CN114909385B - A Screw Pretensioning System to Avoid Loosening - Google Patents

A Screw Pretensioning System to Avoid LooseningDownload PDFInfo

- Publication number

- CN114909385B CN114909385BCN202210522792.3ACN202210522792ACN114909385BCN 114909385 BCN114909385 BCN 114909385BCN 202210522792 ACN202210522792 ACN 202210522792ACN 114909385 BCN114909385 BCN 114909385B

- Authority

- CN

- China

- Prior art keywords

- gasket

- screw

- loosening

- level

- sealing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16B—DEVICES FOR FASTENING OR SECURING CONSTRUCTIONAL ELEMENTS OR MACHINE PARTS TOGETHER, e.g. NAILS, BOLTS, CIRCLIPS, CLAMPS, CLIPS OR WEDGES; JOINTS OR JOINTING

- F16B39/00—Locking of screws, bolts or nuts

- F16B39/22—Locking of screws, bolts or nuts in which the locking takes place during screwing down or tightening

- F16B39/24—Locking of screws, bolts or nuts in which the locking takes place during screwing down or tightening by means of washers, spring washers, or resilient plates that lock against the object

- F16B39/26—Locking of screws, bolts or nuts in which the locking takes place during screwing down or tightening by means of washers, spring washers, or resilient plates that lock against the object with spring washers fastened to the nut or bolt-head

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/56—Surgical instruments or methods for treatment of bones or joints; Devices specially adapted therefor

- A61B17/58—Surgical instruments or methods for treatment of bones or joints; Devices specially adapted therefor for osteosynthesis, e.g. bone plates, screws or setting implements

- A61B17/68—Internal fixation devices, including fasteners and spinal fixators, even if a part thereof projects from the skin

- A61B17/84—Fasteners therefor or fasteners being internal fixation devices

- A61B17/86—Pins or screws or threaded wires; nuts therefor

- A61B17/8695—Washers

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16B—DEVICES FOR FASTENING OR SECURING CONSTRUCTIONAL ELEMENTS OR MACHINE PARTS TOGETHER, e.g. NAILS, BOLTS, CIRCLIPS, CLAMPS, CLIPS OR WEDGES; JOINTS OR JOINTING

- F16B43/00—Washers or equivalent devices; Other devices for supporting bolt-heads or nuts

- F16B43/001—Washers or equivalent devices; Other devices for supporting bolt-heads or nuts for sealing or insulation

Landscapes

- Health & Medical Sciences (AREA)

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Orthopedic Medicine & Surgery (AREA)

- Surgery (AREA)

- Mechanical Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Heart & Thoracic Surgery (AREA)

- Nuclear Medicine, Radiotherapy & Molecular Imaging (AREA)

- Biomedical Technology (AREA)

- Neurology (AREA)

- Medical Informatics (AREA)

- Molecular Biology (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Gasket Seals (AREA)

- Portable Nailing Machines And Staplers (AREA)

- Clamps And Clips (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及紧固件技术领域,特别涉及一种避免松动的螺钉预紧系统。The invention relates to the technical field of fasteners, in particular to a screw pretensioning system for preventing loosening.

背景技术Background technique

在医疗上进行骨折治疗,需要植入钢板螺钉,实现骨折端的稳定,为骨折愈合提供良好的力学环境。但是,在人体日常的运动过程中,骨骼系统在冲击、振动或变载荷作用下,螺钉与钢板的连接处容易产生松动,甚至完全脱离,引起骨折治疗失败。To treat fractures in medicine, it is necessary to implant plates and screws to stabilize the fracture end and provide a good mechanical environment for fracture healing. However, during the daily movement of the human body, the skeletal system is subject to impact, vibration or variable loads, and the connection between the screw and the steel plate is prone to loosening, or even completely detaching, resulting in fracture treatment failure.

目前的防松措施可分为摩擦防松、机械防松和破坏螺纹副防松三种。摩擦防松是增大螺纹副间的压力和摩擦力,以防止相对转动。由于螺纹连接件和被连接件的材料会发生蠕变和应力松弛,使预紧力和摩擦力减小,失去防松作用,因此摩擦防松的可靠性较低。机械防松是用止动元件约束螺纹副防松。机械防松需要在螺纹连接件上预先加工出与止动元件配合的防松结构,如轴向槽,影响螺纹连接的强度。由于加工误差的存在,止动元件与防松结构之间存在间隙,没有防松预紧力,在螺纹连接的预紧力减小,甚至松动后,才会止动;因此,严格地说机械防松仅仅具有止退作用。破坏螺纹副防松是把螺纹副转变为非运动副,排除相对转动的可能,例如用螺纹胶粘接。破坏螺纹副防松方便可靠,缺点是将螺纹连接转变为不可拆连接,破拆困难。The current anti-loosening measures can be divided into three types: frictional anti-loosening, mechanical anti-loosening and thread-destruction anti-loosening. Friction and anti-loosening is to increase the pressure and friction between thread pairs to prevent relative rotation. Since the materials of the threaded connection and the connected parts will undergo creep and stress relaxation, the pre-tightening force and friction force will be reduced, and the anti-loosening effect will be lost, so the reliability of frictional anti-loosening is low. Mechanical anti-loosening is to use a stop element to constrain the thread pair to prevent loosening. Mechanical anti-loosening needs to pre-process an anti-loosening structure on the threaded connection to cooperate with the stop element, such as an axial groove, which affects the strength of the threaded connection. Due to the existence of machining errors, there is a gap between the stop element and the anti-loosening structure, there is no anti-loosening pre-tightening force, and the threaded connection will stop after the pre-tightening force is reduced or even loosened; therefore, strictly speaking, the mechanical Anti-loosening only has the effect of preventing retreat. Destroying the thread pair to prevent loosening is to transform the thread pair into a non-moving pair, eliminating the possibility of relative rotation, such as bonding with thread glue. It is convenient and reliable to destroy the thread pair to prevent loosening. The disadvantage is that the threaded connection is transformed into a non-detachable connection, which is difficult to break.

现有的螺钉预紧系统虽然为螺钉提供了一定的防松退效果,但在高强度震动环境下螺钉依旧会发生松退,同时为便于螺钉的安装,垫片与螺钉仍是相互独立设计,进而造成了在垫片的防松退结构作用的过程中,外界杂质会进入螺钉与垫片之间的间隙内,在长时间的使用过程中对垫片的防滑纹路以及防松退结构造成磨损,进而影响防松退结构的有效性和使用寿命,因此,本申请提供了一种避免松动的螺钉预紧系统来满足需求。Although the existing screw pre-tightening system provides a certain anti-loosening effect for the screws, the screws will still loosen and retreat under high-intensity vibration environments. At the same time, to facilitate the installation of the screws, the gasket and the screw are still designed independently of each other In turn, during the process of the anti-loosening and retreating structure of the gasket, external impurities will enter the gap between the screw and the gasket, causing wear to the anti-slip texture and the anti-loosing and retreating structure of the gasket during long-term use. , which in turn affects the effectiveness and service life of the anti-loosening structure. Therefore, the present application provides a screw pretensioning system that avoids loosening to meet the demand.

发明内容Contents of the invention

本发明要解决的技术问题是提供一种避免松动的螺钉预紧系统以解决现有的螺钉预紧系统在高强度震动环境下螺钉依旧会发生松退,同时为便于螺钉的安装,垫片与螺钉仍是相互独立设计,进而造成了在垫片的防松退结构作用的过程中,外界杂质会进入螺钉与垫片之间的间隙内,在长时间的使用过程中对垫片的防滑纹路以及防松退结构造成磨损的问题。The technical problem to be solved by the present invention is to provide a screw pre-tightening system that avoids loosening to solve the problem that the existing screw pre-tightening system will still loosen the screws in a high-intensity vibration environment. The screws are still designed independently of each other, which in turn causes foreign impurities to enter the gap between the screw and the gasket during the anti-loosening and retreating structure of the gasket, which will affect the anti-slip texture of the gasket during long-term use. And the problem of wear and tear caused by the anti-loosening structure.

为解决上述技术问题,本发明提供如下技术方案:In order to solve the above technical problems, the present invention provides the following technical solutions:

一种避免松动的螺钉预紧系统,包括一级垫片、二级垫片和螺钉,所述一级垫片和所述二级垫片的一侧均设置有若干防滑齿,若干所述防滑齿的一侧均与水平面垂直,所述一级垫片和所述二级垫片的另一侧均设置有若干相互卡合的防松齿,若干所述防松齿的一侧均与水平面夹有α角,所述螺钉的螺纹升角为β角,所述α角大于所述β角,若干所述防松齿的另一侧均与水平面垂直,若干所述防滑齿与若干所述防松齿的斜面间夹有锐角,所述防松齿一侧的倾斜方向与所述螺钉的螺旋方向相同;所述一级垫片上安装有一级密封部件,所述二级垫片上安装有二级密封部件,所述一级垫片和所述二级垫片上均安装有预紧部件;所述一级密封部件用于密封所述螺钉与一级垫片,所述一级垫片用于遮盖所述二级垫片,所述一级密封部件还用于配合所述二级密封部件对所述二级垫片与安装点表面密封,所述预紧部件用于增加所述一级垫片与所述螺钉的摩擦力,所述预紧部件用于增加所述二级垫片与所述安装点的摩擦力,所述预紧部件还用于增加所述螺钉与所述安装点的预紧力。A screw pretensioning system for avoiding loosening, comprising a first-level gasket, a second-level gasket and screws, one side of the first-level gasket and the second-level gasket are provided with a number of anti-skid teeth, and several of the anti-skid teeth One side of the teeth is perpendicular to the horizontal plane, and the other side of the first-level gasket and the second-level gasket are provided with a number of anti-loosening teeth that engage with each other, and one side of the plurality of anti-loosening teeth is aligned with the horizontal plane. There is an angle α, the thread lead angle of the screw is β angle, the angle α is greater than the angle β, the other side of the plurality of anti-loosening teeth is perpendicular to the horizontal plane, and the number of anti-slip teeth is connected with the number of the anti-loosening teeth. There is an acute angle between the slopes of the anti-loosening teeth, and the inclination direction of one side of the anti-loosening teeth is the same as the helical direction of the screw; the first-level gasket is equipped with a first-level sealing component, and the second-level gasket is installed. There is a secondary sealing part, and pre-tightening parts are installed on the primary gasket and the secondary gasket; the primary sealing part is used to seal the screw and the primary gasket, and the primary gasket The sheet is used to cover the secondary gasket, the primary sealing part is also used to cooperate with the secondary sealing part to seal the surface of the secondary gasket and the installation point, and the pre-tightening part is used to increase the The frictional force between the primary gasket and the screw, the preloading part is used to increase the frictional force between the secondary gasket and the installation point, and the preloading part is also used to increase the frictional force between the screw and the Preload at the mounting point.

优选的,所述一级密封部件包括开设在所述一级垫片一侧的第一限位槽,所述第一限位槽内固定安装有第一密封圈,所述第一密封圈与所述螺钉的螺帽底部抵触,所述一级垫片的一侧底部设置有多个挤压环,所述一级垫片的一侧夹角处固定安装有多个加强筋。Preferably, the primary sealing part includes a first limiting groove opened on one side of the primary gasket, and a first sealing ring is fixedly installed in the first limiting groove, and the first sealing ring and The bottom of the nut of the screw is in contact with each other, a plurality of extrusion rings are arranged on the bottom of one side of the first-stage gasket, and a plurality of reinforcing ribs are fixedly installed at the corners of one side of the first-stage gasket.

优选的,所述二级密封部件包括固定安装在所述二级垫片一侧的第二密封圈,所述第二密封圈的一侧固定安装有多个第三密封圈,所述第二密封圈的内部开设有弱化槽,所述第二密封圈的底部关于所述弱化槽的中心线对称固定安装有两个第四密封圈。Preferably, the secondary sealing component includes a second sealing ring fixedly installed on one side of the secondary gasket, a plurality of third sealing rings are fixedly installed on one side of the second sealing ring, the second A weakening groove is provided inside the sealing ring, and two fourth sealing rings are symmetrically fixedly installed on the bottom of the second sealing ring with respect to the center line of the weakening groove.

优选的,所述第三密封圈位于两个所述第四密封圈的之间,所述第三密封圈的长度小于所述第四密封圈的长度。Preferably, the third sealing ring is located between the two fourth sealing rings, and the length of the third sealing ring is shorter than the length of the fourth sealing ring.

优选的,所述一级垫片和所述二级垫片均为硬质合金,所述第二密封圈、所述第三密封圈和所述第四密封圈均为柔性橡胶材质。Preferably, the primary gasket and the secondary gasket are made of cemented carbide, and the second sealing ring, the third sealing ring and the fourth sealing ring are all made of flexible rubber.

优选的,所述一级垫片和所述二级垫片的一侧均开设有第一滑槽,所述第一滑槽的一侧呈环形阵列设置有多个第二滑槽。Preferably, one side of the primary gasket and the secondary gasket is provided with a first sliding groove, and one side of the first sliding groove is provided with a plurality of second sliding grooves in an annular array.

优选的,所述预紧部件包括固定安装在所述第一滑槽底部内壁的弹性圈,所述第一滑槽内滑动套接有防滑环,所述防滑环侧一侧固定安装有与所述第二滑槽数量相同的限位滑块,所述限位滑块与所述第二滑槽滑动连接。Preferably, the pre-tightening part includes an elastic ring fixedly installed on the inner wall of the bottom of the first chute, an anti-slip ring is slidably sleeved in the first chute, and one side of the anti-slip ring is fixedly installed with the inner wall of the first chute. There are limit sliders with the same number of the second chute, and the limit slider is slidably connected with the second chute.

优选的,所述防滑环的一侧与所述弹性圈的外侧抵触,所述防滑环的顶部呈环形阵列设置有若干凸点。Preferably, one side of the anti-slip ring is in conflict with the outer side of the elastic ring, and the top of the anti-slip ring is provided with a plurality of convex points in an annular array.

优选的,所述防滑环的横截面为T型,所述凸点与所述螺帽底部抵触。Preferably, the cross-section of the anti-slip ring is T-shaped, and the protrusion is in contact with the bottom of the nut.

本发明与现有技术相比,至少具有如下有益效果:Compared with the prior art, the present invention has at least the following beneficial effects:

通过设置一级垫片和二级垫片,使得该螺钉预紧系统在振动、冲击的情况下,一级垫片和二级垫片会发生松动的趋势,此时螺帽通过防滑齿带动一级垫片松退的方向是一级垫片和二级垫片的拧紧方向,一级垫片和二级垫片的拧紧恰恰阻止了螺钉的松退,进而使得螺钉无法松动,有效的避免了螺钉的松退情况,同时因α角大于β角使得螺钉倒退的距离永远小于一级垫片和二级垫片退格的距离,并产生自锁机制,进一步避免了螺钉的松退,并保障了安装点的连接稳定性;By setting the first-level gasket and the second-level gasket, the screw pretensioning system will have a tendency to loosen under the condition of vibration and impact. At this time, the nut drives the first-level gasket through the anti-skid teeth. The loosening direction of the primary gasket is the tightening direction of the primary gasket and the secondary gasket. The tightening of the primary gasket and the secondary gasket just prevents the screw from loosening, so that the screw cannot be loosened, effectively avoiding the At the same time, because the α angle is greater than the β angle, the screw back distance is always smaller than the backspace distance between the first-level gasket and the second-level gasket, and a self-locking mechanism is generated, which further avoids the screw loosening and guarantees The connection stability of the installation point is improved;

通过设置第一密封圈,螺帽对第一密封圈进行挤压,受挤压的第一密封圈使一级垫片和螺帽的连接处封闭,以避免外界杂质进入螺帽与一级垫片的连接处内,进而使一级垫片上的防滑齿发生磨损,避免防滑齿的摩擦力减小,提高了防滑齿的有效性和使用寿命,同时通过一级垫片对二级垫片进行遮挡,避免了相互卡合的防松齿之间进入外界杂质,避免防松齿发生磨损,以进一步保障预紧系统的防松退效果的稳定性并提高预紧系统的使用寿命;By setting the first sealing ring, the nut squeezes the first sealing ring, and the squeezed first sealing ring seals the connection between the primary gasket and the nut to prevent external impurities from entering the nut and the primary gasket. In the connection of the sheet, the anti-skid teeth on the first-level gasket are worn away, the friction force of the anti-skid teeth is avoided, and the effectiveness and service life of the anti-skid teeth are improved. Shielding prevents the interlocking anti-loosening teeth from entering external impurities and avoids the wear of the anti-loosening teeth, so as to further ensure the stability of the anti-loosening effect of the preloading system and improve the service life of the preloading system;

通过设置第二密封圈,挤压环对第二密封圈进行挤压使弱化槽发生形变,进而使第二密封圈将挤压环包覆,从而使一级垫片和第二密封圈之间密封,通过开设弱化槽可增加第二密封圈受挤压后的形变量,进一步保障一级垫片和第二密封圈的密封效果,同时第二密封圈受挤压后,会使第四密封圈发生形变并与安装点表面紧贴,进而避免外界杂质进入二级垫片与安装点的连接处增加二级垫片底部的防滑齿磨损,保障了防滑齿的有效使用并延长了其使用寿命;By setting the second sealing ring, the extrusion ring squeezes the second sealing ring to deform the weakening groove, and then the second sealing ring wraps the extrusion ring, so that the gap between the primary gasket and the second sealing ring Sealing, by opening a weakening groove, the deformation of the second sealing ring after being squeezed can be increased, and the sealing effect of the first-level gasket and the second sealing ring can be further guaranteed. At the same time, after the second sealing ring is squeezed, the fourth sealing ring will The ring is deformed and closely attached to the surface of the installation point, thereby preventing external impurities from entering the connection between the secondary gasket and the installation point, increasing the wear of the anti-skid teeth at the bottom of the secondary gasket, ensuring the effective use of the anti-skid teeth and prolonging its service life ;

通过设置防滑环,限位滑块对防滑环进行限制,避免螺帽通过摩擦力带动防滑环发生转动,使得防滑环与一级垫片保持同步,通过弹性圈对防滑环提供弹性支撑,通过增设预紧部件进一步提高预紧系统对螺帽和地面的摩擦力,以保障预紧系统的使用稳定性,延长预紧系统的使用寿命。By setting the anti-slip ring, the limit slider restricts the anti-slip ring to prevent the nut from driving the anti-slip ring to rotate through friction, so that the anti-slip ring and the first-level gasket are kept in sync, and the elastic ring provides elastic support for the anti-slip ring. The pre-tightening part further improves the frictional force of the pre-tightening system on the nut and the ground, so as to ensure the stability of the pre-tightening system and prolong the service life of the pre-tightening system.

附图说明Description of drawings

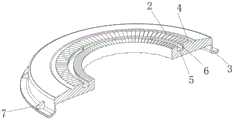

图1为避免松动的螺钉预紧系统立体结构示意图;Fig. 1 is a three-dimensional structural schematic diagram of a screw pre-tightening system for avoiding loosening;

图2为一级垫片局部剖视立体结构示意图;Figure 2 is a schematic diagram of a three-dimensional structure of a partial section of the first-stage gasket;

图3为一级垫片与预紧部件装配后局部剖视立体结构示意图;Fig. 3 is a partial cross-sectional three-dimensional structural schematic diagram after the assembly of the primary gasket and the pre-tightening part;

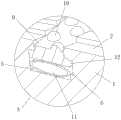

图4为避免松动的螺钉预紧系统去除二级垫片上预紧结构的局部剖视立体结构示意图;Fig. 4 is a schematic diagram of a partial cutaway three-dimensional structure for removing the preloading structure on the secondary gasket for the screw preloading system to avoid loosening;

图5为图4中B处立体放大结构示意图;FIG. 5 is a schematic diagram of a three-dimensional enlarged structure at B in FIG. 4;

图6为二级垫片立体放大结构示意图;Fig. 6 is a schematic diagram of a three-dimensional enlarged structure of a secondary gasket;

图7为图3中A出立体放大结构示意图;Fig. 7 is a schematic diagram of a three-dimensional enlarged structure of A in Fig. 3;

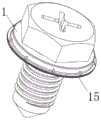

图8避免松动的螺钉预紧系统局部剖视立体结构示意图;Figure 8 is a schematic diagram of a partially cut-away three-dimensional structure of a screw pretensioning system that prevents loosening;

图9避免松动的螺钉预紧系统局部剖视与螺钉装配立体结构示意图;Fig. 9 is a partial section view of the screw pretensioning system to avoid loosening and a three-dimensional structural schematic diagram of screw assembly;

图10避免松动的螺钉预紧系统局部剖视与螺钉装配后局部剖视立体结构示意图。Fig. 10 is a partial sectional view of the screw pretensioning system for preventing loosening and a partial sectional three-dimensional structure diagram after the screw is assembled.

[附图标记][reference sign]

1、一级垫片;2、防滑齿;3、挤压环;4、第一限位槽;5、第一滑槽;6、第二滑槽;7、加强筋;8、第一密封圈;9、防滑环;10、凸点;11、弹性圈;12、限位滑块;13、防松齿;14、二级垫片;15、第二密封圈;16、第三密封圈;17、弱化槽;18、第四密封圈。1. First-level gasket; 2. Anti-skid teeth; 3. Squeeze ring; 4. First limit groove; 5. First chute; 6. Second chute; 7. Reinforcing rib; 8. First seal ring; 9, anti-slip ring; 10, convex point; 11, elastic ring; 12, limit slider; 13, anti-loosening tooth; 14, secondary gasket; 15, second sealing ring; 16, third sealing ring ; 17, weakening groove; 18, the fourth sealing ring.

具体实施方式Detailed ways

为使本发明要解决的技术问题、技术方案和优点更加清楚,下面将结合附图及具体实施例进行详细描述。In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

如图4、图9和图10所示的,本发明的实施例提供一种避免松动的螺钉预紧系统,包括一级垫片1、二级垫片14和螺钉,一级垫片1和二级垫片14均为硬质合金,一级垫片1和二级垫片14的一侧均设置有若干防滑齿2,通过防滑齿2增加一级垫片1和二级垫片14的摩擦力,进而提高一级垫片1和螺帽的连接稳定性以及二级垫片14与安装点表面的连接稳定性,若干防滑齿2的一侧均与水平面垂直,一级垫片1和二级垫片14的另一侧均设置有若干相互卡合的防松齿13,若干防松齿13的一侧均与水平面夹有α角,螺钉的螺纹升角为β角,α角大于β角,若干防松齿13的另一侧均与水平面垂直,若干防滑齿2与若干防松齿13的斜面间夹有锐角,防松齿13一侧的倾斜方向与螺钉的螺旋方向相同。As shown in Fig. 4, Fig. 9 and Fig. 10, the embodiment of the present invention provides a screw pretensioning system for avoiding loosening, including a

该螺钉预紧系统在振动、冲击的情况下,一级垫片1和二级垫片14会发生松动的趋势,此时螺帽通过防滑齿2带动一级垫片1松退的方向是一级垫片1和二级垫片14的拧紧方向,一级垫片1和二级垫片14的拧紧恰恰阻止了螺钉的松退,进而使得螺钉无法松动,有效的避免了螺钉的松退情况,同时因α角大于β角使得螺钉倒退的距离永远小于一级垫片1和二级垫片14退格的距离,并产生自锁机制,进一步避免了螺钉的松退,并保障了安装点的连接稳定性。In the case of vibration and impact of the screw pre-tightening system, the

如图4、图9和图10所示,所述一级垫片1上安装有一级密封部件,二级垫片14上安装有二级密封部件,一级垫片1和二级垫片14上均安装有预紧部件,一级密封部件用于密封螺钉与一级垫片1,一级垫片1用于遮盖二级垫片14,一级密封部件还用于配合二级密封部件对二级垫片14与安装点表面密封,预紧部件用于增加一级垫片1与螺钉的摩擦力,预紧部件用于增加二级垫片14与安装点的摩擦力,预紧部件还用于增加螺钉与安装点的预紧力。As shown in Figure 4, Figure 9 and Figure 10, the

如图1~3所示,所述一级密封部件包括开设在一级垫片1一侧的第一限位槽4,第一限位槽4内固定安装有第一密封圈8,第一密封圈8与螺钉的螺帽底部抵触,一级垫片1的一侧底部设置有多个挤压环3,一级垫片1的一侧夹角处固定安装有多个加强筋7。As shown in Figures 1 to 3, the primary sealing component includes a first limiting

螺钉拧紧时,螺帽对第一密封圈8进行挤压,受挤压的第一密封圈8使一级垫片1和螺帽的连接处封闭,以避免外界杂质进入螺帽与一级垫片1的连接处内,进而使一级垫片1上的防滑齿2发生磨损,避免防滑齿2的摩擦力减小,提高了防滑齿2的有效性和使用寿命,同时通过一级垫片1对二级垫片14进行遮挡,避免了相互卡合的防松齿13之间进入外界杂质,避免防松齿13发生磨损,以进一步保障预紧系统的防松退效果的稳定性并提高预紧系统的使用寿命。When the screw is tightened, the nut squeezes the

如图4~5所示,所述二级密封部件包括固定安装在二级垫片14一侧的第二密封圈15,第二密封圈15的一侧固定安装有多个第三密封圈16,第二密封圈15的内部开设有弱化槽17,第二密封圈15的底部关于弱化槽17的中心线对称固定安装有两个第四密封圈18,第二密封圈15、第三密封圈16和第四密封圈18均为柔性橡胶材质。As shown in Figures 4 to 5, the secondary sealing component includes a

螺钉拧紧时,挤压环3对第二密封圈15进行挤压使弱化槽17发生形变,进而使第二密封圈15将挤压环3包覆,从而使一级垫片1和第二密封圈15之间密封,通过开设弱化槽17可增加第二密封圈15受挤压后的形变量,进一步保障一级垫片1和第二密封圈15的密封效果,同时第二密封圈15受挤压后,会使第四密封圈18发生形变并与安装点表面紧贴,进而避免外界杂质进入二级垫片14与安装点的连接处增加二级垫片14底部的防滑齿2磨损,保障了防滑齿2的有效使用并延长了其使用寿命。When the screw is tightened, the

如图4~5所示,所述第三密封圈16位于两个第四密封圈18的之间,第三密封圈16的长度小于第四密封圈18的长度,通过第三密封圈16进一步提高第二密封圈15与安装点表面的密封性和防尘效果,提高了第二密封圈15的密封稳定性。As shown in Figures 4-5, the

如图4、图7和图8所示,所述一级垫片1和二级垫片14的一侧均开设有第一滑槽5,第一滑槽5的一侧呈环形阵列设置有多个第二滑槽6,预紧部件包括固定安装在第一滑槽5底部内壁的弹性圈11,第一滑槽5内滑动套接有防滑环9,防滑环9侧一侧固定安装有与第二滑槽6数量相同的限位滑块12,限位滑块12与第二滑槽6滑动连接,防滑环9的一侧与弹性圈11的外侧抵触,防滑环9的顶部呈环形阵列设置有若干凸点10,防滑环9的横截面为T型,凸点10与螺帽底部抵触。As shown in Fig. 4, Fig. 7 and Fig. 8, one side of the first-

通过限位滑块12对防滑环9进行限制,避免螺帽通过摩擦力带动防滑环9发生转动,使得防滑环9与一级垫片1保持同步,通过弹性圈11对防滑环9提供弹性支撑,通过增设预紧部件进一步提高预紧系统对螺帽和地面的摩擦力,以保障预紧系统的使用稳定性,延长预紧系统的使用寿命,同时通过预紧部件增加对螺钉的支撑效果,以提高螺钉的预紧力,进一步提高螺钉的使用稳定性。The

本发明提供的技术方案,通过设置一级垫片和二级垫片,使得该螺钉预紧系统在振动、冲击的情况下,一级垫片和二级垫片会发生松动的趋势,此时螺帽通过防滑齿带动一级垫片松退的方向是一级垫片和二级垫片的拧紧方向,一级垫片和二级垫片的拧紧恰恰阻止了螺钉的松退,进而使得螺钉无法松动,有效的避免了螺钉的松退情况,同时因α角大于β角使得螺钉倒退的距离永远小于一级垫片和二级垫片退格的距离,并产生自锁机制,进一步避免了螺钉的松退,并保障了安装点的连接稳定性;In the technical solution provided by the present invention, by setting the first-level gasket and the second-level gasket, the screw pre-tightening system will have a tendency to loosen under the condition of vibration and impact. The direction in which the nut drives the primary gasket to loosen and retreat through the anti-skid teeth is the tightening direction of the primary gasket and the secondary gasket. The tightening of the primary gasket and the secondary gasket just prevents the screw from loosening and retreating, thereby making the screw It cannot be loosened, which effectively avoids the loosening and retreating of the screw. At the same time, because the α angle is greater than the β angle, the screw backing distance is always smaller than the backspace distance of the first-level gasket and the second-level gasket, and a self-locking mechanism is generated to further avoid The looseness of the screws ensures the connection stability of the installation point;

螺钉拧紧时,螺帽对第一密封圈进行挤压,受挤压的第一密封圈使一级垫片和螺帽的连接处封闭,以避免外界杂质进入螺帽与一级垫片的连接处内,进而使一级垫片上的防滑齿发生磨损,避免防滑齿的摩擦力减小,提高了防滑齿的有效性和使用寿命,同时通过一级垫片对二级垫片进行遮挡,避免了相互卡合的防松齿之间进入外界杂质,避免防松齿发生磨损,以进一步保障预紧系统的防松退效果的稳定性并提高预紧系统的使用寿命;When the screw is tightened, the nut squeezes the first sealing ring, and the squeezed first sealing ring seals the connection between the primary gasket and the nut to prevent external impurities from entering the connection between the nut and the primary gasket In this way, the anti-skid teeth on the first-level gasket are worn away, the friction of the anti-skid teeth is avoided, and the effectiveness and service life of the anti-skid teeth are improved. At the same time, the second-level gasket is blocked by the first-level gasket. It avoids the entry of foreign impurities between the interlocking anti-loosening teeth, and avoids the wear of the anti-loosening teeth, so as to further ensure the stability of the anti-loosening effect of the preloading system and improve the service life of the preloading system;

螺钉拧紧时,挤压环对第二密封圈进行挤压使弱化槽发生形变,进而使第二密封圈将挤压环包覆,从而使一级垫片和第二密封圈之间密封,通过开设弱化槽可增加第二密封圈受挤压后的形变量,进一步保障一级垫片和第二密封圈的密封效果,同时第二密封圈受挤压后,会使第四密封圈发生形变并与安装点表面紧贴,进而避免外界杂质进入二级垫片与安装点的连接处增加二级垫片底部的防滑齿磨损,保障了防滑齿的有效使用并延长了其使用寿命;When the screw is tightened, the extrusion ring squeezes the second sealing ring to deform the weakened groove, and then the second sealing ring wraps the extrusion ring, so that the seal between the primary gasket and the second sealing ring is achieved. The weakening groove can increase the deformation of the second sealing ring after being squeezed, and further ensure the sealing effect of the first-level gasket and the second sealing ring, and at the same time, the fourth sealing ring will be deformed after the second sealing ring is squeezed And it is close to the surface of the installation point, thereby preventing external impurities from entering the connection between the secondary gasket and the installation point, increasing the wear of the anti-skid teeth at the bottom of the secondary gasket, ensuring the effective use of the anti-skid teeth and prolonging their service life;

通过限位滑块对防滑环进行限制,避免螺帽通过摩擦力带动防滑环发生转动,使得防滑环与一级垫片保持同步,通过弹性圈对防滑环提供弹性支撑,通过增设预紧部件进一步提高预紧系统对螺帽和地面的摩擦力,以保障预紧系统的使用稳定性,延长预紧系统的使用寿命,同时通过预紧部件增加对螺钉的支撑效果,以提高螺钉的预紧力,进一步提高螺钉的使用稳定性。The anti-slip ring is limited by the limit slider to prevent the nut from rotating the anti-slip ring through friction, so that the anti-slip ring and the first-level gasket are kept in sync, and the elastic ring provides elastic support for the anti-slip ring. Improve the frictional force of the preloading system on the nut and the ground to ensure the stability of the preloading system and prolong the service life of the preloading system. At the same time, increase the support effect on the screws through the preloading parts to improve the preloading force of the screws , to further improve the stability of the screw.

以上所述是本发明的优选实施方式,应当指出,对于本技术领域的普通技术人员来说,在不脱离本发明所述原理的前提下,还可以做出若干改进和润饰,这些改进和润饰也应视为本发明的保护范围。The above description is a preferred embodiment of the present invention, it should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, some improvements and modifications can also be made, these improvements and modifications It should also be regarded as the protection scope of the present invention.

Claims (8)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210522792.3ACN114909385B (en) | 2022-05-13 | 2022-05-13 | A Screw Pretensioning System to Avoid Loosening |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210522792.3ACN114909385B (en) | 2022-05-13 | 2022-05-13 | A Screw Pretensioning System to Avoid Loosening |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114909385A CN114909385A (en) | 2022-08-16 |

| CN114909385Btrue CN114909385B (en) | 2023-03-17 |

Family

ID=82766117

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210522792.3AExpired - Fee RelatedCN114909385B (en) | 2022-05-13 | 2022-05-13 | A Screw Pretensioning System to Avoid Loosening |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114909385B (en) |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE445848B (en)* | 1983-06-10 | 1986-07-21 | Nobex Ab | DOUBLE WASHING PLATE WITH VILWORK |

| WO2004033139A2 (en)* | 2002-10-09 | 2004-04-22 | Terry Sydney L | Wedge cam lock washer for threaded fasteners |

| DE102011056692A1 (en)* | 2011-12-20 | 2013-06-20 | Parker Hannifin Manufacturing Germany GmbH & Co. KG | Seal with pressure relief function |

| SE537673C2 (en)* | 2013-02-28 | 2015-09-29 | Nord Lock Ab | Låsbrickanordning |

| CN206988268U (en)* | 2017-06-14 | 2018-02-09 | 沈航 | Anti-loose screw gasket based on common fastening piece |

| CN207777621U (en)* | 2017-12-28 | 2018-08-28 | 广州柏泰液压密封有限公司 | A kind of sealing ring that leakproofness effect is strong |

| US11242884B2 (en)* | 2019-09-18 | 2022-02-08 | Laitram, L.L.C. | Sealing wedge-lock washer and fastening system |

| JP6797323B1 (en)* | 2020-03-31 | 2020-12-09 | 株式会社トープラ | Screw fastener |

| CN113550966A (en)* | 2020-04-24 | 2021-10-26 | 中国气动工业股份有限公司 | Bolt clamping force induction washer |

| CN213628440U (en)* | 2020-09-03 | 2021-07-06 | 常州市碧源车辆配件有限公司 | Fastener with pretension function |

- 2022

- 2022-05-13CNCN202210522792.3Apatent/CN114909385B/ennot_activeExpired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| CN114909385A (en) | 2022-08-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA2220090C (en) | Extrusion resistant hydrodynamically lubricated multiple modulus rotary shaft seal | |

| CN109114092B (en) | Anti-loosening and retaining nut | |

| CN108386439B (en) | Permanent-looseness screw fastening assembly | |

| CN114909385B (en) | A Screw Pretensioning System to Avoid Loosening | |

| US20190107141A1 (en) | Lock bolt assembly | |

| CN209083771U (en) | A kind of nail lock reducing derotation fastened by screw component of never becoming loose | |

| CN108662005A (en) | A kind of special eccentric locking nut | |

| CN102654156A (en) | Novel locking fastener | |

| CN209195919U (en) | A kind of locking conjunction type reducing derotation fastened by screw component | |

| CN111442024A (en) | Self-tightening anti-loose fastening device | |

| CN112240339A (en) | Double-layer anti-loosening bolt pad | |

| US715891A (en) | Nut-lock. | |

| CN212131444U (en) | Valve body and shutoff part complex structure and valve of releasing | |

| CN211778445U (en) | Anti-loosening bearing bolt | |

| CN217558747U (en) | Double-disc anti-loose washer with wear-resistant function | |

| CN212225732U (en) | Anti-loosening sealing screw | |

| CN212175349U (en) | Rail fastener | |

| CN213655428U (en) | An anti-vibration loose composite nut | |

| CN209511368U (en) | High-strength corrosion-resisting protection type kirsite hose coupling | |

| CN112983957A (en) | Locknut assembly | |

| CN208417208U (en) | An anti-loosening fastening nut | |

| JP3017331B2 (en) | Loosening prevention screw | |

| CN217761646U (en) | Fastener with strong locking looseness prevention performance | |

| CN221879957U (en) | Novel lock nut | |

| CN208816495U (en) | A kind of locking nonstandard left-handed screw cap of automobile fan locking |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee | Granted publication date:20230317 | |

| CF01 | Termination of patent right due to non-payment of annual fee |