CN115125547A - Preparation and application of Mo/Nb double-doped Co hollow mesoporous carbon nano box catalyst - Google Patents

Preparation and application of Mo/Nb double-doped Co hollow mesoporous carbon nano box catalystDownload PDFInfo

- Publication number

- CN115125547A CN115125547ACN202210486471.2ACN202210486471ACN115125547ACN 115125547 ACN115125547 ACN 115125547ACN 202210486471 ACN202210486471 ACN 202210486471ACN 115125547 ACN115125547 ACN 115125547A

- Authority

- CN

- China

- Prior art keywords

- transition metal

- metal salt

- mcnbs

- preparation

- niobium

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B1/00—Electrolytic production of inorganic compounds or non-metals

- C25B1/01—Products

- C25B1/02—Hydrogen or oxygen

- C25B1/04—Hydrogen or oxygen by electrolysis of water

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B11/00—Electrodes; Manufacture thereof not otherwise provided for

- C25B11/04—Electrodes; Manufacture thereof not otherwise provided for characterised by the material

- C25B11/051—Electrodes formed of electrocatalysts on a substrate or carrier

- C25B11/055—Electrodes formed of electrocatalysts on a substrate or carrier characterised by the substrate or carrier material

- C25B11/057—Electrodes formed of electrocatalysts on a substrate or carrier characterised by the substrate or carrier material consisting of a single element or compound

- C25B11/065—Carbon

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B11/00—Electrodes; Manufacture thereof not otherwise provided for

- C25B11/04—Electrodes; Manufacture thereof not otherwise provided for characterised by the material

- C25B11/051—Electrodes formed of electrocatalysts on a substrate or carrier

- C25B11/073—Electrodes formed of electrocatalysts on a substrate or carrier characterised by the electrocatalyst material

- C25B11/091—Electrodes formed of electrocatalysts on a substrate or carrier characterised by the electrocatalyst material consisting of at least one catalytic element and at least one catalytic compound; consisting of two or more catalytic elements or catalytic compounds

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/30—Hydrogen technology

- Y02E60/36—Hydrogen production from non-carbon containing sources, e.g. by water electrolysis

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Inorganic Chemistry (AREA)

- Catalysts (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于电解水催化剂技术领域,具体涉及Mo/Nb双掺杂Co中空介孔碳纳米盒催化剂制备方法及在电解水装置中的应用。The invention belongs to the technical field of water electrolysis catalysts, and in particular relates to a preparation method of Mo/Nb double-doped Co hollow mesoporous carbon nano-box catalyst and its application in a water electrolysis device.

背景技术Background technique

21世纪,随着工业的发展,能源的开采与利用推动着人类的文明进步,各国对能源的需求越来越迫切,当前的能源结构主要有:天然气、煤炭、石油等。但过度开采,已经造成化石能源的快速枯竭,能源危机凸显,环境污染和一系列气候问题也逐渐浮出水面,因此需要对生态危机密切关注。众所周知,经济发展和能源密不可分。随着传统能源的日趋耗竭和由之带来的全球气候变暖、酸雨、雾霾等环境问题,人类的健康生活受到了严重的影响,同时也影响着国家经济持续增长的潜能。这就需要开发绿色、可持续的能源,合理设计高效的可再生能源转换系统是实现能源高效、可持续利用的关键。其中,高效的利用自然资源也是关键的手段,但世界上存在的自然资源,例如:太阳能、风能、地热能、生物质能等存在不稳定性、不连续性且受地域限制,若大规模的应用到全国,可能存在一些安全性及设施浪费的问题。石油能源的有限性和应用对环境保护的危害是不可避免的,因此开发一种可替代的、可持续的、清洁的能源技术来供应或替代化石能源是极其必要的。电化学储能装置的出现,可以说为解决这个问题提供了关键性的方向。In the 21st century, with the development of industry, the exploitation and utilization of energy promote the progress of human civilization, and the demand for energy in various countries is more and more urgent. The current energy structure mainly includes: natural gas, coal, oil and so on. However, over-exploitation has caused the rapid depletion of fossil energy, the energy crisis has become prominent, and environmental pollution and a series of climate problems have gradually surfaced. Therefore, it is necessary to pay close attention to the ecological crisis. As we all know, economic development and energy are inseparable. With the increasing depletion of traditional energy sources and the resulting environmental problems such as global warming, acid rain, and smog, human health has been seriously affected, and it has also affected the country's potential for sustained economic growth. This requires the development of green and sustainable energy, and the rational design of efficient renewable energy conversion systems is the key to achieving efficient and sustainable energy utilization. Among them, the efficient use of natural resources is also a key means, but the natural resources existing in the world, such as solar energy, wind energy, geothermal energy, biomass energy, etc. are unstable, discontinuous and subject to geographical restrictions. Applied to the whole country, there may be some problems of safety and waste of facilities. The limitation of petroleum energy and the harm of application to environmental protection are inevitable, so it is extremely necessary to develop an alternative, sustainable and clean energy technology to supply or replace fossil energy. The emergence of electrochemical energy storage devices can be said to provide a key direction for solving this problem.

在全球经济快速发展的时代,人类随环境污染越来越重视,而其中,化石能源污染是一个不容小觑的方面。氢作为一种零排放的能源,被认为是替代化石燃料能源的替代能源载体,近几年,各个国家均制定了氢能的发展规划。而在工业上制氢的主要方法有:热解天然气或水煤气制氢,但是这些方法在实际中不仅能耗巨大,还会对环境产生一定的污染;而电解水制氢生产安全且可靠,生产的氢气较纯,污染小。相较而言,电解水技术也显得尤为重要了。In the era of rapid global economic development, human beings pay more and more attention to environmental pollution, and among them, fossil energy pollution is an aspect that cannot be underestimated. As a zero-emission energy, hydrogen is considered to be an alternative energy carrier to replace fossil fuel energy. In recent years, various countries have formulated hydrogen energy development plans. The main methods of hydrogen production in industry are: pyrolysis of natural gas or water gas to produce hydrogen, but these methods not only consume a lot of energy in practice, but also cause certain pollution to the environment; while the production of hydrogen by electrolysis of water is safe and reliable, and the production The hydrogen is purer and less polluting. Comparatively speaking, electrolyzed water technology is also very important.

通过可再生能源获取电能,然后利用电解水技术将电能转化为化学能储存于氢气中,随后氢气被分装至全社会,经过燃料电池反应将化学能重新转化为电能并被利用,这就可以建立起基于氢气-水循环的全程清洁无污染的新能源系统。在这其中氢气作为一种高能量密度的能源载体而存在。电解水制氢是实现这一循环的重要技术组成部分。传统的甲烷蒸汽重整制氢技术虽然更为廉价,但其本质依然依赖于使用化石燃料并且会产生与释放CO2。随着可再生能源利用规模的逐渐扩大,电解水技术也具有着更加广泛的应用前景Obtain electrical energy through renewable energy, and then use water electrolysis technology to convert electrical energy into chemical energy and store it in hydrogen, then the hydrogen is distributed to the whole society, and the chemical energy is re-converted into electrical energy and used through the fuel cell reaction. Establish a clean and pollution-free new energy system based on the hydrogen-water cycle. In this, hydrogen exists as a high-energy-density energy carrier. Hydrogen production from water electrolysis is an important technological component to realize this cycle. Although the traditional methane steam reforming hydrogen production technology is cheaper, its essence still relies on the use of fossil fuels and will generate and release CO2 . With the gradual expansion of the scale of renewable energy utilization, water electrolysis technology also has wider application prospects.

电解水制氢由阳极(氧析出OER)和阴极(氢析出HER)组成,这种方法因其几乎零排放量,被认为是一种很有发展前景的方法。Hydrogen production by electrolysis of water, which consists of an anode (oxygen evolution OER) and a cathode (hydrogen evolution HER), is considered a promising method due to its almost zero emissions.

阳极:2H2O→O2+4H++4e-Anode: 2H2 O→O2 +4H+ +4e-

阴极:2H++2e-→H2Cathode: 2H+ +2e-→H2

总反应:2H2O→O2+2H2Overall reaction: 2H2 O → O2 + 2H2

析氧反应(OER)主要包括三个主要步骤:The oxygen evolution reaction (OER) mainly consists of three main steps:

(1)H2O/OH-在电催化剂表面的吸附(1) Adsorption of H2 O/OH- on the surface of electrocatalyst

(2)反应中间体的形成(2) Formation of reaction intermediates

(3)O2分子的释放。在电解水中,理论上的热力学势能为1.23V,但由于电解水中电池电压需要一个过大的电位,这会导致反应过程电荷传递速率变慢,产氢产氧的过程变得迟缓,从而导致能量额外消耗,结果就是热力学势能远远大于1.23V。贵金属,如Ru,Pt和Ir基材料,由于其巨大的表面积;出色的电催化反应和优异的导电性是燃料电池水分解过程的理想选择。然而,稳定性、来源不足和成本限制了其商业化。为了避免这些问题,在过去的几十年里,科学家们正努力寻找易于合成和大量可用的替代品,以显著降低OER过程的过度潜力。所以电解水制氢技术要与传统制氢行业竞争,这就需要要探索合适的、稳定的、廉价的 OER/HER催化剂,来降低额外消耗的能量,保持较低的过电位,提高反应速率,使电解水过程更环保。(3) The release of O2 molecules. In electrolyzed water, the theoretical thermodynamic potential energy is 1.23V, but because the battery voltage in electrolyzed water requires an excessive potential, which will cause the charge transfer rate to slow down during the reaction process, and the process of hydrogen and oxygen production to become slow, resulting in energy Additional consumption, the result is that the thermodynamic potential energy is much greater than 1.23V. Noble metals, such as Ru, Pt, and Ir-based materials, are ideal for fuel cell water splitting processes due to their large surface area; excellent electrocatalytic reaction and excellent electrical conductivity. However, stability, insufficient sources and cost limit its commercialization. To avoid these problems, over the past few decades, scientists have worked hard to find easily synthesized and abundantly available alternatives that can significantly reduce the excessive potential of the OER process. Therefore, the water electrolysis hydrogen production technology needs to compete with the traditional hydrogen production industry, which requires the exploration of suitable, stable and inexpensive OER/HER catalysts to reduce the additional energy consumption, maintain a low overpotential, and improve the reaction rate. Make the water electrolysis process more environmentally friendly.

发明内容SUMMARY OF THE INVENTION

本发明以碳正立方体作为导电网络,钼、铌元素掺杂形成的金属氧酸盐、金属氧化物颗粒负载于导电碳网络上,获得一种高比表面积、活性位点多、电化学性能良好的Mo和Nb元素双掺杂Co中空介孔碳纳米盒生长着含氧空位Co2Mo3O8/Nb2O5异质结催化剂,并应用于电解水装置中。In the present invention, carbon cubes are used as the conductive network, and oxometalate and metal oxide particles formed by doping molybdenum and niobium elements are supported on the conductive carbon network to obtain a high specific surface area, many active sites and good electrochemical performance. Mo and Nb element double-doped Co hollow mesoporous carbon nanoboxes grow oxygen-vacancy Co2 Mo3 O8 /Nb2 O5 heterojunction catalysts and are used in water electrolysis devices.

为了实现上述发明目的,本发明提供了一种Mo/Nb双掺杂Co中空介孔碳纳米盒催化剂制备方法,具体包括如下步骤:In order to achieve the above purpose of the invention, the present invention provides a preparation method of Mo/Nb double-doped Co hollow mesoporous carbon nanobox catalyst, which specifically includes the following steps:

步骤一、钴基沸石咪唑酯骨架材料(ZIF-67)的制备:将钴过渡金属盐、十六烷基三甲基溴化铵的水溶液和二甲基咪唑的水溶液混合,搅拌反应并离心,置于真空烘箱中干燥后得到前驱体正立方体ZIF-67;

步骤二、Co中空介孔碳纳米盒催化剂的制备(Co@MCNBs):将步骤一产物在惰性气体氛围的管式炉中退火得到Co@MCNBs;

步骤三、Co中空介孔碳纳米盒生长着含氧空位Nb2O5异质结催化剂的制备(Co(Nb)@MCNBs):将含ZIF-67的乙醇溶液和含钴过渡金属盐、铌过渡金属盐的乙醇溶液混合搅拌后,通过高压反应釜水热反应负载铌元素,离心收集固体,将其置于真空烘箱中干燥后再在惰性气体氛围的在管式炉中退火得到Co(Nb)@MCNBs;Step3. Preparation ofNb2O5 heterojunction catalysts containing oxygen vacancies for growth of Co hollow mesoporous carbon nanoboxes (Co(Nb)@MCNBs): ZIF-67-containing ethanol solution and cobalt-containing transition metal salt, niobium After the ethanol solution of the transition metal salt is mixed and stirred, the niobium element is loaded by the hydrothermal reaction of the autoclave, the solid is collected by centrifugation, dried in a vacuum oven, and then annealed in a tube furnace in an inert gas atmosphere to obtain Co(Nb )@MCNBs;

步骤四、Co中空介孔碳纳米盒生长着含氧空位Co2Mo3O8异质结催化剂的制备(Co(Mo) @MCNBs):将含ZIF-67的乙醇溶液和含钴过渡金属盐、钼过渡金属盐的乙醇溶液混合搅拌后,通过高压反应釜水热反应负载钼元素,离心收集固体,将其置于真空烘箱中干燥后再在惰性气体氛围的在管式炉中退火得到Co(Mo)@MCNBs;

步骤五、Co中空介孔碳纳米盒生长着含氧空位Co2Mo3O8和Nb2O5异质结催化剂的制备 (Co(Mo,Nb)@MCNBs):将含ZIF-67的乙醇溶液和含钴过渡金属盐、钼过渡金属盐、铌过渡金属盐的乙醇溶液混合搅拌后,通过高压反应釜水热反应负载钼元素和铌元素,离心收集固体,将其置于真空烘箱中干燥后再在惰性气体氛围管式炉中退火得到Co(Mo,Nb)@MCNBs。

作为优选,步骤一中所述钴过渡金属盐溶液、十六烷基三甲基溴化铵、二甲基咪唑、水质量比为0.2-1:0.2-1:0.2-1:20-40。Preferably, the cobalt transition metal salt solution, cetyltrimethylammonium bromide, dimethylimidazole, and water in

作为优选,步骤三中所述的ZIF-67、钴过渡金属盐溶液、铌过渡金属盐溶液、乙醇的质量比为0.2-1:0.2-1:0.2-1:10-100。Preferably, the mass ratio of ZIF-67, cobalt transition metal salt solution, niobium transition metal salt solution, and ethanol described in

作为优选步骤四中所述的ZIF-67、钴过渡金属盐溶液、钼过渡金属盐溶液、乙醇的质量比为0.2-1:0.2-1:0.2-1:10-100。As preferred

作为优选,步骤五中所述的ZIF-67、钴过渡金属盐溶液、钼过渡金属盐溶液、铌过渡金属盐溶液、乙醇的质量比为0.2-1:0.2-1:0.2-1:0.2-1:10-100。Preferably, the mass ratio of ZIF-67, cobalt transition metal salt solution, molybdenum transition metal salt solution, niobium transition metal salt solution and ethanol described in

作为优选,步骤一中的钴过渡金属盐采用Co(NO3)2·6H2O、CoCl2·6H2O、Co(CH3COO)2、 CoCl2、CoSO4·7H2O、CoSO4·H2O中的一种或几种。Preferably, the cobalt transition metal salt in

作为优选,步骤二、三、四、五中,所述惰性气体氛围为N2、Ar、He中的一种或几种;Preferably, in

作为优选,步骤二、三、四、五中所述退火工艺为在惰性气氛中以1℃/min升温速率到 600~700℃保温3h。Preferably, the annealing process described in

如上述所述Mo/Nb双掺杂Co中空介孔碳纳米盒催化剂作为电解水电极材料的应用,将其与Co中空介孔碳纳米盒一起应用于电解水装置OER和HER反应,所述通过金属双掺杂方式有效负载含氧空位的铌氧化物和钼钴氧酸盐异质结,同时铌元素起协同促进作用,含铌异质结可以促进与其他异质结的合作,发挥出1+1>2的效果;氧空位的出现更有益于氢氧根的吸附,从而促进OER反应;空心纳米盒结构,可以使更多的活性位点暴露,提高了活性位点的活性,增加催化剂的电催化性能。As described above, the Mo/Nb double-doped Co hollow mesoporous carbon nanobox catalyst is used as an electrode material for water electrolysis, and it is used together with the Co hollow mesoporous carbon nanobox in the OER and HER reactions of water electrolysis devices. The metal double-doping method effectively supports the heterojunction of niobium oxide and molybdenum cobalt oxolate containing oxygen vacancies, and at the same time, the niobium element plays a synergistic role in promoting the cooperation with other heterojunctions. The effect of +1>2; the appearance of oxygen vacancies is more beneficial to the adsorption of hydroxide radicals, thereby promoting the OER reaction; the hollow nanobox structure can expose more active sites, improve the activity of the active sites, and increase the catalyst. electrocatalytic performance.

相对于现有技术,本发明具有如下有益效果:Compared with the prior art, the present invention has the following beneficial effects:

(1)本发明用Co源代替贵金属是Pt、Ir和Ru基等贵金属材料,大大降低了成本,扩大应用范围。(1) In the present invention, the Co source is used to replace the precious metal materials such as Pt, Ir and Ru-based precious metal materials, which greatly reduces the cost and expands the application range.

(2)目前在电催化剂中研究较多的金属是Fe、Ni、V等,对一些不常见且在地球上储量丰富的元素的探索较少。在本发明中,我们探索了Nb这种元素,Nb由于其活性和复杂的化学性质,可以与其他主相活性物质形成很好的连接,在电催化领域是一种开发协同促进剂。(2) At present, the most studied metals in electrocatalysts are Fe, Ni, V, etc., and the exploration of some uncommon and abundant elements on earth is less. In the present invention, we explored the element Nb, which can form a good connection with other main-phase active substances due to its activity and complex chemical properties, and is a development synergistic promoter in the field of electrocatalysis.

(3)本发明中通过在Co中空介孔碳纳米盒外面生长两种异质结,既不会改变原有纳米盒中空有微孔的形貌,而且通过异质结间的化学协同作用,使生长的颗粒更加均匀化、有序化,从而引入缺陷,造成了氧空位的增加,提高对氢氧根的吸附,增强电化学OER性能。(3) In the present invention, by growing two kinds of heterojunctions on the outside of the Co hollow mesoporous carbon nanobox, the morphology of the original nanobox with hollow pores will not be changed, and through the chemical synergy between the heterojunctions, The grown particles are made more uniform and ordered, thereby introducing defects, resulting in the increase of oxygen vacancies, improving the adsorption of hydroxide, and enhancing the electrochemical OER performance.

附图说明Description of drawings

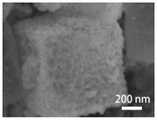

图1为实施例1制备的Mo和Nb元素双掺杂Co中空介孔碳纳米盒生长着含氧空位Co2Mo3O8/Nb2O5异质结催化剂于扫描电子显微镜下(SEM)的微观形貌;Figure 1 shows the growth of the oxygen-containing vacancy Co2 Mo3 O8 /Nb2 O5 heterojunction catalyst prepared by Mo and Nb element double-doped Co hollow mesoporous carbon nanoboxes prepared in Example 1 under a scanning electron microscope (SEM) the microscopic appearance;

图2为对比例1和实施例1,2,3样品和商业RuO2催化剂的析氧反应(OER)的线性扫描伏安测试图(LSV);Figure 2 is a linear sweep voltammetry (LSV) test chart of the oxygen evolution reaction (OER) of Comparative Example 1 and Example 1,2 , 3 samples and commercial RuO catalysts;

图3为对比例1和实施例1,2,3样品催化剂的析氢反应反应(HER)的线性扫描伏安测试图(LSV)。3 is a linear sweep voltammetry (LSV) test chart of the hydrogen evolution reaction (HER) of the catalysts of Comparative Example 1 and Examples 1, 2, and 3. FIG.

具体实施方式Detailed ways

为了使本发明的目的、技术方案和有益技术效果更加清晰,下面结合附图和具体实施方式,对本发明Mo/Nb双掺杂Co中空介孔碳纳米盒催化剂制备方法及其在电解水中应用的有益效果进行详细说明。应当理解的是,本说明书中描述的实施例仅仅是为了解释本发明,并非为了限定本发明,实施例的参数、比例等可因地制宜做出选择而对结果并无实质性影响。In order to make the purposes, technical solutions and beneficial technical effects of the present invention clearer, the following describes the preparation method of the Mo/Nb double-doped Co hollow mesoporous carbon nanobox catalyst and its application in electrolyzed water of the present invention with reference to the accompanying drawings and specific embodiments. The beneficial effects are described in detail. It should be understood that the embodiments described in this specification are only for explaining the present invention, not for limiting the present invention.

对比例1:一种负载Co颗粒的中空介孔碳纳米盒催化剂的制备,具体包括以下步骤:Comparative Example 1: Preparation of a hollow mesoporous carbon nanobox catalyst loaded with Co particles, including the following steps:

(1)ZIF-67的合成:(1) Synthesis of ZIF-67:

以0.292g的Co(NO3)2.6H2O为Co源溶解在10mL的去离子水(DI)中,该去离子水包含4mg 的十六烷基三甲基溴化铵(CTAB)。然后将该溶液快速注入70mL的含4.54g 2-甲基咪唑(2-MIM)的水溶液中,并在室温下搅拌30分钟。通过以12000rpm离心3分钟收集产物,用乙醇洗涤几次。0.292 g of Co(NO3 )2 .6H2 O as the Co source was dissolved in 10 mL of deionized water (DI) containing 4 mg of cetyltrimethylammonium bromide (CTAB). The solution was then quickly poured into 70 mL of an aqueous solution containing 4.54 g of 2-methylimidazole (2-MIM) and stirred at room temperature for 30 minutes. The product was collected by centrifugation at 12000 rpm for 3 minutes and washed several times with ethanol.

(2)负载Co颗粒的中空介孔碳纳米盒催化剂的合成:(2) Synthesis of hollow mesoporous carbon nanobox catalysts loaded with Co particles:

将上述制得的粉末在氩气流下以1℃min-1的加热速率在650℃下进一步退火3h,然后自然冷却至室温。The powders prepared above were further annealed at 650 °C for 3 h at a heating rate of 1 °C min−1 under an argon flow, and then naturally cooled to room temperature.

实施例1:Mo/Nb双掺杂Co中空介孔碳纳米盒催化剂的制备,具体包括以下步骤:Example 1: Preparation of Mo/Nb double-doped Co hollow mesoporous carbon nanobox catalyst, including the following steps:

(1)ZIF-67的合成:(1) Synthesis of ZIF-67:

以0.292g的Co(NO3)2.6H2O为Co源溶解在10mL的去离子水(DI)中,该去离子水包含4mg 的十六烷基三甲基溴化铵(CTAB)。然后将该溶液快速注入70mL的含4.54g 2-甲基咪唑(2-MIM)的水溶液中,并在室温下搅拌30分钟。通过以12000rpm离心3分钟收集产物,用乙醇洗涤几次。0.292 g of Co(NO3 )2 .6H2 O as the Co source was dissolved in 10 mL of deionized water (DI) containing 4 mg of cetyltrimethylammonium bromide (CTAB). The solution was then quickly poured into 70 mL of an aqueous solution containing 4.54 g of 2-methylimidazole (2-MIM) and stirred at room temperature for 30 minutes. The product was collected by centrifugation at 12000 rpm for 3 minutes and washed several times with ethanol.

(2)Mo和Nb元素双掺杂Co中空介孔碳纳米盒生长着含氧空位Co2Mo3O8/Nb2O5异质结催化剂的合成:(2) Synthesis of Mo and Nb element double-doped Co hollow mesoporous carbon nanoboxes grown with oxygen vacancies Co2 Mo3 O8 /Nb2 O5 heterojunction catalysts:

首先将0.06g的ZIF-67和5mL含0.05M(NH4)2MoS4溶于20ml的乙醇中,恒速搅拌1h。然后将10ml含Co(NO3)2.6H2O(6mM)和NbCl5(3mM)乙醇溶液缓慢滴加到上述溶液中,恒速搅拌3h。然后将上述溶液转移到衬有Teflon的不锈钢高压釜(50mL)中,并保持在200℃下保持6小时。冷却至室温后,离心收集产物,用乙醇洗涤几次,然后在70℃的烘箱中干燥。将制得的粉末在在氩气流下以1℃min-1的加热速率在650℃退火3h,然后自然冷却至室温,得到Mo和Nb元素双掺杂Co中空介孔碳纳米盒生长着含氧空位Co2Mo3O8/Nb2O5异质结催化剂 Co(Mo,Nb)@MCNBs。实验中,管式炉始终保持恒定压力。First, 0.06 g of ZIF-67 and 5 mL of 0.05M (NH4 )2 MoS4 were dissolved in 20 ml of ethanol and stirred at a constant speed for 1 h. Then, 10 ml of an ethanol solution containing Co(NO3 )2 .6H2 O (6 mM) and NbCl5 (3 mM) was slowly added dropwise to the above solution, and stirred at a constant speed for 3 h. The above solution was then transferred to a Teflon lined stainless steel autoclave (50 mL) and kept at 200°C for 6 hours. After cooling to room temperature, the product was collected by centrifugation, washed several times with ethanol, and then dried in an oven at 70°C. The prepared powders were annealed at 650 °C for 3 h at a heating rate of 1 °C min-1 under argon flow, and then cooled to room temperature naturally to obtain Mo and Nb elements double-doped Co hollow mesoporous carbon nanoboxes grown with oxygen-containing carbon nanoboxes. Vacant Co2 Mo3 O8 /Nb2 O5 heterojunction catalyst Co(Mo,Nb)@MCNBs. In the experiment, the tube furnace was kept at constant pressure all the time.

通过扫描电子显微镜(SEM)对实施例1获得的Co(Mo,Nb)@MCNBs材料的形貌进行分析,结果如图1所示依旧保持立方体结构,异质结结构负载于表面。The morphology of the Co(Mo,Nb)@MCNBs material obtained in Example 1 was analyzed by scanning electron microscopy (SEM). The results showed that the cubic structure was still maintained as shown in Figure 1, and the heterojunction structure was supported on the surface.

实施例2:Nb掺杂Co中空介孔碳纳米盒催化剂的合成的制备,具体包括以下步骤:Example 2: Synthesis and preparation of Nb-doped Co hollow mesoporous carbon nanobox catalyst, including the following steps:

(1)ZIF-67的合成:(1) Synthesis of ZIF-67:

以0.292g的Co(NO3)2.6H2O为Co源溶解在10mL的去离子水(DI)中,该去离子水包含4mg 的十六烷基三甲基溴化铵(CTAB)。然后将该溶液快速注入70mL的含4.54g 2-甲基咪唑(2-MIM)的水溶液中,并在室温下搅拌30分钟。通过以12000rpm离心3分钟收集产物,用乙醇洗涤几次。0.292 g of Co(NO3 )2 .6H2 O as the Co source was dissolved in 10 mL of deionized water (DI) containing 4 mg of cetyltrimethylammonium bromide (CTAB). The solution was then quickly poured into 70 mL of an aqueous solution containing 4.54 g of 2-methylimidazole (2-MIM) and stirred at room temperature for 30 minutes. The product was collected by centrifugation at 12000 rpm for 3 minutes and washed several times with ethanol.

(2)Nb元素掺杂Co中空介孔碳纳米盒生长着含氧空位Nb2O5异质结催化剂的合成:(2) Synthesis of Nb-doped Co hollow mesoporous carbon nanoboxes grown with oxygen- containing vacanciesNb2O5 heterojunction catalysts:

首先将0.06g的ZIF-67溶于20ml的乙醇中,恒速搅拌1h。然后将10ml含Co(NO3)2.6H2O(6mM) 和NbCl5(3mM)乙醇溶液缓慢滴加到上述溶液中,恒速搅拌3h。然后将上述溶液转移到衬有 Teflon的不锈钢高压釜(50mL)中,并保持在200℃下保持6小时。冷却至室温后,离心收集产物,用乙醇洗涤几次,然后在70℃的烘箱中干燥。将制得的粉末在在氩气流下以1℃min-1的加热速率在650℃退火3h,然后自然冷却至室温,得到Nb元素掺杂Co中空介孔碳纳米盒生长着含氧空位Nb2O5异质结催化剂Co(Nb)@MCNBs。实验中,管式炉始终保持恒定压力。First, 0.06 g of ZIF-67 was dissolved in 20 ml of ethanol and stirred at a constant speed for 1 h. Then, 10 ml of an ethanol solution containing Co(NO3 )2 .6H2 O (6 mM) and NbCl5 (3 mM) was slowly added dropwise to the above solution and stirred at a constant speed for 3 h. The above solution was then transferred to a Teflon lined stainless steel autoclave (50 mL) and kept at 200°C for 6 hours. After cooling to room temperature, the product was collected by centrifugation, washed several times with ethanol, and then dried in an oven at 70°C. The obtained powder was annealed at 650 °C for 3 h at a heating rate of 1 °C min-1 under argon flow, and then cooled to room temperature naturally to obtain Nb element-doped Co hollow mesoporous carbon nanoboxes grown with oxygen-containing vacancies Nb2 O heterojunction catalyst Co(Nb)@MCNBs . In the experiment, the tube furnace was kept at constant pressure all the time.

实施例3:Mo掺杂Co中空介孔碳纳米盒催化剂的制备,具体包括以下步骤:Example 3: Preparation of Mo-doped Co hollow mesoporous carbon nanobox catalyst, including the following steps:

(1)ZIF-67的合成:(1) Synthesis of ZIF-67:

以0.292g的Co(NO3)2.6H2O为Co源溶解在10mL的去离子水(DI)中,该去离子水包含4mg 的十六烷基三甲基溴化铵(CTAB)。然后将该溶液快速注入70mL的含4.54g 2-甲基咪唑(2-MIM)的水溶液中,并在室温下搅拌30分钟。通过以12000rpm离心3分钟收集产物,用乙醇洗涤几次。0.292 g of Co(NO3 )2 .6H2 O as the Co source was dissolved in 10 mL of deionized water (DI) containing 4 mg of cetyltrimethylammonium bromide (CTAB). The solution was then quickly poured into 70 mL of an aqueous solution containing 4.54 g of 2-methylimidazole (2-MIM) and stirred at room temperature for 30 minutes. The product was collected by centrifugation at 12000 rpm for 3 minutes and washed several times with ethanol.

(2)Mo元素掺杂Co中空介孔碳纳米盒生长着含氧空位Co2Mo3O8异质结催化剂的合成:(2 ) Synthesis of Mo element- doped Co hollow mesoporous carbon nanoboxes grown with oxygen-vacancyCo2Mo3O8 heterojunction catalysts:

首先将0.06g的ZIF-67和5mL含0.05M(NH4)2MoS4溶于20ml的乙醇中,恒速搅拌1h。然后将10ml含Co(NO3)2.6H2O(6mM)乙醇溶液缓慢滴加到上述溶液中,恒速搅拌3h。然后将上述溶液转移到衬有Teflon的不锈钢高压釜(50mL)中,并保持在200℃下保持6小时。冷却至室温后,离心收集产物,用乙醇洗涤几次,然后在70℃的烘箱中干燥。将制得的粉末在在氩气流下以1℃min-1的加热速率在650℃退火3h,然后自然冷却至室温,得到Mo元素掺杂Co中空介孔碳纳米盒生长着含氧空位Co2Mo3O8异质结催化剂Co(Mo)@MCNBs。实验中,管式炉始终保持恒定压力。First, 0.06 g of ZIF-67 and 5 mL of 0.05M (NH4 )2 MoS4 were dissolved in 20 ml of ethanol and stirred at a constant speed for 1 h. Then, 10 ml of Co(NO3 )2 .6H2 O (6 mM) ethanol solution was slowly added dropwise to the above solution, and stirred at a constant speed for 3 h. The above solution was then transferred to a Teflon lined stainless steel autoclave (50 mL) and kept at 200°C for 6 hours. After cooling to room temperature, the product was collected by centrifugation, washed several times with ethanol, and then dried in an oven at 70°C. The obtained powder was annealed at 650 °C for 3 h at a heating rate of 1 °C min-1 under argon flow, and then cooled to room temperature naturally to obtain Mo element-doped Co hollow mesoporous carbon nanoboxes grown with oxygen-containing vacanciesCo2Mo3O8 heterojunction catalyst Co(Mo)@MCNBs . In the experiment, the tube furnace was kept at constant pressure all the time.

双功能催化性能评估:Bifunctional catalytic performance evaluation:

所有的电化学测试使用的电化学工作站型号为CHI 760E测试体系,电化学测试都在室温下进行。The electrochemical workstation model used for all electrochemical tests is the CHI 760E test system, and the electrochemical tests are carried out at room temperature.

工作电极的制备:准确称量5mg Mo和Nb元素双掺杂Co中空介孔碳纳米盒生长着含氧空位Co2Mo3O8/Nb2O5异质结催化剂、0.5mg乙炔黑、0.5mg聚偏二氟乙烯(PVDF),然后混合溶解在750mL n-甲基-吡咯烷酮(NMP)中,将混合物超声处理30min,最后将上述制备的墨汁滴涂在面积0.5cm×0.5cm的碳纸表面,红外灯烘干后继续滴涂,重复,最后称量得负载量约为0.4mg。作为对照实验,商业RuO2催化剂也采用相同的制备方法进行制备并测试。Preparation of working electrode: Accurately weighing 5mg Mo and Nb element double-doped Co hollow mesoporous carbon nanoboxes grown with oxygen-vacancy Co2 Mo3 O8 /Nb2 O5 heterojunction catalyst, 0.5mg acetylene black, 0.5mg mg of polyvinylidene fluoride (PVDF), then mixed and dissolved in 750 mL of n-methyl-pyrrolidone (NMP), the mixture was ultrasonically treated for 30 min, and finally the ink prepared above was dripped onto carbon paper with an area of 0.5 cm×0.5 cm On the surface, after drying with infrared light, continue to drop coating, repeat, and finally weigh the load to be about 0.4mg. As a control experiment, a commercialRuO catalyst was also prepared and tested using the same preparation method.

电化学性能测试:在测试过程中采用标准的三电极电化学测试体系,其中,对电极为Pt 网,参比电极为饱和甘汞电极(SCE)以及上述制备的工作电极。Electrochemical performance test: A standard three-electrode electrochemical test system was used in the test process, wherein the counter electrode was a Pt mesh, the reference electrode was a saturated calomel electrode (SCE) and the working electrode prepared above.

利用电化学工作站分别测试了对比例1和实施例1,2,3样品在1.0M KOH溶液中的OER-LSV曲线如图2所示,对比例1和实施例1,2,3样品在电流密度为10mA cm-2时,OER 过电位分别为364mV,284mV,351mV和317mV。在相同测试条件下,比商业RuO2催化剂的过电位和空白碳纸低,说明Mo和Nb元素双掺杂Co中空介孔碳纳米盒生长着含氧空位 Co2Mo3O8/Nb2O5异质结催化剂样品具有优异的OER电催化活性,可以应用于电解水装置的正极中。The OER-LSV curves of the samples of Comparative Example 1 and Examples 1, 2, and 3 in 1.0 M KOH solution were tested using an electrochemical workstation, as shown in Figure 2. At a density of 10 mA cm-2 , the OER overpotentials were 364 mV, 284 mV, 351 mV and 317 mV, respectively. Under the same test conditions, the overpotential is lowerthan that of commercial RuO2 catalyst and blank carbon paper, indicating that Mo and Nb elementdouble -doped Co hollow mesoporous carbonnanobox grows oxygen-containing vacanciesCo2Mo3O8 /Nb2O5 The heterojunction catalyst samples have excellent OER electrocatalytic activity and can be applied in the cathode of water electrolysis devices.

利用电化学工作站分别测试了对比例1和实施例1,2,3样品在1.0M KOH溶液中的HER-LSV曲线如图2所示,对比例1和实施例1,2,3样品在电流密度为10mA cm-2时,HER 过电位分别为206mV,229mV,314mV和245mV,说明负载Co颗粒的中空介孔碳纳米盒催化剂催化剂样品也有一定的HER电催化活性,可以应用于电解水装置的负极中。The HER-LSV curves of Comparative Example 1 and Examples 1, 2, and 3 in 1.0 M KOH solution were tested using an electrochemical workstation, respectively, as shown in Figure 2. Comparative Example 1 and Examples 1, 2, and 3 were tested at current When the density is 10 mA cm-2 , the HER overpotentials are 206 mV, 229 mV, 314 mV and 245 mV, respectively, indicating that the hollow mesoporous carbon nanobox catalyst samples loaded with Co particles also have certain HER electrocatalytic activity, which can be applied to the electrolysis of water. in the negative pole.

最后还应说明的是:以上各实施例仅用以说明本发明的技术方案,而非对其限制;尽管参照前述各实施例对本发明进行了详细的说明,本领域的普通技术人员应当理解:其依然可以对前述各实施例所记载的技术方案进行修改,或者对其中部分或者全部技术特征进行等同替换;而这些修改或者替换,并不使相应技术方案的本质脱离本发明各实施例技术方案的范围。Finally, it should be noted that: the above embodiments are only used to illustrate the technical solutions of the present invention, but not to limit it; although the present invention has been described in detail with reference to the foregoing embodiments, those of ordinary skill in the art should understand: It is still possible to modify the technical solutions recorded in the foregoing embodiments, or perform equivalent replacements to some or all of the technical features; and these modifications or replacements do not make the essence of the corresponding technical solutions deviate from the technical solutions of the embodiments of the present invention. range.

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210486471.2ACN115125547B (en) | 2022-05-06 | 2022-05-06 | Preparation and Application of Mo/Nb Double-doped Co Hollow Mesoporous Carbon Nanobox Catalysts |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210486471.2ACN115125547B (en) | 2022-05-06 | 2022-05-06 | Preparation and Application of Mo/Nb Double-doped Co Hollow Mesoporous Carbon Nanobox Catalysts |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN115125547Atrue CN115125547A (en) | 2022-09-30 |

| CN115125547B CN115125547B (en) | 2023-07-25 |

Family

ID=83376769

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210486471.2AActiveCN115125547B (en) | 2022-05-06 | 2022-05-06 | Preparation and Application of Mo/Nb Double-doped Co Hollow Mesoporous Carbon Nanobox Catalysts |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115125547B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115555025A (en)* | 2022-10-31 | 2023-01-03 | 河北建材职业技术学院 | Preparation method of high-dispersion cobalt-molybdenum bimetallic catalyst |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112553643A (en)* | 2020-12-07 | 2021-03-26 | 上海电力大学 | Nitrogen-doped carbon-coated non-noble bimetallic cobalt-molybdenum oxide oxygen evolution reaction catalyst, preparation method and application |

- 2022

- 2022-05-06CNCN202210486471.2Apatent/CN115125547B/enactiveActive

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112553643A (en)* | 2020-12-07 | 2021-03-26 | 上海电力大学 | Nitrogen-doped carbon-coated non-noble bimetallic cobalt-molybdenum oxide oxygen evolution reaction catalyst, preparation method and application |

Non-Patent Citations (1)

| Title |

|---|

| XIAOHUI CHEN ET. AL.: "Regulation of the electronic structure of Co4N with novel Nb to form hierarchical porous nanosheets for electrocatalytic overall water splitting", 《MATERIALS TODAY PHYSICS》, vol. 15, pages 100268* |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115555025A (en)* | 2022-10-31 | 2023-01-03 | 河北建材职业技术学院 | Preparation method of high-dispersion cobalt-molybdenum bimetallic catalyst |

| CN115555025B (en)* | 2022-10-31 | 2024-01-26 | 河北建材职业技术学院 | Preparation method of highly dispersed cobalt-molybdenum bimetallic catalyst |

Also Published As

| Publication number | Publication date |

|---|---|

| CN115125547B (en) | 2023-07-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Gao et al. | Next-generation green hydrogen: progress and perspective from electricity, catalyst to electrolyte in electrocatalytic water splitting | |

| Lv et al. | Recent advances in high-efficiency electrocatalytic water splitting systems | |

| CN109569683B (en) | Preparation method and application of nitrogen-phosphorus-codoped porous carbon sheet/transition metal phosphide composite material | |

| CN110148762B (en) | A kind of carbon material with nitrogen, fluorine and transition metal co-doped graphene structure and its one-step carbonization preparation method | |

| CN109659143A (en) | A kind of nickel hydroxide/three nickel of curing/foam nickel composite and the preparation method and application thereof | |

| CN105977467A (en) | A preparation method of Co3O4@CoP composite electrode based on MOF template | |

| CN108630438A (en) | Cobaltous selenide/titanium net decomposes water oxygen electrode and preparation method thereof | |

| CN113955728B (en) | Preparation of cobalt phosphide/cobalt manganese phosphide with hollow grade structure and application of electrolytic water | |

| Qian et al. | Free-standing bimetallic CoNiTe2 nanosheets as efficient catalysts with high stability at large current density for oxygen evolution reaction | |

| CN114289043A (en) | Preparation method and application of self-supporting porous nano-plate cobalt-nickel phosphide catalyst | |

| CN110624573A (en) | A kind of nickel-doped cobalt selenide electrocatalytic hydrogen evolution catalyst and preparation method thereof | |

| CN111545238A (en) | Co9S8-MoS2Load g-C3N4Electrocatalytic hydrogen production catalyst and preparation method thereof | |

| CN110699701A (en) | A kind of nickel foam loaded with metal nickel and vanadium trioxide composite and its preparation method and application | |

| CN113856711A (en) | Design synthesis and electrolytic water hydrogen evolution research of high-efficiency nickel-cobalt phosphide heterojunction catalyst | |

| CN113105645A (en) | Preparation method, product and application of nickel-based metal organic framework compound | |

| CN106544694A (en) | Metallic composite, its preparation method and application, hydrogen manufacturing electrolytic cell | |

| CN116377497B (en) | Preparation method and application of self-supporting Fe-Mn co-doped nickel-cobalt selenide nanorod array catalyst | |

| CN112553643B (en) | A nitrogen-doped carbon-coated non-precious bimetallic cobalt-molybdenum oxide catalyst for oxygen evolution reaction, preparation method and application | |

| CN107803212A (en) | A kind of rich defect Fe2O3‑FeF2Nano-porous film, preparation method and applications | |

| CN117328084A (en) | Lignocharcoal-derived self-supporting integrated electrode materials and their preparation methods and applications | |

| CN115125547B (en) | Preparation and Application of Mo/Nb Double-doped Co Hollow Mesoporous Carbon Nanobox Catalysts | |

| CN112058297B (en) | Nickel-based electro-catalytic material and preparation method and application thereof | |

| CN113943950A (en) | Multi-metal hydroxide pre-catalyst and preparation method and application thereof | |

| CN113428847A (en) | Nickel-molybdenum-copper ternary metal phosphide, preparation method and application thereof | |

| CN113668012A (en) | An iron/ruthenium nitrogen-doped porous carbon electrocatalyst and its preparation method and application |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |