CN115141977B - High-wear-resistance hot rolled strip steel and steel tube for casting blank production pump truck and manufacturing method thereof - Google Patents

High-wear-resistance hot rolled strip steel and steel tube for casting blank production pump truck and manufacturing method thereofDownload PDFInfo

- Publication number

- CN115141977B CN115141977BCN202210727796.5ACN202210727796ACN115141977BCN 115141977 BCN115141977 BCN 115141977BCN 202210727796 ACN202210727796 ACN 202210727796ACN 115141977 BCN115141977 BCN 115141977B

- Authority

- CN

- China

- Prior art keywords

- rolling

- temperature

- casting blank

- equal

- pump truck

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21C—MANUFACTURE OF METAL SHEETS, WIRE, RODS, TUBES, PROFILES OR LIKE SEMI-MANUFACTURED PRODUCTS OTHERWISE THAN BY ROLLING; AUXILIARY OPERATIONS USED IN CONNECTION WITH METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL

- B21C37/00—Manufacture of metal sheets, rods, wire, tubes, profiles or like semi-manufactured products, not otherwise provided for; Manufacture of tubes of special shape

- B21C37/06—Manufacture of metal sheets, rods, wire, tubes, profiles or like semi-manufactured products, not otherwise provided for; Manufacture of tubes of special shape of tubes or metal hoses; Combined procedures for making tubes, e.g. for making multi-wall tubes

- B21C37/08—Making tubes with welded or soldered seams

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/18—Hardening; Quenching with or without subsequent tempering

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D1/00—General methods or devices for heat treatment, e.g. annealing, hardening, quenching or tempering

- C21D1/26—Methods of annealing

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0205—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips of ferrous alloys

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0221—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the working steps

- C21D8/0226—Hot rolling

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/02—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips

- C21D8/0247—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of plates or strips characterised by the heat treatment

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D8/00—Modifying the physical properties by deformation combined with, or followed by, heat treatment

- C21D8/10—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of tubular bodies

- C21D8/105—Modifying the physical properties by deformation combined with, or followed by, heat treatment during manufacturing of tubular bodies of ferrous alloys

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/08—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for tubular bodies or pipes

- C21D9/085—Cooling or quenching

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D9/00—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor

- C21D9/52—Heat treatment, e.g. annealing, hardening, quenching or tempering, adapted for particular articles; Furnaces therefor for wires; for strips ; for rods of unlimited length

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C33/00—Making ferrous alloys

- C22C33/04—Making ferrous alloys by melting

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/06—Ferrous alloys, e.g. steel alloys containing aluminium

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/42—Ferrous alloys, e.g. steel alloys containing chromium with nickel with copper

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/18—Ferrous alloys, e.g. steel alloys containing chromium

- C22C38/40—Ferrous alloys, e.g. steel alloys containing chromium with nickel

- C22C38/44—Ferrous alloys, e.g. steel alloys containing chromium with nickel with molybdenum or tungsten

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/004—Dispersions; Precipitations

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D2211/00—Microstructure comprising significant phases

- C21D2211/008—Martensite

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P10/00—Technologies related to metal processing

- Y02P10/20—Recycling

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Heat Treatment Of Steel (AREA)

Abstract

Description

Translated fromChinese技术领域Technical Field

本发明属于钢铁冶炼技术领域,具体涉及一种铸坯生产泵车用高耐磨性热轧带钢和钢管及其制造方法。The invention belongs to the technical field of steel smelting, and in particular relates to a high-wear-resistant hot-rolled strip steel and steel pipe for producing a pump truck by casting and a manufacturing method thereof.

背景技术Background Art

随着社会的大力发展,摩天大楼在城市各处随处可见,这些现代超高层建筑都是用混凝土浇筑高楼骨架,混凝土采用高压泵通过输送管道输送到浇筑高度,输送管内压力大,内壁极易磨损。With the vigorous development of society, skyscrapers can be seen everywhere in the city. These modern super-high-rise buildings are all made of concrete to cast the high-rise frame. The concrete is transported to the pouring height through a delivery pipe using a high-pressure pump. The pressure in the delivery pipe is high and the inner wall is easily worn.

目前混凝土输送管品种主要采用单层淬硬耐磨管,单层淬硬耐磨管由于需要兼顾硬度和韧性,寿命较短,造成资源较大浪费。为避免单层耐磨钢管缺陷,目前开始研发双金属复合耐磨钢管,将硬度和韧性分成两部分,由相互独立的内管和外管组成。内管硬度高、耐磨性好,但韧性较低,用于承受混凝土的冲蚀和磨损,外管硬度低、韧性好以保证输送管整体的韧性。薄规格内管设计,势必影响管道寿命,从而增加混凝土输送的成本。厚规格内管设计会造成输送骨架支撑断裂造成安全事故,因此,合适的管道厚度也即合适的带钢厚度选择显得尤为重要。At present, the main types of concrete conveying pipes are single-layer hardened wear-resistant pipes. Single-layer hardened wear-resistant pipes have a short lifespan due to the need to take into account both hardness and toughness, resulting in a large waste of resources. In order to avoid the defects of single-layer wear-resistant steel pipes, bimetallic composite wear-resistant steel pipes are currently being developed, which divide hardness and toughness into two parts, consisting of an independent inner pipe and outer pipe. The inner pipe has high hardness and good wear resistance, but low toughness, and is used to withstand the erosion and wear of concrete. The outer pipe has low hardness and good toughness to ensure the overall toughness of the conveying pipe. The design of thin inner pipes will inevitably affect the life of the pipeline, thereby increasing the cost of concrete transportation. The design of thick inner pipes will cause the support of the conveying skeleton to break and cause safety accidents. Therefore, the selection of appropriate pipe thickness, that is, appropriate strip steel thickness, is particularly important.

目前国内混凝土泵车输送管道一般采用65Mn、NM600无缝管生产或在此基础上添加合金Cr、Ti、Re元素。生产工艺流程主要包括钢管、冷拔、冷拔(复合)、去应力退火、下料、焊接、热处理、喷砂、镶套。但由于生产所得钢管的耐磨性差,平均耐磨寿命只在1.5-3万立方米。At present, the domestic concrete pump truck delivery pipeline is generally produced by 65Mn, NM600 seamless pipe or adding alloy Cr, Ti, Re elements on this basis. The production process mainly includes steel pipe, cold drawing, cold drawing (compound), stress relief annealing, cutting, welding, heat treatment, sandblasting, and sleeve insertion. However, due to the poor wear resistance of the steel pipe produced, the average wear life is only 15,000-30,000 cubic meters.

国内很多钢厂均在研究热轧板带钢的生产工艺,大部分研究都集中在板带钢生产中的应力、板带钢的常规力学性能等,但对热轧带钢的高耐磨性以及带钢制成产品的使用性能的研究则较少,已公布的专利文献中的产品在实际工程中的应用更是微乎其微。Many domestic steel mills are studying the production process of hot-rolled strip steel. Most of the research focuses on the stress in strip steel production and the conventional mechanical properties of strip steel. However, there is less research on the high wear resistance of hot-rolled strip steel and the performance of products made from strip steel. The application of products in published patent documents in actual engineering is even more minimal.

经检索,公开号为:CN111974801A的申请案公开了一种热轧带钢的生产方法,其通过合理的热轧生产工艺,得到了较好力学性能,但该申请案通篇未阐述其成分设计理念,且轧制工艺重点描述了加热冷却工艺,以改善窄带钢应力分布。After searching, the application with publication number: CN111974801A discloses a method for producing hot-rolled strip steel, which obtains good mechanical properties through a reasonable hot rolling production process. However, the application does not explain its composition design concept throughout the application, and the rolling process focuses on the heating and cooling process to improve the stress distribution of narrow strip steel.

公开号为:CN105239011A的申请案公开了一种混凝土泵车用耐磨无缝钢管的制造方法,其制造方法包括以下步骤:(1)炼钢:铁水脱硫→转炉/电炉→LF精练炉→VD真空处理→连铸圆坯;(2)轧管:管坯在环形炉加热,按1150~1230℃加热后,经穿孔、连轧管机轧制、张减机定减径、矫直,完成管坯的轧制;(3)钢管去应力退火:采用连续炉进行退火处理。该申请案采用“VD连铸坯→热轧→去应力退火→探伤→后序处理”工艺可以稳定生产混凝土泵车输送用耐磨无缝钢管,大大提高了产品成材率,降低生产成本,且生产所得无缝钢管具有高硬度高耐磨性。但该申请案所用的原料是圆坯,生产难度较大。The application with publication number: CN105239011A discloses a method for manufacturing a wear-resistant seamless steel pipe for concrete pump trucks, which includes the following steps: (1) Steelmaking: hot metal desulfurization → converter/electric furnace → LF refining furnace → VD vacuum treatment → continuous casting of round billets; (2) Pipe rolling: the billet is heated in a ring furnace at 1150-1230°C, then pierced, rolled on a continuous tube mill, reduced in diameter by a tension-reducing mill, and straightened to complete the rolling of the billet; (3) Stress relieving annealing of the steel pipe: annealing is performed in a continuous furnace. The application adopts the process of "VD continuous casting billet → hot rolling → stress relieving annealing → flaw detection → post-processing" to stably produce wear-resistant seamless steel pipes for concrete pump trucks, greatly improve the product yield, reduce production costs, and the seamless steel pipes produced have high hardness and high wear resistance. However, the raw materials used in the application are round billets, which are difficult to produce.

发明内容Summary of the invention

1.要解决的问题1. Problem to be solved

本发明的目的在于提供一种铸坯生产泵车用高耐磨性热轧带钢和钢管及其制造方法,以满足大规格(厚度5mm)泵车用热轧带钢焊管后对表面硬度和耐磨性等力学性能的要求,为高寿命的泵车输送管的制造提供指导意义。The purpose of the present invention is to provide a casting process for producing high wear-resistant hot-rolled strip steel and steel pipe for pump trucks and a manufacturing method thereof, so as to meet the requirements of mechanical properties such as surface hardness and wear resistance after welding of large-size (thickness 5mm) hot-rolled strip steel pipes for pump trucks, and provide guidance for the manufacture of long-life pump truck delivery pipes.

2.技术方案2. Technical solution

为了解决上述问题,本发明所采用的技术方案如下:In order to solve the above problems, the technical solution adopted by the present invention is as follows:

本发明的一种铸坯生产泵车用高耐磨性热轧带钢,其原料包括如下质量百分比的组分:C:1.0-1.2,Si:0.20-0.40,Mn:0.20-0.35,Cr:1.20-1.40,Alt:0.010-0.020,P≤0.010,S≤0.002,且C+Mn/6+(Cr+Mo+V)/5+(Cu+Ni)/15≤1.48。The invention discloses a high wear-resistant hot-rolled strip steel for pump trucks produced by casting, wherein the raw materials thereof include the following components in percentage by mass: C: 1.0-1.2, Si: 0.20-0.40, Mn: 0.20-0.35, Cr: 1.20-1.40, Alt: 0.010-0.020, P≤0.010, S≤0.002, and C+Mn/6+(Cr+Mo+V)/5+(Cu+Ni)/15≤1.48.

本发明通过对热轧带钢的元素组成及质量配比进行优化,即通过高碳+低锰+1.30%Cr的合金化成分设计,并控制C+Mn/6+(Cr+Mo+V)/5+(Cu+Ni)/15≤1.48,从而可以有效保证带钢的硬度和耐磨性,并使其焊管后的韧性之间达到良好匹配,进而保证该带钢能够有效满足较大规格(5mm)泵车用管道对耐磨性及使用寿命的要求。The present invention optimizes the element composition and mass ratio of the hot-rolled steel strip, that is, designs an alloying component of high carbon + low manganese + 1.30% Cr, and controls C + Mn / 6 + (Cr + Mo + V) / 5 + (Cu + Ni) / 15 ≤ 1.48, thereby effectively ensuring the hardness and wear resistance of the steel strip, and achieving a good match between the toughness after the welded pipe, thereby ensuring that the steel strip can effectively meet the requirements of larger specification (5mm) pump truck pipelines on wear resistance and service life.

进一步优选的,控制带钢中Cr元素的质量百分比为1.30%。Further preferably, the mass percentage of Cr element in the steel strip is controlled to be 1.30%.

本发明的一种铸坯生产泵车用高耐磨性热轧带钢,该钢管采用上述热轧带钢取样焊接成管制成,热轧带钢的厚度为5mm,其金相组织为低温回火马氏体+碳化物,表面硬度≥70HRC,泵送方量≥7万立方米。The invention discloses a high wear-resistant hot-rolled steel strip for pump trucks produced by casting. The steel pipe is made by sampling and welding the above hot-rolled steel strip into a pipe. The thickness of the hot-rolled steel strip is 5 mm, and its metallographic structure is low-temperature tempered martensite + carbide. The surface hardness is ≥70HRC, and the pumping volume is ≥70,000 cubic meters.

本发明的铸坯生产泵车用高耐磨性热轧带钢的制造方法,其生产工艺包括冶炼、连铸、铸坯加热、轧制、卷曲、退火、焊接和焊后热处理,其中轧制采用控制粗轧+精轧连轧+在线控冷工艺,粗轧终轧温度≥1000℃,精轧终轧温度为850-895℃,通过在线控冷控制卷曲温度为700-850℃。The invention discloses a method for manufacturing a high wear-resistant hot-rolled strip steel for pump trucks by using a casting, and the production process includes smelting, continuous casting, heating of the casting, rolling, curling, annealing, welding and post-weld heat treatment, wherein the rolling adopts a controlled rough rolling + finishing rolling continuous rolling + online controlled cooling process, the rough rolling final rolling temperature is ≥1000°C, the finishing rolling final rolling temperature is 850-895°C, and the curling temperature is controlled to be 700-850°C by online controlled cooling.

本发明通过对带钢的组分进行合金化设计,同时对其制备工艺进行优化控制,尤其是采用控轧控冷工艺,对粗轧与精轧终轧温度以及卷曲温度进行严格控制,从而可以有效保证所得大规格(厚度为5mm)带钢的力学性能,使其达到技术标准要求,保证焊管后具有良好的淬透性以及较高的耐磨性。The present invention performs alloying design on the components of the strip steel and optimizes and controls its preparation process, especially adopts a controlled rolling and controlled cooling process to strictly control the rough rolling and finishing rolling temperatures as well as the curling temperature, thereby effectively ensuring the mechanical properties of the obtained large-size (5 mm thick) strip steel to meet the technical standard requirements and ensure that the welded pipe has good hardenability and high wear resistance.

更进一步的,采用在线辊底式退火炉进行退火处理,退火温度为740-780℃,退火时间为13-15小时;焊管后热处理采用淬火+回火工艺,其中淬火温度为850-870℃,保温时间为20-30min,淬火介质为40-50℃机械油,回火温度为135-145℃,保温时间为120min。Furthermore, an online roller bottom annealing furnace is used for annealing treatment, the annealing temperature is 740-780℃, and the annealing time is 13-15 hours; the post-heat treatment of the welded pipe adopts a quenching + tempering process, in which the quenching temperature is 850-870℃, the holding time is 20-30min, the quenching medium is 40-50℃ mechanical oil, the tempering temperature is 135-145℃, and the holding time is 120min.

通过控轧控冷、在线退火及随后的淬火+低温回火热处理的共同配合,有利于进一步保证所得焊管后的使用性能。其中,经在线退火后产品单边总脱碳层深度≤0.02mm,表面硬度在40-45HRC,带状碳化物≤0.5级,网状碳化物≤0.5级;试样焊成钢管后,经淬火+低温回火热处理后,所得钢管的金相组织为低温回火马氏体+碳化物,表面硬度≥70HRC,泵送方量≥7万立方米。The combined efforts of controlled rolling and controlled cooling, online annealing, and subsequent quenching + low-temperature tempering heat treatment are conducive to further ensuring the performance of the welded pipe. Among them, after online annealing, the total decarburization layer depth of the product on one side is ≤0.02mm, the surface hardness is 40-45HRC, the band carbide is ≤0.5 grade, and the network carbide is ≤0.5 grade; after the sample is welded into a steel pipe, after quenching + low-temperature tempering heat treatment, the metallographic structure of the steel pipe is low-temperature tempered martensite + carbide, the surface hardness is ≥70HRC, and the pumping volume is ≥70,000 cubic meters.

更进一步的,铸坯加热的加热温度为1120-1200℃,出钢温度≥1100℃,坯料在炉总时间为234-286min。Furthermore, the heating temperature of the ingot is 1120-1200°C, the tapping temperature is ≥1100°C, and the total time of the ingot in the furnace is 234-286min.

更进一步的,粗轧终轧温度为1000-1020℃,铸坯加热的出钢温度为1100-1155℃。Furthermore, the rough rolling and final rolling temperatures are 1000-1020°C, and the steel tapping temperature of the heated ingot is 1100-1155°C.

更进一步的,坯料出炉后,经过1次17MPa的除鳞,然后开始粗轧;粗轧结束后,经过1次12MPa的除鳞,然后进入10台平立连轧机组进行精轧,精轧终轧前再经过1次7MPa除鳞,精轧结束后打开在线风冷机组进行控冷。Furthermore, after the billet is taken out of the furnace, it undergoes a descaling at 17MPa before rough rolling begins; after the rough rolling is completed, it undergoes a descaling at 12MPa and then enters 10 horizontal and vertical continuous rolling mills for finishing rolling. Before the final finishing rolling, it undergoes another descaling at 7MPa. After the finishing rolling is completed, the online air cooling unit is turned on for controlled cooling.

更进一步的,连铸后对铸坯进行堆垛缓冷,缓冷温度控制在≥700℃,缓冷时间为48小时,同时确保出缓冷坑温度为300-350℃。Furthermore, after continuous casting, the ingots are stacked and slowly cooled, the slow cooling temperature is controlled at ≥700°C, the slow cooling time is 48 hours, and at the same time, the temperature out of the slow cooling pit is ensured to be 300-350°C.

3.有益效果3. Beneficial effects

综上所述,相比于现有技术,本发明的有益效果为:In summary, compared with the prior art, the present invention has the following beneficial effects:

(1)本发明通过合金化设计对带钢的元素组成及配比进行优化,从而可以满足大规格(5mm厚度)铸坯生产泵车用管道对使用性能,尤其是对硬度、耐磨性和使用寿命的要求,从而有效克服了5mm厚度热轧带钢在焊接成管服役要求下,难以达到高耐磨性、单边总低脱碳层、低网带状碳化物、高使用寿命的技术难点。(1) The present invention optimizes the element composition and proportion of the strip steel through alloying design, so as to meet the performance requirements of large-size (5 mm thickness) ingots for producing pump truck pipelines, especially the requirements for hardness, wear resistance and service life, thereby effectively overcoming the technical difficulties of 5 mm thick hot-rolled strip steel being difficult to achieve high wear resistance, low total decarburization layer on one side, low web-like carbides and long service life under the service requirements of welded pipes.

(2)本发明在合金化成分设计的基础上,对钢管生产工艺进行优化设计,通过控轧控冷+在线退火+淬火-低温回火焊后热处理的工艺配合,从而可以进一步保证所得钢管的力学性能和使用寿命,且其生产工序简单、快捷交付、成本低廉。该生产工艺已在国内某钢厂采用2辊粗轧机+10架平立连轧可逆轧机生产线生产试行,所得钢管性能经验证可以满足5mm厚度泵车用管道的要求,具有高耐磨性、高淬透性、高寿命。(2) Based on the alloying composition design, the present invention optimizes the steel pipe production process, and further ensures the mechanical properties and service life of the obtained steel pipe through the process coordination of controlled rolling and controlled cooling + online annealing + quenching-low temperature tempering welding and heat treatment, and its production process is simple, fast delivery and low cost. The production process has been tested in a domestic steel plant using a 2-roller roughing mill + 10-frame horizontal and vertical continuous rolling reversible rolling mill production line. The performance of the obtained steel pipe has been verified to meet the requirements of 5mm thick pump truck pipelines, with high wear resistance, high hardenability and long service life.

附图说明BRIEF DESCRIPTION OF THE DRAWINGS

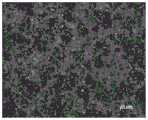

图1为实施例4经焊后热处理所得钢管的金相组织。FIG. 1 is the metallographic structure of the steel pipe obtained by post-weld heat treatment in Example 4.

具体实施方式DETAILED DESCRIPTION

考虑到城市建设需要高质量的混凝土泵车,高耐磨性热轧带钢作为原材料,为延长高压高输送的泵车服役寿命,除常规低倍夹杂物控制优良外,还需要有优良的高耐磨性能,同时还要易于生产且成本较低。因此,本发明的发明人针对铸坯生产的泵车用高耐磨性热轧带钢化学成分设计和生产工艺进行了大量研究,从而得到本申请的方案。Considering that urban construction requires high-quality concrete pump trucks, high-wear-resistant hot-rolled strip steel is used as raw material. In order to extend the service life of high-pressure and high-transportation pump trucks, in addition to good control of conventional low-multiple inclusions, it is also required to have excellent high wear resistance, easy production and low cost. Therefore, the inventor of the present invention has conducted a lot of research on the chemical composition design and production process of high-wear-resistant hot-rolled strip steel for pump trucks produced by casting, thereby obtaining the solution of the present application.

虽然公开号为:CN113913705A的申请案公开了一种混凝土泵车用耐磨钢管及其制备方法,其通过合理的冶炼成分设计,采用连铸坯生产(2.7-3.7)*285mm窄带钢,并对热轧工艺、退火工艺及淬火+回火工艺进行了改善,从而可以得到较好的硬度性能和泵送方量情况,但其制备所得钢管的最大尺寸仅为3.7mm,不能很好适用于更大规格钢管的生产,且其表面硬度和泵送方量也有很大的差距。Although the application with publication number: CN113913705A discloses a wear-resistant steel pipe for concrete pump trucks and a preparation method thereof, it adopts reasonable smelting composition design, adopts continuous casting billet to produce (2.7-3.7)*285mm narrow strip steel, and improves the hot rolling process, annealing process and quenching + tempering process, so as to obtain better hardness performance and pumping volume, but the maximum size of the steel pipe prepared is only 3.7mm, which is not well suitable for the production of larger specifications of steel pipes, and there is also a big gap between its surface hardness and pumping volume.

本发明的大厚度铸坯生产泵车用高耐磨性热轧带钢的制造方法,主要包括以下工序:铁水脱硫预处理→电炉冶炼→LF+VD精炼→连铸→铸坯堆垛缓冷→铸坯检验→铸坯判定→铸坯验收→铸坯加热→除鳞→2台粗轧+10架平立连轧+在线控冷→卷曲→检验→在线退火热处理→切割、取样→检验→焊管→淬火+回火→检测→挂牌标识→入库。其中:The manufacturing method of the thick billet for producing high wear-resistant hot-rolled strip steel for pump trucks mainly includes the following steps: hot metal desulfurization pretreatment → electric furnace smelting → LF+VD refining → continuous casting → billet stacking slow cooling → billet inspection → billet determination → billet acceptance → billet heating → descaling → 2 rough rolling + 10 horizontal and vertical continuous rolling + online controlled cooling → curling → inspection → online annealing heat treatment → cutting, sampling → inspection → welded pipe → quenching + tempering → testing → labeling → storage. Among them:

(1)炼钢成分设计:其化学成分按重量百分比计,包括,C:1.0-1.2,Si:0.20-0.40,Mn:0.20-0.35,P≤0.010,S≤0.002,Cr:1.20-1.40,Alt:0.010-0.020,Pb:≤0.002,Cu、Ni、Mo等为残余元素,不刻意添加,C+Mn/6+(Cr+Mo+V)/5+(Cu+Ni)/15≤1.48,余量为Fe及不可避免的杂质。(1) Steelmaking composition design: Its chemical composition, by weight percentage, includes, C: 1.0-1.2, Si: 0.20-0.40, Mn: 0.20-0.35, P≤0.010, S≤0.002, Cr: 1.20-1.40, Alt: 0.010-0.020, Pb: ≤0.002, Cu, Ni, Mo, etc. are residual elements and are not intentionally added, C+Mn/6+(Cr+Mo+V)/5+(Cu+Ni)/15≤1.48, and the balance is Fe and unavoidable impurities.

(2)坯料缓冷工艺:因成分设计属于高碳高铬,碳当量也很高,因此坯料必须入缓冷坑缓冷。缓冷温度控制在≥700℃,缓冷时间为48小时,同时要确保出缓冷坑温度:300-350℃。(2) Billet slow cooling process: Because the composition design is high carbon and high chromium, the carbon equivalent is also high, so the billet must be slow cooled in the slow cooling pit. The slow cooling temperature is controlled at ≥700℃, the slow cooling time is 48 hours, and the temperature out of the slow cooling pit must be ensured to be: 300-350℃.

(3)加热轧制工艺:坯料加热温度:1120-1200℃,出钢温度均≥1100℃,采用150mm×260mm矩形铸坯:轧成5mm*225mm带钢,坯料在炉总时间为234-286min,坯料出炉后,经过1次17MPa的除鳞,开始粗轧,粗轧终轧温度为≥1000℃,粗轧结束后,经过1次12MPa的除鳞,然后快速进入10台平立连轧机精轧,精轧终轧前再经过1次7MPa除鳞,确保表面无氧化铁皮压入,精轧终轧温度:850-900℃。精轧结束,打开多组在线风冷机进行控冷(优选为3组),以确保卷曲温度:700-850℃。(3) Heating and rolling process: billet heating temperature: 1120-1200℃, steel tapping temperature ≥1100℃, 150mm×260mm rectangular billet: rolled into 5mm*225mm strip steel, the total time of billet in the furnace is 234-286min, after billet is discharged from the furnace, it is descaled once at 17MPa, and then rough rolling begins, the final rough rolling temperature is ≥1000℃, after rough rolling, it is descaled once at 12MPa, and then quickly enters 10 horizontal and vertical continuous rolling mills for finishing rolling, and it is descaled once again at 7MPa before finishing rolling to ensure that there is no iron oxide pressed into the surface, and the final finishing rolling temperature is 850-900℃. After finishing rolling, open multiple sets of online air coolers for controlled cooling (preferably 3 sets) to ensure the coiling temperature is 700-850℃.

由于高耐磨性热轧带钢需要耐磨性能优良,因此本生产方法除成分设计采用高碳高铬外,还采用精轧连轧,同时采用了风冷作为控冷手段,从而解决了带钢卷曲温度控制生产办法。Since high wear-resistant hot-rolled strip steel needs to have excellent wear resistance, this production method not only adopts high carbon and high chromium in the composition design, but also adopts finishing rolling and continuous rolling, and uses air cooling as a cooling control method, thereby solving the production method of strip steel curling temperature control.

(4)热处理工艺:为了控制热轧态网带状碳化物大小,卷曲后进入在线辊底式退火炉,退火温度:740-780℃,退火时间:13-15小时,优选15小时;取样检测网带状碳化物大小及表面硬度。同时为便于后续加工检测,取样后,试样焊接成钢管,对钢管进行淬火+回火热处理。淬火温度:850-870℃,保温时间:20-30min,优选30min;淬火介质:50℃机械油;回火温度:135-145℃,保温120min。(4) Heat treatment process: In order to control the size of hot-rolled mesh-shaped carbides, the steel pipe enters an online roller-bottom annealing furnace after curling, with an annealing temperature of 740-780°C and an annealing time of 13-15 hours, preferably 15 hours; sampling is performed to detect the size and surface hardness of mesh-shaped carbides. At the same time, in order to facilitate subsequent processing and testing, after sampling, the sample is welded into a steel pipe, and the steel pipe is subjected to quenching + tempering heat treatment. Quenching temperature: 850-870°C, holding time: 20-30 minutes, preferably 30 minutes; quenching medium: 50°C machine oil; tempering temperature: 135-145°C, holding time: 120 minutes.

经在线退火后产品单边总脱碳层深度≤0.02mm,表面硬度在40-45HRC,带状碳化物≤0.5级,网状碳化物≤0.5级。试样焊成钢管后,淬火+低温回火热处理后,金相组织为低温回火马氏体+碳化物,表面硬度≥70HRC,泵送方量≥7万立方米,具有良好的淬透性,同时具有很高的耐磨性性能。After online annealing, the total decarburization layer depth of the product on one side is ≤0.02mm, the surface hardness is 40-45HRC, the band carbide is ≤0.5 grade, and the network carbide is ≤0.5 grade. After the sample is welded into a steel pipe, after quenching + low-temperature tempering heat treatment, the metallographic structure is low-temperature tempered martensite + carbide, the surface hardness is ≥70HRC, the pumping volume is ≥70,000 cubic meters, and it has good hardenability and high wear resistance.

下面结合具体实施例对本发明进一步进行描述。The present invention is further described below in conjunction with specific embodiments.

实施例1-5Examples 1-5

实施例1-5中大厚度铸坯生产泵车用高耐磨性热轧带钢钢管的制造方法,主要包括冶炼→LF+VD精炼→连铸→铸坯堆垛缓冷→铸坯加热→除鳞→2台粗轧+10架平立连轧+在线控冷→卷曲→在线退火热处理→取样→焊管→淬火+回火工艺,其中:The manufacturing method of producing high wear-resistant hot-rolled strip steel pipe for pump trucks from thick ingots in Example 1-5 mainly includes smelting → LF+VD refining → continuous casting → slow cooling of ingot stacking → heating of ingots → descaling → 2 rough rolling + 10 horizontal and vertical continuous rolling + online controlled cooling → curling → online annealing heat treatment → sampling → welded pipe → quenching + tempering process, wherein:

(1)铸坯生产泵车用高耐磨性热轧带钢的化学成分分别如下表1所示。其中,实施例1-5中C+Mn/6+(Cr+Mo+V)/5+(Cu+Ni)/15分别为1.32、1.43、1.48、1.39和1.48。(1) Ingot casting production The chemical compositions of high wear-resistant hot-rolled steel strips for pump trucks are shown in Table 1. In Examples 1-5, C+Mn/6+(Cr+Mo+V)/5+(Cu+Ni)/15 are 1.32, 1.43, 1.48, 1.39 and 1.48, respectively.

表1实施例1-5中化学成分(wt%)Table 1 Chemical composition (wt%) in Examples 1-5

(2)铸坯加热工艺(2) Billet heating process

实施例1-5中的铸坯加热工艺参数分别如下表2所示。The heating process parameters of the casting in Examples 1-5 are shown in Table 2 below.

表2铸坯加热工艺参数Table 2 Billet heating process parameters

由于实验钢具有高耐磨性能特征,坯料选用150*260矩形铸坯尺寸,为减小铸坯心部网带状碳化物大小,钢板采用控制粗轧+精轧连轧以及风冷控制卷曲温度轧制模式,降低高温状态下晶粒长大速度,本生产方法选用的坯料出炉温度采用高温出炉即温度≥1100℃,因合金只有铬和少量的锰,在炉时间按照坯料最大厚度的0.9-1.1min/mm加热系数控制,以确保坯料钢温整体均匀,增加轧制渗透至心部的能力,从而提高心部变形能力,降低心部组织晶粒尺寸。Due to the high wear resistance of the experimental steel, a rectangular ingot size of 150*260 was selected for the billet. In order to reduce the size of the mesh-shaped carbides in the core of the ingot, the steel plate adopted a rolling mode of controlled rough rolling + fine rolling and air cooling to control the curling temperature, thereby reducing the grain growth rate under high temperature conditions. The billet furnace temperature selected in this production method is high temperature, that is, the temperature is ≥1100℃. Since the alloy contains only chromium and a small amount of manganese, the furnace time is controlled according to the heating coefficient of 0.9-1.1min/mm of the maximum thickness of the billet to ensure that the overall billet steel temperature is uniform, increase the ability of rolling to penetrate into the core, thereby improving the deformation ability of the core and reducing the grain size of the core structure.

(3)控轧工艺(3) Controlled rolling process

实施例1-5中的轧制工艺参数分别如下表3所示。The rolling process parameters in Examples 1-5 are respectively shown in Table 3 below.

表3轧制工艺参数Table 3 Rolling process parameters

(4)在线退火工艺(4) Online annealing process

实施例1-5中的在线退火工艺参数分别如下表4所示。The online annealing process parameters in Examples 1-5 are respectively shown in Table 4 below.

表4在线退火工艺参数Table 4 Online annealing process parameters

经在线退火后的带钢性能参数如下表5所示。The performance parameters of the strip after online annealing are shown in Table 5 below.

表5在线退火后的性能参数Table 5 Performance parameters after online annealing

(5)试样焊成5mm(管厚)*225mm(管高)钢管后,进行淬火+回火热处理,实施例1-5的淬火和回火工艺参数分别如下表6、表7所示。(5) After the sample is welded into a 5 mm (tube thickness) * 225 mm (tube height) steel tube, a quenching + tempering heat treatment is performed. The quenching and tempering process parameters of Examples 1-5 are shown in Tables 6 and 7 below, respectively.

表6淬火工艺参数Table 6 Quenching process parameters

表7回火工艺参数Table 7 Tempering process parameters

试样焊管后淬火+回火后的性能参数如下表8所示。结合表格可以看出,本发明通过合金化成分设计,并经过控轧控冷、在线退火及随后的淬火+低温回火热处理后,所得钢管的金相组织为低温回火马氏体+碳化物(实施例4中焊后热处理后的金相组织如图1所示),表面硬度≥70HRC,泵送方量≥7万立方米,具有良好的淬透性,同时具有很高的耐磨性能,所得钢管的网带状碳化物等级、表面硬度、泵送方量指标均达到技术标准要求。由于高耐磨性热轧带钢受矩形铸坯冶炼质量发展影响,网带状碳化物尺寸、高硬度与高耐磨性一致性能要求,在实际工业化大生产过程中,为避免在生产过程中出现加热开裂,轧制形变不足,易造成原始晶粒尺寸粗大,甚至出现混晶现象,从而严重影响表面硬度性能,故对坯料的缓冷工艺、卷曲温度控制工艺、在线退火工艺,试样焊管后,管件淬火+回火工艺进行了摸索优化,并进行了规定,从而实现工业化大生产采用较低的生产装备条件即能够生产高耐磨性泵车用带钢。The performance parameters of the sample welded pipe after quenching + tempering are shown in Table 8. It can be seen from the table that the metallographic structure of the obtained steel pipe is low-temperature tempered martensite + carbide (the metallographic structure after post-weld heat treatment in Example 4 is shown in Figure 1) through alloying component design, and after controlled rolling and controlled cooling, online annealing and subsequent quenching + low-temperature tempering heat treatment, the surface hardness is ≥70HRC, the pumping volume is ≥70,000 cubic meters, it has good hardenability, and has high wear resistance. The mesh carbide grade, surface hardness, and pumping volume of the obtained steel pipe meet the technical standard requirements. Since high wear-resistant hot-rolled strip steel is affected by the development of rectangular ingot smelting quality, the mesh-shaped carbide size, high hardness and high wear resistance consistent performance requirements, in the actual industrial large-scale production process, in order to avoid heating cracking during the production process, insufficient rolling deformation is easy to cause coarse original grain size, and even mixed crystal phenomenon, which seriously affects the surface hardness performance, so the billet slow cooling process, curling temperature control process, online annealing process, sample welding pipe, pipe fittings quenching + tempering process were explored and optimized, and regulations were made, so as to achieve industrial large-scale production with lower production equipment conditions, that is, to produce high wear-resistant pump truck strip steel.

表8淬火+回火后的性能参数Table 8 Performance parameters after quenching + tempering

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210727796.5ACN115141977B (en) | 2022-06-24 | 2022-06-24 | High-wear-resistance hot rolled strip steel and steel tube for casting blank production pump truck and manufacturing method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210727796.5ACN115141977B (en) | 2022-06-24 | 2022-06-24 | High-wear-resistance hot rolled strip steel and steel tube for casting blank production pump truck and manufacturing method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN115141977A CN115141977A (en) | 2022-10-04 |

| CN115141977Btrue CN115141977B (en) | 2023-05-05 |

Family

ID=83407306

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210727796.5AActiveCN115141977B (en) | 2022-06-24 | 2022-06-24 | High-wear-resistance hot rolled strip steel and steel tube for casting blank production pump truck and manufacturing method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115141977B (en) |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2004190127A (en)* | 2002-11-28 | 2004-07-08 | Jfe Steel Kk | Bearing wire rod and steel bar having spheroidized carbide structure and method for producing the same |

| JP5030695B2 (en)* | 2007-07-19 | 2012-09-19 | 住友金属工業株式会社 | High carbon steel excellent in break separation and production method thereof |

| CN101186960B (en)* | 2007-12-05 | 2010-07-28 | 南京钢铁股份有限公司 | Method for producing wear-resistant hot-rolled steel plate and steel plate produced by using steel coil mill |

| EP3447156B1 (en)* | 2016-04-19 | 2019-11-06 | JFE Steel Corporation | Abrasion-resistant steel sheet and method for producing abrasion-resistant steel sheet |

| CN105925909B (en)* | 2016-06-24 | 2017-11-14 | 邢台钢铁有限责任公司 | A kind of bearing steel wire rod and its production method |

| CN111349859B (en)* | 2020-05-09 | 2021-07-30 | 安徽工业大学 | A kind of composite billet rolling large thickness 500MPa grade high Z-direction layered performance low temperature container steel plate and its manufacturing method |

| CN113774275A (en)* | 2021-08-05 | 2021-12-10 | 莱芜钢铁集团银山型钢有限公司 | Easily-formed high-wear-resistance steel plate for silt conveying pipeline and preparation method thereof |

| CN113913705A (en)* | 2021-09-18 | 2022-01-11 | 南京钢铁股份有限公司 | Wear-resistant steel pipe for concrete pump truck and preparation method thereof |

- 2022

- 2022-06-24CNCN202210727796.5Apatent/CN115141977B/enactiveActive

Also Published As

| Publication number | Publication date |

|---|---|

| CN115141977A (en) | 2022-10-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110438414B (en) | A method for eliminating surface cracks of ultra-wide ferritic stainless steel medium and thick plates | |

| WO2022205939A1 (en) | Hydrogen-induced-cracking-resistant pressure vessel steel plate with thickness greater than 200-250 mm and manufacturing method therefor | |

| CN101928876B (en) | TRIP/TWIP high-strength plastic automobile steel with excellent processability and preparation method thereof | |

| CN109500130B (en) | Manufacturing method of seamless steel tube with diameter of 920mm for long-tube trailer gas cylinder | |

| CN106811700B (en) | Thick acid-resistant X60MS hot-rolled coil and manufacturing method thereof | |

| CN111321345A (en) | A quenched and tempered high-quality coiled tube and its manufacturing method | |

| CN114774663A (en) | A production method of on-line heat-treated bainite rails for heavy-duty railways with a fixed length of 75kg/m | |

| CN110306103A (en) | A 555MPa class H2S corrosion resistant steel strip for oil pipe and its preparation method | |

| CN117089769A (en) | A short-process, high-strength, super atmospheric corrosion-resistant hot-rolled strip steel and its production method | |

| WO2024027526A1 (en) | Extra-thick q500qe bridge steel plate and production method therefor | |

| CN107988548B (en) | X80 pipeline steel plate adapting to low-temperature exposed environment and production method thereof | |

| CN111349859A (en) | A kind of composite billet rolling large thickness 500MPa grade high Z-direction layered performance low temperature container steel plate and its manufacturing method | |

| CN114574776A (en) | Method for producing weather-resistant Q235NHB middle plate by double-stand rolling mill and Q235NHB middle plate | |

| CN114774770A (en) | Low-cost L290 hot-rolled steel plate for HIC-resistant oil and gas pipeline and manufacturing method | |

| CN110205551B (en) | Method for improving DWTT performance of thick gauge L555M grade pipeline steel | |

| CN114405996B (en) | CSP process low-carbon steel plate and manufacturing method thereof | |

| CN116770198B (en) | A low compression ratio steel plate for hydropower and its preparation method | |

| CN115141977B (en) | High-wear-resistance hot rolled strip steel and steel tube for casting blank production pump truck and manufacturing method thereof | |

| CN110964971A (en) | Production method of X65M-grade pipeline steel plate with thin specification and high crack resistance | |

| CN117604385A (en) | Steel pipe for cold rotary forging ERW oil cylinder and manufacturing method thereof | |

| CN103160751B (en) | Bulb flat steel with yield strength of 590MPa and production method thereof | |

| CN111235479B (en) | Manufacturing method of economical pipeline steel | |

| CN116623087A (en) | Steel for producing thick 240MPa high-toughness tubular pile from thin blank and production method | |

| CN101992213B (en) | Production method of pipeline steel coil plate with fine grains on surface layer and thick specification | |

| CN116145048A (en) | Economical high-toughness L555M pipeline steel hot-rolled coil and production method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |