CN115211802A - Laparoscopic flushing method and flushing equipment - Google Patents

Laparoscopic flushing method and flushing equipmentDownload PDFInfo

- Publication number

- CN115211802A CN115211802ACN202210784283.8ACN202210784283ACN115211802ACN 115211802 ACN115211802 ACN 115211802ACN 202210784283 ACN202210784283 ACN 202210784283ACN 115211802 ACN115211802 ACN 115211802A

- Authority

- CN

- China

- Prior art keywords

- gas

- flushing

- control switch

- rinsing

- pressure

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B1/00—Instruments for performing medical examinations of the interior of cavities or tubes of the body by visual or photographical inspection, e.g. endoscopes; Illuminating arrangements therefor

- A61B1/12—Instruments for performing medical examinations of the interior of cavities or tubes of the body by visual or photographical inspection, e.g. endoscopes; Illuminating arrangements therefor with cooling or rinsing arrangements

- A61B1/126—Instruments for performing medical examinations of the interior of cavities or tubes of the body by visual or photographical inspection, e.g. endoscopes; Illuminating arrangements therefor with cooling or rinsing arrangements provided with means for cleaning in-use

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Surgery (AREA)

- Nuclear Medicine, Radiotherapy & Molecular Imaging (AREA)

- Biomedical Technology (AREA)

- Optics & Photonics (AREA)

- Pathology (AREA)

- Radiology & Medical Imaging (AREA)

- Biophysics (AREA)

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Heart & Thoracic Surgery (AREA)

- Medical Informatics (AREA)

- Molecular Biology (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Endoscopes (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及手术设备技术领域,尤其涉及一种腔镜冲洗方法及冲洗设备。The present invention relates to the technical field of surgical equipment, and in particular, to a method for flushing a laparoscope and a flushing device.

背景技术Background technique

目前大部分对腔镜镜头的清洁操作是由人工完成的,具体过程为将腔镜取出,再清洗镜头并擦拭镜头。在完成清洁操作后,再将其放入腹腔继续进行手术,这样会浪费手术时间,降低手术效率,并且配备专门人员清洁镜头会增加手术成本,且清洗效果往往不理想,不能解决残留水渍的问题。At present, most of the cleaning operations on the lens of the endoscope are done manually. The specific process is to take out the endoscope, then clean the lens and wipe the lens. After the cleaning operation is completed, it will be put into the abdominal cavity to continue the operation, which will waste the operation time and reduce the operation efficiency. Moreover, the provision of specialized personnel to clean the lens will increase the operation cost, and the cleaning effect is often unsatisfactory, which cannot solve the problem of residual water stains. question.

发明内容SUMMARY OF THE INVENTION

为了解决上述技术问题,本发明提供了一种腔镜冲洗方法及冲洗设备,解决了传统清洗腔镜方法所导致的清洗效果不理想,进而影响手术效率,浪费手术时间及成本的问题。In order to solve the above technical problems, the present invention provides a laparoscope flushing method and flushing equipment, which solve the problems of unsatisfactory cleaning effect caused by traditional laparoscope cleaning methods, thereby affecting operation efficiency and wasting operation time and cost.

根据本发明的一个方面,提供一种腔镜冲洗方法,包括:冲洗步骤和吹净步骤;冲洗步骤为向冲洗件通入清洗液,以使得所述冲洗件冲洗腔镜;吹净步骤为向冲洗件通入吹净气体,以使得所述冲洗件向腔镜吹气。According to one aspect of the present invention, a method for rinsing a cavity mirror is provided, which includes: a rinsing step and a blowing step; the rinsing step is to pass a cleaning solution into the rinsing part, so that the rinsing part rinses the cavity mirror; The flushing piece is passed through the blowing gas, so that the flushing piece blows air to the cavity mirror.

其中,所述腔镜冲洗方法包括:交替执行所述冲洗步骤和所述吹净步骤,和/或,单独执行所述吹净步骤,和/或单独执行所述冲洗步骤。Wherein, the method for rinsing a cavity mirror includes: performing the rinsing step and the blowing step alternately, and/or individually performing the blowing step, and/or performing the rinsing step alone.

根据本发明的另一个方面,提供一种腔镜冲洗设备,包括:冲洗件、冲洗装置和吹净装置;冲洗装置与所述冲洗件连接,所述冲洗装置用于向所述冲洗件通入清洗液;吹净装置与所述冲洗件连接,所述吹净装置用于向所述冲洗件通入吹净气体。According to another aspect of the present invention, there is provided a device for rinsing a cavity mirror, comprising: a rinsing part, a rinsing device and a blowing device; the rinsing device is connected to the rinsing part, and the rinsing device is used to pass into the rinsing part cleaning liquid; a blowing device is connected to the flushing element, and the blowing device is used for introducing blowing gas to the flushing element.

优选地,所述腔镜冲洗设备包括:排气件、排气出口以及设置于所述排气件与所述排气出口之间的排气装置,所述排气装置用于控制由所述排气件向所述排气出口排出的气体的流量;Preferably, the cavity mirror cleaning device comprises: an exhaust part, an exhaust outlet, and an exhaust device disposed between the exhaust part and the exhaust outlet, the exhaust device is used to control the the flow rate of the gas discharged from the exhaust element to the exhaust outlet;

优选地,所述排气件与所述排气装置之间设置有气体滤芯;Preferably, a gas filter element is arranged between the exhaust member and the exhaust device;

优选地,所述排气装置包括流量传感器和第三控制开关,所述流量传感器用于检测流经所述排气装置的气体流量,所述第三控制开关用于控制流经所述排气装置的气体流量。Preferably, the exhaust device includes a flow sensor and a third control switch, the flow sensor is used to detect the flow of gas flowing through the exhaust device, and the third control switch is used to control the flow of the exhaust gas The gas flow of the device.

其中,所述冲洗装置包括清洗液容置部,所述清洗液容置部用于容置清洗液和可调压力气体,所述清洗液容置部通过清洗管与所述冲洗件连接;和/或,Wherein, the flushing device includes a cleaning liquid accommodating portion, the cleaning liquid accommodating portion is used for accommodating cleaning liquid and adjustable pressure gas, and the cleaning liquid accommodating portion is connected with the flushing member through a cleaning pipe; and /or,

所述吹净装置包括缓冲腔,所述缓冲腔用于容置吹净气体,所述缓冲腔通过吹气管与所述冲洗件连接。The blowing device includes a buffer cavity, the buffer cavity is used for accommodating the blowing gas, and the buffer cavity is connected with the flushing member through a blowing pipe.

其中,所述清洗管上设置有第一控制开关;Wherein, the cleaning pipe is provided with a first control switch;

所述吹气管上设置有第二控制开关和/或压力检测器件。The blowing pipe is provided with a second control switch and/or a pressure detection device.

其中,所述腔镜冲洗设备还包括压力气体输入端口,用于连接压力气体供应装置,所述压力气体输入端口通过输气管组分别与所述清洗液容置部以及所述缓冲腔连通,其中,Wherein, the endoscopic rinsing device further includes a pressure gas input port for connecting to a pressure gas supply device, and the pressure gas input port is respectively communicated with the cleaning liquid accommodating part and the buffer chamber through the gas delivery tube group, wherein ,

所述输气管组包括:The air delivery tube group includes:

主输气管,其一端与所述压力气体输入端口连接;a main gas pipeline, one end of which is connected to the pressure gas input port;

第一分支输气管,其一端与所述主输气管的另一端连接,其另一端与所述清洗液容置部连接;a first branch gas pipeline, one end of which is connected with the other end of the main gas pipeline, and the other end is connected with the cleaning liquid accommodating part;

第二分支输气管,其一端与所述主输气管的另一端连接,其另一端与所述缓冲腔连接;One end of the second branch gas pipeline is connected with the other end of the main gas pipeline, and the other end is connected with the buffer cavity;

所述输气管组上设置有控制开关组,用于控制所述主输气管的通断、所述第一分支输气管的通断和/或所述第二分支输气管的通断。A control switch group is provided on the gas delivery pipe group, which is used to control the on-off of the main gas delivery pipe, the on-off of the first branch gas delivery pipe and/or the on-off of the second branch gas delivery pipe.

其中,所述清洗液容置部的外围设置有第一加热装置;和/或,Wherein, a first heating device is provided on the periphery of the cleaning liquid accommodating part; and/or,

所述压力气体输入端口处设置有第二加热装置;和/或,A second heating device is provided at the pressure gas input port; and/or,

所述缓冲腔的外围设置有第三加热装置。A third heating device is arranged on the periphery of the buffer cavity.

其中,所述腔镜冲洗设备还包括操作部件以及与所述操作部件连接的控制装置,所述控制装置与所述第一控制开关、所述第二控制开关、所述压力检测器件以及所述控制开关组连接;Wherein, the endoscopic rinsing equipment further includes an operating part and a control device connected with the operating part, the control device is connected with the first control switch, the second control switch, the pressure detection device and the Control switch group connection;

所述控制装置用于响应于所述操作部件发送的操作指令,控制所述第一控制开关、所述第二控制开关以及所述控制开关组,和/或,所述控制装置用于响应于所述压力检测器件发送的压力信号,控制所述第一控制开关、所述第二控制开关以及所述控制开关组。The control device is configured to control the first control switch, the second control switch and the control switch group in response to an operation instruction sent by the operating component, and/or the control device is configured to respond to the The pressure signal sent by the pressure detection device controls the first control switch, the second control switch and the control switch group.

其中,所述腔镜冲洗设备还包括外壳,所述清洗液容置部、所述缓冲腔、所述操作部件、所述控制装置均设置于所述外壳内,所述压力气体输入端口设置于所述外壳上;Wherein, the cavity mirror washing equipment further includes a casing, the cleaning liquid accommodating part, the buffer chamber, the operating part, and the control device are all disposed in the casing, and the pressure gas input port is disposed in the casing. on the housing;

所述外壳上还设置有清洗液输出端口以及压力气体输出端口,所述清洗液输出端口与所述清洗液容置部连通,所述吹气管包括第一吹气管和第二吹气管,所述第一吹气管连接所述缓冲腔和所述压力气体输出端口,所述第二控制开关和所述压力检测器件设置于所述第一吹气管上,所述第二吹气管连接所述压力气体输出端口和所述冲洗件。The casing is also provided with a cleaning liquid output port and a pressure gas output port, the cleaning liquid output port is communicated with the cleaning liquid accommodating part, and the air blowing pipe includes a first air blowing pipe and a second air blowing pipe. The first blowing pipe is connected to the buffer chamber and the pressure gas output port, the second control switch and the pressure detection device are arranged on the first blowing pipe, and the second blowing pipe is connected to the pressure gas output port and the flush piece.

其中,所述腔镜冲洗设备还包括脚踏装置,所述脚踏装置与所述控制装置连接,所述控制装置用于响应于所述脚踏装置发送的操作指令,控制所述第一控制开关、所述第二控制开关以及所述控制开关组。Wherein, the endoscopic washing equipment further includes a foot pedal device, the foot pedal device is connected with the control device, and the control device is used for controlling the first control device in response to an operation instruction sent by the foot pedal device a switch, the second control switch, and the control switch group.

本发明的优点在于:The advantages of the present invention are:

本发明的腔镜冲洗方法,通过冲洗步骤和吹净步骤分别向冲洗件提供清洗液和吹净气体,以供冲洗件完成冲洗操作和吹净操作,通过分别执行冲洗步骤和吹净步骤可以先对腔镜进行冲洗操作,以将被污染的腔镜表面洗净,再进行吹掉的操作,以将腔镜上残留的清洗液吹掉,避免残留水渍。该腔镜冲洗方法可以提升设备清洗效果,无需再由人工清洗腔镜设备,清洗效率高,降低手术成本,节约手术时间。In the method for rinsing a cavity mirror of the present invention, the cleaning liquid and the blowing gas are respectively provided to the rinsing part through the rinsing step and the blowing step, so that the rinsing part can complete the rinsing operation and the blowing operation. Rinse the cavity mirror to clean the contaminated surface of the cavity mirror, and then perform a blow-off operation to blow off the residual cleaning solution on the cavity mirror to avoid residual water stains. The endoscopic flushing method can improve the cleaning effect of the equipment, no need to manually clean the endoscopic equipment, the cleaning efficiency is high, the operation cost is reduced, and the operation time is saved.

参照附图来阅读对于示例性实施例的以下描述,本发明的其他特性特征和优点将变得清晰。Other characteristic features and advantages of the present invention will become apparent upon reading the following description of exemplary embodiments with reference to the accompanying drawings.

附图说明Description of drawings

并入到说明书中并且构成说明书的一部分的附图示出了本发明的实施例,并且与描述一起用于解释本发明的原理。在这些附图中,类似的附图标记用于表示类似的要素。下面描述中的附图是本发明的一些实施例,而不是全部实施例。对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,可以根据这些附图获得其他的附图。The accompanying drawings, which are incorporated in and constitute a part of the specification, illustrate embodiments of the invention and, together with the description, serve to explain the principles of the invention. In the figures, like reference numerals are used to refer to like elements. The drawings in the following description are some, but not all, embodiments of the invention. For those of ordinary skill in the art, other drawings can be obtained from these drawings without creative effort.

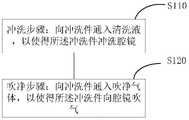

图1是本发明示出的腔镜冲洗方法的流程图;Fig. 1 is the flow chart of the endoscopic flushing method shown in the present invention;

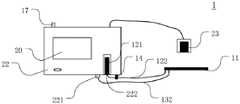

图2是本发明示出的腔镜冲洗设备的结构的示意图;2 is a schematic diagram of the structure of the endoscopic flushing device shown in the present invention;

图3是本发明示出的实施例的腔镜冲洗设备结构的示意图;3 is a schematic diagram of the structure of the endoscopic flushing device according to the embodiment shown in the present invention;

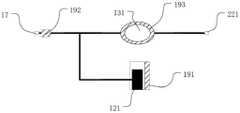

图4是本发明示出的腔镜冲洗设备的内部结构示意图;4 is a schematic diagram of the internal structure of the endoscopic flushing device shown in the present invention;

图5是本发明示出的实施例的腔镜冲洗设备的内部结构示意图;5 is a schematic diagram of the internal structure of the endoscopic flushing device according to the embodiment shown in the present invention;

图6是本发明示出的实施例的腔镜冲洗设备结构的示意图;6 is a schematic diagram of the structure of the endoscopic flushing device according to the embodiment shown in the present invention;

图7是本发明示出的实施例的腔镜冲洗设备的结构示意图;7 is a schematic structural diagram of the endoscopic rinsing device according to the embodiment shown in the present invention;

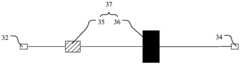

图8是本发明示出的实施例的腔镜冲洗设备的排气装置的结构示意图。FIG. 8 is a schematic structural diagram of an exhaust device of a cavity mirror washing device according to an embodiment of the present invention.

附图标记:Reference number:

1、腔镜冲洗设备;1. Endoscopic flushing equipment;

11、冲洗件;11. Flushing parts;

12、冲洗装置;121、清洗液容置部;122、清洗管;12. Rinsing device; 121. Cleaning liquid accommodating part; 122. Cleaning pipe;

13、吹净装置;131、缓冲腔;132、吹气管;1321、第一吹气管;1322、第二吹气管;13, blowing device; 131, buffer chamber; 132, blowing pipe; 1321, first blowing pipe; 1322, second blowing pipe;

14、第一控制开关;14. The first control switch;

15、第二控制开关;15. The second control switch;

16、压力检测器件;16. Pressure detection device;

17、压力气体输入端口;172、输气管组;173、主输气管;174、第一分支输气管;175、第二分支输气管;17. Pressure gas input port; 172, gas pipeline group; 173, main gas pipeline; 174, first branch gas pipeline; 175, second branch gas pipeline;

18、控制开关组;18. Control switch group;

191、第一加热装置;192、第二加热装置;193、第三加热装置;191, the first heating device; 192, the second heating device; 193, the third heating device;

20、操作部件;20. Operating parts;

21、减压装置;21. Decompression device;

22、外壳;221、压力气体输出端口;222、清洗液输出端口;22. Shell; 221. Pressure gas output port; 222. Cleaning fluid output port;

23、脚踏装置;23. Pedal device;

31、排气件;32、排气端口;33、气体滤芯;34、排气出口;37、排气装置;35、流量传感器;36、控制开关;38、排气管。31, exhaust part; 32, exhaust port; 33, gas filter element; 34, exhaust outlet; 37, exhaust device; 35, flow sensor; 36, control switch; 38, exhaust pipe.

具体实施方式Detailed ways

为使本发明实施例的目的、技术方案和优点更加清楚,下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。需要说明的是,在不冲突的情况下,本申请中的实施例及实施例中的特征可以相互任意组合。In order to make the purposes, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments These are some embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention. It should be noted that, the embodiments in the present application and the features in the embodiments may be arbitrarily combined with each other if there is no conflict.

随着工业制造技术的突飞猛进,腔镜手术是未来手术发展的一个必然趋势,腔镜是用于腹腔内检查和治疗的内窥镜,可以直接清楚地观察到患者腹腔内的情况,并可以对异常情况做手术治疗。但在手术过程中,腔镜镜头很容易被体内组织或设备产生的烟雾污染,因此不得不暂时中断手术,将腔镜取出并对镜头进行清洁。目前,大部分对腔镜镜头的清洁操作是由人工完成的,具体过程为将腔镜取出后清洗镜头并擦拭镜头,随后,再将其放入腹腔继续进行手术。这样的清洗方式不仅会浪费手术时间,降低手术效率,并且配备专门人员清洁镜头会增加手术成本,并且清洗效果往往不理想,不能彻底解决残留水渍的问题,导致清洁效果达不到实际使用需求。并且现有的腔镜冲洗方式中,为冲洗设备提供清洗液主要是依靠手动压出,例如,通过按压压力袋或推动注射器来为清洗液提供动力,这样的清洗液达不到实际需要的冲洗压力,无法彻底清除腔镜镜头上的污渍,且在冲洗后,腔镜镜头上会留有水渍,仍然会影响腔镜的镜头清晰度,进而影响手术的顺利进行。With the rapid development of industrial manufacturing technology, laparoscopic surgery is an inevitable trend in the development of surgery in the future. Laparoscopic surgery is an endoscope used for intra-abdominal inspection and treatment, which can directly and clearly observe the situation in the abdominal cavity of patients, and can make Surgical treatment for abnormal conditions. However, during the operation, the lens of the endoscope is easily contaminated by the smoke generated by the body tissue or equipment, so the operation has to be temporarily interrupted, the endoscope is taken out and the lens is cleaned. At present, most of the cleaning operations on the lens of the endoscope are done manually. The specific process is to clean the lens and wipe the lens after taking out the endoscope, and then put it into the abdominal cavity to continue the operation. Such cleaning method will not only waste the operation time and reduce the operation efficiency, but also will increase the operation cost with specialized personnel to clean the lens, and the cleaning effect is often unsatisfactory. . Moreover, in the existing endoscopic flushing methods, the cleaning solution for the flushing equipment mainly relies on manual pressing. For example, the cleaning solution is powered by pressing the pressure bag or pushing the syringe. Such cleaning solution cannot meet the actual needs of the flushing. Pressure cannot completely remove the stains on the lens of the endoscope, and after rinsing, there will be water stains on the lens of the endoscope, which will still affect the clarity of the lens of the endoscope, thereby affecting the smooth progress of the operation.

为了解决上述问题,本发明提供一种腔镜冲洗方法及冲洗设备。在使用过程中,通过实施冲洗步骤提供清洗液,可以使冲洗件在手术过程中对腔镜进行冲洗操作;再通过吹净步骤提供吹净气体,可以使冲洗件在手术过程中对腔镜上残留的水渍进行吹净操作。从而避免了人工清洗腔镜导致清洗不彻底而影响手术进度的问题,并解决了浪费手术时间,增加手术成本等问题。In order to solve the above-mentioned problems, the present invention provides a method for rinsing a cavity mirror and a rinsing device. In the process of use, by implementing the flushing step to provide cleaning liquid, the flushing piece can be used to flush the endoscope during the operation; and then the flushing gas can be provided by the blowing step, so that the flushing piece can be flushed against the endoscope during the operation. Blow out the remaining water stains. This avoids the problem that manual cleaning of the endoscope results in incomplete cleaning and affects the progress of the operation, and solves the problems of wasting operation time and increasing operation costs.

下面结合附图,对根据本发明所提供的腔镜冲洗方法及冲洗设备进行详细说明。The method and apparatus for rinsing a cavity mirror provided by the present invention will be described in detail below with reference to the accompanying drawings.

参考图1,图1为腔镜冲洗方法的流程图,该腔镜冲洗方法包括:冲洗步骤和吹净步骤。在本实施例中,可以先执行冲洗步骤后执行吹净步骤。具体地,腔镜冲洗方法包括:Referring to FIG. 1 , FIG. 1 is a flow chart of a method for rinsing an endoscope. The method for rinsing an endoscope includes a rinsing step and a blowing step. In this embodiment, the flushing step may be performed first and then the blowing step may be performed. Specifically, the endoscopic flushing method includes:

S110、冲洗步骤:向冲洗件通入清洗液,以使得冲洗件冲洗腔镜。S110. Rinsing step: passing cleaning liquid into the rinsing part, so that the rinsing part rinses the cavity mirror.

该步骤中,清洗液通入冲洗件的方式可以为增加清洗液储存装置的压力,以将清洗液压出的方式进行,或是以其他方式压出,在此不做具体限定。该步骤中,冲洗过程可以采用连续冲洗或脉冲冲洗方式。例如,在一些实施例中,持续地向冲洗件通入清洗液,以通过冲洗件对腔镜进行连续冲洗,在另一些实施例中,以脉冲地形式向冲洗件通入清洗液,例如,以每间隔t1时长向冲洗件通t2时长的清洗液,以使得冲洗件以脉冲形式对腔镜进行冲洗。腔镜在经过冲洗步骤后,已经可以将腔镜上的体内组织、血液等或手术过程中设备产生的烟雾冲洗干净。In this step, the cleaning fluid may be passed into the flushing member by increasing the pressure of the cleaning fluid storage device, by expelling the cleaning fluid, or by pressing out in other ways, which are not specifically limited herein. In this step, the flushing process may adopt continuous flushing or pulse flushing. For example, in some embodiments, the cleaning fluid is continuously supplied to the flushing element to continuously flush the endoscope through the flushing element, and in other embodiments, the cleaning fluid is supplied to the flushing element in a pulsed manner, for example, The cleaning solution for the duration of t2 is supplied to the flushing element at intervals of t1, so that the flushing element flushes the endoscope in the form of pulses. After the laparoscope goes through the flushing step, the body tissue, blood, etc. on the laparoscope or the fumes generated by the equipment during the operation can be washed away.

S120、吹净步骤:向冲洗件通入吹净气体,以使得冲洗件向腔镜吹气。S120, the blowing step: blowing the cleaning gas into the flushing piece, so that the flushing piece blows the cavity mirror.

通常情况下,腔镜在经过冲洗步骤后虽然已经达到清洁的效果,但镜头上还可能会存有少量清洗液,清洗液可能会在镜头上形成水渍。通过向冲洗件通入吹净气体,以使得冲洗件向腔镜吹气。与步骤S110类似地,该步骤中,吹气过程可采用连续吹气或采用脉冲吹气方式。例如,在一些实施例中,持续地向冲洗件通入吹净气体,以通过冲洗件对腔镜进行连续吹气,在另一些实施例中,以脉冲地形式向冲洗件通入吹净气体,例如,以每间隔t3时长向冲洗件通t4时长的吹净气体,以使得冲洗件以脉冲形式对腔镜进行吹气。通过吹净步骤后可以避免镜头上残留水渍,达到彻底清洁腔镜的效果。并且整个冲洗过程中无需暂停手术,以及将腔镜取出等步骤,因此节省了手术时间和手术过程中的清洗设备的成本。Usually, although the endoscope has achieved the cleaning effect after the rinsing step, there may still be a small amount of cleaning fluid on the lens, and the cleaning fluid may form water stains on the lens. The flushing piece is blown to the cavity mirror by passing the flushing gas into the flushing piece. Similar to step S110, in this step, the air blowing process may adopt continuous air blowing or pulse air blowing. For example, in some embodiments, the flushing gas is continuously fed to the flushing member to continuously flush the cavity mirror through the flushing member, and in other embodiments, the flushing gas is fed to the flushing member in a pulsed fashion For example, blowing gas for a duration of t4 is passed to the flushing element at every interval t3, so that the flushing element blows the cavity mirror in the form of pulses. After the blowing step, the residual water stains on the lens can be avoided, and the effect of thoroughly cleaning the cavity mirror can be achieved. In the whole flushing process, there is no need to suspend the operation and take out the endoscope, thus saving the operation time and the cost of cleaning equipment during the operation.

在一个具体的实施例中,腔镜冲洗方法包括:在一次冲洗过程中,可以根据实际需要选择,采用冲洗步骤和吹净步骤交替进行,可以及时、快速地将腔镜镜头冲洗干净,以使在整个手术过程中,可以始终保持腔镜镜头整洁,提高清洗效果。在另一个实施例中,还可以单独执行吹净步骤以及冲洗步骤。根据实际操作的需要,可能仅需要单独执行冲洗步骤或单独执行吹净步骤来完成相应的操作,便于使用者操作,优化腔镜的使用效果。In a specific embodiment, the method for rinsing the endoscope includes: in one rinsing process, it can be selected according to actual needs, and the rinsing step and the blowing step are alternately performed, so that the endoscope lens can be rinsed in time and quickly, so that the During the entire operation, the endoscope lens can be kept clean and tidy, and the cleaning effect can be improved. In another embodiment, the blowing step and the rinsing step may also be performed separately. According to actual operation needs, it may only be necessary to perform the flushing step or the blowing step separately to complete the corresponding operation, which is convenient for the user to operate and optimizes the use effect of the endoscope.

本公开一个示例性实施例提供一种腔镜冲洗设备,该腔镜冲洗设备可用于执行上述的腔镜冲洗方法。参考图2和图4所示,腔镜冲洗设备包括冲洗件11、冲洗装置12和吹净装置13。其中,冲洗件11为可以执行上述冲洗步骤和吹净步骤的装置。如图2和图4所示,冲洗装置12和吹净装置13均与冲洗件11连接,分别为冲洗件11提供清洗液和吹净气体,以执行上述冲洗步骤和吹净步骤。在一个实施例中,参考图2、图3和图4,冲洗装置12和吹净装置13与冲洗件11连接的方式,可以设置为如图2所示的冲洗装置12和吹净装置13共同连接同一冲洗件11,其中冲洗装置12与吹净装置13输出的清洗液和吹净气体在冲洗件11中互不连通,便于冲洗步骤与吹净步骤的快速切换。还可以设置为如图3所示的冲洗装置12与吹净装置13分别单独对应设置两个冲洗件11,使两个冲洗件分别单独输出清洗液和吹净气体,更便于使用者的精准控制。An exemplary embodiment of the present disclosure provides an endoscope rinsing device, which can be used to perform the above-mentioned endoscope rinsing method. Referring to FIG. 2 and FIG. 4 , the endoscopic flushing device includes a flushing

在一个具体的实施例中,冲洗装置12包括清洗液容置部121,清洗液容置部121用于容置清洗液和可调压力气体,清洗液容置部121通过清洗管122与冲洗件11连接。在本实施例中,可调压力气体为可以依据实际操作过程中所需要的压力进行调节的气体。如图2所示,清洗液容置部121可以为存有清洗液的容置装置来为冲洗装置12提供充足的清洗液,并通过压力气体将清洗液容置部121内的清洗液压出,以便于后续通过清洗管122将清洗液容置部121内的清洗液输送至冲洗件11的操作顺利、连续的进行。如图4所示,吹净装置13包括缓冲腔131,缓冲腔131用于容置吹净气体,缓冲腔131通过吹气管132与冲洗件11连接。缓冲腔131可以在使用冲洗装置12之前先对缓冲腔131进行充气、加压等操作,使缓冲腔131充满吹净气体,再通过吹气管132将冲洗件11与缓冲腔131连接,便于后续吹净步骤的顺利执行,以及可以达到实际吹净操作中所需要的吹净气体的压力。In a specific embodiment, the rinsing

如图2和图4所示的一个具体的实施例中,清洗管122上设置有第一控制开关14,第一控制开关14可用于对清洗液容置部121内的清洗液进行释放或关断的控制。具体地,将第一控制开关14设置于清洗液容置部121与冲洗件11之间的清洗管122上,即打开第一控制开关14时,清洗液容置部121内的清洗液可以被释放,并通过清洗管122输送至冲洗件11上。具体地,需先对清洗液容置部121内通入标准量的压力气体,当通入的压力气体达到需要的标准量时,再打开第一控制开关14即可通过压力气体压出清洗液容置部121内的清洗液。在另一个实施例中,吹气管132上设置有第二控制开关15,吹气管132连通缓冲腔131和冲洗件11,可以对吹净气体输出的流量进行控制,还可以对腔镜冲洗设备1何时进行吹净步骤进行控制。打开第二控制开关15时,缓冲腔131内的吹净气体可以通过吹气管132到达冲洗件11中,以进行吹净操作。当第二控制开关15关闭时,缓冲腔131用于储存吹净气体,不再通过吹气管132向冲洗件11提供吹净气体,此时,无法再执行吹净操作。其中,吹净气体可以为医用CO2气体等。在一个实施例中,吹气管132上还设置有压力检测器件16。压力检测器件16可以实时检测患者腹腔中的气压,如当压力检测器件16检测到腹腔中的气压达到一定值时,此时即使打开第二控制开关15也不能再实现对患者腹腔进行吹气、加压等操作。即当患者腹腔中压力达到一定值时,无论对第一控制开关14、第二控制开关15等如何操作均不会发生实际的控制效果,使腔镜冲洗设备1的操作过程更加安全。其中,第一控制开关14和第二控制开关15可以采用其他控制方式实现,如手动开关、夹管阀或其他机电部件来实现控制功能。In a specific embodiment as shown in FIG. 2 and FIG. 4 , the

如图4所示的一个具体的实施例中,腔镜冲洗设备1还包括压力气体输入端口17,用于连接压力气体供应装置。通过压力气体输入端口17为腔镜冲洗设备1的冲洗装置12和吹净装置13提供压力气体。在压力气体输入端口17还设有具备减压功能的装置,如图4所示的控制装置。由于压力气体输入端口输入的气体压强较大,不可以直接使用,因此,在输入冲洗装置12和吹净装置13之前,需要将气体的压力由高压降为较低的压力。其中,具备减压功能的装置可以为在压力气体输入端口17处,设置如图4所示的减压装置21来将气体的压力将至便于使用的压力。随后,压力气体输入端口17通过输气管组172分别与清洗液容置部121以及缓冲腔131连通。一实施例中,输气管组172包括:主输气管173、第一分支输气管174和第二分支输气管175。主输气管173的一端与压力气体输入端口17连接,如图3所示,主输气管173的一端连通压力气体输入端口17,另一端用于与清洗液容置部121以及缓冲腔131对应的分支输气管连通,便于对对应部分输送压力气体。In a specific embodiment shown in FIG. 4 , the

具体地,第一分支输气管174,其一端与主输气管173的另一端连接,其另一端与清洗液容置部121连接;可以使从压力气体输入端口17的压力气体进入到清洗液容置部121内,对清洗液容置部121内进行加压,便于完成将清洗液输送至冲洗件11的操作。如图3所示,第一分支输气管174一端与主输气管173连接,一端与清洗液容置部121连接,将从主输气管173传来的压力气体输送至清洗液容置部121内,对清洗也容置部121内进行加压。通过对清洗液容置部121内进行加压,再打开第一控制开关14即可将清洗液容置部121内的清洗液压出,并通过对清洗液容置部121内压力的调整,可以使清洗液达到实际需要的压力来对腔镜镜头表面的污渍进行冲洗。Specifically, one end of the first

继续参考图4,第二分支输气管175,其一端与主输气管173的另一端连接,其另一端与缓冲腔131连接;通过压力气体输入端口17将压力气体输入至缓冲腔131内,便于缓存压力气体以及增加缓冲腔131内吹净气体的压力。由于腔镜镜头在冲洗后往往还会残留清洗液,残留的清洗液可能会在镜头上形成水渍,通过调节缓冲腔内的气体压强,可以控制对腔镜镜头的吹净操作的时长和吹净气体的强度,避免镜头上留有水渍的情况。Continue to refer to FIG. 4 , one end of the second

其中,输气管组172上设置有控制开关组18,用于控制主输气管的通断、第一分支输气管174的通断、第二分支输气管175的通断。控制开关组18可以控制输气管组172与第一分支输气管174和第二分支输气管175的通断,通过控制开关组18控制后续支气管的进气量。其中,控制开关组18可以为电磁阀开关,电磁开关阀可以通过pwm脉冲进行控制、采用微处理器计时控制,或是通过与缓冲腔131连接的压力检测器件16及微处理器算法进行控制,在此对于该控制方法不做具体限定。设置控制开关组18为电磁阀开关,可以自动控制输气管组172与第一分支输气管174和第二分支输气管175的通断,以及控制输气管组172分别对第一分支输气管174和第二分支输气管175输送的进气量。The

在一个具体的实施例中,压力气体输入端口17接入医用高压CO2,经减压装置21将CO2压强降到所需压强,例如压强降至2bar。降压后的CO2分为两路,一路经过控制开关组18中对应的开关后进入清洗液容置部121进行预存储,可以在输出清洗液时形成一定的压强,便于操作人员控制,第一控制开关14打开,清洗液容置部121内具有一定压强的CO2将清洗液压出。冲洗件11输出的清洗液强度依赖于清洗液容置部121内CO2的压强大小,且该压强大小受控制开关组18中对应的开关控制,控制方式可以为PWM控制、打开持续时间控制、压力值积分控制等。清洗液容置部121内压强大小可以在0bar至Nbar的范围内调节,其中,水压越大对腔镜镜头的冲洗能力越强,但综合安全性及患者体感舒适度,将该压强设置为0.5bar-1.5bar。另一路降压后的CO2,经过控制开关组18中对应的开关后进入缓冲腔131,缓冲腔131内存储一定体积、一定压强的CO2气体,受操作人员控制打开第二控制开关15,缓冲腔131内CO2气体喷出。冲洗件11喷出的CO2的强度依赖于缓冲腔131内CO2的压强大小,缓冲腔131内CO2的压强大小受控制开关组18中对应的开关控制。缓冲腔131内压强大小可以在0bar至Nbar范围内调节,气压越大则对镜头上的水渍的清洁能力越强,但综合安全性及患者舒适度,该压强设置为0.5bar-1bar。压力检测器件16的作用是监测患者腹腔内压力,如果患者腹腔内压力大于一定压强,例如大于20mmHg,则设备禁止第二控制开关15受控打开,确保患者安全。只有当患者腹腔压力低于安全气压以下,才能启动喷气功能。第二控制开关15处于打开状态下,即设备处于喷气过程中时,压力检测器件16实时监测患者腹腔压力,当大于一定压强时,例如30mmHg,立即关闭第二控制开关15停止喷气,必要时可以通过其他外接降压装置对患者的腹腔进行快速降压。In a specific embodiment, the pressure

本公开一示例性实施例中,如图7所示,腔镜冲洗设备包括排气件31、排气出口34以及设置于排气件31与排气出口34之间的排气装置37,排气装置37用于控制由排气件31向排气出口34排出的气体的流量。在实施腔镜手术时,可将排气件31至少部分地置于患者腹腔中,在向患者腹腔中通入吹净气体来对腔镜进行吹净处理时,患者腹腔中增加的气体可依次经排气件31和排气装置37,最终由排气出口34排出,排气装置37能够控制由排气件31向排气出口34排出的气体的流量,使得排气量与通入的吹净气体的量大致相同,从而保证患者腹腔中的气压平衡,提高手术的安全性。In an exemplary embodiment of the present disclosure, as shown in FIG. 7 , the cavity mirror cleaning device includes an

示例性地,如图7所示,在腔镜冲洗设备包括外壳22的实施例中,排气出口34设置于外壳22上,排气装置37设置于外壳22内部,外壳22上还设置有排气端口32,排气端口32与外壳22内的排气装置37连接,排气端口32经排气管38与排气件31连接,如此,提高了腔镜冲洗设备的集成度以及安装的便捷性。Exemplarily, as shown in FIG. 7 , in the embodiment in which the endoscopic washing device includes the

一实施例中,排气件31与排气装置37之间设置有气体滤芯33,通过气体滤芯33能够对患者体内排出的多余的气体进行过滤,滤除其中的有害气体颗粒后再排出,从而避免有害气体排入外部环境。示例性地,气体滤芯33设置在排气端口32处。In one embodiment, a gas filter element 33 is arranged between the

一实施例中,如图8所示,排气装置37包括流量传感器35和第三控制开关36,流量传感器35用于检测流经排气装置37的气体流量,第三控制开关36用于控制流经所述排气装置37的气体流量,示例性地,参考图8,流量传感器35的一端连接排气端口32,另一端经第三控制开关36连接排气出口34。In one embodiment, as shown in FIG. 8 , the

本实施例中,在执行吹净步骤过程中,冲洗件11向患者体内吹入吹净气体,例如CO2气体,于此同时,打开第三控制开关36,使得患者体内多余的气体依次经排气件31、排气管38、气体滤芯33、排气端口32、流量传感器35、第三控制开关36和排气出口34排出,流量传感器35实时监测排气流量,并通过第三控制开关36来控制排气流量,以使得排气流量与吹净过程中吹入患者体内的吹净气体总量大致相等,以保持患者体内气压恒定。In this embodiment, during the blowing step, the flushing

本公开一示例性实施例中,如图2和图5所示,清洗液容置部121的外围设置有第一加热装置191,第一加热装置191可以设置在清洗液容置部121外侧,如可以包含整个清洗液容置部121,也可如图5所示设置于清洗液容置部121外壁的一侧。第一加热装置191用于对清洗液容置部121内的清洗液进行加热,直至将清洗液加热至达到或接近患者体温,并在使用过程中保持该温度恒定。通过第一加热装置191可以使进入患者腹腔的清洗液不会因温度过低而导致患者不适,并且,具有一定温度的清洗液更便于冲洗腔镜镜头上的污渍。在一个实施例中,压力气体输入端口17上设置有第二加热装置192,第二加热装置192用于对输入的高压气体进行加热,其中,将第二加热装置192加热的温度设置为不高于后续加热装置加热的温度。第二加热装置192用以减小缓冲腔131和清洗液容置部121内由于温度系数引起的气压测量误差,减小后续装置中的气体膨胀率。在一个实施例中,缓冲腔131的外围设置有第三加热装置193,第三加热装置193可以设置于与缓冲腔131相接的外侧,还可以将第三加热装置193设置为完全包覆整个缓冲腔131的结构。用于对缓冲腔131内的气体加热到接近患者体温的温度,使进入患者腹腔的气体不会因温度过低而导致患者不适。对于加热装置,除了上述设置方式,还可采用外接独立设备来对清洗液和吹净气体进行单独加热,再将加热后的清洗液和吹净气体输送至清洗液容置部121以及缓冲腔131中,或是在清洗管122以及吹气管132外侧对清洗液及气体进行加热,同样可以达到上述加热效果。In an exemplary embodiment of the present disclosure, as shown in FIG. 2 and FIG. 5 , a

在一个具体的实施例中,第二加热装置192在气体输入端口17位置处对经过压力气体输入端口17的高压CO2气体进行初级加热,加热温度可以设置为20℃至30℃,既可以有效避免入口处因CO2气化或膨胀气压变小导致周边环境下降而结霜,也可以使CO2气体在进入缓冲腔131和清洗液容置部121前初步受热膨胀,减小缓冲腔131和清洗液容置部121内由于温度系数引起的气压测量误差。经第二加热装置192的初步加热后的CO2气体进入缓冲腔131暂存,CO2在缓冲腔131暂存过程中,经第三加热装置193加热,使CO2保持恒温,使温度恒定在适合人体适应的温度。在第二控制开关15打开后,具有适当温度的CO2气体进入患者腹腔吹掉镜头水渍。第一加热装置191对清洗液容置部121进行加热,使清洗液保持一定温度,使清洗液保持在适合人体适应的温度,第一控制开关14打开后,具有适当温度的清洗液进入患者腹腔清洗镜头污渍。In a specific embodiment, the

在一个具体的实施例中,如图2和图4所示,腔镜冲洗设备1还包括操作部件20以及与操作部件20连接的控制装置,控制装置与第一控制开关14、第二控制开关15、压力检测器件16以及控制开关组18连接。操作部件20设置于便于使用者操作的位置,可以对控制装置与第一控制开关14、第二控制开关15、压力检测器件16以及控制开关组18等部分进行具体、精准的控制操作。如通过操作部件20设置压力气体输出端口221输出气体的压力及温度,设置清洗液容置部121内清洗液的压力及温度,以及调节腔镜冲洗过程中的其他部分的参数等。使用者通过操作部件20将对腔镜冲洗设备1的控制指令输送到控制装置,控制装置用于响应于操作部件20发送的操作指令,控制第一控制开关14、第二控制开关15以及控制开关组18等,以完成对腔镜冲洗设备1各种功能的实现。在一个实施例中,控制装置用于响应压力检测器件16发送的压力信号,进而控制第一控制开关14、第二控制开关15以及控制开关组18。在腔镜冲洗设备1的使用过程中,当压力检测器件16检测到患者腹腔内的压力达到一定程度后,向控制装置发送一压力信号,控制装置响应于此信号,进行对第一控制开关14、第二控制开关15以及控制开关组18的操作的限制。具体地,当患者腹腔内的压力达到一定程度后,即使使用者在此时没有判断出患者腹腔中的压力,继续使用操作部件20对各个部分进行控制,也不会输出相应的控制结果。提高了腔镜冲洗设备1的使用安全性。其中,操作部件20可以设置为实体操作按键或触控操作按键,还可增设操作显示部件为操作部件20的具体操作进行显示,操作显示部件可以为LED、LCD显示部件。In a specific embodiment, as shown in FIG. 2 and FIG. 4 , the

在一个具体的实施例中,如图2、图3和图4所示,腔镜冲洗设备1还包括外壳22,清洗液容置部121、缓冲腔131、操作部件20、控制装置等均设置于外壳22内,压力气体输入端口17设置于外壳22上。压力气体供应装置于外壳22上的压力气体输入端口17处接入,清洗液容置部121、缓冲腔131、操作部件20、控制装置等均设置于外壳22内,使腔镜冲洗设备1结构更加紧凑,便于设备布置和安放,优化操作空间。外壳22上还设置有压力气体输出端口221以及清洗液输出端口222,清洗液输出端口222与清洗液容置部121连通,如图2结合图4所示,吹气管132包括第一吹气管1321和第二吹气管1322,第一吹气管1321连接缓冲腔131和压力气体输出端口221,第二控制开关15和压力检测器件16设置于第一吹气管1321上,可以使第二控制开关15和压力检测器件16均可放置于外壳22内,再通过第二吹气管1322完成吹净气体的引出,便于使用。In a specific embodiment, as shown in FIG. 2 , FIG. 3 and FIG. 4 , the

本公开一示例性实施例中,如图2所示,腔镜冲洗设备1还包括脚踏装置23,脚踏装置23与控制装置连接,控制装置用于响应于脚踏装置23发送的操作指令,控制第一控制开关14、第二控制开关15以及控制开关组18。其中,脚踏装置23设置于靠近使用者的位置,当使用者不便于操作操作部件20时,可以通过脚踏装置23对控制装置进行控制,控制装置通过脚踏装置23发出的指令对应控制第一控制开关14、第二控制开关15以及控制开关组18。可以实现腔镜冲洗设备的冲洗操作、吹净操作,以及两种操作交替进行的操作。例如,腔镜冲洗设备1正在进行冲洗操作,此时使用者想要切换成吹净操作,只需踩下脚踏装置23,并使踩下脚踏装置23的时间达到预设时间即可完成切换操作。如当踩下脚踏装置23的时长达到预设时间时,腔镜冲洗设备1执行的操作方式可以由当前执行的冲洗操作切换为吹净操作。若再次切换操作方式,同样踩下脚踏装置23保持预设时长即可。再如,使用者不仅可以切换腔镜冲洗设备1的操作方式,还可以启动和关闭腔镜冲洗设备1,即当使用者想要开启处于关闭状态的腔镜冲洗设备1时,连续两次踩下脚踏装置23,即可开启腔镜冲洗设备。上述操作方式仅是脚踏装置23控制方式的示例,其具体的控制方式在此不做限定。并且,对于脚踏装置23还可通过语音识别、感应识别等方式替换,在此同样不做具体限定。In an exemplary embodiment of the present disclosure, as shown in FIG. 2 , the

在一个实施例中,腔镜冲洗设备1通过压力气体输入端口17接入医用高压CO2,将含有清洗液的清洗液容置部121设置于第一加热装置191中,通过操作部件20设置清洗液喷出压力、清洗液冲洗时间、CO2喷出压力、CO2喷出时间、清洗喷气流程、清洗液温度、输出CO2温度等参数。在腔镜手术过程中,冲洗件11与腔镜镜头一同放置于患者腹腔内。如果腔镜镜头被污染影响手术正常进行,操作者可以通过脚踏装置23启动冲洗流程,例如冲洗步骤与吹净步骤交替操作步骤、单独冲洗步骤、单独吹净步骤等。In one embodiment, the

如图4和图6所示,腔镜冲洗设备1通过压力气体输入端口17接入医用高压CO2,分别对两个含有冲洗液的清洗液容置部121内进行加压,且两个清洗液容置部121的外侧分别设置有第一加热装置191中,并设置其中两个清洗液容置部121中容置的清洗液不同,不同的清洗液可以满足不同的清洗需求。当识别到输出第一个清洗液容置部121内的清洗液时,自动执行单独冲洗步骤,第一个清洗液容置部121中的清洗液可以为不易残留在腔镜镜头的清洗液,或者不易产生水渍的清洗液,在执行冲洗步骤后即可完成对腔镜镜头的清洁。当识别到输出第二个清洗液容置部121内的清洗液时为自动执行冲洗步骤与吹净步骤交替操作,第二个清洗液容置部中的清洗液可以为易残留在腔镜镜头的清洗液,或者易产生水渍的清洗液,执行冲洗步骤和吹净步骤交替操作可以自动将残留在腔镜镜头上的清洗液吹净。其中,自动操作步骤还包括自动调节清洗液喷出压力,清洗液冲洗时间,冲洗喷气流程,清洗液温度等参数。对于上述参数的调节也可依据实际情况通过操作部件20设置。As shown in FIGS. 4 and 6 , the

在腔镜手术过程中,冲洗器械11与腔镜镜头一同放置于患者腹腔内。如果腔镜镜头被污染影响手术正常进行,操作者可以通过脚踏装置23启动冲洗步骤。第一控制开关14打开,清洗液容置部121中具有一定压强的CO2气体将清洗液经冲洗件11压出,冲洗掉腔镜镜头上的污渍。在冲洗步骤与吹净步骤交替操作步骤中,先启动冲洗步骤,第一控制开关14打开,清洗液容置部121中的清洗液经冲洗件11喷出,冲洗掉腔镜镜头上的污渍;启动吹净步骤,第二控制开关15打开,缓冲腔131中的CO2气体经压力气体输出端口221与冲洗件11将腔镜镜头上残留的液体喷掉,确保腔镜镜头清洁干净。During laparoscopic surgery, the

上面描述的内容可以单独地或者以各种方式组合起来实施,而这些变型方式都在本发明的保护范围之内。The above-described contents can be implemented individually or in various combinations, and these modifications are all within the protection scope of the present invention.

需要说明的是,在本文中,诸如第一和第二等之类的关系术语仅仅用来将一个实体或者操作与另一个实体或操作区分开来,而不一定要求或者暗示这些实体或操作之间存在任何这种实际的关系或者顺序。而且,术语“包括”、“包含”或者其任何其他变体意在涵盖非排他性的包含,从而使得包含一系列要素的过程、方法、物品或者设备不仅包括那些要素,而且还包括没有明确列出的其他要素,或者是还包括为这种过程、方法、物品或者设备所固有的要素。在没有更多限制的情况下,由语句“包括一个…”限定的要素,并不排除在包括所述要素的过程、方法、物品或者设备中还存在另外的相同要素。It should be noted that, in this document, relational terms such as first and second are used only to distinguish one entity or operation from another entity or operation, and do not necessarily require or imply any relationship between these entities or operations. any such actual relationship or sequence exists. Moreover, the terms "comprising", "comprising" or any other variation thereof are intended to encompass non-exclusive inclusion such that a process, method, article or device comprising a list of elements includes not only those elements, but also includes not explicitly listed or other elements inherent to such a process, method, article or apparatus. Without further limitation, an element qualified by the phrase "comprising a..." does not preclude the presence of additional identical elements in a process, method, article or apparatus that includes the element.

最后应说明的是:以上实施例仅用以说明本发明的技术方案,而非对其限制。尽管参照前述实施例对本发明进行了详细的说明,本领域的普通技术人员应当理解:其依然可以对前述各实施例所记载的技术方案进行修改,或者对其中部分技术特征进行等同替换;而这些修改或者替换,并不使相应技术方案的本质脱离本发明各实施例技术方案的精神和范围。Finally, it should be noted that the above embodiments are only used to illustrate the technical solutions of the present invention, but not to limit them. Although the present invention has been described in detail with reference to the foregoing embodiments, those of ordinary skill in the art should understand that: it is still possible to modify the technical solutions described in the foregoing embodiments, or perform equivalent replacements to some of the technical features; and these Modifications or substitutions do not make the essence of the corresponding technical solutions deviate from the spirit and scope of the technical solutions of the embodiments of the present invention.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210784283.8ACN115211802A (en) | 2022-07-05 | 2022-07-05 | Laparoscopic flushing method and flushing equipment |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210784283.8ACN115211802A (en) | 2022-07-05 | 2022-07-05 | Laparoscopic flushing method and flushing equipment |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115211802Atrue CN115211802A (en) | 2022-10-21 |

Family

ID=83609643

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210784283.8APendingCN115211802A (en) | 2022-07-05 | 2022-07-05 | Laparoscopic flushing method and flushing equipment |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115211802A (en) |

Citations (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5053002A (en)* | 1988-01-11 | 1991-10-01 | Olympus Corporation | Irrigation system for angioscope |

| US20050171401A1 (en)* | 2004-02-03 | 2005-08-04 | Woltjen John A. | Endoscope tip pressure feedback control system for insufflated fluids and gases |

| CN101347628A (en)* | 2007-07-19 | 2009-01-21 | 富士胶片株式会社 | Method of rinsing endoscopes |

| JP2012071028A (en)* | 2010-09-29 | 2012-04-12 | Fujifilm Corp | Endoscope washing control system, and endoscope washing control method |

| US20120184897A1 (en)* | 2010-07-19 | 2012-07-19 | Minimally Invasive Devices, Llc | Integrated systems and methods for maintenance and management of an intra-abdominal gas environment during laparoscopic surgery |

| CN104757928A (en)* | 2014-01-02 | 2015-07-08 | 中国科学院沈阳自动化研究所 | Digestive endoscopy assisting interventional robot control system and method |

| US20150265784A1 (en)* | 2014-03-21 | 2015-09-24 | Storz Endoskop Produktions Gmbh | Insufflation System And Method For Operating The Insufflation System |

| CN207996330U (en)* | 2017-04-28 | 2018-10-23 | 田渤涛 | A kind of Medical pressurizer of the laparoscope cleaner of carbon dioxide driving |

| CN208301736U (en)* | 2017-10-25 | 2019-01-01 | 徐双苗 | A kind of laparoscopic surgery smog sterilizing and purifying device |

| CN209474567U (en)* | 2019-01-08 | 2019-10-11 | 上海市第一人民医院 | Washing and drying equipment for laparoscopic lens |

| CN110573055A (en)* | 2017-03-19 | 2019-12-13 | 莫图斯吉医疗科技有限公司 | Method for evacuating the colon in an uncollapsed state |

| CN110636812A (en)* | 2017-05-26 | 2019-12-31 | 索尼公司 | Control device, control method and surgical system |

| CN210871498U (en)* | 2019-07-26 | 2020-06-30 | 重庆市荣昌区人民医院 | Arthroscope flushing device |

| CN113208549A (en)* | 2021-05-14 | 2021-08-06 | 宁波海泰科迈医疗器械有限公司 | Method and system for real-time monitoring and cleaning of laparoscopic lenses |

| CN215017021U (en)* | 2021-03-24 | 2021-12-07 | 朱长波 | Negative pressure suction air and water supply integrated machine device for endoscope |

| CN114344669A (en)* | 2021-11-16 | 2022-04-15 | 生一健康科技发展(上海)有限公司 | Irrigation suction tube and surgical device |

- 2022

- 2022-07-05CNCN202210784283.8Apatent/CN115211802A/enactivePending

Patent Citations (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5053002A (en)* | 1988-01-11 | 1991-10-01 | Olympus Corporation | Irrigation system for angioscope |

| US20050171401A1 (en)* | 2004-02-03 | 2005-08-04 | Woltjen John A. | Endoscope tip pressure feedback control system for insufflated fluids and gases |

| CN101347628A (en)* | 2007-07-19 | 2009-01-21 | 富士胶片株式会社 | Method of rinsing endoscopes |

| US20120184897A1 (en)* | 2010-07-19 | 2012-07-19 | Minimally Invasive Devices, Llc | Integrated systems and methods for maintenance and management of an intra-abdominal gas environment during laparoscopic surgery |

| JP2012071028A (en)* | 2010-09-29 | 2012-04-12 | Fujifilm Corp | Endoscope washing control system, and endoscope washing control method |

| CN104757928A (en)* | 2014-01-02 | 2015-07-08 | 中国科学院沈阳自动化研究所 | Digestive endoscopy assisting interventional robot control system and method |

| US20150265784A1 (en)* | 2014-03-21 | 2015-09-24 | Storz Endoskop Produktions Gmbh | Insufflation System And Method For Operating The Insufflation System |

| CN110573055A (en)* | 2017-03-19 | 2019-12-13 | 莫图斯吉医疗科技有限公司 | Method for evacuating the colon in an uncollapsed state |

| CN207996330U (en)* | 2017-04-28 | 2018-10-23 | 田渤涛 | A kind of Medical pressurizer of the laparoscope cleaner of carbon dioxide driving |

| CN110636812A (en)* | 2017-05-26 | 2019-12-31 | 索尼公司 | Control device, control method and surgical system |

| CN208301736U (en)* | 2017-10-25 | 2019-01-01 | 徐双苗 | A kind of laparoscopic surgery smog sterilizing and purifying device |

| CN209474567U (en)* | 2019-01-08 | 2019-10-11 | 上海市第一人民医院 | Washing and drying equipment for laparoscopic lens |

| CN210871498U (en)* | 2019-07-26 | 2020-06-30 | 重庆市荣昌区人民医院 | Arthroscope flushing device |

| CN215017021U (en)* | 2021-03-24 | 2021-12-07 | 朱长波 | Negative pressure suction air and water supply integrated machine device for endoscope |

| CN113208549A (en)* | 2021-05-14 | 2021-08-06 | 宁波海泰科迈医疗器械有限公司 | Method and system for real-time monitoring and cleaning of laparoscopic lenses |

| CN114344669A (en)* | 2021-11-16 | 2022-04-15 | 生一健康科技发展(上海)有限公司 | Irrigation suction tube and surgical device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN109433715B (en) | A cleaning method for a full immersion endoscope cleaning machine | |

| CN109498182B (en) | Devices and methods for repeatedly filling and purging endoscope channels | |

| KR100982769B1 (en) | Cleansing and Suction Apparatus for Medical | |

| JPH06503489A (en) | Cleaning and disinfection of medical equipment | |

| JP3236067B2 (en) | Insufflation device | |

| CN115211802A (en) | Laparoscopic flushing method and flushing equipment | |

| KR101460227B1 (en) | Portable mouse cleaning apparatus based on one compressor | |

| JP4911631B2 (en) | Isolator | |

| JP6827149B2 (en) | Cleaning system, cleaning unit and cleaning method | |

| JP2835139B2 (en) | Endoscope cleaning and disinfecting equipment | |

| JP2004313933A (en) | Spraying washing machine | |

| JPH03111026A (en) | Device for cleaning and disinfecting endoscope | |

| CN115887026A (en) | Cleaning and disinfection equipment and medical device cleaning and disinfection method | |

| CN111012534B (en) | Dental spray gun and application method thereof | |

| JPH06304138A (en) | Endoscope washing and disinfecting device | |

| JP3557319B2 (en) | Endoscope cleaning and disinfecting equipment | |

| JP4513115B2 (en) | Steam sterilization system | |

| CN114099835A (en) | Biliary pulse type frequency conversion irrigator | |

| JPH10258019A (en) | Endoscope cleaning device | |

| JP4226356B2 (en) | Sanitary washing device | |

| JP3115992B2 (en) | Endoscope cleaning and disinfecting equipment | |

| KR20020038662A (en) | Endoscope apparatus and method for processing suction and irrigation | |

| JP3954387B2 (en) | Endoscope cleaning water injection device | |

| WO2016129142A1 (en) | Endoscope reprocessor | |

| KR200288827Y1 (en) | Endoscope apparatus for processing suction and irrigation |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |