CN115162317A - Backfill tamping device and method for building engineering construction - Google Patents

Backfill tamping device and method for building engineering constructionDownload PDFInfo

- Publication number

- CN115162317A CN115162317ACN202211008411.6ACN202211008411ACN115162317ACN 115162317 ACN115162317 ACN 115162317ACN 202211008411 ACN202211008411 ACN 202211008411ACN 115162317 ACN115162317 ACN 115162317A

- Authority

- CN

- China

- Prior art keywords

- transmission

- rammed earth

- compaction device

- wheel

- building engineering

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- E—FIXED CONSTRUCTIONS

- E02—HYDRAULIC ENGINEERING; FOUNDATIONS; SOIL SHIFTING

- E02D—FOUNDATIONS; EXCAVATIONS; EMBANKMENTS; UNDERGROUND OR UNDERWATER STRUCTURES

- E02D3/00—Improving or preserving soil or rock, e.g. preserving permafrost soil

- E02D3/02—Improving by compacting

- E02D3/046—Improving by compacting by tamping or vibrating, e.g. with auxiliary watering of the soil

Landscapes

- Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Structural Engineering (AREA)

- Agronomy & Crop Science (AREA)

- Environmental & Geological Engineering (AREA)

- Soil Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Mining & Mineral Resources (AREA)

- Paleontology (AREA)

- Civil Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Investigation Of Foundation Soil And Reinforcement Of Foundation Soil By Compacting Or Drainage (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及建筑工程技术领域,具体为一种建筑工程施工用回填土夯实装置与方法。The invention relates to the technical field of construction engineering, in particular to a backfill soil compaction device and method for construction engineering.

背景技术Background technique

建筑工程,指通过对各类房屋建筑及其附属设施的建造和与其配套的线路、管道、设备的安装活动所形成的工程实体。其中“房屋建筑”指有顶盖、梁柱、墙壁、基础以及能够形成内部空间,满足人们生产、居住、学习、公共活动需要的工程。土建学科教学指导委员会下设土木工程、建筑环境与能源应用工程、给排水科学与工程、建筑电气与智能化、建筑学、城乡规划、风景园林、工程管理和工程造价、房地产开发与管理和物业管理9个学科专业指导委员会(以下简称专业指导委员会),对应《高等学校本科专业目录》中的土木类、建筑类、管理科学与工程类(部分)和工商管理类(部分)11个专业。Construction engineering refers to the engineering entity formed through the construction of various housing buildings and their ancillary facilities and the installation of their supporting lines, pipelines, and equipment. Among them, "house construction" refers to projects with roofs, beams, columns, walls, foundations, and the ability to form internal spaces to meet the needs of people's production, living, learning, and public activities. Civil Engineering Teaching Steering Committee consists of Civil Engineering, Building Environment and Energy Application Engineering, Water Supply and Drainage Science and Engineering, Building Electrical and Intelligent, Architecture, Urban and Rural Planning, Landscape Architecture, Engineering Management and Engineering Cost, Real Estate Development and Management and Property Management of 9 disciplines and professional steering committees (hereinafter referred to as professional steering committees), corresponding to 11 majors in civil engineering, architecture, management science and engineering (part) and business administration (part) in the "Catalogue of Undergraduate Majors in Colleges and Universities".

回填土,指的是工程施工中,完成基础等地面以下工程后,再返还填实的土。回填土是指基础、垫层等隐蔽工程完工后,在5m以内的取土回填的施工过程。主要有地基填土、基坑(槽)或管沟回填、室内地坪回填、室外场地回填平整等。对地下设施工程(如地下结构物、沟渠、管线沟等)的两侧或四周及上部的回填土,应先对地下工程进行各项检查,办理验收手续后方可回填。在建筑施工工程中,经常需要对地基填土、基坑回填或室外场地进行回填平整工作。现有操作过程中通常采用夯实机对回填土进行夯实。Backfill refers to the return of the filled soil after the completion of the foundation and other works below the ground during the construction of the project. Backfill refers to the construction process of backfilling the soil within 5m after the completion of the foundation, cushion and other concealed works. There are mainly foundation filling, foundation pit (slot) or pipe trench backfilling, indoor floor backfilling, and outdoor site backfilling and leveling. For the backfilling of the two sides or around and the upper part of the underground facilities projects (such as underground structures, ditches, pipeline trenches, etc.), various inspections of the underground projects should be carried out first, and the backfilling should be carried out after the acceptance procedures. In construction projects, it is often necessary to carry out backfilling and leveling work for foundation filling, foundation pit backfilling or outdoor sites. The backfill is usually compacted with a compactor during existing operations.

现有技术中,如中国专利号为:CN202010981342.1的“一种方便调整夯实位置的回填土夯实机及方法”,其包括:焊接箱,所述焊接箱的右侧固定连接有电机,所述电机的动力端连接有驱动组件,所述驱动组件位于焊接箱的内部,所述驱动组件上设置有连接组件,所述焊接箱底部的前后两侧均固定连接有竖板,两组所述竖板的相对侧均连接有移动组件,且两组所述移动组件均与连接组件连接,所述焊接箱的顶部和底部均设置有通风口,通过电动推杆配合电机工作,可以在前后左右四个方向上进行夯实,解决了回填土容易下陷,导致不方便调整夯实位置的问题,有效地保证了回填土夯实的施工进度,在行业里具有较大的推广前景。In the prior art, for example, "A backfill compactor and method for convenient adjustment of compaction position" in Chinese Patent No. CN202010981342.1, which includes: a welding box, the right side of the welding box is fixedly connected with a motor, so the The power end of the motor is connected with a drive assembly, the drive assembly is located inside the welding box, the drive assembly is provided with a connecting assembly, and the front and rear sides of the bottom of the welding box are fixedly connected with vertical plates. The opposite sides of the vertical plate are connected with moving components, and the two sets of moving components are connected with the connecting components. The top and bottom of the welding box are provided with air vents, and the electric push rod cooperates with the motor to work. Compacting in four directions solves the problem that the backfill soil is easy to sag, which makes it inconvenient to adjust the compaction position, effectively guarantees the construction progress of the backfill soil compaction, and has great promotion prospects in the industry.

但现有技术中,现有的回填土夯实装置由于与地面接触进行夯实的部分其体积设计较小,只可进行小范围的夯实工作,其夯实的效率较慢,若遇到大面积需要夯实的回填土则会导致整体的施工进度降低,同时还会出现增加人工劳动成本的问题。However, in the prior art, the existing backfill soil compaction device has a small volume design due to the part that is in contact with the ground for compaction, and can only perform compaction work in a small range, and its compaction efficiency is slow. If a large area needs to be compacted If the backfill is not enough, the overall construction progress will be reduced, and at the same time, there will be problems of increasing labor costs.

所以我们提出了一种建筑工程施工用回填土夯实装置与方法,以便于解决上述中提出的问题。Therefore, we propose a backfill compaction device and method for building engineering construction, in order to solve the above-mentioned problems.

发明内容SUMMARY OF THE INVENTION

本发明的目的在于提供一种建筑工程施工用回填土夯实装置与方法,以解决上述背景技术提出的回填土夯实装置其与地面接触的部分体积设计较小,进而导致接触面积缩小,使得仅可进行小范围的夯实工作,导致了夯实效率以及施工进度出现降低的问题。The purpose of the present invention is to provide a backfill soil compaction device and method for building engineering construction, so as to solve the problem that the backfill soil compaction device proposed in the above-mentioned background art has a smaller volume design of the part in contact with the ground, thereby reducing the contact area, so that only the Small-scale compaction work led to problems of compaction efficiency and reduced construction progress.

为实现上述目的,本发明提供如下技术方案:一种建筑工程施工用回填土夯实装置,包括夯实装置,所述夯实装置的内壁底部安装有电动机,所述电动机的一端缠绕有传动带一,所述传动带一的一端设置有传动轮一,所述传动轮一的中心部位贯穿有传动轴,所述传动轴的外壁设置有传动轮二,所述传动轴的两端设置有传动架,所述传动轮二的外壁缠绕有传动带二,所述传动带二的一端设置有传动轮三,所述传动轮三的外侧安装有曲轴,所述传动轮三的两端设置有夯土架,所述夯土架的底部安装有夯土板;In order to achieve the above purpose, the present invention provides the following technical solutions: a backfill soil compaction device for building engineering construction, comprising a compaction device, a motor is installed at the bottom of the inner wall of the compaction device, and a transmission belt is wound around one end of the motor, and the One end of the transmission belt is provided with a transmission wheel 1, the center of the transmission wheel 1 is provided with a transmission shaft, the outer wall of the transmission shaft is provided with a

所述夯土板的侧面安装有延伸板,所述延伸板顶部分布有三个支撑条,所述支撑条的一端设置有固定卡扣,所述延伸板的侧面分布有四个插销杆,所述夯土板的侧面开设有四个插销孔,所述插销杆的一端贯穿入插销孔的内侧;An extension plate is installed on the side of the rammed earth plate, three support bars are distributed on the top of the extension plate, one end of the support bar is provided with a fixed buckle, and four latch rods are distributed on the side of the extension plate. The side of the rammed earth plate is provided with four bolt holes, and one end of the bolt rod penetrates into the inner side of the bolt holes;

所述夯实装置的内侧底部安装有配重块,所述配重块的侧面安装有侧装架,所述侧装架的一端活动安装有碾压辊。A counterweight block is installed at the inner bottom of the compaction device, a side mounting frame is installed on the side of the counterweight block, and a rolling roller is movably installed at one end of the side mounting frame.

优选的,所述夯土板的顶部固定安装有加强支撑框,所述固定卡扣的内侧与加强支撑框的外壁相互卡装。Preferably, a reinforced support frame is fixedly installed on the top of the rammed earth plate, and the inner side of the fixed buckle and the outer wall of the reinforced support frame are mutually clamped.

优选的,所述夯土板的顶部分布有多个加强筋条,所述加强筋条设置在加强支撑框的内侧,所述加强筋条的内侧与夯土架的底部之间连接。Preferably, a plurality of reinforcing bars are distributed on the top of the rammed earth plate, the reinforcing bars are arranged on the inner side of the reinforced support frame, and the inner side of the reinforcing bars is connected with the bottom of the rammed earth frame.

优选的,所述夯土板的顶部贯穿有四个固定栓,所述固定栓的底部贯穿于插销杆的一端。Preferably, four fixing bolts penetrate through the top of the rammed earth plate, and the bottom of the fixing bolts penetrate through one end of the bolt rod.

优选的,所述配重块的顶部固定安装有供电装置,所述侧装架的一端设置有转轴,所述转轴均与碾压辊的侧面相连接。Preferably, a power supply device is fixedly installed on the top of the counterweight, and a rotating shaft is provided at one end of the side mounting frame, and the rotating shafts are all connected to the side surface of the rolling roller.

优选的,所述夯实装置的内侧安装有驾控机构,所述驾控机构的顶部活动安装有方向盘,所述驾控机构的顶部与方向盘的底部之间连接方向轴。Preferably, a driving control mechanism is installed on the inner side of the tamping device, a steering wheel is movably mounted on the top of the driving control mechanism, and a direction shaft is connected between the top of the driving control mechanism and the bottom of the steering wheel.

优选的,所述夯实装置的内侧安装有操控挡杆,所述夯实装置的内侧固定安装有座椅,所述操控挡杆设置在座椅的侧方。Preferably, a control bar is installed on the inner side of the tamping device, a seat is fixedly installed on the inner side of the tamping device, and the control bar is arranged on the side of the seat.

优选的,所述夯实装置的底部一端安装有转向机构,所述转向机构的两端活动安装有方向轮。Preferably, a steering mechanism is installed at one end of the bottom of the tamping device, and steering wheels are movably installed at both ends of the steering mechanism.

优选的,所述转向机构的侧面连接有传动机构,所述传动机构的一端安装有驱动机构,所述驱动机构设置在夯实装置的底部另一端,所述驱动机构的两端活动安装有驱动轮。Preferably, a transmission mechanism is connected to the side of the steering mechanism, a drive mechanism is installed at one end of the transmission mechanism, the drive mechanism is arranged at the other end of the bottom of the tamping device, and a drive wheel is movably installed at both ends of the drive mechanism .

一种建筑工程施工用回填土夯实装置的使用方法,包括以下步骤:A method for using a backfill soil compaction device for building engineering construction, comprising the following steps:

S1、在建筑施工需要进行回填土的时候,工人可通过坐在座椅的位置,对方向盘和操控挡杆进行操作,即可方便驾驶夯实装置整体移动,由驱动轮驱动机构进行移动,传动机构进行传动四驱传动工作,同时转向机构则方便了进行专项,进而方便了移动至需要夯实的土壤位置;S1. When backfilling is required for construction, workers can operate the steering wheel and the control lever by sitting on the seat, so as to facilitate the overall movement of the tamping device, which is moved by the driving mechanism of the driving wheel, and the transmission mechanism The four-wheel drive transmission work is carried out, and the steering mechanism is convenient for special projects, which in turn facilitates the movement to the soil position that needs to be compacted;

S2、当移动至该位置后,即可通过启动电动机,电动机连接的传动带一则将动力传动至传动轮一,传动轮一随之带动传动轴进行转动,随后安装在传动轴上传动轮二则随之转动,进而可带动传动带二带动传动轮三进行转动;S2. After moving to this position, the motor can be started by starting the motor. The first transmission belt connected to the motor transmits the power to the first transmission wheel. The first transmission wheel drives the transmission shaft to rotate, and then the second transmission wheel is installed on the transmission shaft. The rotation of the

S3、通过传动轮三的转动则可带动曲轴进行转动,随之产生了离心力,进而可以利用其惯性带动传动架、活动连杆、夯土架以及夯土板的部分对回填土进行夯实工作;S3. The rotation of the

S4、通过将夯土板拍打在地面则实现了有效地夯实,若需要大面积的夯实,则可通过在夯土板的侧面安装有延伸板,通过将延伸板侧面的插装有插销杆,并将插销杆插装在夯土板侧面开设的插销孔内侧,即可扩大夯实的面积同时提升了支撑性,同时支撑条与加强支撑框之间的卡接则进一步提升了支撑性;S4. Effective compaction is achieved by slapping the rammed earth plate on the ground. If a large area of compaction is required, an extension plate can be installed on the side of the rammed earth plate, and the side of the extension plate can be inserted with a latch rod. By inserting the bolt rod inside the bolt hole opened on the side of the rammed earth plate, the rammed area can be expanded and the supportability can be improved at the same time.

S5、在对回填土通过夯土板夯实过后,可继续驾驶该装置进行移动,通过碾压辊对夯实过后的回填土来回碾压,可方便了在夯实过后保证了回填土的平整性。S5. After the backfill is compacted by the rammed earth plate, the device can continue to be driven to move, and the compacted backfill can be rolled back and forth by the rolling roller, which is convenient to ensure the flatness of the backfill after compaction.

与现有技术相比,本发明的有益效果是:Compared with the prior art, the beneficial effects of the present invention are:

1、通过延伸板的设置,通过将夯土板拍打在地面则实现了有效地夯实,若需要大面积的夯实,则可通过在夯土板的侧面安装有延伸板,通过将延伸板侧面的插装有插销杆,并将插销杆插装在夯土板侧面开设的插销孔内侧,即可扩大夯实的面积同时提升了支撑性,同时支撑条与加强支撑框之间的卡接则进一步提升了支撑性,进而有利于通过增加了与地面的接触面,使得可以进行大面积的夯实工作,有利于提升了回填土夯实的效率,且延伸板便于快速地进行拆卸,便于在针对小面积或进一步夯实的过程中提升了夯实的效果;1. Through the setting of the extension plate, the rammed earth plate is slapped on the ground to achieve effective compaction. If a large area of compaction is required, an extension plate can be installed on the side of the rammed earth plate, and the side of the extension plate can be rammed. The bolt rod is inserted, and the bolt rod is inserted into the inner side of the bolt hole opened on the side of the rammed earth plate, which can expand the rammed area and improve the support. It is more supportive, which is beneficial to increase the contact surface with the ground, making it possible to carry out large-area compaction work, which is conducive to improving the efficiency of backfill compaction, and the extension plate is easy to disassemble quickly, which is convenient for small areas or In the process of further compaction, the effect of compaction is improved;

2、通过碾压辊的设置,在对回填土通过夯土板夯实过后,可继续驾驶该装置进行移动,通过碾压辊对夯实过后的回填土来回碾压,可方便了在夯实过后保证了回填土的平整性,同时还通过配重块进一步增加了整体的配重,有利于进一步地提升了平整压实的效果;2. Through the setting of the rolling roller, after the backfill has been compacted by the rammed earth plate, the device can continue to be driven to move, and the compacted backfill can be rolled back and forth by the rolling roller, which is convenient to ensure the safety after compaction. The flatness of the backfill soil, and at the same time, the overall counterweight is further increased through the counterweight block, which is conducive to further improving the effect of leveling and compaction;

3、通过驾控机构的设置,工人可通过坐在座椅的位置,对方向盘和操控挡杆进行操作,即可方便驾驶夯实装置整体移动,由驱动轮驱动机构进行移动,传动机构进行传动四驱传动工作,同时转向机构则方便了进行专项,进而方便了移动至需要夯实的土壤位置,此方式相比较传统夯实装置有利于减少了人工体力消耗,同时提升了机动速度,进而有利于提升了施工的效率。3. Through the setting of the driving control mechanism, the worker can operate the steering wheel and the control lever by sitting on the seat, so as to facilitate the overall movement of the driving tamping device, which is moved by the driving wheel driving mechanism, and the transmission mechanism is used to drive the four parts. Compared with the traditional compaction device, this method is conducive to reducing manual physical strength, and at the same time improving the maneuvering speed, which is conducive to improving the construction efficiency.

附图说明Description of drawings

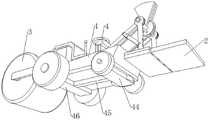

图1为本发明一种建筑工程施工用回填土夯实装置的立体结构示意图;Fig. 1 is a three-dimensional schematic diagram of a backfill soil compaction device for building engineering construction of the present invention;

图2为本发明一种建筑工程施工用回填土夯实装置另一角度的结构示意图;2 is a schematic structural diagram of another angle of a backfill soil compaction device for construction of a building project according to the present invention;

图3为本发明一种建筑工程施工用回填土夯实装置的夯土部分结构示意图;3 is a schematic diagram of the structure of the rammed earth part of a backfill tamping device for building engineering construction according to the present invention;

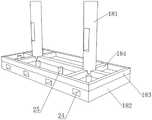

图4为本发明一种建筑工程施工用回填土夯实装置延伸板的结构立体图;4 is a structural perspective view of an extension plate of a backfill soil compaction device for building engineering construction according to the present invention;

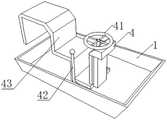

图5为本发明一种建筑工程施工用回填土夯实装置夯土连接部分的结构示意图;5 is a schematic structural diagram of a rammed earth connection part of a backfill tamping device for building engineering construction according to the present invention;

图6为本发明一种建筑工程施工用回填土夯实装置驾控机构的结构示意图;6 is a schematic structural diagram of a driving control mechanism of a backfill soil compaction device for building engineering construction according to the present invention;

图7为本发明一种建筑工程施工用回填土夯实装置碾压机构的结构示意图。FIG. 7 is a schematic structural diagram of a rolling mechanism of a backfill soil compaction device for building engineering construction according to the present invention.

图中:In the picture:

1、夯实装置;2、延伸板;3、碾压辊;4、驾控机构;11、电动机;12、传动带一;13、传动轮一;14、传动轴;15、传动轮二;16、传动架;17、传动带二;18、传动轮三;19、曲轴;21、支撑条;22、固定卡扣;23、插销杆;24、插销孔;25、固定栓;31、侧装架;32、配重块;33、供电装置;41、方向盘;42、操控挡杆;43、座椅;44、转向机构;45、传动机构;46、驱动机构;161、活动连杆;181、夯土架;182、夯土板;183、加强支撑框;184、加强筋条。1. Compacting device; 2. Extension plate; 3. Rolling roller; 4. Driving control mechanism; 11. Electric motor; 12. Transmission belt 1; 13. Transmission wheel 1; 14. Transmission shaft; 15.

具体实施方式Detailed ways

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施条例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described implementation regulations are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

实施例1Example 1

请参阅图1-7,本发明提供一种技术方案:一种建筑工程施工用回填土夯实装置,包括夯实装置1,夯实装置1的内壁底部安装有电动机11,电动机11的一端缠绕有传动带一12,传动带一12的一端设置有传动轮一13,传动轮一13的中心部位贯穿有传动轴14,传动轴14的外壁设置有传动轮二15,传动轴14的两端设置有传动架16,传动轮二15的外壁缠绕有传动带二17,传动带二17的一端设置有传动轮三18,传动轮三18的外侧安装有曲轴19,传动轮三18的两端设置有夯土架181,夯土架181的底部安装有夯土板182,通过启动电动机11,电动机11连接的传动带一12则将动力传动至传动轮一13,传动轮一13随之带动传动轴14进行转动,随后安装在传动轴14上传动轮二15则随之转动,进而可带动传动带二17带动传动轮三18进行转动,通过传动轮三18的转动则可带动曲轴19进行转动,随之产生了离心力,进而可以利用其惯性带动传动架16、活动连杆161、夯土架181以及夯土板182的部分对回填土进行夯实工作;1-7, the present invention provides a technical solution: a backfill soil compaction device for building engineering construction, including a compaction device 1, a

夯土板182的侧面安装有延伸板2,延伸板2顶部分布有三个支撑条21,支撑条21的一端设置有固定卡扣22,延伸板2的侧面分布有四个插销杆23,夯土板182的侧面开设有四个插销孔24,插销杆23的一端贯穿入插销孔24的内侧,通过将夯土板182拍打在地面则实现了有效地夯实,若需要大面积的夯实,则可通过在夯土板182的侧面安装有延伸板2,通过将延伸板2侧面的插装有插销杆23,并将插销杆23插装在夯土板182侧面开设的插销孔24内侧,即可扩大夯实的面积同时提升了支撑性,同时支撑条21与加强支撑框183之间的卡接则进一步提升了支撑性,进而有利于通过增加了与地面的接触面,使得可以进行大面积的夯实工作,有利于提升了回填土夯实的效率,且延伸板2便于快速地进行拆卸,便于在针对小面积或进一步夯实的过程中提升了夯实的效果;An

夯实装置1的内侧底部安装有配重块32,配重块32的侧面安装有侧装架31,侧装架31的一端活动安装有碾压辊3,在对回填土通过夯土板182夯实过后,可继续驾驶该装置进行移动,通过碾压辊3对夯实过后的回填土来回碾压,可方便了在夯实过后保证了回填土的平整性,同时还通过配重块32进一步增加了整体的配重,有利于进一步地提升了平整压实的效果。A

如图3所示,夯土板182的顶部固定安装有加强支撑框183,固定卡扣22的内侧与加强支撑框183的外壁相互卡装,通过加强支撑框183有利于对夯土板182提升强度,同时方便了对固定卡扣22进行安装连接。As shown in FIG. 3 , a reinforced

如图3和图5所示,夯土板182的顶部分布有多个加强筋条184,加强筋条184设置在加强支撑框183的内侧,加强筋条184的内侧与夯土架181的底部之间连接,通过加强筋条184同样可提升了夯土板182在夯实工作时的强度,有利于提升夯实的效果。As shown in FIG. 3 and FIG. 5 , a plurality of reinforcing

如图5所示,夯土板182的顶部贯穿有四个固定栓25,固定栓25的底部贯穿于插销杆23的一端,通过固定栓25可方便了对插销杆23以及延伸板2的部分进行固定。As shown in FIG. 5 , four fixing

如图7所示,配重块32的顶部固定安装有供电装置33,侧装架31的一端设置有转轴,转轴均与碾压辊3的侧面相连接,供电装置33则可为整体提供了有效的供电作用。As shown in FIG. 7 , a

如图6所示,夯实装置1的内侧安装有驾控机构4,驾控机构4的顶部活动安装有方向盘41,驾控机构4的顶部与方向盘41的底部之间连接方向轴,通过驾控机构4则方便了对整体进行控制,方向盘41则可调整方向。As shown in FIG. 6 , a driving

如图6所示,夯实装置1的内侧安装有操控挡杆42,夯实装置1的内侧固定安装有座椅43,操控挡杆42设置在座椅43的侧方,操控挡杆42则可进行动力变速调节,座椅43则方便了提供了坐的位置,便于辅助进行操作。As shown in FIG. 6 , a

如图1和图2所示,夯实装置1的底部一端安装有转向机构44,转向机构44的两端活动安装有方向轮,通过转向机构44则可与方向轮配合进行转向移动。As shown in FIGS. 1 and 2 , a

如图1和图2所示,转向机构44的侧面连接有传动机构45,传动机构45的一端安装有驱动机构46,驱动机构46设置在夯实装置1的底部另一端,驱动机构46的两端活动安装有驱动轮,传动机构45则可进行传动便于提供四驱的效果,驱动机构46则可驱动整体进行移动。As shown in FIG. 1 and FIG. 2 , a

一种建筑工程施工用回填土夯实装置的使用方法,包括以下步骤:A method for using a backfill soil compaction device for building engineering construction, comprising the following steps:

S1、在建筑施工需要进行回填土的时候,工人可通过坐在座椅43的位置,对方向盘41和操控挡杆42进行操作,即可方便驾驶夯实装置1整体移动,由驱动轮驱动机构46进行移动,传动机构45进行传动四驱传动工作,同时转向机构44则方便了进行专项,进而方便了移动至需要夯实的土壤位置;S1. When backfilling is required for construction, the worker can operate the

S2、当移动至该位置后,即可通过启动电动机11,电动机11连接的传动带一12则将动力传动至传动轮一13,传动轮一13随之带动传动轴14进行转动,随后安装在传动轴14上传动轮二15则随之转动,进而可带动传动带二17带动传动轮三18进行转动;S2. After moving to this position, you can start the

S3、通过传动轮三18的转动则可带动曲轴19进行转动,随之产生了离心力,进而可以利用其惯性带动传动架16、活动连杆161、夯土架181以及夯土板182的部分对回填土进行夯实工作;S3. The

S4、通过将夯土板182拍打在地面则实现了有效地夯实,若需要大面积的夯实,则可通过在夯土板182的侧面安装有延伸板2,通过将延伸板2侧面的插装有插销杆23,并将插销杆23插装在夯土板182侧面开设的插销孔24内侧,即可扩大夯实的面积同时提升了支撑性,同时支撑条21与加强支撑框183之间的卡接则进一步提升了支撑性;S4. Effective compaction is achieved by beating the rammed

S5、在对回填土通过夯土板182夯实过后,可继续驾驶该装置进行移动,通过碾压辊3对夯实过后的回填土来回碾压,可方便了在夯实过后保证了回填土的平整性。S5. After the backfill has been compacted by the rammed

尽管参照前述实施例对本发明进行了详细的说明,对于本领域的技术人员来说,其依然可以对前述各实施例所记载的技术方案进行修改,或者对其中部分技术特征进行等同替换,凡在本发明的精神和原则之内,所作的任何修改、等同替换、改进等,均应包含在本发明的保护范围之内。Although the present invention has been described in detail with reference to the foregoing embodiments, for those skilled in the art, it is still possible to modify the technical solutions described in the foregoing embodiments, or to perform equivalent replacements for some of the technical features. Any modification, equivalent replacement, improvement, etc. made within the spirit and principle of the present invention shall be included within the protection scope of the present invention.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211008411.6ACN115162317A (en) | 2022-08-22 | 2022-08-22 | Backfill tamping device and method for building engineering construction |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211008411.6ACN115162317A (en) | 2022-08-22 | 2022-08-22 | Backfill tamping device and method for building engineering construction |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115162317Atrue CN115162317A (en) | 2022-10-11 |

Family

ID=83482292

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211008411.6APendingCN115162317A (en) | 2022-08-22 | 2022-08-22 | Backfill tamping device and method for building engineering construction |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115162317A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118345779A (en)* | 2024-05-17 | 2024-07-16 | 甘肃九州岩土工程有限公司 | Soil environment is earth volume backfill ramming device for restoration |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH256425A (en)* | 1947-03-24 | 1948-08-31 | Wiener Pfahl Und Betongesellsc | Device for the production of in-situ concrete piles. |

| SU1574728A1 (en)* | 1988-03-01 | 1990-06-30 | Полтавский инженерно-строительный институт | Device for tamping out foundation pit |

| US5048425A (en)* | 1989-06-16 | 1991-09-17 | Franz Plasser Bahnbaumaschinen-Industriegesellschaft M.B.H. | Ballast tamping unit for mounting on a tamping machine and a tamping tool therefor |

| CN107035216A (en)* | 2017-05-31 | 2017-08-11 | 日照博科电力器材有限公司 | Hydraulic High-speed electric power bar base rammer compacter |

| CN207419804U (en)* | 2017-11-16 | 2018-05-29 | 广州市世博建筑工程有限公司 | A kind of detachable floor support plate for building of module |

| CN108999175A (en)* | 2018-08-31 | 2018-12-14 | 安徽金贺财建筑工程有限公司 | A kind of dual-purpose evener in rammed soil type of foundation face |

| CN209308007U (en)* | 2018-11-12 | 2019-08-27 | 高新志 | A kind of building site rammer for building |

| CN210482276U (en)* | 2019-07-25 | 2020-05-08 | 浙江港汇园林工程有限公司 | Soil compacting device for garden engineering |

| CN212257097U (en)* | 2020-05-29 | 2020-12-29 | 郭洪 | Detachable construction transformer underframe |

| CN212801488U (en)* | 2020-06-10 | 2021-03-26 | 杭州海川水利工程有限公司 | Revetment foundation treatment device |

| CN214219620U (en)* | 2020-11-10 | 2021-09-17 | 张根保 | Rammer convenient to remove |

| CN214883557U (en)* | 2021-02-03 | 2021-11-26 | 蒋冠琦 | Construction is with long-pending native tamping unit |

- 2022

- 2022-08-22CNCN202211008411.6Apatent/CN115162317A/enactivePending

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH256425A (en)* | 1947-03-24 | 1948-08-31 | Wiener Pfahl Und Betongesellsc | Device for the production of in-situ concrete piles. |

| SU1574728A1 (en)* | 1988-03-01 | 1990-06-30 | Полтавский инженерно-строительный институт | Device for tamping out foundation pit |

| US5048425A (en)* | 1989-06-16 | 1991-09-17 | Franz Plasser Bahnbaumaschinen-Industriegesellschaft M.B.H. | Ballast tamping unit for mounting on a tamping machine and a tamping tool therefor |

| CN107035216A (en)* | 2017-05-31 | 2017-08-11 | 日照博科电力器材有限公司 | Hydraulic High-speed electric power bar base rammer compacter |

| CN207419804U (en)* | 2017-11-16 | 2018-05-29 | 广州市世博建筑工程有限公司 | A kind of detachable floor support plate for building of module |

| CN108999175A (en)* | 2018-08-31 | 2018-12-14 | 安徽金贺财建筑工程有限公司 | A kind of dual-purpose evener in rammed soil type of foundation face |

| CN209308007U (en)* | 2018-11-12 | 2019-08-27 | 高新志 | A kind of building site rammer for building |

| CN210482276U (en)* | 2019-07-25 | 2020-05-08 | 浙江港汇园林工程有限公司 | Soil compacting device for garden engineering |

| CN212257097U (en)* | 2020-05-29 | 2020-12-29 | 郭洪 | Detachable construction transformer underframe |

| CN212801488U (en)* | 2020-06-10 | 2021-03-26 | 杭州海川水利工程有限公司 | Revetment foundation treatment device |

| CN214219620U (en)* | 2020-11-10 | 2021-09-17 | 张根保 | Rammer convenient to remove |

| CN214883557U (en)* | 2021-02-03 | 2021-11-26 | 蒋冠琦 | Construction is with long-pending native tamping unit |

Non-Patent Citations (1)

| Title |

|---|

| "《Autodesk Inventor Professional 2020中文版从入门到精通》", vol. 1, 31 October 2020, 北京:机械工业出版社, pages: 87 - 89* |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118345779A (en)* | 2024-05-17 | 2024-07-16 | 甘肃九州岩土工程有限公司 | Soil environment is earth volume backfill ramming device for restoration |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111778994A (en) | Pipe-jacking working well supporting device for municipal pipeline engineering and construction method | |

| CN111997088A (en) | Groove type prefabricated assembly type cable duct bank and working well installation and construction method | |

| CN201972155U (en) | Topdown-construction-method foundation pit supporting structure of steel plate pile | |

| CN206396783U (en) | Assembled prefabricated ring main unit basis | |

| CN115162317A (en) | Backfill tamping device and method for building engineering construction | |

| CN110670603A (en) | An assembled long strip foundation pit support device and method | |

| CN113202143A (en) | Prefabricated assembled cable shaft basis | |

| CN216713040U (en) | Full-prefabricated pier type portal inclined support pile structure system | |

| CN212428824U (en) | A fully recovered and assembled rectangular pipe jacking working well steel structure support device | |

| CN111749277B (en) | A pipe-jacking building wall structure and construction method thereof | |

| CN211523223U (en) | Rectangular shape foundation ditch supporting device of assembled | |

| CN211873086U (en) | Synergistic Envelope Structure of Underground Space under Existing Underground Pipe Corridor | |

| CN210737607U (en) | A hang braced system for reverse construction method beam slab construction | |

| CN220377306U (en) | Prefabricated pile wall superposed assembled underground structure | |

| CN218911491U (en) | Combined temporary building fast-assembling foundation | |

| CN212477825U (en) | Pipe jacking building wall structure | |

| CN212270960U (en) | A new type of prefabricated foundation pit enclosure structure | |

| CN113090066A (en) | Construction method for newly added entrances and exits of existing buildings and elevator shaft | |

| CN113006087B (en) | A kind of foundation pit support method based on reverse method | |

| CN222525836U (en) | Single-sided formwork fixing structure of concrete wall | |

| CN105421338A (en) | Splicing structure for vertical connection of prefabricated underground diaphragm walls | |

| CN210737553U (en) | Recoverable assembled underground structure | |

| CN206034461U (en) | Subway foundation pit large -span support system | |

| CN222632270U (en) | Layered supporting structure in pit-in-pit construction process | |

| CN221504152U (en) | A composite structure of pipe jacking reaction wall in soft soil area |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20221011 |