CN115127974A - Magnetic beads and methods of making the same - Google Patents

Magnetic beads and methods of making the sameDownload PDFInfo

- Publication number

- CN115127974A CN115127974ACN202110313578.2ACN202110313578ACN115127974ACN 115127974 ACN115127974 ACN 115127974ACN 202110313578 ACN202110313578 ACN 202110313578ACN 115127974 ACN115127974 ACN 115127974A

- Authority

- CN

- China

- Prior art keywords

- magnetic

- microspheres

- magnetic nanoparticles

- nanoparticles

- core

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N15/00—Investigating characteristics of particles; Investigating permeability, pore-volume or surface-area of porous materials

- G01N15/10—Investigating individual particles

- G01N15/14—Optical investigation techniques, e.g. flow cytometry

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/62—Systems in which the material investigated is excited whereby it emits light or causes a change in wavelength of the incident light

- G01N21/63—Systems in which the material investigated is excited whereby it emits light or causes a change in wavelength of the incident light optically excited

- G01N21/64—Fluorescence; Phosphorescence

- G01N21/6428—Measuring fluorescence of fluorescent products of reactions or of fluorochrome labelled reactive substances, e.g. measuring quenching effects, using measuring "optrodes"

Landscapes

- Health & Medical Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- Immunology (AREA)

- General Health & Medical Sciences (AREA)

- Pathology (AREA)

- General Physics & Mathematics (AREA)

- Life Sciences & Earth Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Nuclear Medicine, Radiotherapy & Molecular Imaging (AREA)

- Optics & Photonics (AREA)

- Dispersion Chemistry (AREA)

- Hard Magnetic Materials (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本申请涉及磁珠修饰技术领域,尤其是涉及一种磁珠及其制作方法。The present application relates to the technical field of magnetic bead modification, and in particular, to a magnetic bead and a manufacturing method thereof.

背景技术Background technique

磁性微球是一类直径在纳米或微米级的球形复合材料,磁性微球由微 球以及吸附于微球表面的磁性纳米颗粒构成,磁性微球的外围包覆有聚合 物保护层。Magnetic microspheres are a kind of spherical composite materials with a diameter of nanometer or micrometer. Magnetic microspheres are composed of microspheres and magnetic nanoparticles adsorbed on the surface of the microspheres.

本申请发明人在长期研发过程中,发现若微球表面过量吸附磁性纳米 颗粒,如图26所示,会导致磁性微球上的杂质增加,杂质的信号会严重干 扰流式细胞仪上的主团信号,且包覆聚合物保护层的过程中需要加热,容 易使微球产生较强的自体荧光,导致检测灵敏度降低。In the long-term research and development process, the inventors of the present application found that if the surface of the microspheres adsorbs magnetic nanoparticles excessively, as shown in Figure 26, the impurities on the magnetic microspheres will increase, and the signal of the impurities will seriously interfere with the main flow cytometer on the flow cytometer. In addition, heating is required in the process of coating the polymer protective layer, which easily causes the microspheres to generate strong autofluorescence, resulting in a decrease in detection sensitivity.

发明内容SUMMARY OF THE INVENTION

本申请旨在至少解决现有技术中存在的技术问题之一。为此,本申请 的一个目的在于提出一种磁珠及其制作方法,在提高磁珠的磁响应的同时, 降低杂质带来的干扰信号,且能降低无磁微球的自体荧光,提高检测灵敏 度。The present application aims to solve at least one of the technical problems existing in the prior art. Therefore, an object of the present application is to propose a magnetic bead and a method for making the same, which can reduce the interference signal caused by impurities while improving the magnetic response of the magnetic bead, and can reduce the autofluorescence of non-magnetic microspheres, improve detection sensitivity.

本申请第一方面提供一种磁珠,磁珠包括:有磁微球,包括核微球、 偶联于核微球外表面的第一磁性纳米颗粒以及包覆于核微球外表面以及第 一磁性纳米颗粒外表面的第一包覆层;第二磁性纳米颗粒,偶联于第一包 覆层的外表面;第三磁性纳米颗粒,至少弥散分布于核微球的内部和/或第 一包覆层的内部。A first aspect of the present application provides a magnetic bead, the magnetic bead includes: a magnetic microsphere, including a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a first magnetic nanoparticle coated on the outer surface of the core microsphere and a first magnetic nanoparticle. A first coating layer on the outer surface of the magnetic nanoparticle; a second magnetic nanoparticle, coupled to the outer surface of the first coating layer; a third magnetic nanoparticle, dispersed at least inside the core microsphere and/or the first The interior of a cladding.

本申请第二方面提供一种磁珠的制作方法,该方法包括:提供一有磁 微球,有磁微球包括核微球、偶联于核微球外表面的第一磁性纳米颗粒以 及包覆于核微球外表面以及第一磁性纳米颗粒外表面的第一包覆层;采用 吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性纳米颗粒偶联 于第一包覆层的外表面;其中,在采用吸附技术组合有磁微球与第二磁性 纳米颗粒,使得第二磁性纳米颗粒偶联于第一包覆层的外表面的步骤之前, 或者,在采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面的步骤之后,该方法还包括:采用溶 胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性纳米颗粒弥散分 布于核微球的内部和/或第一包覆层的内部。A second aspect of the present application provides a method for manufacturing a magnetic bead, the method comprising: providing a magnetic microsphere, the magnetic microsphere comprising a core microsphere, first magnetic nanoparticles coupled to the outer surface of the core microsphere, and a package A first coating layer covering the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle; the magnetic microsphere and the second magnetic nanoparticle are combined by adsorption technology, so that the second magnetic nanoparticle is coupled to the first coating The outer surface of the layer; wherein, before the step of combining magnetic microspheres and second magnetic nanoparticles using adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer, or, before adopting adsorption technology After the step of combining the magnetic microspheres and the second magnetic nanoparticles so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer, the method further includes: combining the magnetic microspheres and the third magnetic nanoparticles by a swelling technique nanoparticles, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microsphere and/or the interior of the first coating layer.

区别于现有技术的情况,本申请的磁珠包括:有磁微球、第二磁性纳 米颗粒以及第三磁性纳米颗粒,有磁微球包括核微球、偶联于核微球外表 面的第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外 表面的第一包覆层,第二磁性纳米颗粒偶联于有磁微球的外表面,第三磁 性纳米颗粒至少弥散分布于核微球的内部,如图27所示,在避免有磁微球 表面过量吸附磁性纳米颗粒的前提下,通过内部溶胀有第三磁性纳米颗粒 以及外部偶联第二磁性纳米颗粒,能够增强磁珠的磁响应信号,并降低杂 质带来的干扰信号,且能够降低有磁微球的自体荧光,提高检测灵敏度。Different from the situation in the prior art, the magnetic beads of the present application include: magnetic microspheres, second magnetic nanoparticles and third magnetic nanoparticles, the magnetic microspheres include core microspheres, and a magnetic microsphere coupled to the outer surface of the core microspheres. The first magnetic nanoparticle and the first coating layer coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle, the second magnetic nanoparticle is coupled to the outer surface of the magnetic microsphere, and the third magnetic nanoparticle At least disperse and distribute in the interior of the core microspheres, as shown in Figure 27, under the premise of avoiding excessive adsorption of magnetic nanoparticles on the surface of the magnetic microspheres, there are third magnetic nanoparticles and externally coupled second magnetic nanoparticles through internal swelling , can enhance the magnetic response signal of the magnetic beads, reduce the interference signal caused by impurities, and can reduce the autofluorescence of the magnetic microspheres, and improve the detection sensitivity.

本申请的附加方面和优点将在下面的描述中部分给出,部分将从下面 的描述中变得明显,或通过本申请的实践了解到。Additional aspects and advantages of the present application will be set forth, in part, from the following description, and in part will be apparent from the following description, or may be learned by practice of the present application.

附图说明Description of drawings

本申请的上述和/或附加的方面和优点从结合下面附图对实施例的描述 中将变得明显和容易理解,其中:The above and/or additional aspects and advantages of the present application will become apparent and readily understood from the following description of embodiments in conjunction with the accompanying drawings, wherein:

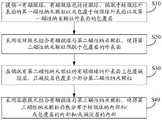

图1是本申请第一实施例提出的磁珠的制作方法的流程示意图;1 is a schematic flowchart of a method for making magnetic beads according to the first embodiment of the present application;

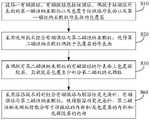

图2是本申请第二实施例提出的磁珠的制作方法的流程示意图;2 is a schematic flowchart of a method for making magnetic beads according to a second embodiment of the present application;

图3是本申请第三实施例提出的磁珠的制作方法的流程示意图;3 is a schematic flowchart of a method for making magnetic beads according to a third embodiment of the present application;

图4是图1-3中步骤S10的流程示意图;Fig. 4 is a schematic flowchart of step S10 in Figs. 1-3;

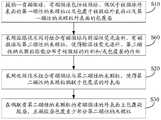

图5是本申请第四实施例提出的磁珠的制作方法的流程示意图;5 is a schematic flowchart of a method for manufacturing a magnetic bead according to a fourth embodiment of the present application;

图6是本申请第五实施例提出的磁珠的制作方法的流程示意图;6 is a schematic flowchart of a method for making magnetic beads according to the fifth embodiment of the present application;

图7是本申请第六实施例提出的磁珠的制作方法的流程示意图;FIG. 7 is a schematic flowchart of a method for making magnetic beads according to the sixth embodiment of the present application;

图8是本申请第七实施例提出的磁珠的制作方法的流程示意图;8 is a schematic flowchart of a method for making magnetic beads according to the seventh embodiment of the present application;

图9是本申请第八实施例提出的磁珠的制作方法的流程示意图;9 is a schematic flowchart of a method for manufacturing a magnetic bead according to an eighth embodiment of the present application;

图10是本申请第九实施例提出的磁珠的制作方法的流程示意图;10 is a schematic flowchart of a method for making magnetic beads according to the ninth embodiment of the present application;

图11是本申请第十实施例提出的磁珠的制作方法的流程示意图;11 is a schematic flowchart of a method for producing magnetic beads according to the tenth embodiment of the present application;

图12是本申请第十一实施例提出的磁珠的制作方法的流程示意图;12 is a schematic flowchart of a method for manufacturing a magnetic bead according to the eleventh embodiment of the present application;

图13是本申请第十二实施例提出的磁珠的制作方法的流程示意图;13 is a schematic flowchart of a method for making magnetic beads according to the twelfth embodiment of the present application;

图14是本申请第十三实施例提出的磁珠的制作方法的流程示意图;14 is a schematic flowchart of a method for producing magnetic beads according to the thirteenth embodiment of the present application;

图15是本申请第十四实施例提出的磁珠的制作方法的流程示意图;15 is a schematic flowchart of a method for manufacturing a magnetic bead according to the fourteenth embodiment of the present application;

图16是本申请第十五实施例提出的磁珠的制作方法的流程示意图;16 is a schematic flowchart of a method for making magnetic beads according to the fifteenth embodiment of the present application;

图17是本申请第十六实施例提出的磁珠的制作方法的流程示意图;17 is a schematic flowchart of a method for making magnetic beads according to the sixteenth embodiment of the present application;

图18是本申请第十七实施例提出的磁珠的制作方法的流程示意图;18 is a schematic flowchart of a method for manufacturing a magnetic bead according to the seventeenth embodiment of the present application;

图19是本申请第十八实施例提出的磁珠的制作方法的流程示意图;19 is a schematic flowchart of a method for making magnetic beads according to the eighteenth embodiment of the present application;

图20是图1-图3、图5-图19中步骤S30的流程示意图;Fig. 20 is a schematic flowchart of step S30 in Fig. 1-Fig. 3 and Fig. 5-Fig. 19;

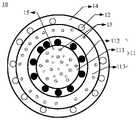

图21是本申请提出的磁珠的第一结构示意图;21 is a schematic diagram of the first structure of the magnetic bead proposed in the present application;

图22是本申请提出的磁珠的第二结构示意图;Fig. 22 is the second structural schematic diagram of the magnetic bead proposed by the present application;

图23是本申请提出的有磁微球的制作方法的示意图;23 is a schematic diagram of a method for making magnetic microspheres proposed by the present application;

图24是本申请提出的磁珠的第三结构示意图;Fig. 24 is the third structural schematic diagram of the magnetic bead proposed by the present application;

图25是本申请提出的磁珠的第四结构示意图;FIG. 25 is a schematic diagram of the fourth structure of the magnetic bead proposed by the present application;

图26是现有技术中微球表面过量吸附磁性纳米颗粒时的磁响应信号图;Fig. 26 is the magnetic response signal diagram when the magnetic nanoparticles are excessively adsorbed on the surface of the microsphere in the prior art;

图27是本申请磁珠的磁响应信号图;Fig. 27 is the magnetic response signal diagram of the magnetic beads of the present application;

图28是本申请提出的磁珠的第五结构示意图;Fig. 28 is the fifth structural schematic diagram of the magnetic bead proposed by the present application;

图29是本申请提出的磁珠的第六结构示意图。FIG. 29 is a schematic diagram of the sixth structure of the magnetic bead proposed in the present application.

具体实施方式Detailed ways

下面将结合本申请实施例中的附图,对本申请实施例中的技术方案进 行清楚、完整地描述,显然,所描述的实施例仅仅是本申请的一部分实施 例,而不是全部的实施例。基于本申请中的实施例,本领域普通技术人员 在没有作出创造性劳动前提下所获得的所有其他实施例,都属于本申请保 护的范围。The technical solutions in the embodiments of the present application will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present application. Obviously, the described embodiments are only a part of the embodiments of the present application, rather than all the embodiments. Based on the embodiments in the present application, all other embodiments obtained by those of ordinary skill in the art without creative work fall within the scope of protection of the present application.

在整个说明书中,除非另有特别说明,本文使用的术语应理解为如本 领域中通常所使用的含义。因此,除非另有定义,本文使用的所有技术和 科学术语具有与本申请所属领域技术人员的一般理解相同的含义。若存在 矛盾,本说明书优先。Throughout the specification, unless specifically stated otherwise, terms used herein are to be understood as commonly used in the art. Therefore, unless otherwise defined, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this application belongs. In case of conflict, this specification takes precedence.

需要说明的是,在本申请实施例中,术语“包括”、“包含”或者其任 何其他变体意在涵盖非排他性的包含,从而使得包括一系列要素的方法或 者装置不仅包括所明确记载的要素,而且还包括没有明确列出的其他要素, 或者是还包括为实施方法或者装置所固有的要素。在没有更多限制的情况 下,由语句“包括一个……”限定的要素,并不排除在包括该要素的方法 或者装置中还存在另外的相关要素(例如方法中的步骤或者装置中的单元,这里的单元可以是部分电路、部分处理器、部分程序或软件等等)。It should be noted that, in the embodiments of the present application, the terms "comprising", "comprising" or any other variations thereof are intended to cover non-exclusive inclusion, so that a method or device including a series of elements not only includes the explicitly stated elements, but also other elements not expressly listed or inherent to the implementation of the method or apparatus. Without further limitation, an element defined by the phrase "comprising a..." does not preclude the presence of additional related elements (eg, steps in a method or elements in an apparatus) in the method or apparatus that includes the element , where a unit may be part of a circuit, part of a processor, part of a program or software, etc.).

需要说明的是,本申请实施例所涉及的术语“第一\第二\第三”仅仅是 区别类似的对象,不代表针对对象的特定排序,可以理解地,“第一\第二\ 第三”在允许的情况下可以互换特定的顺序或先后次序。应该理解“第一\ 第二\第三”区分的对象在适当情况下可以互换,以使这里描述的本申请实 施例能够以除了在这里图示或描述的那些以外的顺序实施。It should be noted that the term "first\second\third" involved in the embodiments of the present application is only to distinguish similar objects, and does not represent a specific ordering of objects. It is understood that "first\second\third" "Three" may be interchanged in a particular order or sequence where permitted. It should be understood that the "first\second\third" distinctions may be interchanged under appropriate circumstances, so that the embodiments of the application described herein can be implemented in sequences other than those illustrated or described herein.

参阅图1,本申请第一实施例提出一种磁珠的制作方法,该方法包括以 下步骤:Referring to Fig. 1, a first embodiment of the present application proposes a method for making a magnetic bead, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

上述第一磁性纳米颗粒可以为水溶性磁性纳米颗粒。The above-mentioned first magnetic nanoparticles may be water-soluble magnetic nanoparticles.

可选地,核微球的外表面可以通过化学手段修饰所需要的带电荷官能 团,其中,带电荷官能团包括带电荷的羧基、氨基、磺酸基或巯基中的至 少一种,为核微球偶联第一磁性纳米颗粒提供了可能性。Optionally, the outer surface of the core microspheres can be chemically modified with required charged functional groups, wherein the charged functional groups include at least one of charged carboxyl groups, amino groups, sulfonic acid groups or sulfhydryl groups, which are core microspheres. Coupling the first magnetic nanoparticles offers the possibility.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

具体而言,第二磁性纳米颗粒可以为水溶性磁性纳米颗粒,第一包覆 层与第二磁性纳米颗粒之间可通过吸附、范德华力和/或共价结合实现偶联。Specifically, the second magnetic nanoparticles can be water-soluble magnetic nanoparticles, and the coupling between the first coating layer and the second magnetic nanoparticles can be realized by adsorption, van der Waals force and/or covalent bonding.

可选地,第一包覆层的外表面可以通过化学手段修饰所需要的带电荷 官能团,其中,带电荷官能团包括带电荷的羧基、氨基、磺酸基或巯基中 的至少一种,为第一包覆层偶联第二磁性纳米颗粒提供了可能性。Optionally, the outer surface of the first coating layer can be modified by chemical means with required charged functional groups, wherein the charged functional groups include at least one of a charged carboxyl group, an amino group, a sulfonic acid group or a sulfhydryl group, which is the first A coating layer offers the possibility to couple a second magnetic nanoparticle.

取第二磁性纳米颗粒溶于去离子水中,并加入有磁微球,第二磁性纳 米颗粒与有磁微球发生交联反应,以使核微球的外表面偶联有第二磁性纳 米颗粒。Dissolve the second magnetic nanoparticles in deionized water, add magnetic microspheres, and cross-link the second magnetic nanoparticles with the magnetic microspheres, so that the outer surface of the core microspheres is coupled with the second magnetic nanoparticles .

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

将步骤S20制备的外表面偶联有第二磁性纳米颗粒的有磁微球与凝胶 材料混合,加入交联剂,搅拌反应,所得产物静置后,磁分离,去除残留 的凝胶材料,获得外表面包覆有凝胶层的微球。其中,凝胶层包覆至少部 分第二磁性纳米颗粒。Mixing the magnetic microspheres prepared in step S20 with the second magnetic nanoparticles coupled on the outer surface and the gel material, adding a cross-linking agent, stirring the reaction, and after the obtained product is allowed to stand, magnetic separation is performed to remove the residual gel material, Microspheres whose outer surface is covered with a gel layer are obtained. Wherein, the gel layer covers at least part of the second magnetic nanoparticles.

其中,凝胶层的材料可以为壳聚糖、海藻酸钠、聚丙烯酸、聚甲基丙 烯酸、聚丙烯酰胺、聚N-聚代丙烯酰胺中的至少一种。Wherein, the material of the gel layer can be at least one of chitosan, sodium alginate, polyacrylic acid, polymethacrylic acid, polyacrylamide, and polyN-polyacrylamide.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部和/或凝胶层的 内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined using the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer and/or the interior of the gel layer.

具体而言,第三磁性纳米颗粒可以为脂溶性磁性纳米颗粒。Specifically, the third magnetic nanoparticles may be fat-soluble magnetic nanoparticles.

将有磁微球分散于第一介质中,提供一含有第三磁性纳米颗粒的第二 介质,混合,然后进行溶胀反应(涡旋分散均匀,旋转反应预设时间),第 三磁性纳米颗粒包埋进有磁微球的内部和/或凝胶层的内部,磁分离去上清 液,获得内部分布有第三磁性纳米颗粒的微球。其中,第一介质与第二介 质均为溶胀介质,具体为既可以使第三磁性纳米颗粒弥散分布,又能使有 磁微球溶胀的单一或混合溶剂,例如,溶胀介质可以为氯仿、二氯甲烷、乙醇、甲醇、己二醇、正丁醇、异丁醇、正己烷、环己烷、四氢呋喃中的 一种或几种的组合,但不局限于上述几种物质。Disperse the magnetic microspheres in the first medium, provide a second medium containing the third magnetic nanoparticles, mix, and then perform a swelling reaction (the vortex is dispersed uniformly, and the rotation reaction time is preset), and the third magnetic nanoparticles are packaged. The magnetic microspheres are embedded in the interior of the magnetic microspheres and/or the gel layer, and the supernatant liquid is magnetically separated to obtain the microspheres with the third magnetic nanoparticles distributed inside. Wherein, the first medium and the second medium are both swelling media, specifically a single or mixed solvent that can not only disperse and distribute the third magnetic nanoparticles, but also swell magnetic microspheres, for example, the swelling medium can be chloroform, two One or a combination of methyl chloride, ethanol, methanol, hexanediol, n-butanol, isobutanol, n-hexane, cyclohexane, and tetrahydrofuran, but not limited to the above-mentioned substances.

可以理解的是,第三磁性纳米颗粒通过溶胀进入核微球的内部后,第 三磁性纳米颗粒包埋在核微球的内部。进一步地,在脂溶性磁性纳米颗粒、 脂溶性荧光染料包埋进核微球的内部的过程中,脂溶性磁性纳米颗粒、脂 溶性荧光染料可包埋进凝胶层的内部。It can be understood that, after the third magnetic nanoparticles enter the interior of the core microspheres through swelling, the third magnetic nanoparticles are embedded in the interior of the core microspheres. Further, during the process of embedding the lipid-soluble magnetic nanoparticles and lipid-soluble fluorescent dyes into the interior of the core microspheres, the lipid-soluble magnetic nanoparticles and lipid-soluble fluorescent dyes can be embedded into the interior of the gel layer.

参阅图2,本申请第二实施例提出一种磁珠的制作方法,该方法包括以 下步骤:Referring to Fig. 2, the second embodiment of the present application proposes a method for making a magnetic bead, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

上述第一磁性纳米颗粒可以为水溶性磁性纳米颗粒。The above-mentioned first magnetic nanoparticles may be water-soluble magnetic nanoparticles.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined by the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer.

上述第三磁性纳米颗粒可以为脂溶性磁性纳米颗粒。The above-mentioned third magnetic nanoparticles may be fat-soluble magnetic nanoparticles.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

上述第二磁性纳米颗粒为水溶性磁性纳米颗粒。The above-mentioned second magnetic nanoparticles are water-soluble magnetic nanoparticles.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

不同于第一实施例的是,第二实施例“采用溶胀技术组合有磁微球与 第三磁性纳米颗粒”发生在“采用吸附技术组合有磁微球与第二磁性纳米 颗粒”之前,因此,可避免因水溶性磁性纳米颗粒的亲水性(即疏油性) 而导致脂溶性磁性纳米颗粒难以进入有磁微球的内部,更大地提升有磁微 球内的脂溶性磁性纳米颗粒的包埋数量。Different from the first embodiment, the second embodiment “combines magnetic microspheres and third magnetic nanoparticles using swelling technology” occurs before “combining magnetic microspheres and second magnetic nanoparticles using adsorption technology”, so , which can avoid the difficulty of fat-soluble magnetic nanoparticles entering the interior of the magnetic microspheres due to the hydrophilicity (ie oleophobicity) of the water-soluble magnetic nanoparticles, and greatly improve the encapsulation of the lipid-soluble magnetic nanoparticles in the magnetic microspheres. Buried quantity.

参阅图3,本申请第三实施例提出一种磁珠的制作方法,该方法包括以 下步骤:Referring to Fig. 3, the third embodiment of the present application proposes a method for making a magnetic bead, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

上述第一磁性纳米颗粒可以为水溶性磁性纳米颗粒。The above-mentioned first magnetic nanoparticles may be water-soluble magnetic nanoparticles.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

上述第二磁性纳米颗粒可以为水溶性磁性纳米颗粒。The above-mentioned second magnetic nanoparticles may be water-soluble magnetic nanoparticles.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined by the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer.

上述第三磁性纳米颗粒可以为脂溶性磁性纳米颗粒。The above-mentioned third magnetic nanoparticles may be fat-soluble magnetic nanoparticles.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

不同于第一实施例的是,第三实施例的“采用溶胀技术组合有磁微球 与第三磁性纳米颗粒”发生在包覆凝胶层之前,因此,第三磁性纳米颗粒 更易进入核微球的内部,更大地提升有磁微球内的第三磁性纳米颗粒的包 埋数量。Different from the first embodiment, the “combination of magnetic microspheres and third magnetic nanoparticles using swelling technology” in the third embodiment occurs before the coating of the gel layer, so the third magnetic nanoparticles are more likely to enter the core microparticles. Inside the sphere, the embedding quantity of the third magnetic nanoparticles in the magnetic microsphere is greatly increased.

可选地,上述第一实施例至第三实施例步骤S30中的凝胶层可替换为 聚合物包覆层,聚合物包覆层的材料为聚苯乙烯、聚甲基丙烯酸甲酯、聚 乙烯-甲基丙烯酸甲酯、聚丙烯腈、聚乙烯、聚丙烯、聚丙烯酸乙酯中的至 少一种。Optionally, the gel layer in step S30 of the first embodiment to the third embodiment can be replaced with a polymer coating layer, and the material of the polymer coating layer is polystyrene, polymethyl methacrylate, poly At least one of ethylene-methyl methacrylate, polyacrylonitrile, polyethylene, polypropylene, and polyethyl acrylate.

由此,通过上述第一实施例至第三实施例制得的磁珠10结构如图21 或22所示,磁珠10包括:有磁微球11、第二磁性纳米颗粒12、第三磁性 纳米颗粒13以及第二包覆层14。其中,有磁微球11包括核微球111、偶联 于核微球111外表面的第一磁性纳米颗粒112以及包覆于核微球111外表面 以及第一磁性纳米颗粒112外表面的第一包覆层113。第二磁性纳米颗粒 12可偶联于核微球111的外表面。第二包覆层14包覆于核微球111外表面 以及第一磁性纳米颗粒112外表面。可选地,第二包覆层14包覆全部第二 磁性纳米颗粒12,磁珠10的外表面为光滑表面。第三磁性纳米颗粒13弥 散分布于核微球111的内部和/或第二包覆层14的内部,可以理解的是,第 三磁性纳米颗粒13通过溶胀进入核微球111的内部后,第三磁性纳米颗粒 13包埋在核微球111的内部。其中,上述第二包覆层14可以为凝胶层或聚 合物包覆层。可以理解的是,第三磁性纳米颗粒13可弥散分布于凝胶层的 内部,而受限于聚合物包覆层的材料,第三磁性纳米颗粒13不可弥散分布 于聚合物包覆层的内部。Therefore, the structure of the

更进一步地,可删减上述第一实施例至第三实施例中的步骤S30,由此 制得的磁珠10结构如图28所示,磁珠10包括:有磁微球11、第二磁性纳 米颗粒12以及第三磁性纳米颗粒13。其中,有磁微球11包括核微球111、 偶联于核微球111外表面的第一磁性纳米颗粒112以及包覆于核微球111 外表面以及第一磁性纳米颗粒112外表面的第一包覆层113。第二磁性纳米 颗粒12可偶联于核微球111的外表面。第三磁性纳米颗粒13至少弥散分 布于核微球111的内部,可以理解的是,第三磁性纳米颗粒13通过溶胀进 入核微球111的内部后,第三磁性纳米颗粒13包埋在核微球111的内部。Further, step S30 in the above-mentioned first embodiment to third embodiment can be deleted, and the structure of the

区别于现有技术的情况,本申请实施例制得的磁珠10包括:有磁微球 11、第二磁性纳米颗粒12以及第三磁性纳米颗粒13,有磁微球11包括核 微球111、偶联于核微球111外表面的第一磁性纳米颗粒112以及包覆于核 微球111外表面以及第一磁性纳米颗粒112外表面的第一包覆层113,第二 磁性纳米颗粒12偶联于有磁微球11的外表面,第三磁性纳米颗粒13至少 弥散分布于核微球111的内部和/或第二包覆层14的内部的,如图27所示, 在避免有磁微球11表面过量吸附磁性纳米颗粒的前提下,通过内部溶胀有 第三磁性纳米颗粒13以及外部偶联第二磁性纳米颗粒12,本申请的磁珠能 够增强磁珠的磁响应信号(即主团信号),并可降低杂质带来的干扰信号, 且能够降低有磁微球11的自体荧光,提高检测灵敏度。Different from the situation in the prior art, the

可选的,核微球111为聚合物核微球111。Optionally, the

具体而言,上述核微球111的材料为有机单体分子聚合物,可包括聚 苯乙烯、聚甲基丙烯酸甲酯、聚乙烯-甲基丙烯酸甲酯、聚丙烯腈、聚乙烯、 聚丙烯、聚丙烯酸乙酯中的至少一种。Specifically, the material of the above-mentioned

可选的,第一包覆层113为聚合物第一包覆层113。Optionally, the

具体而言,上述第一包覆层113的材料为有机单体分子聚合物,可包 括聚苯乙烯、聚甲基丙烯酸甲酯、聚乙烯-甲基丙烯酸甲酯、聚丙烯腈、聚 乙烯、聚丙烯、聚丙烯酸乙酯中的至少一种。Specifically, the material of the

在一些实施例中,上述第一包覆层113的外表面含有带电荷官能团, 带电荷官能团包括带电荷的羧基、氨基、磺酸基或巯基中的至少一种。第 一包覆层113通过带电荷官能团偶联第二磁性纳米颗粒12。In some embodiments, the outer surface of the

在一些实施例中,上述水溶性磁性纳米颗粒为具有顺磁性的纳米颗粒, 其中,具有顺磁性的纳米颗粒可选自四氧化三铁、三氧化二铁、含有镍或 钴的合金型顺磁性磁颗粒中的至少一种。In some embodiments, the above water-soluble magnetic nanoparticles are paramagnetic nanoparticles, wherein the paramagnetic nanoparticles can be selected from ferric oxide, ferric oxide, alloy-type paramagnetic containing nickel or cobalt at least one of the magnetic particles.

在一些实施例中,上述脂溶性磁性纳米颗粒为具有顺磁性的纳米颗粒, 其中,具有顺磁性的纳米颗粒可选自四氧化三铁或三氧化二铁中的至少一 种。此外,脂溶性磁性纳米颗粒含有不饱和脂肪酸、饱和脂肪酸、不饱和 脂肪胺或饱和脂肪胺中至少一种的脂溶性配体。上述脂溶性配体能够结合 脂溶性磁性纳米颗粒的表面,从而使脂溶性磁性纳米颗粒稳定。其中,脂 溶性配体可以包括油酸、油胺或硬脂酸中的至少一种。In some embodiments, the above-mentioned fat-soluble magnetic nanoparticles are nanoparticles with paramagnetic properties, wherein the nanoparticles with paramagnetic properties can be selected from at least one of ferric oxide or ferric oxide. In addition, the fat-soluble magnetic nanoparticles contain a fat-soluble ligand of at least one of unsaturated fatty acids, saturated fatty acids, unsaturated fatty amines or saturated fatty amines. The above-mentioned lipid-soluble ligand can bind to the surface of the lipid-soluble magnetic nanoparticles, thereby stabilizing the lipid-soluble magnetic nanoparticles. Wherein, the fat-soluble ligand may include at least one of oleic acid, oleylamine or stearic acid.

在一些实施例中,有磁微球11的粒径为1μm~50μm(例如1μm、5μm、 10μm、20μm、50μm),第三磁性纳米颗粒13的粒径为1nm~200nm(例如 1nm、5nm、50nm、100nm、200nm),第二磁性纳米颗粒12的粒径为 1nm~200nm(例如1nm、5nm、50nm、100nm、200nm)。In some embodiments, the particle size of the

在一些实施例中,按质量百分比计,磁珠10包括:50%~99.5%的有磁 微球11、0.1%~49.9%的第二磁性纳米颗粒12、0.1%~49.9%的第三磁性纳米 颗粒13。申请人发现在上述数值范围内,可在避免有磁微球表面过量吸附 磁性纳米颗粒的前提下,提高磁珠的磁响应,并降低杂质带来的干扰信号, 且能够降低有磁微球的自体荧光,提高检测灵敏度。In some embodiments, by mass percentage, the

参阅图4和图23,在一些实施例中,上述步骤S10包括以下步骤:4 and 23, in some embodiments, the above step S10 includes the following steps:

S11:采用吸附技术组合核微球与第一磁性纳米颗粒,使得第一磁性纳 米颗粒偶联于核微球的外表面。S11: Combining the core microspheres and the first magnetic nanoparticles using adsorption technology, so that the first magnetic nanoparticles are coupled to the outer surface of the core microspheres.

具体而言,核微球为聚合物核微球,聚合物可以为聚苯乙烯、聚甲基 丙烯酸甲酯、聚乙烯-甲基丙烯酸甲酯、聚丙烯腈、聚乙烯、聚丙烯、聚丙 烯酸乙酯中的至少一种。可选地,核微球的外表面可以通过化学手段修饰 所需要的带电荷官能团,其中,带电荷官能团包括带电荷的羧基、氨基、 磺酸基或巯基中的至少一种,为核微球偶联第一磁性纳米颗粒提供了可能 性。Specifically, the core microsphere is a polymer core microsphere, and the polymer can be polystyrene, polymethyl methacrylate, polyethylene-methyl methacrylate, polyacrylonitrile, polyethylene, polypropylene, polyacrylic acid At least one of ethyl esters. Optionally, the outer surface of the core microspheres can be modified by chemical means with required charged functional groups, wherein the charged functional groups include at least one of charged carboxyl groups, amino groups, sulfonic acid groups or sulfhydryl groups, which are core microspheres. Coupling the first magnetic nanoparticles offers the possibility.

S12:在偶联有第一磁性纳米颗粒的核微球的外表面上包覆一第一包覆 层,且第一包覆层包覆核微球的外表面以及第一磁性纳米颗粒的外表面。S12: Coating a first coating layer on the outer surface of the core microsphere coupled with the first magnetic nanoparticles, and the first coating layer coating the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle surface.

具体而言,第一包覆层为聚合物第一包覆层,聚合物可以为聚苯乙烯、 聚甲基丙烯酸甲酯、聚乙烯-甲基丙烯酸甲酯、聚丙烯腈、聚乙烯、聚丙烯、 聚丙烯酸乙酯中的至少一种。可选地,第一包覆层的外表面可以通过化学 手段修饰所需要的带电荷官能团,其中,带电荷官能团包括带电荷的羧基、 氨基、磺酸基或巯基中的至少一种,为第一包覆层偶联第二磁性纳米颗粒 提供了可能性。Specifically, the first coating layer is a polymer first coating layer, and the polymer can be polystyrene, polymethyl methacrylate, polyethylene-methyl methacrylate, polyacrylonitrile, polyethylene, polyethylene At least one of propylene and polyethyl acrylate. Optionally, the outer surface of the first coating layer can be modified by chemical means with required charged functional groups, wherein the charged functional groups include at least one of a charged carboxyl group, an amino group, a sulfonic acid group or a sulfhydryl group, which is the first A coating layer offers the possibility to couple a second magnetic nanoparticle.

参阅图5,本申请第四实施例提出一种磁珠的制作方法,该方法包括以 下步骤:Referring to Fig. 5, the fourth embodiment of the present application proposes a method for making a magnetic bead, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S50:采用溶胀技术组合有磁微球与脂溶性荧光染料,使得脂溶性荧光 染料弥散分布于核微球的内部和/或第一包覆层的内部。S50: Magnetic microspheres and liposoluble fluorescent dyes are combined using swelling technology, so that the liposoluble fluorescent dyes are dispersed and distributed inside the core microspheres and/or the inside of the first coating layer.

具体而言,将有磁微球分散于第一介质中,提供一含有脂溶性荧光染 料的第三介质,混合,然后进行溶胀反应(涡旋分散均匀,旋转反应预设 时间),脂溶性荧光染料包埋进核微球的内部,磁分离去上清液,获得内部 分布有脂溶性荧光染料的荧光微球。其中,第一介质与第三介质均为溶胀 介质,具体为既可以使脂溶性磁性纳米颗粒弥散分布,又能使有磁微球溶 胀的单一或混合溶剂,例如,溶胀介质可以为氯仿、二氯甲烷、乙醇、甲 醇、己二醇、正丁醇、异丁醇、正己烷、环己烷、四氢呋喃中的一种或几 种的组合,但不局限于上述几种物质。Specifically, the magnetic microspheres are dispersed in the first medium, a third medium containing a fat-soluble fluorescent dye is provided, mixed, and then a swelling reaction is performed (the vortex is dispersed uniformly, and the rotation reaction time is preset), and the fat-soluble fluorescent dye is The dye is embedded in the core microspheres, and the supernatant is magnetically separated to obtain fluorescent microspheres with lipid-soluble fluorescent dyes distributed inside. Wherein, the first medium and the third medium are both swelling media, specifically a single or mixed solvent that can not only disperse the lipid-soluble magnetic nanoparticles, but also swell the magnetic microspheres, for example, the swelling media can be chloroform, two One or a combination of methyl chloride, ethanol, methanol, hexanediol, n-butanol, isobutanol, n-hexane, cyclohexane, and tetrahydrofuran, but not limited to the above-mentioned substances.

进一步地,可多次进行步骤S50,分别组合具有不同荧光特征的脂溶性 荧光染料和有磁微球,或者,分别组合不同浓度的脂溶性荧光染料和有磁 微球,以获得多个不同荧光强度的微球,即荧光编码微球。其中,可以将 不同的脂溶性荧光染料按不同比例混合,以制备出不同的编码的微球。正 是由于不同脂溶性荧光染料的不同比例,赋予了荧光编码微球不同的荧光 特征。Further, step S50 may be performed multiple times, respectively combining lipid-soluble fluorescent dyes with different fluorescence characteristics and magnetic microspheres, or combining lipid-soluble fluorescent dyes and magnetic microspheres with different concentrations, respectively, to obtain a plurality of different fluorescent dyes. Intensity of the microspheres, that is, fluorescently encoded microspheres. Wherein, different fat-soluble fluorescent dyes can be mixed in different proportions to prepare different encoded microspheres. It is precisely because of the different ratios of different lipid-soluble fluorescent dyes that endow the fluorescently encoded microspheres with different fluorescent characteristics.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部和/或凝胶层的 内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined using the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer and/or the interior of the gel layer.

参阅图6,本申请第五实施例提出一种磁珠的制作方法,该方法包括以 下步骤:Referring to Figure 6, the fifth embodiment of the present application proposes a method for making a magnetic bead, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S50:采用溶胀技术组合有磁微球与脂溶性荧光染料,使得脂溶性荧光 染料弥散分布于核微球的内部和/或第一包覆层的内部。S50: Magnetic microspheres and liposoluble fluorescent dyes are combined using swelling technology, so that the liposoluble fluorescent dyes are dispersed and distributed inside the core microspheres and/or the inside of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部和/或凝胶层的 内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined using the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer and/or the interior of the gel layer.

参阅图7,本申请第六实施例提出一种磁珠的制作方法,该方法包括以 下步骤:Referring to Fig. 7, the sixth embodiment of the present application proposes a method for making a magnetic bead, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

S50:采用溶胀技术组合有磁微球与脂溶性荧光染料,使得脂溶性荧光 染料弥散分布于核微球的内部和/或第一包覆层的内部和/或凝胶层的内部。S50: Magnetic microspheres and liposoluble fluorescent dyes are combined using swelling technology, so that the liposoluble fluorescent dyes are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer and/or the interior of the gel layer.

进一步地,在脂溶性荧光染料包埋进核微球的内部的过程中,脂溶性 荧光染料可包埋进凝胶层的内部。Further, during the process of embedding the lipid-soluble fluorescent dye into the interior of the core microspheres, the lipid-soluble fluorescent dye may be embedded into the interior of the gel layer.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部和/或凝胶层的 内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined using the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer and/or the interior of the gel layer.

参阅图8,本申请第七实施例提出一种磁珠的制作方法,该方法包括以 下步骤:Referring to Figure 8, a seventh embodiment of the present application proposes a method for making magnetic beads, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部和/或凝胶层的 内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined using the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer and/or the interior of the gel layer.

S50:采用溶胀技术组合有磁微球与脂溶性荧光染料,使得脂溶性荧光 染料弥散分布于核微球的内部和/或第一包覆层的内部和/或凝胶层的内部。S50: Magnetic microspheres and liposoluble fluorescent dyes are combined using swelling technology, so that the liposoluble fluorescent dyes are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer and/or the interior of the gel layer.

参阅图9,本申请第八实施例提出一种磁珠的制作方法,该方法包括以 下步骤:Referring to Figure 9, the eighth embodiment of the present application proposes a method for making a magnetic bead, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

S60:采用溶胀技术同时组合有磁微球与脂溶性荧光染料、有磁微球与 第三磁性纳米颗粒,使得脂溶性荧光染料、第三磁性纳米颗粒弥散分布于 核微球的内部和/或第一包覆层的内部和/或凝胶层的内部。S60: Using swelling technology to combine magnetic microspheres and lipid-soluble fluorescent dyes, magnetic microspheres and third magnetic nanoparticles simultaneously, so that the lipid-soluble fluorescent dyes and third magnetic nanoparticles are dispersed and distributed inside the core microspheres and/or The interior of the first cladding layer and/or the interior of the gel layer.

具体而言,将有磁微球分散于第一介质中,提供一含有脂溶性磁性纳 米颗粒的第二介质,提供一含有脂溶性荧光染料的第三介质,混合,然后 进行溶胀反应(涡旋分散均匀,旋转反应预设时间),脂溶性磁性纳米颗粒、 脂溶性荧光染料包埋进核微球的内部,磁分离去上清液,获得核微球内部 分布有脂溶性磁性纳米颗粒和脂溶性荧光染料的荧光磁珠。Specifically, magnetic microspheres are dispersed in a first medium, a second medium containing lipid-soluble magnetic nanoparticles is provided, a third medium containing lipid-soluble fluorescent dyes is provided, mixed, and then a swelling reaction (vortex) is performed. Disperse uniformly, rotate reaction preset time), lipid-soluble magnetic nanoparticles and lipid-soluble fluorescent dyes are embedded in the interior of core microspheres, magnetically separate the supernatant to obtain core microspheres with lipid-soluble magnetic nanoparticles and lipids distributed inside the core microspheres. Fluorescent magnetic beads for soluble fluorescent dyes.

进一步地,在脂溶性磁性纳米颗粒、脂溶性荧光染料包埋进核微球的 内部的过程中,脂溶性磁性纳米颗粒、脂溶性荧光染料可包埋进凝胶层的 内部。Further, in the process of embedding the lipid-soluble magnetic nanoparticles and lipid-soluble fluorescent dyes into the interior of the core microspheres, the lipid-soluble magnetic nanoparticles and lipid-soluble fluorescent dyes can be embedded into the interior of the gel layer.

进一步地,可多次进行步骤S60,分别组合具有不同荧光特征的脂溶性 荧光染料和有磁微球,或者,分别组合不同浓度的脂溶性荧光染料和有磁 微球,同时组合脂溶性磁性纳米颗粒和有磁微球,以获得多个不同荧光强 度的磁珠,即荧光编码磁珠。其中,可以将不同的脂溶性荧光染料按不同 比例混合,以制备出不同的编码的磁珠。正是由于不同脂溶性荧光染料的 不同比例,赋予了制备的荧光编码磁珠不同的荧光特征。Further, step S60 can be performed multiple times, respectively combining lipid-soluble fluorescent dyes with different fluorescent characteristics and magnetic microspheres, or, respectively combining lipid-soluble fluorescent dyes and magnetic microspheres with different concentrations, and combining lipid-soluble magnetic nanospheres. Particles and magnetic microspheres to obtain multiple magnetic beads with different fluorescence intensities, that is, fluorescently encoded magnetic beads. Among them, different liposoluble fluorescent dyes can be mixed in different proportions to prepare different encoded magnetic beads. It is precisely because of the different ratios of different lipid-soluble fluorescent dyes that the prepared fluorescently encoded magnetic beads have different fluorescent characteristics.

参阅图10,本申请第九实施例提出一种磁珠的制作方法,该方法包括 以下步骤:Referring to Figure 10, the ninth embodiment of the present application proposes a method for making magnetic beads, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined by the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer.

S50:采用溶胀技术组合有磁微球与脂溶性荧光染料,使得脂溶性荧光 染料弥散分布于核微球的内部和/或第一包覆层的内部。S50: Magnetic microspheres and liposoluble fluorescent dyes are combined using swelling technology, so that the liposoluble fluorescent dyes are dispersed and distributed inside the core microspheres and/or the inside of the first coating layer.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

参阅图11,本申请第十实施例提出一种磁珠的制作方法,该方法包括 以下步骤:Referring to FIG. 11 , a tenth embodiment of the present application proposes a method for making magnetic beads, and the method includes the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined by the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S50:采用溶胀技术组合有磁微球与脂溶性荧光染料,使得脂溶性荧光 染料弥散分布于核微球的内部和/或第一包覆层的内部。S50: Magnetic microspheres and liposoluble fluorescent dyes are combined using swelling technology, so that the liposoluble fluorescent dyes are dispersed and distributed inside the core microspheres and/or the inside of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

参阅图12,本申请第十一实施例提出一种磁珠的制作方法,该方法包 括以下步骤:Referring to Figure 12, the eleventh embodiment of the present application proposes a method for making a magnetic bead, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S50:采用溶胀技术组合有磁微球与脂溶性荧光染料,使得脂溶性荧光 染料弥散分布于核微球的内部和/或第一包覆层的内部。S50: Magnetic microspheres and liposoluble fluorescent dyes are combined using swelling technology, so that the liposoluble fluorescent dyes are dispersed and distributed inside the core microspheres and/or the inside of the first coating layer.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined by the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

参阅图13,本申请第十二实施例提出一种磁珠的制作方法,该方法包 括以下步骤:Referring to Figure 13, the twelfth embodiment of the present application proposes a method for making a magnetic bead, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined by the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

S50:采用溶胀技术组合有磁微球与脂溶性荧光染料,使得脂溶性荧光 染料弥散分布于核微球的内部和/或第一包覆层的内部和/或凝胶层的内部。S50: Magnetic microspheres and liposoluble fluorescent dyes are combined using swelling technology, so that the liposoluble fluorescent dyes are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer and/or the interior of the gel layer.

参阅图14,本申请第十三实施例提出一种磁珠的制作方法,该方法包 括以下步骤:Referring to Figure 14, the thirteenth embodiment of the present application proposes a method for making magnetic beads, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S60:采用溶胀技术同时组合有磁微球与脂溶性荧光染料、有磁微球与 第三磁性纳米颗粒,使得脂溶性荧光染料、第三磁性纳米颗粒弥散分布于 核微球的内部和/或第一包覆层的内部。S60: Using swelling technology to combine magnetic microspheres and lipid-soluble fluorescent dyes, magnetic microspheres and third magnetic nanoparticles simultaneously, so that the lipid-soluble fluorescent dyes and third magnetic nanoparticles are dispersed and distributed inside the core microspheres and/or Inside of the first cladding.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

参阅图15,本申请第十四实施例提出一种磁珠的制作方法,该方法包 括以下步骤:Referring to Figure 15, the fourteenth embodiment of the present application proposes a method for making a magnetic bead, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S50:采用溶胀技术组合有磁微球与脂溶性荧光染料,使得脂溶性荧光 染料弥散分布于核微球的内部和/或第一包覆层的内部。S50: Magnetic microspheres and liposoluble fluorescent dyes are combined using swelling technology, so that the liposoluble fluorescent dyes are dispersed and distributed inside the core microspheres and/or the inside of the first coating layer.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined by the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

参阅图16,本申请第十五实施例提出一种磁珠的制作方法,该方法包 括以下步骤:Referring to Figure 16, a fifteenth embodiment of the present application proposes a method for making magnetic beads, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined by the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer.

S50:采用溶胀技术组合有磁微球与脂溶性荧光染料,使得脂溶性荧光 染料弥散分布于核微球的内部和/或第一包覆层的内部。S50: Magnetic microspheres and liposoluble fluorescent dyes are combined using swelling technology, so that the liposoluble fluorescent dyes are dispersed and distributed inside the core microspheres and/or the inside of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

参阅图17,本申请第十六实施例提出一种磁珠的制作方法,该方法包 括以下步骤:Referring to Figure 17, the sixteenth embodiment of the present application proposes a method for making a magnetic bead, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S50:采用溶胀技术组合有磁微球与脂溶性荧光染料,使得脂溶性荧光 染料弥散分布于核微球的内部和/或第一包覆层的内部。S50: Magnetic microspheres and liposoluble fluorescent dyes are combined using swelling technology, so that the liposoluble fluorescent dyes are dispersed and distributed inside the core microspheres and/or the inside of the first coating layer.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined by the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

参阅图18,本申请第十七实施例提出一种磁珠的制作方法,该方法包 括以下步骤:Referring to Figure 18, the seventeenth embodiment of the present application proposes a method for making a magnetic bead, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S40:采用溶胀技术组合有磁微球与第三磁性纳米颗粒,使得第三磁性 纳米颗粒弥散分布于核微球的内部和/或第一包覆层的内部。S40: The magnetic microspheres and the third magnetic nanoparticles are combined by the swelling technology, so that the third magnetic nanoparticles are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

S50:采用溶胀技术组合有磁微球与脂溶性荧光染料,使得脂溶性荧光 染料弥散分布于核微球的内部和/或第一包覆层的内部和/或凝胶层的内部。S50: Magnetic microspheres and liposoluble fluorescent dyes are combined using swelling technology, so that the liposoluble fluorescent dyes are dispersed and distributed in the interior of the core microspheres and/or the interior of the first coating layer and/or the interior of the gel layer.

参阅图19,本申请第十八实施例提出一种磁珠的制作方法,该方法包 括以下步骤:Referring to Figure 19, the eighteenth embodiment of the present application proposes a method for making a magnetic bead, the method comprising the following steps:

S10:提供一有磁微球,有磁微球包括核微球、偶联于核微球外表面的 第一磁性纳米颗粒以及包覆于核微球外表面以及第一磁性纳米颗粒外表面 的第一包覆层。S10: Provide a magnetic microsphere, the magnetic microsphere includes a core microsphere, a first magnetic nanoparticle coupled to the outer surface of the core microsphere, and a magnetic nanoparticle coated on the outer surface of the core microsphere and the outer surface of the first magnetic nanoparticle first cladding.

S20:采用吸附技术组合有磁微球与第二磁性纳米颗粒,使得第二磁性 纳米颗粒偶联于第一包覆层的外表面。S20: The magnetic microspheres and the second magnetic nanoparticles are combined by the adsorption technology, so that the second magnetic nanoparticles are coupled to the outer surface of the first coating layer.

S60:采用溶胀技术同时组合有磁微球与脂溶性荧光染料、有磁微球与 第三磁性纳米颗粒,使得脂溶性荧光染料、第三磁性纳米颗粒弥散分布于 核微球的内部和/或第一包覆层的内部。S60: Using swelling technology to combine magnetic microspheres and lipid-soluble fluorescent dyes, magnetic microspheres and third magnetic nanoparticles simultaneously, so that the lipid-soluble fluorescent dyes and third magnetic nanoparticles are dispersed and distributed inside the core microspheres and/or Inside of the first cladding.

S30:在偶联有第二磁性纳米颗粒的有磁微球的外表面上包覆凝胶层, 且凝胶层包覆至少部分第二磁性纳米颗粒。S30: Coating a gel layer on the outer surface of the magnetic microspheres coupled with the second magnetic nanoparticles, and coating at least part of the second magnetic nanoparticles with the gel layer.

可选地,上述第四实施例至第十八实施例步骤S30中的凝胶层可替换 为聚合物包覆层,聚合物包覆层的材料为聚苯乙烯、聚甲基丙烯酸甲酯、 聚乙烯-甲基丙烯酸甲酯、聚丙烯腈、聚乙烯、聚丙烯、聚丙烯酸乙酯中的 至少一种。Optionally, the gel layer in step S30 of the fourth embodiment to the eighteenth embodiment can be replaced with a polymer coating layer, and the material of the polymer coating layer is polystyrene, polymethyl methacrylate, At least one of polyethylene-methyl methacrylate, polyacrylonitrile, polyethylene, polypropylene, and polyethyl acrylate.

通过上述第四实施例至第十八实施例制得的磁珠10结构如图24或图 25所示,磁珠10包括:有磁微球11、脂溶性荧光染料15、第二磁性纳米 颗粒12、第三磁性纳米颗粒13以及第二包覆层14。其中,脂溶性荧光染 料15、第三磁性纳米颗粒13弥散分布于核微球111的内部,可以理解的是, 通过溶胀进入有磁微球11的内部后,脂溶性荧光染料15、第三磁性纳米颗 粒13包埋在核微球111的内部。第二磁性纳米颗粒12可偶联于核微球111 的外表面。第二包覆层14包覆于有磁微球11的外表面,且第二包覆层14 包覆至少部分第二磁性纳米颗粒12。可选地,第二包覆层14包覆全部第二 磁性纳米颗粒12,磁珠10的外表面为光滑表面。其中,上述第二包覆层 14可以为凝胶层或聚合物包覆层。可以理解的是,第三磁性纳米颗粒13、 脂溶性荧光染料15可弥散分布于凝胶层的内部,而受限于聚合物包覆层的 材料,第三磁性纳米颗粒13、脂溶性荧光染料15不可弥散分布于聚合物包 覆层的内部。The structures of the

更进一步地,可删减上述第四实施例至第十实施例中的步骤S30,由此 制得的磁珠10结构如图29所示,磁珠10包括:有磁微球11、脂溶性荧光 染料15、第二磁性纳米颗粒12以及第三磁性纳米颗粒13。其中,脂溶性 荧光染料15、第三磁性纳米颗粒13弥散分布于核微球111的内部,可以理 解的是,通过溶胀进入有磁微球11的内部后,脂溶性荧光染料15、第三磁 性纳米颗粒13包埋在核微球111的内部。第二磁性纳米颗粒12可偶联于 核微球111的外表面。Further, step S30 in the fourth embodiment to the tenth embodiment above can be deleted, and the structure of the

参阅图20,进一步地,上述第一实施例至第十八实施例中,步骤S30 具体包括以下步骤:Referring to FIG. 20 , further, in the above-mentioned first embodiment to the eighteenth embodiment, step S30 specifically includes the following steps:

S31:将偶联有第二磁性纳米颗粒的有磁微球与凝胶材料混合,加入交 联剂,进行交联反应,使得偶联有第二磁性纳米颗粒的有磁微球的外表面 上包覆凝胶层。S31: Mix the magnetic microspheres coupled with the second magnetic nanoparticles and the gel material, add a cross-linking agent, and perform a cross-linking reaction, so that the outer surfaces of the magnetic microspheres coupled with the second magnetic nanoparticles are Coat the gel layer.

在凝胶材料为壳聚糖时,交联剂可以为戊二醛,其中,壳聚糖与有磁 微球的质量比为:0.01~20%,壳聚糖通过静电相互作用和戊二醛发生化学 反应产生交联作用。When the gel material is chitosan, the cross-linking agent can be glutaraldehyde, wherein the mass ratio of chitosan to magnetic microspheres is 0.01-20%, and chitosan interacts with glutaraldehyde through electrostatic interaction. A chemical reaction occurs to produce cross-linking.

进一步地,上述实施例中的步骤S20的操作温度为0~100℃(例如0℃、 25℃、30℃、50℃、65℃、100℃),步骤S30的操作温度为20~65℃(例如 20℃、30℃、50℃、65℃),步骤S40的操作温度为0~65℃(例如0℃、25℃、 30℃、50℃、65℃),步骤S50的操作温度为0~65℃(例如0℃、25℃、30℃、 50℃、65℃)。在上述温度范围内,可有效避免因加热导致有磁微球的自体 荧光升高,进而提高检测灵敏度。Further, the operating temperature of step S20 in the above embodiment is 0-100°C (for example, 0°C, 25°C, 30°C, 50°C, 65°C, 100°C), and the operating temperature of step S30 is 20-65°C ( For example, 20°C, 30°C, 50°C, 65°C), the operating temperature of step S40 is 0~65°C (for example, 0°C, 25°C, 30°C, 50°C, 65°C), and the operating temperature of step S50 is 0~65°C 65°C (eg 0°C, 25°C, 30°C, 50°C, 65°C). Within the above temperature range, the autofluorescence increase of the magnetic microspheres caused by heating can be effectively avoided, thereby improving the detection sensitivity.

优选地,上述实施例中的步骤S20的操作温度为0~30℃(例如0℃、 25℃、30℃),步骤S30的操作温度为20~30℃(例如20℃、25℃、30℃), 步骤S40的操作温度为0~30℃(例如0℃、25℃、30℃),步骤S50的操作 温度为0~30℃(例如0℃、25℃、30℃)。在上述操作温度范围内,可有效 避免因加热导致无磁有磁微球的自体荧光升高,进而提高检测灵敏度。Preferably, the operating temperature of step S20 in the above embodiment is 0-30°C (eg 0°C, 25°C, 30°C), and the operating temperature of step S30 is 20-30°C (eg 20°C, 25°C, 30°C) ), the operating temperature of step S40 is 0-30°C (eg 0°C, 25°C, 30°C), and the operating temperature of step S50 is 0-30°C (eg 0°C, 25°C, 30°C). Within the above operating temperature range, the autofluorescence increase of the non-magnetic and magnetic microspheres caused by heating can be effectively avoided, thereby improving the detection sensitivity.

更优选地,上述实施例中的步骤S20的操作温度为室温(23℃±2℃), 步骤S30的操作温度为室温(23℃±2℃),步骤S40的操作温度为室温(23℃ ±2℃),步骤S50的操作温度为室温(23℃±2℃)。在上述操作温度范围 内,可有效避免因加热导致无磁有磁微球的自体荧光升高,进而提高检测 灵敏度。More preferably, the operating temperature of step S20 in the above-mentioned embodiment is room temperature (23 ℃ ± 2 ℃), the operating temperature of step S30 is room temperature (23 ℃ ± 2 ℃), and the operating temperature of step S40 is room temperature (23 ℃ ± 2 ℃). 2° C.), and the operating temperature of step S50 is room temperature (23° C.±2° C.). Within the above operating temperature range, the autofluorescence increase of the non-magnetic and magnetic microspheres caused by heating can be effectively avoided, thereby improving the detection sensitivity.

在一些实施例中,按质量百分比计,在上述实施例制得的磁珠10中, 有磁微球11:第二磁性纳米颗粒12:第三磁性纳米颗粒13为(50%~99.5%): (0.1%~49.9%):(0.1%~49.9%)。申请人发现在上述数值范围内,可在避 免有磁微球11表面过量吸附磁性纳米颗粒的前提下,提高磁珠10的磁响 应,并降低杂质带来的干扰信号,且能够降低有磁微球11的自体荧光,提 高检测灵敏度。In some embodiments, in the

区别于现有技术的情况,本申请的磁珠10包括:有磁微球11、第二磁 性纳米颗粒12、凝胶层以及第三磁性纳米颗粒13,有磁微球11包括核微 球111、偶联于核微球111外表面的第一磁性纳米颗粒112以及包覆于核微 球111外表面以及第一磁性纳米颗粒112外表面的第一包覆层113,第二磁 性纳米颗粒12偶联于有磁微球11的外表面,凝胶层包覆于有磁微球11的 外表面且包覆至少部分第二磁性纳米颗粒12,第三磁性纳米颗粒13弥散分 布于核微球111的内部和/或凝胶层的内部的,在避免有磁微球11表面过量 吸附磁性纳米颗粒的前提下,能够提高磁珠10的磁响应,并降低杂质带来 的干扰信号,且能够降低有磁微球11的自体荧光,提高检测灵敏度。Different from the situation in the prior art, the

在本申请所提供的几个实施方式中,应该理解到,所揭露的方法以及 设备,可以通过其它的方式实现。例如,以上所描述的设备实施方式仅仅 是示意性的,例如,所述模块或单元的划分,仅仅为一种逻辑功能划分, 实际实现时可以有另外的划分方式,例如多个单元或组件可以结合或者可 以集成到另一个系统,或一些特征可以忽略,或不执行。In the several embodiments provided in this application, it should be understood that the disclosed method and apparatus may be implemented in other manners. For example, the device implementations described above are only illustrative. For example, the division of the modules or units is only a logical function division. In actual implementation, there may be other divisions. For example, multiple units or components may be Incorporation may either be integrated into another system, or some features may be omitted, or not implemented.

所述作为分离部件说明的单元可以是或者也可以不是物理上分开的, 作为单元显示的部件可以是或者也可以不是物理单元,即可以位于一个地 方,或者也可以分布到多个网络单元上。可以根据实际的需要选择其中的 部分或者全部单元来实现本实施方式方案的目的。The units described as separate components may or may not be physically separated, and the components shown as units may or may not be physical units, that is, may be located in one place, or may be distributed to multiple network units. Some or all of the units may be selected according to actual needs to achieve the purpose of the solution in this implementation manner.

另外,在本申请各个实施方式中的各功能单元可以集成在一个处理单 元中,也可以是各个单元单独物理存在,也可以两个或两个以上单元集成 在一个单元中。上述集成的单元既可以采用硬件的形式实现,也可以采用 软件功能单元的形式实现。In addition, each functional unit in each embodiment of the present application may be integrated into one processing unit, or each unit may exist physically alone, or two or more units may be integrated into one unit. The above-mentioned integrated units can be implemented in the form of hardware, and can also be implemented in the form of software functional units.

以上所述仅为本申请的实施例,并非因此限制本申请的专利范围,凡 是利用本申请说明书及附图内容所作的等效结构或等效流程变换,或直接 或间接运用在其他相关的技术领域,均同理包括在本申请的专利保护范围 内。The above are only the embodiments of the present application, and are not intended to limit the scope of the patent of the present application. Any equivalent structure or equivalent process transformation made by using the contents of the description and drawings of the present application, or directly or indirectly applied to other related technologies Fields are similarly included within the scope of patent protection of this application.

Claims (19)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110313578.2ACN115127974A (en) | 2021-03-24 | 2021-03-24 | Magnetic beads and methods of making the same |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110313578.2ACN115127974A (en) | 2021-03-24 | 2021-03-24 | Magnetic beads and methods of making the same |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115127974Atrue CN115127974A (en) | 2022-09-30 |

Family

ID=83374011

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110313578.2APendingCN115127974A (en) | 2021-03-24 | 2021-03-24 | Magnetic beads and methods of making the same |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115127974A (en) |

Citations (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1468898A (en)* | 2003-07-02 | 2004-01-21 | 北京倍爱康生物技术股份有限公司 | A kind of preparation method of superparamagnetic polymer microsphere |

| CN1475805A (en)* | 2002-08-15 | 2004-02-18 | 陕西西大北美基因股份有限公司 | Magnetic fluorescence microsphere and its preparation method and method of proceeding biomolecule detection using said magnetic fluorescence microsphere |

| CN101650998A (en)* | 2005-01-20 | 2010-02-17 | 卢米尼克斯股份有限公司 | Microspheres, populations of microspheres, and methods for forming microspheres |

| CN102302918A (en)* | 2011-06-13 | 2012-01-04 | 天津大学 | Magnetic fluorescent composite microsphere and method for preparing same |

| CN103157412A (en)* | 2013-03-25 | 2013-06-19 | 哈尔滨工业大学 | Preparation method of electromagnetic composite hollow microspheres |

| CN103242494A (en)* | 2013-05-27 | 2013-08-14 | 上海交通大学 | Preparation method of composite microgel with temperature, pH and magnetic field sensitivities |

| CN103990443A (en)* | 2014-03-27 | 2014-08-20 | 华南师范大学 | Single-stranded DNA nucleic acid modified chitosan magnetic microsphere preparation method |

| CN107245196A (en)* | 2017-06-22 | 2017-10-13 | 成都爱兴生物科技有限公司 | Multilayer assembles the preparation method of micron size polystyrene magnetic composite microsphere |

| CN107812500A (en)* | 2017-10-11 | 2018-03-20 | 广州新诚生物科技有限公司 | A kind of magnetic polymer microsphere and preparation method thereof |

| CN109158063A (en)* | 2018-07-31 | 2019-01-08 | 湖南华腾制药有限公司 | A kind of magnetic macromolecular microsphere structure and its preparation |

| CN110343218A (en)* | 2019-06-10 | 2019-10-18 | 东莞东阳光科研发有限公司 | Immunomagnetic bead and preparation method thereof |

| CN111359551A (en)* | 2020-03-24 | 2020-07-03 | 北京唯公医疗技术有限公司 | Magnetic polymer microsphere and preparation method thereof |

| CN111426659A (en)* | 2020-03-24 | 2020-07-17 | 深圳唯公生物科技有限公司 | Magnetic fluorescent coding microsphere and preparation method thereof |

- 2021

- 2021-03-24CNCN202110313578.2Apatent/CN115127974A/enactivePending

Patent Citations (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1475805A (en)* | 2002-08-15 | 2004-02-18 | 陕西西大北美基因股份有限公司 | Magnetic fluorescence microsphere and its preparation method and method of proceeding biomolecule detection using said magnetic fluorescence microsphere |

| CN1468898A (en)* | 2003-07-02 | 2004-01-21 | 北京倍爱康生物技术股份有限公司 | A kind of preparation method of superparamagnetic polymer microsphere |

| US20140042366A1 (en)* | 2005-01-20 | 2014-02-13 | Luminex Corporation | Magnetic microspheres for use in fluorescence-based applications |

| CN101650998A (en)* | 2005-01-20 | 2010-02-17 | 卢米尼克斯股份有限公司 | Microspheres, populations of microspheres, and methods for forming microspheres |

| US20130095573A1 (en)* | 2005-01-20 | 2013-04-18 | Don J. Chandler | Magnetic Microspheres For Use In Fluorescence-Based Applications |

| CN102302918A (en)* | 2011-06-13 | 2012-01-04 | 天津大学 | Magnetic fluorescent composite microsphere and method for preparing same |

| CN103157412A (en)* | 2013-03-25 | 2013-06-19 | 哈尔滨工业大学 | Preparation method of electromagnetic composite hollow microspheres |

| CN103242494A (en)* | 2013-05-27 | 2013-08-14 | 上海交通大学 | Preparation method of composite microgel with temperature, pH and magnetic field sensitivities |

| CN103990443A (en)* | 2014-03-27 | 2014-08-20 | 华南师范大学 | Single-stranded DNA nucleic acid modified chitosan magnetic microsphere preparation method |

| CN107245196A (en)* | 2017-06-22 | 2017-10-13 | 成都爱兴生物科技有限公司 | Multilayer assembles the preparation method of micron size polystyrene magnetic composite microsphere |

| CN107812500A (en)* | 2017-10-11 | 2018-03-20 | 广州新诚生物科技有限公司 | A kind of magnetic polymer microsphere and preparation method thereof |

| CN109158063A (en)* | 2018-07-31 | 2019-01-08 | 湖南华腾制药有限公司 | A kind of magnetic macromolecular microsphere structure and its preparation |

| CN110343218A (en)* | 2019-06-10 | 2019-10-18 | 东莞东阳光科研发有限公司 | Immunomagnetic bead and preparation method thereof |

| CN111359551A (en)* | 2020-03-24 | 2020-07-03 | 北京唯公医疗技术有限公司 | Magnetic polymer microsphere and preparation method thereof |

| CN111426659A (en)* | 2020-03-24 | 2020-07-17 | 深圳唯公生物科技有限公司 | Magnetic fluorescent coding microsphere and preparation method thereof |

Non-Patent Citations (4)

| Title |

|---|

| 周慧睿;陶可;孙康;: "荧光磁性纳米复合颗粒的制备及展望", 化学进展, no. 06, 24 June 2011 (2011-06-24)* |

| 张治好 等: "功能高分子材料", 31 October 2022, pages: 69* |

| 王晔晨 等: "磁性聚合物微球的制备及其应用研究进展", 化工进展, vol. 36, no. 8, 31 December 2017 (2017-12-31)* |

| 罗成 等: "磁性聚合物微球的制备及其应用研究进展", 中国科学, vol. 49, no. 2, 31 December 2019 (2019-12-31)* |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101721967B (en) | Hollow microsphere containing superparamagnetic Fe3O4 nanocrystal and preparation method thereof | |

| CN102358783B (en) | A kind of preparation method of polystyrene/gold composite microsphere | |

| CN104031201B (en) | A kind of preparation method and applications of the magnetic microsphere separated for bioprotein | |

| CN112666140B (en) | Poly (undecylenic acid-divinylbenzene) -coated magnetic fluorescently encoded microspheres | |

| JP4947288B2 (en) | Magnetic particle, method for producing the same, and carrier for biochemistry | |

| CN102344632A (en) | Three-layer core-shell-structure inorganic nanoparticle/silicon dioxide/high polymer composite microspheres and preparation method thereof | |

| CN111375360B (en) | Preparation method of magnetic microspheres with uniform particle size | |

| CN105435753A (en) | A mesoporous magnetic polymer composite sphere, a preparing method thereof and applications of the composite sphere | |

| CN111393574A (en) | Magnetic microspheres with functional groups on the surface and preparation method and use thereof | |

| CN112175150A (en) | Novel preparation method of functionalized porous magnetic microspheres | |