CN114910801A - A kind of helicopter emergency battery capacity test method and tester - Google Patents

A kind of helicopter emergency battery capacity test method and testerDownload PDFInfo

- Publication number

- CN114910801A CN114910801ACN202110173905.9ACN202110173905ACN114910801ACN 114910801 ACN114910801 ACN 114910801ACN 202110173905 ACN202110173905 ACN 202110173905ACN 114910801 ACN114910801 ACN 114910801A

- Authority

- CN

- China

- Prior art keywords

- capacity

- charging

- battery

- emergency battery

- circuit

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01R—MEASURING ELECTRIC VARIABLES; MEASURING MAGNETIC VARIABLES

- G01R31/00—Arrangements for testing electric properties; Arrangements for locating electric faults; Arrangements for electrical testing characterised by what is being tested not provided for elsewhere

- G01R31/36—Arrangements for testing, measuring or monitoring the electrical condition of accumulators or electric batteries, e.g. capacity or state of charge [SoC]

- G01R31/382—Arrangements for monitoring battery or accumulator variables, e.g. SoC

- G01R31/3842—Arrangements for monitoring battery or accumulator variables, e.g. SoC combining voltage and current measurements

- G—PHYSICS

- G01—MEASURING; TESTING

- G01R—MEASURING ELECTRIC VARIABLES; MEASURING MAGNETIC VARIABLES

- G01R31/00—Arrangements for testing electric properties; Arrangements for locating electric faults; Arrangements for electrical testing characterised by what is being tested not provided for elsewhere

- G01R31/36—Arrangements for testing, measuring or monitoring the electrical condition of accumulators or electric batteries, e.g. capacity or state of charge [SoC]

- G01R31/385—Arrangements for measuring battery or accumulator variables

- G01R31/387—Determining ampere-hour charge capacity or SoC

- G01R31/388—Determining ampere-hour charge capacity or SoC involving voltage measurements

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/0029—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries with safety or protection devices or circuits

- H02J7/0034—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries with safety or protection devices or circuits using reverse polarity correcting or protecting circuits

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/0068—Battery or charger load switching, e.g. concurrent charging and load supply

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/0069—Charging or discharging for charge maintenance, battery initiation or rejuvenation

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Secondary Cells (AREA)

- Charge And Discharge Circuits For Batteries Or The Like (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及航空应急供电设备技术领域,具体涉及一种直升机应急电瓶容量测试方法及测试仪。The invention relates to the technical field of aviation emergency power supply equipment, in particular to a method and a tester for measuring the capacity of a helicopter emergency battery.

背景技术Background technique

直升机应急电瓶主要用于直升机备用地平仪应急供电。当直升机正常供电失效后由应急电瓶供电,维持直升机飞行至就近机场着陆,因此应急电瓶工作是否可靠、容量是否充足,直接影响到飞行安全。Helicopter emergency battery is mainly used for emergency power supply of helicopter backup horizon. When the helicopter's normal power supply fails, the emergency battery will supply power to maintain the helicopter's flight to the nearest airport. Therefore, whether the emergency battery works reliably and has sufficient capacity will directly affect flight safety.

由于直升机应急电瓶供电要求提高,容量测试时需要测试电压负增量,在容量测试过程中检测电瓶特性是否符合要求,普通的充放电方法已经无法满足测试要求,不能很好地对电瓶容量进行测试和恢复。Due to the increased power supply requirements of helicopter emergency batteries, it is necessary to test negative voltage increments during capacity testing. In the process of capacity testing, it is necessary to check whether the characteristics of the battery meet the requirements. The ordinary charging and discharging method can no longer meet the testing requirements, and the battery capacity cannot be tested well. and recovery.

发明内容SUMMARY OF THE INVENTION

针对现有技术存在的不足,本发明的目的在于提供一种直升机应急电瓶容量测试方法及测试仪。In view of the deficiencies in the prior art, the purpose of the present invention is to provide a method and a tester for measuring the capacity of a helicopter emergency battery.

为了实现上述目的,本发明提供如下技术方案:In order to achieve the above object, the present invention provides the following technical solutions:

一种直升机应急电瓶容量测试方法,包括容量测试和容量恢复处理,其中容量测试包括按序进行的快速放电、静置、快速充电、静置、快速放电、静置、快速充电,在容量测试中,测试不合格的应急电瓶中止容量测试,转为进行容量恢复处理,容量恢复处理包括对应急电瓶进行慢速充电和慢速放电。A helicopter emergency battery capacity test method, including capacity test and capacity recovery processing, wherein the capacity test includes sequential rapid discharge, rest, rapid charge, rest, rapid discharge, rest, and rapid charge, in the capacity test , the emergency battery that fails the test shall terminate the capacity test and switch to capacity recovery processing. The capacity recovery processing includes slow charging and slow discharging of the emergency battery.

在本发明中,优选的,所述容量测试具体包括如下步骤:In the present invention, preferably, the capacity test specifically includes the following steps:

S1:将应急电瓶快速放电至电瓶电压不大于18V,静置30-60分钟;S1: Quickly discharge the emergency battery until the battery voltage is not greater than 18V, and let it stand for 30-60 minutes;

S2:对应急电瓶快速充电60分钟,同时进行电压负增量测试,当电压负增量大于等于2V,或电瓶电压达到32V,但充电时间小于40分钟,电瓶不合格,容量测试结束,进行容量恢复处理,否则,继续下一步骤;S2: Quickly charge the emergency battery for 60 minutes, and conduct a negative voltage increment test at the same time. When the negative voltage increment is greater than or equal to 2V, or the battery voltage reaches 32V, but the charging time is less than 40 minutes, the battery is unqualified and the capacity test is over. Resume processing, otherwise, continue to the next step;

S3:静置30-60分钟;S3: let stand for 30-60 minutes;

S4:将应急电瓶快速放电至电瓶电压不大于18V,同时进行容量检测,当容量小于75%,电瓶不合格,容量测试结束,进行容量恢复处理,否则进行下一步;S4: Quickly discharge the emergency battery until the battery voltage is not greater than 18V, and perform capacity detection at the same time. When the capacity is less than 75%, the battery is unqualified, the capacity test is over, and the capacity recovery process is performed, otherwise, proceed to the next step;

S5:静置30-60分钟;S5: let stand for 30-60 minutes;

S6:将应急电瓶快速充电60分钟,同时进行电压负增量测试,当电压负增量大于等于2V,或电瓶电压大于等于32V,但充电时间小于40分钟,电瓶不合格,容量测试结束,进行容量恢复处理,否则,电瓶合格,容量测试结束,自动打印测量结果。S6: Quickly charge the emergency battery for 60 minutes, and conduct a negative voltage increment test at the same time. When the negative voltage increment is greater than or equal to 2V, or the battery voltage is greater than or equal to 32V, but the charging time is less than 40 minutes, the battery is unqualified and the capacity test is over. Capacity recovery processing, otherwise, the battery is qualified, the capacity test is over, and the measurement results are automatically printed.

在本发明中,优选的,所述容量恢复处理包括3次慢速充电和慢速放电,慢速充电具体步骤包括:In the present invention, preferably, the capacity recovery process includes three times of slow charging and slow discharging, and the specific steps of slow charging include:

S01:设定充电电流、限制电压和充电时间,进行慢速充电,慢速充电电流为0.45A,充电时间600分钟;S01: Set the charging current, limit voltage and charging time, perform slow charging, the slow charging current is 0.45A, and the charging time is 600 minutes;

S02:开始充电同时计时,采集应急电瓶电压和电流,计算电压负增量值,并对其进行判断,大于等于2V,应急电瓶充电特性不佳,应急电瓶不合格,打印记录数据,结束充电,否则,继续充电;S02: Start charging at the same time, collect the voltage and current of the emergency battery, calculate the negative voltage increment value, and judge it, if it is greater than or equal to 2V, the charging characteristics of the emergency battery are not good, the emergency battery is unqualified, print the recorded data, and end the charging, Otherwise, continue charging;

S03:判断电瓶电压值是否大于等于32V,当电瓶电压大于等于32V且充电时间小于等于400分钟,应急电瓶不合格,打印记录数据,结束充电,否则,继续充电;S03: Determine whether the battery voltage value is greater than or equal to 32V, when the battery voltage is greater than or equal to 32V and the charging time is less than or equal to 400 minutes, the emergency battery is unqualified, print and record data, and end charging, otherwise, continue charging;

S04:计时时间到,结束充电。S04: When the time is up, the charging ends.

在本发明中,优选的,所述慢速放电具体步骤包括:In the present invention, preferably, the specific steps of the slow discharge include:

S11:设定放电电流、额定容量和放电终止电压,进行慢速放电,放电电流为0.90A,终止电压18V;S11: Set the discharge current, rated capacity and discharge termination voltage, perform slow discharge, the discharge current is 0.90A, and the termination voltage is 18V;

S12:开始放电的同时计时,采集应急电瓶电压和电流,计算放出容量百分比;S12: Time the discharge at the same time, collect the voltage and current of the emergency battery, and calculate the discharge capacity percentage;

S13:判断是否达到终止电压,如果达到终止电压但容量小于等于75%,电瓶不合格,否则为合格,打印记录数据,容量恢复处理结束。S13: Judging whether the termination voltage is reached, if the termination voltage is reached but the capacity is less than or equal to 75%, the battery is unqualified; otherwise, the battery is qualified, print and record data, and the capacity recovery process ends.

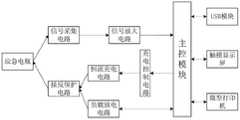

一种直升机应急电瓶容量测试仪,包括恒流充电电路、负载放电电路、信号放大电路、信号采集电路、接反保护电路以及主控模块;所述恒流充电电路、负载放电电路通过接反保护电路与应急电瓶连接,分别用于对应急电瓶进行充放电,所述接反保护电路用于对应急电瓶进行接反保护,防止损坏应急电瓶;所述信号采集电路包括一霍尔传感器U112,所述霍尔传感器U112与应急电瓶连接;所述信号放大电路接收所述信号采集电路信号将其处理后传递给所述主控模块,且所述主控模块通过充电控制电路给所述恒流充电电路发送充电控制信号,所述主控模块直接与所述负载放电电路连接并发送放电控制信号。A helicopter emergency battery capacity tester, comprising a constant current charging circuit, a load discharging circuit, a signal amplification circuit, a signal acquisition circuit, a reverse connection protection circuit and a main control module; the constant current charging circuit and the load discharge circuit are protected by reverse connection The circuit is connected with the emergency battery and is used to charge and discharge the emergency battery respectively. The reverse connection protection circuit is used for reverse connection protection of the emergency battery to prevent damage to the emergency battery; the signal acquisition circuit includes a Hall sensor U112, so The Hall sensor U112 is connected to the emergency battery; the signal amplifying circuit receives the signal of the signal acquisition circuit, processes it and transmits it to the main control module, and the main control module charges the constant current through the charging control circuit The circuit sends a charge control signal, and the main control module is directly connected to the load discharge circuit and sends a discharge control signal.

在本发明中,优选的,所述接反保护电路包括控制继电器K1、保护继电器 K12和开关管Q3,所述控制继电器K1的线圈与所述开关管Q3串联,所述控制继电器K1的第一触点与所述保护继电器K12的第三触点连接,所述保护继电器K12的线圈一端连接电瓶,另一端通过二极管D60接地。In the present invention, preferably, the reverse connection protection circuit includes a control relay K1, a protection relay K12 and a switch tube Q3, the coil of the control relay K1 is connected in series with the switch tube Q3, and the first The contact is connected to the third contact of the protection relay K12, one end of the coil of the protection relay K12 is connected to the battery, and the other end is grounded through the diode D60.

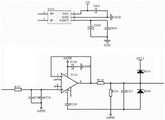

在本发明中,优选的,信号放大电路包括跟随器U114,所述跟随器U114 输出端串联有电阻R116,并通过电阻R210和电容C211并联电路接地,并连接有二极管D114和D116组成的保护电路,信号放大电路用于放大电流采样信号。In the present invention, preferably, the signal amplifying circuit includes a follower U114, the output end of the follower U114 is connected with a resistor R116 in series, and is grounded through a parallel circuit of the resistor R210 and the capacitor C211, and is connected with a protection circuit composed of diodes D114 and D116 , the signal amplification circuit is used to amplify the current sampling signal.

在本发明中,优选的,所述充电控制电路包括电压放大电路、电流放大电路,所述电压放大电路包括运放U200,所述运放U200用于将放大电压控制信号,所述电流放大电路包括运放U201,所述运放U201用于放大电流控制信号。In the present invention, preferably, the charging control circuit includes a voltage amplifier circuit and a current amplifier circuit, the voltage amplifier circuit includes an operational amplifier U200, and the operational amplifier U200 is used to amplify the voltage control signal, and the current amplifier circuit The operational amplifier U201 is included, and the operational amplifier U201 is used to amplify the current control signal.

在本发明中,优选的,所述主控模块还连接有USB模块、触摸显示屏和微型打印机,所述USB模块用于保存电子版测量数据;所述触摸显示屏用于实现人机交互;所述微型打印机用于对测量数据进行打印。In the present invention, preferably, the main control module is further connected with a USB module, a touch display screen and a micro-printer, the USB module is used to save the measurement data of the electronic version; the touch display screen is used to realize human-computer interaction; The micro-printer is used for printing the measurement data.

与现有技术相比,本发明的有益效果是:Compared with the prior art, the beneficial effects of the present invention are:

本发明的方法根据直升机应急电瓶的固有特点,能按照应急电瓶维护手册要求完成应急电瓶在各种状态下的电瓶容量检测、常规充放电和容量恢复等工作,由此延长了应急电瓶的使用寿命,保证飞行安全;同时具有结构设计合理、测试方便,并且能自主完成容量测试和容量恢复,节约大量的人力物力。According to the inherent characteristics of the helicopter emergency battery, the method of the invention can complete the battery capacity detection, routine charging and discharging and capacity recovery of the emergency battery in various states according to the requirements of the emergency battery maintenance manual, thereby prolonging the service life of the emergency battery , to ensure flight safety; at the same time, it has reasonable structural design, convenient testing, and can independently complete capacity testing and capacity recovery, saving a lot of manpower and material resources.

附图说明Description of drawings

图1为本发明所述的一种直升机应急电瓶容量测试方法的容量测试流程图。FIG. 1 is a flow chart of capacity testing of a method for testing the capacity of a helicopter emergency battery according to the present invention.

图2为本发明所述的一种直升机应急电瓶容量测试方法的充电流程图。FIG. 2 is a charging flow chart of a method for testing the capacity of a helicopter emergency battery according to the present invention.

图3为本发明所述的一种直升机应急电瓶容量测试方法的放电流程图。FIG. 3 is a discharge flow chart of a method for testing the capacity of a helicopter emergency battery according to the present invention.

图4为本发明所述的一种直升机应急电瓶容量测试仪的结构框图。FIG. 4 is a structural block diagram of a helicopter emergency battery capacity tester according to the present invention.

图5为本发明所述的一种直升机应急电瓶容量测试仪的接反保护电路图。5 is a circuit diagram of a reverse connection protection circuit of a helicopter emergency battery capacity tester according to the present invention.

图6为本发明所述的一种直升机应急电瓶容量测试仪的信号采集电路图。6 is a circuit diagram of a signal acquisition circuit of a helicopter emergency battery capacity tester according to the present invention.

图7为本发明所述的一种直升机应急电瓶容量测试仪的信号放大电路图。FIG. 7 is a signal amplification circuit diagram of a helicopter emergency battery capacity tester according to the present invention.

具体实施方式Detailed ways

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

需要说明的是,当组件被称为“固定于”另一个组件,它可以直接在另一个组件上或者也可以存在居中的组件。当一个组件被认为是“连接”另一个组件,它可以是直接连接到另一个组件或者可能同时存在居中组件。当一个组件被认为是“设置于”另一个组件,它可以是直接设置在另一个组件上或者可能同时存在居中组件。本文所使用的术语“垂直的”、“水平的”、“左”、“右”以及类似的表述只是为了说明的目的。It should be noted that when a component is referred to as being "fixed to" another component, it can be directly on the other component or there may also be a centered component. When a component is considered to be "connected" to another component, it may be directly connected to the other component or there may be a co-existence of an intervening component. When a component is considered to be "set on" another component, it may be directly set on the other component or there may be a co-existing centered component. The terms "vertical," "horizontal," "left," "right," and similar expressions are used herein for illustrative purposes only.

除非另有定义,本文所使用的所有的技术和科学术语与属于本发明的技术领域的技术人员通常理解的含义相同。本文中在本发明的说明书中所使用的术语只是为了描述具体的实施例的目的,不是旨在于限制本发明。本文所使用的术语“及/或”包括一个或多个相关的所列项目的任意的和所有的组合。Unless otherwise defined, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs. The terms used herein in the description of the present invention are for the purpose of describing specific embodiments only, and are not intended to limit the present invention. As used herein, the term "and/or" includes any and all combinations of one or more of the associated listed items.

请同时参见图1至图3,本发明一较佳实施方式提供一种直升机应急电瓶容量测试方法,对应急电瓶的SB和相关CMM手册进行了输入研究提出了最佳容量测试和容量恢复方法,其中包括2次充电、2次放电和3次静置等待7个步骤,并在充电、放电过程中,自动完成对电瓶的状态检测,依据电压负增量(Negative Voltage slope-ΔU)、充放电电压、电流和时间数据进行合格评估,包括容量测试和容量恢复处理,其中容量测试包括按序进行的快速放电、静置、快速充电、静置、快速放电、静置、快速充电,在容量测试中,测试不合格的应急电瓶中止容量测试,转为进行容量恢复处理,容量恢复处理包括对应急电瓶进行慢速充电和慢速放电。Please refer to FIG. 1 to FIG. 3 at the same time. A preferred embodiment of the present invention provides a method for testing the capacity of a helicopter emergency battery. The SB and related CMM manuals of the emergency battery are input and researched, and an optimal capacity testing and capacity recovery method is proposed. It includes 7 steps of 2 times of charging, 2 times of discharge and 3 times of standing and waiting. During the process of charging and discharging, the state detection of the battery is automatically completed. According to the negative voltage increment (Negative Voltage slope-ΔU), charge and discharge Voltage, current and time data for qualification assessment, including capacity testing and capacity recovery processing, where capacity testing includes sequential rapid discharge, rest, rapid charge, rest, rapid discharge, rest, rapid charge, in the capacity test During the test, the capacity test of the emergency battery that fails the test is terminated, and the capacity recovery process is performed. The capacity recovery process includes slow charging and slow discharging of the emergency battery.

具体的,容量测试具体包括如下步骤:Specifically, the capacity test specifically includes the following steps:

S1:将应急电瓶快速放电至电瓶电压不大于18V,静置30-60分钟,等待电瓶内部化学反应彻底完成和降低电瓶温度;S1: Quickly discharge the emergency battery until the battery voltage is not greater than 18V, let it stand for 30-60 minutes, wait for the chemical reaction inside the battery to be completely completed and reduce the battery temperature;

S2:对应急电瓶快速充电60分钟,快速充电电流为4.5A,同时进行电压负增量测试,当电压负增量大于等于2V,或电瓶电压达到32V,但充电时间小于 40分钟,电瓶不合格,容量测试结束,进行容量恢复处理,否则,继续下一步骤;S2: Quickly charge the emergency battery for 60 minutes, the rapid charging current is 4.5A, and conduct a negative voltage increment test at the same time. When the negative voltage increment is greater than or equal to 2V, or the battery voltage reaches 32V, but the charging time is less than 40 minutes, the battery is unqualified , the capacity test is over, and the capacity recovery process is performed, otherwise, continue to the next step;

S3:静置30-60分钟,等待电瓶内部化学反应彻底完成和降低电瓶温度;S3: Stand for 30-60 minutes, wait for the chemical reaction inside the battery to be completely completed and reduce the battery temperature;

S4:将应急电瓶快速放电至电瓶电压不大于18V,快速放电电流为4A,同时进行容量检测,当容量小于75%,电瓶不合格,容量测试结束,进行容量恢复处理,否则进行下一步;S4: Quickly discharge the emergency battery until the battery voltage is not greater than 18V, the rapid discharge current is 4A, and the capacity test is carried out at the same time. When the capacity is less than 75%, the battery is unqualified, the capacity test is over, and the capacity recovery process is performed, otherwise, proceed to the next step;

S5:静置30-60分钟,等待电瓶内部化学反应彻底完成和降低电瓶温度;S5: Stand for 30-60 minutes, wait for the chemical reaction inside the battery to be completely completed and reduce the battery temperature;

S6:将应急电瓶快速充电60分钟,快速充电电流为4.5A,同时进行电压负增量测试,当电压负增量大于等于2V,或电瓶电压大于等于32V,但充电时间小于40分钟,电瓶不合格,容量测试结束,进行容量恢复处理,否则,电瓶合格,容量测试结束,自动打印测量结果。S6: Quickly charge the emergency battery for 60 minutes, the rapid charging current is 4.5A, and conduct a negative voltage increment test at the same time. When the negative voltage increment is greater than or equal to 2V, or the battery voltage is greater than or equal to 32V, but the charging time is less than 40 minutes, the battery will not If the battery is qualified, the capacity test is over, and the capacity recovery process is performed. Otherwise, the battery is qualified, the capacity test is over, and the measurement result is automatically printed.

在本实施方式中,容量恢复处理包括3次慢速充电和慢速放电,慢速充电具体步骤包括:In this embodiment, the capacity recovery process includes three times of slow charging and slow discharging, and the specific steps of slow charging include:

S01:设定充电电流、限制电压和充电时间,进行慢速充电,慢速充电电流为0.45A,充电时间600分钟;S01: Set the charging current, limit voltage and charging time, perform slow charging, the slow charging current is 0.45A, and the charging time is 600 minutes;

S02:开始充电同时计时,采集应急电瓶电压和电流,计算电压负增量值,并对其进行判断,大于等于2V,应急电瓶充电特性不佳,应急电瓶不合格,打印记录数据,结束充电,否则,继续充电;S02: Start charging at the same time, collect the voltage and current of the emergency battery, calculate the negative voltage increment value, and judge it, if it is greater than or equal to 2V, the charging characteristics of the emergency battery are not good, the emergency battery is unqualified, print the recorded data, and end the charging, Otherwise, continue charging;

S03:判断电瓶电压值是否大于等于32V,当电瓶电压大于等于32V且充电时间小于等于400分钟,应急电瓶不合格,打印记录数据,结束充电,否则,继续充电;S03: Determine whether the battery voltage value is greater than or equal to 32V, when the battery voltage is greater than or equal to 32V and the charging time is less than or equal to 400 minutes, the emergency battery is unqualified, print and record data, and end charging, otherwise, continue charging;

S04:计时时间到,结束充电。S04: When the time is up, the charging ends.

进一步的,慢速放电具体步骤包括:Further, the specific steps of the slow discharge include:

S11:设定放电电流、额定容量和放电终止电压,进行慢速放电,放电电流为0.90A,终止电压18V;S11: Set the discharge current, rated capacity and discharge termination voltage, perform slow discharge, the discharge current is 0.90A, and the termination voltage is 18V;

S12:开始放电的同时计时,采集应急电瓶电压和电流,计算放出容量百分比;S12: Time the discharge at the same time, collect the voltage and current of the emergency battery, and calculate the discharge capacity percentage;

S13:判断是否达到终止电压,如果达到终止电压但容量小于等于75%,电瓶不合格,否则为合格,打印记录数据,容量恢复处理结束。S13: Judging whether the termination voltage is reached, if the termination voltage is reached but the capacity is less than or equal to 75%, the battery is unqualified; otherwise, the battery is qualified, print and record data, and the capacity recovery process ends.

请参见图4,本发明另一较佳实施方式提供一种直升机应急电瓶容量测试仪,包括恒流充电电路、负载放电电路、信号放大电路、信号采集电路、接反保护电路以及主控模块;恒流充电电路、负载放电电路通过接反保护电路与应急电瓶连接,分别用于对应急电瓶进行充放电,接反保护电路用于对应急电瓶进行接反保护,防止损坏应急电瓶;信号采集电路包括一霍尔传感器U112,霍尔传感器U112与应急电瓶连接,用于采集应急电瓶的电压电流信号;信号放大电路接收信号采集电路信号将其处理后传递给主控模块,且主控模块通过充电控制电路给恒流充电电路发送充电控制信号,主控模块直接与负载放电电路连接并发送放电控制信号;主控模块用于对传递过来的信号进行采样和运算,在充放电过程中对该应急电瓶的容量进行判断。Referring to FIG. 4, another preferred embodiment of the present invention provides a helicopter emergency battery capacity tester, including a constant current charging circuit, a load discharging circuit, a signal amplification circuit, a signal acquisition circuit, a reverse connection protection circuit, and a main control module; The constant current charging circuit and the load discharging circuit are connected to the emergency battery through the reverse connection protection circuit, and are used to charge and discharge the emergency battery respectively. The reverse connection protection circuit is used to protect the emergency battery from reverse connection to prevent damage to the emergency battery; signal acquisition circuit Including a hall sensor U112, the hall sensor U112 is connected with the emergency battery, and is used to collect the voltage and current signals of the emergency battery; the signal amplification circuit receives the signal of the signal acquisition circuit and transmits it to the main control module after processing, and the main control module is charged by charging The control circuit sends a charging control signal to the constant current charging circuit, and the main control module is directly connected to the load discharge circuit and sends a discharge control signal; the main control module is used to sample and calculate the transmitted signal, and the emergency Determine the capacity of the battery.

具体的,主控模块采用单片机系统,由主控模块通过充电控制电路给恒流充电电路发送充电指令,恒流充电电路对应急电瓶进行充电,主控模块发送放电指令给负载放电电路,负载放电电路对应急电瓶进行放电,在应急电瓶充电或放电过程中,与应急电瓶连接的霍尔传感器U112采集电流信号传送给信号放大电路,信号放大电路对信号进行处理再传递给主控模块,主控模块依据输入的信号进行运算,计算出充电时间和电压负增量-ΔU,通过对比得出应急电瓶容量是否合格,整个过程自动完成应急电瓶的恒流限压充电、放电和容量测试,设计合理、测试方便,节约大量人力物力。Specifically, the main control module adopts a single-chip microcomputer system. The main control module sends a charging command to the constant current charging circuit through the charging control circuit, the constant current charging circuit charges the emergency battery, and the main control module sends a discharge command to the load discharge circuit. The load discharges The circuit discharges the emergency battery. During the charging or discharging process of the emergency battery, the Hall sensor U112 connected to the emergency battery collects the current signal and transmits it to the signal amplifying circuit. The signal amplifying circuit processes the signal and then transmits it to the main control module. The module performs operations based on the input signal, calculates the charging time and the negative voltage increment -ΔU, and determines whether the emergency battery capacity is qualified through comparison. The whole process automatically completes the constant current and voltage limiting charging, discharging and capacity testing of the emergency battery, and the design is reasonable. , The test is convenient, saving a lot of manpower and material resources.

请参见图5,在本实施方式中,接反保护电路包括控制继电器K1、保护继电器K12和开关管Q3,控制继电器K1的线圈与开关管Q3串联,控制继电器 K1的第一触点与保护继电器K12的第三触点连接,保护继电器K12的线圈一端连接电瓶,另一端通过二极管D60接地。Referring to FIG. 5 , in this embodiment, the reverse connection protection circuit includes a control relay K1, a protection relay K12 and a switch tube Q3, the coil of the control relay K1 is connected in series with the switch tube Q3, and the first contact of the control relay K1 is connected to the protection relay. The third contact of K12 is connected, one end of the coil of the protection relay K12 is connected to the battery, and the other end is grounded through the diode D60.

具体的,控制继电器K1的线圈一端接5V电源,另一端通过开关管Q3接地,开关管Q3的基极通过电阻R31接主控模块,电阻R31与开关管Q3之间还通过电容C65接地,控制继电器K1的线圈还并联有续流二极管D5,控制继电器K1的公共触点接有15V电源,控制继电器K1的第一触点与保护继电器K12 的第三触点连接,且反接二极管D6后接地,保护继电器K12的线圈一端连接电瓶,另一端通过二极管D60接地,两端并联有续流二极管D61,保护继电器 K12的公共触点通过插座P6连接充放电控制接触器,保护继电器K12在电瓶没接反时无电流通过,第三触点处于闭合状态,在需要对电瓶进行充放电时,主控模块发送一信号给开关管Q3,导致开关管Q3导通,控制继电器K1的线圈得电,作用于第一触点使得第一触点闭合,电流经过第三触点到充放电控制接触器,使得充放电控制接触器通电;当电瓶接反时,保护继电器K12的线圈得电,保护继电器K12的第四触点闭合,第三触点断开,控制继电器K1的线圈即使得电,充放电控制接触器不通电,从而保护电瓶。Specifically, one end of the coil of the control relay K1 is connected to the 5V power supply, and the other end is grounded through the switch tube Q3. The base of the switch tube Q3 is connected to the main control module through the resistor R31. The resistor R31 and the switch tube Q3 are also grounded through the capacitor C65. The coil of the relay K1 is also connected with a freewheeling diode D5 in parallel, the common contact of the control relay K1 is connected to a 15V power supply, the first contact of the control relay K1 is connected to the third contact of the protection relay K12, and the diode D6 is reversely connected and then grounded. , One end of the coil of the protection relay K12 is connected to the battery, the other end is grounded through the diode D60, and the two ends are connected with a freewheeling diode D61 in parallel. When there is no current passing in reverse time, the third contact is in a closed state. When the battery needs to be charged and discharged, the main control module sends a signal to the switch tube Q3, which causes the switch tube Q3 to be turned on, and the coil of the control relay K1 is energized. At the first contact, the first contact is closed, and the current passes through the third contact to the charge and discharge control contactor, so that the charge and discharge control contactor is energized; when the battery is reversely connected, the coil of the protection relay K12 is energized, and the protection relay K12 The fourth contact is closed and the third contact is disconnected, the coil of the control relay K1 is energized, and the charge and discharge control contactor is not energized, thereby protecting the battery.

请参见图6,在本实施方式中,霍尔传感器U112输出端输出电流反馈值,电流反馈值经过电容C618和电容C619滤波后输入到信号放大电路,信号放大电路包括跟随器U114,跟随器U114的反向输入端接入输出端,二极管D114 和D116的保护电路一端接3.3V电源另一端接地,信号放大电路依照电流反馈值将信号进行放大,并将其输入到主控模块。Referring to FIG. 6 , in this embodiment, the output terminal of the Hall sensor U112 outputs a current feedback value, and the current feedback value is filtered by the capacitor C618 and the capacitor C619 and then input to the signal amplifying circuit. The signal amplifying circuit includes a follower U114 and a follower U114 The reverse input end of the diode D114 and D116 are connected to the output end. One end of the protection circuit of diodes D114 and D116 is connected to the 3.3V power supply and the other end is grounded. The signal amplification circuit amplifies the signal according to the current feedback value and inputs it to the main control module.

请参见图7,在本实施方式中,充电控制电路包括电压放大电路、电流放大电路,电压放大电路包括运放U200,运放U200用于将放大电压控制信号,电流放大电路包括运放U201,运放U201用于放大电流控制信号。Referring to FIG. 7, in this embodiment, the charging control circuit includes a voltage amplifier circuit and a current amplifier circuit, the voltage amplifier circuit includes an operational amplifier U200, and the operational amplifier U200 is used to amplify the voltage control signal, and the current amplifier circuit includes an operational amplifier U201, The operational amplifier U201 is used to amplify the current control signal.

具体的,电压放大电路包括运放U200,运放U200用于放大充电电压信号,电流放大电路包括运放U201,运放U201用于将放大充电电流信号,电压放大电路与电流放大电路均采用负反馈放大电路,运放U200的反向输入端通过电阻 R204接入输出端,输出端通过电容C202、电阻R201和二极管D201组成的并联电路接地;运放U201的反向输入端通过电阻R208接入输出端,输出端通过电容C205、电阻R202和二极管D202组成的并联电路接地。Specifically, the voltage amplifier circuit includes an operational amplifier U200, which is used to amplify the charging voltage signal, the current amplifier circuit includes an operational amplifier U201, and the operational amplifier U201 is used to amplify the charging current signal. Both the voltage amplifier circuit and the current amplifier circuit use negative Feedback amplifier circuit, the reverse input terminal of the operational amplifier U200 is connected to the output terminal through the resistor R204, and the output terminal is grounded through the parallel circuit composed of the capacitor C202, the resistor R201 and the diode D201; the reverse input terminal of the operational amplifier U201 is connected through the resistor R208 Output terminal, the output terminal is grounded through a parallel circuit composed of capacitor C205, resistor R202 and diode D202.

在本实施方式中,主控模块还连接有USB模块,USB模块为外接存储器,用于保存电子版测量数据;主控模块还连接有触摸显示屏,触摸显示屏用于实现人机交互,对航空电池进行充放电的控制;主控模块还连接有微型打印机,微型打印机用于对测量数据进行打印,以便进行分析。In this embodiment, the main control module is further connected with a USB module, which is an external memory and used to save the electronic version of the measurement data; the main control module is also connected with a touch display screen, which is used to realize human-computer interaction. The aviation battery controls the charge and discharge; the main control module is also connected with a micro-printer, which is used to print the measurement data for analysis.

工作原理:working principle:

容量测试过程:首先,在触摸显示屏上选择容量测试,再选择具体电瓶型号,测试仪自动提取数据库中的电瓶参数和充放电参数,按照顺序执行步骤S1 到S6,如果容量达不到要求或充电特性不佳,通过慢速充电和慢速放电进行容量恢复,一般容量恢复需要3个循环,如果3个循环达不到要求,该电瓶报废;Capacity test process: First, select the capacity test on the touch screen, and then select the specific battery model, the tester will automatically extract the battery parameters and charging and discharging parameters in the database, and perform steps S1 to S6 in sequence, if the capacity does not meet the requirements or The charging characteristics are not good. The capacity recovery is carried out through slow charging and slow discharging. Generally, the capacity recovery needs 3 cycles. If the 3 cycles cannot meet the requirements, the battery will be scrapped;

容量恢复过程:慢速充电时,通过触摸显示屏输入待测电瓶的型号、充电电流、限制电压和充电时间等参数,通过主控模块运算,输出指令给接触器K11,接触器K11的第一触点吸合,恒流充电电路对应急电瓶进行充电,霍尔传感器U112采集应急电瓶的电流信号传送给信号放大电路,经信号放大电路进行信号处理,再传送给主控模块进行运算,并计算充电时间和电压负增量-ΔU;最后通过触摸显示屏进行显示;由主控模块通过充电控制电路控制恒流充电电路进行恒流充电,当满足充电结束时间条件时,充电结束。充电时当电压负增量-Δ U超标或充电时间不足时,主控模块将通过触摸显示屏进行报警;最后将测量数据通过USB模块保存到存储器中,并可通过微型打印机进行打印,以便进行分析。当电瓶极性接反时,由接反保护电路实现保护,防止损坏电瓶和测试仪。Capacity recovery process: During slow charging, input parameters such as the battery type, charging current, limit voltage, and charging time of the battery to be tested through the touch screen, and output commands to the contactor K11 through the calculation of the main control module. The contact is pulled in, the constant current charging circuit charges the emergency battery, and the Hall sensor U112 collects the current signal of the emergency battery and transmits it to the signal amplification circuit. The charging time and the negative voltage increment -ΔU; finally, it is displayed on the touch screen; the main control module controls the constant current charging circuit to perform constant current charging through the charging control circuit, and when the charging end time condition is met, the charging ends. When charging, when the negative voltage increment -ΔU exceeds the standard or the charging time is insufficient, the main control module will give an alarm through the touch screen; finally, the measured data will be saved to the memory through the USB module, and can be printed through a micro printer for easy processing. analyze. When the battery polarity is reversed, it is protected by the reverse connection protection circuit to prevent damage to the battery and the tester.

放电时,首先通过触摸显示屏输入待充电应急电瓶的型号、放电电流、终止电压和额定容量等参数,通过主控模块运算,输出指令给电子负载放电电路,对应急电瓶进行放电;霍尔传感器U112采集应急电瓶的电流信号传送给信号放大电路,经信号放大电路,再传送给主控模块进行运算,并计算电瓶放出容量百分比,最后通过触摸显示屏进行显示;由主控模块通过控制电子负载放电电路进行恒流充放电,当满足放电终止电压结束条件时,放电结束;当容量不符合要求时充电时,主控模块将通过触摸显示屏进行报警,最后将测量数据通过 USB接口保存到存储器中,并可通过微型打印机进行打印,以便进行分析。When discharging, first input parameters such as the model, discharge current, termination voltage and rated capacity of the emergency battery to be charged through the touch screen, and through the calculation of the main control module, output commands to the electronic load discharge circuit to discharge the emergency battery; Hall sensor U112 collects the current signal of the emergency battery and transmits it to the signal amplifying circuit. After the signal amplifying circuit, it is transmitted to the main control module for calculation, and the battery discharge capacity percentage is calculated, and finally displayed through the touch screen; the main control module controls the electronic load through the The discharge circuit performs constant current charge and discharge. When the discharge termination voltage end condition is met, the discharge ends; when the capacity does not meet the requirements, the main control module will give an alarm through the touch screen, and finally save the measurement data to the memory through the USB interface , and can be printed on a micro-printer for analysis.

上述说明是针对本发明较佳可行实施例的详细说明,但实施例并非用以限定本发明的专利申请范围,凡本发明所提示的技术精神下所完成的同等变化或修饰变更,均应属于本发明所涵盖专利范围。The above description is a detailed description of the preferred feasible embodiments of the present invention, but the embodiments are not intended to limit the scope of the patent application of the present invention. All equivalent changes or modifications completed under the technical spirit suggested by the present invention shall belong to This invention covers the scope of the patent.

Claims (9)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110173905.9ACN114910801B (en) | 2021-02-09 | 2021-02-09 | Helicopter emergency storage battery capacity testing method and tester |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110173905.9ACN114910801B (en) | 2021-02-09 | 2021-02-09 | Helicopter emergency storage battery capacity testing method and tester |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114910801Atrue CN114910801A (en) | 2022-08-16 |

| CN114910801B CN114910801B (en) | 2025-07-29 |

Family

ID=82762067

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110173905.9AActiveCN114910801B (en) | 2021-02-09 | 2021-02-09 | Helicopter emergency storage battery capacity testing method and tester |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114910801B (en) |

Citations (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2183629Y (en)* | 1993-12-10 | 1994-11-23 | 杨建钢 | Quick-charging device for nickel-cadium cell |

| US5818197A (en)* | 1996-10-30 | 1998-10-06 | Alexander Manufacturing Corp. | Adaptive battery charger with universal interface plate |

| US5900718A (en)* | 1996-08-16 | 1999-05-04 | Total Battery Management, | Battery charger and method of charging batteries |

| US6008628A (en)* | 1997-08-20 | 1999-12-28 | Black & Decker Inc. | Method for charging batteries |

| US20040095096A1 (en)* | 2002-11-14 | 2004-05-20 | Gerod Melton | Adaptive battery conditioning employing battery chemistry determination |

| CN101252213A (en)* | 2008-03-24 | 2008-08-27 | 中兴通讯股份有限公司 | Method for charging nickel-hydrogen, nickel-cadmium batteries |

| CN101604774A (en)* | 2009-07-09 | 2009-12-16 | 中国电子科技集团公司第四十一研究所 | Intelligent activating method for accumulator |

| CN101635470A (en)* | 2009-08-19 | 2010-01-27 | 王广生 | Quick charger of power-saving storage battery and intelligent charging method |

| CN102324582A (en)* | 2011-08-12 | 2012-01-18 | 重庆东电通信技术有限公司 | Intelligent maintenance device of multifunctional lead-acid battery and capacity prediction method |

| RU2539876C1 (en)* | 2014-03-18 | 2015-01-27 | Федеральное государственное казенное учреждение "27 Центральный научно-исследовательский институт" Министерства обороны Российской Федерации | Recovery of sealed nickel-cadmium storage battery capacity |

| CN107703449A (en)* | 2016-08-08 | 2018-02-16 | 深圳市雄韬电源科技股份有限公司 | The quick determination method of service life of lead accumulator |

| CN108462229A (en)* | 2018-03-19 | 2018-08-28 | 天津奥科盛科技有限公司 | A kind of aviation battery analysis by charged and discharged instrument and charging/discharging thereof |

| CN209432982U (en)* | 2019-01-15 | 2019-09-24 | 天津奥科盛科技有限公司 | An aviation battery charge and discharge analysis integrated instrument |

- 2021

- 2021-02-09CNCN202110173905.9Apatent/CN114910801B/enactiveActive

Patent Citations (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN2183629Y (en)* | 1993-12-10 | 1994-11-23 | 杨建钢 | Quick-charging device for nickel-cadium cell |

| US5900718A (en)* | 1996-08-16 | 1999-05-04 | Total Battery Management, | Battery charger and method of charging batteries |

| US5818197A (en)* | 1996-10-30 | 1998-10-06 | Alexander Manufacturing Corp. | Adaptive battery charger with universal interface plate |

| US6008628A (en)* | 1997-08-20 | 1999-12-28 | Black & Decker Inc. | Method for charging batteries |

| US20040095096A1 (en)* | 2002-11-14 | 2004-05-20 | Gerod Melton | Adaptive battery conditioning employing battery chemistry determination |

| CN101252213A (en)* | 2008-03-24 | 2008-08-27 | 中兴通讯股份有限公司 | Method for charging nickel-hydrogen, nickel-cadmium batteries |

| CN101604774A (en)* | 2009-07-09 | 2009-12-16 | 中国电子科技集团公司第四十一研究所 | Intelligent activating method for accumulator |

| CN101635470A (en)* | 2009-08-19 | 2010-01-27 | 王广生 | Quick charger of power-saving storage battery and intelligent charging method |

| CN102324582A (en)* | 2011-08-12 | 2012-01-18 | 重庆东电通信技术有限公司 | Intelligent maintenance device of multifunctional lead-acid battery and capacity prediction method |

| RU2539876C1 (en)* | 2014-03-18 | 2015-01-27 | Федеральное государственное казенное учреждение "27 Центральный научно-исследовательский институт" Министерства обороны Российской Федерации | Recovery of sealed nickel-cadmium storage battery capacity |

| CN107703449A (en)* | 2016-08-08 | 2018-02-16 | 深圳市雄韬电源科技股份有限公司 | The quick determination method of service life of lead accumulator |

| CN108462229A (en)* | 2018-03-19 | 2018-08-28 | 天津奥科盛科技有限公司 | A kind of aviation battery analysis by charged and discharged instrument and charging/discharging thereof |

| CN209432982U (en)* | 2019-01-15 | 2019-09-24 | 天津奥科盛科技有限公司 | An aviation battery charge and discharge analysis integrated instrument |

Non-Patent Citations (6)

| Title |

|---|

| SIMONIN M: "Bilateral vocal palsy following coin cell lithium battery ingestion: a case report and review", EUROPEAN JOURNAL OF PEDIATRICS, vol. 172, no. 7, 31 December 2013 (2013-12-31), pages 991 - 993* |

| 任仁良: "通用航空电瓶充电及容量测试方法", 电源技术, vol. 39, no. 7, 20 July 2015 (2015-07-20), pages 1562 - 1563* |

| 任仁良等: "G-16EP通用航空电瓶充放电及寿命研究", 航空维修与工程, 20 November 2016 (2016-11-20), pages 68 - 70* |

| 王瑶: "油田通信电源蓄电池充电研究", 石油石化节能, vol. 10, no. 4, 20 April 2020 (2020-04-20), pages 30 - 32* |

| 胡亮: "基于镍氢电池的后备电源管理系统设计", 煤矿机械, vol. 38, no. 4, 15 April 2017 (2017-04-15), pages 1 - 3* |

| 陈继永等: "风光互补发电技术", 31 July 2020, 中国铁道出版社有限公司, pages: 111 - 112* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114910801B (en) | 2025-07-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102981122B (en) | Method and system of electric automobile battery test | |

| CN109078871B (en) | A method for eliminating parallel modules of retired batteries for cascade utilization | |

| CN102157759B (en) | Method for charging management of emergent blade-changing battery pack of wind driven generator | |

| CN109116264A (en) | Device and method for diagnosing charging pile fault | |

| CN207263852U (en) | A kind of test system of electric automobile direct-current charging post | |

| CN105954685A (en) | Electric vehicle battery short circuit test bench with remote control function, and method | |

| CN104898068A (en) | Portable multifunctional storage battery detection system | |

| CN210690758U (en) | a detection circuit | |

| CN101187696A (en) | A method for testing a power battery source | |

| CN108614217A (en) | A battery management system fully automatic test system and implementation method | |

| CN106443545A (en) | Battery management system fault diagnosing and positioning system and method of battery electric vehicle | |

| CN112909367B (en) | Storage battery activation nuclear capacity and repairing method | |

| CN113552495B (en) | Online detection method and device for leakage of storage battery of power supply system | |

| CN106569053A (en) | Simulation system and method for external characteristic of vehicle battery of battery electric vehicle | |

| CN203275628U (en) | High voltage battery pack external characteristic simulator | |

| CN109546741A (en) | The self-checking system of battery remote maintenance equipment | |

| CN203502567U (en) | Charge and discharge testing device for power lithium battery pack | |

| CN205920161U (en) | Two -way power with internal resistance of cell measurement function | |

| CN114910801A (en) | A kind of helicopter emergency battery capacity test method and tester | |

| CN110133504A (en) | A detection system for battery charging and discharging equipment based on supercapacitor | |

| CN111731123B (en) | Battery system pre-inspection method, battery system and battery management system | |

| CN215678733U (en) | Detection device of portable storage battery charge and discharge tester | |

| CN214669494U (en) | A helicopter emergency battery capacity tester | |

| CN110341550A (en) | A kind of power battery management system | |

| CN113075573B (en) | Low-voltage BMS testing system and method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| TR01 | Transfer of patent right | ||

| TR01 | Transfer of patent right | Effective date of registration:20250827 Address after:100020 Room 6211, Second Floor, Building K2, No. 98 Guangqu Road, Chaoyang District, Beijing Patentee after:Aokesheng (Beijing) Technology Co.,Ltd. Country or region after:China Address before:300000 Tianjin City, Dongli District, Hangshuang Road, Tianjin Airport International Headquarters Base A Area, A2 Building, 2002 Room Patentee before:TIANJIN OXEN TECHNOLOGY Co.,Ltd. Country or region before:China |