CN114962019A - Method for correcting air inflow of engine and engine system - Google Patents

Method for correcting air inflow of engine and engine systemDownload PDFInfo

- Publication number

- CN114962019A CN114962019ACN202210687977.XACN202210687977ACN114962019ACN 114962019 ACN114962019 ACN 114962019ACN 202210687977 ACN202210687977 ACN 202210687977ACN 114962019 ACN114962019 ACN 114962019A

- Authority

- CN

- China

- Prior art keywords

- fuel

- engine

- air

- lambda

- correction value

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D41/00—Electrical control of supply of combustible mixture or its constituents

- F02D41/0002—Controlling intake air

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D41/00—Electrical control of supply of combustible mixture or its constituents

- F02D41/0025—Controlling engines characterised by use of non-liquid fuels, pluralities of fuels, or non-fuel substances added to the combustible mixtures

- F02D41/0047—Controlling exhaust gas recirculation [EGR]

- F02D41/005—Controlling exhaust gas recirculation [EGR] according to engine operating conditions

- F02D41/0052—Feedback control of engine parameters, e.g. for control of air/fuel ratio or intake air amount

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D41/00—Electrical control of supply of combustible mixture or its constituents

- F02D41/0025—Controlling engines characterised by use of non-liquid fuels, pluralities of fuels, or non-fuel substances added to the combustible mixtures

- F02D41/0047—Controlling exhaust gas recirculation [EGR]

- F02D41/0077—Control of the EGR valve or actuator, e.g. duty cycle, closed loop control of position

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D41/00—Electrical control of supply of combustible mixture or its constituents

- F02D41/02—Circuit arrangements for generating control signals

- F02D41/021—Introducing corrections for particular conditions exterior to the engine

- F02D41/0235—Introducing corrections for particular conditions exterior to the engine in relation with the state of the exhaust gas treating apparatus

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02D—CONTROLLING COMBUSTION ENGINES

- F02D41/00—Electrical control of supply of combustible mixture or its constituents

- F02D41/0002—Controlling intake air

- F02D2041/0017—Controlling intake air by simultaneous control of throttle and exhaust gas recirculation

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/10—Internal combustion engine [ICE] based vehicles

- Y02T10/40—Engine management systems

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Electrical Control Of Air Or Fuel Supplied To Internal-Combustion Engine (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本申请涉及发动机技术领域,尤其涉及一种发动机进气量的修正方法和发动机系统。The present application relates to the technical field of engines, and in particular, to a method and an engine system for correcting an intake air amount of an engine.

背景技术Background technique

废气再循环(Exhaust Gas Recirculation,简称EGR),是发动机在燃烧后将一部分排出气体分离并导入进气侧使其再度燃烧的方法,该技术主要用于降低废气中NOX的含量,以满足机动车污染物排放要求。Exhaust gas recirculation (Exhaust GasRecirculation , EGR for short) is a method for the engine to separate a part of the exhaust gas after combustion and introduce it to the intake side for re-combustion. Motor vehicle pollutant emission requirements.

现有的发动机常采用空气流量传感器对新鲜空气进气量进行检测,并基于空气流量传感器的测量结果进行EGR控制。然而,空气流量传感器会受到管路和运行过程中产生的水汽、灰尘、油污等的影响,其检测数值会发生漂移,导致空气流量传感器的测量精度下降,进而导致EGR控制结果不准确,影响发动机的排放。Existing engines often use an air flow sensor to detect the fresh air intake, and perform EGR control based on the measurement result of the air flow sensor. However, the air flow sensor will be affected by water vapor, dust, oil pollution, etc. generated in the pipeline and during operation, and its detection value will drift, resulting in a decrease in the measurement accuracy of the air flow sensor, resulting in inaccurate EGR control results and affecting the engine. emissions.

发明内容SUMMARY OF THE INVENTION

本申请提供一种发动机进气量的修正方法和发动机系统,用于修正发动机中空气流量传感器产生的漂移,以提高发动机排放的尾气质量。The present application provides a method and an engine system for correcting the intake air volume of an engine, which are used to correct the drift generated by an air flow sensor in an engine, so as to improve the exhaust gas quality emitted by the engine.

本申请提供一种发动机进气量的修正方法,其包括:The present application provides a method for correcting the intake air volume of an engine, which includes:

获取油量和过量空气系数之间的转换系数faclambda以及上次修正计算得到的前馈修正值Mfuel;Obtain the conversion coefficient faclambda between the fuel quantity and the excess air coefficient and the feedforward correction value Mfuel obtained from the last correction calculation;

基于转换系数faclambda和上次修正计算得到的前馈修正值Mfuel,得到过量空气系数模型值Lambda模型;Based on the conversion coefficient faclambda and the feedforward correction value Mfuel obtained from the last correction calculation, the excess air coefficient model value Lambdamodel is obtained;

获取过量空气系数实测值Lambda实测,并基于过量空气系数实测值Lambda实测、过量空气系数模型值Lambda模型和转换系数faclambda,得到油量修正值Δmfuel;Obtaining the measured value of excess air coefficient Lambdameasured , and based on the measured value of excess air coefficient Lambdameasured , the model value of excess air coefficient Lambdamodel and the conversion coefficient faclambda , to obtain the fuel quantity correction value Δmfuel ;

获取喷油量mfuel,并基于油量修正值Δmfuel和喷油量mfuel,得到前馈修正值Mfuel’,完成本次修正计算;Obtain the fuel injection quantity mfuel , and obtain the feedforward correction value Mfuel ' based on the fuel quantity correction value Δmfuel and the fuel injection quantity mfuel ', and complete this correction calculation;

基于每次修正计算得到的前馈修正值,调节发动机的进气量。Based on the feedforward correction value calculated for each correction, the intake air volume of the engine is adjusted.

本申请提供的发动机进气量的修正方法,获取转换系数faclambda和上次修正计算得到的前馈修正值Mfuel后,可通过转换系数faclambda直接转换上一次修正得到的前馈修正值,得到过量空气系数模型值Lambda模型,较现有的过量空气系数模型值Lambda模型的求取方法,本申请过量空气系数模型值Lambda模型的计算过程简单,需要的修正系数少,仅需一个转换系数faclambda即可实时计算本次修正所需的过量空气系数模型值Lambda模型,且准确度高。得到过量空气系数模型值Lambda模型后,本申请再通过获取过量空气系数实测值Lambda实测,并基于过量空气系数实测值Lambda实测、过量空气系数模型值Lambda模型和转换系数faclambda,得到油量修正值Δmfuel,然后,获取喷油量mfuel,并基于油量修正值Δmfuel和喷油量mfuel,得到前馈修正值Mfuel’,完成本次修正计算。得到前馈修正值后,基于每次修正计算得到的前馈修正值,调节发动机的进气量,以进行实时调节,可提高系统响应的即时性。In the method for correcting the intake air volume of the engine provided by this application, after obtaining the conversion coefficient faclambda and the feedforward correction value Mfuel calculated from the previous correction, the feedforward correction value obtained by the previous correction can be directly converted by the conversion coefficient faclambda , Obtain the excess air coefficient model value Lambdamodel , compared with the method for obtaining the existing excess air coefficient model value Lambdamodel , the calculation process of the excess air coefficient model value Lambdamodel of the application is simple, and the required correction coefficient is few, only a conversion coefficient is required Faclambda can calculate the excess air coefficient model value Lambdamodel required for this correction in real time, and the accuracy is high. After obtaining the excess air coefficient model value Lambdamodel , the application obtains the actual measurement value Lambda of the excess air coefficient by obtaining the actual measurement of the excess aircoefficient , and based on the actualmeasurement of the excess air coefficient value Lambda, the excess air coefficient model value Lambdamodel and the conversion coefficient faclambda , obtain oil quantity correction Then, obtain the fuel injection quantity mfuel , and obtain the feedforward correction value Mfuel ' based on the fuel quantity correction value Δmfuel and thefuel injection quantity mfuel , and complete the correction calculation. After the feedforward correction value is obtained, the intake air volume of the engine is adjusted based on the feedforward correction value calculated for each correction to perform real-time adjustment, which can improve the immediacy of the system response.

在一种实现方式中,基于前馈修正值,调节发动机的进气量,包括:In an implementation manner, based on the feedforward correction value, the intake air amount of the engine is adjusted, including:

基于前馈修正值和新鲜空气进气量mair,调节发动机中废气再循环阀的开度。Based on the feedforward correction value and the fresh air intake amount mair , the opening degree of the exhaust gas recirculation valve in the engine is adjusted.

在一种实现方式中,基于前馈修正值,调节发动机的进气量,包括:In an implementation manner, based on the feedforward correction value, the intake air amount of the engine is adjusted, including:

基于前馈修正值和新鲜空气进气量mair,调节发动机中节流阀的开度。Based on the feedforward correction value and the fresh air intake amount mair , the opening degree of the throttle valve in the engine is adjusted.

在一种实现方式中,基于前馈修正值,调节发动机的进气量,包括:In an implementation manner, based on the feedforward correction value, the intake air amount of the engine is adjusted, including:

获取进气压力,并基于前馈修正值、新鲜空气进气量mair和进气压力,调节发动机中放气阀的开度。The intake pressure is obtained, and the opening of the bleed valve in the engine is adjusted based on the feedforward correction value, the fresh air intake amount mair and the intake pressure.

在一种实现方式中,获取油量和过量空气系数之间的转换系数faclambda以及上次修正计算得到的前馈修正值Mfuel,包括:In an implementation manner, the conversion coefficient faclambda between the fuel quantity and the excess air coefficient and the feedforward correction value Mfuel obtained from the last correction calculation are obtained, including:

获取新鲜空气进气量mair和上次修正计算得到的前馈修正值Mfuel;Obtain the fresh air intake amount mair and the feedforward correction value Mfuel obtained from the last correction calculation;

基于新鲜空气进气量mair,确定油量和过量空气系数之间的转换系数faclambda。Based on the fresh air intake quantity mair , the conversion factor faclambda between the oil quantity and the excess air factor is determined.

在一种实现方式中,基于新鲜空气进气量mair,确定油量和空气系数之间的转换系数faclambda,包括:In one implementation, the conversion factor faclambda between the oil quantity and the air coefficient is determined based on the fresh air intake air quantity mair , including:

基于以下公式,确定转换系数faclambda:The conversion factor faclambda is determined based on the following formula:

其中,fac1为发动机的理论空燃比,fac2为发动机的密度修正因子,理论空燃比和密度修正因子均为已知常数。Among them, fac1 is the theoretical air-fuel ratio of the engine, fac2 is the density correction factor of the engine, and both the theoretical air-fuel ratio and the density correction factor are known constants.

在一种实现方式中,基于转换系数faclambda和上次修正计算得到的前馈修正值Mfuel,得到过量空气系数模型值Lambda模型,包括:In an implementation manner, the excess air coefficient model value Lambdamodel is obtained based on the conversion coefficient faclambda and the feedforward correction value Mfuel obtained by the last correction calculation, including:

基于以下公式:Based on the following formula:

1/Lambda模型=Mfuel*faclambda1/Lambdamodel = Mfuel *faclambda

确定过量空气系数模型值Lambda模型。Determine the excess air coefficient model value Lambdamodel .

在一种实现方式中,获取喷油量mfuel,并基于油量修正值Δmfuel和喷油量mfuel,得到前馈修正值Mfuel’,包括:In an implementation manner, the fuel injection quantity mfuel is obtained, and based on the fuel quantity correction value Δmfuel and the fuel injection quantity mfuel , the feedforward correction value Mfuel ' is obtained, including:

获取喷油量mfuel,并将油量修正值Δmfuel和喷油量mfuel相加,得到前馈修正值Mfuel’。The fuel injection quantity mfuel is obtained, and the fuel quantity correction value Δmfuel and the fuel injection quantity mfuel are added to obtain the feedforward correction value Mfuel '.

本申请还提供一种发动机系统,其包括发动机和电控单元;The present application also provides an engine system, which includes an engine and an electronic control unit;

发动机上设有多个传感器和多个阀门;There are multiple sensors and multiple valves on the engine;

电控单元与多个传感器和多个阀门电连接,电控单元采用如上述任一项实现方式提供的修正方法调节多个阀门的开度,以调节发动机的进气量。The electronic control unit is electrically connected to a plurality of sensors and a plurality of valves, and the electronic control unit adjusts the opening of the plurality of valves by using the correction method provided by any of the above implementation manners, so as to adjust the intake air volume of the engine.

本申请提供的发动机系统,包括发动机和电控单元,发动机上设有多个传感器和多个阀门,电控单元与多个传感器和多个阀门电连接。其中,电控单元通过发动机上的传感器获取转换系数faclambda和上次修正计算得到的前馈修正值Mfuel,并通过转换系数faclambda直接转换上一次修正得到的前馈修正值,得到过量空气系数模型值Lambda模型,较现有的过量空气系数模型值Lambda模型的求取方法,本申请过量空气系数模型值Lambda模型的计算过程简单,需要的修正系数少,仅需一个转换系数faclambda即可实时计算本次修正所需的过量空气系数模型值Lambda模型,且准确度高。得到过量空气系数模型值Lambda模型后,本申请再通过获取过量空气系数实测值Lambda实测,并基于过量空气系数实测值Lambda实测、过量空气系数模型值Lambda模型和转换系数faclambda,得到油量修正值Δmfuel,然后,获取喷油量mfuel,并基于油量修正值Δmfuel和喷油量mfuel,得到前馈修正值Mfuel’,完成本次修正计算。得到前馈修正值后,基于每次修正计算得到的前馈修正值,调节发动机的进气量,以进行实时调节,可提高系统响应的即时性。The engine system provided by the present application includes an engine and an electronic control unit, the engine is provided with a plurality of sensors and a plurality of valves, and the electronic control unit is electrically connected with the plurality of sensors and a plurality of valves. Among them, the electronic control unit obtains the conversion coefficient faclambda and the feedforward correction value Mfuel obtained by the last correction calculation through the sensor on the engine, and directly converts the feedforward correction value obtained by the previous correction through the conversion coefficient faclambda to obtain excess air. The coefficient model value Lambdamodel , compared with the method for obtaining the existing excess air coefficient model value Lambdamodel , the calculation process of the excess air coefficient model value Lambdamodel of the present application is simple, and the required correction coefficient is few, only a conversion coefficient faclambda is required. The excess air coefficient model value Lambdamodel required for this correction can be calculated in real time with high accuracy. After obtaining the excess air coefficient model value Lambdamodel , the application obtains the actual measurement value Lambda of the excess air coefficient by obtaining the actual measurement of the excess aircoefficient , and based on the actualmeasurement of the excess air coefficient value Lambda, the excess air coefficient model value Lambdamodel and the conversion coefficient faclambda , obtain oil quantity correction Then, obtain the fuel injection quantity mfuel , and obtain the feedforward correction value Mfuel ' based on the fuel quantity correction value Δmfuel and thefuel injection quantity mfuel , and complete the correction calculation. After the feedforward correction value is obtained, the intake air volume of the engine is adjusted based on the feedforward correction value calculated for each correction to perform real-time adjustment, which can improve the immediacy of the system response.

在一种实现方式中,多个传感器包括氧传感器、空气流量传感器和进气压力传感器,氧传感器安装在发动机的排气管道上,空气流量传感器安装在发动机的进气管道上,进气压力传感器安装在发动机的进气管道上;In one implementation, the plurality of sensors include an oxygen sensor, an air flow sensor and an intake pressure sensor, the oxygen sensor is installed on the exhaust pipe of the engine, the air flow sensor is installed on the intake pipe of the engine, and the intake pressure sensor Installed on the intake duct of the engine;

多个阀门包括废气再循环阀、节流阀和放气阀,废气再循环阀安装在发动机的废气再循环管道上,节流阀安装在发动机的进气管道上,放气阀安装在发动机的排气管道上;The multiple valves include an exhaust gas recirculation valve, a throttle valve and a bleed valve. The exhaust gas recirculation valve is installed on the exhaust gas recirculation pipeline of the engine, the throttle valve is installed on the intake pipeline of the engine, and the bleed valve is installed on the engine's exhaust gas recirculation pipeline. on the exhaust duct;

电控单元包括废气再循环阀控制模块、节流阀控制模块和放气阀控制模块,废气再循环阀控制模块与空气流量传感器和废气再循环阀电连接,节流阀控制模块与空气流量传感器和节流阀电连接,放气阀控制模块与空气流量传感器、进气压力传感器和放气阀电连接。The electronic control unit includes an exhaust gas recirculation valve control module, a throttle valve control module and a bleed valve control module. The exhaust gas recirculation valve control module is electrically connected with the air flow sensor and the exhaust gas recirculation valve, and the throttle valve control module is connected with the air flow sensor. It is electrically connected with the throttle valve, and the air release valve control module is electrically connected with the air flow sensor, the intake pressure sensor and the air release valve.

本申请的构造以及它的其他发明目的及有益效果将会通过结合附图而对优选实施例的描述而更加明显易懂。The configuration of the present application and its other inventive objects and beneficial effects will be more clearly understood by the description of the preferred embodiments in conjunction with the accompanying drawings.

附图说明Description of drawings

通过参照附图的以下详细描述,本申请实施例的上述和其他目的、特征和优点将变得更容易理解。在附图中,将以示例以及非限制性的方式对本申请的多个实施例进行说明,其中:The above and other objects, features and advantages of embodiments of the present application will become more readily understood from the following detailed description with reference to the accompanying drawings. In the accompanying drawings, various embodiments of the present application will be illustrated by way of example and not limitation, wherein:

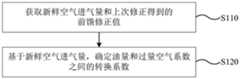

图1为本申请实施例提供的一种发动机进气量的修正方法的流程图;FIG. 1 is a flow chart of a method for correcting the intake air volume of an engine provided by an embodiment of the application;

图2为本申请实施例提供的转换系数faclambda的获取方法的流程图;Fig. 2 is the flow chart of the acquisition method of conversion coefficient faclambda provided by the embodiment of this application;

图3为本申请实施例提供的一种发动机系统的结构示意图。FIG. 3 is a schematic structural diagram of an engine system according to an embodiment of the present application.

附图标记:Reference number:

100-发动机;100 - engine;

111-氧传感器;112-空气流量传感器;113-进气压力传感器;111-oxygen sensor; 112-air flow sensor; 113-intake pressure sensor;

121-废气再循环阀;122-节流阀;121-exhaust gas recirculation valve; 122-throttle valve;

131-进气管道;132-排气管道;133-废气再循环管道。131 - intake pipe; 132 - exhaust pipe; 133 - exhaust gas recirculation pipe.

具体实施方式Detailed ways

下面详细描述本申请的实施例,所述实施例的示例在附图中示出,其中自始至终相同或类似的标号表示相同或类似的元件或具有相同或类似功能的元件。下面通过参考附图描述的实施例是示例性的,旨在用于解释本申请,而不能理解为对本申请的限制。The following describes in detail the embodiments of the present application, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar elements or elements having the same or similar functions throughout. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to be used to explain the present application, but should not be construed as a limitation to the present application.

应当理解的是,下面的实施例并不限制本申请所保护的方法中各步骤的执行顺序。本申请的方法的各个步骤在不相互矛盾的情况下能够以任意可能的顺序并且能够以循环的方式来执行。It should be understood that the following embodiments do not limit the execution order of each step in the method protected by the present application. The various steps of the methods of the present application can be performed in any possible order and can be performed in a cyclic fashion without conflicting each other.

废气再循环(Exhaust Gas Recirculation,简称EGR),是发动机在燃烧后将排出气体的一部分分离出、并导入进气侧使其再度燃烧的方法,该技术主要用于降低废气中NOX的含量,以满足国家第六阶段机动车污染物排放标准的排放要求。Exhaust gas recirculation (Exhaust Gas Recirculation, EGR for short) is a method in which part of the exhaust gas is separated from the engine after combustion and introduced into the intake side for re-combustion. This technology is mainly used to reduce the content of NOX in the exhaust gas. In order to meet the emission requirements of the national sixth stage motor vehicle pollutant emission standards.

现有的发动机常采用空气流量传感器对新鲜空气进气量进行检测,并基于空气流量传感器的测量结果进行EGR控制。然而,空气流量传感器会受到管路和运行过程中产生的水汽、灰尘、油污等的影响,其检测数值发生漂移,导致空气流量传感器的测量精度下降,进而导致EGR控制结果不准确,影响发动机的排放。Existing engines often use an air flow sensor to detect the fresh air intake, and perform EGR control based on the measurement result of the air flow sensor. However, the air flow sensor will be affected by water vapor, dust, oil pollution, etc. generated in the pipeline and during operation, and its detection value will drift, resulting in a decrease in the measurement accuracy of the air flow sensor, resulting in inaccurate EGR control results and affecting the engine's performance. emission.

在相关技术中,对于空气流量传感器漂移进行修正的方法,通常会设及到过量空气系数模型值的计算。In the related art, the method for correcting the drift of the air flow sensor usually involves the calculation of the model value of the excess air coefficient.

现有的过量空气系数模型值多是基于新鲜空气进气量、喷油量和发动机的理论空燃比计算得到的,并且,计算过程会用到较多的修正系数,这些修正系数可根据发动机台架性能进行标定获取,计算过程复杂。The existing excess air coefficient model values are mostly calculated based on the fresh air intake volume, fuel injection volume and the theoretical air-fuel ratio of the engine, and many correction coefficients are used in the calculation process. The frame performance is calibrated and obtained, and the calculation process is complicated.

现有的对于空气流量传感器漂移进行修正的方法,其执行机构也各有不同,常见的有发动机的喷油机构或废气再循环阀这两种机构,通过控制发动机的喷油量或进入到发动机进气端的废气的含量,以达到修正空气流量传感器漂移的目的,然而,该方法下执行机构响应的即时性和修正准确度较差。The existing methods for correcting the drift of the air flow sensor have different actuators. The common ones are the engine fuel injection mechanism or the exhaust gas recirculation valve. By controlling the fuel injection amount of the engine or entering the engine The content of the exhaust gas at the intake end is used to correct the drift of the air flow sensor. However, the immediacy of the response of the actuator and the correction accuracy under this method are poor.

综上可知,现有的对于空气流量传感器漂移进行修正的方法,计算过程复杂,且即时性和准确度较差。To sum up, it can be seen that the existing method for correcting the drift of the air flow sensor has a complicated calculation process and poor immediacy and accuracy.

有鉴于此,本申请实施例提供一种发动机进气量的修正方法和发动机系统,可通过转换系数faclambda直接转换上一次修正得到的前馈修正值,得到过量空气系数模型值Lambda模型,其计算过程简单,需要的修正系数少,仅需一个转换系数faclambda即可实时计算本次修正所需的过量空气系数模型值Lambda模型,且准确度高。并且,本申请实施例基于每次修正计算得到的前馈修正值,调节发动机的进气量,以进行实时调节,可提高系统响应的即时性。In view of this, the embodiment of the present application provides a correction method and an engine system for the intake air volume of an engine, which can directly convert the feedforward correction value obtained by the last correction through the conversion coefficient faclambda to obtain the excess air coefficient model value Lambdamodel , which is The calculation process is simple and requires few correction coefficients. Only one conversion coefficient faclambda can be used to calculate the excess air coefficient model value Lambdamodel required for this correction in real time, and the accuracy is high. Moreover, the embodiment of the present application adjusts the intake air amount of the engine based on the feedforward correction value obtained by each correction calculation, so as to perform real-time adjustment, which can improve the immediacy of the system response.

下面将结合附图对本申请实施例提供的发动机进气量的修正方法和发动机系统进行详细说明。The method for correcting the intake air volume of the engine and the engine system provided by the embodiments of the present application will be described in detail below with reference to the accompanying drawings.

实施例一Example 1

图1为本申请实施例提供的一种发动机进气量的修正方法的流程图。如图1所示,本实施例提供一种发动机进气量的修正方法,该修正方法包括:FIG. 1 is a flowchart of a method for correcting the intake air volume of an engine provided by an embodiment of the present application. As shown in FIG. 1 , the present embodiment provides a method for correcting the intake air volume of an engine, and the correction method includes:

S100、获取油量和过量空气系数之间的转换系数faclambda以及上次修正计算得到的前馈修正值Mfuel。S100. Obtain the conversion coefficient faclambda between the fuel quantity and the excess air coefficient and the feedforward correction value Mfuel obtained from the last correction calculation.

在实际应用中,油量和过量空气系数之间的转换系数faclambda可以通过发动机的相关参数得到,上次修正计算得到的前馈修正值Mfuel为已知变量,可以从上次修正计算中获取。In practical applications, the conversion coefficient faclambda between the fuel quantity and the excess air coefficient can be obtained from the relevant parameters of the engine. The feedforward correction value Mfuel obtained from the last revision calculation is a known variable, which can be obtained from the last revision calculation. Obtain.

图2为本申请实施例提供的转换系数faclambda的获取方法的流程图。示例性的,如图2所示,获取油量和过量空气系数之间的转换系数faclambda以及上次修正计算得到的前馈修正值Mfuel,可以包括:FIG. 2 is a flowchart of a method for obtaining a conversion coefficient faclambda provided by an embodiment of the present application. Exemplarily, as shown in FIG. 2 , obtaining the conversion coefficient faclambda between the fuel quantity and the excess air coefficient and the feedforward correction value Mfuel obtained by the last correction calculation may include:

S110、获取新鲜空气进气量mair和上次修正计算得到的前馈修正值Mfuel。其中,新鲜空气进气量mair可以通过发动机上的空气流量传感器测得,上次修正计算得到的前馈修正值Mfuel为已知变量。S110. Obtain the fresh air intake air amount mair and the feedforward correction value Mfuel obtained from the previous correction calculation. Among them, the fresh air intake amount mair can be measured by the air flow sensor on the engine, and the feedforward correction value Mfuel obtained by the last correction calculation is a known variable.

S120、基于新鲜空气进气量mair,确定油量和过量空气系数之间的转换系数faclambda。S120. Based on the fresh air intake amount mair , determine the conversion coefficient faclambda between the oil amount and the excess air coefficient.

具体的,基于新鲜空气进气量mair,确定油量和空气系数之间的转换系数faclambda,包括:Specifically, based on the fresh air intake amount mair , the conversion coefficient faclambda between the oil amount and the air coefficient is determined, including:

基于以下公式,确定转换系数faclambda:The conversion factor faclambda is determined based on the following formula:

其中,fac1为发动机的理论空燃比,fac2为发动机的密度修正因子,理论空燃比和密度修正因子均为已知常数。Among them, fac1 is the theoretical air-fuel ratio of the engine, fac2 is the density correction factor of the engine, and both the theoretical air-fuel ratio and the density correction factor are known constants.

示例性的,柴油机的理论空燃比fac1已知为14.5,其他类型发动机的理论空燃比fac1可根据发动机台架性能进行标定,并且,由于修正计算中无需进行密度校正,可令fac2=1。Exemplarily, the theoretical air-fuel ratio fac1 of a diesel engine is known to be 14.5, and the theoretical air-fuel ratio fac1 of other types of engines can be calibrated according to the performance of the engine bench, and since density correction is not required in the correction calculation, fac2 = 1.

可见,较现有的过量空气系数模型值Lambda模型的求取方法,本申请实施例的过量空气系数模型值Lambda模型的计算过程简单,仅用到发动机的理论空燃比fac1和发动机的密度修正因子fac2两个修正系数,需要的修正系数少,其中,仅发动机的理论空燃比fac1需要进行标定,甚至对于柴油机,理论空燃比fac1也无需进行标定,仅需少量标定即可实时计算本次修正所需的过量空气系数模型值Lambda模型,且准确度高。As can be seen, compared to the method for obtaining of the existing excess air coefficient model value Lambdamodel , the calculation process of the excess air coefficient model value Lambdamodel of the embodiment of the application is simple, only uses the theoretical air-fuel ratio fac1 of the engine and the density correction of the engine The factor fac2 has two correction coefficients, which requires less correction coefficients. Among them, only the theoretical air-fuel ratio fac1 of the engine needs to be calibrated, and even for a diesel engine, the theoretical air-fuel ratio fac1 does not need to be calibrated, only a small amount of calibration can be calculated in real time The excess air coefficient model value Lambdamodel required for this correction has high accuracy.

S200、基于转换系数faclambda和上次修正计算得到的前馈修正值Mfuel,得到过量空气系数模型值Lambda模型。S200 , based on the conversion coefficient faclambda and the feedforward correction value Mfuel obtained by the last correction calculation, obtain an excess air coefficient model value Lambdamodel .

需要说明的是,第一次修正计算时,过量空气系数模型值Lambda模型可以通过发动机系统模型获得,示例性的,发动机系统模型可基于测得的新鲜空气进气量、喷油量以及自身的理论空燃比,确定该新鲜空气进气量和喷油量下对应的过量空气系数模型值Lambda模型。从第二次修正计算开始,过量空气系数模型值Lambda模型即可基于转换系数faclambda和上次修正计算得到的前馈修正值Mfuel确定。It should be noted that, in the first correction calculation, the excess air coefficient model value Lambdamodel can be obtained from the engine system model. Exemplarily, the engine system model can be based on the measured fresh air intake, fuel injection and its own The theoretical air-fuel ratio is used to determine the corresponding excess air coefficient model value Lambdamodel under the fresh air intake amount and fuel injection amount. Starting from the second correction calculation, the excess air coefficient model value Lambdamodel can be determined based on the conversion coefficient faclambda and the feedforward correction value Mfuel obtained from the previous correction calculation.

还需要说明的是,本实施提供的修正方法主要应用于稳态工况下的发动机,初次修正影响的只是初始的一瞬不必太精确,第一次修正计算中的过量空气系数模型值Lambda模型确定出大致数值即可,计算过程不必使用过多的修正系数,以简化计算。It should also be noted that the correction method provided in this implementation is mainly applied to the engine under steady state conditions. The initial correction only affects the initial moment and does not have to be too accurate. The excess air coefficient model value in the first correction calculation is determined by the Lambdamodel . The approximate value can be obtained, and the calculation process does not need to use too many correction coefficients to simplify the calculation.

具体的,基于转换系数faclambda和上次修正计算得到的前馈修正值Mfuel,得到过量空气系数模型值Lambda模型,可以包括:Specifically, based on the conversion coefficient faclambda and the feedforward correction value Mfuel obtained by the last correction calculation, the excess air coefficient model value Lambdamodel is obtained, which may include:

基于以下公式:Based on the following formula:

1/Lambda模型=Mfuel*faclambda1/Lambdamodel = Mfuel *faclambda

确定过量空气系数模型值Lambda模型。其中,转换系数faclambda和上次修正计算得到的前馈修正值Mfuel均可由S100获知。Determine the excess air coefficient model value Lambdamodel . Wherein, the conversion coefficient faclambda and the feedforward correction value Mfuel obtained by the last correction calculation can be known from S100.

S300、获取过量空气系数实测值Lambda实测,并基于过量空气系数实测值Lambda实测、过量空气系数模型值Lambda模型和转换系数faclambda,得到油量修正值Δmfuel。S300 , obtaining the measured value of excess air coefficient Lambdameasured , and based on the measured value of excess air coefficient Lambdameasured , the model value of excess air coefficient Lambdamodel and the conversion coefficient faclambda , obtain the fuel quantity correction value Δmfuel .

示例性的,获取过量空气系数实测值Lambda实测,可以包括:Exemplarily, obtaining the actual measured value Lambda of excess aircoefficient can include:

由发动机上的氧传感器测得废气氧气浓度值C,并基于以下公式,确定过量空气系数实测值Lambda实测:The exhaust gas oxygen concentration value C is measured by the oxygen sensor on the engine, and based on the following formula, the measured value of excess air coefficient Lambda isdetermined :

其中,fac3为第一氧浓度转换系数,fac4为第二氧浓度转换系数,第一氧浓度转换系数和第二氧浓度转换系数均为已知常数。具体的,第一氧浓度转换系数和第二氧浓度转换系数可根据发动机台架性能进行标定,实际应用时,第一氧浓度转换系数和第二氧浓度转换系数也可以根据经验确定,以减少标定过程,简化计算,第一氧浓度转换系数的经验值一般为3.36,第二氧浓度转换系数的经验值一般为4.23。Wherein, fac3 is a first oxygen concentration conversion coefficient, fac4 is a second oxygen concentration conversion coefficient, and both the first oxygen concentration conversion coefficient and the second oxygen concentration conversion coefficient are known constants. Specifically, the first oxygen concentration conversion coefficient and the second oxygen concentration conversion coefficient can be calibrated according to the performance of the engine bench. In practical applications, the first oxygen concentration conversion coefficient and the second oxygen concentration conversion coefficient can also be determined based on experience to reduce In the calibration process, the calculation is simplified. The empirical value of the first oxygen concentration conversion coefficient is generally 3.36, and the empirical value of the second oxygen concentration conversion coefficient is generally 4.23.

示例性的,基于过量空气系数实测值Lambda实测、过量空气系数模型值Lambda模型和转换系数faclambda,得到油量修正值Δmfuel,可以包括:Exemplarily, based on the measured value of excess air coefficient Lambdameasured , the model value of excess air coefficient Lambdamodel and the conversion coefficient faclambda , the fuel quantity correction value Δmfuel is obtained, which may include:

基于以下公式,确定油量修正值Δmfuel:The fuel quantity correction value Δmfuel is determined based on the following formula:

其中,△1/Lambda为修正值,由过量空气系数实测值Lambda实测和过量空气系数模型值Lambda模型作差得到,具体的,Δ1/Lambda=1Lambda实测-1/Lambda模型。Among them, Δ1/Lambda is the correction value, which is obtained by the difference between themeasured value of excess air coefficient Lambda and the model value of excess air coefficient Lambdamodel . Specifically, Δ1/Lambda=1Lambdameasured value-1/Lambdamodel .

S400、获取喷油量mfuel,并基于油量修正值Δmfuel和喷油量mfuel,得到前馈修正值Mfuel’,完成本次修正计算。S400: Obtain the fuel injection quantity mfuel , and obtain a feedforward correction value Mfuel ' based on the fuel quantity correction value Δmfuel and the fuel injection quantity mfuel , and complete the correction calculation.

示例性的,获取喷油量mfuel,并基于油量修正值Δmfuel和喷油量mfuel,得到前馈修正值Mfuel’,可以包括:Exemplarily, the fuel injection quantity mfuel is obtained, and based on the fuel quantity correction value Δmfuel and the fuel injection quantity mfuel , the feedforward correction value Mfuel ' is obtained, which may include:

获取喷油量mfuel,并将油量修正值Δmfuel和喷油量mfuel相加,得到前馈修正值Mfuel’。需要说明的是,本次修正计算得到的前馈修正值Mfuel和上次修正计算得到的前馈修正值Mfuel’,虽然都被称为前馈修正值,但其实是不同的两个值,分别存在于不同次的修正计算中。The fuel injection quantity mfuel is obtained, and the fuel quantity correction value Δmfuel and the fuel injection quantity mfuel are added to obtain the feedforward correction value Mfuel '. It should be noted that the feedforward correction value Mfuel obtained by this correction calculation and the feedforward correction value Mfuel ' obtained by the previous correction calculation are both called feedforward correction values, but they are actually two different values. , respectively exist in different correction calculations.

S500、基于每次修正计算得到的前馈修正值,调节发动机的进气量。如此,以便对发动机的进气量进行实时调节,可提高系统响应的即时性以及修正的准确度。S500. Adjust the intake air amount of the engine based on the feedforward correction value obtained by each correction calculation. In this way, in order to adjust the intake air volume of the engine in real time, the immediacy of the system response and the accuracy of the correction can be improved.

示例性的,基于前馈修正值,调节发动机的进气量,可以包括:Exemplarily, adjusting the intake air amount of the engine based on the feedforward correction value may include:

基于前馈修正值和新鲜空气进气量mair,调节发动机中废气再循环阀的开度,以便控制调节回流至发动机进气端的废气量。Based on the feedforward correction value and the fresh air intake amount mair , the opening of the exhaust gas recirculation valve in the engine is adjusted to control the amount of exhaust gas returned to the intake end of the engine.

示例性的,调节发动机的进气量,还可以包括:Exemplarily, adjusting the intake air volume of the engine may further include:

基于前馈修正值和新鲜空气进气量mair,调节发动机中节流阀的开度,以便控制调节发动机进气端的新鲜空气进气量。Based on the feedforward correction value and the fresh air intake amount mair , the opening degree of the throttle valve in the engine is adjusted so as to control and adjust the fresh air intake amount at the intake end of the engine.

另外,基于前馈修正值,调节发动机的进气量,还可以包括:In addition, adjusting the intake air volume of the engine based on the feedforward correction value may also include:

获取进气压力,并基于前馈修正值、新鲜空气进气量mair和进气压力,调节发动机中放气阀的开度,以便通控制放气阀开度,控制增压器的转速。The intake pressure is obtained, and based on the feedforward correction value, the fresh air intake amount mair and the intake pressure, the opening of the bleed valve in the engine is adjusted, so as to control the speed of the supercharger by controlling the opening of the bleed valve.

在实际应用中,基于每次修正计算得到的前馈修正值,可以实现对废气再循环阀、节流阀、增压器等其他多种执行机构的优化控制,对发动机进气量进行多方修正,进而修正空气流量传感器漂移后的排放结果,保证修正后的排放满足排放要求,且修正的准确度高。In practical applications, based on the feedforward correction value calculated by each correction, the optimal control of other actuators such as exhaust gas recirculation valve, throttle valve, and supercharger can be realized, and the engine intake air volume can be corrected in multiple ways. , and then correct the emission result after the drift of the air flow sensor, so as to ensure that the corrected emission meets the emission requirements and the correction accuracy is high.

实施例二Embodiment 2

图3为本申请实施例提供的一种发动机100系统的结构示意图。如图3所示,本实施例还提供一种发动机100系统,该发动机100系统包括发动机100和电控单元(ElectronicControl Unit,简称ECU,图中未标示),发动机100上设有多个传感器和多个阀门,电控单元与各传感器和各阀门电连接,其中,电控单元采用实施例一提供的修正方法调节各阀门的开度,以调节发动机100的进气量。FIG. 3 is a schematic structural diagram of an

如图3所示,发动机100上设置的传感器可以包括氧传感器111、空气流量传感器112和进气压力传感器113,氧传感器111安装在发动机100的排气管道132上,空气流量传感器112安装在发动机100的进气管道131上,进气压力传感器113安装在发动机100的进气管道131上。As shown in FIG. 3 , the sensors provided on the

具体的,氧传感器111可以安装在发动机100的涡轮机和氧化催化器之间,空气流量传感器112和进气压力传感器113可以安装在废气再循环管道133与进气管道131的连通点之前。Specifically, the

发动机100上设置的阀门可以包括废气再循环阀121(EGR阀)、节流阀122和放气阀(图中未标示),废气再循环阀121安装在发动机100的废气再循环管道133上,节流阀122安装在发动机100的进气管道131上,放气阀安装在发动机100的排气管道132上。The valves provided on the

电控单元可以包括废气再循环阀121控制模块(EGR阀控制模块)、节流阀122控制模块和放气阀控制模块,废气再循环阀121控制模块与空气流量传感器112和废气再循环阀121电连接,以便控制调节回流至发动机100进气端的废气量;节流阀122控制模块与空气流量传感器112和节流阀122电连接,以便控制调节发动机100进气端的新鲜空气进气量;放气阀控制模块与空气流量传感器112、进气压力传感器113和放气阀电连接,以便通控制放气阀开度,控制增压器的转速,进而修正空气流量传感器112漂移后的排放结果,保证修正后的排放满足排放要求,且修正的准确度高。The electronic control unit may include an exhaust

另外,电控单元还可以包括PID控制器,以便计算出修正值△1/Lambda。如图3所示,在采用PID控制器计算时,将过量空气系数实测值Lambda实测的倒数和过量空气系数模型值Lambda模型的倒数输入到PID控制器中,PID控制器输出修正值△1/Lambda,之后,电控单元在通过实施例一提供的修正方法计算出油量修正值Δmfuel,然后再将油量修正值Δmfuel和喷油量mfuel相加得到前馈修正值,并基于前馈修正值调节各阀门开度。In addition, the electronic control unit may also include a PID controller in order to calculate the correction value Δ1/Lambda. As shown in Figure 3, when the PID controller is used for calculation, the reciprocal of themeasured excess air coefficient Lambda and the reciprocal of the excess air coefficient model value Lambdamodel are input into the PID controller, and the PID controller outputs the corrected value △1/ Lambda, after that, the electronic control unit calculates the fuel quantity correction value Δmfuel through the correction method provided in the first embodiment, and then adds the fuel quantity correction value Δmfuel and the fuel injection quantity mfuel to obtain a feedforward correction value, and based on The feedforward correction value adjusts the opening of each valve.

其中,修正方法的具体步骤在实施例一中进行了详细的介绍,此处不再赘述。The specific steps of the correction method are described in detail in Embodiment 1, and are not repeated here.

可以理解的是,本申请实施例示意的结构并不构成对发动机系统的具体限定。在本申请另一些实施例中,发动机系统可以包括比图示更多或更少的部件,或者组合某些部件,或者拆分某些部件,或者不同的部件布置。例如,发动机系统还可以包括颗粒捕捉器和中冷器等器件。It can be understood that the structures illustrated in the embodiments of the present application do not constitute a specific limitation on the engine system. In other embodiments of the present application, the engine system may include more or less components than shown, or combine some components, or separate some components, or different component arrangements. For example, the engine system may also include devices such as particle traps and intercoolers.

此外,参考术语“实施例”、“示例”、“具体示例”、或“一些示例”等的描述意指结合该实施例或示例描述的具体特征、结构、材料或者特点包含于本申请的至少一个实施例或示例中。在本说明书中,对上述术语的示意性表述不必须针对的是相同的实施例或示例。而且,描述的具体特征、结构、材料或者特点可以在任一个或多个实施例或示例中以合适的方式结合。此外,在不相互矛盾的情况下,本领域的技术人员可以将本说明书中描述的不同实施例或示例以及不同实施例或示例的特征进行结合和组合。Furthermore, description with reference to the terms "an embodiment," "example," "specific example," or "some examples," etc. means that a particular feature, structure, material, or characteristic described in connection with the embodiment or example is included in at least one of the present application. in one embodiment or example. In this specification, schematic representations of the above terms are not necessarily directed to the same embodiment or example. Furthermore, the particular features, structures, materials or characteristics described may be combined in any suitable manner in any one or more embodiments or examples. Furthermore, those skilled in the art may combine and combine the different embodiments or examples described in this specification, as well as the features of the different embodiments or examples, without conflicting each other.

最后应说明的是:以上实施方式仅用以说明本申请的技术方案,而非对其进行限制;尽管参照前述实施方式对本申请已经进行了详细的说明,但本领域的普通技术人员应当理解:其依然可以对前述实施方式所记载的技术方案进行修改,或者对其中部分或者全部技术特征进行等同替换;而这些修改或者替换,并不使相应技术方案的本质脱离本申请实施方式技术方案的范围。Finally, it should be noted that: the above embodiments are only used to illustrate the technical solutions of the application, rather than limiting them; although the application has been described in detail with reference to the foregoing embodiments, those of ordinary skill in the art should understand: It is still possible to modify the technical solutions recorded in the foregoing embodiments, or perform equivalent replacements to some or all of the technical features; and these modifications or replacements do not make the essence of the corresponding technical solutions depart from the scope of the technical solutions of the embodiments of the present application. .

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210687977.XACN114962019B (en) | 2022-06-17 | 2022-06-17 | Engine air inflow correction method and engine system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210687977.XACN114962019B (en) | 2022-06-17 | 2022-06-17 | Engine air inflow correction method and engine system |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114962019Atrue CN114962019A (en) | 2022-08-30 |

| CN114962019B CN114962019B (en) | 2023-09-15 |

Family

ID=82972380

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210687977.XAActiveCN114962019B (en) | 2022-06-17 | 2022-06-17 | Engine air inflow correction method and engine system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114962019B (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116988869A (en)* | 2023-08-07 | 2023-11-03 | 一汽解放汽车有限公司 | Combustion control system and control method for gas ignition engine |

| CN119664515A (en)* | 2024-12-03 | 2025-03-21 | 一汽解放汽车有限公司 | Hydrogen engine mixed gas concentration control method, device and vehicle |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08232722A (en)* | 1994-12-30 | 1996-09-10 | Honda Motor Co Ltd | Fuel injection control device for internal combustion engine |

| US6397830B1 (en)* | 1999-09-27 | 2002-06-04 | Denso Corporation | Air-fuel ratio control system and method using control model of engine |

| US20020124832A1 (en)* | 2000-12-26 | 2002-09-12 | Nissan Motor Co., Ltd. | Excess air factor control device for internal combustion engine |

| CN1975135A (en)* | 2005-11-30 | 2007-06-06 | 福特环球技术公司 | Engine with two port fuel injectors |

| JP2012154288A (en)* | 2011-01-28 | 2012-08-16 | Honda Motor Co Ltd | Internal combustion engine control device |

| CN107664073A (en)* | 2016-07-28 | 2018-02-06 | 长城汽车股份有限公司 | EGR rate computational methods, system and vehicle with low pressure EGR system |

| US20180195451A1 (en)* | 2015-07-15 | 2018-07-12 | Hitachi Automotive Systems, Ltd. | Control Apparatus for Internal Combustion Engine |

| CN109026415A (en)* | 2017-06-08 | 2018-12-18 | 株式会社三国 | Engine control system and computer readable recording medium |

| CN110805498A (en)* | 2019-11-11 | 2020-02-18 | 奇瑞汽车股份有限公司 | Engine fuel correction control method |

| CN111075582A (en)* | 2019-12-30 | 2020-04-28 | 北汽福田汽车股份有限公司 | Exhaust gas recirculation rate control method, device, medium, equipment and vehicle |

| CN111337109A (en)* | 2018-12-18 | 2020-06-26 | 北京福田康明斯发动机有限公司 | Apparatus and method for automatic calibration of engine air flow MAF sensor |

| CN111894748A (en)* | 2020-07-24 | 2020-11-06 | 东风商用车有限公司 | Control method and control system for smoke limit under idle working condition of engine |

| CN111997769A (en)* | 2020-10-30 | 2020-11-27 | 潍柴动力股份有限公司 | EGR control method and device and engine system |

| CN113431690A (en)* | 2021-07-20 | 2021-09-24 | 潍柴动力股份有限公司 | Control method and device of engine management system |

- 2022

- 2022-06-17CNCN202210687977.XApatent/CN114962019B/enactiveActive

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08232722A (en)* | 1994-12-30 | 1996-09-10 | Honda Motor Co Ltd | Fuel injection control device for internal combustion engine |

| US6397830B1 (en)* | 1999-09-27 | 2002-06-04 | Denso Corporation | Air-fuel ratio control system and method using control model of engine |

| US20020124832A1 (en)* | 2000-12-26 | 2002-09-12 | Nissan Motor Co., Ltd. | Excess air factor control device for internal combustion engine |

| CN1975135A (en)* | 2005-11-30 | 2007-06-06 | 福特环球技术公司 | Engine with two port fuel injectors |

| JP2012154288A (en)* | 2011-01-28 | 2012-08-16 | Honda Motor Co Ltd | Internal combustion engine control device |

| US20180195451A1 (en)* | 2015-07-15 | 2018-07-12 | Hitachi Automotive Systems, Ltd. | Control Apparatus for Internal Combustion Engine |

| CN107664073A (en)* | 2016-07-28 | 2018-02-06 | 长城汽车股份有限公司 | EGR rate computational methods, system and vehicle with low pressure EGR system |

| CN109026415A (en)* | 2017-06-08 | 2018-12-18 | 株式会社三国 | Engine control system and computer readable recording medium |

| CN111337109A (en)* | 2018-12-18 | 2020-06-26 | 北京福田康明斯发动机有限公司 | Apparatus and method for automatic calibration of engine air flow MAF sensor |

| CN110805498A (en)* | 2019-11-11 | 2020-02-18 | 奇瑞汽车股份有限公司 | Engine fuel correction control method |

| CN111075582A (en)* | 2019-12-30 | 2020-04-28 | 北汽福田汽车股份有限公司 | Exhaust gas recirculation rate control method, device, medium, equipment and vehicle |

| CN111894748A (en)* | 2020-07-24 | 2020-11-06 | 东风商用车有限公司 | Control method and control system for smoke limit under idle working condition of engine |

| CN111997769A (en)* | 2020-10-30 | 2020-11-27 | 潍柴动力股份有限公司 | EGR control method and device and engine system |

| CN113431690A (en)* | 2021-07-20 | 2021-09-24 | 潍柴动力股份有限公司 | Control method and device of engine management system |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116988869A (en)* | 2023-08-07 | 2023-11-03 | 一汽解放汽车有限公司 | Combustion control system and control method for gas ignition engine |

| CN119664515A (en)* | 2024-12-03 | 2025-03-21 | 一汽解放汽车有限公司 | Hydrogen engine mixed gas concentration control method, device and vehicle |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114962019B (en) | 2023-09-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US7536249B2 (en) | System and method for a pumping torque estimation model for all air induction configurations | |

| JP5681813B2 (en) | Intake control device for internal combustion engine | |

| US20090132153A1 (en) | Controlling exhaust gas recirculation in a turbocharged compression-ignition engine system | |

| CN114962019B (en) | Engine air inflow correction method and engine system | |

| JP4715799B2 (en) | Exhaust gas recirculation device for internal combustion engine | |

| CN1416541A (en) | Method and device for mass flow determination via control valve and for determining modeled induction pipe pressure | |

| JP4173565B2 (en) | Method for determining the load signal of an internal combustion engine with external exhaust gas recirculation | |

| US6705303B2 (en) | Air-fuel ratio control apparatus and method for internal combustion engine | |

| CN113389644B (en) | Feedforward control method and device for opening of VGT valve | |

| US20150275810A1 (en) | Apparatus and method for controlling diesel engine | |

| CN111219263B (en) | Determination method and storage medium for turbocharger feedforward control coefficient of exhaust gas turbine engine | |

| CN111315976B (en) | Control system for a vehicle powertrain and method of operating a vehicle powertrain | |

| JP2006070701A (en) | Control device for internal combustion engine | |

| WO2018142510A1 (en) | Intake control method and intake control device for internal combustion engine | |

| CN113847150B (en) | Emission control method and device for gas engine | |

| CN113431690B (en) | Control method and device of engine management system | |

| WO2011027439A1 (en) | Egr control system of internal combustion engine | |

| JP6930902B2 (en) | Valve controller | |

| JP2011157942A (en) | Egr control device of internal combustion engine | |

| JP2017002810A (en) | Control device for turbocharged engine | |

| JP2020041435A (en) | Operation control method for exhaust gas recirculation device, and exhaust gas recirculation device | |

| EP4015808B1 (en) | System and method for controlling an internal combustion engine based on filling performance | |

| EP3752727A1 (en) | Engine air flow estimation | |

| JPH1026049A (en) | Intake / exhaust system pressure estimation device for internal combustion engine | |

| JP6292169B2 (en) | Control device for internal combustion engine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |