CN115139026B - Automatic welding line and welding method for automobile front wall plate - Google Patents

Automatic welding line and welding method for automobile front wall plateDownload PDFInfo

- Publication number

- CN115139026B CN115139026BCN202211067507.XACN202211067507ACN115139026BCN 115139026 BCN115139026 BCN 115139026BCN 202211067507 ACN202211067507 ACN 202211067507ACN 115139026 BCN115139026 BCN 115139026B

- Authority

- CN

- China

- Prior art keywords

- plate

- cylinder

- positioning

- welding

- rotating

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K37/00—Auxiliary devices or processes, not specially adapted for a procedure covered by only one of the other main groups of this subclass

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K37/00—Auxiliary devices or processes, not specially adapted for a procedure covered by only one of the other main groups of this subclass

- B23K37/04—Auxiliary devices or processes, not specially adapted for a procedure covered by only one of the other main groups of this subclass for holding or positioning work

- B23K37/0426—Fixtures for other work

- B23K37/0435—Clamps

- B23K37/0443—Jigs

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/10—Greenhouse gas [GHG] capture, material saving, heat recovery or other energy efficient measures, e.g. motor control, characterised by manufacturing processes, e.g. for rolling metal or metal working

Landscapes

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Automatic Assembly (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及一种汽车前围板自动化焊接线及其焊接方法。The invention relates to an automatic welding line and a welding method for an automobile dash panel.

背景技术Background technique

汽车产业是我国的支柱产业之一,车身板件则是汽车的核心部件之一。目前车身制造是按照下车身总成平台车型进行细分,不同的生产基地生产不同的细分车型。其缺点在于当前的车身总成焊接生产线仅仅能实现单一车型的焊接生产,无法实现多车型混线生产,新增车型或改款车型时需要新建或改造线体,周期很长,投入成本巨大,也大大降低了生产效率。The automobile industry is one of the pillar industries of our country, and the body panel is one of the core components of the automobile. At present, body manufacturing is subdivided according to the lower body assembly platform models, and different production bases produce different subdivided models. Its disadvantage is that the current body assembly welding production line can only realize the welding production of a single model, and cannot realize the mixed production of multiple models. When adding a new model or changing a model, it is necessary to build or modify the line body. The cycle is very long and the input cost is huge. Also greatly reduced production efficiency.

发明内容Contents of the invention

本发明目的是克服了现有技术的不足,提供一种汽车前围板自动化焊接线及其焊接方法,以缓解现有技术中存在的车身焊接生产线仅仅能实现单一车型的焊接生产,无法实现多车型混线生产的技术问题,大大提高效率。The object of the present invention is to overcome the deficiencies of the prior art, and provide an automatic welding line and its welding method for the front panel of the automobile, so as to alleviate the existing welding production line of the car body in the prior art, which can only realize the welding production of a single vehicle type, and cannot realize multiple The technical problems of the mixed-line production of models have greatly improved efficiency.

本发明是通过以下技术方案实现的:The present invention is achieved through the following technical solutions:

一种汽车前围板自动化焊接线,其特征在于包括有:An automatic welding line for an automobile dash panel, characterized in that it comprises:

第一输入积放链13:用于输送前围下板12;The first input accumulating chain 13: used for conveying the cowl

第二输入积放链14:用于输送前围上板11;The second input accumulation chain 14: used for conveying the cowl

第一搬运机器人9:用于分别搬运前围下板12和前围上板11;The first transport robot 9: used to transport the cowl

第一焊接台7:用于承载第一搬运机器人9搬运过来的前围下板12和前围上板11;The first welding station 7: used to carry the cowl

第一焊接机器人8:用于在第一焊接台7上将前围下板12和前围上板11焊接成前围下板组件;The first welding robot 8: for welding the cowl

第一固定焊枪位15:用于第二次焊接从第一焊接台7转运过来的前围下板组件;The first fixed welding torch position 15: used for the second welding of the cowl lower plate assembly transferred from the

第一中转台16:用于转运从第一固定焊枪位15搬运过来的前围下板组件;The first transfer platform 16: used to transfer the cowl lower panel assembly transported from the first fixed

第二搬运机器人10:用于搬运第一焊接台7或第一固定焊枪位15上的板件;The second handling robot 10: used to transport the plate on the

螺柱焊接位17:用于第三次焊接从第一中转台16搬运过来的前围下板组件;Stud welding position 17: used for the third welding of the cowl lower plate assembly transported from the first transfer table 16;

第三搬运机器人19:用于将第一中转台16上的前围下板组件搬运至螺柱焊接位17,或者将螺柱焊接位17上的前围下板组件搬运至旋转台18;The third transport robot 19: used to transport the cowl lower panel assembly on the

旋转台18:能360度水平转动、用于承载螺柱焊接位17转运过来的前围下板组件与前围上盖板27;Rotary table 18: capable of 360-degree horizontal rotation, used to carry the cowl lower plate assembly and the cowl

第二焊接机器人20:设在旋转台18的外端两侧用于将前围下板组件与人工上件的前围上盖板27焊接形成前围板总成,第二焊接机器人20设有两台,分别设在旋转台18外端的两侧;The second welding robot 20: set on both sides of the outer end of the rotary table 18 for welding the cowl lower panel assembly and the cowl

第三焊接机器人21:设在旋转台18的内端两侧待旋转台18旋转回来时将前围下板组件与前围上盖板27连接的另一面焊接,第三焊接机器人21也设有两台,分别设在旋转台18内端的两侧;The third welding robot 21: it is arranged on both sides of the inner end of the rotary table 18. When the rotary table 18 is rotated back, the other side of the cowl lower panel assembly and the cowl

第二固定焊枪位22:用于将旋转台18转运过来的前围板总成进行第三次焊接;The second fixed welding torch position 22: used for the third welding of the dash panel assembly transferred from the rotary table 18;

第二中转台23:用于接收从第二固定焊枪位22转运过来的前围板总成;The second transfer platform 23: used to receive the dash panel assembly transferred from the second fixed

第四搬运机器人24:用于将第二固定焊枪位22上的前围板总成搬运到第二中转台23上;The fourth transport robot 24: used to transport the dash panel assembly on the second fixed

检查台26:用于接收从第二中转台23转运过来的前围板总成并进行人工检查;Inspection platform 26: used to receive the dashboard assembly transferred from the

第五搬运机器人25:用于将第二中转台23上的前围板总成搬运至检查台26,然后将检查台26上的前围板总成搬运至输出积放链29,或者直接将第二中转台23上的前围板总成搬运至输出积放链29;The fifth transport robot 25: used to transport the cowl assembly on the

输出积放链29:用于将焊接好的前围板总成输送至下一工序。Output accumulation chain 29: used to transport the welded dash panel assembly to the next process.

如上所述的汽车前围板自动化焊接线,其特征在于:在所述第二搬运机器人10的抓手上设有用于定位板件的剪刀叉装置1,所述剪刀叉装置1包括第一滑动机构、被第一滑动机构驱动滑动的第一旋转机构、被第一旋转机构驱动转动的第一勾销缸机构,所述第一滑动机构包括第一滑轨101、被第一气缸102驱动能沿第一滑轨101滑动的第一滑动板103,在所述第一滑动板103上设有多个安装板116;所述第一旋转机构包括固定在其中一个所述安装板116上的第四固定架117,在第四固定架117上分别设有第一铰接点104和第二铰接点105,在第四固定架117上还设有能绕第一铰接点104转动的第二气缸106、被第二气缸106驱动能绕第二铰接点105转动的第一旋转板107。The automatic welding line for the automobile dash panel as described above is characterized in that: a scissor-fork device 1 for positioning panels is provided on the gripper of the

如上所述的汽车前围板自动化焊接线,其特征在于:所述第一勾销缸机构包括设在第一旋转板107上的第三气缸110,在第一旋转板107上且位于第三气缸110的上方设有第一定位销112,所述第一定位销112由两块板通过固定销114连接组成,第一定位销112的顶部呈锥形,组成第一定位销112的两块板之间设有两个对称、且被第三气缸110驱动升降的定位勾111,第三气缸110的活塞杆与两定位勾111的底端铰接,在定位勾111上设有第一限位孔113,所述固定销114从两个定位勾111的第一限位孔113穿过,所述第一限位孔113包括竖直的上部孔和沿内侧倾斜的下部孔,上部孔和下部孔连通,在第一定位销112的锥形顶部外侧设有环形台阶115,被驱动下降的定位勾111夹于所述环形台阶115上。The above-mentioned automatic welding line for the front wall of the automobile is characterized in that: the first detent cylinder mechanism includes a

如上所述的汽车前围板自动化焊接线,其特征在于:在所述第一焊接台7上设有对板件定位的第一定位装置2,所述第一定位装置2包括第一固定架201,在第一固定架201上设有第二滑轨202、能沿第二滑轨202滑动的第二滑动板203、驱动第二滑动板203上下滑动的第四气缸204,在第二滑动板203上设有下安装位和上安装位,在所述下安装位上分别设有第五固定架214和第五气缸208,在第五固定架214上分别设有第三铰接点207、被第五气缸208驱动绕第三铰接点207转动的第二旋转板206,在所述第二旋转板206上分别设有第十三气缸205以及由第十三气缸205驱动升降的第一固定板209,在第一固定板209的侧面固定连接有第一固定块210,在第一固定块210上设有能够从板件上的孔穿出从而对板件定位的第二定位销211;在第二旋转板206上还设有分别对板件侧向定位的第一定位块212、第一板件感应器213。The above-mentioned automatic welding line for the front panel of the automobile is characterized in that: the

如上所述的汽车前围板自动化焊接线,其特征在于:在所述第一搬运机器人9的抓手上设有能对两种板件定位的第三定位装置4,所述第三定位装置4包括第三固定架401,在第三固定架401上设有第三滑轨402、能沿第三滑轨402上下滑动的第三滑动板403、驱动第三滑动板403滑动的第九气缸404,在第三滑动板403上设有第五铰接点405、能绕第五铰接点405旋转的第三旋转板406、用于驱动第三旋转板406转动的第十气缸407,在第三旋转板406上固定连接有第四旋转板408,在第三旋转板406的外端设有在第十气缸407的活塞杆缩回时对所述板件的底面定位的第五定位块409,在第四旋转板408的外端设有在第十气缸407的活塞杆上升时对另一种板件定位的第三定位销411。The automatic welding line for the front panel of the automobile as described above is characterized in that: the gripper of the

如上所述的汽车前围板自动化焊接线,其特征在于:在所述旋转台18上设有对多种板件定位的第二定位装置3,所述第二定位装置3包括有下压装置、用于带动第一上托块B312作升降运动的第一上托机构B、用于带动第二上托块B313作旋转运动的第二旋转上托机构B、用于带动第三上托块1A314和第三上托块2A315作升降运动的第三上托机构A、用于带动第四上托块A316作旋转运动的第四旋转上托机构A;下压装置又包括用于带动旋转架303转动的第二旋转机构、第二下压机构B、第四下压机构A、第一旋转下压机构B、第三下压机构A,其中第二下压机构B、第四下压机构A、第一旋转下压机构B、第三下压机构A又分别设在第二旋转机构上。The above-mentioned automatic welding line for the front panel of the automobile is characterized in that: the

如上所述的汽车前围板自动化焊接线,其特征在于:所述第二旋转机构包括第二固定架301,在第二固定架301上分别设有第四铰接点302、能绕第四铰接点302旋转的旋转架303、用于驱动旋转架303转动的第六气缸304;在所述旋转架303上的左右两侧分别设有吊架305,在吊架305上设有多个安装位,在其中一个安装位设有带动第二下压块B307作升降运动的第二下压机构B,在另一个安装位上设有带动第四下压块A308作升降运动的第四下压机构A;在旋转架303的自由端设有托板306,在所述托板306上设有多个安装位,在其中一个安装位设有带动第一下压块B309转动的第一旋转下压机构B,在另一个安装位上设有带动第三下压块1A310和第三下压块2A311作升降运动的第三下压机构A。The above-mentioned automatic welding line for the front wall of the automobile is characterized in that: the second rotating mechanism includes a

如上所述的汽车前围板自动化焊接线,其特征在于:所述第二下压机构B包括有设在所述吊架305一个安装位上的第七气缸322、由第七气缸322驱动的第二下压块B307;The above-mentioned automatic welding line for the front panel of the automobile is characterized in that: the second pressing mechanism B includes a

所述第四下压机构A包括有设在所述吊架305另一个安装位上的第十四气缸317、由第十四气缸317驱动的第四下压块A308,所述第十四气缸317与所述第七气缸322设在所述吊架305的同一侧;The fourth depressing mechanism A includes a

所述第一旋转下压机构B包括有固定在所述托板306其中一个安装位上的第二固定板318,在所述第二固定板318上水平设有第十六气缸319,第十六气缸319的活塞杆沿水平方向伸缩,第十六气缸319的活塞杆铰接有第十四旋转板320,在第十四旋转板320的自由端底面设有第一下压块B309;The first rotary pressing mechanism B includes a

所述第三下压机构A包括固定在所述另一个安装位上的第三固定板321,在所述第三固定板321上设有第十九气缸323、由第十九气缸323驱动升降的第三下压块1A310和第三下压块2A311;The third depressing mechanism A includes a third

所述第一上托机构B包括固定在第六固定架33上的第一升降气缸324、被第一升降气缸324驱动升降的第一上托块B312;The first lifting mechanism B includes a

所述第二旋转上托机构B包括固定在第十固定架327上的第十一固定板328,在所述第十一固定板328上分别铰接有第十七气缸329、被第十七气缸329驱动转动的第十三旋转板330,在第十三旋转板330的自由端设有第二上托块B313;The second rotating lifting mechanism B includes an

所述第三上托机构A包括有设在第十一固定架331上的第十八气缸332、被第十八气缸332驱动升降的第十二固定板333,在所述第十二固定板333的顶部分别设有第三上托块1A314和第三上托块2A315;The third lifting mechanism A includes an

所述第四旋转上托机构A的结构与第二旋转上托机构B的结构相同。The structure of the fourth rotating lifting mechanism A is the same as that of the second rotating lifting mechanism B.

如上所述的汽车前围板自动化焊接线,其特征在于:所述第二定位装置3还包括有第二定位机构B6,第二定位机构B6包括有固定在第六固定架33上的第二升降气缸601、被第二升降气缸601驱动升降的第七固定板602,在第七固定板602上固定有第二支撑板603,在第二支撑板603上分别铰接有第二十气缸604、由第二十气缸604驱动绕第八铰接点605转动的第八旋转板606,在所述第八旋转板606上分别铰接有第十五气缸607、由第十五气缸607驱动绕第九铰接点608转动的第九旋转板610,在第九旋转板610上设有第一连接板609,在第一连接板609上从下至上分别设有第一下定位块611、第一上定位块612,在第八旋转板606上由下至上分别设有第二下定位块613、第二上定位块614。The above-mentioned automatic welding line for the front panel of the automobile is characterized in that: the

一种如上所述的汽车前围板自动化焊接线焊接的方法,其特征在于包括有:A method for automatic welding line welding of an automobile dash panel as described above, characterized in that it includes:

通过第一输入积放链13输送上一工序的前围下板12,通过第二输入积放链14输送人工放入的前围上板11,通过第一搬运机器人9分别将一块前围下板12和一块前围上板11搬运至第一焊接台7,通过第一焊接机器人8将第一焊接台7上的一块前围下板12和一块前围上板11一次焊接形成前围下板组件,第二搬运机器人10将前围下板组件转运至第一固定焊枪位15进行二次焊接,第二搬运机器人10将二次焊接后的前围下板组件转运至第一中转台16,第三搬运机器人19将第一中转台16上的前围下板组件搬运至螺柱焊接位17进行第三次焊接;The cowl

第三搬运机器人19将三次焊接后的前围下板组件搬运至旋转台18的内端,旋转台18水平旋转180度将内端的前围下板组件旋转至外端与人工上料的前围上盖板27通过两台第二焊接机器人20进行第四次焊接形成前围板总成,也是前围板总成的第一次焊接,此时焊接的是前围下板组件与前围上盖板27连接的其中一面,然后旋转台18旋转180度转回内端,两台第三焊接机器人21对前围板总成进行第二次焊接,此时焊接的是前围下板组件与前围上盖板27连接的另一面;The

第四搬运机器人24将旋转台18上二次焊接的前围板总成搬运至第二固定焊枪位22进行第三次焊接,第四搬运机器人24将三次焊接后的前围板总成搬运至第二中转台23;第五搬运机器人25将第二中转台23上的前围板总成搬运至检查台26人工检查,质量符合要求的由第五搬运机器人25搬运至输出积放链29,通过输出积放链29输送至下一工序;The

当板件转运至旋转台18时,通过以下方法夹紧板件:When the panels are transferred to the rotary table 18, the panels are clamped by:

要夹紧a型前围板总成28-a时,第三下压机构A中的第十九气缸323驱动第三下压块1A310和第三下压块2A311下降,第三上托机构A中的第十八气缸332驱动第三上托块1A314和第三上托块2A315上升分别与第三下压块1A310和第三下压块2A311配合;第四下压机构A中的第十四气缸317驱动第四下压块A308下降,第四旋转上托机构A驱动第四上托块A316上升与第四下压块A308配合,同时用于夹紧b型前围板总成28-b的机构主动避让,避让的动作与夹紧的动作刚好相反;When the a-type dash panel assembly 28-a is to be clamped, the

要夹紧b型前围板总成28-b时,第一旋转下压机构B中的第十六气缸319驱动第一下压块B309旋转下降,第一上托机构B中的第一升降气缸324驱动第一上托块B312上升与第一下压块B309配合,第二下压机构B中的第七气缸322驱动第二下压块B307下降,第二旋转上托机构B中的第十七气缸329驱动第二上托块B313上升与第二下压块B307配合,第二定位机构B6中的第二升降气缸601、第二十气缸604、第十五气缸607先后动作使得第一下定位块611和第一上定位块612分别与第二下定位块613和第二上定位块614,同时用于夹紧a型前围板总成28-a的机构主动避让,避让的动作与夹紧的动作刚好相反。When the b-type dash panel assembly 28-b is to be clamped, the

与现有技术相比,本发明有如下优点:Compared with prior art, the present invention has following advantage:

1、本发明汽车前围板自动化焊接线,自动化程度高,每个板件在焊接的同时,搬运动作同时在进行,大大提高了生产效率;并且可根据需要在不同的安装位上安装不同的升降机构或旋转机构以夹住不同的车型板件,适用范围广。1. The automatic cowl panel welding line of the present invention has a high degree of automation. While each panel is being welded, the moving action is carried out at the same time, which greatly improves the production efficiency; and different installation positions can be installed according to needs. Lifting mechanism or rotating mechanism to clamp different car models, with a wide range of applications.

2、本发明的剪刀叉装置设有多个安装板,可以根据需要安装不同的机构以定位不同的车型板件,并且设置的第一滑动机构和第一旋转机构,在不使用时,可用于避让不同的车型板件,避免干涉,即不使用时也不需要拆下这些机构。另外第一勾销缸机构在定位板件时,第一定位销的锥形顶部与板件上待定位的孔适配,能够卡住该孔,而且两个定位勾能够同时往下将板件压在环形台阶上。2. The scissors and fork device of the present invention is provided with a plurality of mounting plates, and different mechanisms can be installed according to needs to locate different vehicle panels, and the first sliding mechanism and the first rotating mechanism provided can be used when not in use. Avoid different car models panels, avoid interference, and do not need to remove these mechanisms even when not in use. In addition, when the first detent cylinder mechanism is positioning the plate, the conical top of the first positioning pin is adapted to the hole to be positioned on the plate, and can block the hole, and the two positioning hooks can simultaneously press the plate downward. on the circular steps.

3、本发明的第一定位装置设有上下两个安装位,可以根据需要安装不同的机构以定位不同的车型板件,设置的升降机构和旋转机构既可以根据板件位置以适配调节,也可以在不使用时用于避让。3. The first positioning device of the present invention is provided with two installation positions up and down, and different mechanisms can be installed according to needs to locate different car models. The lifting mechanism and the rotating mechanism can be adjusted according to the position of the plate. Can also be used for evasion when not in use.

4、本发明第二定位装置中设有三个下压装置,下压装置的吊架具有多个安装位,可以根据需要安装多个不同的升降下压机构,下压装置的托板也具有多个安装位,可以根据需要安装多个升降下压机构或旋转下压机构,可以下压多个不同的车型板件;第六固定架和第十固定架也设有三个,第六固定架和第十固定架也具有多个安装位,可以根据需要安装多个不同的升降上托机构或旋转上托机构,分别与下压装置中的下压机构配合,或者安装能够单独夹紧板件的第二定位机构B,夹住板件的多个部位,并且能够夹紧不同的车型板件。4. Three pressing devices are arranged in the second positioning device of the present invention. The hanger of the pressing device has a plurality of installation positions, and a plurality of different lifting and lowering mechanisms can be installed as required. The supporting plate of the pressing device also has multiple mounting positions. A plurality of lifting and lowering mechanisms or rotary pressing mechanisms can be installed according to the needs, and a plurality of different car models can be pressed down; the sixth fixed frame and the tenth fixed frame are also provided with three, the sixth fixed frame and the tenth fixed frame. The tenth fixed frame also has multiple installation positions, and can be installed with a plurality of different lift-up mechanisms or rotating up-hold mechanisms according to needs, which are respectively matched with the down-press mechanism in the down-press device, or can be installed to clamp the plate separately. The second positioning mechanism B clamps multiple parts of the panels, and can clamp panels of different models.

5、本发明第三定位装置在第十气缸的活塞杆上升时,驱动第三定位销旋转上升插入b型前围板总成待定位的孔内,第十气缸的活塞杆下降时,驱动第五定位块旋转上升托住a型前围板总成,一物两用,当不使用时,通过第九气缸驱动下降避让以避免干涉。5. When the piston rod of the tenth cylinder rises, the third positioning device of the present invention drives the third positioning pin to rotate up and insert it into the hole to be positioned in the b-type dash panel assembly. When the piston rod of the tenth cylinder descends, it drives the third positioning pin. The five positioning blocks rotate and rise to support the A-shaped dash panel assembly, which is dual-purpose. When not in use, it is driven down by the ninth cylinder to avoid interference.

附图说明Description of drawings

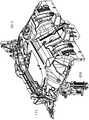

图1是本发明汽车前围板自动化焊接线的平面示意图;Fig. 1 is the schematic plan view of the automatic welding line of automobile dash panel of the present invention;

图2是本发明剪刀叉装置的立体图之一,图中处于定位状态;Fig. 2 is one of perspective views of the scissors and fork device of the present invention, in the positioning state among the figure;

图3是本发明剪刀叉装置的立体图之二,图中处于避让状态;Fig. 3 is the second perspective view of the scissors and fork device of the present invention, which is in an avoidance state in the figure;

图4是本发明剪刀叉装置定位板件的状态图;Fig. 4 is a state diagram of the positioning plate of the scissors and fork device of the present invention;

图5是本发明第一勾销缸机构的夹紧状态图,图中隐藏了第一定位销的前部分;Fig. 5 is a clamping state view of the first detent cylinder mechanism of the present invention, in which the front part of the first positioning pin is hidden;

图6是本发明第一勾销缸机构的松开状态图,图中隐藏了第一定位销的前部分;Fig. 6 is a view of the unclamped state of the first detent cylinder mechanism of the present invention, in which the front part of the first positioning pin is hidden;

图7是本发明第一勾销缸机构的立体图;Fig. 7 is a perspective view of the first cancellation cylinder mechanism of the present invention;

图8是本发明第一定位装置的立体图;Fig. 8 is a perspective view of the first positioning device of the present invention;

图9是本发明第一定位装置定位板件的状态图;Fig. 9 is a state diagram of the positioning plate of the first positioning device of the present invention;

图10是本发明第三定位装置立体图之一;Fig. 10 is one of the perspective views of the third positioning device of the present invention;

图11是本发明第三定位装置立体图之二;Fig. 11 is the second perspective view of the third positioning device of the present invention;

图12是本发明第三定位装置定位板件的状态图之一;Fig. 12 is one of the state diagrams of the positioning plate of the third positioning device of the present invention;

图13是本发明第三定位装置定位板件的状态图之二;Fig. 13 is the second state diagram of the positioning plate of the third positioning device of the present invention;

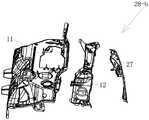

图14是本发明a型前围板总成的分解图;Fig. 14 is an exploded view of the a-type dash panel assembly of the present invention;

图15是本发明b型前围板总成的分解图;Fig. 15 is an exploded view of the b-type dash panel assembly of the present invention;

图16是本发明下压装置的立体图之一;Figure 16 is one of the perspective views of the pressing device of the present invention;

图17是本发明下压装置的立体图之二;Fig. 17 is the second perspective view of the pressing device of the present invention;

图18是本发明下压装置的立体图之三,图中第二旋转机构旋转至竖直状态;Fig. 18 is the third perspective view of the pressing device of the present invention, in which the second rotating mechanism rotates to a vertical state;

图19是本发明第二定位机构B夹紧状态下的立体图;Fig. 19 is a perspective view of the clamping state of the second positioning mechanism B of the present invention;

图20是本发明第二定位机构B张开状态下的立体图;Fig. 20 is a perspective view of the second positioning mechanism B in the opened state of the present invention;

图21是本发明第二旋转上托机构B和第四旋转上托机构A的状态图之一,图中第二旋转上托机构B处于托住板件的状态,第四旋转上托机构A处于避让状态;Fig. 21 is one of the state diagrams of the second rotating lifting mechanism B and the fourth rotating lifting mechanism A of the present invention. In the figure, the second rotating lifting mechanism B is in the state of supporting the plate, and the fourth rotating lifting mechanism A in avoidance state;

图22是本发明第二旋转上托机构B和第四旋转上托机构A的状态图之二,图中第四旋转上托机构A处于托住板件的状态,第二旋转上托机构B处于避让状态;Fig. 22 is the second state diagram of the second rotating lifting mechanism B and the fourth rotating lifting mechanism A of the present invention, in which the fourth rotating lifting mechanism A is in the state of supporting the plate, and the second rotating lifting mechanism B in avoidance state;

图23是本发明第二定位装置的状态图之一,图中的状态能够夹住a型前围板总成,图中隐藏了第二定位机构B;Fig. 23 is one of the state diagrams of the second positioning device of the present invention, the state in the figure can clamp the a-type dash panel assembly, and the second positioning mechanism B is hidden in the figure;

图24是本发明第二定位装置的状态图之二,图中的状态能够夹住b型前围板总成;Fig. 24 is the second state diagram of the second positioning device of the present invention, the state in the figure can clamp the b-type dash panel assembly;

图25是本发明完整的第二定位装置的状态图之三;Fig. 25 is the third state diagram of the complete second positioning device of the present invention;

图26是本发明第二定位装置定位a型前围板总成的状态图。Fig. 26 is a state view of positioning the a-type dash panel assembly by the second positioning device of the present invention.

图中:1为剪刀叉装置;101为第一滑轨;102为第一气缸;103为第一滑动板;104为第一铰接点;105为第二铰接点;106为第二气缸;107为第一旋转板;108为第一公限位块;109为第一母限位块;110为第三气缸;111为定位勾;112为第一定位销;113为第一限位孔;114为固定销;115为环形台阶;116为安装板;117为第四固定架;Among the figure: 1 is a scissors and fork device; 101 is the first slide rail; 102 is the first cylinder; 103 is the first slide plate; 104 is the first hinge point; 105 is the second hinge point; 106 is the second cylinder; 107 108 is the first public spacer block; 109 is the first female spacer block; 110 is the third cylinder; 111 is a positioning hook; 112 is the first positioning pin; 113 is the first spacer hole; 114 is a fixed pin; 115 is an annular step; 116 is a mounting plate; 117 is a fourth fixed frame;

2为第一定位装置;201为第一固定架;202为第二滑轨;203为第二滑动板;204为第四气缸;205为第十三气缸;206为第二旋转板;207为第三铰接点;208为第五气缸;209为第一固定板;210为第一固定块;211为第二定位销;212为第一定位块;213为第一板件感应器;214为第五固定架;2 is the first positioning device; 201 is the first fixed mount; 202 is the second slide rail; 203 is the second sliding plate; 204 is the fourth cylinder; 205 is the thirteenth cylinder; 206 is the second rotating plate; 207 is The third hinge point; 208 is the fifth cylinder; 209 is the first fixed plate; 210 is the first fixed block; 211 is the second positioning pin; 212 is the first positioning block; 213 is the first plate inductor; 214 is fifth fixed frame;

3为第二定位装置;301为第二固定架;302为第四铰接点;303为旋转架;304为第六气缸;305为吊架;306为托板;307为第二下压块B;308为第四下压块A;309为第一下压块B;310为第三下压块1A;311为第三下压块2A;312为第一上托块B;313为第二上托块B;314为第三上托块1A;315为第三上托块2A;316为第四上托块A;317为第十四气缸;318为第二固定板;319为第十六气缸;320为第十四旋转板;321为第三固定板;322为第七气缸;323为第十九气缸;324为第一升降气缸;325为第五固定板;326为第一支撑板;327为第十固定架;328为第十一固定板;329为第十七气缸;330为第十三旋转板;331为第十一固定架;332为第十八气缸;333为第十二固定板;334为第二勾销缸机构;3 is the second positioning device; 301 is the second fixed frame; 302 is the fourth hinge point; 303 is the rotating frame; 304 is the sixth cylinder; 305 is the hanger; 306 is the supporting plate; 307 is the second

4为第三定位装置;401为第三固定架;402为第三滑轨;403为第三滑动板;404为第九气缸;405为第五铰接点;406为第三旋转板;407为第十气缸;408为第四旋转板;409为第五定位块;411为第三定位销;412为第二公限位块;413为第三公限位块;414为第二母限位块;415为第三母限位块;5为第一上托机构A;4 is the third positioning device; 401 is the third fixed mount; 402 is the third slide rail; 403 is the third sliding plate; 404 is the ninth cylinder; 405 is the fifth hinge point; 406 is the third rotating plate; 407 is The tenth cylinder; 408 is the fourth rotating plate; 409 is the fifth positioning block; 411 is the third positioning pin; 412 is the second public limit block; 413 is the third public limit block; 414 is the second female limit block Block; 415 is the third female limit block; 5 is the first upper support mechanism A;

6为第二定位机构B;601为第二升降气缸;602为第七固定板;603为第二支撑板;604为第二十气缸;605为第八铰接点;606为第八旋转板;607为第十五气缸;608为第九铰接点;609为第一连接板;610为第九旋转板;611为第一下定位块;612为第一上定位块;613为第二下定位块;614为第二上定位块;6 is the second positioning mechanism B; 601 is the second lifting cylinder; 602 is the seventh fixed plate; 603 is the second support plate; 604 is the twentieth cylinder; 605 is the eighth hinge point; 606 is the eighth rotating plate; 607 is the fifteenth cylinder; 608 is the ninth hinge point; 609 is the first connecting plate; 610 is the ninth rotating plate; 611 is the first lower positioning block; 612 is the first upper positioning block; 613 is the second lower positioning block; 614 is the second upper positioning block;

7为第一焊接台;8为第一焊接机器人;10为第二搬运机器人;11为前围上板;12为前围下板;13为第一输入积放链;14为第二输入积放链;15为第一固定焊枪位;16为第一中转台;17为螺柱焊接位;18为旋转台;19为第三搬运机器人;20为第二焊接机器人;21为第三焊接机器人;22为第二固定焊枪位;23为第二中转台;24为第四搬运机器人;25为第五搬运机器人;26为检查台;27为前围上盖板;28-a为a型前围板总成;28-b为b型前围板总成;29为输出积放链;33为第六固定架。7 is the first welding station; 8 is the first welding robot; 10 is the second handling robot; 11 is the upper panel of the cowl; 12 is the lower panel of the cowl; 13 is the first input storage chain; 14 is the

具体实施方式Detailed ways

下面结合附图对本发明技术特征作进一步详细说明以便于所述领域技术人员能够理解。The technical features of the present invention will be described in further detail below in conjunction with the accompanying drawings so that those skilled in the art can understand.

一种汽车前围板自动化焊接线,如图1至图26所示,包括有:An automatic welding line for an automobile dash panel, as shown in Fig. 1 to Fig. 26, comprising:

第一输入积放链13:用于输送前围下板12;The first input accumulating chain 13: used for conveying the cowl

第二输入积放链14:用于输送前围上板11;The second input accumulation chain 14: used for conveying the cowl

第一搬运机器人9:用于分别搬运前围下板12和前围上板11;The first transport robot 9: used to transport the cowl

第一焊接台7:用于承载第一搬运机器人9搬运过来的前围下板12和前围上板11;The first welding station 7: used to carry the cowl

第一焊接机器人8:用于在第一焊接台7上将前围下板12和前围上板11焊接成前围下板组件;The first welding robot 8: for welding the cowl

第一固定焊枪位15:用于第二次焊接从第一焊接台7转运过来的前围下板组件;The first fixed welding torch position 15: used for the second welding of the cowl lower plate assembly transferred from the

第一中转台16:用于转运从第一固定焊枪位15搬运过来的前围下板组件;The first transfer platform 16: used to transfer the cowl lower panel assembly transported from the first fixed

第二搬运机器人10:用于搬运第一焊接台7或第一固定焊枪位15上的板件;The second handling robot 10: used to transport the plate on the

螺柱焊接位17:用于第三次焊接从第一中转台16搬运过来的前围下板组件;Stud welding position 17: used for the third welding of the cowl lower plate assembly transported from the first transfer table 16;

第三搬运机器人19:用于将第一中转台16上的前围下板组件搬运至螺柱焊接位17,或者将螺柱焊接位17上的前围下板组件搬运至旋转台18;The third transport robot 19: used to transport the cowl lower panel assembly on the

旋转台18:能360度水平转动、用于承载螺柱焊接位17转运过来的前围下板组件与前围上盖板27,旋转台18的旋转结构为现有技术;Rotary table 18: can rotate 360 degrees horizontally, and is used to carry the cowl lower plate assembly and the cowl

第二焊接机器人20:设在旋转台18的外端两侧用于将前围下板组件与人工上件的前围上盖板27的一面焊接形成前围板总成,第二焊接机器人20设有两台,分别设在旋转台18外端的两侧;The second welding robot 20: set on both sides of the outer end of the rotary table 18, is used to weld the cowl lower panel assembly and one side of the cowl

第三焊接机器人21:设在旋转台18的内端两侧待旋转台18旋转回来时将前围下板组件与前围上盖板27连接的另一面焊接,即对前围板总成二次焊接,前围下板组件与前围上盖板27连接的两面需要两台焊接机器人分别焊接,第三焊接机器人21也设有两台,分别设在旋转台18内端的两侧;The third welding robot 21: be located at the inner end both sides of the

第二固定焊枪位22:用于将旋转台18转运过来的前围板总成进行第三次焊接;The second fixed welding torch position 22: used for the third welding of the dash panel assembly transferred from the rotary table 18;

第二中转台23:用于接收从第二固定焊枪位22转运过来的前围板总成;The second transfer platform 23: used to receive the dash panel assembly transferred from the second fixed

第四搬运机器人24:用于将第二固定焊枪位22上的前围板总成搬运到第二中转台23上;The fourth transport robot 24: used to transport the dash panel assembly on the second fixed

检查台26:用于接收从第二中转台23转运过来的前围板总成并进行人工检查;Inspection platform 26: used to receive the dashboard assembly transferred from the

第五搬运机器人25:用于将第二中转台23上的前围板总成搬运至检查台26,然后将检查台26上的前围板总成搬运至输出积放链29,或者直接将第二中转台23上的前围板总成搬运至输出积放链29;The fifth transport robot 25: used to transport the cowl assembly on the

输出积放链29:用于将焊接好的前围板总成输送至下一工序。Output accumulation chain 29: used to transport the welded dash panel assembly to the next process.

该汽车前围板自动化焊接线设备众多,而搬运机器人的作业半径有限,为确保安全、高效工作,避免出现干涉,在第一固定焊枪位15和螺柱焊接位17之间设置第一中转台16;在第二固定焊枪位22和检查台26之间设置第二中转台23,第一中转台16和第二中转台23结构相同,上述没有描写具体结构的设备均为现有技术。There are many equipments in the automatic welding line for the front panel of the automobile, and the operating radius of the handling robot is limited. In order to ensure safe and efficient work and avoid interference, a first transfer table is set between the first fixed

本专利申请汽车前围板自动化焊接线适配多种车型的前围板总成,现举例两种:a型前围板总成28-a和b型前围板总成28-b,如图14和图15所示。The automatic welding line of the automobile dash panel of this patent application is adapted to the dash panel assembly of various vehicle types, and two examples are given now: a-type dash panel assembly 28-a and b-type dash panel assembly 28-b, such as Figure 14 and Figure 15.

本专利申请还请求保护一种汽车前围板自动化焊接线焊接的方法,包括有:通过第一输入积放链13输送上一工序焊接的前围下板12,人工往第二输入积放链14放入前围上板11,通过第一搬运机器人9分别将一块前围下板12和一块前围上板11搬运至第一焊接台7,通过第一焊接机器人8将第一焊接台7上的一块前围下板12和一块前围上板11一次焊接形成前围下板组件,第二搬运机器人10将前围下板组件转运至第一固定焊枪位15进行第二次焊接,第二搬运机器人10将二次焊接后的前围下板组件转运至第一中转台16,第三搬运机器人19将第一中转台16上的前围下板组件搬运至螺柱焊接位17进行第三次焊接;This patent application also claims to protect a method for automatic welding line welding of automobile cowl panels, including: transporting the cowl

第三搬运机器人19将三次焊接后的前围下板组件搬运至旋转台18的内端,旋转台18水平旋转180度将内端的前围下板组件旋转至外端与人工上料的前围上盖板27通过两台第二焊接机器人20进行第四次焊接形成前围板总成,也是前围板总成的第一次焊接,此时焊接的是前围下板组件与前围上盖板27连接的其中一面,然后旋转台18旋转180度转回内端,两台第三焊接机器人21对前围板总成进行第二次焊接,此时焊接的是前围下板组件与前围上盖板27连接的另一面;The

第四搬运机器人24将旋转台18上二次焊接的前围板总成搬运至第二固定焊枪位22进行第三次焊接,第四搬运机器人24将三次焊接后的前围板总成搬运至第二中转台23;第五搬运机器人25将第二中转台23上的前围板总成搬运至检查台26人工检查,质量符合要求的由第五搬运机器人25搬运至输出积放链29,通过输出积放链29输送至下一工序,其中的人工检查为抽检,没抽中的话,通过第五搬运机器人25直接将第二中转台23上的前围板总成搬运至输出积放链29。The

如图2至图7所示,在所述第二搬运机器人10的抓手上设有用于定位板件的剪刀叉装置1,所述剪刀叉装置1包括第一滑动机构、被第一滑动机构驱动滑动的第一旋转机构、被第一旋转机构驱动转动的第一勾销缸机构。As shown in Figures 2 to 7, a scissor-fork device 1 for positioning a plate is provided on the gripper of the

所述第一滑动机构包括第一滑轨101、被第一气缸102驱动能沿第一滑轨101滑动的第一滑动板103,在所述第一滑动板103上设有多个安装板116。第一旋转机构被第一滑动机构沿第一滑轨101上滑动,第一旋转机构只占用了其中一个安装板116,其他安装板116预留用于安装其他机构用于定位其他车型板件,因此可以适配多种车型板件。因为不同车型板件需要用第一勾销缸机构定位的孔的位置不同,故设置第一滑动机构来移动第一勾销缸机构。所述第一滑动机构除了第一气缸102驱动外也可以用丝杠机构代替。The first sliding mechanism includes a first sliding

所述第一旋转机构包括固定在其中一个安装板116上的第四固定架117,在第四固定架117上分别设有第一铰接点104和第二铰接点105,在第四固定架117上还设有能绕第一铰接点104转动的第二气缸106、被第二气缸106驱动能绕第二铰接点105转动的第一旋转板107,在第四固定架117上设有第一公限位块108,在第一旋转板107上设有与第一公限位块108对应的第一母限位块109。在第一旋转板107旋转到竖直方向时,第一母限位块109会撞到第一公限位块108。下文中的旋转机构也都是用公母限位块碰撞的方式来进行限位。Described first rotating mechanism comprises the 4th

设置第一旋转板107的目的是:因为该剪刀叉装置1要适配多车型板件,不同板件的形状会相差很大,需要用第一勾销缸机构定位的孔的高度也不同,虽然竖直状态下的第一旋转板107沿第一滑轨101滑过去不会撞到本实施例a型前围板总成28-a,但不能保证换成另外一种板件也不会撞到,所以为了避让板件,设置一个能够旋转的第一旋转板107,第一旋转机构滑动到待定位的板件正下方时,才将第一旋转板107旋转至竖直状态。The purpose of arranging the first

如图5至图7所示,所述第一勾销缸机构包括设在第一旋转板107上的第三气缸110,在第一旋转板107上且位于第三气缸110的上方设有第一定位销112,所述第一定位销112由两块板通过固定销114连接组成,第一定位销112的顶部呈锥形,组成第一定位销112的两块板之间设有两个对称、且能被第三气缸110驱动升降的定位勾111,第三气缸110的活塞杆与两定位勾111的底端铰接,在定位勾111上设有第一限位孔113,所述固定销114从两个定位勾111的第一限位孔113穿过,所述第一限位孔113包括竖直的上部孔和沿内侧倾斜的下部孔,上部孔和下部孔连通,在第一定位销112的锥形顶部外侧设有环形台阶115,被驱动下降的定位勾111夹于所述环形台阶115上。As shown in FIGS. 5 to 7 , the first detent cylinder mechanism includes a

因此,剪刀叉装置1设置多个用于安装其他机构的安装板116、用于移动第一勾销缸机构的第一滑动机构、用于避让的第一旋转机构,均是为了适配更多车型板件。Therefore, the scissors and fork device 1 is provided with a plurality of mounting

两个定位勾111对称设置,第三气缸110驱动定位勾111上升时,如图6所示,两个定位勾111也向内收缩在一起,此时只是第一定位销112对板件起到定位作用,即向上托住板件,定位勾111不能夹紧板件。第三气缸110驱动定位勾11下降时,如图5所示,第一限位孔113沿固定销114下移,定位勾111向外侧展开将板件下压于环形台阶115上。The two positioning hooks 111 are arranged symmetrically. When the

剪刀叉装置1的工作方法和原理如下:首先通过第一气缸102驱动第一滑动板103沿第一滑轨101滑动至指定的位置,然后第二气缸106驱动第一旋转板107绕第二铰接点105逆时针旋转,将第一定位销112旋转升起,直到第一母限位块109碰到第一公限位块108,第一定位销112就处于竖直状态,也刚好插入板件中要定位的孔内,环形台阶115托住板件的底面,最后第三气缸110驱动定位勾111下降,定位勾向外侧展开下压将板件夹于环形台阶115上;松开板件的步骤与夹紧板件的步骤顺序相反。The working method and principle of the scissor-fork device 1 are as follows: first, the first sliding

在所述第一焊接台7上设有对板件定位的第一定位装置2,如图8和图9所示,第一焊接台7接收第一搬运机器人9搬运过来的板件后,第一搬运机器人9就会有信号反馈给第一定位装置2,第一定位装置2自动开始动作定位好板件。The

所述第一定位装置2包括第一固定架201,在第一固定架201上设有第二滑轨202、能沿第二滑轨202滑动的第二滑动板203、驱动第二滑动板203上下滑动的第四气缸204,在第二滑动板203上设有下安装位和上安装位,在所述下安装位上分别设有第五固定架214和第五气缸208,在第五固定架214上分别设有第三铰接点207、被第五气缸208驱动绕第三铰接点207转动的第二旋转板206,在所述第二旋转板206上分别设有第十三气缸205以及由第十三气缸205驱动升降的第一固定板209,在第一固定板209的侧面固定连接有第一固定块210,在第一固定块210上设有能够从板件上的孔穿出从而对板件定位的第二定位销211;在第二旋转板206上还设有分别对板件侧向定位的第一定位块212、第一板件感应器213。The

图9中的板件为a型前围板总成28-a,第五固定架214通过螺丝固定在第二滑动板203的下安装位上,上安装位上也设有用于固定其他夹紧单元的螺丝孔,使得该第一定位装置2能够适配多种车型板件。The panel in Fig. 9 is a-type dash panel assembly 28-a, and the

第四气缸204驱动第二滑动板203升降的高度可以通过公母限位块的配合来实现。第一板件感应器213为接近开关,当定位好板件后,第一板件感应器213就能感应到板件并且给焊接装置发送信号,以自动开始板件的焊接工作。The height to which the

第一定位装置2的工作方法和原理:首先第四气缸204驱动第二滑动板203上升至指定的高度,然后第五气缸208驱动第二旋转板206转动靠近板件,最后第十三气缸205驱动第一固定板209上升,第一固定板209带动第二定位销211和第一定位块212运动,第二定位销211插入板件中要定位的孔内,第一定位块212也从侧面对板件进行定位;松开板件的步骤与夹紧板件的步骤顺序相反。The working method and principle of the first positioning device 2: first the

如图10至图13所示,在所述第一搬运机器人9的抓手上设有能对两种板件定位的第三定位装置4,所述第三定位装置4包括第三固定架401,在第三固定架401上设有第三滑轨402、能沿第三滑轨402上下滑动的第三滑动板403、驱动第三滑动板403滑动的第九气缸404,在第三滑动板403上设有第五铰接点405、能绕第五铰接点405旋转的第三旋转板406、用于驱动第三旋转板406转动的第十气缸407,在第三旋转板406上固定连接有第四旋转板408,在第三旋转板406的外端设有在第十气缸407的活塞杆缩回时对所述板件的底面定位的第五定位块409,在第四旋转板408的外端设有在第十气缸407的活塞杆伸出时对另一种板件定位的第三定位销411。As shown in Figures 10 to 13, a

在第三滑动板403上且位于第五铰接点405的两侧分别设有第二公限位块412和第三公限位块413,在第三旋转板406的两侧对应设有与第二公限位块412配合的第二母限位块414、与第三公限位块413配合的第三母限位块415。第九气缸404用于调节第五定位块409和第三定位销411的高度,可定位不同高度的板件,也可用于避让。On the third sliding

如图11和图13所示,第十气缸407的活塞杆缩回,第三旋转板406和第四旋转板408顺时针转动,当第三母限位块415撞到第三公限位块413时就说明转到了最高位置,第三定位销411转下去以避让板件,第五定位块409转上去至竖直状态,从一种板件的底面进行定位,具体是托住a型前围板总成28-a。As shown in Figure 11 and Figure 13, the piston rod of the

如图10和图12所示,第十气缸407的活塞杆升上去,第三旋转板406和第四旋转板408逆时针转动,当第二母限位块414撞到第二公限位块412时就说明转到位了,第五定位块409转下去以避让板件,第三定位销411转上去至竖直状态,插入另一种板件的孔内来定位,具体是定位b型前围板总成28-b。因此第三定位装置4至少可以适用两种车型板件,用途广泛。As shown in Figure 10 and Figure 12, the piston rod of the

在所述旋转台18上设有对多种板件定位的第二定位装置3,所述第二定位装置3包括有:下压装置、用于带动第一上托块B312作升降运动的第一上托机构B、用于带动第二上托块B313作旋转运动的第二旋转上托机构B、用于带动第三上托块1A314和第三上托块2A315作升降运动的第三上托机构A、用于带动第四上托块A316作旋转运动的第四旋转上托机构A;下压装置包括用于带动旋转架303转动的第二旋转机构、第二下压机构B、第四下压机构A、第一旋转下压机构B、第三下压机构A,第二下压机构B、第四下压机构A、第一旋转下压机构B、第三下压机构A分别设在第二旋转机构上;The

为便于区分,这里的机构A表示用于对a型前围板总成28-a定位,机构B用于对b型前围板总成28-b定位。For ease of distinction, the mechanism A here is used to position the a-type dash panel assembly 28-a, and the mechanism B is used to position the b-type dash panel assembly 28-b.

在旋转架303上的左右两侧分别设有吊架305,在吊架305上设有多个安装位,在其中一个安装位设有带动第二下压块B307作升降运动的第二下压机构B,在另一个安装位上设有带动第四下压块A308作升降运动的第四下压机构A;在旋转架303的自由端设有托板306,在所述托板306上设有多个安装位,在其中一个安装位设有带动第一下压块B309转动的第一旋转下压机构B,在另一个安装位上设有带动第三下压块1A310和第三下压块2A311作升降运动的第三下压机构A;

第一上托块B312与第一下压块B309配合将b型前围板总成28-b夹紧;具体是第一上托块B312在b型前围板总成28-b的一处托住,第一下压块B309又在该处下压,实现夹紧,下文同理;The first upper support block B312 cooperates with the first lower pressure block B309 to clamp the b-type dash panel assembly 28-b; specifically, the first upper support block B312 is at a position of the b-type dash panel assembly 28-b Hold it, and the first pressing block B309 presses down there again to realize clamping, the same reason below;

第二上托块B313与第二下压块B307配合将b型前围板总成28-b夹紧;The second upper support block B313 cooperates with the second lower pressing block B307 to clamp the b-type dash panel assembly 28-b;

第三上托块1A314与第三下压块1A310配合、第三上托块2A315与第三下压块2A311配合将a型前围板总成28-a夹紧;The third upper support block 1A314 cooperates with the third lower pressing block 1A310, and the third upper supporting block 2A315 cooperates with the third lower pressing block 2A311 to clamp the a-shaped dash panel assembly 28-a;

第四上托块A316与第四下压块A308配合将a型前围板总成28-a夹紧;The fourth upper support block A316 cooperates with the fourth lower pressing block A308 to clamp the a-type dash panel assembly 28-a;

具体地,所述第二旋转机构包括第二固定架301,在第二固定架301上分别设有第四铰接点302、能绕第四铰接点302旋转的旋转架303、用于驱动旋转架303转动的第六气缸304,旋转架303可以被转动至竖直状态,方便避让,如图18和图25所示;Specifically, the second rotating mechanism includes a second fixed

所述第二下压机构B包括有设在所述吊架305一个安装位上的第七气缸322、由第七气缸322驱动的第二下压块B307,如图16至图18所示;The second pressing mechanism B includes a

所述第四下压机构A包括有设在所述吊架305另一个安装位上的第十四气缸317、由第十四气缸317驱动的第四下压块A308,本专利所述第十四气缸317与所述第七气缸322是设在所述吊架305的同一侧,如图16至图18所示;The fourth pressing mechanism A includes a

所述第一旋转下压机构B包括有固定在所述托板306其中一个安装位上的第二固定板318,在所述第二固定板318上水平设有第十六气缸319,第十六气缸319的活塞杆沿水平方向伸缩,第十六气缸319的活塞杆铰接有第十四旋转板320,在第十四旋转板320的自由端底面设有第一下压块B309,如图16至图18所示;The first rotary pressing mechanism B includes a

所述第三下压机构A包括固定在所述托板306另一个安装位上的第三固定板321,在所述第三固定板321上设有第十九气缸323、由第十九气缸323驱动升降的第三下压块1A310和第三下压块2A311,如图16至图18所示;The third depressing mechanism A includes a third

所述第一上托机构B包括有固定在第六固定架33上的第一升降气缸324、被第一升降气缸324驱动升降的第五固定板325,第五固定板325升降时通过两根导向柱导向;在第五固定板325上固定有第一支撑板326,在第一支撑板326上设有托住b型前围板总成28-b底面的第一上托块B312,当要定位a型前围板总成28-a时,第一升降气缸324驱动第一上托块B312下降避让,如图23所示。The first lifting mechanism B includes a

在所述旋转架303的下方设有第十固定架327,在所述第十固定架327上设有多个安装位,所述第二旋转上托机构B设在其中一个安装位上,所述第四旋转上托机构A设在另一个安装位上,所述第二旋转上托机构B包括固定在第十固定架327其中一个安装位上的第十一固定板328,在所述第十一固定板328上铰接有第十七气缸329,第十七气缸329的活塞杆铰接有第十三旋转板330,驱动第十三旋转板330绕第十一固定板328的铰接点转动,在第十三旋转板330的自由端设有用于托住b型前围板总成28-b的第二上托块B313,如图21和图22所示。A tenth fixed

所述第四旋转上托机构A的结构与第二旋转上托机构B的结构相同,如图21和图22所示。The structure of the fourth rotating lifting mechanism A is the same as that of the second rotating lifting mechanism B, as shown in FIG. 21 and FIG. 22 .

在所述第十固定架327的前方设有能被伺服机构驱动左右滑动的第十一固定架331,伺服机构包括伺服电机和丝杠机构,在所述第十一固定架331上设有多个安装位,所述第三上托机构A设在其中一个安装位上,所述第三上托机构A包括有设在第十一固定架331其中一个安装位上的第十八气缸332、被第十八气缸332驱动升降的第十二固定板333,所述的第三上托块1A314和第三上托块2A315设在所述第十二固定板333的顶部。In front of the tenth

在所述第十二固定板333的侧部设有用于定位a型前围板总成28-a的第二勾销缸机构334,所述第二勾销缸机构334的结构与第一勾销缸机构的结构相同,如图24所示。The side of the

所述的第六固定架33至少设有三个,两侧的第六固定架33的一个安装位上都设有一个第一上托机构B,所述的下压装置也对应设有三个,两侧的下压装置与两侧的第一上托机构B配合将b型前围板总成28-b的两侧夹住;在中间的第六固定架33的一个安装位上设有用于托住a型前围板总成28-a的第一上托机构A5,第一上托机构A5与第一上托机构B的结构相同,只是为适配a型前围板总成28-a,第一上托机构A5的支撑板、上托块的形状做的与第一上托机构B的不同,如图25所示,第一上托机构A5与中间的下压装置配合夹住a型前围板总成28-a的中部,当要夹住b型前围板总成28-b时,第一上托机构A5下降避让。The sixth fixed

另外,第二定位装置3还包括有第二定位机构B6,当然还可以包括其他机构,限于篇幅的原因就不再一一描述,如图25和图26所示;在中间的第六固定架33的另一个安装位上设有第二定位机构B6,用于夹住b型前围板总成28-b后部翘起的部分,即前围上盖板27,第二定位机构B6包括有固定在第六固定架33上的第二升降气缸601、被第二升降气缸601驱动升降的第七固定板602,第七固定板602升降时通过两根导向柱导向;在第七固定板602上固定有第二支撑板603,在第二支撑板603上分别铰接有第二十气缸604、由第二十气缸604驱动绕第八铰接点605转动的第八旋转板606,在所述第八旋转板606上分别铰接有第十五气缸607、由第十五气缸607驱动绕第九铰接点608转动的第九旋转板610,在第九旋转板610上设有第一连接板609,在第一连接板609上从下至上分别设有第一下定位块611、第一上定位块612,在第八旋转板606上由下至上分别设有第二下定位块613、第二上定位块614,如图20所示,第九旋转板610旋转后,第一连接板609从上方穿过b型前围板总成28-b,第一下定位块611和第一上定位块612从一面顶住b型前围板总成28-b,第二下定位块613和第二上定位块614从另一面顶住b型前围板总成28-b,第一下定位块611与第二下定位块613配合,第一上定位块612与第二上定位块614配合,如图19所示,将该b型前围板总成28-b夹住,在第八旋转板606上也设有板件感应器,用于定位好b型前围板总成28-b后通知焊接机械手进行焊接。In addition, the

第一升降气缸324、第二升降气缸601均固定在第六固定架33的底部,在第六固定架33的顶部设有限位架,第五固定板325、第七固定板602撞到限位架后就说明其上升到位了,旋转板的限位都是通过公限位块和母限位块的配合来实现的。The

第二定位机构B6的工作方法和原理:要夹紧b型前围板总成28-b时,首先第二升降气缸601驱动第二支撑板603上升,然后第二十气缸604驱动第八旋转板606逆时针转动至竖直状态,最后十五气缸607驱动第九旋转板610逆时针转动,使得第一下定位块611和第一上定位块612穿过b型前围板总成28-b分别与第二下定位块613和第二上定位块614配合夹住b型前围板总成28-b,松开的动作顺序刚好相反。The working method and principle of the second positioning mechanism B6: when the b-type dash panel assembly 28-b is to be clamped, first the

第二定位机构B6先后有三个气缸动作,故为三级夹紧机构,其优点是夹口可以张开得更大,方便避让,可以满足特殊板件的夹紧和打开,也可以为后续车型做切换,设备也可以因此做的很低,操作方便,更符合人机工程。The second positioning mechanism B6 has three cylinders in succession, so it is a three-stage clamping mechanism. Its advantage is that the clamping mouth can be opened wider, which is convenient to avoid, and can meet the clamping and opening of special panels, and can also be used for subsequent models. For switching, the equipment can also be made very low, easy to operate, and more in line with ergonomics.

第三上托机构A也左右对称设有两个,两侧的第三上托机构A与两侧的下压装置配合将a型前围板总成28-a的两侧夹住。The third support mechanism A is also provided with two left and right symmetry, and the third support mechanism A on both sides cooperates with the pressing device on both sides to clamp the both sides of the a-type dash panel assembly 28-a.

因此,a型前围板总成28-a前部两侧由两侧的第三上托机构A与两侧的下压装置配合配合夹住,a型前围板总成28-a前部中间位置由第一上托机构A5与中间的下压装置配合夹住;b型前围板总成28-b前部两侧由两侧的第一上托机构B与两侧的下压装置配合夹住,b型前围板总成28-b前部中间位置由第二定位机构B6夹住。Therefore, both sides of the front part of the a-type dash panel assembly 28-a are clamped by the third upper supporting mechanism A on both sides and the pressing device on both sides, and the front part of the a-type dash panel assembly 28-a The middle position is clamped by the cooperation of the first lifting mechanism A5 and the pressing device in the middle; the two sides of the front part of the b-type dash panel assembly 28-b are formed by the first supporting mechanism B on both sides and the pressing devices on both sides. Cooperate with clamping, the middle position of the front portion of the b-type dash panel assembly 28-b is clamped by the second positioning mechanism B6.

至于a型前围板总成28-a和b型前围板总成28-b的后部,第十固定架327与下压装置一样也对应设有三个,设在下压装置的下方,每个第十固定架327上都设有第二旋转上托机构B和第四旋转上托机构A,三个第四旋转上托机构A分别与其上方的下压装置配合将a型前围板总成28-a后部的两侧和中间位置夹住,如图25和图26所示;三个第二旋转上托机构B分别与其上方的下压装置配合将b型前围板总成28-b后部的两侧和中间位置夹住。这样就完成了两种车型板件的定位。As for the rear portion of the a-type dash panel assembly 28-a and the b-type dash panel assembly 28-b, the

因此,当板件转运至旋转台18时,通过以下方法夹紧板件:Therefore, when the panels are transferred to the rotary table 18, the panels are clamped by:

要夹紧a型前围板总成28-a时,第三下压机构A中的第十九气缸323驱动第三下压块1A310和第三下压块2A311下降,第三上托机构A中的第十八气缸332驱动第三上托块1A314和第三上托块2A315上升分别与第三下压块1A310和第三下压块2A311配合;第四下压机构A中的第十四气缸317驱动第四下压块A308下降,第四旋转上托机构A中的第四上托块A316上升与第四下压块A308配合,用于夹紧b型前围板总成28-b的机构同时主动避让,避让的动作与夹紧的动作顺序刚好相反;When the a-type dash panel assembly 28-a is to be clamped, the

要夹紧b型前围板总成28-b时,第一旋转下压机构B中的第十六气缸319驱动第一下压块B309旋转下降,第一上托机构B中的第一升降气缸324驱动第一上托块B312上升与第一下压块B309配合,第二下压机构B中的第七气缸322驱动第二下压块B307下降,第二旋转上托机构B中的第十七气缸329驱动第二上托块B313上升与第二下压块B307配合,第二定位机构B6中的第二升降气缸601、第二十气缸604、第十五气缸607先后动作使得第一下定位块611和第一上定位块612分别与第二下定位块613和第二上定位块614,用于夹紧a型前围板总成28-a的机构同时主动避让,避让的动作与夹紧的动作顺序刚好相反。When the b-type dash panel assembly 28-b is to be clamped, the

Claims (9)

Translated fromChinesePriority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211335230.4ACN115625454B (en) | 2022-09-01 | 2022-09-01 | Automatic welding line welding method for automobile front wall plate |

| CN202211337006.9ACN115625455B (en) | 2022-09-01 | 2022-09-01 | Revolving stage of automatic weld line of bounding wall before car |

| CN202211067507.XACN115139026B (en) | 2022-09-01 | 2022-09-01 | Automatic welding line and welding method for automobile front wall plate |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202211067507.XACN115139026B (en) | 2022-09-01 | 2022-09-01 | Automatic welding line and welding method for automobile front wall plate |

Related Child Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211335230.4ADivisionCN115625454B (en) | 2022-09-01 | 2022-09-01 | Automatic welding line welding method for automobile front wall plate |

| CN202211337006.9ADivisionCN115625455B (en) | 2022-09-01 | 2022-09-01 | Revolving stage of automatic weld line of bounding wall before car |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN115139026A CN115139026A (en) | 2022-10-04 |

| CN115139026Btrue CN115139026B (en) | 2022-11-25 |

Family

ID=83416606

Family Applications (3)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211335230.4AActiveCN115625454B (en) | 2022-09-01 | 2022-09-01 | Automatic welding line welding method for automobile front wall plate |

| CN202211337006.9AActiveCN115625455B (en) | 2022-09-01 | 2022-09-01 | Revolving stage of automatic weld line of bounding wall before car |

| CN202211067507.XAActiveCN115139026B (en) | 2022-09-01 | 2022-09-01 | Automatic welding line and welding method for automobile front wall plate |

Family Applications Before (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202211335230.4AActiveCN115625454B (en) | 2022-09-01 | 2022-09-01 | Automatic welding line welding method for automobile front wall plate |

| CN202211337006.9AActiveCN115625455B (en) | 2022-09-01 | 2022-09-01 | Revolving stage of automatic weld line of bounding wall before car |

Country Status (1)

| Country | Link |

|---|---|

| CN (3) | CN115625454B (en) |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06277882A (en)* | 1993-03-31 | 1994-10-04 | Mazda Motor Corp | Welding equipment for car body |

| CN102935563A (en)* | 2012-10-26 | 2013-02-20 | 安徽瑞祥工业有限公司 | Multi-vehicle-mixed automatic-turntable robot welding line for vehicle side surround parts |

| CN206915216U (en)* | 2017-07-21 | 2018-01-23 | 广州富士汽车整线集成有限公司 | A kind of car body welding producing line |

| CN208019669U (en)* | 2018-02-05 | 2018-10-30 | 西华大学 | Vehicle body wheel cover sub-unit welding workstation |

| CN109366145A (en)* | 2018-11-28 | 2019-02-22 | 中山鑫辉精密技术股份有限公司 | Equipment for automatically assembling and processing rear lower guide rail of automobile rear door |

| CN110039226A (en)* | 2019-05-09 | 2019-07-23 | 广州丰桥智能装备有限公司 | A kind of automobile rear floor assembly welder |

| CN110355577A (en)* | 2019-05-29 | 2019-10-22 | 广州广汽荻原模具冲压有限公司 | Automobile left front longitudinal beam flexible automatic production line |

| CN110640407A (en)* | 2019-10-24 | 2020-01-03 | 秦皇岛信越智能装备有限公司 | Automatic welding and assembling production line for automobile aluminum alloy box body |

| CN111390554A (en)* | 2020-04-30 | 2020-07-10 | 东风柳州汽车有限公司 | Flexible welding production line for automobile body-in-white side wall assembly |

| CN213351323U (en)* | 2020-07-29 | 2021-06-04 | 重庆卓通汽车工业有限公司 | Front wall plate assembly welding clamp |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5321542B2 (en)* | 1973-12-14 | 1978-07-03 | ||

| US4573626A (en)* | 1983-10-05 | 1986-03-04 | Toyota Jidosha Kabushiki Kaisha | Apparatus for assembling front under portion of vehicle body |

| JP2000043767A (en)* | 1998-07-31 | 2000-02-15 | Himu Kenkyusho:Kk | Manufacture of full-open gate type vehicle body, and its device |

| CN102873488B (en)* | 2012-09-14 | 2015-03-11 | 迈赫机器人自动化股份有限公司 | Total tailored welding clamp for multi-vehicle automobile bodies |

| CN105171287B (en)* | 2015-09-30 | 2018-04-06 | 安徽瑞祥工业有限公司 | A kind of multi-vehicle-type gusset tetrahedron flexible automation batch welding line |

| CN205465045U (en)* | 2016-01-28 | 2016-08-17 | 浙江正泰电器股份有限公司 | Automatic clamping rotating device pushes down |

| CN106271318B (en)* | 2016-08-31 | 2019-02-19 | 庆铃汽车(集团)有限公司 | Multi-model body-in-white welding general assembly fixture |

| CN207615960U (en)* | 2017-05-20 | 2018-07-17 | 上汽通用五菱汽车股份有限公司 | A kind of front panel stud mounted welder rotation spelling platform |

| CN108080870A (en)* | 2017-12-30 | 2018-05-29 | 安徽大昌科技股份有限公司 | Vehicle right and left side-wall inner-plate forepart assembly welding middle part combination clamping tool |

| CN211490246U (en)* | 2019-12-20 | 2020-09-15 | 赛柯(昆山)机电科技有限公司 | Auxiliary clamp for machining automobile parts |

| CN114669943B (en)* | 2022-03-23 | 2023-12-19 | 上汽通用五菱汽车股份有限公司 | Welding tool for front coaming |

| CN114799605B (en)* | 2022-06-10 | 2023-12-19 | 庆铃汽车(集团)有限公司 | Carriage automatic welding production line |

- 2022

- 2022-09-01CNCN202211335230.4Apatent/CN115625454B/enactiveActive

- 2022-09-01CNCN202211337006.9Apatent/CN115625455B/enactiveActive

- 2022-09-01CNCN202211067507.XApatent/CN115139026B/enactiveActive

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH06277882A (en)* | 1993-03-31 | 1994-10-04 | Mazda Motor Corp | Welding equipment for car body |

| CN102935563A (en)* | 2012-10-26 | 2013-02-20 | 安徽瑞祥工业有限公司 | Multi-vehicle-mixed automatic-turntable robot welding line for vehicle side surround parts |

| CN206915216U (en)* | 2017-07-21 | 2018-01-23 | 广州富士汽车整线集成有限公司 | A kind of car body welding producing line |

| CN208019669U (en)* | 2018-02-05 | 2018-10-30 | 西华大学 | Vehicle body wheel cover sub-unit welding workstation |

| CN109366145A (en)* | 2018-11-28 | 2019-02-22 | 中山鑫辉精密技术股份有限公司 | Equipment for automatically assembling and processing rear lower guide rail of automobile rear door |

| CN110039226A (en)* | 2019-05-09 | 2019-07-23 | 广州丰桥智能装备有限公司 | A kind of automobile rear floor assembly welder |

| CN110355577A (en)* | 2019-05-29 | 2019-10-22 | 广州广汽荻原模具冲压有限公司 | Automobile left front longitudinal beam flexible automatic production line |

| CN110640407A (en)* | 2019-10-24 | 2020-01-03 | 秦皇岛信越智能装备有限公司 | Automatic welding and assembling production line for automobile aluminum alloy box body |

| CN111390554A (en)* | 2020-04-30 | 2020-07-10 | 东风柳州汽车有限公司 | Flexible welding production line for automobile body-in-white side wall assembly |

| CN213351323U (en)* | 2020-07-29 | 2021-06-04 | 重庆卓通汽车工业有限公司 | Front wall plate assembly welding clamp |

Also Published As

| Publication number | Publication date |

|---|---|

| CN115625454B (en) | 2023-05-26 |

| CN115139026A (en) | 2022-10-04 |

| CN115625455B (en) | 2023-05-26 |

| CN115625455A (en) | 2023-01-20 |

| CN115625454A (en) | 2023-01-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN104708319B (en) | Simple slide rail assembly machine | |

| CN110076490B (en) | Flexible welding workstation of intelligent robot for bins | |

| CN109273308B (en) | Full-automatic keyboard assembly line | |

| CN117300510A (en) | Pass-through automatic team welding tool for large box workpieces | |

| CN115139026B (en) | Automatic welding line and welding method for automobile front wall plate | |

| CN201044932Y (en) | Integrated tank making equipment | |

| CN113857742B (en) | Intelligent manufacturing system and method for assembly welding of non-standard parts | |

| CN110625996A (en) | Carton hook bending, dispensing and assembling integrated machine | |

| CN212239715U (en) | Welding workstation at bottom of elevator sedan-chair | |

| CN210100000U (en) | Clamp for truss robot | |

| CN217965524U (en) | Multifunctional welding fixture tool for front connecting plate of floor in thermal forming | |

| CN206985116U (en) | A feeding robot | |

| CN217776074U (en) | Quick positioner of irregular many specifications rectangle work piece | |

| CN110227891A (en) | Bottom frame spot-welding work station and bottom frame spot-welding system | |

| CN114682946B (en) | Full-automatic line production formula lift stand welding production line | |

| CN215698636U (en) | Double-sided automatic tin soldering equipment | |

| CN212169380U (en) | Automatic flexible welding system for box-type section beam | |

| CN214165556U (en) | Labeling and walking equipment for automobile seat slide rail | |

| CN209306479U (en) | XY axis transfer machine | |

| CN118405481B (en) | Product transfer device and automation system | |

| CN207155120U (en) | A kind of multi-vehicle-type Flexible Main spells switching device | |

| CN106625530B (en) | Car wheel cover special grip holder | |

| CN107350418B (en) | Automatic assembling machine for magnetic sheet framework | |

| CN215880516U (en) | Carriage welding and splicing mechanism | |

| CN206614166U (en) | Robot gripping and handling device for three vehicle types |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |