CN114965246A - Comprehensive environment corrosion state characterization sensor and real-time co-location monitoring method - Google Patents

Comprehensive environment corrosion state characterization sensor and real-time co-location monitoring methodDownload PDFInfo

- Publication number

- CN114965246A CN114965246ACN202210539183.9ACN202210539183ACN114965246ACN 114965246 ACN114965246 ACN 114965246ACN 202210539183 ACN202210539183 ACN 202210539183ACN 114965246 ACN114965246 ACN 114965246A

- Authority

- CN

- China

- Prior art keywords

- pair

- corrosion

- electrodes

- sensor

- metal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N17/00—Investigating resistance of materials to the weather, to corrosion, or to light

- G01N17/02—Electrochemical measuring systems for weathering, corrosion or corrosion-protection measurement

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N17/00—Investigating resistance of materials to the weather, to corrosion, or to light

- G01N17/04—Corrosion probes

- G—PHYSICS

- G01—MEASURING; TESTING

- G01R—MEASURING ELECTRIC VARIABLES; MEASURING MAGNETIC VARIABLES

- G01R27/00—Arrangements for measuring resistance, reactance, impedance, or electric characteristics derived therefrom

- G01R27/02—Measuring real or complex resistance, reactance, impedance, or other two-pole characteristics derived therefrom, e.g. time constant

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Chemical & Material Sciences (AREA)

- Ecology (AREA)

- Environmental & Geological Engineering (AREA)

- Environmental Sciences (AREA)

- Health & Medical Sciences (AREA)

- Biodiversity & Conservation Biology (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Investigating Or Analyzing Materials By The Use Of Electric Means (AREA)

- Testing Resistance To Weather, Investigating Materials By Mechanical Methods (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及环境腐蚀状态检测设备,具体的说是一种综合环境腐蚀状态表征传感器和实时同位监测方法。The invention relates to environmental corrosion state detection equipment, in particular to a comprehensive environmental corrosion state characterization sensor and a real-time isotopic monitoring method.

背景技术Background technique

随着我国现代化深入发展,电气设备在其技术复杂程度和对环境的敏感性方面不断提高,也大大的增强了其对环境适应性的要求。特别在我国南方沿海、南方热带海岛地区具有高温、高辐照、高湿和高盐雾的显著气候特点,环境苛刻,电气设备环境故障失效问题突出。在该环境下运行电气设备极易发生腐蚀,引起电气性能下降、故障失效等问题,频繁的更换与维护造成严重经济损失。金属大气腐蚀起因于电解液薄膜下形成微电池所引发的电化学腐蚀;金属大气腐蚀与外界环境密切相关,因此对金属大气腐蚀进行测量的同时,监测表面状态及环境特征对掌握材料的腐蚀特性十分重要。为保障电子电气设备安全运行,需要对其设备腐蚀速率、表面状态特征进行实时同位监测。With the in-depth development of my country's modernization, the technical complexity of electrical equipment and the sensitivity to the environment have been continuously improved, and its requirements for environmental adaptability have also been greatly enhanced. Especially in the coastal areas of southern my country and tropical islands in the south, there are significant climatic characteristics of high temperature, high radiation, high humidity and high salt fog, the environment is harsh, and the problem of environmental failures of electrical equipment is prominent. Electrical equipment operating in this environment is prone to corrosion, causing electrical performance degradation, failures and other problems, and frequent replacement and maintenance cause serious economic losses. Atmospheric metal corrosion is caused by electrochemical corrosion caused by the formation of micro-batteries under the electrolyte film; atmospheric corrosion of metals is closely related to the external environment, so while measuring atmospheric corrosion of metals, monitoring the surface state and environmental characteristics is essential to grasp the corrosion characteristics of materials very important. In order to ensure the safe operation of electrical and electronic equipment, it is necessary to carry out real-time co-location monitoring of the corrosion rate and surface state characteristics of the equipment.

发明内容SUMMARY OF THE INVENTION

本发明所要解决的技术问题之一是:提供一种综合环境腐蚀状态表征传感器,以解决现有技术中难以实现金属大气腐蚀速率和表面湿润状态进行实时同位监测的问题。One of the technical problems to be solved by the present invention is to provide a comprehensive environmental corrosion state characterization sensor, so as to solve the problem in the prior art that it is difficult to realize real-time co-location monitoring of metal atmospheric corrosion rate and surface wetness state.

解决上述技术问题,本发明所采用的技术方案如下:To solve the above-mentioned technical problems, the technical scheme adopted in the present invention is as follows:

一种综合环境腐蚀状态表征传感器,其特征在于,包括:传感器探头;A comprehensive environmental corrosion state characterization sensor, characterized by comprising: a sensor probe;

所述传感器探头包括玻璃基板,该玻璃基板的顶面设有叉指电极和绝缘材料,所述叉指电极由沿电极宽度方向依次循环排列且长度宽度厚度一致的第一对电极、第二对电极和标准工作电极构成,且任意相邻的两个电极之间均留有间隙,所述绝缘材料填充所述间隙,且所述叉指电极的顶面和绝缘材料的顶面共面构成所述传感器探头的测试面,其中,所述标准工作电极采用被测金属,所述第一对电极和第二对电极采用不同于被测金属的同种惰性金属,且所述惰性金属的自然电位高于所述标准工作电极,所述绝缘材料的作用是使所述测试面成为平面,以避免液滴附着时受各个电极之间的间隙凹槽影响而无法正常铺展或影响铺展方向。The sensor probe includes a glass substrate, and the top surface of the glass substrate is provided with interdigital electrodes and insulating materials. The electrode and the standard working electrode are formed, and a gap is left between any two adjacent electrodes, the insulating material fills the gap, and the top surface of the interdigital electrode and the top surface of the insulating material are coplanar to form the structure. The test surface of the sensor probe, wherein the standard working electrode adopts the metal to be measured, the first pair of electrodes and the second pair of electrodes adopt the same kind of inert metal different from the metal to be measured, and the natural potential of the inert metal Higher than the standard working electrode, the function of the insulating material is to make the test surface flat, so as to prevent the droplet from being affected by the gap grooves between the electrodes and not spreading normally or affecting the spreading direction when the droplet is attached.

优选的:所述第一对电极、第二对电极和标准工作电极均通过物理气相沉积技术即PVD技术在所述玻璃基板的顶面沉积相应金属形成。Preferably: the first pair of electrodes, the second pair of electrodes and the standard working electrode are formed by depositing corresponding metals on the top surface of the glass substrate by physical vapor deposition technology, namely PVD technology.

优选的:所述第一对电极、第二对电极和标准工作电极的沉积厚度在以上5μm,以保证电极能够在被测环境中长时间使用;所述第一对电极、第二对电极和标准工作电极的最小宽度以及所述间隙的最小宽度均为50μm。Preferably: the deposition thickness of the first pair of electrodes, the second pair of electrodes and the standard working electrode is above 5 μm to ensure that the electrodes can be used for a long time in the measured environment; the first pair of electrodes, the second pair of electrodes and the The minimum width of the standard working electrode and the minimum width of the gap are both 50 μm.

其中:本发明的综合环境腐蚀状态表征传感器可以仅设置所述传感器探头作为独立产品,将下述实施例的零阻电流计、激励信号生成电路、电流测量电路、控制器和温湿度传感器作为综合环境腐蚀状态表征传感器的外部电路,也可以如下述实施例般将零阻电流计、激励信号生成电路、电流测量电路、控制器和温湿度传感器集成到综合环境腐蚀状态表征传感器内。Wherein: the comprehensive environmental corrosion state characterization sensor of the present invention can only set the sensor probe as an independent product, and use the zero-resistance ammeter, excitation signal generation circuit, current measurement circuit, controller and temperature and humidity sensor of the following embodiments as a comprehensive The external circuit of the environmental corrosion state characterization sensor can also integrate a zero-resistance ammeter, an excitation signal generation circuit, a current measurement circuit, a controller and a temperature and humidity sensor into a comprehensive environmental corrosion state characterization sensor as in the following embodiments.

作为本发明的优选实施方式:所述综合环境腐蚀状态表征传感器还包括零阻电流计、激励信号生成电路和电流测量电路;As a preferred embodiment of the present invention: the comprehensive environmental corrosion state characterization sensor further includes a zero-resistance ammeter, an excitation signal generation circuit and a current measurement circuit;

第一对电极引线电性连接在每一个所述第一对电极与第一对电极汇流端之间;第二对电极引线电性连接在每一个所述第二对电极与第二对电极汇流端之间,且所述第二对电极汇流端接地;标准工作电极引线电性连接在每一个所述标准工作电极与标准工作电极汇流端之间;The first pair of electrode leads are electrically connected between each of the first pair of electrodes and the bus terminal of the first pair of electrodes; the second pair of electrode leads are electrically connected between each of the second pair of electrodes and the second pair of electrodes. between the terminals, and the second pair of electrode bus terminals is grounded; the standard working electrode leads are electrically connected between each of the standard working electrodes and the standard working electrode bus terminals;

所述零阻电流计由第一运算放大器和第一反馈电阻组成,所述第一运算放大器的同相输入端接地,反相输入端分为两路,一路与所述标准工作电极汇流端电性连接,另一路通过第一反馈电阻与所述第一运算放大器的输出端电性连接;在所述传感器探头的测试面曝露于被测环境时,所述零阻电流计(也即第一运算放大器的输出端)输出实时关联所述被测环境对所述被测金属的腐蚀速率的腐蚀电流信号;The zero-resistance ammeter is composed of a first operational amplifier and a first feedback resistor. The non-inverting input terminal of the first operational amplifier is grounded, and the inverting input terminal is divided into two paths, one of which is electrically connected to the bus terminal of the standard working electrode. connection, and the other way is electrically connected to the output end of the first operational amplifier through the first feedback resistor; when the test surface of the sensor probe is exposed to the measured environment, the zero-resistance ammeter (that is, the first operational amplifier) The output end of the amplifier) outputs a corrosion current signal correlating in real time the corrosion rate of the tested environment to the tested metal;

所述电流测量电路由第二运算放大器和第二反馈电阻组成,所述第二运算放大器的同相输入端接入偏置电压,反相输入端分为两路,一路与所述第一对电极汇流端电性连接,另一路通过第二反馈电阻与所述第二运算放大器的输出端电性连接;在所述传感器探头的测试面曝露于被测环境且所述激励信号生成电路对所述第二对电极汇流端施加定频交流激励信号时,所述电流测量电路也即第二运算放大器的输出端输出实时关联所述被测金属(也即所述传感器探头的测试面)在所述被测环境下的表面湿润状态的反馈电流信号;其中,所述定频交流激励信号的频率通过对本发明传感器的材质、结构理论分析和试验数据所得,在该频率下,本发明传感器在润湿和非润湿状态变化的过程中,其阻抗值有较为明显且重复性较好的变化;所述定频交流激励信号的电压与激励信号生成电路、电流测量电路的设计有关,该电压应能确保可以获得足够分辨率的且稳定的反馈电流信号,以确保表面润湿状态测量的准确性。The current measurement circuit is composed of a second operational amplifier and a second feedback resistor. The non-inverting input terminal of the second operational amplifier is connected to a bias voltage, and the inverting input terminal is divided into two paths, one of which is connected to the first pair of electrodes. The bus terminal is electrically connected, and the other channel is electrically connected to the output terminal of the second operational amplifier through a second feedback resistor; the test surface of the sensor probe is exposed to the measured environment, and the excitation signal generation circuit When a constant-frequency AC excitation signal is applied to the second pair of electrode bus ends, the output of the current measurement circuit, that is, the output end of the second operational amplifier, correlates in real time with the measured metal (that is, the test surface of the sensor probe) in the The feedback current signal of the surface wet state under the measured environment; wherein, the frequency of the constant-frequency AC excitation signal is obtained by theoretical analysis of the material and structure of the sensor of the present invention and experimental data, and at this frequency, the sensor of the present invention is wetted at this frequency. In the process of changing from the non-wetting state to the non-wetting state, its impedance value has obvious and repeatable changes; the voltage of the constant-frequency AC excitation signal is related to the design of the excitation signal generation circuit and the current measurement circuit, and the voltage should be able to Ensure that a stable feedback current signal with sufficient resolution can be obtained to ensure the accuracy of the surface wetting state measurement.

从而,本发明的综合环境腐蚀状态表征传感器,采用由玻璃基板、绝缘材料以及依次循环排列的第一对电极、第二对电极和标准工作电极构成的传感器探头,通过零阻电流计对标准工作电极汇流端和第二对电极汇流端进行测量,得到实时关联传感器探头所在被测环境对标准工作电极所采用被测金属的腐蚀速率的腐蚀电流信号,并在激励信号生成电路对第二对电极汇流端施加定频交流激励信号时,通过电流测量电路对第一对电极汇流端和第二对电极汇流端进行测量,得到实时关联所述被测金属在所述被测环境下的表面湿润状态的反馈电流信号;因此,本发明能够实现对金属大气腐蚀速率和表面湿润状态的实时同位监测,保证了两个监测结果的空间对应性与时效性。Therefore, the comprehensive environmental corrosion state characterization sensor of the present invention adopts a sensor probe composed of a glass substrate, an insulating material, and a first pair of electrodes, a second pair of electrodes and a standard working electrode arranged in sequence, and uses a zero-resistance ammeter to measure the standard working electrode. The electrode bus terminal and the second pair of electrode bus terminals are measured to obtain a corrosion current signal that correlates in real time with the corrosion rate of the measured metal used in the standard working electrode in the measured environment where the sensor probe is located. When a constant-frequency AC excitation signal is applied to the bus terminal, the first pair of electrode bus terminals and the second pair of electrode bus terminals are measured through the current measurement circuit, and the surface wet state of the metal to be measured in the measured environment is obtained in real time. Therefore, the present invention can realize the real-time co-location monitoring of the metal atmospheric corrosion rate and the surface wet state, and ensure the spatial correspondence and timeliness of the two monitoring results.

其中,测得所述腐蚀电流信号的原理为:在所述传感器探头的测试面曝露于会引起金属大气腐蚀的润湿的被测环境时,受被测环境影响,会在所述传感器探头的测试面形成薄液膜,所述标准工作电极和与其临近的第二对电极之间通过薄液膜构成电气回路,此状态下满足大气腐蚀发生的基本条件;标准工作电极和第二对电极该两种采用异种金属的电极发生的电偶腐蚀,使得所述零阻电流计监测到电化学反应电流,也即所述第一运算放大器的输出端以电压方式输出实时关联所述被测环境对所述被测金属的实时腐蚀速率的腐蚀电流信号。Wherein, the principle of measuring the corrosion current signal is: when the test surface of the sensor probe is exposed to a wetted environment to be measured that can cause atmospheric corrosion of metals, under the influence of the environment to be measured, the surface of the sensor probe will A thin liquid film is formed on the test surface, and an electrical circuit is formed between the standard working electrode and the second pair of electrodes adjacent to it through the thin liquid film. In this state, the basic conditions for atmospheric corrosion are met; the standard working electrode and the second pair of electrodes are The galvanic corrosion of two electrodes using dissimilar metals makes the zero-resistance galvanometer monitor the electrochemical reaction current, that is, the output terminal of the first operational amplifier outputs the voltage in real time and correlates with the measured environment pair. Corrosion current signal of the real-time corrosion rate of the tested metal.

其中,测得所述反馈电流信号的原理为:在所述激励信号生成电路对所述第二对电极汇流端施加定频交流激励信号时,所述传感器探头可视为一变化的阻抗,采用同种金属的第一对电极汇流端和第二对电极汇流端则可视为该阻抗的两端,由于大气腐蚀伴随金属表面形成电解质薄液膜,电极间的电解质液膜状态极大影响阻抗的测量值,因此,在传感器探头结构确定的情况下,在某一固定频率的定频交流激励信号的激励下,前述阻抗的阻抗值大小与其表面润湿状态相关,根据交流电路的阻抗公式,前述阻抗的阻抗值可通过所述定频交流激励信号的电压大小和阻抗上通过的反馈电流计算得出,由此,所述电流测量电路也即第二运算放大器的输出端以电压方式输出实时关联所述被测金属(也即所述传感器探头的测试面)在所述被测环境下的表面湿润状态的反馈电流信号。Wherein, the principle of measuring the feedback current signal is as follows: when the excitation signal generating circuit applies a constant frequency AC excitation signal to the second pair of electrode bus terminals, the sensor probe can be regarded as a changing impedance, using The confluence end of the first pair of electrodes and the confluence end of the second pair of electrodes of the same metal can be regarded as the two ends of the impedance. Since atmospheric corrosion accompanies the formation of a thin electrolyte film on the metal surface, the state of the electrolyte film between the electrodes greatly affects the impedance. Therefore, when the structure of the sensor probe is determined, under the excitation of a fixed frequency and constant frequency AC excitation signal, the impedance value of the aforementioned impedance is related to the surface wetting state. According to the impedance formula of the AC circuit, The impedance value of the aforementioned impedance can be calculated from the voltage magnitude of the constant-frequency AC excitation signal and the feedback current passing through the impedance. Therefore, the current measurement circuit, that is, the output terminal of the second operational amplifier, outputs the real-time output in voltage mode. The feedback current signal correlates with the surface wet state of the tested metal (that is, the test surface of the sensor probe) under the tested environment.

作为本发明的优选实施方式:所述综合环境腐蚀状态表征传感器还包括温湿度传感器;所述温湿度传感器设置在所述传感器探头的旁侧位置,且所述温湿度传感器的感应端与所述传感器探头的测试面位于同一平面上,以用于同时测量所述被测环境的温湿度变化。其中,所述温湿度传感器可选用市售通用的温湿度传感器。As a preferred embodiment of the present invention: the comprehensive environmental corrosion state characterization sensor further includes a temperature and humidity sensor; the temperature and humidity sensor is arranged at the side of the sensor probe, and the sensing end of the temperature and humidity sensor is connected to the temperature and humidity sensor. The test surfaces of the sensor probes are located on the same plane, so as to measure the temperature and humidity changes of the measured environment at the same time. Wherein, the temperature and humidity sensor may be a commercially available general temperature and humidity sensor.

优选的:所述综合环境腐蚀状态表征传感器还包括控制器,所述控制器分别通过A/D转换器接收所述零阻电流计输出的腐蚀电流信号、所述电流测量电路输出的反馈电流信号、所述温湿度传感器输出的温湿度数据。其中,所述控制器优选采用单片机;所述控制器还能够对A/D转换器进行配置,如根据预估的电流大小设定A/D转换器量程以获得更加准确的测量结果。Preferably: the comprehensive environmental corrosion state characterization sensor further includes a controller, and the controller receives the corrosion current signal output by the zero-resistance ammeter and the feedback current signal output by the current measurement circuit through an A/D converter, respectively. , the temperature and humidity data output by the temperature and humidity sensor. Wherein, the controller preferably adopts a single-chip microcomputer; the controller can also configure the A/D converter, such as setting the range of the A/D converter according to the estimated current to obtain a more accurate measurement result.

本发明所要解决的技术问题之二是:提供一种实时同位监测方法。The second technical problem to be solved by the present invention is to provide a real-time co-location monitoring method.

解决上述技术问题,本发明所采用的技术方案如下:To solve the above-mentioned technical problems, the technical scheme adopted in the present invention is as follows:

一种实时同位监测方法,其特征在于,包括:A real-time isotopic monitoring method, comprising:

步骤一、将所述综合环境腐蚀状态表征传感器安装在被测环境,以实时测得所述腐蚀电流信号、反馈电流信号和温湿度数据;Step 1. Install the comprehensive environmental corrosion state characterization sensor in the measured environment to measure the corrosion current signal, feedback current signal and temperature and humidity data in real time;

步骤二、依据所述标准工作电极的横截面面积,将所述腐蚀电流信号处理成能够实时表征所述被测环境对所述被测金属的腐蚀速率的腐蚀电流密度,也即将所述腐蚀电流信号对应的电流值除以所述横截面面积换算得到所述腐蚀电流密度;并且,依据所述定频交流激励信号的电压和所述电流测量电路的跨阻增益,将所述反馈电流信号处理成能够实时表征所述被测金属(也即所述传感器探头的测试面)在所述被测环境下的表面湿润状态的表面润湿阻抗,也即将所述定频交流激励信号的电压除以所述反馈电流信号对应的电流值再乘以所述电流测量电路的跨阻增益换算得到所述表面润湿阻抗。Step 2: According to the cross-sectional area of the standard working electrode, the corrosion current signal is processed into a corrosion current density that can represent the corrosion rate of the measured metal to the measured metal in real time, that is, the corrosion current The current value corresponding to the signal is divided by the cross-sectional area to convert the corrosion current density; and, according to the voltage of the constant-frequency AC excitation signal and the transimpedance gain of the current measurement circuit, the feedback current signal is processed The surface wetting impedance that can characterize the surface wetting state of the measured metal (that is, the test surface of the sensor probe) in the measured environment in real time, that is, dividing the voltage of the constant frequency AC excitation signal by The current value corresponding to the feedback current signal is then multiplied by the transimpedance gain of the current measurement circuit and converted to obtain the surface wetting impedance.

优选的:所述实时同位监测方法还包括:Preferably: the real-time isotopic monitoring method further includes:

步骤三、依据所述综合环境腐蚀状态表征传感器的表面润湿阻抗-表面湿润状态关系曲线,查询得到与所述步骤二在目标时刻测得的表面润湿阻抗相对应的表面湿润状态,即为所述被测金属于所述目标时刻在所述被测环境中的表面湿润状态;Step 3: According to the comprehensive environmental corrosion state characterizing the surface wetting impedance-surface wetting state relationship curve of the sensor, query to obtain the surface wetting state corresponding to the surface wetting impedance measured at the target time in the second step, namely: the surface wet state of the tested metal in the tested environment at the target moment;

其中,所述表面润湿阻抗-表面湿润状态关系曲线通过预先将所述综合环境腐蚀状态表征传感器置于不同的表面湿润状态下测得对应的表面润湿阻抗并绘制成平滑曲线得到,且每一个所述表面湿润状态对应一个表面液膜厚度和一个液膜电解质浓度的组合。Wherein, the surface wetting impedance-surface wetting state relationship curve is obtained by preliminarily placing the comprehensive environmental corrosion state characterization sensor in different surface wetting states to measure the corresponding surface wetting impedance and drawing a smooth curve, and each A said surface wet state corresponds to a combination of a surface liquid film thickness and a liquid film electrolyte concentration.

优选的:所述实时同位监测方法还包括:Preferably: the real-time isotopic monitoring method further includes:

步骤四、根据所述腐蚀电流密度和法拉第定律,计算所述被测金属在目标时间段的腐蚀量,以将所述腐蚀量划分为现有标准所规定的腐蚀等级,所述现有标准可以是ISO9223-2012、ISA 71.04-2013等定义了腐蚀等级的标准;并且,依据所述温湿度数据、表面湿润状态和腐蚀等级,定义所述被测环境的环境腐蚀严酷度等级。Step 4. According to the corrosion current density and Faraday's law, calculate the corrosion amount of the tested metal in the target time period, so as to divide the corrosion amount into the corrosion grade specified by the existing standard. The existing standard can be It is ISO9223-2012, ISA 71.04-2013 and other standards that define the corrosion level; and, according to the temperature and humidity data, the surface wet state and the corrosion level, the environmental corrosion severity level of the measured environment is defined.

其中,所述步骤二至步骤四可以通过综合环境腐蚀状态表征传感器自带的控制器实现,也可以通过外部运算设备实现。Wherein, the steps 2 to 4 can be realized by a controller provided with the comprehensive environmental corrosion state characterization sensor, or can be realized by an external computing device.

与现有技术相比,本发明具有以下有益效果:Compared with the prior art, the present invention has the following beneficial effects:

第一,本发明的综合环境腐蚀状态表征传感器,采用由玻璃基板、绝缘材料以及依次循环排列的第一对电极、第二对电极和标准工作电极构成的传感器探头,通过零阻电流计对标准工作电极汇流端和第二对电极汇流端进行测量,得到实时关联传感器探头所在被测环境对标准工作电极所采用被测金属的腐蚀速率的腐蚀电流信号,并在激励信号生成电路对第二对电极汇流端施加定频交流激励信号时,通过电流测量电路对第一对电极汇流端和第二对电极汇流端进行测量,得到实时关联所述被测金属在所述被测环境下的表面湿润状态的反馈电流信号;因此,本发明能够实现对金属大气腐蚀速率和表面湿润状态的实时同位监测,保证了两个监测结果的空间对应性与时效性。First, the comprehensive environmental corrosion state characterization sensor of the present invention adopts a sensor probe composed of a glass substrate, an insulating material and a first pair of electrodes, a second pair of electrodes and a standard working electrode arranged in sequence, and the standard The working electrode confluence end and the second pair of electrode confluence ends are measured to obtain a corrosion current signal that correlates in real time with the corrosion rate of the measured metal used in the standard working electrode in the measured environment where the sensor probe is located. When a constant-frequency AC excitation signal is applied to the electrode bus terminal, the first pair of electrode bus terminals and the second pair of electrode bus terminals are measured through the current measurement circuit, and the surface wetness of the measured metal in the measured environment is obtained in real time. The feedback current signal of the state; therefore, the present invention can realize the real-time co-location monitoring of the metal atmospheric corrosion rate and the surface wet state, and ensure the spatial correspondence and timeliness of the two monitoring results.

第二,本发明的综合环境腐蚀状态表征传感器,具有制造本低工艺简单、监测数据准确、设备体积小便于携带、测试周期短,动态测试方便的优点,可用于封闭或开放机箱环境内。Second, the comprehensive environmental corrosion state characterization sensor of the present invention has the advantages of low manufacturing cost, simple process, accurate monitoring data, small size of equipment, easy portability, short testing period, and convenient dynamic testing, and can be used in a closed or open case environment.

第三,本发明的实时同位监测方法,能够实时同位的监测到能够实时表征所述被测环境对所述被测金属的腐蚀速率的腐蚀电流密度,以及,能够实时表征所述被测金属在所述被测环境下的表面湿润状态的表面润湿阻抗。Thirdly, the real-time isotopic monitoring method of the present invention can monitor in real time the corrosion current density that can characterize the corrosion rate of the tested metal to the tested metal by the tested environment in real time, and can characterize the tested metal in real time The surface wetting resistance of the surface wetting state in the measured environment.

附图说明Description of drawings

下面结合附图和具体实施例对本发明作进一步的详细说明:The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

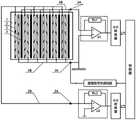

图1为本发明的综合环境腐蚀状态表征传感器的结构示意图。FIG. 1 is a schematic structural diagram of the comprehensive environmental corrosion state characterization sensor of the present invention.

具体实施方式Detailed ways

下面结合实施例及其附图对本发明进行详细说明,以帮助本领域的技术人员更好的理解本发明的发明构思,但本发明权利要求的保护范围不限于下述实施例,对本领域的技术人员来说,在不脱离本发明之发明构思的前提下,没有做出创造性劳动所获得的所有其他实施例,都属于本发明的保护范围。The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings, to help those skilled in the art to better understand the inventive concept of the present invention, but the protection scope of the claims of the present invention is not limited to the following embodiments, and it is not limited to the following embodiments. As far as personnel are concerned, without departing from the inventive concept of the present invention, all other embodiments obtained without creative work fall within the protection scope of the present invention.

实施例一Example 1

如图1所示,本发明公开的是一种综合环境腐蚀状态表征传感器,包括:传感器探头;As shown in FIG. 1 , the present invention discloses a comprehensive environmental corrosion state characterization sensor, comprising: a sensor probe;

所述传感器探头包括玻璃基板1,该玻璃基板1的顶面设有叉指电极和绝缘材料,所述叉指电极由沿电极宽度方向依次循环排列且长度宽度厚度一致的第一对电极2、第二对电极3和标准工作电极4构成,且任意相邻的两个电极之间均留有间隙,所述绝缘材料填充所述间隙,且所述叉指电极的顶面和绝缘材料的顶面共面构成所述传感器探头的测试面,其中,所述标准工作电极4采用被测金属,所述第一对电极2和第二对电极3采用不同于被测金属的同种惰性金属,且所述惰性金属的自然电位高于所述标准工作电极4,所述绝缘材料的作用是使所述测试面成为平面,以避免液滴附着时受各个电极之间的间隙凹槽影响而无法正常铺展或影响铺展方向。The sensor probe includes a glass substrate 1, and the top surface of the glass substrate 1 is provided with interdigital electrodes and insulating materials. The second pair of electrodes 3 and the standard working electrode 4 are formed, and a gap is left between any two adjacent electrodes, the insulating material fills the gap, and the top surface of the interdigital electrode and the top surface of the insulating material The surface coplanarity constitutes the test surface of the sensor probe, wherein the standard working electrode 4 adopts the metal to be measured, and the first pair of electrodes 2 and the second pair of electrodes 3 adopt the same kind of inert metal different from the metal to be measured, And the natural potential of the inert metal is higher than that of the standard working electrode 4, the function of the insulating material is to make the test surface a plane, so as to avoid being affected by the gap grooves between the electrodes when the droplets are attached. Spread normally or affect the spread direction.

以上为本实施例一的基本实施方式,可以在该基本实施方式的基础上做进一步的优化、改进和限定:The above is the basic implementation of the first embodiment, which can be further optimized, improved and limited on the basis of this basic implementation:

优选的:所述第一对电极2、第二对电极3和标准工作电极4均通过物理气相沉积技术即PVD技术在所述玻璃基板1的顶面沉积相应金属形成。Preferably, the first pair of electrodes 2 , the second pair of electrodes 3 and the standard working electrode 4 are formed by depositing corresponding metals on the top surface of the glass substrate 1 by physical vapor deposition technology, namely PVD technology.

优选的:所述第一对电极2、第二对电极3和标准工作电极4的沉积厚度在以上5μm,以保证电极能够在被测环境中长时间使用;所述第一对电极2、第二对电极3和标准工作电极4的最小宽度以及所述间隙的最小宽度均为50μm。Preferably: the deposition thickness of the first pair of electrodes 2, the second pair of electrodes 3 and the standard working electrode 4 is above 5 μm to ensure that the electrodes can be used in the measured environment for a long time; The minimum width of the two pairs of electrodes 3 and the standard working electrode 4 and the minimum width of the gap are both 50 μm.

其中:本发明的综合环境腐蚀状态表征传感器可以仅设置所述传感器探头作为独立产品,将下述实施例的零阻电流计、激励信号生成电路、电流测量电路、控制器和温湿度传感器作为综合环境腐蚀状态表征传感器的外部电路,也可以如下述实施例般将零阻电流计、激励信号生成电路、电流测量电路、控制器和温湿度传感器集成到综合环境腐蚀状态表征传感器内。Wherein: the comprehensive environmental corrosion state characterization sensor of the present invention can only set the sensor probe as an independent product, and use the zero-resistance ammeter, excitation signal generation circuit, current measurement circuit, controller and temperature and humidity sensor of the following embodiments as a comprehensive The external circuit of the environmental corrosion state characterization sensor can also integrate a zero-resistance ammeter, an excitation signal generation circuit, a current measurement circuit, a controller and a temperature and humidity sensor into a comprehensive environmental corrosion state characterization sensor as in the following embodiments.

实施例二Embodiment 2

如图1所示,在上述实施例一的基础上,本实施例二还采用了以下优选的实施方式:As shown in Figure 1, on the basis of the above-mentioned first embodiment, the second embodiment also adopts the following preferred implementations:

所述综合环境腐蚀状态表征传感器还包括零阻电流计、激励信号生成电路和电流测量电路;The comprehensive environmental corrosion state characterization sensor further includes a zero-resistance ammeter, an excitation signal generation circuit and a current measurement circuit;

第一对电极引线2B电性连接在每一个所述第一对电极2与第一对电极汇流端2A之间;第二对电极引线3B电性连接在每一个所述第二对电极3与第二对电极汇流端3A之间,且所述第二对电极汇流端3A接地;标准工作电极引线4B电性连接在每一个所述标准工作电极4与标准工作电极汇流端4A之间;The first pair of electrode leads 2B are electrically connected between each of the first pair of electrodes 2 and the first pair of

所述零阻电流计由第一运算放大器U1和第一反馈电阻Rc1组成,所述第一运算放大器U1的同相输入端接地,反相输入端分为两路,一路与所述标准工作电极汇流端4A电性连接,另一路通过第一反馈电阻Rc1与所述第一运算放大器U1的输出端电性连接;在所述传感器探头的测试面曝露于被测环境时,所述零阻电流计(也即第一运算放大器U1的输出端)输出实时关联所述被测环境对所述被测金属的腐蚀速率的腐蚀电流信号;The zero-resistance ammeter is composed of a first operational amplifier U1 and a first feedback resistor Rc1. The non-inverting input terminal of the first operational amplifier U1 is grounded, and the inverting input terminal is divided into two channels, one of which is connected to the standard working electrode.

所述电流测量电路由第二运算放大器U2和第二反馈电阻Rc2组成,所述第二运算放大器U2的同相输入端接入偏置电压,反相输入端分为两路,一路与所述第一对电极汇流端2A电性连接,另一路通过第二反馈电阻Rc2与所述第二运算放大器U2的输出端电性连接;在所述传感器探头的测试面曝露于被测环境且所述激励信号生成电路对所述第二对电极汇流端3A施加定频交流激励信号时,所述电流测量电路也即第二运算放大器U2的输出端输出实时关联所述被测金属(也即所述传感器探头的测试面)在所述被测环境下的表面湿润状态的反馈电流信号;其中,所述定频交流激励信号的频率通过对本发明传感器的材质、结构理论分析和试验数据所得,在该频率下,本发明传感器在润湿和非润湿状态变化的过程中,其阻抗值有较为明显且重复性较好的变化;所述定频交流激励信号的电压与激励信号生成电路、电流测量电路的设计有关,该电压应能确保可以获得足够分辨率的且稳定的反馈电流信号,以确保表面润湿状态测量的准确性。The current measurement circuit is composed of a second operational amplifier U2 and a second feedback resistor Rc2. The non-inverting input terminal of the second operational amplifier U2 is connected to a bias voltage, and the inverting input terminal is divided into two channels, and one channel is connected to the first channel. A pair of

从而,本发明的综合环境腐蚀状态表征传感器,采用由玻璃基板1、绝缘材料以及依次循环排列的第一对电极2、第二对电极3和标准工作电极4构成的传感器探头,通过零阻电流计对标准工作电极汇流端4A和第二对电极汇流端3A进行测量,得到实时关联传感器探头所在被测环境对标准工作电极4所采用被测金属的腐蚀速率的腐蚀电流信号,并在激励信号生成电路对第二对电极汇流端3A施加定频交流激励信号时,通过电流测量电路对第一对电极汇流端2A和第二对电极汇流端3A进行测量,得到实时关联所述被测金属在所述被测环境下的表面湿润状态的反馈电流信号;因此,本发明能够实现对金属大气腐蚀速率和表面湿润状态的实时同位监测,保证了两个监测结果的空间对应性与时效性。Therefore, the comprehensive environmental corrosion state characterization sensor of the present invention adopts a sensor probe composed of a glass substrate 1, an insulating material, a first pair of electrodes 2, a second pair of electrodes 3 and a standard working electrode 4 which are arranged in sequence, and passes through zero resistance current. The meter measures the standard working

其中,测得所述腐蚀电流信号的原理为:在所述传感器探头的测试面曝露于会引起金属大气腐蚀的润湿的被测环境时,受被测环境影响,会在所述传感器探头的测试面形成薄液膜,所述标准工作电极4和与其临近的第二对电极3之间通过薄液膜构成电气回路,此状态下满足大气腐蚀发生的基本条件;标准工作电极4和第二对电极3该两种采用异种金属的电极发生的电偶腐蚀,使得所述零阻电流计监测到电化学反应电流,也即所述第一运算放大器U1的输出端以电压方式输出实时关联所述被测环境对所述被测金属的实时腐蚀速率的腐蚀电流信号。Wherein, the principle of measuring the corrosion current signal is: when the test surface of the sensor probe is exposed to a wetted environment under test that can cause atmospheric corrosion of metals, the test surface of the sensor probe will be affected by the environment under test. A thin liquid film is formed on the test surface, and an electrical circuit is formed between the standard working electrode 4 and the second pair of electrodes 3 adjacent to it through the thin liquid film. In this state, the basic conditions for atmospheric corrosion are met; the standard working electrode 4 and the second pair of electrodes 3 The galvanic corrosion of the two electrodes using dissimilar metals on the electrode 3 makes the zero-resistance galvanometer monitor the electrochemical reaction current, that is, the output terminal of the first operational amplifier U1 outputs the real-time correlation in the voltage mode. Corrosion current signal of the real-time corrosion rate of the tested environment to the tested metal.

其中,测得所述反馈电流信号的原理为:在所述激励信号生成电路对所述第二对电极汇流端3A施加定频交流激励信号时,所述传感器探头可视为一变化的阻抗,采用同种金属的第一对电极汇流端2A和第二对电极汇流端3A则可视为该阻抗的两端,由于大气腐蚀伴随金属表面形成电解质薄液膜,电极间的电解质液膜状态极大影响阻抗的测量值,因此,在传感器探头结构确定的情况下,在某一固定频率的定频交流激励信号的激励下,前述阻抗的阻抗值大小与其表面润湿状态相关,根据交流电路的阻抗公式,前述阻抗的阻抗值可通过所述定频交流激励信号的电压大小和阻抗上通过的反馈电流计算得出,由此,所述电流测量电路也即第二运算放大器U2的输出端以电压方式输出实时关联所述被测金属(也即所述传感器探头的测试面)在所述被测环境下的表面湿润状态的反馈电流信号。The principle of measuring the feedback current signal is as follows: when the excitation signal generating circuit applies a constant-frequency AC excitation signal to the second pair of

实施例三Embodiment 3

在上述实施例二的基础上,本实施例三还采用了以下优选的实施方式:On the basis of the second embodiment above, the third embodiment also adopts the following preferred implementations:

所述综合环境腐蚀状态表征传感器还包括温湿度传感器;所述温湿度传感器设置在所述传感器探头的旁侧位置,且所述温湿度传感器的感应端与所述传感器探头的测试面位于同一平面上,以用于同时测量所述被测环境的温湿度变化。其中,所述温湿度传感器可选用市售通用的温湿度传感器。The comprehensive environmental corrosion state characterization sensor further includes a temperature and humidity sensor; the temperature and humidity sensor is arranged at the side of the sensor probe, and the sensing end of the temperature and humidity sensor and the test surface of the sensor probe are located on the same plane to measure the temperature and humidity changes of the measured environment at the same time. Wherein, the temperature and humidity sensor may be a commercially available general temperature and humidity sensor.

以上为本实施例三的基本实施方式,可以在该基本实施方式的基础上做进一步的优化、改进和限定:The above is the basic implementation of the third embodiment, which can be further optimized, improved and limited on the basis of this basic implementation:

优选的:所述综合环境腐蚀状态表征传感器还包括控制器,所述控制器分别通过A/D转换器接收所述零阻电流计输出的腐蚀电流信号、所述电流测量电路输出的反馈电流信号、所述温湿度传感器输出的温湿度数据。其中,所述控制器优选采用单片机;所述控制器还能够对A/D转换器进行配置,如根据预估的电流大小设定A/D转换器量程以获得更加准确的测量结果。Preferably: the comprehensive environmental corrosion state characterization sensor further includes a controller, and the controller receives the corrosion current signal output by the zero-resistance ammeter and the feedback current signal output by the current measurement circuit through an A/D converter, respectively. , the temperature and humidity data output by the temperature and humidity sensor. Wherein, the controller preferably adopts a single-chip microcomputer; the controller can also configure the A/D converter, such as setting the range of the A/D converter according to the estimated current to obtain a more accurate measurement result.

实施例四Embodiment 4

本本发明实施例四公开了一种实时同位监测方法,包括:Embodiment 4 of the present invention discloses a real-time co-location monitoring method, including:

步骤一、将实施例二或实施例三所述综合环境腐蚀状态表征传感器安装在被测环境,以实时测得所述腐蚀电流信号、反馈电流信号和温湿度数据;Step 1: Install the comprehensive environmental corrosion state characterization sensor described in Embodiment 2 or Embodiment 3 in the measured environment to measure the corrosion current signal, feedback current signal and temperature and humidity data in real time;

步骤二、依据所述标准工作电极4的横截面面积,将所述腐蚀电流信号处理成能够实时表征所述被测环境对所述被测金属的腐蚀速率的腐蚀电流密度,也即将所述腐蚀电流信号对应的电流值除以所述横截面面积换算得到所述腐蚀电流密度;并且,依据所述定频交流激励信号的电压和所述电流测量电路的跨阻增益,将所述反馈电流信号处理成能够实时表征所述被测金属(也即所述传感器探头的测试面)在所述被测环境下的表面湿润状态的表面润湿阻抗,也即将所述定频交流激励信号的电压除以所述反馈电流信号对应的电流值再乘以所述电流测量电路的跨阻增益换算得到所述表面润湿阻抗。Step 2: According to the cross-sectional area of the standard working electrode 4, the corrosion current signal is processed into a corrosion current density that can characterize the corrosion rate of the measured metal to the measured metal in real time, that is, the corrosion current density. The current value corresponding to the current signal is divided by the cross-sectional area to obtain the corrosion current density; and, according to the voltage of the constant-frequency AC excitation signal and the transimpedance gain of the current measurement circuit, the feedback current signal is The surface wetting impedance is processed to be able to characterize the surface wetting impedance of the measured metal (that is, the test surface of the sensor probe) in the measured environment in real time, that is, dividing the voltage of the constant frequency AC excitation signal The surface wetting impedance is converted by multiplying the current value corresponding to the feedback current signal by the transimpedance gain of the current measurement circuit.

以上为本实施例四的基本实施方式,可以在该基本实施方式的基础上做进一步的优化、改进和限定:The above is the basic implementation of the fourth embodiment, which can be further optimized, improved and limited on the basis of this basic implementation:

优选的:所述实时同位监测方法还包括:Preferably: the real-time isotopic monitoring method further includes:

步骤三、依据所述综合环境腐蚀状态表征传感器的表面润湿阻抗-表面湿润状态关系曲线,查询得到与所述步骤二在目标时刻测得的表面润湿阻抗相对应的表面湿润状态,即为所述被测金属于所述目标时刻在所述被测环境中的表面湿润状态;Step 3: According to the comprehensive environmental corrosion state characterizing the surface wetting impedance-surface wetting state relationship curve of the sensor, query to obtain the surface wetting state corresponding to the surface wetting impedance measured at the target time in the second step, namely: the surface wet state of the tested metal in the tested environment at the target moment;

其中,所述表面润湿阻抗-表面湿润状态关系曲线通过预先将所述综合环境腐蚀状态表征传感器置于不同的表面湿润状态下测得对应的表面润湿阻抗并绘制成平滑曲线得到,且每一个所述表面湿润状态对应一个表面液膜厚度和一个液膜电解质浓度的组合。Wherein, the surface wetting impedance-surface wetting state relationship curve is obtained by preliminarily placing the comprehensive environmental corrosion state characterization sensor in different surface wetting states to measure the corresponding surface wetting impedance and drawing a smooth curve, and each A said surface wet state corresponds to a combination of a surface liquid film thickness and a liquid film electrolyte concentration.

优选的:所述实时同位监测方法还包括:Preferably: the real-time isotopic monitoring method further includes:

步骤四、根据所述腐蚀电流密度和法拉第定律,计算所述被测金属在目标时间段的腐蚀量,以将所述腐蚀量划分为现有标准所规定的腐蚀等级,所述现有标准可以是ISO9223-2012、ISA 71.04-2013等定义了腐蚀等级的标准;并且,依据所述温湿度数据、表面湿润状态和腐蚀等级,定义所述被测环境的环境腐蚀严酷度等级。Step 4. According to the corrosion current density and Faraday's law, calculate the corrosion amount of the tested metal in the target time period, so as to divide the corrosion amount into the corrosion grade specified by the existing standard. The existing standard can be It is ISO9223-2012, ISA 71.04-2013 and other standards that define the corrosion level; and, according to the temperature and humidity data, the surface wet state and the corrosion level, the environmental corrosion severity level of the measured environment is defined.

其中,所述步骤二至步骤四可以通过综合环境腐蚀状态表征传感器自带的控制器实现,也可以通过外部运算设备实现。Wherein, the steps 2 to 4 can be realized by a controller provided with the comprehensive environmental corrosion state characterization sensor, or can be realized by an external computing device.

本发明不局限于上述具体实施方式,根据上述内容,按照本领域的普通技术知识和惯用手段,在不脱离本发明上述基本技术思想前提下,本发明还可以做出其它多种形式的等效修改、替换或变更,均落在本发明的保护范围之中。The present invention is not limited to the above-mentioned specific embodiments. According to the above-mentioned content, according to the common technical knowledge and conventional means in the field, and without departing from the above-mentioned basic technical idea of the present invention, the present invention can also make other equivalents in various forms. Modifications, substitutions or changes all fall within the protection scope of the present invention.

Claims (9)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210539183.9ACN114965246A (en) | 2022-05-18 | 2022-05-18 | Comprehensive environment corrosion state characterization sensor and real-time co-location monitoring method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210539183.9ACN114965246A (en) | 2022-05-18 | 2022-05-18 | Comprehensive environment corrosion state characterization sensor and real-time co-location monitoring method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114965246Atrue CN114965246A (en) | 2022-08-30 |

Family

ID=82982559

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210539183.9APendingCN114965246A (en) | 2022-05-18 | 2022-05-18 | Comprehensive environment corrosion state characterization sensor and real-time co-location monitoring method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114965246A (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116087086A (en)* | 2023-02-03 | 2023-05-09 | 深圳职业技术学院 | A metal corrosion detection device and detection system |

| CN118837289A (en)* | 2024-07-29 | 2024-10-25 | 武汉理工大学 | Metal bipolar plate coating primary battery corrosion test method based on inhibition voltage |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001099777A (en)* | 1999-07-29 | 2001-04-13 | Hitachi Ltd | Corrosion environment monitoring device |

| JP2011220717A (en)* | 2010-04-05 | 2011-11-04 | Hiroshima Univ | Method of measuring polarization resistance, method of monitoring corrosion speed, and polarization resistance measuring device |

| CN105973794A (en)* | 2016-05-30 | 2016-09-28 | 中国科学院金属研究所 | Atmospheric corrosivity monitoring equipment |

| CN110426331A (en)* | 2019-08-12 | 2019-11-08 | 武汉科思特仪器股份有限公司 | A kind of atmospheric environment concentration of saline fog monitoring device and test method |

| CN113125846A (en)* | 2021-04-16 | 2021-07-16 | 成都理工大学 | Weak current measuring system |

| CN113970576A (en)* | 2021-09-14 | 2022-01-25 | 中国电器科学研究院股份有限公司 | Real-time monitoring device and method for surface salt sedimentation amount |

- 2022

- 2022-05-18CNCN202210539183.9Apatent/CN114965246A/enactivePending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2001099777A (en)* | 1999-07-29 | 2001-04-13 | Hitachi Ltd | Corrosion environment monitoring device |

| JP2011220717A (en)* | 2010-04-05 | 2011-11-04 | Hiroshima Univ | Method of measuring polarization resistance, method of monitoring corrosion speed, and polarization resistance measuring device |

| CN105973794A (en)* | 2016-05-30 | 2016-09-28 | 中国科学院金属研究所 | Atmospheric corrosivity monitoring equipment |

| CN110426331A (en)* | 2019-08-12 | 2019-11-08 | 武汉科思特仪器股份有限公司 | A kind of atmospheric environment concentration of saline fog monitoring device and test method |

| CN113125846A (en)* | 2021-04-16 | 2021-07-16 | 成都理工大学 | Weak current measuring system |

| CN113970576A (en)* | 2021-09-14 | 2022-01-25 | 中国电器科学研究院股份有限公司 | Real-time monitoring device and method for surface salt sedimentation amount |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116087086A (en)* | 2023-02-03 | 2023-05-09 | 深圳职业技术学院 | A metal corrosion detection device and detection system |

| CN118837289A (en)* | 2024-07-29 | 2024-10-25 | 武汉理工大学 | Metal bipolar plate coating primary battery corrosion test method based on inhibition voltage |

| CN118837289B (en)* | 2024-07-29 | 2025-09-09 | 武汉理工大学 | Metal bipolar plate coating primary battery corrosion test method based on inhibition voltage |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN104792255B (en) | A kind of film thickness test device and film thickness test method | |

| CN114965246A (en) | Comprehensive environment corrosion state characterization sensor and real-time co-location monitoring method | |

| CN106093575A (en) | A kind of method measuring conductor resistivity at room temperature and temperature-coefficient of electrical resistance under alternating temperature | |

| CN103105355A (en) | Method and device for detecting corrosion of grounding grid of electric transmission line iron tower | |

| CN100543491C (en) | Accuracy Test System for Electric Fast Transient Burst Interference Test of Electric Energy Meter | |

| CN109612920A (en) | A method for monitoring atmospheric corrosion of metal components | |

| CN114720516A (en) | A method, device and sensing system for evaluating the aging degree of transformer oil | |

| CN104390907A (en) | Four-electrode soil corrosion detection probe | |

| CN205826750U (en) | Conductor resistivity at room temperature and the device of temperature-coefficient of electrical resistance is measured under a kind of alternating temperature | |

| CN210199207U (en) | Ultralow frequency dielectric loss test system | |

| CN102156001A (en) | Method for diagnosing self-biased probe of radio-frequency discharge plasma | |

| Su et al. | A theoretical study on resistance of electrolytic solution: Measurement of electrolytic conductivity | |

| CN207198240U (en) | Solid electrolyte ion conductivity test jig and system | |

| CN118731119A (en) | A method for detecting water content in oil based on interdigital capacitance | |

| CN107561001A (en) | Resistance probe and the device for measuring metal etching extent in surrounding medium | |

| CN103424629A (en) | Simple method for testing impedance of graphene oxide solution | |

| CN113791028B (en) | A detection device and method for directly detecting soil corrosion rate of metal materials | |

| CN109612919A (en) | A method for detecting galvanic type atmospheric corrosion sensor | |

| TWI228591B (en) | Solution concentration detection device of fuel cell and solution concentration detection method thereof | |

| CN114137470A (en) | Bandwidth testing device and measuring method thereof | |

| Zhao et al. | A simple control and high accuracy measurement method of open-cell four-electrode conductivity electrode | |

| CN106153528A (en) | A kind of metal covering Corrosion monitoring instrument and measuring method thereof | |

| CN106597113A (en) | Power line tower grounding resistance online tester based on proportion detection | |

| CN219084718U (en) | Metal atmospheric corrosion detector | |

| CN205506247U (en) | Trail device of measuring silicon steel clad plate temperature |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |