CN115094433A - Hybrid hydrogen production system for coupling electrochemical power supply and super capacitor and control method - Google Patents

Hybrid hydrogen production system for coupling electrochemical power supply and super capacitor and control methodDownload PDFInfo

- Publication number

- CN115094433A CN115094433ACN202210610755.8ACN202210610755ACN115094433ACN 115094433 ACN115094433 ACN 115094433ACN 202210610755 ACN202210610755 ACN 202210610755ACN 115094433 ACN115094433 ACN 115094433A

- Authority

- CN

- China

- Prior art keywords

- hydrogen production

- current

- supercapacitor

- alkaline

- subsystem

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 229910052739hydrogenInorganic materials0.000titleclaimsabstractdescription104

- 239000001257hydrogenSubstances0.000titleclaimsabstractdescription104

- UFHFLCQGNIYNRP-UHFFFAOYSA-NHydrogenChemical compound[H][H]UFHFLCQGNIYNRP-UHFFFAOYSA-N0.000titleclaimsabstractdescription100

- 238000004519manufacturing processMethods0.000titleclaimsabstractdescription98

- 238000000034methodMethods0.000titleclaimsabstractdescription17

- 239000003990capacitorSubstances0.000titleclaimsabstractdescription14

- 230000008878couplingEffects0.000titleclaimsabstractdescription12

- 238000010168coupling processMethods0.000titleclaimsabstractdescription12

- 238000005859coupling reactionMethods0.000titleclaimsabstractdescription12

- 238000005868electrolysis reactionMethods0.000claimsabstractdescription73

- 238000010248power generationMethods0.000claimsabstractdescription38

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsdescription38

- 239000007788liquidSubstances0.000claimsdescription20

- 239000012528membraneSubstances0.000claimsdescription12

- 238000000926separation methodMethods0.000claimsdescription12

- HBBGRARXTFLTSG-UHFFFAOYSA-NLithium ionChemical compound[Li+]HBBGRARXTFLTSG-UHFFFAOYSA-N0.000claimsdescription9

- 229910001416lithium ionInorganic materials0.000claimsdescription9

- 238000004146energy storageMethods0.000claimsdescription6

- DGAQECJNVWCQMB-PUAWFVPOSA-MIlexoside XXIXChemical compoundC[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+]DGAQECJNVWCQMB-PUAWFVPOSA-M0.000claimsdescription3

- WHXSMMKQMYFTQS-UHFFFAOYSA-NLithiumChemical compound[Li]WHXSMMKQMYFTQS-UHFFFAOYSA-N0.000claimsdescription3

- FKNQFGJONOIPTF-UHFFFAOYSA-NSodium cationChemical compound[Na+]FKNQFGJONOIPTF-UHFFFAOYSA-N0.000claimsdescription3

- 239000002253acidSubstances0.000claimsdescription3

- 238000012983electrochemical energy storageMethods0.000claimsdescription3

- 229910052744lithiumInorganic materials0.000claimsdescription3

- 229910052708sodiumInorganic materials0.000claimsdescription3

- 239000011734sodiumSubstances0.000claimsdescription3

- 229910001415sodium ionInorganic materials0.000claimsdescription3

- 230000009977dual effectEffects0.000claims1

- 150000002500ionsChemical class0.000claims1

- 238000010586diagramMethods0.000description3

- 238000009826distributionMethods0.000description3

- 238000007599dischargingMethods0.000description2

- 230000005611electricityEffects0.000description2

- 238000005516engineering processMethods0.000description2

- 230000009286beneficial effectEffects0.000description1

- 230000007547defectEffects0.000description1

- 150000002431hydrogenChemical class0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 230000010355oscillationEffects0.000description1

- 239000000126substanceSubstances0.000description1

- 238000006467substitution reactionMethods0.000description1

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B1/00—Electrolytic production of inorganic compounds or non-metals

- C25B1/01—Products

- C25B1/02—Hydrogen or oxygen

- C25B1/04—Hydrogen or oxygen by electrolysis of water

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B15/00—Operating or servicing cells

- C25B15/02—Process control or regulation

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B9/00—Cells or assemblies of cells; Constructional parts of cells; Assemblies of constructional parts, e.g. electrode-diaphragm assemblies; Process-related cell features

- C25B9/17—Cells comprising dimensionally-stable non-movable electrodes; Assemblies of constructional parts thereof

- C25B9/19—Cells comprising dimensionally-stable non-movable electrodes; Assemblies of constructional parts thereof with diaphragms

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B9/00—Cells or assemblies of cells; Constructional parts of cells; Assemblies of constructional parts, e.g. electrode-diaphragm assemblies; Process-related cell features

- C25B9/60—Constructional parts of cells

- C25B9/65—Means for supplying current; Electrode connections; Electric inter-cell connections

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B9/00—Cells or assemblies of cells; Constructional parts of cells; Assemblies of constructional parts, e.g. electrode-diaphragm assemblies; Process-related cell features

- C25B9/70—Assemblies comprising two or more cells

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J1/00—Circuit arrangements for DC mains or DC distribution networks

- H02J1/04—Constant-current supply systems

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J1/00—Circuit arrangements for DC mains or DC distribution networks

- H02J1/10—Parallel operation of DC sources

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J1/00—Circuit arrangements for DC mains or DC distribution networks

- H02J1/10—Parallel operation of DC sources

- H02J1/106—Parallel operation of DC sources for load balancing, symmetrisation, or sharing

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J1/00—Circuit arrangements for DC mains or DC distribution networks

- H02J1/10—Parallel operation of DC sources

- H02J1/109—Scheduling or re-scheduling the operation of the DC sources in a particular order, e.g. connecting or disconnecting the sources in sequential, alternating or in subsets, to meet a given demand

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J1/00—Circuit arrangements for DC mains or DC distribution networks

- H02J1/14—Balancing the load in a network

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/34—Parallel operation in networks using both storage and other DC sources, e.g. providing buffering

- H02J7/345—Parallel operation in networks using both storage and other DC sources, e.g. providing buffering using capacitors as storage or buffering devices

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/34—Parallel operation in networks using both storage and other DC sources, e.g. providing buffering

- H02J7/35—Parallel operation in networks using both storage and other DC sources, e.g. providing buffering with light sensitive cells

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J2300/00—Systems for supplying or distributing electric power characterised by decentralized, dispersed, or local generation

- H02J2300/20—The dispersed energy generation being of renewable origin

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J2300/00—Systems for supplying or distributing electric power characterised by decentralized, dispersed, or local generation

- H02J2300/20—The dispersed energy generation being of renewable origin

- H02J2300/22—The renewable source being solar energy

- H02J2300/24—The renewable source being solar energy of photovoltaic origin

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J2300/00—Systems for supplying or distributing electric power characterised by decentralized, dispersed, or local generation

- H02J2300/20—The dispersed energy generation being of renewable origin

- H02J2300/28—The renewable source being wind energy

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J2300/00—Systems for supplying or distributing electric power characterised by decentralized, dispersed, or local generation

- H02J2300/40—Systems for supplying or distributing electric power characterised by decentralized, dispersed, or local generation wherein a plurality of decentralised, dispersed or local energy generation technologies are operated simultaneously

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P20/00—Technologies relating to chemical industry

- Y02P20/10—Process efficiency

- Y02P20/133—Renewable energy sources, e.g. sunlight

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Power Engineering (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Automation & Control Theory (AREA)

- Inorganic Chemistry (AREA)

- Electrolytic Production Of Non-Metals, Compounds, Apparatuses Therefor (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及制氢技术领域,尤其是涉及一种耦合电化学电源和超级电容器的混合制氢系统及控制方法。The invention relates to the technical field of hydrogen production, in particular to a hybrid hydrogen production system and a control method coupled with an electrochemical power source and a supercapacitor.

背景技术Background technique

新能源的大类主要分为太阳能,核能,氢能,风能等,其中氢能作为没有任何二次污染产物,最清洁的能源,有望成为未来主要能源之一。电解水制氢是目前最常用的制氢技术之一,其中碱水电解制氢技术相对成熟,已经实现了商业化。对于碱水电解制氢系统的电能来源,主要包括电网、可再生能源等,可再生能源能够实现本质低碳化,实现全产业链无碳生成。The main categories of new energy are solar energy, nuclear energy, hydrogen energy, wind energy, etc. Among them, hydrogen energy, as the cleanest energy source without any secondary pollution, is expected to become one of the main energy sources in the future. Hydrogen production from water electrolysis is one of the most commonly used hydrogen production technologies, among which the alkaline water electrolysis hydrogen production technology is relatively mature and has been commercialized. For the electricity source of the alkaline water electrolysis hydrogen production system, it mainly includes the power grid and renewable energy.

可再生能源主要包括风电和太阳能电池等,但是这些可再生能源会受到气候环境的影响,具有间歇性和不稳定性,例如风向和风速的变化、太阳光角度和强度的变化等,因此进入电解系统的电流存在波动。根据电流的变化特点,典型的电流变化主要分为两大类,一类是电流存在稳定且大范围波动,导致产生的电流急剧变化,直接导致电解槽产氢能力的变化;一类是电流在一个小范围内振荡,导致电解槽系统工作状态存在瞬时的高频次波动,导致电解槽稳定性和使用寿命的下降。目前现有技术中还未有一种考虑可再生能源的上述特性来进行制氢的系统。Renewable energy mainly includes wind power and solar cells, etc., but these renewable energy will be affected by the climate environment, with intermittent and unstable, such as changes in wind direction and speed, changes in the angle and intensity of sunlight, etc., so enter the electrolysis process. The current of the system fluctuates. According to the characteristics of current changes, typical current changes are mainly divided into two categories. One is that the current has stable and large-scale fluctuations, resulting in a sharp change in the generated current, which directly leads to changes in the hydrogen production capacity of the electrolyzer; Oscillation within a small range leads to instantaneous high-frequency fluctuations in the working state of the electrolytic cell system, resulting in a decrease in the stability and service life of the electrolytic cell. At present, there is no system for hydrogen production considering the above-mentioned characteristics of renewable energy in the prior art.

发明内容SUMMARY OF THE INVENTION

本发明的目的就是为了克服上述现有技术存在的缺陷而提供一种能够保证电解制氢系统高效稳定工作、提高能源利用率、延长碱性电解槽和电化学电源的使用寿命的耦合电化学电源和超级电容器的混合制氢系统及控制方法。The purpose of the present invention is to provide a coupled electrochemical power source that can ensure the efficient and stable operation of the electrolytic hydrogen production system, improve the energy utilization rate, and prolong the service life of the alkaline electrolytic cell and the electrochemical power source in order to overcome the defects of the above-mentioned prior art. Hybrid hydrogen production system and control method with supercapacitor.

本发明的目的可以通过以下技术方案来实现:The object of the present invention can be realized through the following technical solutions:

作为本发明的第一方面,提供一种耦合电化学电源和超级电容器的混合制氢系统,所述的混合制氢系统包括碱性电解制氢子系统、分流模块、超级电容器、电化学电源和发电子系统;所述的发电子系统接入分流模块;所述的超级电容器、电化学电源和碱性电解制氢子系统分别接入分流模块;所述的分流模块根据是否存在超过预设阈值的电流波动来将稳定电流输入碱性电解制氢子系统,将波动电流输入超级电容器,将高于碱性电解制氢子系统的电流输入超级电容器和电化学电源。As a first aspect of the present invention, a hybrid hydrogen production system coupled with an electrochemical power source and a supercapacitor is provided. The hybrid hydrogen production system includes an alkaline electrolysis hydrogen production subsystem, a shunt module, a supercapacitor, an electrochemical power source and The power generation subsystem; the power generation subsystem is connected to the shunt module; the supercapacitor, the electrochemical power supply and the alkaline electrolysis hydrogen production subsystem are respectively connected to the shunt module; The stable current is input into the alkaline electrolysis hydrogen production subsystem, the fluctuating current is input into the supercapacitor, and the current higher than the alkaline electrolysis hydrogen production subsystem is input into the supercapacitor and the electrochemical power supply.

作为优选的技术方案,所述的碱性电解制氢子系统包括碱水电解制氢装置和碱性膜电解制氢装置;所述的碱水电解制氢装置和碱性膜电解制氢装置分别接入分流模块。As a preferred technical solution, the alkaline electrolysis hydrogen production subsystem includes an alkaline water electrolysis hydrogen production device and an alkaline membrane electrolysis hydrogen production device; the alkaline water electrolysis hydrogen production device and the alkaline membrane electrolysis hydrogen production device are respectively Access the shunt module.

作为优选的技术方案,所述的碱水电解制氢装置包括碱水电解槽、碱液循环设备和气液分离设备;所述的碱液循环设备和气液分离设备分别接入碱水电解槽;所述的碱水电解槽由正负极、隔膜和端板组装而成。As a preferred technical solution, the alkaline water electrolysis hydrogen production device includes an alkaline water electrolytic cell, an alkaline liquid circulation equipment and a gas-liquid separation equipment; the alkaline liquid circulation equipment and the gas-liquid separation equipment are respectively connected to the alkaline water electrolytic cell; The alkaline water electrolyzer described above is assembled from positive and negative electrodes, diaphragms and end plates.

作为优选的技术方案,所述的碱性膜电解制氢装置包括碱水电解槽、碱液循环设备和气液分离设备;所述的碱液循环设备和气液分离设备分别接入碱水电解槽;所述的碱水电解槽由正负极、碱性膜和端板组装而成。As a preferred technical solution, the alkaline membrane electrolysis hydrogen production device includes an alkaline water electrolytic cell, an alkaline liquid circulation equipment and a gas-liquid separation equipment; the alkaline liquid circulation equipment and the gas-liquid separation equipment are respectively connected to the alkaline water electrolytic cell; The alkaline water electrolyzer is assembled from positive and negative electrodes, alkaline membranes and end plates.

作为优选的技术方案,所述的碱水电解槽的数量为单个或多个。As a preferred technical solution, the number of the alkaline water electrolysis cells is single or multiple.

作为优选的技术方案,所述的超级电容器具体为:高功率密度储能设备。As a preferred technical solution, the supercapacitor is specifically: a high power density energy storage device.

作为优选的技术方案,所述的超级电容器为双电层超级电容器、赝电容超级电容器或电池-电容混合型超级电容器。As a preferred technical solution, the supercapacitor is an electric double layer supercapacitor, a pseudocapacitor supercapacitor or a battery-capacitor hybrid supercapacitor.

作为优选的技术方案,所述的电化学电源具体为:通过电化学储能的高能量密度储能设备。As a preferred technical solution, the electrochemical power source is specifically: a high-energy-density energy storage device through electrochemical energy storage.

作为优选的技术方案,所述的电化学电源为铅酸电池、镍氢电池、锂离子电池、锂电池、钠离子电池、钠电池、双离子电池和水系电池。As a preferred technical solution, the electrochemical power source is a lead-acid battery, a nickel-hydrogen battery, a lithium-ion battery, a lithium battery, a sodium-ion battery, a sodium battery, a dual-ion battery and an aqueous battery.

作为本发明的第二方面,提供一种用于上述混合制氢系统的控制方法,所述的控制方法包括:As a second aspect of the present invention, a control method for the above-mentioned hybrid hydrogen production system is provided, the control method comprising:

步骤1:发电子系统将可再生能源转换成直流电,并输入分流模块;Step 1: The power generation subsystem converts the renewable energy into direct current and inputs it into the shunt module;

步骤2:分流模块检测发电子系统输出电流值;Step 2: The shunt module detects the output current value of the power generation subsystem;

若发电子系统的输出电流超过电解槽的额定电流,则将电流分流,对碱性电解制氢子系统分配100%工况所需的电流,将剩余电流输入电化学电源;If the output current of the power generation subsystem exceeds the rated current of the electrolytic cell, the current will be split, and the current required for 100% of the working conditions will be allocated to the alkaline electrolysis hydrogen production subsystem, and the remaining current will be input into the electrochemical power source;

在对电化学电源充电时,若检测到电流存在超过预设阈值的高频电流波动,则将波动电流分流输入到超级电容器,将稳定电流分流输入到电化学电源;When charging the electrochemical power supply, if it is detected that the current has high-frequency current fluctuations exceeding the preset threshold, the fluctuating current is shunted and input to the supercapacitor, and the stable current is shunted and input to the electrochemical power supply;

若发电子系统的输出电流低于电解槽的额定电流,但高于电解槽的最低工作电流,则将发电子系统的输出电流输入到碱性电解制氢子系统,若电流存在超过预设阈值的高频电流波动,则将波动电流输入超级电容器,或者调用超级电容器为碱性电解制氢子系统供电,以弥补电流波动,对碱性电解制氢子系统进行稳定供电;If the output current of the power generation subsystem is lower than the rated current of the electrolytic cell, but higher than the minimum operating current of the electrolytic cell, the output current of the power generation subsystem is input to the alkaline electrolysis hydrogen production subsystem. If the current exceeds the preset threshold If the high-frequency current fluctuates, the fluctuating current is input into the supercapacitor, or the supercapacitor is called to supply power to the alkaline electrolysis hydrogen production subsystem to compensate for the current fluctuation and provide stable power supply to the alkaline electrolysis hydrogen production subsystem;

若发电子系统的输出电流低于电解槽最低工作电流,则将将发电子系统的输出电流输入到碱性电解制氢子系统,同时调用电化学电源系统同时对电解槽系统供电,若电流信号存在超过预设阈值的高频电流波动,则将波动电流输入到超级电容器或者调用超级电容器弥补电流波动,对碱性电解系统进行稳定供电。If the output current of the power generation subsystem is lower than the minimum working current of the electrolytic cell, the output current of the power generation subsystem will be input to the alkaline electrolysis hydrogen production subsystem, and the electrochemical power supply system will be called at the same time to supply power to the electrolytic cell system. If there are high-frequency current fluctuations exceeding the preset threshold, the fluctuating current is input to the supercapacitor or the supercapacitor is called to make up for the current fluctuation, and the alkaline electrolysis system is stably powered.

与现有技术相比,本发明具有以下有益效果:Compared with the prior art, the present invention has the following beneficial effects:

一、保证电解制氢系统高效稳定工作:本发明中的混合制氢系统及其控制方法在发电子系统在电流低于电解系统最低电流时,电化学电源和超级电容器能够作为电源为电解系统功能,保证电解系统的高效稳定工作;在电流段时间内低于电解系统额定电流时,电化学电源能够提供电能保证电解系统处于额定工况工作;同时采用超级电容器能够消除可再生能源发电高频次波动的特征,使输入电解槽和电化学电源的电流保持一个稳定的状态。1. Ensure the efficient and stable operation of the electrolytic hydrogen production system: the hybrid hydrogen production system and its control method in the present invention can be used as a power source for the electrolytic system function when the current of the power generation subsystem is lower than the minimum current of the electrolytic system. , to ensure the efficient and stable operation of the electrolysis system; when the current is lower than the rated current of the electrolysis system during the period of time, the electrochemical power supply can provide electrical energy to ensure that the electrolysis system works under rated conditions; at the same time, the use of super capacitors can eliminate the high frequency of renewable energy generation. The characteristic of fluctuation keeps the current input to the electrolytic cell and electrochemical power source in a stable state.

二、提高能源利用率:本发明中的混合制氢系统及其控制方法在电流高于电解系统额定电流时,电化学电源和超级电容器能够有效地储存电能,提高可再生能源发电产生电能的利用率。2. Improve energy utilization rate: when the current of the hybrid hydrogen production system and its control method in the present invention is higher than the rated current of the electrolysis system, the electrochemical power source and the supercapacitor can effectively store electric energy, thereby improving the utilization of electric energy generated by renewable energy power generation Rate.

三、延长碱性电解槽和电化学电源的使用寿命:本发明中的混合制氢系统及其控制方法采用超级电容器系统能够消除可再生能源发电高频次波动的特征,使输入电解槽和电化学电源的电流保持一个稳定的状态,显著提升碱性电解槽和电化学电源的使用寿命。3. Extend the service life of the alkaline electrolyzer and the electrochemical power source: the hybrid hydrogen production system and its control method in the present invention use the super capacitor system to eliminate the characteristics of high-frequency fluctuations in the power generation of renewable energy, and make the input electrolyzer and electricity The current of the chemical power source is maintained in a stable state, which significantly increases the service life of alkaline electrolyzers and electrochemical power sources.

附图说明Description of drawings

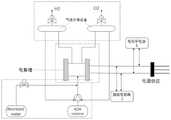

图1为本发明实施例中混合制氢系统的结构示意图;1 is a schematic structural diagram of a hybrid hydrogen production system in an embodiment of the present invention;

图2为本发明实施例中混合制氢系统的另一结构示意图。FIG. 2 is another schematic structural diagram of the hybrid hydrogen production system in the embodiment of the present invention.

具体实施方式Detailed ways

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例是本发明的一部分实施例,而不是全部实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动的前提下所获得的所有其他实施例,都应属于本发明保护的范围。The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

此处所称的“一个实施例”或“实施例”是指可包含于本申请至少一个实现方式中的特定特征、结构或特性。在本申请的描述中,需要理解的是,术语“上”、“下”、“左”、“右”、“顶”、“底”等指示的方位或位置关系为基于附图所示的方位或位置关系,仅是为了便于描述本申请和简化描述,而不是指示或暗示所指的装置或元件必须具有特定的方位、以特定的方位构造和操作,因此不能理解为对本申请的限制。此外,术语“第一”、“第二”仅用于描述目的,而不能理解为指示或暗示相对重要性或者隐含指明所指示的技术特征的数量。由此,限定有“第一”、“第二”的特征可以明示或者隐含的包括一个或者更多个该特征。而且,术语“第一”、“第二”等是用于区别类似的对象,而不必用于描述特定的顺序或先后次序。应该理解这样使用的数据在适当情况下可以互换,以便这里描述的本申请的实施例能够以除了在这里图示或描述的那些以外的顺序实施。Reference herein to "one embodiment" or "an embodiment" refers to a particular feature, structure, or characteristic that may be included in at least one implementation of the present application. In the description of the present application, it should be understood that the orientations or positional relationships indicated by the terms "upper", "lower", "left", "right", "top", "bottom", etc. are based on those shown in the accompanying drawings. The orientation or positional relationship is only for the convenience of describing the present application and simplifying the description, rather than indicating or implying that the indicated device or element must have a specific orientation, be constructed and operated in a specific orientation, and therefore should not be construed as a limitation on the present application. In addition, the terms "first" and "second" are only used for descriptive purposes, and should not be construed as indicating or implying relative importance or implying the number of indicated technical features. Thus, a feature defined as "first" or "second" may expressly or implicitly include one or more of that feature. Also, the terms "first," "second," etc. are used to distinguish between similar objects, and are not necessarily used to describe a particular order or precedence. It is to be understood that data so used may be interchanged under appropriate circumstances so that the embodiments of the application described herein can be practiced in sequences other than those illustrated or described herein.

图1和图2是本申请实施例中提供的一种耦合电化学电源和超级电容器的混合制氢系统的结构示意图,包括:碱性电解制氢子系统1、分流模块2、超级电容器3、发电子系统4和电化学电源5。发电子系统4接入分流模块2,超级电容器3、电化学电源5和碱性电解制氢子系统1分别接入分流模块2,分流模块2根据是否存在超过预设阈值的电流波动来将稳定电流输入碱性电解制氢子系统1,将波动电流输入超级电容器3。1 and 2 are schematic structural diagrams of a hybrid hydrogen production system coupling an electrochemical power source and a supercapacitor provided in the embodiments of the present application, including: an alkaline electrolysis

具体的,碱性电解制氢子系统1包括碱水电解制氢装置和碱性膜电解制氢装置,碱水电解制氢装置和碱性膜电解制氢装置分别接入分流模块。Specifically, the alkaline electrolysis

可选的,碱水电解制氢装置包括碱水电解槽、碱液循环设备和气液分离设备,碱液循环设备和气液分离设备分别接入碱水电解槽,碱水电解槽由正负极、隔膜和端板组装而成。常见的产氢能力包括但不限于200Nm3/h,500Nm3/h,800Nm3/h,1000Nm3/h,1500Nm3/h,3000Nm3/h等。Optionally, the alkaline water electrolysis hydrogen production device includes an alkaline water electrolytic cell, an alkaline liquid circulation equipment and a gas-liquid separation equipment, and the alkaline liquid circulation equipment and the gas-liquid separation equipment are respectively connected to the alkaline water electrolytic cell. The diaphragm and end plate are assembled. Common hydrogen production capacities include but are not limited to 200Nm3/h, 500Nm3/h, 800Nm3/h, 1000Nm3/h, 1500Nm3/h, 3000Nm3/h, etc.

可选的,碱性膜电解制氢装置包括碱水电解槽、碱液循环设备和气液分离设备,碱液循环设备和气液分离设备分别接入碱水电解槽,碱水电解槽由正负极、碱性膜和端板组装而成。常见的产氢能力包括但不限于50Nm3/h,100Nm3/h,200Nm3/h,500Nm3/h等。Optionally, the alkaline membrane electrolysis hydrogen production device includes an alkaline water electrolytic cell, an alkaline liquid circulation device and a gas-liquid separation device, and the alkaline liquid circulation equipment and the gas-liquid separation equipment are respectively connected to the alkaline water electrolytic cell, and the alkaline water electrolytic cell consists of positive and negative electrodes. , alkaline membrane and end plate assembled. Common hydrogen production capacities include but are not limited to 50Nm3/h, 100Nm3/h, 200Nm3/h, 500Nm3/h, etc.

可选的,碱水电解槽的数量为单个或多个。Optionally, the number of alkaline water electrolysis cells is single or multiple.

具体的,超级电容器具体为:高功率密度储能设备,可以选用双电层超级电容器、赝电容超级电容器或电池-电容混合型超级电容器。Specifically, the supercapacitor is specifically: a high power density energy storage device, an electric double layer supercapacitor, a pseudocapacitor supercapacitor or a battery-capacitor hybrid supercapacitor can be selected.

具体的,电化学电源具体为:通过电化学储能的高能量密度储能设备,可以选用铅酸电池、镍氢电池、锂离子电池、锂电池、钠离子电池、钠电池、双离子电池和水系电池。Specifically, the electrochemical power source is specifically: a high-energy-density energy storage device through electrochemical energy storage, which can be selected from lead-acid batteries, nickel-hydrogen batteries, lithium-ion batteries, lithium batteries, sodium-ion batteries, sodium batteries, dual-ion batteries and Water battery.

以上是关于系统实施例的介绍,以下通过方法实施例,对本发明所述方案进行进一步说明。The above is an introduction to the system embodiments, and the solution of the present invention is further described below through the method embodiments.

一种用上述混合制氢系统的控制方法,包括:A control method using the above-mentioned mixed hydrogen production system, comprising:

步骤1:发电子系统将可再生能源转换成直流电,并输入分流模块;Step 1: The power generation subsystem converts the renewable energy into direct current and inputs it into the shunt module;

步骤2:分流模块检测发电子系统输出电流值;Step 2: The shunt module detects the output current value of the power generation subsystem;

若发电子系统的输出电流超过电解槽的额定电流,则将电流分流,对碱性电解制氢子系统分配100%工况所需的电流,将剩余电流输入电化学电源;If the output current of the power generation subsystem exceeds the rated current of the electrolytic cell, the current will be split, and the current required for 100% of the working conditions will be allocated to the alkaline electrolysis hydrogen production subsystem, and the remaining current will be input into the electrochemical power source;

在对电化学电源充电时,若检测到电流存在超过预设阈值的高频电流波动,则将波动电流分流输入到超级电容器,将稳定电流分流输入到电化学电源;When charging the electrochemical power supply, if it is detected that the current has high-frequency current fluctuations exceeding the preset threshold, the fluctuating current is shunted and input to the supercapacitor, and the stable current is shunted and input to the electrochemical power supply;

若发电子系统的输出电流低于电解槽的额定电流,但高于电解槽的最低工作电流,则将发电子系统的输出电流输入到碱性电解制氢子系统,若电流存在超过预设阈值的高频电流波动,则将波动电流输入超级电容器,或者调用超级电容器为碱性电解制氢子系统供电,以弥补电流波动,对碱性电解制氢子系统进行稳定供电;If the output current of the power generation subsystem is lower than the rated current of the electrolytic cell, but higher than the minimum operating current of the electrolytic cell, the output current of the power generation subsystem is input to the alkaline electrolysis hydrogen production subsystem. If the current exceeds the preset threshold If the high-frequency current fluctuates, the fluctuating current is input into the supercapacitor, or the supercapacitor is called to supply power to the alkaline electrolysis hydrogen production subsystem to compensate for the current fluctuation and provide stable power supply to the alkaline electrolysis hydrogen production subsystem;

若发电子系统的输出电流低于电解槽最低工作电流,则将将发电子系统的输出电流输入到碱性电解制氢子系统,同时调用电化学电源系统同时对电解槽系统供电,若电流信号存在超过预设阈值的高频电流波动,则将波动电流输入到超级电容器或者调用超级电容器弥补电流波动,对碱性电解系统进行稳定供电。If the output current of the power generation subsystem is lower than the minimum working current of the electrolytic cell, the output current of the power generation subsystem will be input to the alkaline electrolysis hydrogen production subsystem, and the electrochemical power supply system will be called at the same time to supply power to the electrolytic cell system. If there are high-frequency current fluctuations exceeding the preset threshold, the fluctuating current is input to the supercapacitor or the supercapacitor is called to make up for the current fluctuation, and the alkaline electrolysis system is stably powered.

下面提供三个应用例来验证本实施例所提混合制氢系统及其控制方法的有效性:Three application examples are provided below to verify the effectiveness of the hybrid hydrogen production system and its control method proposed in this embodiment:

一、针对可再生能源发电产生的电流密度具有间歇性和不稳定性的特点,提出一种耦合碱性电解系统,电化学电源和超级电容器的混合制氢系统,碱性电解系统为碱水电解系统,额定功率为5MW,产氢效率为1000Nm3/h,额定电流为6000A;电化学电源为锂离子电池,额定功率为2MW;超级电容器为双电层电容器,额定功率为0.5MW。当可再生能源发电端电流输入为8000A,瞬时电流波动正负100A,通过电流分配,6000A稳定电流用于电解系统产氢,2000A对锂离子电池充电,过程中利用超级电容器高频次充放电消纳可再生能源发生瞬时电流波动。1. Aiming at the intermittent and unstable characteristics of the current density generated by renewable energy power generation, a hybrid hydrogen production system coupled with an alkaline electrolysis system, an electrochemical power source and a supercapacitor is proposed. The alkaline electrolysis system is an alkaline water electrolysis system. The system has a rated power of 5MW, a hydrogen production efficiency of 1000Nm3/h, and a rated current of 6000A; the electrochemical power source is a lithium-ion battery with a rated power of 2MW; the supercapacitor is an electric double-layer capacitor with a rated power of 0.5MW. When the current input of the renewable energy power generation terminal is 8000A, the instantaneous current fluctuates plus or minus 100A, through the current distribution, the stable current of 6000A is used for the electrolysis system to produce hydrogen, and the 2000A is used to charge the lithium-ion battery. Instantaneous current fluctuations occur in nano renewable energy sources.

二、针对可再生能源发电产生的电流密度具有间歇性和不稳定性的特点,提出一种耦合碱性电解系统,电化学电源和超级电容器的混合制氢系统,碱性电解系统为碱水电解系统,额定功率为5MW,产氢效率为1000Nm3/h,额定电流为6000A;电化学电源为锂离子电池,额定功率为2MW;超级电容器为双电层电容器,额定功率为0.5MW。当可再生能源发电端电流输入为4000A,瞬时电流波动正负100A,通过电流分配,电解系统产氢的工作输入电流稳定在5000A,其中1000A电流由锂离子电池提供,过程中利用超级电容器高频次充放电消纳可再生能源发生瞬时电流波动。2. Aiming at the intermittent and unstable characteristics of the current density generated by renewable energy power generation, a hybrid hydrogen production system that couples an alkaline electrolysis system, an electrochemical power source and a supercapacitor is proposed. The alkaline electrolysis system is an alkaline water electrolysis system. The system has a rated power of 5MW, a hydrogen production efficiency of 1000Nm3/h, and a rated current of 6000A; the electrochemical power source is a lithium-ion battery with a rated power of 2MW; the supercapacitor is an electric double-layer capacitor with a rated power of 0.5MW. When the current input of the renewable energy power generation terminal is 4000A, and the instantaneous current fluctuates plus or minus 100A, through the current distribution, the working input current of the electrolysis system for hydrogen production is stabilized at 5000A, of which 1000A is provided by the lithium-ion battery, and the supercapacitor high-frequency is used in the process. Instantaneous current fluctuations occur during secondary charging and discharging to absorb renewable energy.

三、针对可再生能源发电产生的电流密度具有间歇性和不稳定性的特点,提出一种耦合碱性电解系统,电化学电源和超级电容器的混合制氢系统,碱性电解系统为碱水电解系统,额定功率为5MW,产氢效率为1000Nm3/h,额定电流为6000A;电化学电源为锂离子电池,额定功率为2MW;超级电容器为双电层电容器,额定功率为0.5MW。当可再生能源发电端电流输入为1000A,瞬时电流波动正负50A,通过电流分配,电解系统产氢的工作输入电流稳定在1200A(最低工作电流),其中200A电流由锂离子电池提供,过程中利用超级电容器高频次充放电消纳可再生能源发生瞬时电流波动。3. In view of the intermittent and unstable characteristics of the current density generated by renewable energy power generation, a hybrid hydrogen production system coupled with an alkaline electrolysis system, an electrochemical power source and a supercapacitor is proposed. The alkaline electrolysis system is an alkaline water electrolysis system. The system has a rated power of 5MW, a hydrogen production efficiency of 1000Nm3/h, and a rated current of 6000A; the electrochemical power source is a lithium-ion battery with a rated power of 2MW; the supercapacitor is an electric double-layer capacitor with a rated power of 0.5MW. When the current input of the renewable energy power generation terminal is 1000A, the instantaneous current fluctuates plus or minus 50A, and through the current distribution, the working input current of the electrolysis system for hydrogen production is stable at 1200A (minimum working current), of which 200A is provided by the lithium-ion battery. Use supercapacitors high-frequency charging and discharging to absorb instantaneous current fluctuations in renewable energy.

以上所述,仅为本发明的具体实施方式,但本发明的保护范围并不局限于此,任何熟悉本技术领域的技术人员在本发明揭露的技术范围内,可轻易想到各种等效的修改或替换,这些修改或替换都应涵盖在本发明的保护范围之内。因此,本发明的保护范围应以权利要求的保护范围为准。The above are only specific embodiments of the present invention, but the protection scope of the present invention is not limited to this. Any person skilled in the art can easily think of various equivalents within the technical scope disclosed by the present invention. Modifications or substitutions should be included within the protection scope of the present invention. Therefore, the protection scope of the present invention should be subject to the protection scope of the claims.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210610755.8ACN115094433A (en) | 2022-05-31 | 2022-05-31 | Hybrid hydrogen production system for coupling electrochemical power supply and super capacitor and control method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210610755.8ACN115094433A (en) | 2022-05-31 | 2022-05-31 | Hybrid hydrogen production system for coupling electrochemical power supply and super capacitor and control method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN115094433Atrue CN115094433A (en) | 2022-09-23 |

Family

ID=83289179

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210610755.8APendingCN115094433A (en) | 2022-05-31 | 2022-05-31 | Hybrid hydrogen production system for coupling electrochemical power supply and super capacitor and control method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN115094433A (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115637447A (en)* | 2022-10-31 | 2023-01-24 | 中车山东风电有限公司 | A renewable energy coupled cascade hydrogen production system and hydrogen production method |

| WO2023231274A1 (en)* | 2022-05-31 | 2023-12-07 | 同济大学 | Hybrid hydrogen production system coupled with supercapacitor, and control method therefor |

| CN118895520A (en)* | 2024-08-16 | 2024-11-05 | 上海科技大学 | A hybrid electrolysis hydrogen production system and an energy management method based on its dynamic characteristics |

| CN118895519A (en)* | 2024-08-16 | 2024-11-05 | 上海科技大学 | A hybrid electrolysis hydrogen production system and its energy management and capacity configuration method |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101863138B1 (en)* | 2017-12-11 | 2018-05-31 | 주식회사 키스톤에너지 | Power-controlled energy storage device using lithium battery and supercapacitor |

| CN109936156A (en)* | 2019-01-30 | 2019-06-25 | 中国华能集团清洁能源技术研究院有限公司 | A high-efficiency and high-safety wind power hydrogen production peak regulation and frequency regulation system |

| CN111668860A (en)* | 2020-05-18 | 2020-09-15 | 南京工程学院 | A wind-hydrogen coupled power generation system and its control method |

| WO2021082423A1 (en)* | 2019-10-28 | 2021-05-06 | 阳光电源股份有限公司 | Direct-current coupling hydrogen production system and control method therefor |

| CN113249738A (en)* | 2021-05-28 | 2021-08-13 | 全球能源互联网研究院有限公司 | Novel water electrolysis hydrogen production system and operation method thereof |

| CN114243782A (en)* | 2021-12-23 | 2022-03-25 | 温州大学 | Hybrid energy storage energy routing management system based on wave energy power generation |

| CN114447968A (en)* | 2022-01-10 | 2022-05-06 | 中国长江三峡集团有限公司 | Large-scale photovoltaic electrolyzed water hydrogen production system and method utilizing hybrid energy storage device |

- 2022

- 2022-05-31CNCN202210610755.8Apatent/CN115094433A/enactivePending

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101863138B1 (en)* | 2017-12-11 | 2018-05-31 | 주식회사 키스톤에너지 | Power-controlled energy storage device using lithium battery and supercapacitor |

| CN109936156A (en)* | 2019-01-30 | 2019-06-25 | 中国华能集团清洁能源技术研究院有限公司 | A high-efficiency and high-safety wind power hydrogen production peak regulation and frequency regulation system |

| WO2021082423A1 (en)* | 2019-10-28 | 2021-05-06 | 阳光电源股份有限公司 | Direct-current coupling hydrogen production system and control method therefor |

| CN111668860A (en)* | 2020-05-18 | 2020-09-15 | 南京工程学院 | A wind-hydrogen coupled power generation system and its control method |

| CN113249738A (en)* | 2021-05-28 | 2021-08-13 | 全球能源互联网研究院有限公司 | Novel water electrolysis hydrogen production system and operation method thereof |

| CN114243782A (en)* | 2021-12-23 | 2022-03-25 | 温州大学 | Hybrid energy storage energy routing management system based on wave energy power generation |

| CN114447968A (en)* | 2022-01-10 | 2022-05-06 | 中国长江三峡集团有限公司 | Large-scale photovoltaic electrolyzed water hydrogen production system and method utilizing hybrid energy storage device |

Non-Patent Citations (1)

| Title |

|---|

| FANG, RUIMING等: ""Control strategy of electrolyzer in a wind-hydrogen system considering the constraints of switching times"", 《INTERNATIONAL JOURNAL OF HYDROGEN ENERGY》, vol. 44, no. 36, pages 25104 - 25111, XP085832630, DOI: 10.1016/j.ijhydene.2019.03.033* |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023231274A1 (en)* | 2022-05-31 | 2023-12-07 | 同济大学 | Hybrid hydrogen production system coupled with supercapacitor, and control method therefor |

| CN115637447A (en)* | 2022-10-31 | 2023-01-24 | 中车山东风电有限公司 | A renewable energy coupled cascade hydrogen production system and hydrogen production method |

| CN118895520A (en)* | 2024-08-16 | 2024-11-05 | 上海科技大学 | A hybrid electrolysis hydrogen production system and an energy management method based on its dynamic characteristics |

| CN118895519A (en)* | 2024-08-16 | 2024-11-05 | 上海科技大学 | A hybrid electrolysis hydrogen production system and its energy management and capacity configuration method |

| CN118895520B (en)* | 2024-08-16 | 2025-06-03 | 上海科技大学 | A hybrid electrolysis hydrogen production system and an energy management method based on its dynamic characteristics |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN115094433A (en) | Hybrid hydrogen production system for coupling electrochemical power supply and super capacitor and control method | |

| CN102522767B (en) | Schedulable-type photovoltaic energy storage grid-connected power generation system and operating method thereof | |

| CN102842963B (en) | Secondary battery and super capacitor mixed energy storage management system | |

| CN106057477B (en) | A kind of water system Na ion chargeable capacitor batteries and preparation method thereof | |

| CN115011969A (en) | A hybrid hydrogen production system coupled with supercapacitors and its control method | |

| CN101309017A (en) | A complementary power supply system for wind power generation and photovoltaic power generation based on supercapacitor battery hybrid energy storage | |

| CN207587857U (en) | A kind of zinc-nickel single flow battery | |

| CN115882515A (en) | Micro-grid system for cooperating multi-type electrolytic hydrogen production and energy storage battery and operation method | |

| CN106099981B (en) | A kind of smooth hydrogen hybrid power system power coordination control method | |

| CN105680082A (en) | Long-lifetime zinc-bromine flow battery structure and electrolyte | |

| CN106876765B (en) | A flow battery stack | |

| CN102867978A (en) | Flow energy storage battery structure | |

| CN105514531B (en) | A kind of lithium ion-halogen flow battery | |

| CN116979703A (en) | Hydrogen-electricity hybrid energy storage system and energy management method thereof | |

| CN106532093A (en) | Quinone metal redox couple flow cell system | |

| CN111312526A (en) | Battery-super capacitor hybrid energy storage device and preparation method thereof | |

| CN118763226A (en) | Sodium supplement material and preparation method thereof, positive electrode sheet, and sodium ion battery | |

| CN104092280A (en) | Fuel cell standby power source system based on super capacitor starting | |

| CN106602181A (en) | Chlorine-magnesium battery and energy storage method thereof | |

| CN112491081A (en) | Combined power generation system | |

| CN106450404A (en) | Flow battery stack | |

| CN207410098U (en) | Empty iron clad aluminum-air, lithium ion battery drive system | |

| CN214013879U (en) | A power frequency modulation system coupled with supercapacitor and lithium battery | |

| Antonucci et al. | Electrochemical energy storage | |

| Hasan et al. | A review of grid-connected supercapacitor systems |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20220923 |