CN114941129A - A kind of infrared selective absorption composite film with adjustable refractive index and preparation method thereof - Google Patents

A kind of infrared selective absorption composite film with adjustable refractive index and preparation method thereofDownload PDFInfo

- Publication number

- CN114941129A CN114941129ACN202210718094.0ACN202210718094ACN114941129ACN 114941129 ACN114941129 ACN 114941129ACN 202210718094 ACN202210718094 ACN 202210718094ACN 114941129 ACN114941129 ACN 114941129A

- Authority

- CN

- China

- Prior art keywords

- absorption

- infrared

- sputtering

- refractive index

- substrate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/34—Sputtering

- C23C14/35—Sputtering by application of a magnetic field, e.g. magnetron sputtering

- C23C14/352—Sputtering by application of a magnetic field, e.g. magnetron sputtering using more than one target

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/02—Pretreatment of the material to be coated

- C23C14/021—Cleaning or etching treatments

- C23C14/022—Cleaning or etching treatments by means of bombardment with energetic particles or radiation

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/34—Sputtering

- C23C14/3492—Variation of parameters during sputtering

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/40—Solar thermal energy, e.g. solar towers

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physical Vapour Deposition (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及光学薄膜技术领域,具体涉及一种折射率可调的红外选择性吸收复合膜及其制备方法。The invention relates to the technical field of optical films, in particular to an infrared selective absorption composite film with adjustable refractive index and a preparation method thereof.

背景技术Background technique

红外吸收材料在能源转换、红外传感探测以及热辐射管理等领域有着广泛的应用,然而很多应用领域要求吸收材料具有一定带宽的高选择性吸收物性。例如辐射制冷材料需要在8-13μm的大气窗口波段有高吸收,而在其余波段有高透或高反的特性;红外隐身则需要材料在5-8μm波段有高发射率,而在3-5μm和8-13μm两个大气窗口波段的吸收率又要尽可能的低。然而,自然界红外吸收材料的本征吸收频段或不足以覆盖整个目标波段,或选择性过低且难以调控,因此越来越不能应对愈发复杂的选频高吸收的需求。Infrared absorbing materials have a wide range of applications in energy conversion, infrared sensing and detection, and thermal radiation management. However, many application fields require absorbing materials to have highly selective absorption properties with a certain bandwidth. For example, radiation cooling materials need to have high absorption in the atmospheric window band of 8-13μm, and high transmittance or high reflectivity in other bands; infrared stealth requires materials to have high emissivity in the 5-8μm band, and 3-5μm. The absorption rate of the two atmospheric window bands of 8-13 μm should be as low as possible. However, the intrinsic absorption band of natural infrared absorbing materials is either insufficient to cover the entire target band, or the selectivity is too low and difficult to control, so it is increasingly unable to meet the increasingly complex requirements for frequency selection and high absorption.

此外,单层的吸收材料通常需要较高的光学厚度以达到理想的吸收。因此,光学腔设计常与吸收材料组合,在满足高吸收的同时能有效降低吸收膜层的厚度。但是光学腔结构的引入又会带来阻抗匹配的问题,对吸收层材料的折射率做出了进一步的要求。现有红外吸收材料的折射率固定,无法根据阻抗匹配的要求进行自由调控,限制了吸收材料在目标波段的吸收。In addition, monolayers of absorbing materials typically require higher optical thicknesses to achieve desirable absorption. Therefore, the optical cavity design is often combined with absorbing materials, which can effectively reduce the thickness of the absorbing film layer while satisfying high absorption. However, the introduction of the optical cavity structure will bring about the problem of impedance matching, which makes further requirements on the refractive index of the absorption layer material. The refractive index of the existing infrared absorbing material is fixed and cannot be freely adjusted according to the requirements of impedance matching, which limits the absorption of the absorbing material in the target wavelength band.

目前的红外吸收材料一般为金属及其类金属等离激元化合物、无机电介质以及有机材料。比如典型的金属微结构依靠其共振吸收和/或多重光散射等物理效应叠加,能在红外波段具备宽谱高吸收特性。如公开号为CN112786772A的中国发明专利,利用疏松多孔的纳米金黑(金的微纳结构)作为吸收材料实现了宽谱红外增强吸收,在可见-中红外频段平均吸收高达96%以上。然而,由于金属在整个红外波段的消光系数普遍较高,上述类型微结构吸收材料不具备频段选择性;类金属等离激元化合物比如氮化钛、氮化锆等依靠其微纳结构表面等离激元效应激发来完成红外吸收,其吸收波段严格受限于等离激元激发波段限制,吸收带宽通常较窄,进一步获得一定带宽的选择性吸收能力往往需要复杂的微纳多级结构集成才能实现,缺乏简便的调控手段对吸收波段进行灵活调控。The current infrared absorbing materials are generally metals and their metalloid plasmonic compounds, inorganic dielectrics and organic materials. For example, typical metal microstructures can have broad-spectrum high absorption properties in the infrared band by virtue of their superposition of physical effects such as resonant absorption and/or multiple light scattering. For example, the Chinese invention patent with publication number CN112786772A uses loose and porous nano-gold black (gold micro-nano structure) as the absorption material to achieve broad-spectrum infrared enhanced absorption, and the average absorption in the visible-mid-infrared frequency band is as high as more than 96%. However, due to the generally high extinction coefficient of metals in the entire infrared band, the above-mentioned types of microstructured absorbing materials do not have frequency band selectivity; metalloid plasmonic compounds such as titanium nitride, zirconium nitride, etc. Infrared absorption is accomplished by excitation of the plasmon effect. The absorption band is strictly limited by the plasmon excitation band, and the absorption bandwidth is usually narrow. Further selective absorption capability of a certain bandwidth often requires complex micro-nano multi-level structure integration. To achieve this, there is a lack of simple control means to flexibly control the absorption band.

与之相比,无机电介质材料依靠其特定化学键的振动和转动导致的声子共振吸收,具备红外选频吸收的先天优势,因此利用不同化学键间的组合,可以方便灵活地实现一定带宽的红外选择性吸收调控。In contrast, inorganic dielectric materials rely on the phonon resonance absorption caused by the vibration and rotation of their specific chemical bonds, and have the inherent advantage of infrared frequency selective absorption. Therefore, the combination of different chemical bonds can easily and flexibly achieve a certain bandwidth of infrared selection. Sexual absorption regulation.

近期Lin等(Lin C,Li Y,Chi C,et al.A Solution-processed InorganicEmitter with High Spectral Effectiveness for Efficient Daytime RadiativeCooling in Hot Humid Climates.2021.)将SiOxNy作为吸收材料,将在8.5、9.4、12.5μm处具备本征吸收的Si-O键以及在11μm处有本征吸收的Si-N键联用,基于此设计的三层结构的红外选择性吸收膜系,其在8-13μm的大气窗口波段达到了94.6%的吸收。但是现有无机电介质材料简单的化学键组合策略,获得的红外选择性吸收复合膜,通常折射率偏低且不具备大范围调控的可能,实现长波段红外的高吸收往往要依赖过厚的吸收膜层;另外,大多数有机基团(化学键)在多数红外波段也能依靠振动和转动产生优异的红外吸收,但是同无机电介质吸收材料类似,多数红外吸收有机材料折射率均较低且调控范围小,需要更厚的吸收膜层才能达到理想的吸收效果。且有机高分子材料内通常包含了多个红外吸收基团,宽谱响应特性突出,结合较大吸收膜厚时,很难实现理想选择性吸收的效果。Recently Lin et al. (Lin C, Li Y, Chi C, et al. A Solution-processed Inorganic Emitter with High Spectral Effectiveness for Efficient Daytime Radiative Cooling in Hot Humid Climates. 2021.) used SiOx Ny as an absorbing material, which will be used in 8.5, 9.4. The Si-O bond with intrinsic absorption at 12.5μm and the Si-N bond with intrinsic absorption at 11μm are used in combination. Based on this design, the three-layer structure of the infrared selective absorption film system is 8-13μm. The atmospheric window band reaches 94.6% absorption. However, the simple chemical bond combination strategy of the existing inorganic dielectric materials, the obtained infrared selective absorption composite film usually has a low refractive index and does not have the possibility of large-scale adjustment, and the realization of high absorption in the long-band infrared often relies on an excessively thick absorption film. In addition, most organic groups (chemical bonds) can also rely on vibration and rotation to produce excellent infrared absorption in most infrared bands, but similar to inorganic dielectric absorbing materials, most infrared absorbing organic materials have a low refractive index and a small control range. , requires a thicker absorbing film layer to achieve the ideal absorption effect. In addition, organic polymer materials usually contain multiple infrared absorbing groups, and the broad-spectrum response characteristics are outstanding. When combined with a large absorbing film thickness, it is difficult to achieve an ideal selective absorption effect.

综上所述,目前基于金属及其类金属等离激元化合物微结构的红外吸收材料,均难实现理想宽谱响应的红外高选择性,往往需要复杂的微纳结构集成才能获得。而大多数无机电介质、有机材料受低折射率的限制,需要较高的膜层厚度才能在长波段红外有高吸收,且其吸收波段也受到材料本征吸收频段的限制,目前也均远不能满足实际红外选频高吸收的要求。而折射率作为材料的固有属性,由光波作用下其极化效应强弱来决定,与自身自由电子态密切相关,而单一材料的折射率通常大范围调控难。In summary, the current infrared absorbing materials based on the microstructure of metals and their metalloid plasmonic compounds are difficult to achieve high infrared selectivity with ideal broad-spectrum response, and often require complex micro-nano structure integration. However, most inorganic dielectrics and organic materials are limited by the low refractive index, and require a high film thickness to have high absorption in the long-band infrared, and their absorption band is also limited by the intrinsic absorption band of the material. Meet the requirements of practical infrared frequency selection and high absorption. The refractive index, as an inherent property of a material, is determined by the strength of its polarization effect under the action of light waves, and is closely related to its own free electronic state. The refractive index of a single material is usually difficult to control in a large range.

因此,要获得具备优异选择性的宽谱响应红外高吸收材料,在要求其在目标波段范围有强烈红外吸收的同时,又兼具大范围折射率调控的能力存在挑战。Therefore, in order to obtain a broad-spectrum response infrared high-absorbing material with excellent selectivity, it is a challenge to have a strong infrared absorption in the target wavelength range, and at the same time, the ability to control a wide range of refractive index.

发明内容SUMMARY OF THE INVENTION

本发明针对现有技术中红外吸收材料选择性低,折射率调控范围窄的问题,提供中红外波长范围内,具有选择性、宽谱吸收的非晶均匀复合材料吸收膜,其制备方法简单、高效且可自由调控材料的折射率以及吸收波段。Aiming at the problems of low selectivity and narrow refractive index control range of mid-infrared absorbing materials in the prior art, the invention provides an amorphous uniform composite material absorbing film with selectivity and broad-spectrum absorption in the mid-infrared wavelength range, and the preparation method is simple, The refractive index and absorption band of the material can be adjusted efficiently and freely.

为实现上述目的,本发明采用的技术方案是:For achieving the above object, the technical scheme adopted in the present invention is:

一种折射率可调的红外选择性吸收复合膜,包括衬底和吸收膜;所述衬底为刚性或柔性衬底,自衬底向外单向形成一层吸收膜;所述吸收膜为非晶结构,由任意数量红外吸收靶材共溅射形成;An infrared selective absorption composite film with adjustable refractive index, comprising a substrate and an absorption film; the substrate is a rigid or flexible substrate, and a layer of absorption film is formed unidirectionally from the substrate to the outside; the absorption film is Amorphous structure, formed by co-sputtering of any number of infrared absorbing targets;

所述红外选择吸收复合膜的折射率、吸收波段根据共溅射参数和/或共溅射红外吸收靶材比例任意调控。The refractive index and absorption band of the infrared selective absorption composite film are arbitrarily regulated according to co-sputtering parameters and/or the ratio of co-sputtering infrared absorption targets.

本发明利用的是红外吸收靶材的化学键振动和转动造成吸收,并通过共溅射选择和调控相应红外吸收靶材的化学键的比例,同时调控溅射参数从而实现能吸收目标波段复合膜,特别是能通过调控红外吸收靶材和溅射参数实现宽谱的吸收和折射率的随意调控,克服了现有选择性吸收材料的不足。The invention utilizes the chemical bond vibration and rotation of the infrared absorption target to cause absorption, selects and regulates the ratio of the chemical bond of the corresponding infrared absorption target through co-sputtering, and regulates the sputtering parameters to realize the composite film that can absorb the target band, especially It is able to achieve broad-spectrum absorption and random adjustment of refractive index by adjusting the infrared absorption target and sputtering parameters, which overcomes the shortcomings of the existing selective absorption materials.

材料的红外吸收可根据目标波段灵活调控,保证该材料在中红外波段具有一定的吸收选择性,且通过改变溅射参数可进一步调控各化学键的相对比例,进而调控膜层吸收峰的位置,波长范围和强度以及吸收材料的折射率。此外材料的折射率可根据共溅射靶材的选择进行灵活调控,尽可能满足光学腔阻抗匹配的要求,降低目标波长下膜系的反射,从而提升其吸收率。The infrared absorption of the material can be flexibly adjusted according to the target wavelength band to ensure that the material has a certain absorption selectivity in the mid-infrared band, and by changing the sputtering parameters, the relative proportion of each chemical bond can be further adjusted, and then the position and wavelength of the absorption peak of the film can be adjusted. range and intensity and the refractive index of the absorbing material. In addition, the refractive index of the material can be flexibly adjusted according to the selection of the co-sputtering target, so as to meet the requirements of impedance matching of the optical cavity as much as possible, reduce the reflection of the film system at the target wavelength, and thus improve its absorptivity.

所述红外选择性吸收复合膜厚度为100-500nm,折射率在在1.5-3之间任意调控;吸收波段在6~25μm之间任意调控。The thickness of the infrared selective absorption composite film is 100-500 nm, the refractive index is arbitrarily adjusted between 1.5-3, and the absorption band is arbitrarily adjusted between 6-25 μm.

所述衬底为硅或铝箔衬底;The substrate is a silicon or aluminum foil substrate;

所述红外吸收靶材包括In2O3、Al2O3、AlN、SiC、Si3N4、SiO2中的一种或多种。The infrared absorption target material includes one or more of In2 O3 , Al2 O3 , AlN, SiC, Si3 N4 , and SiO2 .

无机电介质材料中,与氧化物相比,电阻率相对低的电介质材料(比如氮化物、碳化物等)内其电子电荷更易响应光场极化,从而自身有更大的折射率调控能力。因此,在调控材料光场极化响应程度的基础上,通过不同化学键红外选频吸收特性的协同叠加,能有效拓展红外吸收波段的同时满足高选择性和大折射率调控范围的需要。此外,宽谱响应红外高吸收材料作为吸收体内的吸收层,与光学腔结构设计相结合来调制吸收体的吸收特性,常需要吸收材料折射率具有较大的可调控性以实现阻抗匹配,从而提升整个膜系的吸收能力。Among inorganic dielectric materials, compared with oxides, dielectric materials with relatively low resistivity (such as nitrides, carbides, etc.) have electronic charges more responsive to the polarization of the light field, and thus have greater ability to control the refractive index. Therefore, on the basis of controlling the polarization response of the material in the optical field, the infrared absorption band can be effectively expanded through the synergistic superposition of the infrared frequency-selective absorption characteristics of different chemical bonds, while meeting the needs of high selectivity and large refractive index control range. In addition, the broad-spectrum response infrared high absorption material is used as the absorption layer in the absorber, and the absorption characteristics of the absorber can be modulated in combination with the optical cavity structure design. Improve the absorption capacity of the entire membrane system.

因此本发明具体是选频吸收材料的设计要根据目标波段,对具备不同本征吸收波段和电阻率的材料进行有效复合,最终赋予该材料目标波段的选择吸收和实现阻抗匹配所需的折射率。Therefore, the design of the frequency selective absorption material in the present invention is to effectively compound materials with different intrinsic absorption bands and resistivities according to the target wavelength band, and finally endow the material with the selective absorption of the target wavelength band and the refractive index required to achieve impedance matching. .

本发明还提供所述的折射率可调的红外选择性吸收复合膜的制备方法,包括:The present invention also provides the preparation method of the infrared selective absorption composite film with adjustable refractive index, including:

步骤1,对衬底进行超声清洗,再采用加热或等离子体轰击活化衬底表面;Step 1, ultrasonically clean the substrate, and then activate the substrate surface by heating or plasma bombardment;

步骤2,选取红外吸收靶材作为共溅射靶材,对衬底进行多靶磁控共溅射,得到所述红外选择性吸收复合膜。Step 2, selecting an infrared absorption target as a co-sputtering target, and performing multi-target magnetron co-sputtering on the substrate to obtain the infrared selective absorption composite film.

本发明通过将有红外本征吸收的材料作为靶材,共溅射到衬底上,形成折射率可调的红外选择性吸收复合材料层。在共溅射作用下,不同靶材料粒子互相结合,形成一种或多种红外本征吸收化学键,从而达到红外选择性吸收。且通过组合不同电阻率的靶材进行共溅射,溅射产物的折射率可在大范围内进行调控,从而达到阻抗匹配要求的折射率。该复合材料膜制备步骤简易,膜层结构简单,力学稳定性强。通过调控磁控溅射的沉积参数,可以改变化学键的比例,进而在一定程度上调控材料的折射率,吸收峰位置和强度。In the present invention, a material with intrinsic infrared absorption is used as a target to co-sputter onto a substrate to form an infrared selective absorption composite material layer with adjustable refractive index. Under the action of co-sputtering, particles of different target materials combine with each other to form one or more chemical bonds of infrared intrinsic absorption, thereby achieving infrared selective absorption. And by combining targets with different resistivities for co-sputtering, the refractive index of the sputtered product can be adjusted in a wide range, so as to achieve the refractive index required for impedance matching. The composite material film has simple preparation steps, simple film layer structure and strong mechanical stability. By adjusting the deposition parameters of magnetron sputtering, the ratio of chemical bonds can be changed, and then the refractive index, absorption peak position and intensity of the material can be adjusted to a certain extent.

所述的衬底经上述预处理后,能提高衬底表面清洁度和膜基结合力,有利于磁控溅射薄膜在衬底上的高质量生长。优选地,步骤1中,依次用丙酮、乙醇和去离子水对衬底进行超声清洗。After the substrate is pretreated, the cleanliness of the substrate surface and the bonding force of the film base can be improved, which is beneficial to the high-quality growth of the magnetron sputtering film on the substrate. Preferably, in step 1, the substrate is ultrasonically cleaned with acetone, ethanol and deionized water in sequence.

步骤2中,进行多靶磁控共溅射时,对衬底施加离子轰击辅助;共溅射靶采用脉冲或射频电源驱动,共溅射在氩气气氛或氩氮混合气气氛下进行。In step 2, when performing multi-target magnetron co-sputtering, ion bombardment assistance is applied to the substrate; the co-sputtering target is driven by a pulse or radio frequency power supply, and the co-sputtering is performed in an argon atmosphere or an argon-nitrogen mixed gas atmosphere.

优选地,溅射靶功率密度为1-15W/cm2,溅射气压为0.1-1Pa,氮气分压范围为0~0.5Pa,靶基距高于50mm。其中,增加溅射单一靶功率密度会使产物吸收波段向该靶组成材料的吸收波段增强。Preferably, the power density of the sputtering target is 1-15 W/cm2 , the sputtering gas pressure is 0.1-1 Pa, the partial pressure of nitrogen gas is in the range of 0-0.5 Pa, and the target-to-base distance is higher than 50 mm. Among them, increasing the power density of sputtering a single target will enhance the absorption band of the product toward the absorption band of the target constituent material.

氮化物或碳化物靶材溅射,氮气分压较大时会明显降低溅射速率,腔体中氧残留与膜层作用时间充分,导致制备过程中氧引入的增加,膜层产物的折射率会降低;而氧化物靶材进行溅射的情况下,通入氮气进行反应溅射会引入高折射率的氮化物组分,使得产物的折射率会有一定程度的提升。Nitride or carbide targets are sputtered. When the nitrogen partial pressure is large, the sputtering rate will be significantly reduced, and the residual oxygen in the cavity will have sufficient time to interact with the film, resulting in an increase in the introduction of oxygen during the preparation process and the refractive index of the film product. In the case of sputtering with oxide targets, nitrogen gas is introduced for reactive sputtering to introduce nitride components with high refractive index, which will increase the refractive index of the product to a certain extent.

此外,通过与氮气反应溅射引入氮化物化学键,产物会增加相应氮化物的吸收峰,最终利于吸收波段拓宽。实际制备过程中可根据具体工艺对结果的影响进行调节,获得目标折射率和目标波段的吸收复合膜。In addition, by introducing nitride chemical bonds by reactive sputtering with nitrogen, the product will increase the absorption peak of the corresponding nitride, which is ultimately beneficial to broaden the absorption band. In the actual preparation process, it can be adjusted according to the influence of the specific process on the result, and the absorption composite film of the target refractive index and the target wavelength band can be obtained.

为提高材料折射率和吸收带宽,进一步优选地,共溅射靶的功率密度为2-10W/cm2,溅射气压范围为0.15-0.6Pa,靶基距高于100mm;所述氮气分压范围缩小为0~0.2Pa。In order to improve the refractive index and absorption bandwidth of the material, further preferably, the power density of the co-sputtering target is 2-10W/cm2 , the sputtering gas pressure range is 0.15-0.6Pa, and the target-base distance is higher than 100mm; the nitrogen partial pressure The range is narrowed to 0 to 0.2Pa.

所述的离子轰击辅助为氩粒子轰击。The ion bombardment assistance is argon particle bombardment.

适当的氩离子轰击能使溅射吸收膜更加致密,但是过大的氩离子轰击功率密度会在溅射过程中破坏吸收膜表面已形成的稳定化学键合,从而降低其折射率以及吸收。基于所述靶材料的化学键能和溅射级联碰撞作用机制,优选地,所述的氩粒子轰击功率密度为1-2.5W/cm2,氩粒子轰击能量不小于-40eV。Appropriate argon ion bombardment can make the sputtering absorber film more dense, but excessive argon ion bombardment power density will destroy the stable chemical bonds formed on the surface of the absorber film during the sputtering process, thereby reducing its refractive index and absorption. Based on the chemical bond energy of the target material and the sputtering cascade collision mechanism, preferably, the argon particle bombardment power density is 1-2.5W/cm2 , and the argon particle bombardment energy is not less than -40eV.

通过对陶瓷靶溅射功率的调控以及沉积时间的控制,并在共溅射的同时对衬底施以合适的离子轰击辅助,能够获得合适厚度和折射率的宽谱选择性红外吸收复合材料膜。By controlling the sputtering power of the ceramic target and the deposition time, and applying appropriate ion bombardment assistance to the substrate during co-sputtering, a broad-spectrum selective infrared absorption composite film with suitable thickness and refractive index can be obtained .

与现有技术相比,本发明具有以下有益效果:Compared with the prior art, the present invention has the following beneficial effects:

(1)本发明基于多种化学键的振动或转动在红外波段实现吸收,利用多种红外吸收靶材的共溅射制备折射率可调的红外选择性吸收复合材料膜,拓宽了材料的吸收波段并使其可灵活调控。(1) The invention realizes absorption in the infrared band based on the vibration or rotation of various chemical bonds, and uses the co-sputtering of various infrared absorption targets to prepare an infrared selective absorption composite film with adjustable refractive index, which broadens the absorption band of the material. and make it flexible and controllable.

(2)本发明采用磁控溅射法制备红外吸收膜层,能灵活调控复合膜层中化学键的比例和类型从而实现选择性,能够通过组合不同电阻率的材料使吸收膜折射率在一定范围内可调,且工艺简单,成本低,易于大规模集成制备。(2) The present invention adopts the magnetron sputtering method to prepare the infrared absorption film layer, which can flexibly adjust the ratio and type of chemical bonds in the composite film layer to achieve selectivity, and can make the refractive index of the absorption film within a certain range by combining materials with different resistivities Internally adjustable, simple process, low cost, and easy for large-scale integrated preparation.

附图说明Description of drawings

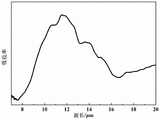

图1为实施例1的红外选择性吸收复合膜在7-20μm波段的红外吸收。Figure 1 shows the infrared absorption of the infrared selective absorption composite membrane of Example 1 in the 7-20 μm band.

图2为实施例1的红外选择性吸收复合膜及其原组分在7-14μm波段的折射率和消光系数。Figure 2 shows the refractive index and extinction coefficient of the infrared selective absorption composite film of Example 1 and its original components in the 7-14 μm waveband.

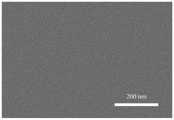

图3为实施例1的红外选择性吸收复合膜表面的SEM图片。FIG. 3 is a SEM picture of the surface of the infrared selective absorption composite membrane of Example 1. FIG.

图4为实施例1的红外选择性吸收复合膜截面的SEM图片。FIG. 4 is a SEM picture of the cross section of the infrared selective absorption composite membrane of Example 1. FIG.

图5为实施例2的红外选择性吸收复合膜在7-20μm波段的红外吸收。FIG. 5 is the infrared absorption of the infrared selective absorption composite membrane of Example 2 in the 7-20 μm band.

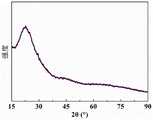

图6为实施例2的红外选择性吸收复合膜XRD测试曲线。FIG. 6 is the XRD test curve of the infrared selective absorption composite membrane of Example 2. FIG.

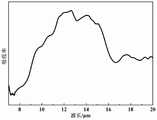

图7为实施例3的红外选择性吸收复合膜在7-20μm波段的红外吸收。FIG. 7 is the infrared absorption of the infrared selective absorption composite membrane of Example 3 in the 7-20 μm band.

图8为实施例3的红外选择性吸收复合膜表面的SEM图片。FIG. 8 is a SEM picture of the surface of the infrared selective absorption composite membrane of Example 3. FIG.

图9为实施例4的红外选择性吸收复合膜在7-20μm波段的红外吸收。FIG. 9 is the infrared absorption of the infrared selective absorption composite membrane of Example 4 in the band of 7-20 μm.

图10为实施例4的红外选择性吸收复合膜及其原组分在全波段的折射率和消光系数。FIG. 10 shows the refractive index and extinction coefficient of the infrared selective absorption composite film of Example 4 and its original components in the whole waveband.

图11为实施例4的红外选择性吸收复合膜表面的SEM图片。FIG. 11 is a SEM picture of the surface of the infrared selective absorption composite membrane of Example 4. FIG.

具体实施方式Detailed ways

为了使本发明的目的、技术方案及优点更加清楚明白,以下结合实施例,对本发明进行进一步详细说明。应当理解,此处所描述的具体实施例仅用以解释本发明,并不用于限定本发明。本领域技术人员在理解本发明的技术方案基础上进行修改或等同替换,而未脱离本发明技术方案的精神和范围,均应涵盖在本发明的保护范围内。In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. Those skilled in the art can make modifications or equivalent replacements on the basis of understanding the technical solutions of the present invention, without departing from the spirit and scope of the technical solutions of the present invention, and all should be included within the protection scope of the present invention.

以下具体实施方式中所采用的原料均购于市场。The raw materials used in the following specific embodiments are all purchased from the market.

实施例1Example 1

本实施例中,刚性衬底为单抛硅和双抛硅,柔性衬底为铝箔,吸收层膜层厚度为100nm。In this embodiment, the rigid substrate is single-polished silicon and double-polished silicon, the flexible substrate is aluminum foil, and the thickness of the absorption layer is 100 nm.

本实施例中单层的红外选择性吸收复合材料吸收膜通过磁控共溅射在单抛硅上沉积薄膜,其中吸收材料靶材为SiO2和Al2O3,其具体制备方法如下:In this embodiment, the single-layer infrared selective absorption composite material absorption film is deposited on single-polish silicon by magnetron co-sputtering, wherein the absorption material targets are SiO2 and Al2 O3 , and the specific preparation method is as follows:

(1)依次用丙酮、乙醇、去离子水超声清洗刚性衬底15min,去除衬底表面污染物,吹干后固定于衬底托盘上;(1) ultrasonically clean the rigid substrate with acetone, ethanol and deionized water successively for 15 minutes to remove the pollutants on the surface of the substrate, and fix it on the substrate tray after drying;

(2)将托盘装载进磁控溅射设备的沉积室中,并利用等离子轰击衬底表面8min,活化衬底;(2) the tray is loaded into the deposition chamber of the magnetron sputtering equipment, and the substrate surface is bombarded with plasma for 8 min to activate the substrate;

(3)采用磁控共溅射,SiO2靶采用射频电源驱动,溅射功率密度为9W/cm2,Al2O3靶采用射频电源驱动,溅射功率密度为4W/cm2,加以衬底氩离子轰击,功率密度为1W/cm2,同时通入氮气,氮气分压为0.1Pa,沉积1h后,关闭陶瓷靶和氩离子轰击的驱动电源,获得复合材料层;(3) Using magnetron co-sputtering, the SiO2 target is driven by radio frequency power supply, the sputtering power density is 9W/cm2 , the Al2 O3 target is driven by radio frequency power supply, and the sputtering power density is 4W/cm2 . Bottom argon ion bombardment, power density is 1W/cm2 , nitrogen gas is introduced at the same time, nitrogen partial pressure is 0.1Pa, after deposition for 1h, the driving power supply of ceramic target and argon ion bombardment is turned off to obtain a composite material layer;

如图1所示,吸收膜在8-20μm均有吸收,且在10和14μm处有一个较明显的吸收峰,其在20μm处吸收也有上升趋势,呈现多峰选择吸收的特性。如图2所示,该复合材料在11.6μm前的折射率位于其原始组分之间,而11.6μm后该复合材料的折射率高于两个原始组分。且其消光系数从7μm处开始不再为0,表明该复合材料在7μm后存在本征吸收,且材料消光系数在10.5μm处达到峰值且在9-14μm维持了较高的数值;如图3所示,该吸收膜表面平整均匀。如图4所示,该复合材料截面未分相,平整均匀。As shown in Figure 1, the absorption film has absorption at 8-20 μm, and has an obvious absorption peak at 10 and 14 μm, and its absorption at 20 μm also has an upward trend, showing the characteristics of multi-peak selective absorption. As shown in Figure 2, the index of refraction of the composite material before 11.6 μm lies between its original components, while the index of refraction of the composite material after 11.6 μm is higher than the two original components. And its extinction coefficient is no longer 0 from 7 μm, indicating that the composite material has intrinsic absorption after 7 μm, and the material extinction coefficient reaches a peak at 10.5 μm and maintains a high value at 9-14 μm; Figure 3 As shown, the surface of the absorbing film is flat and uniform. As shown in Figure 4, the cross-section of the composite material is not phase-separated and is flat and uniform.

实施例2Example 2

本实施例制备红外选择性吸收复合材料膜,与实施例1的主要区别在于,吸收材料靶材为SiC和SiO2,且本实施例中未通入氮气,膜厚为120nm。本实施例的具体制备方法如下:In this example, the infrared selective absorption composite material film is prepared. The main difference from Example 1 is that the absorption material targets are SiC and SiO2 , and nitrogen gas is not introduced in this example, and the film thickness is 120 nm. The concrete preparation method of this embodiment is as follows:

(1)依次用丙酮、乙醇、去离子水超声清洗刚性底15min,去除衬底表面污染物,吹干后固定于衬底托盘上;(1) ultrasonically clean the rigid bottom with acetone, ethanol and deionized water successively for 15 min to remove the pollutants on the surface of the substrate, and fix it on the substrate tray after drying;

(2)将托盘装载进磁控溅射设备的沉积室中,并利用等离子体轰击衬底8min,活化衬底表面;(2) the tray is loaded into the deposition chamber of the magnetron sputtering equipment, and the substrate is bombarded with plasma for 8min to activate the substrate surface;

(3)采用磁控共溅射SiC和SiO2,SiC靶采用射频电源驱动,溅射功率密度为10W/cm2,SiO2靶采用射频电源驱动,溅射功率密度为5.5W/cm2;同时加以衬底氩离子轰击,功率密度为2W/cm2,沉积0.6h后,关闭双靶和氩离子轰击的驱动电源,在单抛硅衬底的表面获得Si-O-C吸收层,取出基片;(3) SiC and SiO2 are co-sputtered by magnetron, the SiC target is driven by radio frequency power, the sputtering power density is 10W/cm2 , the SiO2 target is driven by radio frequency power, and the sputtering power density is 5.5W/cm2 ; At the same time, the substrate was bombarded with argon ions, and the power density was 2W/cm2 . After 0.6h of deposition, the driving power of the double target and the argon ion bombardment was turned off, and the Si-OC absorption layer was obtained on the surface of the single-polished silicon substrate, and the substrate was taken out. ;

如图5所示,吸收膜在10-12μm处有明显的吸收峰。如图6所示,该材料为非晶。As shown in Figure 5, the absorption film has an obvious absorption peak at 10-12 μm. As shown in Figure 6, the material is amorphous.

实施例3Example 3

本实施例制备的红外选择性吸收膜,与实施例1的主要区别在于,制备的吸收膜溅射靶为AlN和SiC,且本实施例中未通入氮气,膜厚为115nm。本实施例的具体制备方法如下:The main difference between the infrared selective absorption film prepared in this example and Example 1 is that the prepared absorption film sputtering targets are AlN and SiC, and nitrogen gas is not introduced in this example, and the film thickness is 115 nm. The specific preparation method of the present embodiment is as follows:

(1)依次用丙酮、乙醇、去离子水超声清洗刚性衬底15min,去除衬底表面污染物,吹干后固定于衬底托盘上;(1) ultrasonically clean the rigid substrate with acetone, ethanol and deionized water successively for 15 minutes to remove the pollutants on the surface of the substrate, and fix it on the substrate tray after drying;

(2)将托盘装载进磁控溅射设备的沉积室中,利用等离子体轰击衬底8min,活化衬底表面;(2) the tray is loaded into the deposition chamber of the magnetron sputtering equipment, and the substrate is bombarded with plasma for 8min to activate the substrate surface;

(3)采用磁控共溅射,SiC靶采用射频电源驱动,溅射功率密度为9W/cm2,AlN靶采用射频电源驱动,溅射功率密度为8W/cm2,同时加以衬底氩离子轰击,功率密度为1W/cm2,沉积0.6h后,关闭SiC,AlN靶和氩离子轰击的驱动电源,获得复合材料吸收层,取出基片;(3) Using magnetron co-sputtering, the SiC target is driven by radio frequency power, the sputtering power density is 9W/cm2 , the AlN target is driven by radio frequency power, the sputtering power density is 8W/cm2 , and the substrate argon ions are added at the same time. Bombardment, the power density is 1W/cm2 , after 0.6h of deposition, the driving power of SiC, AlN target and argon ion bombardment is turned off to obtain the composite material absorption layer, and the substrate is taken out;

如图7所示,吸收膜在8-16μm有明显的吸收峰。如图8所示,吸收膜为未分相的均匀薄膜As shown in Figure 7, the absorption film has an obvious absorption peak at 8-16 μm. As shown in Figure 8, the absorption film is a uniform film without phase separation

实施例4Example 4

本实施例制备的红外选择性吸收膜,与实施例1的主要区别在于,制备的吸收膜溅射靶为AlN和SiO2,膜厚为220nm。本实施例的具体制备方法如下:The main difference between the infrared selective absorption film prepared in this example and Example 1 is that the prepared absorption film sputtering targets are AlN and SiO2 , and the film thickness is 220 nm. The concrete preparation method of this embodiment is as follows:

(1)依次利用丙酮、乙醇、去离子水对刚性衬底进行超声清洗15min,吹干后将透明基底固定于衬底托盘上;(1) Utilize acetone, ethanol, and deionized water successively to ultrasonically clean the rigid substrate for 15 minutes, and fix the transparent substrate on the substrate tray after drying;

(2)将托盘装载进磁控溅射设备的沉积室中,利用等离子体轰击衬底8min,活化衬底表面;(2) the tray is loaded into the deposition chamber of the magnetron sputtering equipment, and the substrate is bombarded with plasma for 8min to activate the substrate surface;

(3)采用磁控共溅射靶为AlN和SiO2,AlN靶采用射频电源驱动,溅射功率密度为5W/cm2,SiO2靶采用射频电源驱动,溅射功率密度为6W/cm2,同时加以衬底氩离子轰击,功率密度为1W/cm2,同时通入氮气,氮气分压为0.05Pa,沉积1.5h后,关闭AlN靶,SiO2靶和氩离子轰击的驱动电源,获得Al-Si-O-N层,取出基片;(3) The magnetron co-sputtering targets are AlN and SiO2 , the AlN target is driven by radio frequency power, the sputtering power density is 5W/cm2 , and the SiO2 target is driven by radio frequency power, and the sputtering power density is 6 W/cm2 At the same time, the substrate was bombarded with argon ions, the power density was 1W/cm2 , and nitrogen gas was introduced at the same time, and the nitrogen partial pressure was0.05Pa . Al-Si-ON layer, take out the substrate;

图9为本实施例制备的吸收膜在7-20μm波段的红外吸收;图10为吸收膜的折射率和消光系数及原组分折射率和吸收系数对比,从图中可以看出,该复合材料在11μm后的折射率始终高于2,且在15μm处达到3。SiO2的消光系数约在9μm处达到峰值,AlN的消光系数在14.5μm处达到峰值,而复合吸收材料的消光系数峰可以覆盖8-16μm的波段;图11所示,该复合材料为单一均匀材料。Figure 9 shows the infrared absorption of the absorption film prepared in this example in the 7-20 μm band; Figure 10 shows the comparison of the refractive index and extinction coefficient of the absorption film and the refractive index and absorption coefficient of the original components. It can be seen from the figure that the composite The index of refraction of the material is consistently higher than 2 after 11 μm and reaches 3 at 15 μm. The extinction coefficient of SiO2 peaks at about 9 μm, the extinction coefficient of AlN peaks at 14.5 μm, and the peak of the extinction coefficient of the composite absorbing material can cover the band of 8-16 μm; as shown in Figure 11, the composite material is a single uniform Material.

以上所述的具体实施方式对本发明的技术方案和有益效果进行了详细说明,应理解的是以上所述仅为本发明的最优选实施例,应当指出,对于本技术领域的普通技术人员来说,在不脱离本发明原理的前提下,还可以做出若干改进和润饰,这些改进和润饰也应视为本发明的保护范围。The above-mentioned specific embodiments describe in detail the technical solutions and beneficial effects of the present invention. It should be understood that the above-mentioned embodiments are only the most preferred embodiments of the present invention. It should be pointed out that for those skilled in the art, , without departing from the principle of the present invention, several improvements and modifications can also be made, and these improvements and modifications should also be regarded as the protection scope of the present invention.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210718094.0ACN114941129A (en) | 2022-06-23 | 2022-06-23 | A kind of infrared selective absorption composite film with adjustable refractive index and preparation method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210718094.0ACN114941129A (en) | 2022-06-23 | 2022-06-23 | A kind of infrared selective absorption composite film with adjustable refractive index and preparation method thereof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114941129Atrue CN114941129A (en) | 2022-08-26 |

Family

ID=82911614

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210718094.0APendingCN114941129A (en) | 2022-06-23 | 2022-06-23 | A kind of infrared selective absorption composite film with adjustable refractive index and preparation method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114941129A (en) |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5346600A (en)* | 1992-08-14 | 1994-09-13 | Hughes Aircraft Company | Plasma-enhanced magnetron-sputtered deposition of materials |

| US5377045A (en)* | 1990-05-10 | 1994-12-27 | The Boc Group, Inc. | Durable low-emissivity solar control thin film coating |

| US20020033330A1 (en)* | 2000-08-07 | 2002-03-21 | Demaray Richard E. | Planar optical devices and methods for their manufacture |

| CN101266080A (en)* | 2008-05-08 | 2008-09-17 | 山东桑乐太阳能有限公司 | Selective solar energy absorbing coating and method for making same |

| CN102121757A (en)* | 2010-01-28 | 2011-07-13 | 北京有色金属研究总院 | Non-vacuum solar spectrum selective absorption coating and preparation method thereof |

| CN103528251A (en)* | 2013-10-14 | 2014-01-22 | 常州深蓝涂层技术有限公司 | High-temperature resistance metal ceramic solar energy selective absorbing coating and preparing method |

| CN106152576A (en)* | 2016-09-14 | 2016-11-23 | 兰州交通大学 | High temperature spectrum coating for selective absorption based on refractory metal boride and preparation method |

| CN108796441A (en)* | 2018-06-06 | 2018-11-13 | 中国科学院宁波材料技术与工程研究所 | A kind of light absorption plated film, preparation method and application |

- 2022

- 2022-06-23CNCN202210718094.0Apatent/CN114941129A/enactivePending

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5377045A (en)* | 1990-05-10 | 1994-12-27 | The Boc Group, Inc. | Durable low-emissivity solar control thin film coating |

| US5346600A (en)* | 1992-08-14 | 1994-09-13 | Hughes Aircraft Company | Plasma-enhanced magnetron-sputtered deposition of materials |

| US20020033330A1 (en)* | 2000-08-07 | 2002-03-21 | Demaray Richard E. | Planar optical devices and methods for their manufacture |

| CN101266080A (en)* | 2008-05-08 | 2008-09-17 | 山东桑乐太阳能有限公司 | Selective solar energy absorbing coating and method for making same |

| CN102121757A (en)* | 2010-01-28 | 2011-07-13 | 北京有色金属研究总院 | Non-vacuum solar spectrum selective absorption coating and preparation method thereof |

| CN103528251A (en)* | 2013-10-14 | 2014-01-22 | 常州深蓝涂层技术有限公司 | High-temperature resistance metal ceramic solar energy selective absorbing coating and preparing method |

| CN106152576A (en)* | 2016-09-14 | 2016-11-23 | 兰州交通大学 | High temperature spectrum coating for selective absorption based on refractory metal boride and preparation method |

| CN108796441A (en)* | 2018-06-06 | 2018-11-13 | 中国科学院宁波材料技术与工程研究所 | A kind of light absorption plated film, preparation method and application |

Non-Patent Citations (2)

| Title |

|---|

| 王小雨: "《耐高温WTi-Al2O3复合金属陶瓷基太阳光谱选择性吸收涂层的研究》", 中国优秀硕士学位论文全文数据库 工程科技Ⅰ辑, no. 01* |

| 田丽等: "《微电子工艺原理与技术》", 31 August 2021, 哈尔滨工业大学出版社, pages: 245 - 246* |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP4854552B2 (en) | Antireflection film and optical component having the same | |

| KR100984221B1 (en) | Optical thin film deposition device and optical thin film fabrication method | |

| JP5394867B2 (en) | Gas barrier film and gas barrier film | |

| US5958155A (en) | Process for producing thin film | |

| WO2019085265A1 (en) | High-refractive index silicon hydride thin film, preparation method therefor, filter stack, and optical filter | |

| EP1557479A1 (en) | Substrate having multilayer film and method for manufacturing the same | |

| CN101588912A (en) | Method for producing a nanostructure on a plastic surface | |

| EP0448426A1 (en) | Absorbant coating composition, preparation thereof and cladding obtained therefrom | |

| CN113249700B (en) | A metamaterial with infrared high refractive index and low dispersion and its preparation method | |

| JP2010268467A (en) | The process of increasing the reflectivity of the reflector surface | |

| WO2011065404A1 (en) | Gas barrier film, device, and process for production of gas barrier film | |

| JP4822786B2 (en) | Antireflection film and optical component having the same | |

| US7120326B2 (en) | Optical element, optical integrated device, optical information transmission system, and manufacturing methods thereof | |

| CN114941129A (en) | A kind of infrared selective absorption composite film with adjustable refractive index and preparation method thereof | |

| JP3454422B2 (en) | Radio wave transmitting wavelength selective substrate and its manufacturing method | |

| CN109972090B (en) | A kind of perfect absorber coating and preparation method thereof | |

| CN104930735A (en) | Solar absorbing film and preparation method thereof | |

| Lin et al. | Crystalline characteristics of annealed AlN films by pulsed laser treatment for solidly mounted resonator applications | |

| JP7162867B2 (en) | ND filter and its manufacturing method | |

| JP2022036766A (en) | Manufacturing method of ND filter and ND filter | |

| Chiba et al. | Fabrication and optical properties of low-emissivity coatings of AlSiN and AgCuNd-Alloy multilayer films on glass | |

| TW201139107A (en) | Decoration film for insert molding, insert molded article, method for producing decoration film for insert molding | |

| JPH06235806A (en) | Laser reflector | |

| CN104561898A (en) | Method for depositing wearing layer of glass window film and glass window film | |

| JP3727679B2 (en) | Thin film manufacturing method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20220826 | |

| RJ01 | Rejection of invention patent application after publication |