor. Because the air compressor is too noisy, build a soundproof room on the air compressor according to the actual area of the laboratory. There is a pressure tank at the exhaust end of the air compressor to reduce the fluctuation of air pressure. Check the

注水、注气管线末端都装有单向止回阀,防止气压、水压的压力不平衡时回流现象。One-way check valves are installed at the ends of the water injection and gas injection pipelines to prevent backflow when the air pressure and water pressure are unbalanced.

实验结束时,关闭第一调节阀105、第二调节阀107、第一开关阀102、停止渣浆泵110,打开排料阀8,排料阀8之后设置有选择性三通阀,可以选择将液体排到沙水分离器中进行分离回收,也可以选择将液体直接排进排污管道中,然后关闭排料阀8。When the experiment ends, close the

实验结束后打开第一调节阀105将水沙混合桶中注满清水,然后打开第一开关阀102门启动渣浆泵110,对井中残留沙冲洗出来系统可以设定含沙量小于某个数值时为已经将沙排净,系统根据水沙分离器中分离出的沙量的大小来自动判断。After the experiment is over, open the

由矿用潜水泵吐出的混合液体首先通过第三压力变送器308测出压力后,由第五调节阀309将压力减小到2.5MPa以下,泵出口的三物混合体经过减压调节阀后,首先需要经过质量流量计对三物混合体的实际流量进行测量。根据混合物的不同比例采用不同的密度进行计算。The mixed liquid discharged by the mining submersible pump first passes the

混合液体通过分沙装置将湿沙分离出来水沙分离器采用旋流分沙器两台串联使用,分沙器的体积不宜过大,如采用大容量的分沙器,对水沙分离的效果将小于采用小型分沙器的效果,湿沙经过称重传感器得到湿沙的重量,然后进入烘干装置,水分以水蒸气模式被排掉,得到干沙湿沙采用分段计量,分段烘干。干沙经过称重后返回沙箱;烘干前后的重量差值就是湿沙所带水分的重量,通过试验软件保存到数据库。The mixed liquid is separated from the wet sand through the sand separator. The water and sand separator uses two cyclone sand separators in series. The volume of the sand separator should not be too large. If a large-capacity sand separator is used, the effect of water and sand separation It will be less than the effect of using a small sand separator. The wet sand passes through the load cell to obtain the weight of the wet sand, and then enters the drying device, and the water is drained in the steam mode to obtain dry sand. Dry. The dry sand is weighed and returned to the sandbox; the weight difference before and after drying is the weight of the moisture carried by the wet sand, which is saved to the database through the test software.

水气混合物经过水气分离器将空气跟水分分离开,空气经过孔板流量计的计量后直接排入大气中根据气量的不同可选择不同量程的压差变送器来进行气量的的测量。提高测量的精度。排气管道可接到室外进行排放。;水经过电磁流量计的计量再返回储水罐中。The water-air mixture passes through the water-air separator to separate the air from the water, and the air is directly discharged into the atmosphere after being measured by the orifice flowmeter. According to the difference in the air volume, different pressure transmitters with different ranges can be selected to measure the air volume. Improve the accuracy of measurement. The exhaust pipe can be connected to the outside for discharge. ; The water is measured by the electromagnetic flowmeter and then returned to the water storage tank.

从以上的描述中,可以看出,本发明上述的实施例实现了如下技术效果:From the above description, it can be seen that the above-mentioned embodiments of the present invention have achieved the following technical effects:

本发明的潜水泵测试系统包括:水沙输送结构100,包括储水罐1、沙箱2以及水沙混合罐3,储水罐1和沙箱2均与水沙混合罐3连通,以分别向水沙混合罐3内通入水和沙,水沙混合罐3具有用于与测试井连通的第一输出口;气体输送结构200,包括空气压缩机4和用于与测试井连通的第二输出口;检测结构,包括分离组件和检测组件,分离组件与位于测试井内的待测试的潜水泵400连通,以将潜水泵400中流出的流体分离为水、气体和干沙;检测组件用于分别检测分离得出后的水、气体和干沙的重量。采用上述设置,通过被模拟井下真实的环境对矿用潜水泵进行分析,分析出泵的真实性能参数,解决现有技术中的测试潜水泵的系统的测试结果存在较大偏差的问题。The submersible pump testing system of the present invention comprises: water-

以上仅为本发明的优选实施例而已,并不用于限制本发明,对于本领域的技术人员来说,本发明可以有各种更改和变化。凡在本发明的精神和原则之内,所作的任何修改、等同替换、改进等,均应包含在本发明的保护范围之内。The above are only preferred embodiments of the present invention, and are not intended to limit the present invention. For those skilled in the art, the present invention may have various modifications and changes. Any modifications, equivalent replacements, improvements, etc. made within the spirit and principles of the present invention shall be included within the protection scope of the present invention.

Claims (12)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210940263.5ACN115263773A (en) | 2022-08-05 | 2022-08-05 | Submersible pump test system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210940263.5ACN115263773A (en) | 2022-08-05 | 2022-08-05 | Submersible pump test system |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115263773Atrue CN115263773A (en) | 2022-11-01 |

Family

ID=83749314

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210940263.5APendingCN115263773A (en) | 2022-08-05 | 2022-08-05 | Submersible pump test system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115263773A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118728709A (en)* | 2024-06-24 | 2024-10-01 | 山东大洋矿用设备有限公司 | A flow test device for variable frequency submersible pumps used in mines |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN204073932U (en)* | 2014-09-05 | 2015-01-07 | 南京奥博电气有限公司 | Frequency conversion Bidirectional agitator |

| CN206474164U (en)* | 2017-02-24 | 2017-09-08 | 潍坊昊海新材料有限公司 | A kind of polyurethane resin is automatically synthesized reaction unit |

| CN206668257U (en)* | 2017-04-29 | 2017-11-24 | 西南石油大学 | A kind of experimental provision simulated production water and shaked out on the influence of individual well Wellbore of Gas Wells |

| CN206688659U (en)* | 2016-12-21 | 2017-12-01 | 中国石油天然气股份有限公司 | Continuous feeding system of solid polyolefin catalyst with temperature control |

| CN107780888A (en)* | 2017-11-30 | 2018-03-09 | 青岛海洋地质研究所 | Gas hydrates pilot production analogue means and method |

| CN107842357A (en)* | 2017-11-30 | 2018-03-27 | 青岛海洋地质研究所 | Hydrate exploits artificial lift characteristic curve of centrifugal pump test system and method |

| CN107956456A (en)* | 2017-11-30 | 2018-04-24 | 青岛海洋地质研究所 | Air-water-sand three-phase the injection distribution system and method for simulating hydrate emulation exploitation |

- 2022

- 2022-08-05CNCN202210940263.5Apatent/CN115263773A/enactivePending

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN204073932U (en)* | 2014-09-05 | 2015-01-07 | 南京奥博电气有限公司 | Frequency conversion Bidirectional agitator |

| CN206688659U (en)* | 2016-12-21 | 2017-12-01 | 中国石油天然气股份有限公司 | Continuous feeding system of solid polyolefin catalyst with temperature control |

| CN206474164U (en)* | 2017-02-24 | 2017-09-08 | 潍坊昊海新材料有限公司 | A kind of polyurethane resin is automatically synthesized reaction unit |

| CN206668257U (en)* | 2017-04-29 | 2017-11-24 | 西南石油大学 | A kind of experimental provision simulated production water and shaked out on the influence of individual well Wellbore of Gas Wells |

| CN107780888A (en)* | 2017-11-30 | 2018-03-09 | 青岛海洋地质研究所 | Gas hydrates pilot production analogue means and method |

| CN107842357A (en)* | 2017-11-30 | 2018-03-27 | 青岛海洋地质研究所 | Hydrate exploits artificial lift characteristic curve of centrifugal pump test system and method |

| CN107956456A (en)* | 2017-11-30 | 2018-04-24 | 青岛海洋地质研究所 | Air-water-sand three-phase the injection distribution system and method for simulating hydrate emulation exploitation |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118728709A (en)* | 2024-06-24 | 2024-10-01 | 山东大洋矿用设备有限公司 | A flow test device for variable frequency submersible pumps used in mines |

| CN118728709B (en)* | 2024-06-24 | 2025-01-21 | 山东大洋矿用设备有限公司 | A flow test device for variable frequency submersible pumps used in mines |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108592978A (en) | A kind of oil gas water multiphase on-line metering calibration calibrating installation | |

| CN107083950B (en) | Calibration system and calibration method based on weighing type single well metering device | |

| CN107587868B (en) | Oil well metering integrated device | |

| CN106979162A (en) | Pump closed testing bench control system and method for testing | |

| CN103279142B (en) | A kind of load test intelligent control water tank loading method | |

| CN104879094B (en) | Downhole throttling gas well shaft simulation experiment device | |

| CN103925205A (en) | Comprehensive testbed for water pumps | |

| CN104776971A (en) | Visualization experiment device for liquid and sand carrying of gas flow | |

| CN105486358A (en) | Gas-liquid two-phase flow parameter measuring method based on double-differential pressure of Venturi tube | |

| CN104502161B (en) | Dust sampler calibrating installation | |

| CN103149012B (en) | Experimental device and method for simulating flow characteristic of coal bed gas gathering and transportation pipeline | |

| CN206801901U (en) | Pump closed testing bench control system | |

| CN115263773A (en) | Submersible pump test system | |

| CN216791618U (en) | Ground source heat pump engineering buried pipe well quality detection device | |

| CN202008432U (en) | Device for detecting passage flow capacity inside turbine blade through adopting constant volume water flow rate | |

| CN206695983U (en) | A kind of air valve performance testing device | |

| CN108104792A (en) | A kind of real-time separate measurement device of oil gas water three phase | |

| CN108843315B (en) | Sensing type comprehensive automatic metering device and oil quality calculation method | |

| CN108254034A (en) | A kind of Novel oil gas moisture phase flow rate on-line metering device and its metering method | |

| CN110031649B (en) | A capacity detection device for air flow velocity and detection method thereof | |

| CN204666329U (en) | A kind of air-flow is taken liquid and is taken sand visual experimental apparatus | |

| CN109839154B (en) | Oil well metering system and method | |

| RU124497U1 (en) | STAND FOR TESTING OF BOREHOLD GAS AND SAND SEPARATORS | |

| CN115406495A (en) | Oil-gas-water three-phase flow metering device and metering method | |

| CN109030300A (en) | A kind of pit shaft and pipeline small particle sand sedimentation experiment device and method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |